Signet GF 5600 User Manual

‡ SIGNET 5600 Batch Controller

ENGLISH

*3-5600.090-1*

3-5600.090-1 (Rev. D-6/03) English

Contents

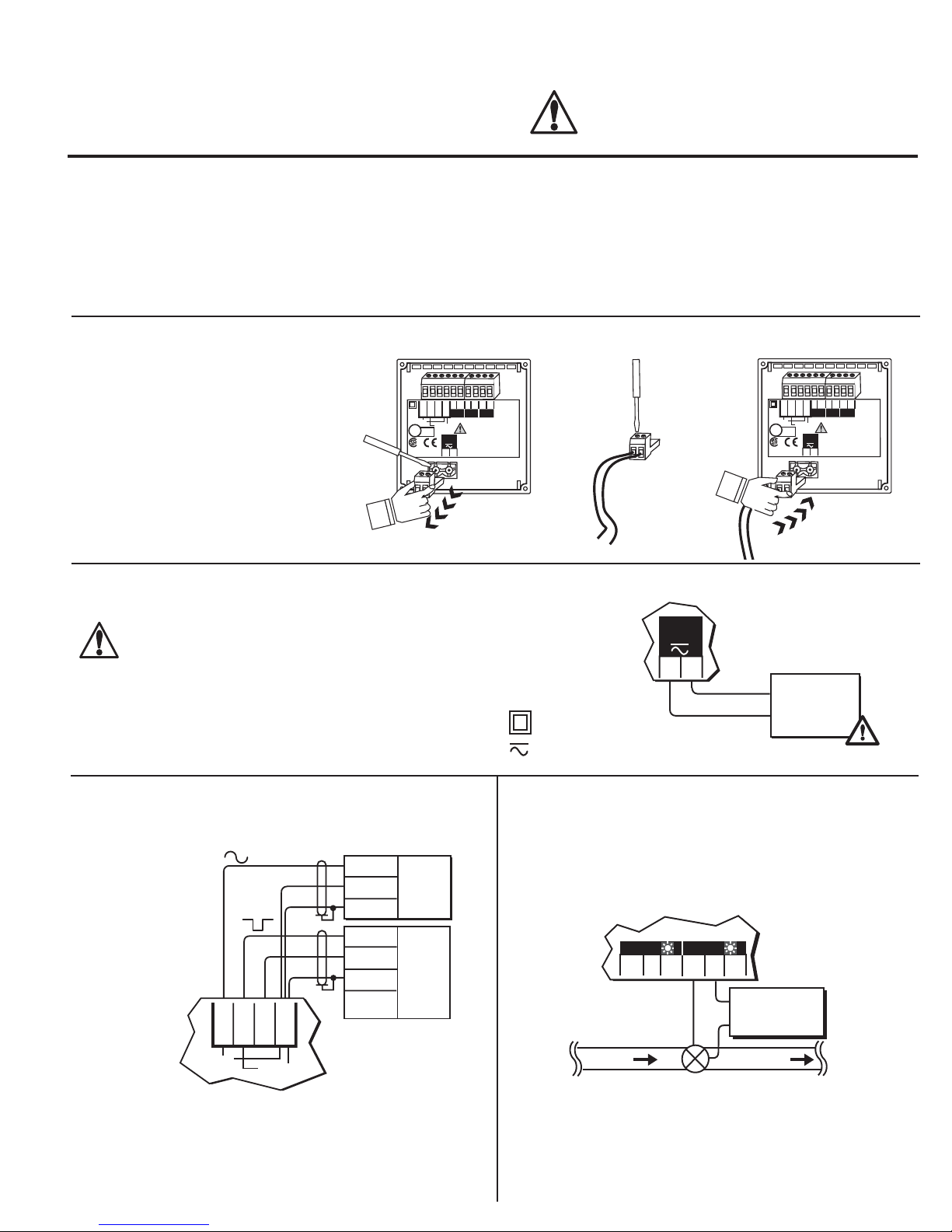

1. Wiring terminals

2. Power Connection

3. Compatible Sensor Wiring

4. Batch Contact Wiring

5. Remote Control Wiring

6. End of Batch/Counter Pulse Output Wiring

7. Option Contact Wiring Options

1. Wiring terminals

• Remove terminal blocks for easy wiring.

