Page 1

Reliable SR

technology for

connected

LED applications

LED Drivers

Design-in Guide

Page 2

Contents

Introduction to this guide 3

Information or support 3

Application note 3

Warnings and instructions 4

Safety warnings and installation instructions 4

Introduction to Advance Xitanium

SR bridge 5

Xitanium SR bridge 5

Xitanium SR bridge versions 5

Programmable interface 5

SimpleSet technology 5

SR bridge wiring diagram 5

Features of Xitanium SR bridge 6

Wide mains input range 6

Switchable output using zero

crossing detection 6

Sensor ready (SR) interface 6

Energy metering 6

MultiOne/SimpleSet congurable features 6

Sensor ready (SR) interface 7

Sensor ready interface 7

Typical examples 8

Digital communication 9

Other considerations for SR interface 9

SR bridge use cases 10

Basic SR bridge use case 10

347V SR bridge use case 1 1

SR bridge dimming curve and dimming range 1 1

SR bridge fault detection use case 1 1

SR bridge class room with occupancy/

daylight harvesting use case 12

SR bridge hallway use case 13

Mechanical design-in 14

Form factors 14

Thermal management 15

Introduction 15

Temperature case point 15

Electrical design-in 16

Inrush current 16

Surge protection 16

Leakage current 17

Electromagnetic compatibility (EMC) 17

Electrical isolation 17

Disclaimer 18

Notes 19

2 Advance Light ing

Page 3

Introduction to this guide

Figure 1. Advance Xitan ium SR br idge.

Xitanium SR Bridge

Design-in Guide

Intro duc tion

to This Gu ide

Thank you for choosing the Advance Xitanium sensor ready

bridge (SRB). In this guide you will nd the information

needed to integrate SRB devices into an LED luminaire

or LED system.

Information or support

For further information or support please consult your local Advance oce or visit:

• Xitanium SR bridges or SR drivers: www.philips.com/xitaniumsr/na

• OEM general info: www.philips.com/oemna

• EasySense: www.philips.com/easysense

Application note

The Advance Xitanium SR bridge allows existing 0-10V dimming systems to become

part of wireless connected lighting systems for indoor lighting such as oces,

public buildings, industrial applications and retail environments.

3

Page 4

Warnings and instructions

Warnings

• Avoid touching live parts!

• Do not use SR bridge and connected driver(s) with damaged housing

and/or connectors!

• Do not use SR bridge and connected driver(s) with damaged wiring!

Safety warnings and installation instructions

• Do not use damaged products.

• Do not short SR bridge output wires.

• SR bridge output wire is a live mains part when switched on.

• The luminaire manufacturer is responsible for complete luminaire design and must

comply with all relevant safety standards.

• The SR bridge is suitable for built-in use only and must not be exposed to the elements

such as snow, water and ice or to any chemical agent that can be expected to have an

adverse eect on the driver (e.g., corrosive environments). It is the responsibility of both

luminaire manufacturer and installer to prevent exposure. The SR bridge specied for UL

damp and dry locations.

• Do not service the SR bridge and connected driver(s) when the mains voltage is

connected; this includes connecting or disconnecting the loads.

• SR bridge and connected driver(s) must be installed in accordance with national and

local electrical codes.

• Proper earth and/or equipotential connections are required whenever possible

or applicable.

4 Advance Li ghtin g

Page 5

Introduction to Advance

Advance Xitanium SR bridge

Figure 2. Advance Xitan ium SR br idge.

Xitanium SR Bridge

Design-in Guide

Intro duc ti on to

Advance Xitanium

SR Bridge

Xitanium SR bridge

The Advance Xitanium SR bridge is designed to connect existing or new 0-10V dimming

indoor lighting systems to SR (wireless) connected systems. Applications include oces,

public buildings, industrial applications and retail environments.

With Xitanium SR functionality, exibility in luminaire design is assured, and with the SR

interface it is simpler than ever to connect to SR certied sensors.

