Signode AMPT-12 Operation, Parts And Safe

AMPT-12

POWERED COMBINATION STRAPPING TOOL

SIGNODE !

! 3620 WEST LAKE AVENUE !!!! GLENVIEW, ILLINOIS 60025

!!

READ THESE INSTRUCTIONS CAREFULLY.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN SEVERE PERSONAL INJURY.

GENERAL SAFETY CONSIDERATIONS

1. STRAP BREAKAGE HAZARD.

Improper operation of the tool or sharp corners on the load can result in strap

breakage during tensioning, which could result in the following:

!!!! A sudden loss of balance causing you to fall.

!!!! Both tool and strap flying violently towards your face.

Failure to place the strap properly around the load or an unstable or shifted load could result

in a sudden loss of strap tension during tensioning. This could result in a sudden loss of

balance causing you to fall.

Read the tool's operating instructions. If the load corners are sharp use edge protectors.

Place the strap correctly around a properly positioned load.

!!!! Positioning yourself in-line with the strap, during tensioning and sealing, can result in

severe personal injury from flying strap or tool. When tensioning or sealing, position

yourself to one side of the strap and keep all bystanders away.

!!!! Using strap not recommended for this tool can result in strap breakage during tensioning.

Use the correct Signode products for your application.

2. TRAINING.

This tool must not be used by persons not properly trained in its use. Be certain that you

receive proper training from your employer. If you have any questions contact your Signode

Representative.

3. EYE INJURY HAZARD.

Failure to wear safety glasses with side shields can result in severe eye injury or

blindness. Always wear safety glasses with side shields which conform to ANSI

Standard Z87.1 or EN 166.

4. FALL HAZARD.

Maintaining improper footing and/or balance when operating the tool can cause you to fall. Do

not use the tool when you are in an awkward position.

5. CUT HAZARD.

Handling strap or sharp parts could result in cut hands or fingers. Wear protective

gloves.

2

6. TOOL CARE.

Take good care of the tool. Inspect and clean it daily, lubricate it weekly and adjust when

necessary. Replace any worn or broken parts.

7. WORK AREA.

Keep work areas uncluttered and well lighted.

Several types of strap can be used with this tool. Use the correct Signode products for your

application. If you need help contact your Signode Representative.

SAFETY PROCEDURES FOR TOOL OPERATION

1. Before using this tool, read its Operation and Safety instructions.

!!!! Do not exceed the operating air pressures stated elsewhere in the manual.

!!!! Use Signode's approved filter-regulator-lubricator unit (P-173111).

!!!! Never operate a pneumatic tool with a bottled air or gas source.

!!!! For tension adjustments, follow instructions in this manual. For all other adjustments,

repairs or cleaning of the tool, disconnect air supply.