CAUTION!

• Remove power to unit before wiring input and

output connections.

• Follow instructions carefully to avoid personal

injury.

8. Current Output Wiring Options

9. 5600 Operation Modes

10. Menu Functions

11. Parts and Accessories

12. Specifications

13. Quick Reference Menu Parameters

14. Maintenance

15. Troubleshooting

1.

1 2 3 4 5 6

1 2 3 4

2

+

1

Gnd

+

Gnd

Total

AUX

Std. Sensor

U

PLS

Freq. IN

Freq. IN

Iso. Gnd

Sen. Pwr.

output

output

Open Collector

Sensor

LISTED

L

77CJ

12-24 V

10 W

+

-

1 2

Flow

reset

Patent No. D376,328

2.

1

2

3.

1 2 3 4 5 6

1 2 3 4

2

+

1

Gnd

+

Gnd

Total

AUX

Std. Sensor

U

PLS

Freq. IN

Freq. IN

Iso. Gnd

Sen. Pwr.

output

output

Open Collector

Sensor

LISTED

L

77CJ

12-24 V

10 W

+

-

1

2

Flow

reset

Patent No. D376,328

2. Power Connection

CAUTION!

Never connect 115 VAC or 230 VAC to rear power

terminals. High voltage AC will damage instrument and

void warranty.

Technical Notes:

• Maximum 4-20 mA loop impedance (sec. 8A) is affected by the

supply voltage.

• To reduce the possibility of noise interference, isolate AC

power lines from signal lines.

3. Compatible Sensor Wiring

+GF+

SIGNET Sensors:

Std. Sensor

Freq. IN

Freq. IN

Iso. Gnd

Sen. Pwr.

Open Collector

Sensor

Red

Black

Shld.

Red

Black

Shld.