Xitanium SR bridge versions

The Xitanium SR bridge described in this guide is available in two versions; a –BS version

with mounting studs to mount the box to an existing (downlight) xture mounting plate and

a –LD version to be mounted inside luminaires.

Detailed specications can be found in the Xitanium SR bridge datasheets, which can be

downloaded at www.philips.com/xitaniumsr/na.

Programmable interface

The Xitanium SR bridges are programmable. Some features and parameters can be set via

the SR Interface or SimpleSet technology using Advance MultiOne Congurator software.

SimpleSet technology

Advance SimpleSet NFC wireless programming technology allows luminaire manufacturers

to quickly and easily program the Xitanium SR bridge during the manufacturing process,

without a connection to mains power, oering great exibility.

For more information on MultiOne or SimpleSet technology, please visit www.philips.com/

multione or contact your local Advance representative.

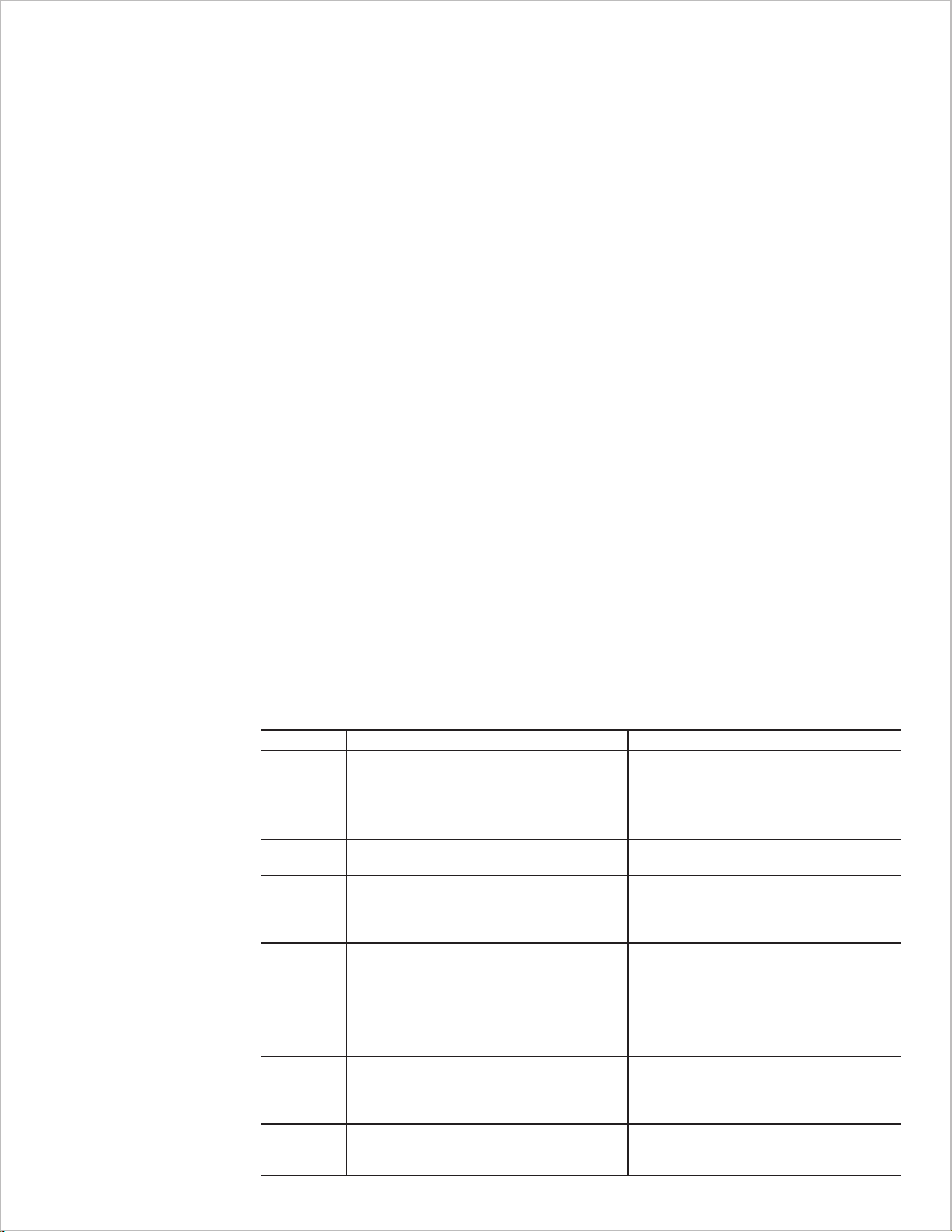

SR bridge wiring diagram

A typical application for the Xitanium SR bridge is to connect the SR bridge to one or more

0-10V (LED) drivers and an SR-certied device (see Figure 3).

Figure 3 . Xitan ium SR br idge w irin g diagram.

5

Page 6

Features of Xitanium SR bridge

Wide mains input range

The Advance Xitanium SR bridge can operate on a wide range of mains input voltages from

120Vac – 347Vac.

Switchable output using zero crossing detection

The output of the Xitanium SR bridge can be switched on/o via integrated relay switching

with advanced zero crossing technology. This allows for higher loads to be switched on/o

with high reliability.

Sensor ready (SR) interface

The Xitanium SR bridge features a digital interface (SR interface) to enable direct

connection to any suitable SR-certied RF sensor.

Energy metering

The Xitanium SR bridge has built-in energy/power measurement capability.

MultiOne/SimpleSet congurable features

6 Advance Ligh ting

Note: These features are only supported from MultiOne 3.4 onward. Please also refer to the

“Advance MultiOne Congurator” user manual that can be accessed from the Help menu

inside the MultiOne software, for more information.

Feature Description of the feature Notes and examples