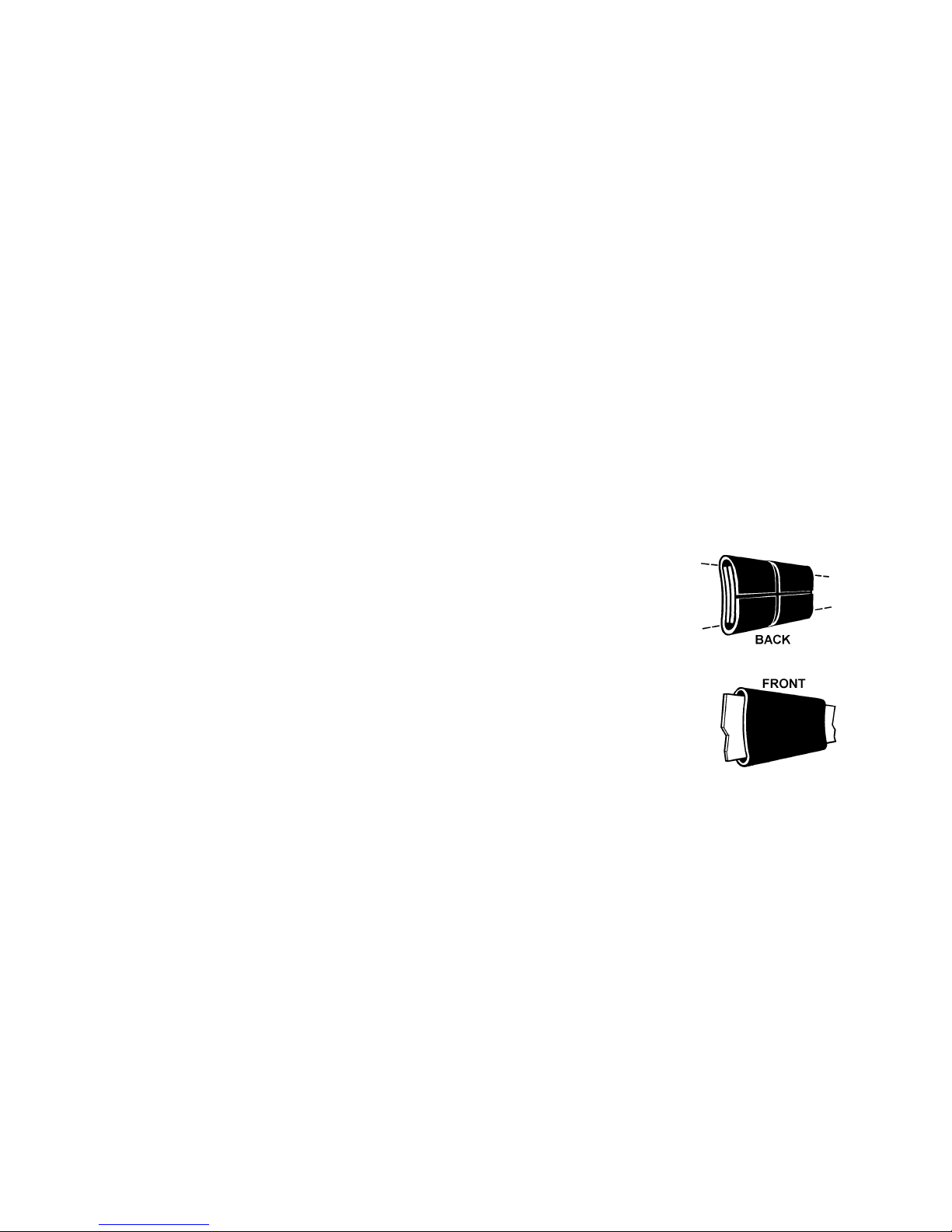

!!!! This tool has a crimp type sealer. A properly made joint will appear as

shown in the illustration. If the joint does not appear as shown, then the

operator must proceed as follows:

A. Insure that the tools operating instructions are

being followed before applying another strap.

B. Cut the strap off and apply another.

If the joint still does not appear as shown, then inspect the tool for worn and/or

damaged parts. Replace tool parts as needed. NEVER HANDLE OR SHIP ANY

LOAD WITH IMPROPERLY FORMED JOINTS. Misformed joints may not secure

the load and could cause serious injury.

!!!! Tuck strap end back into the dispenser when not in use.

CUTTING TENSIONED STRAP

Use only cutters designed for cutting strap; never use claw hammers, crowbars, chisels, axes or

similar tools. Such tools will cause the strap to fly apart with hazardous force. Before using any

Signode product, read its Operation and Safety Manual.

3

TABLE OF CONTENTS

General Safety Instructions 2

Specifications 4

Pneumatic Information 5

Strap Tension 8

Loading Seals 8

Cutter Adjustment 8

Page

Operating Instructions 9

Joint Inspection 10

Tool:

Parts List & Views 11

Disassembly/Assembly 17

Gear Housing

Parts List & View 20

Disassembly/Assembly 20

Air Motor I8R36:

Parts List & View 22

Disassembly/Assembly 24

Troubleshooting 25

Maintenance 33

Declaration of Conformity 35

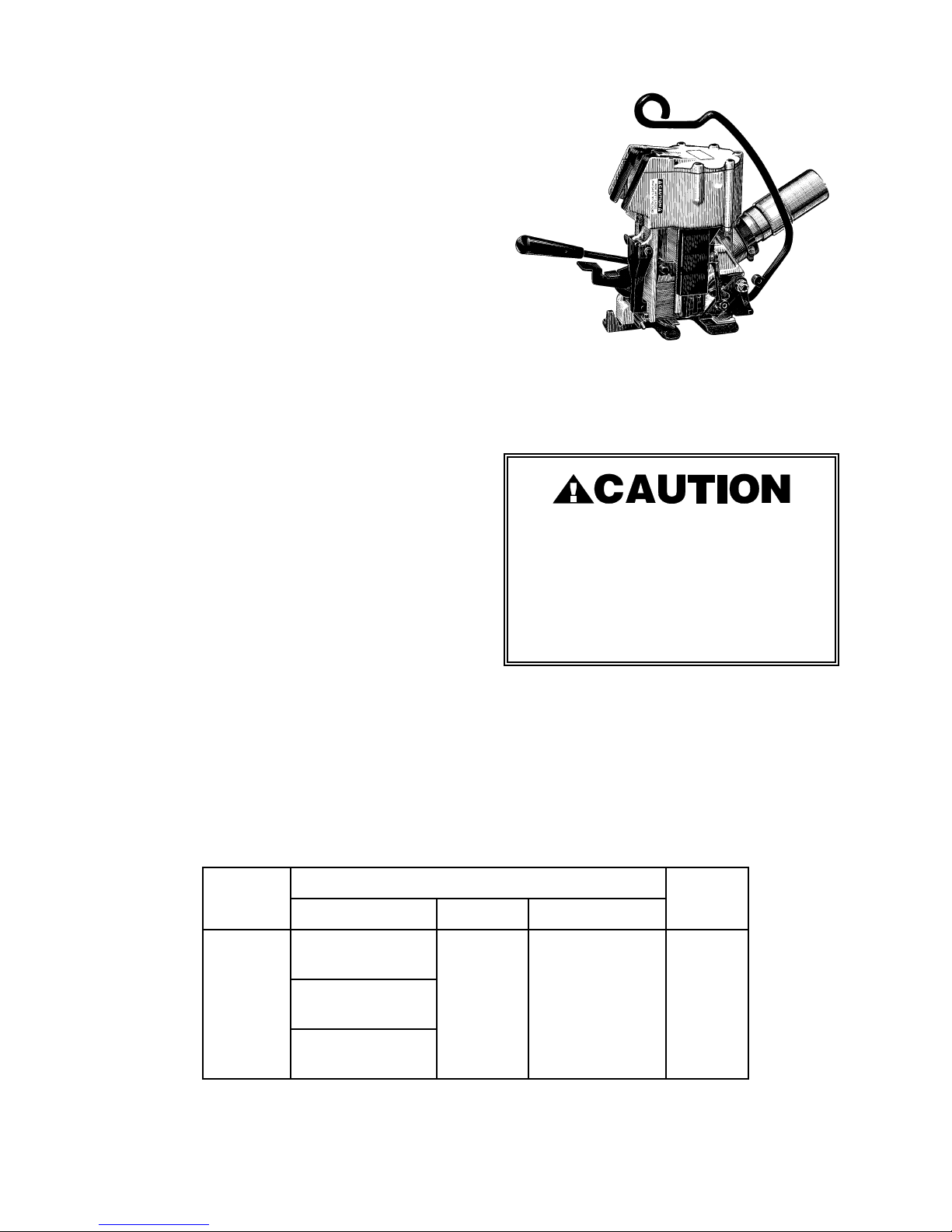

AMPT-12

Part No. 422910

DO NOT USE AMPT-12

WITH STEEL STRAPPING

Using strap not recommended for this

tool can result in strap breakage,

improper joint formation and tool

damage.

MODEL

1822,1818,1816

AMPT-12

508,506,504,502

SPECIFICATIONS

STRAP

TYPE WIDTH THICKNESS

Tenax

Contrax

818,816,814

Dymax

1/2"

(12mm)

4

.015" to .030"

(0.4 - 0.8mm)