5600

Terminals

515

525

2517

2000

2507

2536

2540

2550

Vortex*

5600

12-24 V

10 W

Terminals

External power

+

-

supply

-

12 - 24 VDC

OR

= Double Insulated

12 - 24 VAC

+

= DC or AC power

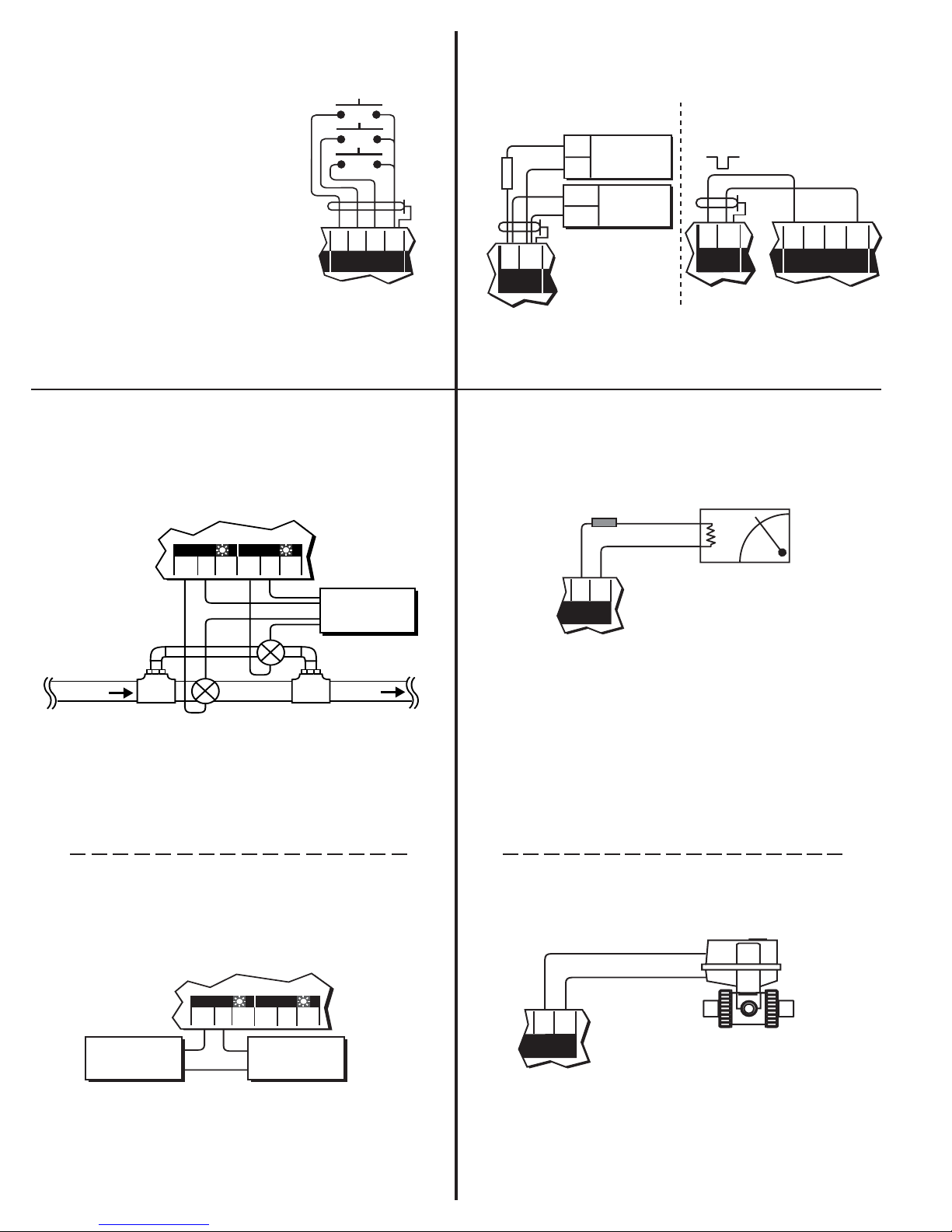

4. Batch Contact Wiring

See section 9 for simple and advanced mode configuration

options.

5600

Option

NO

Batch

C

NC

NO

C

Terminals

NC

AC or DC

power

flow

valve

Technical Notes:

• To reduce the possibility of noise interference, route sensor

cable )away from AC power lines.

• *Vortex sensor or system frequency output

ÐSIGNET 5600 Batch Controller

Technical Notes:

• Maximum alarm contact ratings: 5 A @ 30 VDC, 5 A @ 125

VAC, or 3 A @ 250 VAC

• To reduce the possibility of noise interference, isolate AC power

lines from signal lines.

1 of 12

5. Remo)te Control Wiring

Rear START, STOP, and RESUME

(Rsm) terminals can provide remote

batch control from a distance using

one of four methods:

• Mechanical switch closures (shown)

• End of batch pulse from a second

5600 (sec. 6)

• End of batch contact closure from a

second 5600 (sec. 7C).

• End of batch current pulse from a

second 5600 (sec. 8C).

Momentary Switch Contacts

(customer supplied)

5600

Terminals

Start

Stop

Remote

Rsm

Start

Stop

Resume

RTN

6. End of Batch/Counter Pulse Output Wiring

See section 9 for simple and advanced mode configuration

options.

A. External counter connection

+

5 - 30

VDC

Gnd

-

IN

Gnd

5600

External

Counter

10 kΩ

+

CNT/EOB

output

Terminals

B. Daisy chaining two 5600

batch controllers together

+

Gnd

CNT/EOB

output

First 5600

Start

Remote

Second 5600

Stop

Rsm

RTN

Technical Notes:

• Use 4-conductor shielded cable for remote control lines up to

30 m (100 ft) max.

