Page 1

INSTALLATION INSTRUCTIONS:

Signify North America Corporation Signify Canada Ltd.

200 Franklin Square Drive 281 Hillmount Road,

Somerset, NJ 08873 Markham, ON, Canada L6C 2S3

Telephone 855-486-2216 Telephone 800-668-9008

Safety, Warnings and Suggestions

1

2

9

10

should be taken not to position fixtures in locations where bare skin can come into contact with the potentially high

Care

temperatures on the lens.

3

4

5

6

7

8

sure that electrical power is disconnected before any work in performed.

Make

wiring and installation should meet local, state and national electrical codes. This will help prevent wire connector

All

corrosion due to water penetration from conduit.

correct lamp type and wattage per lamp label.

Install

gaskets and sealing surfaces must be kept clean during installation.

All

Check

that the inside of the housing is free of debris of any kind. This can obstruct the flow of air and

increase the temperature of the lens surface.

Check

that the gap between the lens ring and the casting is clear of any obtruction. Clean

installing fixtures in locations where water collects and stands for long periods.

Avoid

if required. Debris can obstruct the flow of air and increase the temperature on the lens surface.

a rule of thumb, the higher the fixture is mounted above grade potential problems such as foliage over growth or

As

water, mud etc. collecting on lens are reduced.

condensation, built up during installation, is visible on the lens it is recommended that the fixture be turned on before

If

the lens ring is replaced on the fixture for approximately 30 minutes. This should allow the condensation to be exhausted.

Mount fixture as high above grade as

1

8

6 5

4

2

3

7

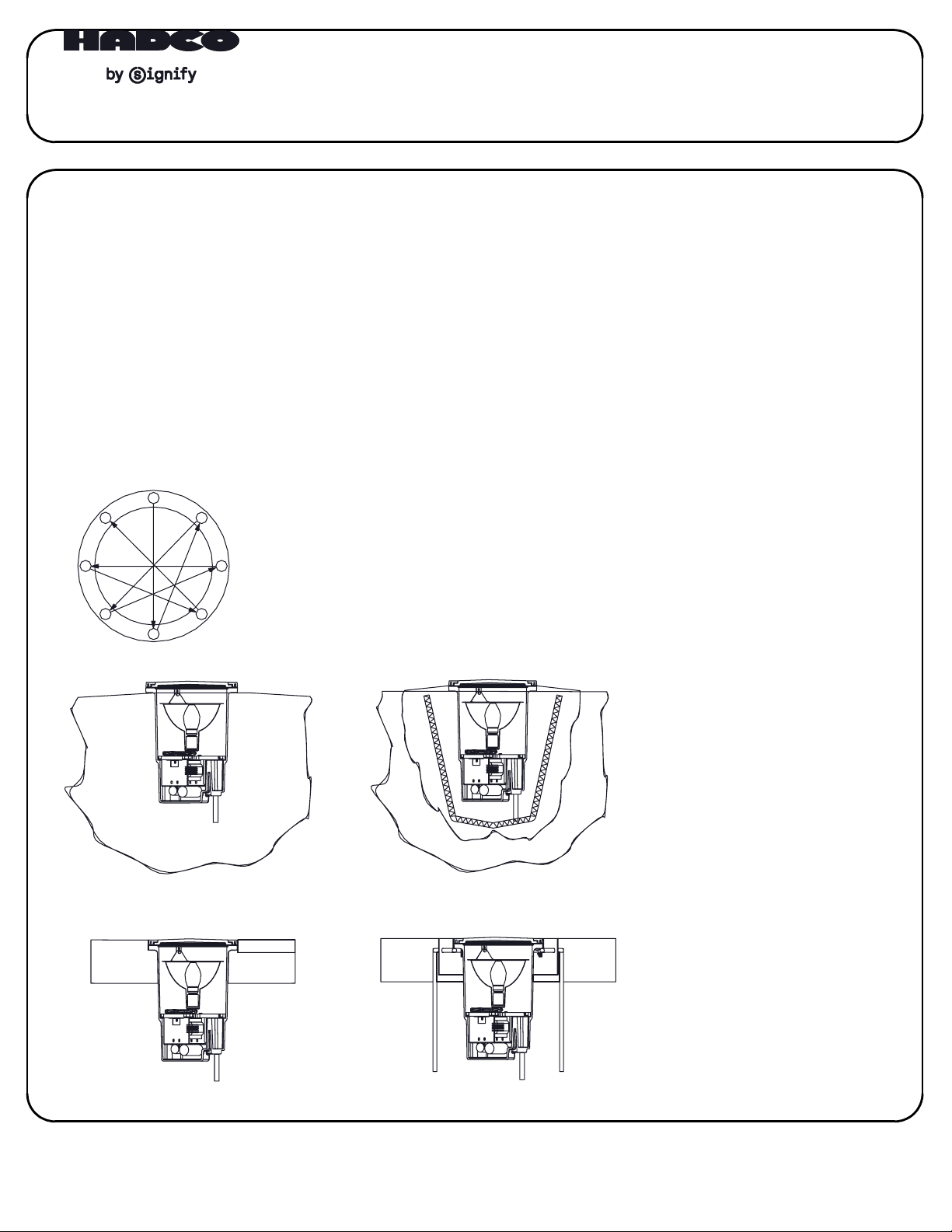

SL-43 In Soil

Use several

rotations of

the following

sequence to

tighten the

lens ring socket

head cap screws

to 50 in/lbs.

possible to prevent debris and water

standing on fixture surface.

