PNSC-2

PNEUMATIC COMBINATION STRAPPING TOOL

READ THESE INSTRUCTIONS CAREFULLY. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN SERIOUS PERSONAL INJURY.

STRAP BREAKAGE HAZARD

Improper operation of the tool or sharp corners on the load can result in strap breakage during

tensioning, which could result in the following:

! A sudden loss of balance causing you to fall.

! Both tool and strap flying violently towards your face.

Failure to place the strap properly around the load or an unstable or shifted load could result in a

sudden loss os strap tension during tensioning. This could result in a sudden loss of balance

causing you to fall.

! If the load corners are sharp use edge protectors.

! Positioning yourself in-line with the strap, during tensioning and sealing, can result in severe

personal injury from flying strap or tool. When tensioning or sealing, position yourself to one

side of the strap and keep all bystanders away.

TRAINING

This tool must not be used by persons not properly trained in its use. Be certain that you receive

proper training from your employer. If you have any questions contact your Signode

Representative.

EYE INJURY HAZARD

Failure to wear safety glasses with side shields can result in severe eye injury or

blindness. Always wear safety glasses with side shields which conform to ANSI

Standard Z87.1 or EN 166.

FALL HAZARD

Maintaining improper footing and/or balance when operating the tool can cause you to fall. Do

not use the tool when you are in an awkward position.

CUT HAZARD

Handling strap or sharp parts could result in cut hands or fingers. Wear protective

gloves.

TOOL CARE

! Inspect and clean the tool daily. Replace all worn or broken parts.

! Lubricate all moving parts weekly unless otherwise specified.

! On air powered tools, always disconnect the pneumatic connection to the tool when

performing part removal and replacement procedures. NEVER connect a pneumatic source to

a disassembled tool unless otherwise specified.

WORK AREAS

Keep work areas uncluttered and well lighted.

22

READ THESE INSTRUCTIONS CAREFULLY. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN SERIOUS PERSONAL INJURY.

Use correct Signode products for your application. If you need help contact your Signode

Representative.

Signode tools and machines are designed and warranted to work together with Signode

strapping and seals. Use of non-Signode strap and seals and/or manufactured or specified

replacement parts may result in strap breakage or joint separation while applying strapping

to a load or during normal shipping and handling. This could result in severe personal

injury.

JOINT FORMATION

! Before using this tool, read its Operation and Safety instructions

contained in this manual.

! This tool is a single reverse notch-joint sealers. Each notch-joint

must be inspected to make certain it has two (2) good notches. A

properly formed notch-joint will appear as shown in the

illustration. If the notch-joint does not appear as shown, then the

operator must proceed as follows.

1. Make certain that the tool's operating instructions are being

followed before applying another strap.

2. Cut the strap off and apply a new strap and seal.

3. An improper formed seal which does not have two (2) good notches, could result in strap

separation. Before moving any package be certain that the seal is formed as shown.

Inspect the joint to make certain it appears as shown in the illustration. If not, remove the

broken strap and check the tool for worn or broken parts. Repair the tool for worn or

broken parts. Repair the tool before applying another strap.

MOVING AND STACKING STRAPPED LOADS

Before moving or stacking any strapped load, follow all standard industry practices regarding

safe material handling procedures.

CUTTING TENSIONED STRAP

Using claw hammers, crowbars, chisels, axes or simialr tools will cause tensioned strap to fly

apart with hazardous force. Use only cutters designed for cutting strap. Read the instructions in

the cutter's manual for proper procedures in cutting strap. Before using any Signode product

read its Operation and Safety Manual.

CLEANING & LUBRICATION

Clean and apply a light weight machine oil to all moving parts on a weekly basis. Clean the

feedwheel daily with a wire brush. Debris accumulated in the teeth of either the feedwheel or the

clutch plug must be removed with a small wire brush. A need to clean the teeth will become

apparent when either the feedwheel skids on the strap or the lower strap slips on the clutch plug

during tensioning. Refer to the Pneumatic Information shown in this manual for lubricant

recommendations with regard to the air motor.