7. Option Contact Wiring Options

A. Two Stage Shutdown (advanced mode only, sec. 9.2)

5600

Terminals

NC

AC or DC

power

to tank

NC

Valve

NO

Batch

C

Main line

flow

Bypass line

Option

NO

C

Technical Notes:

• Maximum alarm contact ratings: 5 A @ 30 VDC, 5 A @ 125

VAC, or 3 A @ 250 VAC

• To reduce the possibility of noise interference, isolate AC power

lines from signal lines.

Technical Notes:

• Use 2-conductor shielded twisted-pair cable for output lines

up to 30 m (100 ft.) max.

8. Current Output Wiring Options

A. Batch Completion (simple or advanced mode, sec. 9)

Fuse**

1/8A

+

4 - 20 mA

*

-

+

Current

output

Technical Notes:

**1/8A fuse recommended (customer supplied)

* 4-20 mA output is internally powered (non-isolated),

maximum loop impedance 350 ý with a 12 V instrument supply

voltage, 950 ý with a 24 V instrument supply voltage.

To isolate output and prevent ground loop problems:

1. Use monitor device with isolated inputs, or

2. Use separate DC supply for 5600 and monitor device, or

3. Power 5600 with 12 - 24 VAC step down transformer

-

5600

Terminals

B. Missing Signal Alarm (simple or advanced mode, sec. 9)

OR Overrun Alarm (advanced mode only, sec. 9.2)

5600

Terminals

Alarm

device

Option

NO

C

NC

Batch

NO

AC or DC

C

power

NC

Technical Notes:

• Maximum alarm contact ratings: 5 A @ 30 VDC, 5 A @ 125

VAC, or 3 A @ 250 VAC

• To reduce the possibility of noise interference, isolate AC power

lines from signal lines.

2 of 12

B. Valve Control (advanced mode only, sec. 9.2)

#5 ( + )

4 - 20 mA

#6 ( - )

-

5600

Terminals

George Fischer electronic

actuator with PE 22P

positioner required

+

Current

output

Technical Notes:

• Output compatible with the following George Fischer electronic

actuators/PE 22P positioner models: EA 20, EA 30, EA 41

and EA 50

ÐSIGNET 5600 Batch Controller

Section 7 Continued...

Section 8 Continued...

C. End of Batch Pulse (advanced mode only, sec. 9.2)

Daisy chaining two 5600 batch controllers together for a second

batching stage.

C. End of Batch Pulse (advanced mode only, sec. 9.2)

Daisy chaining two 5600 batch controllers together for a second

batching stage.

5600

NC

NO

Batch

C

Option

NO

C

First 5600

Technical Notes:

• Use 2-conductor shielded twisted-pair cable for contact lines

up to 30 m (100 ft.) max.

NC

Second

5600

Terminals

Start

Remote

Stop

Rsm

RTN

-

5600

Terminals

Rsm

Stop

Start

Remote

Second 5600

RTN

+

Current

output

First 5600

Technical Notes:

• Wiring MUST be connected exactly as shown.

• Use 2-conductor shielded twisted-pair cable for output lines

up to 30 m (100 ft) max.

9. 5600 Operation Modes

This section gives a detailed description of the 5600's simple and advanced operation modes (sec. 14) and how they affect the batch

contact, End of batch/totalizer output, option contact, and current output.