SEAL

50ASD

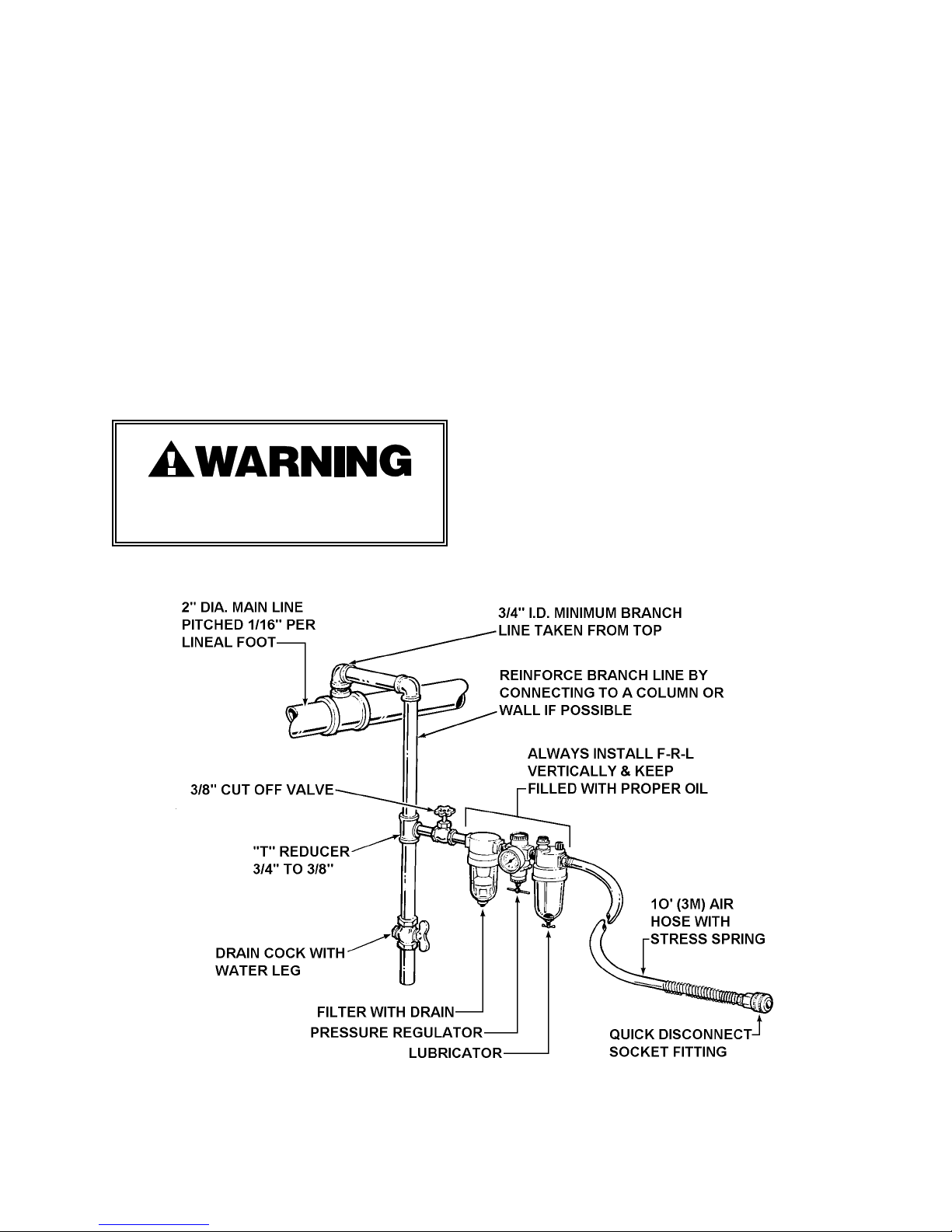

PNEUMATIC INFORMATION

AIR PRESSURE REQUIREMENTS

The AMPT-12 tools are designed to operate

at air pressures ranging between 65 and 90

psig (4.5 - 6.2 Bar).

AIR SUPPLY INSTALLATION

If compressor has a good dryer unit, use

black pickled pipe. When a dryer unit is not

installed, use galvanized or copper pipe.

To perform reliably, a pneumatic tool

requires a continuous source of clean, waterfree air at adequate pressure.

Never operate this tool using a

bottled air or gas source.

A filter-regulator-lubricator unit (Signode Part

No. 173111) must be installed as close to the

air tool as possible, preferably within 10 feet.

It should be placed in a convenient location

where it can easily be drained, adjusted, and

filled with oil. The air hose

must have at least a 1/4" I.D. A quickconnect press-on socket is installed on the

stress spring end of the hose for convenient

hookup to the air tool.

Filter and lubricator bowls are made of

polycarbonate material. Do not install where

bowls may be exposed to materials incompatible with polycarbonate. Certain oils,

solvents, and chemicals or their fumes can

weaken these bowls and possibly cause

them to burst. Clean only with warm water.

A cut-off valve placed ahead of the filter will

be useful when cleaning the filter or

replenishing the lubricator.

5

PNEUMATIC INFORMATION, Continued

MOISTURE

Moisture is always present in air lines due to

condensation within the lines as the air

cools. Steps must be taken to remove this

moisture and to keep it from the air tool.

This is because water tends to wash away

lubricants and cause corrosion, sticking and

failure of internal parts.