Create an isolation barrier around

the fixture to prevent rocks and

foilage from interfering with light output.

Add drainage media below and around

fixture to prevent standing water.

SL-43 In Soil with Concrete Base

and Trim Ring

Concrete

Paver/Marble

Use reinforcement

where necessary to

prevent concrete

cracking.

SL-43 In Concrete with Trim Ring

SL-43 In Concrete with Grout Mask

and Trim Ring

SL-43

1. Prepare the site with adequate

excavation to install fixtures.

Drainage media below fixture will

enhance installation.

2. Remove lens ring and lens with

gasket,

"D" shaped splice box cover plate

and gasket.

3. Connect conduit to the 3/4" NPT

openings in the splice compartment

at the bottom of the fixture, using

the appropriate thread sealing

compound.

4. Position fixture so it is flush or just

above the installation area grade

and orient the fixture with regard to

architectural requirements to obtain

the appropriate accent.

5. Make power and ground connections

using provided waterproff wire nuts.

It is recommended that RTV silicone or

other re-enterable water sealing

compound be used to seal the

conduit entry points.

6. Reinstall "D" shaped splice box cover

plate and gasket ensuring that all

(4) screws are securely tightened.

Reinstall reflector assembly, install

lamp

7. Install lens ring and lens with gasket

IMPORTANT! A CRISS CROSS PATTERN

IS REQUIRED TO ENSURE THAT A GOOD

COMPRESSION SEAL IS MADE.

If this is not accomplished, the fixture

could leak and be damaged.

Tighten socket head cap screws

gradually using multiple tightening

steps to 50 in/lbs.

4

8

and make aiming adjustments.

1

2,3

reflector assembly and

Tighten to 15 ft-lbs. max.

5

7

4

4

32A41398, revision C

page 1 of 2

Page 2

INSTALLATION INSTRUCTIONS:

SL-43 (LED VERSION ONLY)

FOLLOW ALL SAFETY PRECAUTIONS AND SITE PREPERATIONS PER PAGE 1 OF THESE INSTALLATION INSTRUCTIONS.

!!