0-10V / 1 -10V This feature gives the OEM the ability to match the

0-10V (or 1-10V) dimming curve of the connected

driver to the correct translation of the DALI arc

power commands on the SR Bus.

DALI PSU DALI Power Supply. This feature can turn on/o

the build-in SR Power Supply

LFIT Load Fault Indicator Thresholds. This feature

allows the OEM to set a threshold to indicate one

(or more) lights have failed and set the DALI lamp

failure detection properly.

Min dim level Minimum dim level. This feature can be used to

set the minimum (DALI) dim level of the SR Bridge

to match the minimum dim level of the connec ted

0-10V d ri ve r(s).

OEM

Traceability

RSO Relay Switched Output. This feature can be used

Table 1. SR bridge MultiOne/SimpleSet congurable features.

OEM Traceability. This feature allows the OEM to

store a GTIN and identication number and some

additional information that could be used for

Traceability or Asset Management.

to enable/disable the relay of the SR Bridge.

Four xed curves (1-10V curved, 1- 8V linear, 1-9V

linear, 1-8V logarithm) or User specied can be

selected. 1-8V linear is default to match most

Advance Xitanium LED drivers.

By default the SR DALI PSU is turned on

(Enabled).

Typical sett ing corresponds to maximum p ower

of all drivers connected minus one so that if one

driver fails it w ill be detected.

Default setting is 1%. But if the connected driver

can only dim down to 10%, the DALI dim level of

the SR Bridge can be also set to 10% matching

the DALI dim curve to the 1-8V dimming cur ve of

the driver. Any DALI arc level command for < 10%

will result in a 1V output on the 0-10V output of

the SR Bridge.

The GTIN and ID are part of standard DALI.

The additional information can be up to 42

characters long.

In cases where the lights should not be turned o

when the DALI O command is used, the “Always

stays closed” button should be checked.

Page 7

Sensor ready (SR) interface

Figure 4 . Typical VI-curve SR bus

power supply.

Xitanium SR Bridge

Design-in Guide

Sensor Ready (SR)

Interfa ce

Sensor ready interface

The Advance Xitanium LED SR bridge features a digital SR interface to enable direct

connection to any suitable SR-certied RF sensor.