The main line should be pitched so the far

end terminates in a water leg. Branch lines

are taken from the top of the main, never off

the bottom. Every branch should have a

water leg at its lowest point, with a drain

cock which is drained daily.

If these precautions are taken and water is

still present, an after cooler and a moisture

separator are required between the compressor and the air receiver tank. A large air line

separator can be installed in the air tool line,

but precautions must be taken to insure that

it will be drained daily, before the air tool is

operated.

LUBRICATION

The air motor must be properly lubricated.

This is achieved by keeping the air line

lubricator filled with oil and correctly

adjusted. Without proper lubrication, the

motor will become sticky and the tool will

give low and erratic tension and be difficult

to release from the strap.

Install the lubricator as close to the air tool

as possible. The arrow on the lubricator's

top surface must point in the direction of air

flow.

For proper operation, oil must drop through

the lubricator sight glass at a rate of 1 to 4

drops per minute. This rate is checked while

the air tool is running free. Only 20% of this

oil is actually delivered to the tool. The

remaining oil drops back into the oil

reservoir. The unit is factory set and should

require no adjustment. If an adjustment is

required, the adjusting screw on top of the

lubricator may be turned as marked to

reduce or increase the flow of oil.

Water in air lines is a constant threat to the

proper operation of air tools. Even near

freezing operating conditions, a good

refrigerant type dryer is essential. A good

dryer will remove 95% or more of water right

at the compressor. The remaining moisture

is removed at the water leg in the piping

system or in the filter portion of the F-L-R

(Part No. 173111) unit.

NOTE: Additional information is available in

the Signode publication, "Air Supply Manual"

(Part No. 186038). If you have any questions,

contact your local Signode Representative.

The correct grade of oil must be used in the

lubricator; too heavy an oil will not provide

sufficient lubrication and will cause sticking

and sluggish operation of the air tool.

Recommended oils are any good grade of

rust and oxidation inhibiting oil with a

viscosity of 80-120 S.U.S. at 100 degrees

Fahrenheit. (0.15 to 0.25 cm2 /sec. at 38

degrees Celsius), such as:

Non Fluid Oil Co., grade #LS-1236

Signode oil - Part No. 008556

If necessary, use SAE #5 or SAE #10 nondetergent, cut 1 to 1 with kerosene.

NOTE: Some oils contain anti-wear additives

which may disable the air motor. Be certain

to use recommended oil.

Several drops of lubricator oil added to the

inlet of the air motor or into the air line each

day will help insure good operation. A

noticeable reduction of air motor

performance can usually be corrected by

squirting a few drops of oil into the air line.

6

AIR CONSUMPTION

COLD WEATHER OPERATION

Air consumption in cubic feet per minute

(cfm) for the AMPT-12 can be calculated as

follows:

cfm = (a) x (b) x (0.20)

a = Number of straps applied per minute.

b = Number of seconds motor is on per

strap during tensioning, from start to

deceleration to stall including stall

time while making joint when.

0.20 = AMPT-12 efficiency ratio.

Example Calculation:

Peak strapping load: 4 straps/min. so a = 4

Air motor run time: 5 sec./strap, so b = 5

AMPT-12 efficiency ratio is 0.20

(a)x(b)x(0.20) 6

Air pressure is assumed to be 90 psig (6.2

Bar) with recommended size and length of air

hose. Volume of air is at room temperature

and sea level pressure, or so-called "free air"

conditions. For more detailed information

about air supply systems refer to Signode

manual Part No. 186038.

6 4x5x0.20 = 4 cubic ft/min.

66

If a tool does not operate satisfactorily in

freezing temperatures, certain steps can

correct the problem. The following steps can

be taken to improve cold weather operation

of the tool:

a. An air line dryer adjacent to the

compressor.

b. Use lubricant recommended by Signode.

Signode has tested the use of antifreezes, none work well in air tools; the

tool will gum up when anti-freezes are

introduced and will not function properly.

The best lubricant for freezing weather is

the 1 to 1 oil and kerosene combination.

c. If possible, run the air supply line to a

indoor located Filter-RegulatorLubricator or relocate the F-L-R to a

warmer operating area.