33

TABLE OF CONTENTS Page

General Safety Information 2

Specifications 5

Major Components 5

Pneumatic Information 6

Operating Instructions 9

Part Removal & Replacement 11

Parts List 12

Troubleshooting 16

Maintenance 18

Declaration of Conformity 19

PNSC2-12

Part No. 422495

PNSC2-58

Part No. 422496

Signode tools and machines are designed

and warranted to work together with

Signode strapping and seals. Use of non Signode strap and seals and/or

manufactured or specified replacement

parts may result in strap breakage or joint

separation while applying strapping to a

load or during normal shipping and

handling. This could result in severe

personal injury.

PNSC2-34

Part No. 422497

PNSC2-34 HIGH TENSION

Part No. 422881

44

SPECIFICATIONS

MODEL

TYPE WIDTH THICKNESS

STRAP

SEALS

PNSC2-12

PNSC2-58 5/8"(15.8mm) 58SPC

PNSC2-34 3/4"(19mm) 34PNSC

APEX

&

MAGNUS

1/2"(12.7mm)

12SPC

.015"(.38mm)

to

.025"(.64mm)

MAJOR COMPONENTS

55

PNEUMATIC INFORMATION

AIR SUPPLY INSTALLATION

If compressor has a good dryer unit, use black pickled pipe. When a dryer unit is not installed,

use galvanized or copper pipe.

To perform reliably, a pneumatic tool requires a continuous source of clean, water-free air at

adequate pressure.

! Never operate this tool using a bottled air or gas source.

! Bottled air/gas sources do not provide consistent operating pressure and could result in

air pressures that exceed the maximum allowed for this tool.

! Exceeding the maximum allowable air pressure could result in severe personal injury.

A filter-regulator-lubricator unit (P/N 173111) must be installed as close to the air tool as

possible, preferably within 10 feet (3M). It should be placed in a convenient location where it can

easily be drained, adjusted, and filled with oil. The air hose (P/N 008558) must have at least a

3/8" (9.5mm) I.D. A quick-connect press-on socket (P/N 008569) is installed on the stress spring

end of the hose for convenient hookup to the air tool.

Filter and lubricator bowls are made of polycarbonate material. Do not install where bowls may

be exposed to materials incompatible with polycarbonate. Certain oils, solvents, and chemicals

or their fumes can weaken these bowls and possibly cause them to burst. Clean only with warm

water. A cut-off valve placed ahead of the filter will be useful when cleaning the filter or

replenishing the lubricator.

66

MOISTURE

Moisture is always present in air lines due to condensation within the lines as the air cools.

Steps must be taken to remove this moisture and to keep it from the air tool. This is because

water tends to wash away lubricants and cause corrosion, sticking and failure of internal parts.

The main line should be pitched so the far end terminates in a water leg. Branch lines are taken

from the top of the main, never off the bottom. Every branch should have a water leg at its

lowest point, with a drain cock which is drained daily.

If these precautions are taken and water is still present, an after cooler and a moisture separator

are required between the compressor and the air receiver tank. A large air line separator can be

installed in the air tool line, but precautions must be taken to insure that it will be drained daily,

before the air tool is operated.

Water in air lines is a constant threat to the proper operation of air tools. Even near

freezing operating conditions, a good refrigerant type dryer is essential. A good dryer will

remove 95% or more of water right at the compressor. The remaining moisture is removed at the

water leg in the piping system or in the filter, Signode Part No. 173111. Additional information is

available in the Signode publication, "Air Supply Manual" Signode Part No. 186038. If you have

any questions, contact your local Signode Representative.

LUBRICATION

The air motor must be properly lubricated. This is achieved by keeping the air line lubricator

filled with oil and correctly adjusted. Without proper lubrication, the motor will become sticky

and the tool will give low and erratic tension and be difficult to release from the strap.

Install the lubricator as close to the air tool as possible. The arrow on the lubricator's top

surface must point in the direction of air flow.

For proper operation, oil must drop through the lubricator sight glass at a rate of 4 to 10 drops

per minute. This rate is to be checked while the air tool is running free. Only 20% of this oil is

actually delivered to the tool. The remaining oil drops back into the oil reservoir. The unit is

factory set and should require no adjustment. If an adjustment is required, the adjusting screw

on top of the lubricator may be turned as marked to reduce or increase the flow of oil.

