Signode 4A1-114, 4A1-114KR, 4A1-2 Operation, Parts And Safety Manual

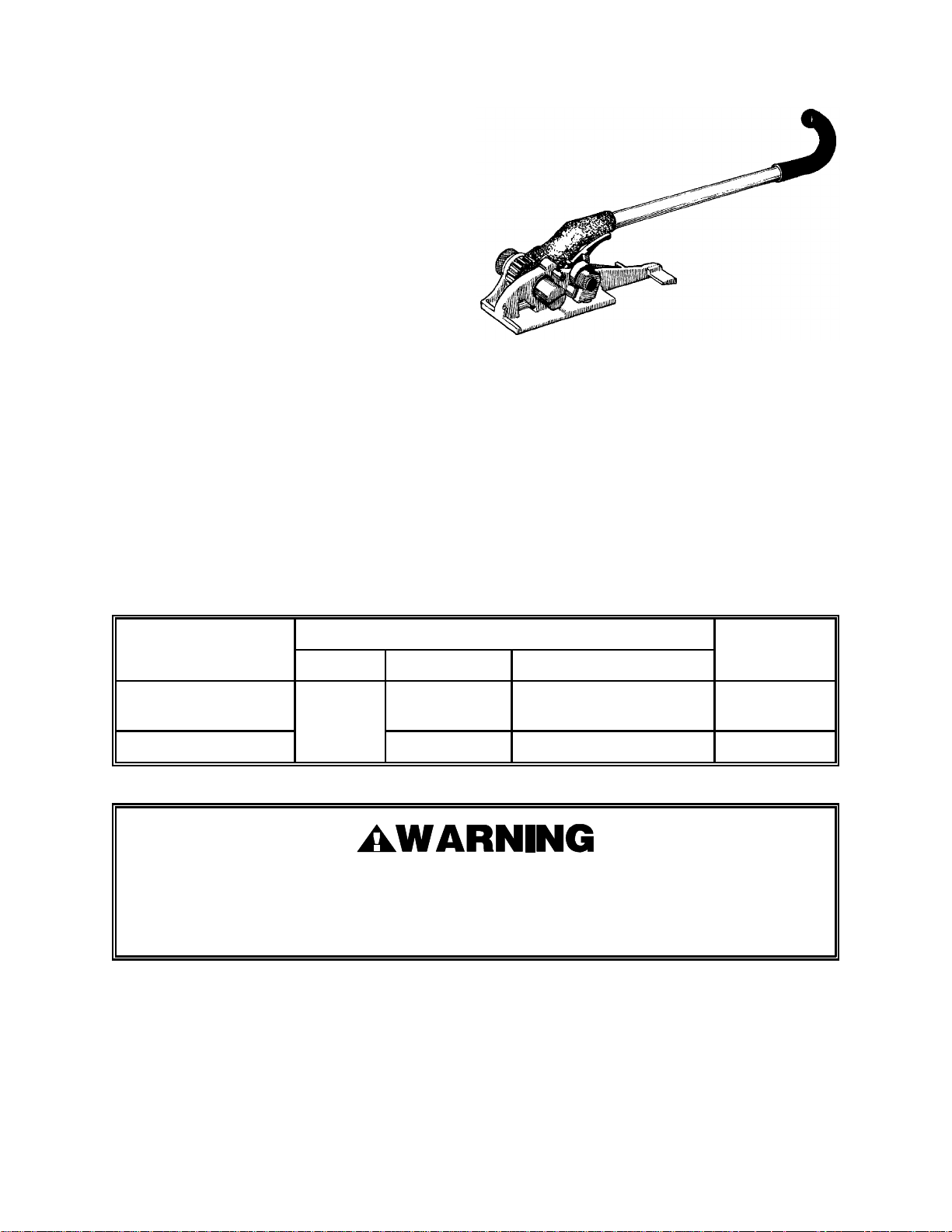

4A1-114/114KR & 4A1-2

MANUAL TENSIONERS

READ THESE INSTRUCTIONS CAREFULLY. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN SEVERE PERSONAL INJURY.

GENERAL SAFETY CONSIDERATIONS

1. TOOL MANUAL

Before using this tool read and understand the operation manual.

2. STRAP BREAKAGE HAZARD

Never position yourself in-line with the strap during tensioning and sealing. Properly position

yourself when tensioning and sealing as shown in the operating instructions.

Improper operation of the tool, sharp corners on the load, improper strap placement around

the load or an unstable or shifted load could result in strap release or breakage, during

tensioning. This could result in the following:

!! A sudden loss of balance causing you to fall.