The simple two-wire SR interface supports these key functions:

• Switchable built-in SR bus power supply to provide power to the connected control

device (e.g., an RF module or a CMS controller)

• Two-way digital communication between the SR bridge and control device, using

standard DALI 2.0 protocol

• Standard DALI dimming, ON/OFF and control functions

• Power and energy reporting utilizing the power monitoring integrated in the SR bridge

• Diagnostic information

Built-in SR bus power supply

The SR bridge has the ability to supply the SR bus with a built-in power supply that can

be turned ON/OFF. By default the power supply is turned on and ready to be used with an

external control device (e.g., RF sensor).

This should in principle be turned o if used in DALI networks with multiple drivers to avoid

incorrect polarity, which can lead to very high currents on the DALI bus. However, we do not

recommend to use this SR bridge in a wired DALI network.

The internal power supply can be turned ON/OFF with the MultiOne conguration software

using the SimpleSet tool or the SR interface (DALI) tool.

The built-in SR supply is capable of delivering a minimum current of 52 mA (ISR) to the SR

bus and the connected device(s).

The built-in SR supply will never supply more than 60mA (ISR_MAX).

The SR bus voltage will be between 12V and 20V depending on the connected device load

and the amount of SR supplies put in parallel. See Figure 4 for the typical VI curve for one

SR supply.

When the internal SR supply is switched OFF, the SR bridge will extract a maximum of 2 mA

from the SR bus (like standard DALI gear).

7

Page 8

Control device(s)

• Most control devices intended to be used in an SR system will be powered from the SR

bus.

• When communication is present on the SR bus, the bus gets pulled down by the data

packages. This reduces the average current available for the power consuming control

device. When communicating the average available current can drop approximately

50%. This should be taken into account when designing the control device.

• The extracted peak current (ISR_EXTRACTED) should be limited by the control device.

Rules for building an SR system

• Respect SR bus polarity when more than one SR supply is connected in parallel.

• The total maximum SR bus current (ISR_MAX_TOTAL) must be ≤250 mA. This current

can be determined by adding ISR_MAX of all SR supplies. As a consequence, a

maximum of four SR supplies can be connected in parallel. The total current delivered

to the SR bus (ISR_DELIVERED) can be determined by adding ISR of all SR supplies.

• The total current extracted from the SR bus (ISR_ EXTRACTED) can be determined by

adding up consuming devices like SR drivers with switched OFF SR supply, other DALI

gear and control devices.

• To guarantee good communication, a margin of 8 mA is needed to drive the SR bus

itself (ISR_MARGIN).

• The following rule should be respected:

ISR_EXTRACTED + ISR_MARGIN ≤ ISR_DELIVERED.

Caution

• When the above rules are not taken into account, communication cannot be

guaranteed and damage to components may occur.

Typical examples

One SR bridge is connected to a control device. The internal SR supply of this bridge is

switched ON. The specication of the control device states that the extracted peak current

is 40 mA. Will this SR system have good communication?

• One SR supply is involved, so BUS polarity is not an issue.

• ISR_MAX_TOTAL = 60 mA. This is ≤250 mA.

• ISR_DELIVERED = 52 mA

• ISR_EXTRACTED = 40 mA

• ISR_MARGIN = 8 mA

• 40 + 8 mA ≤52 mA

8 Advance Lig hting

Page 9

Xitanium SR Bridge

Design-in Guide

Sensor Ready (SR)

Interfa ce

Is it allowed to add an SR bridge with switched OFF SR supply to this SR system?

• Yes, an SR driver with switched OFF SR supply extracts 2 mA from the SR bus.

• ISR_EXTRACTED = 40 + 2 = 42 mA

• 42 + 8 mA ≤52 mA

Can this SR supply also be switched on?

• Yes, but you should check the polarity of both SR supplies.

• ISR_TOTAL = 2 * 60 = 120 mA. This is ≤250 mA.