The correct grade of oil must be used in the lubricator; too heavy an oil will not provide sufficient

lubrication and will cause sticking and sluggish operation of the air tool.

Recommended oils are any good grade of rust and oxidation inhibiting oil with a viscosity of 80120 S.U.S. at 100 degrees Fahrenheit. (0.15 to 0.25 cm2 /sec. at 38 degrees Celsius), such as:

Non Fluid Oil Co., grade #LS-1236

Signode oil - Part No. 008556

If necessary, use SAE #5 or SAE #10, non-detergent, cut 1:1 with kerosene. Some oils contain

anti-wear additives which may disable the air motor. Be certain to use recommended oil.

Several drops of lubricator oil added to the inlet of the air motor or into the air line each day will

help insure good operation. A noticeable reduction of air motor performance can usually be

corrected by squirting a few drops of oil into the air line.

77

PNEUMATIC INFORMATION, Continued

COLD WEATHER OPERATION

If a tool does not operate satisfactorily in freezing temperatures, certain steps can correct the

problem. The following steps can be taken to improve cold weather operation of the tool:

a. An air line dryer adjacent to the compressor.

b. Use lubricant recommended by Signode. Signode has tested the use of anti-freezes, none

work well in air tools; the tool will gum up when anti-freezes are introduced and will not

function properly. The best lubricant for freezing weather is the 1 to 1 oil and kerosene

combination.

c. If possible, run the air supply line to a indoor located Filter-Regulator-Lubricator or relocate

the F-L-R to a warmer operating area.

AIR CONSUMPTION

Air consumption in cubic feet per minute (cfm) for the PNSC-2 can be calculated as follows:

cfm = (a)x(b)x(0.23)

a = Number of straps applied per minute.

b = Number of seconds air motor is on per strap during tensioning, from start to finish

sealing.

0.23 = PNSC-2 efficiency ratio.

Example calculation:

(a)x(b)x(0.23)=4x5x0.23=4.6 cubic ft/min.

Peak strapping load is 4 straps/minute, so a=4.

Air motor is on 5 seconds/strap, so b=5.

PNSC-2 efficiency ratio is 0.23.

Air pressure is assumed to be 90 psig with the recommended size and length of air hose.

Volume of air at room temperature and sea level pressure, or so-called "free air" conditions. For

more detailed information about air supply systems, refer to Signode manual Part No. 186038.

AIR LINE PRECAUTIONS

Strap tension is controlled by air pressure. Use the proper air line piping and lubrication as

specified in this manual. Your air pressure gauge must be accurate, therefore, confirm its

accuracy by comparing it to a calibrated master gauge.

Strap breakage hazard. 3/4" (19mm) strap can break during tensioning if inlet air pressure to

the tool exceeds 70 psig. Strap breakage can result in severe personal injury. Maximum

operating pressure is 90 psig.

88

OPERATING INSTRUCTIONS

! Wear safety glasses which conform to ANSI Standard Z87.1 or EN 166.

! Stand to one side of the strap while tensioning. Make sure all bystanders are clear before

proceeding.

! Failure to follow the above could result in serious personal injury.

1. Thread strap once through seal.

Continue to encircle the bundle

and thread the lead end back

through the seal as shown.

Sharply bend approximately 2

1/2" (64mm) of the strap end back

under the seal. Pull out any strap

slack.

NOTE: A gentle upward bend

on the top strap will hold the

seal in place.

2. While holding the top strap with your left hand and

with the tool in your right hand. squeeze the motor

and stationary handle together to open up the strap

path. Swing tool sideways to accept the top strap,

making certain that the edge of the strap is in

contact with the inside surface of the tensioner foot.

While continuing to hold the motor against the

stationary handle, slide the tool forward as far as

possible.

3. While continuing to hold the tool by the motor, release

the stationary handle. Press the lever marked #1 to it's

locked position (tension) to begin tensioning the strap

around the bundle. The tool will stall when the set

tension level has been reached. If the tension is too

much or too little, the tension can be adjusted as

described elsewhere in this manual.

NOTE: If strap alignment on the package is

unsatisfactory and it becomes necessary to shut off

the tool during tensioning portion of the cycle, move

the tension lock lever to the right to allow the tension

lever to release and stop tensioning. Squeeze handle

and motor together to release tool and realign strap.