!! Both tool and strap flying violently towards your face.

3. TRAINING

This tool must not be used by persons not properly trained in its use. Be certain that you

receive proper training from your employer. If you have any questions contact your Signode

Representative.

4. EYE INJURY HAZARD

Failure to wear safety glasses with side shields can result in severe eye injury or

blindness. Always wear safety glasses with side shields which conform to ANSI

Standard Z87.1 or EN 166.

5. FALL HAZARD

Maintaining improper footing and/or balance when operating the tool can cause you to fall.

Do not use the tool when you are in an awkward position.

6. CUT HAZARD

Handling strap or sharp parts could result in cut hands or fingers. Wear

protective gloves.

7. TOOL CARE

Take good care of the tool. Inspect and clean it daily, lubricate it weekly and adjust when

necessary. Replace any worn or broken parts.

8. WORK AREA

Keep work areas uncluttered and well lighted.

2

9. WARNING LABEL 177896

The warning label shown below is on the tool handle. If this label becomes damaged, replace

it immediately. Ensure that a plastic shrink tube sleeve us applied over the label. Contact

your Signode Sales Representative if you have any questions.

10. CUTTING TENSIONED STRAP

A. Keep all bystanders at a safe distance, away from the danger zone (shaded area) and

possible flying strap ends.

B. Stand to one side of the strap being cut - outside of the danger zone (shaded area).

C. Cut the strap.

3

TABLE OF CONTENTS Page

General Safety Instructions 2

Specifications 4

Operating Instructions Overview 5

Placement Around Load 6

Inserting Strap Into Tool 7

Top of Load 8

Side of Load 9

Wall Anchored Load 10

Part Removal & Replacement 12

Troubleshooting 16

Parts List 20

4A1-114, Part No. 184125

4A1-114KR, Part No. 1844135

4A1-2, Part No. 184140

SPECIFICATIONS

STRAP

TOOL MODEL TYPE WIDTH THICKNESS SEALS

4A1-114

4A1-114KR Magnus

4A1-2 2" Min. .044" Min. to .050"

1-1/4" Min. .031" Min. to .050"

With the 4A1-114 and 4A1-114KR tools, use only 1-1/4" wide (minimum) x .031" thick

(minimum) hi tensile strap. With the 4A1-2 tool, use only 2" wide (minimum) x .044" thick

(minimum) hi tensile strap. Failure to use the proper tool or strap can result in serious

injury. Contact your Signode Sales Representative for the correct strap for your application.

4

OPERATING INSTRUCTIONS

When tensioning or sealing, position yourself according to the operation instructions for

the type of load being strapped. Keep all bystanders away.

It is recommended that safety belts be worn by operators working on at elevated positions.

Never increase the length of the tensioning handle by any means such as extending the

handle length.

Apply tensions that are proper for the size and type of strap being used and is compatible

with the loads being strapped and its corner characteristics. Contact your Signode Sales

Representative if you have any questions.

Tuck the strap end back into the dispenser when you are not using it.

Operating instructions are broken down into the following sequences:

1. Placing strapping around a load.

2. Inserting strapping into tool.

3. Tensioning strap when on top of a load.

4. Tensioning vertical strap for sides of a load.

5. Tensioning strap for wall anchored load and horizontal strap.

The warning label shown below (177896) is installed on every tool handle. If this label becomes

damaged, replace it immediately. Ensure that a plastic shrink tube sleeve us applied over the

label. Contact your Signode Sales Representative if you have any questions.

5

STRAP PLACEMENT AROUND LOAD

1. Place strap around load as shown in the illustrations.

HORIZONTAL STRAP SIDE LOAD

VERTICAL STRAP SIDE LOAD

TOP STRAP LOAD

Failure to place the strap properly around the load or an unstable or shifted load could

result in a sudden loss of strap tension during tensioning. This could result in a sudden

loss of balance casing you to fall.

If the load corners are sharp use edge protectors.

Failure to follow the above could result in serious injury or death.