Digital communication

Dimming is possible through the standard digital interface based on DALI 2.0 (IEC 62386

101, 102 Ed2.0). Dimming range is 1%-100%. Dimming curves can be either logarithmic or

linear (see Figures 5 and 6).

• Note that the output current at 1% and 100% level is determined by the

connected driver.

• The SR bridge has built-in energy measurement capability and can report energy and

actual power consumption. Accuracy of power measurement is higher of following

two values: 0.5W or +/-4 % measured input power. This feature stores parameters in

the non-volatile memory bank provision specied in the DALI 2.0 standard and the

SR Certied specication.

• The SR bridge also supports many diagnostic features/parameters, which can be

accessed via the SR interface, as per SR Certied specication.

• Although the SR interface supports DALI commands, it is not a DALI interface as such

since the interface is polarity-sensitive. We do not advise use of the SR bridge in wired

DALI networks.

Other considerations for SR interface

• Length of wiring: using 18AWG (0.8 mm2), the maximum length of the SR wiring, when

used for DALI communication, should not exceed 50ft (15m).

• The SR control interface terminals are Class 2 as per UL.

DALI Linear Dimming Cur veDALI Logarithmic Dimming Curve

Figure 5. DALI logarithmic dimming curve. Figure 6. DALI line ar dimm ing cur ve.

9

Page 10

SR bridge use cases

Basic SR bridge use case

The basic use case for the SR bridge is to connect one or more 0-10V dimming drivers and

an SR-certied device to the SR bridge as shown in Figure 7.

Figure 7. Bas ic Xitanium SR b ridg e use ca se.

By default, the SR bridge dimming curve is set to linear and the range is 1 – 8V and is meant

to work with standard 0-10V drivers with linear dimming curve and 1-8V range. If other

drivers are used it is possible that the dimming curves will not match.

The maximum load that the SR bridge can handle depends on the mains input voltage.

The maximum allowed loads are given in the SR bridge datasheet.

10 Advance Lighting

Page 11

Xitanium SR Bridge

Design-in Guide

SR Brid ge Use

Cases

347V SR bridge use case

The SR bridge can handle up to 347V mains input. For basic 347V operation the wiring

diagram is similar as for 120/277V operation. Figure 8 shows how a SR bridge can be

connected to a 347V 0-10V LED driver and an SR sensor.

Figure 8 . Basi c Xitan ium SR br idge 3 47V operati on.

SR bridge dimming curve and dimming range

The SR bridge dimming curve and dimming range can be programmed using the MultiOne

Congurator or SimpleSet. By default, the dimming curve is set for DALI linear and the

dimming range is set at 1 – 8V.

The dimming curve can be programmed as either being (DALI) logarithmic or linear.

To meet the DALI logarithmic or linear curve, the physical minimum dimming level and

dimming curve of the connected 0-10V driver should be congured correctly in the SR

bridge using the MultiOne Congurator or SimpleSet.

If you are using a Advance 0-10V driver, you can select the dimming curve and physical

minimum dimming level that are used in that driver. However, if you are using a driver

from another manufacturer, you possibly have to customize/congure the dimming curve

vs. dim percentage and physical minimum dimming level for that driver.

The SR bridge dimming range can be programmed in 19 steps. For each step a voltage

value and dimming percentage need to be set.

The voltage values can be from 0 – 10. The dimming percentage values need to be

within 1 – 100%.

SR bridge fault detection use case

The SR bridge is measuring the power/energy consumed of the connected loads constantly.

This feature can be used to monitor the connected load and determine if a portion of the

load has failed. During normal operation (at full output) the connected load/drivers draw

a certain amount of power. If one or more connected loads fail, the power consumption

will be reduced. The SR bridge has the capability to set the DALI Lamp Failure ag based

on a threshold that can be programmed in the SR Bridge indicating that the load has been

reduced. The fault detection accuracy depends on the trigger point and minimum detection

dim level, which can be congured by MultiOne.