99

OPERATING INSTRUCTIONS, Continued

4. Press and momentarily hold the lever marked #2

(sealer) all the way down until the sealing and cutoff cycle has been completed. Hold onto tool as the

sealer jaws will disengage freeing the tool from the

strap.

5. Squeeze the stationary handle and motor together

to release the cut off strap end. To make sure the

tool has properly formed a joint, closely inspect the

seal for two well formed notches - see Joint

Inspection.

STRAP JOINT APPEARANCE & FORMATION

! Before using this tool, read its Operation and Safety

instructions contained in this manual.

! This tool is a single reverse notch-joint sealers. Each notch-

joint must be inspected to make certain it has two (2) good

notches. A properly formed notch-joint will appear as

shown in the illustration. If the notch-joint does not appear

as shown, then the operator must proceed as follows.

1. Make certain that the tool's operating instructions are

being followed before applying another strap.

2. Cut the strap off and apply a new strap and seal.

3. An improper formed seal which does not have two (2) good notches, could result in strap

separation. Before moving any package be certain that the seal is formed as shown.

Inspect the joint to make certain it appears as shown in the illustration. If not, remove the

broken strap and check the tool for worn or broken parts. Repair the tool for worn or

broken parts. Repair the tool before applying another strap.

NEVER HANDLE OR SHIP ANY LOAD WITH IMPROPERLY FORMED JOINTS. Misformed

joints may not secure the load and could cause serious injury. Follow the joint inspection

procedures in each sealer’s manual.

1010

PART REMOVAL, REPLACEMENT & ADJUSTMENTS

REFER TO PAGES 12, 13, 14 & 15 FOR ADDITIONAL INFORMATION

FEEDWHEEL & WEAR PAD

1. To replace the feedwheel (Pg13, #3), remove the

two socket head cap screws (Pg13, #15) and

lock washers (Pg13, #48) which secure the outer

link (Pg13, #51).

2. Remove the outer link from the gear housing.

3. Slide the feedwheel off the feedwheel shaft.

4. The wear pad (Pg13, #22) can now be easily

replaced. Simply press out the wear plug from

the under side of the tool. Install the wear pad

with a new o-ring (Pg13, #17) making sure the

plug is solidly seated.

5. Replace the feedwheel and outer link.

6. Check the feedwheel to wear pad clearance. The

clearance between these parts should be .002"

to .006" (0.05-0.15mm). Adjust the clearance as

required by turning the M6 socket head set

screw (Pg15, #14). Turning the adjustment screw

clockwise increases the gap.

STRAP TENSION

Strap tension is controlled by air pressure. Use the

proper air line piping and lubrication as specified in

this manual. Your air pressure gauge must be

accurate, therefore, confirm its accuracy by

comparing it to a calibrated master gauge.

Adjust strap tension as follows:

1. Make sure the air pressure is set between 70 and

90 psig (4.8 - 6.2 bar).

2. Turn the adjustment valve screw (Pg15, #55) found on the underside of the air motor in 1/4

turn increments as required. Turn the screw clockwise to decrease tension and

counterclockwise to increase tension.

Strap breakage hazard. 3/4" (19mm) strap can break during tensioning if inlet air pressure to

the tool exceeds 90 psig. Strap breakage can result in severe personal injury. Maximum

operating pressure is 90 psig.

Never remove the adjusting screw from the tool with the air connected. The screw could

become a flying projectile.