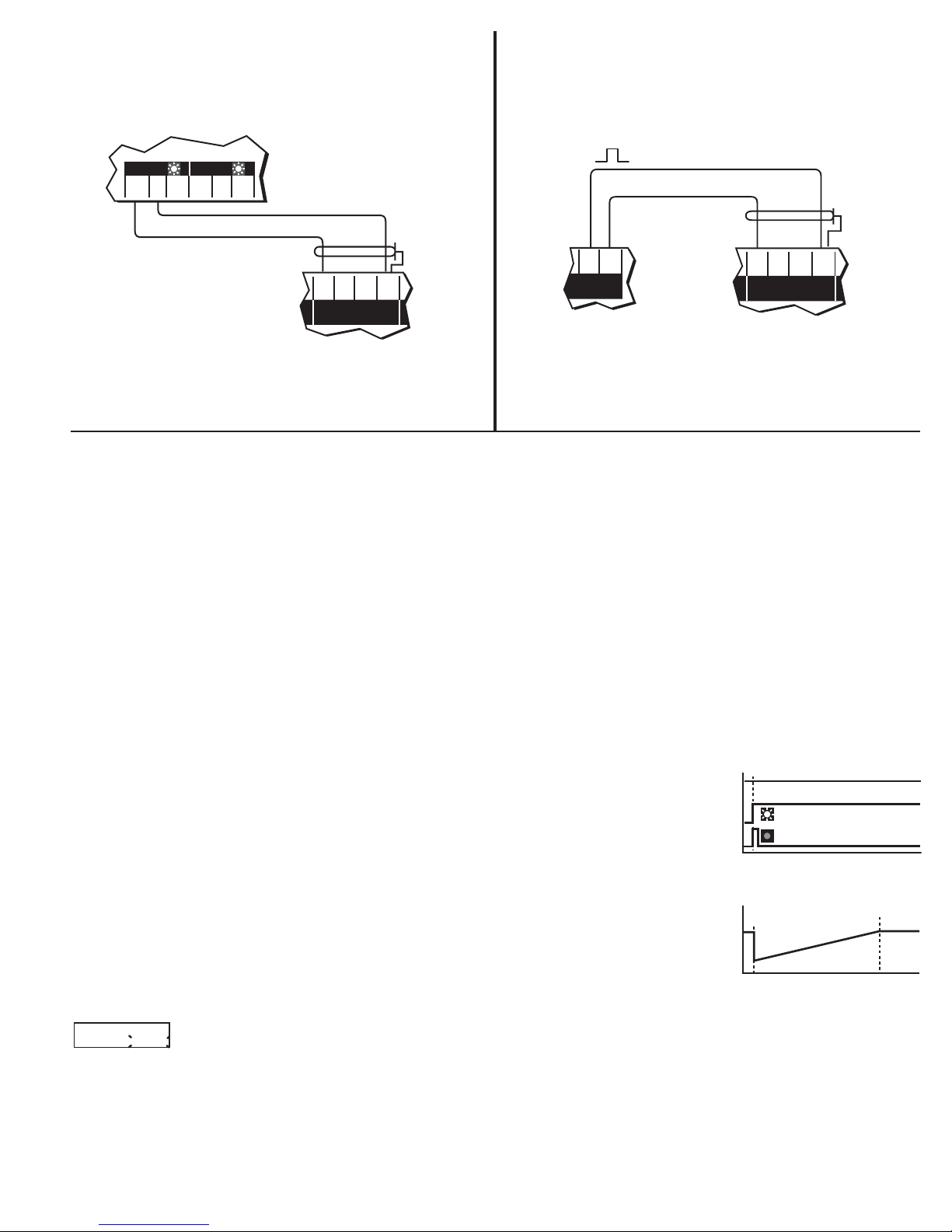

9.1 Simple Operation Mode

• Batch Contact (sec. 4): In simple mode, the batch contact is dedicated for on/off control. It is energized at the start of a batch and

de-energized at the end of a batch. It also de-energizes when STOP is selected from the front keypad or initiated by a remote contact

closure to the rear STOP terminals (sec. 5). A RESUME command can also be initiated by either method to complete the batch. The

front panel batch indicator turns on when the batch contact is energized.

• Counter/End of Batch Pulse Output (sec. 6): In simple mode, the output is configured as a counter pulse output. The output

emits a

130 millisecond pulse for each engineering (total) unit measured. The output is a open collector type which requires an external pull up

resistor and power supply for external counter use (sec. 6).