11

Page 12

For example if (10) 50W drivers are connected a SR Bridge each with a max input power of

50W for a DALI Arc Power command of 254 (full output) then to be able to detect the failure

of (1) driver/LED load, the threshold would be set at (9x50=) 450W. The SR Bridge would

report/set DALI Lamp Failure when the power measured by the SR Bridge becomes less

than 450W. Note, that this power level must be scaled by the SR Bridge if the Arc Power

command is other than 254.

In this case with lights set at 50% Arc Power then the expected power would be 250W and

the SR Bridge would report/set DALI Lamp Failure when the power is less than 225W.

SR bridge class room with occupancy/daylight harvesting use case

Existing class rooms using a 0-10V dimming system can easily be retrotted with a SR bridge

and certied SR sensors using occupancy/daylight harvesting to achieve maximum energy

eciency/savings and to create a connected lighting system. A typical (small) class room has

several rows of dimmable lights controlled by a switch/dimmer near the entrance door.

For this use case we are going to assume a small class room with windows on one side

having 4 rows of 5 lights each. All (0-10V dimmable) lights are controlled by a switch/

dimmer near the entrance door (see Figure 9).

12 Advance Lighting

Figure 9. Typica l small Class ro om wit h 0-10V dimming system.

To make it a occupancy/daylight harvesting connected lighting system we are going to use

2 SR bridges each with a SR certied sensor (like the Advance EasySense SNS series of

sensors). The rst SR bridge and sensor gets connected to the rst 3 rows of the lights with

the (occupancy) sensor placed near the entrance door. The second SR bridge and (daylight

harvesting) sensor gets connected to the last row of lights closest to the windows (see

Figure 10) with the (occupancy/daylight) sensor placed near the window. Retrotting the

existing 0-10V dimming system with the SR Bridge solution does not take much installation

work. The SR Bridges get mounted in between the mains feed and the rst driver in each

section. The dimming wires get disconnected from the existing dimmer and rerouted to

the SR Bridges. All other mains and dimming connections between the other drivers remain

the same.

Page 13

Xitanium SR Bridge

Design-in Guide

SR Brid ge Use

Cases

Figure 10. Small Class roo m retro tted w ith SR Br idge s olution.

SR bridge hallway use case

Hallways/long corridors are another area that can easily be retrotted with SR Bridge and

SR sensor to achieve maximum energy eciency/savings and to create a connected lighting

system. In a typical Hallway 0-10V dimming system the lights can usually be turned on/o at

both ends (see Figure 11).

Figure 11 . Typical Hallw ay 0-10V dimming system.

With the SR Bridge and SR sensor we can now add occupancy detection and create a

connected lighting system that not only can dim up/down but turn on/o the lights where

needed for maximum energy savings. In our use case example we are going to use 2 SR

Bridges and 2 SR occupancy sensors since we assume the hallway is too long to be covered

by one sensor only (contact the sensor manufacturer for more detailed information for

coverage area/distance between sensors. For more detailed information on EasySense

sensors see the EasySense link listed in the introduction section.)

In this example the Hallway lights are going to be divided into 2 sections (one 4 lights and one

3 lights). A SR bridge and SR (occupancy) sensor get connected to each section (see Figure 12).

Figure 12. H allway ret rotted with SR Brid ge and SR s enso rs.

For this retrot installation the mains to the existing 0-10V drivers (on each) end have to

be re-routed to each SR bridge. And 2 sections of lights have to be created by cutting the

mains and dimming wires between 2 of the lights.

13

Page 14

Mechanical design-in

Form factors

The Advance Xitanium SR bridge is available in two dierent versions: model SRB-LD is

for mounting inside luminaires (see Figure 13) and model SRB-BS includes studs to easily

mount the SR bridge onto a mounting plate of a downlight xture (see Figure 14).

The specic dimensions can be found in the SR bridge datasheet.

It is highly recommended to mount the SR bridge by using all available mounting feet/studs

in order to achieve maximum mechanical robustness against shocks and vibration.