1111

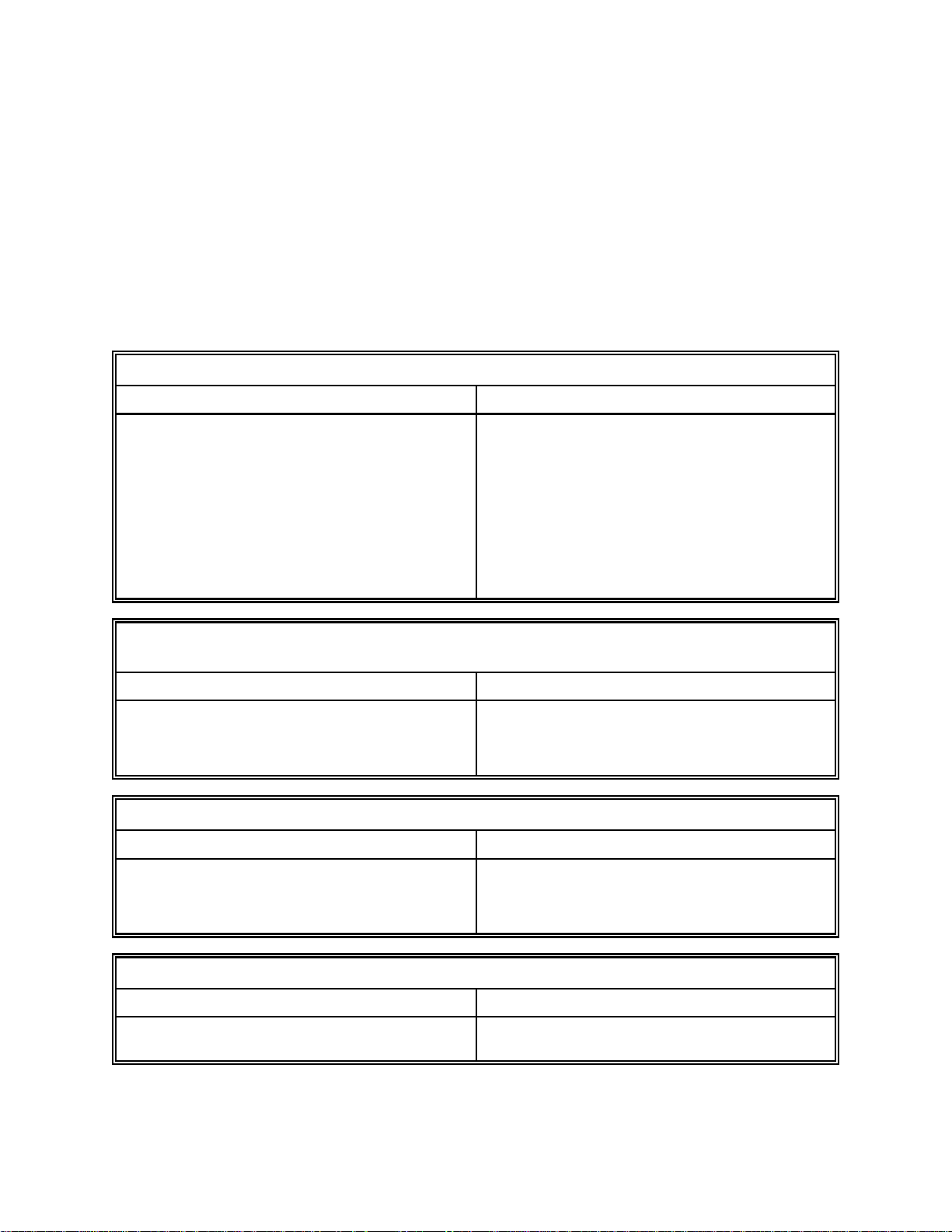

TROUBLESHOOTING

The following items are the most common tool symptoms if problems occur. For symptoms or

remedies not shown, contact your Signode service representative for additional information and

details. The following tool symptoms are shown in this manual:

#1 - Tool runs sluggishly.

#2 - Filter-regulator-lubricator is maintained but still runs sluggishly

#3 - Motor does not pick up speed when oiled.

#4 - Air motor continues to run after sealing/cut-off cycle is completed.

#5 - Low joint strength.

#6 - Sealer valve sticks or leaks.

#7 - Tool will not cut off strap.

#8 - Feedwheel milling on strap.

#9 - Seal pulls open during tensioning.

#1 SYMPTOM: The tool runs sluggishly.

CAUSE REMEDY

1. The air filter-regulator -lubricator is malfunctioning

and is not properly maintained.

1. Check the regulator to see that the correct air

pressure is getting to the tool.

2. Check to see the filter unit is clean and

functioning properly.

3. Examine the lubricator to see there is oil

in the bowl and that the oil is seen

dripping from the sight dome as the tool

operates. This assures the air motor is

being properly lubricated.

#2 SYMPTOM: The filter-regulator lubricator is properly maintained but the tool still runs

sluggishly.