7

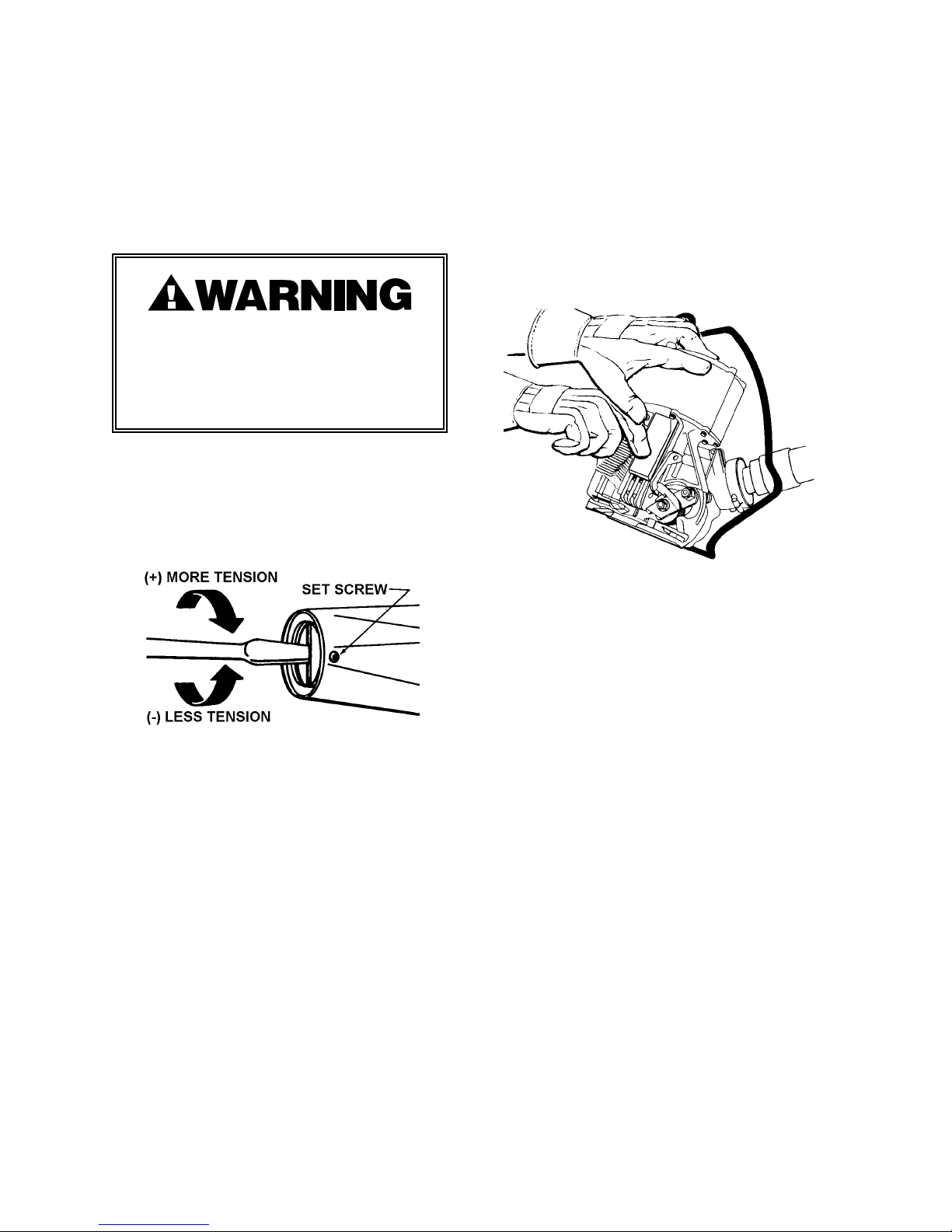

STRAP TENSION

LOADING SEALS

The AMPT-12 tools are factory tested to

ensure that at least 350 lbs. (1554N) of

tension is drawn at 90 psig (6.2 Bar).

NOTE: Make sure the input air pressure to

the tool is set between 65 and 90 psig.

Strap breakage hazard. Strap can break

while tension is being increased. Stand

to one side of the strap as it is being

tensioned. Failure to do so could result

in personal injury.

To adjust the AMPT-58 strap tension, use the

following instrcutions:

1. Loosen the set screw on the side of the

air motor.

To load seals, raise the seal pad assembly

and insert a stack of seals inside the seal

magazine. Release the seal pad. Activate

the sealing mechanism by depressing then

releasing the sealing lever. A seal will be

ejected into the sealing jaws. An extension

on the seal pad closes the top strap loading

slot as a reminder to add seals.

2. Turn the pressure adjustment screw in

increments of 1/8 turns clockwise to

decrease strap tension and counterclockwise to increase strap tension.