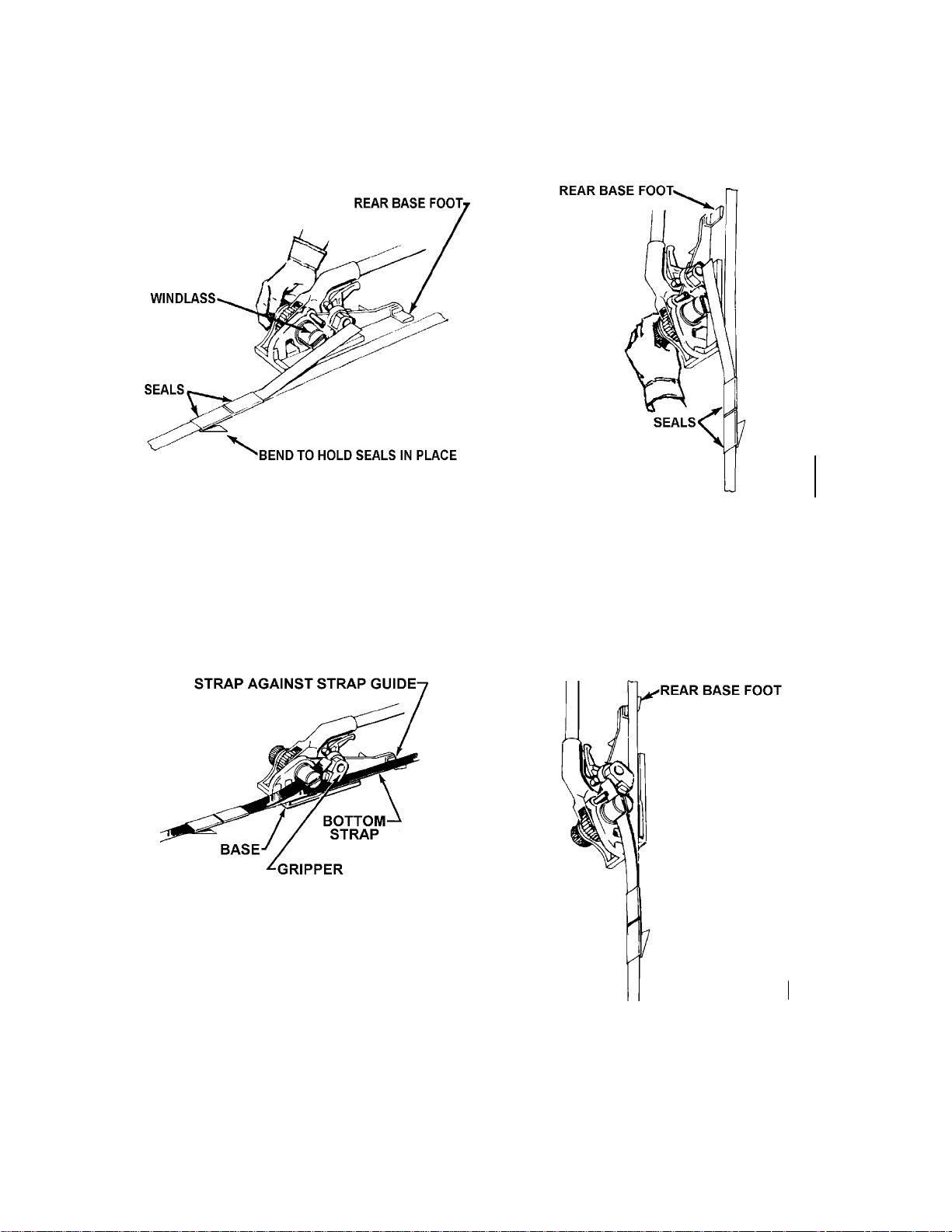

2. Thread the proper number of heavy duty seals on both straps, Contact your Signode Sales

Representative for recommendations. Bend the lower/inner strap backwards to hold seals in

place. Bend the upper/outer strap away from the load to permit insertion into the windlass of

tensioner.

6

INSERTING STRAP INTO THE TOOL

1. Rotate the tensioning handle all the way down to lock the gripper in the open position.

Adjust the windlass so that the slot is in line with angle of strap.

TYPICAL ORIENTATION FOR TOP LOADS

TYPICAL ORIENTATION FOR SIDE LOADS

2. Insert lower/inner strap in opening between gripper and base of tensioner until the strap is

fully in contact with the inner wall of the base (strap guide). Make sure that the lower/inner

strap is inserted over the base foot. Insert top/outer strap fully into windlass slot.

Approximately 2 to 4 inches should extend beyond windlass; cut off any excessive length

before tensioning.