CAUSE REMEDY

The motor is dry, hindering it from providing maximum

performance.

Pour a teaspoon of oil into the motor through the air

inlet, hook the tool up to air and run it. An increase of

speed indicates the motor was dry.

#3 SYMPTOM: The motor does not pick up speed with the addition of oil.

CAUSE REMEDY

The tool may run sluggishly due to clogged or dirty

motor filter screen due to a lack of properly filtered air

supply.

Remove the Hansen plug at the inlet to the air motor

and examine the filter screen in the air strainer and

clean it if necessary. See instructions on installing the

Hansen plug.

#4 SYMPTOM: Air motor continues to run after sealing/cut-off cycle is completed.

CAUSE REMEDY

Excessive air line pressure. Install Filter-Regulator-Lubricator near tool. Reduce air

pressure to 90 psi (6.2 bar) maximum.

1616

#5 SYMPTOM: Low joint strength.

CAUSE REMEDY

Worn jaws, notchers and pins in jaw stack. Disassemble jaw stack and replace worn parts as

required.

#6 SYMPTOM: Sealer valve sticks or leaks.

CAUSE REMEDY

1. Dirt in sealer valve assembly.

2. O-Rings and seals in valve stem are worn or

defective.

#7 SYMPTOM: Tool will not cut off strap.

CAUSE REMEDY

1. Lead edge on breaker foot worn. Inadequate air

pressure.

2. Excessive pressure drop due to air line supply

restrictions.

3. Worn cutter.

#8 SYMPTOM: Feedwheel milling on strap.

CAUSE REMEDY

1. Feedwheel is clogged with dirt.

2. Feedwheel is worn or has chipped teeth.

1. Disassemble and clean valve assembly.

2. Disassemble and replace O rings and

seal as required.

1. Replace breaker foot. Increase air

pressure to 90 psi (6.2 bar) maximum.

2. Use 3/8" I.D. hose of minimum length.

3. Replace cutter.

1. Clean teeth on feedwheel with wire

brush (P/N 269589).

2. Replace feedwheel.

#9 SYMPTOM: Seal pulls open during tensioning.

CAUSE REMEDY

Tool is pulling excessive tension. Lower the strap tension by turning the valve screw

(Key 55 on page 15) clockwise. Note, do not turn the

strap tension screw more than one rotation at a time

without testing tool.

1717

TOOL MAINTENANCE

The most common reason for poor tool performance and incorrectly formed straps joints is

improper tool maintenance. The easiest way to determine if a tool is performing correctly is by

inspecting the strap joint. Having a tool maintenance program is a simple task which consists of

three parts. First, a quick daily inspection of the tool for any worn or broken parts. Secondly,

keep each tool on a schedule of service intervals for cleaning and lubrication. Third, when

problems do occur, use the troubleshooting guide to properly determine and fix problems before

they lead to more serious tool conditions. Each of these three tasks have been outlined for this

particular tool, read and understand all information for improving the life and performance of the

tool.

TOOL INSPECTION

Visually inspect the exterior of the tool on a daily basis. Decreased tool life can be prevented by

early detection of broken parts. Replace all broken parts with new parts. Review the Parts

Removal, Replacement & Adjustments portion of this manual for information and details.

SERVICE INTERVALS

This tool, like most Signode tools, can be used with various sizes of strap which cause different

rates of component wear. Also, wear is affected by the environment and tension that the tool

applies. In the worst case, heavy gauge wide strapping. All critical moving components of the

tool should be inspected at particular intervals, some more often than others. Broken parts can

decrease sealing effort, leading to additional component wear and produce lower joint strength.

Inspect the components of the sealing mechanism when:

A. Joint does not appear as shown in this manual or visually it is detected that the joint is

not all formed or formed improperly.

B. Sealing effort requires higher air pressure or tool is difficult to remove from strap.

C. When scheduled.

If there is any question that joint formation is not as shown or is

suspect, it is important that you contact your tool representative immediately.

The feed wheel and wear plug are also subject to wear and chipping. A daily cleaning of these

parts by brushing off debris will be important to maintaining long life. The first indication of wear

will be strap slippage during tensioning. The operator of the tool should be instructed on how to

determine when the strap slips during tensioning. Sometimes the teeth need to be cleaned with a

wire brush, but if slipping is allowed to continue, the parts will need to be replaced. Using the

tool in a dirty environment will increase feedwheel wear.