Mounting screw dimensions should be based on the specied xing hole diameter in the SR

bridge datasheet. Oversized and undersized screws should not be used in order to prevent

damage to the mounting feet or loose mounting.

Please allow for sucient free space around the SimpleSet antenna (blue areas as shown

in Figure 13 and 14) if the SR bridge is to be congured after mounting in the luminaire. The

minimum recommended space is dependent on the type of SimpleSet conguration tool.

Using the tool as shown in Figure 15 (Feig Electronic Desktop Reader ID CPR30-USB), the

minimum distance is 19 mm (+/-1mm).

14 Advance Lighting

Figure 13. SRB-LD version for luminaire mounting.

Figure 15 . Feig Elec tronic ID CPR30-USB SimpleSet i nterf ace tool.

Figure 14 . SRB-BS version to mount to (downlig ht) xture

mounting plate.

Page 15

Thermal management

Introduction

The following section covers the critical thermal management point to facilitate design-in.

Taking thermal considerations into account will ensure optimal performance and lifetime

of the system. The maximum case temperature (Tc max) of the SR bridge should not be

exceeded. It is mandatory to keep the SR bridge Tc max within specication to meet SR

bridge lifetime and failure rate specications. Please refer to the product datasheet for

specic values. Advance Xitanium SR bridges are designed to provide a lifetime of up to

50,000 hours at the specied Tc max.

Temperature case point

To achieve optimal lifetime and reliability, it is critical that the temperature of the

components in the SR bridge remains within their rating. During design, all precautions

are taken to ensure that the internal components are at the lowest possible temperatures.

Xitanium SR Bridge

Design-in Guide

Thermal

Management

Initial thermal analysis is performed via IR scans at room temperature to identify the

hottest components of the SR bridge. Subsequently, detailed temperature measurements

of the critical components are performed under various input/output conditions at worst

case operating temperatures.

The temperature measurements are then correlated to a Tcase (Tc) point on the SR bridge

as shown in Figure 16. Tc temperature is a proxy for the temperatures of the critical internal

SR bridge components.

The location of the Tc point is identied on the product label (Figure 17).

Note:

The specied Tc max of the SR bridge must NEVER be exceeded. In order to ensure

accurate Tc test results, the case temperature should not vary by more than 1°C for a period

of at least 30 minutes after a stable temperature has been achieved. Tc point should not

be obstructed when mounted in the luminaire/enclosure.

Figure 16. Schematic representation of internal

therm al paths to the SR br idge Tc poin t.

Figure 17. Prod uct label

indicating Tc point.

15

Page 16

Electrical design-in

Inrush current

Inrush current refers to the brief high input current that ows into a device during the

moment of connection to mains; see Figure 18. Typically, the amplitude is much greater

than the steady-state input current.

Advance Xitanium products meet the inrush specication values per NEMA 410.

The SR bridge uses advanced “zero-crossing” technology by turning on the connected load

only when the mains voltage is near the zero crossing. This reduces the inrush current of

the connected load(s) to a minimum.

The peak and duration values are given in the individual product datasheet. It should be

noted that the inrush current measurement given in the datasheet is the absolute worst

case value.

What does inrush current do? High inrush currents can cause circuit breakers or fuses to

open if not designed to handle this current. It can limit how many drivers can be connected

to a circuit breaker (CB) or fuse. In case of the SR bridge, it limits how many drivers can be

connected to the SR bridge.

Surge protection

The Advance Xitanium SR bridge has limited built-in surge protection (in accordance with

IEEE/ANSIC62.41.2 Transient Surge Requirements). The datasheet gives the protection level

of the SR bridge. A specication of 2.5kV means that the SR bridge is tested to

withstand 2.5kV line transient for 100kHz Ring wave with 30 Ohms source impedance.

The SR bridges are tested with the above waveform for all line coupling modes (L to N,

L to PE, N to PE and L&N to PE).