3. Turn the adjustment screw until the

desired tension level has been reached.

4. When a satisfactory tension level has

been reached tighten the set screw.

The tool is now set to operate at a given air

pressure in combination with a particular

strap size. Any change in air pressure or

strap size could result in unsatisfactory tool

performance or strap breakage.

CUTTER ADJUSTMENT

If the cutter on the tool does not cut properly,

loosen the shoulder bolt (39) and cap screw

(42), and adjust set screw (44) to remove

clearance between the cutter blade and the

cutter block. Adjust with the jaws in the

down position. Do not over tighten as the

sealing mechanism can be bound by this

adjustment. When adjustment has been

made, retighten the shoulder bolt and cap

screw.

8

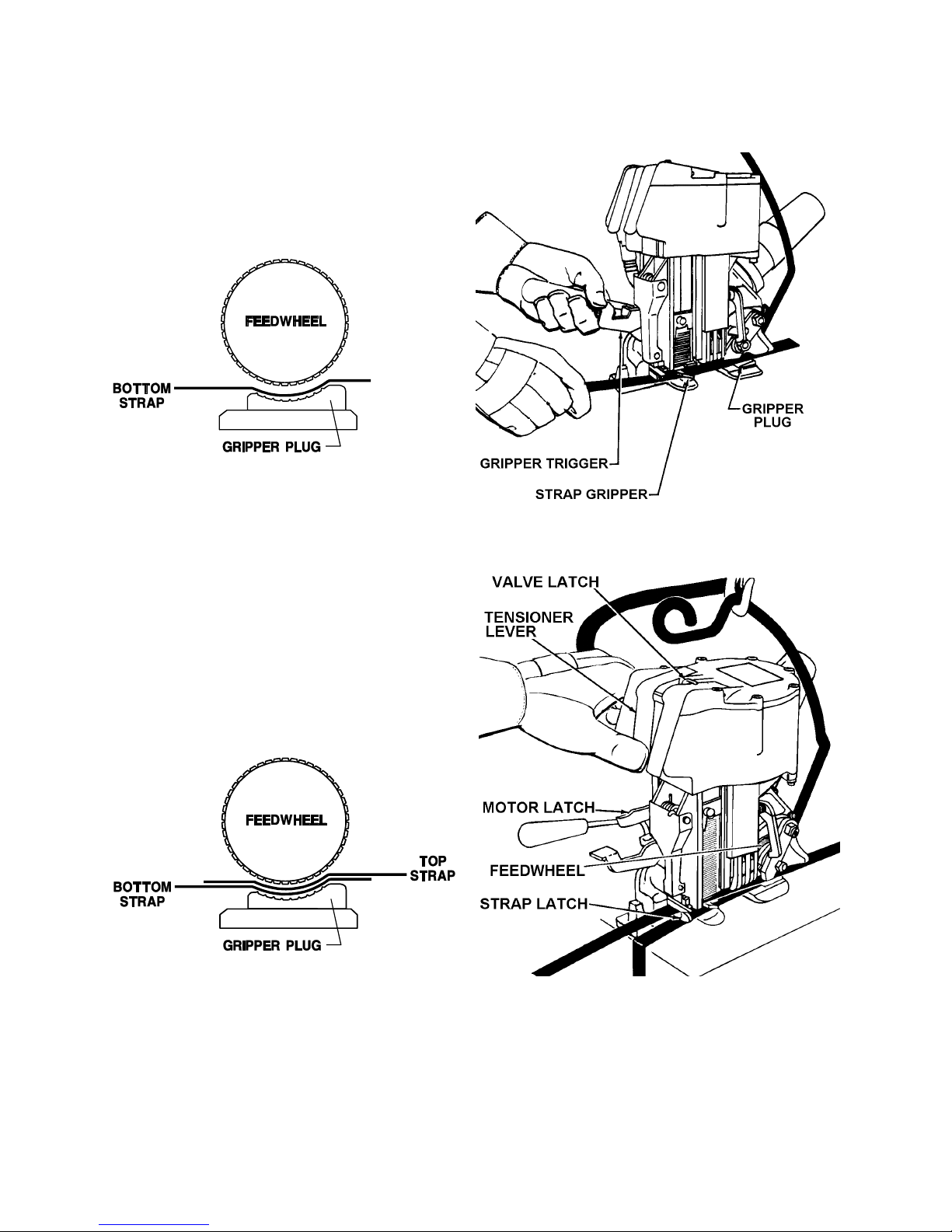

OPERATING INSTRUCTIONS

1. Encircle the package with strap and insert

the bottom end under feedwheel so that it

extends at least 1/2" (12mm) beyond the

gripper plug. Depress the gripper trigger to

actuate the strap gripper.