NOTE: On some Signode tools the feedwheel can be cleaned by holding the tool open in the

strap loading position while the tool runs without strap and using a wire brush to clean the

feedwheel as it rotates.

Inspect the components of the tensioner mechanism when:

A. Strap slips when being tensioned.

B. Evidence of feedwheel milling on the strap face.

C. When scheduled.

TOOL LUBRICATION

Signode tools use a variety of greases and oils, all of which can be ordered through Signode.

When ordering indicate tool model, part number and name.

1818

EU Declaration of Conformity

The Supply of Machinery (safety) Regulations

1992 (S.I. 1992/3073)

It is hereby declared that the undermentioned machinery has been designed and

constructed to comply with the health and safety requirements defined in EC Directive

89/392/EEC

Machine Supplier: Signode, Division of ITW Ltd.

Queensway, Fforestfach

Swansea SA5 4ED

Machine Description: PNSC-2 Series

Machine Type: Pneumatic Combination Hand Strapping tool.

Provisions with which machine complies:

89/392/EEC, 91/368/EEC

Harmonized EuroNorms with which machine complies:

EN 292:1, EN 292:2, EN 294, EN 349

Technical Standards with which machine complies:

NA

Signature: Date: 2 DEC 1996

(Peter Oseland)

1919

SIGNODE

NEW TOOL WARRANTY

Signode Engineered Products Warrants that a new Signode strapping tool will operate per functional

specifications for a period of sixty (60) days after the date of shipment to the owner's place of business.

Normal wearing parts, as outlined in the Operation, Parts & Safety manual, are covered by a thirty (30)

day warranty unless, in Signode's judgement, these parts have been subjected to abnormal or extreme

usage. Signode's sole liability hereunder will be to repair or replace, without charge, F.O.B. Signode's

Glenview, Illinois plant, any tool which proves to not operate per functional specifications within the

stated period. Signode reserves the right to replace any tool which proves not to operate per functional

specifications with a new or like-new tool of the same model if in Signode's judgement such replacement

is appropriate. Any new replacement tool provided to an owner will carry a full sixty (60) day warranty.

Any warranty repaired tool or like-new replacement tool will carry a warranty for the balance of the time

remaining on the initial sixty (60) day warranty. This warranty will be extended to compensate for the

time the tool is in Signode's possession for warranty repairs.

This warranty is void as to any tool which has been: (I) subjected to mis-use, misapplication, accident,

damage, or repaired with other than genuine Signode replacement parts, (II) improperly maintained, or

adjusted, or damaged in transit or handling; (III) used with improperly filtered, unlubricated air or

improper strapping material, (IV) in Signode's opinion, altered or repaired in a way that affects or

detracts from the performance of the tool.

SIGNODE MAKES NO WARRANTY, EXPRESSED OR IMPLIED, RELATING TO MERCHANTABILITY,

FITNESS OR OTHERWISE EXCEPT AS STATED ABOVE AND SIGNODE'S LIABILITY AS ASSUMED ABOVE

IS IN LIEU OF ALL OTHERS ARISING OUT OF OR IN CONNECTION WITH THE USE AND PERFORMANCE

OF THE TOOL. IT IS EXPRESSLY UNDERSTOOD THAT SIGNODE SHALL IN NO EVENT BE LIABLE FOR

ANY INDIRECT OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, DAMAGES WHICH

MAY ARISE FROM LOSS OF ANTICIPATED PROFITS OR PRODUCTION, SPOILAGE OF MATERIALS,

INCREASED COSTS OF OPERATION OR OTHERWISE.

Considerable effort has be made to ensure that this product conforms to our high quality standards.

However, should you experience any difficulties, please contact your Sales Representative providing

samples and the manufacturing code specified on the tool.

Thank you for your help.

SIGNODE ENGINEERED PRODUCTS

Hand Tool Division

3620 W. Lake Avenue, Glenview, Illinois 60025

© Copyright 2002, Signode 286188 Rev. 4/2002

Loading...

Loading...