In case the SR bridge is built into a luminaire, appropriate surge protection should be

designed into the luminaire to meet the specic category for meeting the Energy Star/

ANSI requirement.

Figure 18.Graphical representation of inrush current.

16 Advance Lighting

Page 17

Xitanium SR Bridge

Design-in Guide

Electrical

Design-in

Leakage current

The Advance Xitanium SR bridge is designed to meet leakage current requirements per

UL 916 standards. The specied maximum value is 0.75 mA RMS at 277V. The test is done

with the SR bridge alone. In a luminaire, leakage current may be higher since the LED load

introduces additional leakage capacitance. As such, precautions should be taken on the

luminaire level.

Electromagnetic compatibility (EMC)

The Xitanium LED SR bridge meets EMC requirements per FCC Title 47 Part 15 Class A. These

tests are conducted with a reference setup and the SR bridge mounted on a grounded

metal plate. To maintain good EMC performance at the luminaire level, the input, output

and dim wires should be kept as far apart as possible. The addition of ferrite beads in

series with the wires or coupling the wires through ferrite cores within the luminaire may

improve the overall EMC performance. However, selection of the type and characteristics

of the additional lter depends on what frequency components have to be damped and

by how much.

Electrical isolation

The Advance Xitanium SR bridge output is isolated from the primary (Class 2).

Isolation is also provided between all the electronic circuits and the chassis.

Xitanium bridges meet UL 916, and the output terminals have been qualied as

Class 2 circuit with UL1310 safety standards.

All of the wires in the Advance Xitanium SR bridges meet the UL1452 safety standards.

17

Page 18

Disclaimer

©2017 Advance Lighting Holding B.V. All rights reserved.

Note that the information provided in this document is subject to change.

This document is not an ocial testing certicate and cannot be used or construed

as a document authorizing or otherwise supporting an ocial release of a luminaire.

The user of this document remains at all times liable and responsible for any and all

required testing and approbation prior to the manufacture and sale of any luminaire.

The recommendations and other advice contained in this document, are provided

solely for informational purposes for internal evaluation by the user of this

document. Advance Lighting does not make and hereby expressly disclaims any

warranties or assurances whatsoever as to the accuracy, completeness, reliability,

content and/or quality of any recommendations and other advice contained in this

document, whether express or implied including, without limitation, any warranties

of satisfactory quality, tness for a particular purpose or non-infringement. Advance

Lighting has not investigated, and is under no obligation or duty to investigate, whether

the recommendations and other advice contained in this document are, or may be,

in conict with existing patents or any other intellectual property rights. The

recommendations and other advice contained herein are provided by Advance

Lighting on an “as is” basis, at the user’s sole risk and expense.

Specically mentioned products, materials and/or tools from third parties are

only indicative and reference to these products, materials and/or tools does not

necessarily mean they are endorsed by Advance Lighting. Advance Lighting gives no

warranties regarding these and assumes no legal liability or responsibility for any

loss or damage resulting from the use of the information thereto given here.

18 Advance Lighting

Page 19

Notes

Xitanium SR Bridge

Design-in Guide

Notes

19

Page 20

© 2019 Sig nif y Holding. A ll rig hts re served. The infor mation prov ided h erei n

is subject to change, without notice. Signify does not give any representation

or warranty a s to the accura cy or completenes s of the information i nclu ded

herei n and sh all not be liable for a ny action in re lian ce the reon. T he informat ion

prese ntedin t his document is not inten ded as a ny commercial of fer and does

notform p art of any quot atio n or contract , unle ss othe rwise agreed by S igni fy.

All tra dema rks are owned by Sign ify H oldi ng or th eir respective ow ners.

PAd-1704DG 02/19 www.signify.com/advance

Signify North America Corporation

200 Franklin Square Drive,

Somerset, N J 08873

Telephone 855-486-2216

Signify Canada Ltd.

281 Hillm ount Ro ad,

Markh am, ON , Cana da L6C 2S3

Telephone 800-668-9008

Loading...

Loading...