TYPICAL ORIENTATION FOR TOP LOADS

TYPICAL ORIENTATION

FOR SIDE LOADS

7

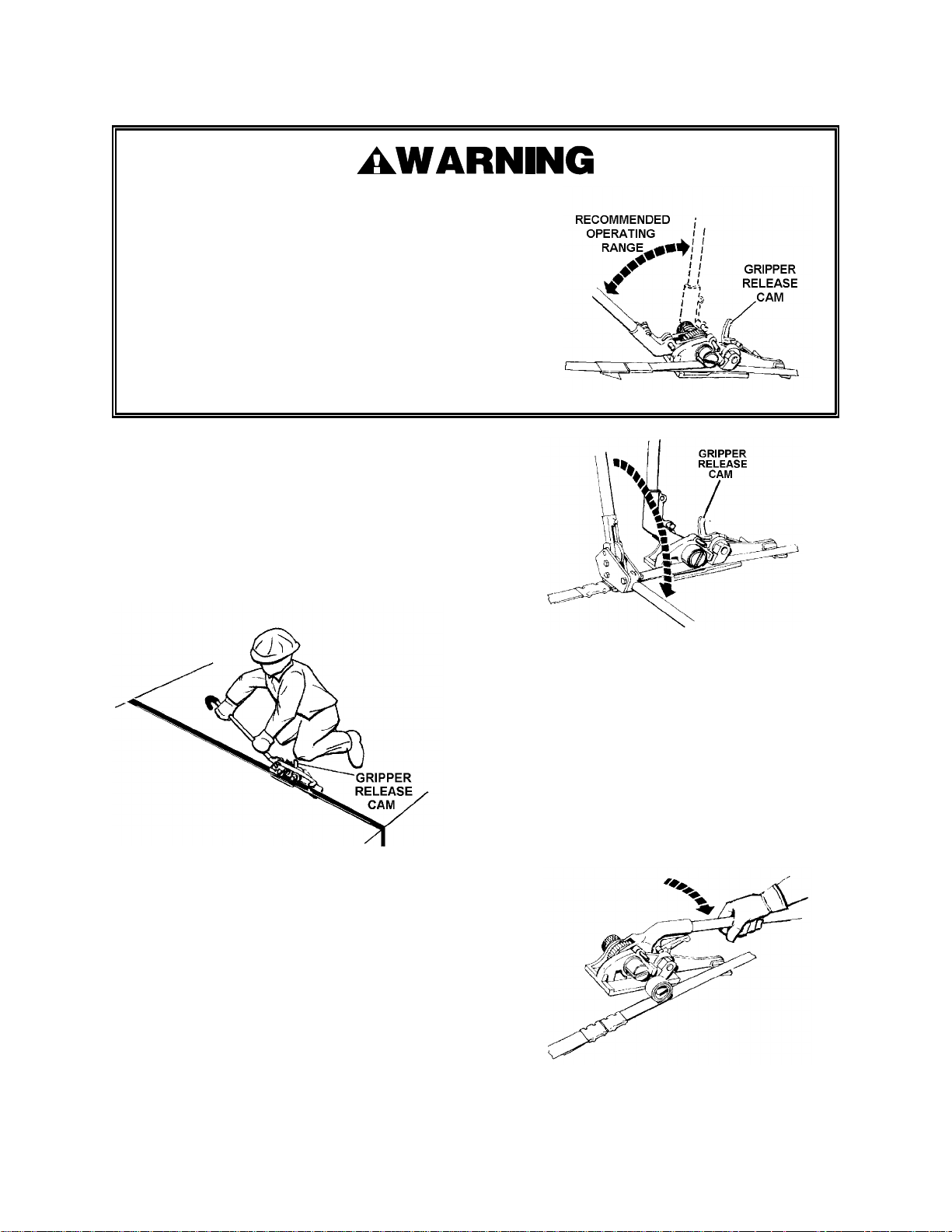

OPERATING INSTRUCTIONS FOR ON TOP OF LOAD

While tensioning strap, do not rotate the tensioning

handle to the point where it will contact the gripper

release cam. This will result in a sudden loss of strap

tension. Be careful when applying final tension, as

excessive tension could cause strap breakage.

Position yourself in such a manner that strap

breakage or hands slipping off the handle will not

cause a loss of balance. Never increase the length of

the tensioning handle by any means, such as, slipping

a pipe over the handle to extend its length. If you have

any questions contact your Signode Sales

Representative.

1. Bring tensioning handle upward,

allowing the gripper to contact the lower

strap. Rotate tensioning handle back

and forth to take up slack in strap. When

strap is snug, the operator should kneel

perpendicular to the strap and apply the

final tension using short tensioning

strokes.

2. Open sealer fully and center sealer jaws

of sealer over each seal. Crimp or notch

each seal the proper number of times by

bringing the top handle downward as far

as it will go.

Consult your sealer manual for the

proper number of crimps or notches

needed for your application.

3. Release tensioner from strap by bringing

handle down until gripper release cam

locks in tensioning handle pin. Remove

tensioner by twisting windlass slot out

of strap curl and sliding tool away from

strap.

8

Loading...

Loading...