2. Insert the top strap between the feedwheel

and the gripper plug and insert it into the slot

of the strap latch. Pull excess slack from the

strap. Make sure you are not standing in line

with the strap and press the tensioner lever

all the way down. It will lock in place. The

feedwheel will engage automatically and the

tool will begin tensioning. Should it become

necessary to stop the tensioning cycle, press

the valve latch forward.

NOTE: The feedwheel can be lowered manually, without starting the motor, by pressing the

motor latch. To start the motor, press the tensioner lever.

9

OPERATING INSTRUCTIONS, Continued

3. The motor will stall when the pre-set tension

level has been reached. Press the sealer

lever all the way down, then release. Do not

hold tensioner lever down while pressing the

sealer lever as the tensioning lever will be

released automatically. The tool will

automatically seal the straps together, cut off

the top strap and eject a new seal into the

jaws. Inspect the joint to make sure the tool

has properly crimped the seal.

4. After the tool has sealed and the sealing

mechanism retracts, the feedwheel will

automatically raise off the straps. Swing the

rear of the tool away from the completed tie

to free the tool.

5. If the resulting tension level is not

satisfactory for your strapping needs, then proceed to adjust

the tension as described earlier in this manual.

JOINT INSPECTION

This tool has a crimp type sealer. A properly made joint will

appear as shown in the illustration. If the joint does not

appear as shown, then the operator must proceed as follows:

1. Insure that the tools operating instructions are being

followed before applying another strap.

2. Cut the strap off and apply another.

If the joint still does not appear as shown, then inspect the

tool for worn and/or damaged parts. Replace tool parts as needed.

NEVER HANDLE OR SHIP ANY LOAD WITH IMPROPERLY FORMED

JOINTS. Misformed joints may not secure the load and could

cause serious injury.

10

PARTS LISTS & EXPLODED VIEWS

TOOL HOUSING

KEY DESCRIPTION QTY. PART NO.

1 SHCS, 10-24 x 13/16 11 180600

1A FHSCS, 10-24 x 3/4 1 008757

2 SHCS, 10-24 x 1 2 004061

3 Valve Latch Pin 1 020658

4 Valve Latch 1 020653

5 Valve Latch Spring 1 020654

6 SHSS, 1/4-28 x 7/16 1 004361

7 Tensioning Lever 1 020656

8 Sealing Lever 1 020655

9 Cover 1 020691

10 Valve Lever Pin 1 020671

11 Cover Gasket 1 016906

12 O-Ring 1 020702

14 Piston 1 020648

15 O-Ring 6 020699

16 Tensioner Valve Sleeve 1 020651

17 O-Ring 5 020701

18 Tensioner Valve 1 020652

19 Valve Spring 1 020665

20 Sealer Valve Sleeve 1 020660

21 Sealer Valve Sleeve 1 020657

22 Sealer Valve 1 020731

23 Sealer Valve Spring 1 020725

24 Sealer Valve Sleeve 1 020732

25 Cylinder 1 020734

27 Hansen Plug 1 020704

28 Pipe Bushing 1 008478

29 Elbow 1 020710

29A Tru-Seal, 1-1/4 NPT 1 023087

29B 90° Elbow, 1/4 Tube x 1/4-18 NPS 1 023524

30 SHSS, 1/4-28 x 1/4 1 003465

31 FHSCS, 10-24 x 1/2 2 020729

32 Cover Plate 1 020726

33 Sure-Seal Spring 1 020724

34 Sure-Seal Pawl 1 020727

35 O-Ring 1 020728

36 O-Ring 1 020680

37 Motor Plunger 1 020668

38 Plunger Spring 1 020669

39 Shoulder Bolt 1 024726

40 Roll Pin, 1/8 x 13/16 2 004658

41 Motor Latch 1 020639

42 SHCS, 5/16-18 x 1 1 009016

43 Sealer Frame 1 267632

44 SHCS, 1/4-20 x 1/2 1 023352

45 Roll Pin, 3/16 x 1 1 006787

46 Roll Pin, 3/16x 1-1/2 1 020707

11

Loading...

Loading...