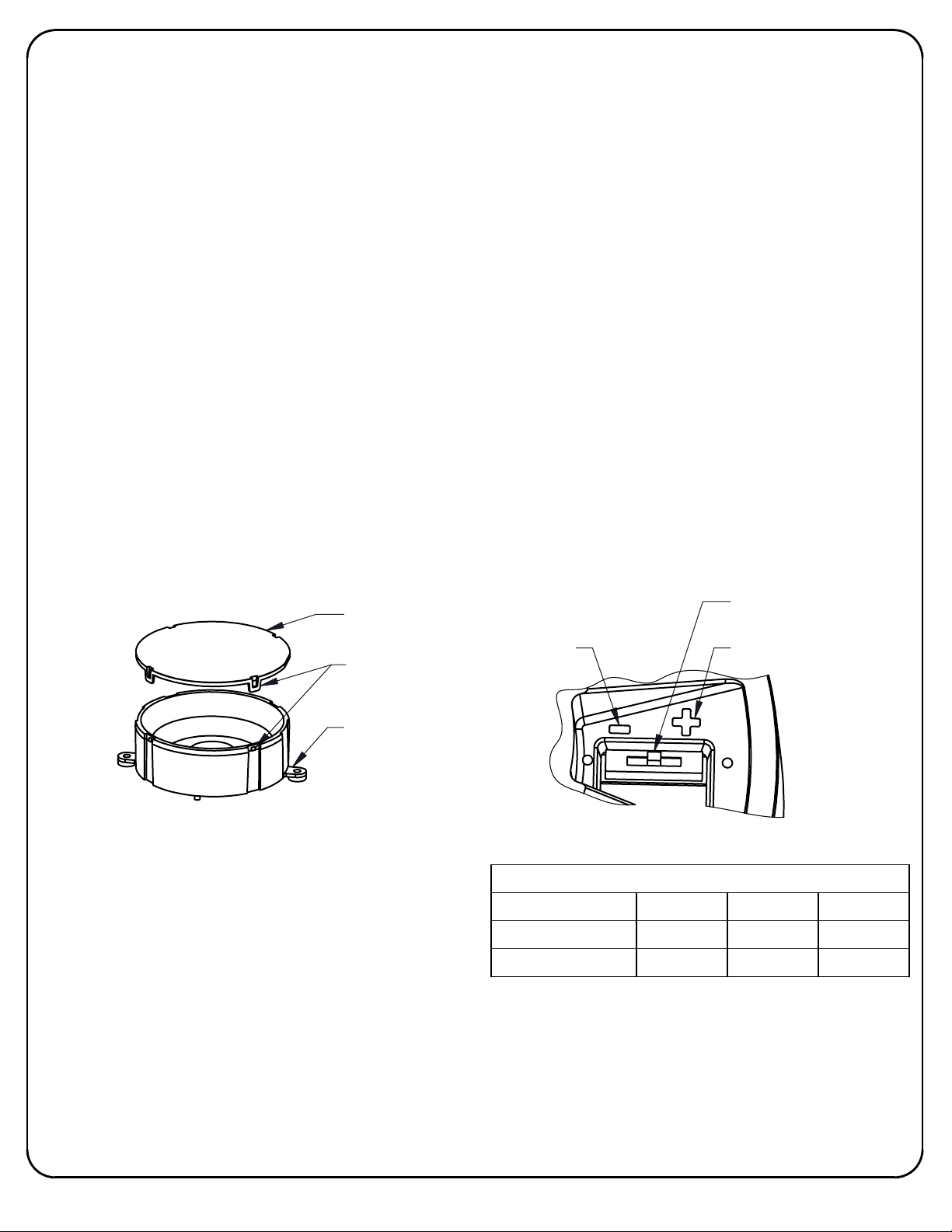

1. Remove lens ring and lens with gasket.

2. Remove foam packing around heatsink used for shipping and discard appropriately.

3. Remove heatsink/ring assembly and "D" shaped splice box cover plate.

4. Connect conduit to the 3/4" NPT openings in the splice compartment at the bottom of the fixture using the appropriate thread sealing

compound.

5. Connect white (neutral) supply wire to white fixture wire, black (hot) supply wire to black fixture wire, and greeen (ground) supply wire

to green fixture wire using provided waterproof wire nuts. It is recommended that RTV Silicone or other re-enterable water sealing

compound be used to seal the conduit entry points.

*Control wires (gray and purple) are crimped to prevent cross wiring. If using a dimming device, cut ends, strip and connect.

- See approved dimmer list per Xitanium driver X1036C100V048DNM1 datatsheet.

- Consider limitation/impact of long wire runs when installing 0-10V dimming systems.

*Input voltage (VAC): 120-277v auto sensing, 50 or 60Hz

*Fixture load: 34W max.

6. Reinstall "D" shaped splice box cover plate ensuring that all four (4) screws are securely tightened.

7. Fixture is pre-installed with "Medium Flood" optic lens from factory. To replace with "Narrow Flood" or "Wide Flood" optics, pop optic lens

off reflector by using fingernails or screw driver at the (4) tabs.

Narrow flood lens (20 deg)

Medium flood lens (36 deg)

Wide flood lens (65 deg)

Align new optic lens with tabs and push onto reflector until all four locations snap into place.

8. Adjust lumen output switch by sliding the switch to the desired setting. There are (5) different settings ranging from 9.5W to 34W.

See chart below for approximate lumen values. Heatsink has a "+" and "-" symbol to illustrate wattage level.

9. Reinstall heatsink/ring assembly. Angle heatsink in orientation desired (typically vertically straight).

10. Reinstall lens ring and lens with gasket. Tighten socket head cap screws gradually using multiple tighening steps

(see pictorial of pattern on page 1).

IMPORTANT! A CRISS CROSS PATTERN IS REQUIRED TO ENSURE THAT A GOOD COMPRESSION SEAL IS MADE.

If this is not accomplished, the fixture could leak and be damaged.

Tighten to 15 ft-lbs. max.

- supplied in bag, marked along edge of lens with "P".

- pre-installed, marked along edge of lens with "I".

- supplied in bag, marked along edge of lens with "S".

OPTIC LENS

(3 OPTIONS)

ALIGN TAB

WITH NOTCH

MIN. (9.5W) SETTING

to 50in/lbs.

OUTPUT SWITCH

(NOMINAL 20W SHOWN)

MAX. (35W) SETTING

!!

REFLECTOR

(DO NOT REMOVE)

REPLACEMENT OPTIONS:

1. Driver - includes driver and mounting screws.

2. Optic lens kit - includes [3] optic lenses (reflector not included)

3. Switch kit - includes switch and mounting screws.

DRIVER REPLACEMENT INSTRUCTIONS:

1. Remove lens ring and lens with gasket.

2. Remove heatsink/ring assembly and driver box cover plate.

3. Remove driver screws and detach driver.

4. Disconnect existing driver wires from connectors and replace driver.

See wiring diagram for Xitanium driver X1036C100V048DNM1.

*Reconnect wires to surge protector (SP1) if applicable.

5. Reattach driver to cover.

6. Reassemble remaining items per installation instructions above (see item numbers 8-10).

Beam/Switch output

Medium Flood (3000K)

Medium Flood (4000K)

Lumen Output Table (Clear Glass Lens Option)

Factory pre-set at this level.

*

9.5W (min)

1030 2055 3075

1095 2185 3269

* 20W (nom)

34W (max)

32A41398, revision C

page 2 of 2

Loading...

Loading...