• Option Contact - Missing Signal Alarm (sec. 7B): This function provides alarm capability if flow is not

detected in 30 seconds after a batch cycle starts. If the flow sensor signal is missing, the option contact

energizes and the front panel contact indicator turns on, signaling the missing sensor signal. The batch

contact also

de-energizes, closing the flow control valve and stopping the batch. The alarm condition will remain until

the front panel ENTER key is pressed or a remote contact closure is made to the rear STOP terminal (sec.

5).

• Current Output - Batch Completion (sec. 8A): This function is offered in the simple or advanced

operation mode. The output is a linear increase from 4 mA at batch start to 20 mA at batch end.

Batch started...

Sensor input

option contact

batch contact

Batch running...

0%

4 mA

100%

20 mA

9.2 Advanced Operation Mode

Overrun Comp:

automatic manual

early, compensating for valve closing time and eliminating batch overrun. Automatic overrun compensation counts sensor pulses

during the batch cycle, and any excess pulses after the batch stops. The instrument calculates the estimated batch overrun based on

the additional sensor pulses, then automatically reduces the next batch size for the next batch. During the next batch cycle, the batch

contact de-energizes early, thus closing the flow control valve early and eliminating batch overrun.

ÐSIGNET 5600 Batch Controller

• Batch Contact (sec. 4): The batch contact is dedicated for on/off control and is either manually or automatically

compensated for batch overrun. Manual overrun compensation allows the operator to compensate for valve closure

time in a batching system. The operator is prompted to enter a batch volume that de-energizes the batch contact

3 of 12

Option Contact:

batch contact

Option contact

0%

100%

90%

Batch running...

Two Stage

• Counter/End of Batch Pulse Output (sec. 6): In advanced mode, the output can be

configured as either a counter pulse output (sec. 9.1) or as an end of batch pulse

output. When configured as an end of batch pulse, the output emits a 500 millisecond pulse at the

completion of every batch. The output is a open collector type which requires an external pull up resistor

and power supply for external counter use (sec. 6).

• Option Contact - Two Stage Shutdown (sec. 7A): This function is designed to prevent over filling or to minimize water hammer.

Both the batch and the option contact are energized when the batch starts. The option contact then de-energizes at a programmed batch percent-

Option Contact:

Overrun Alarm

energizes, completing the sequence. Front keypad and remote START, STOP, and RESUME

inputs (sec. 5) also control the option contact. The front panel contact indicator turns on when

the option contact is energized.

age, forcing flow through a smaller bypass line to reduce the fill rate. After the entire batch is measured, the batch contact de-

Batch running...

0%

Option contact

batch contact

100%

Overrun

• Option Contact - Overrun Alarm (sec. 7B): This function provides overrun alarm

capability for detecting a leaky or stuck valve. If the programmed batch overrun volume is measured after the batch

ends, the option contact is energized and the front panel contact indicator turns on, alarming

Option Contact:

End of Batch

the operator that the flow shut off valve is leaking or stuck open. To cancel alarm, press the

ENTER key (or remote STOP switch) once. The overrun alarm will retrigger if the condition

persists.

Batch running...

0%

Option contact

batch contact

100%

500ms

• Option Contact - End of Batch Pulse (sec. 7C): This function is designed to trigger an external batch counter or second 5600 Batch Controller at

the end of a batch. The option contact is energized for 500 milliseconds at the end of every batch cycle. An external power

Option Contact:

Missing Signal

supply switched through the option contact's common (COM) and normally open (NO) terminal provides a pulse for triggering

these devices.

Option Contact:

Off

Missing Signal

Alarm: On

start-up. An adjustable time delay entry (in seconds) is offered which specifies how long the instrument will wait after batch

start-up before initiating the missing signal alarm. See simple operation mode (sec. 9.1) for alarm operation details.

• Option Contact On/Off (sec. 10.4H): This function enables or disables the option contact and front panel option LED.

When the option contact is configured "Off", the option contact and front panel LED are disabled.

• Missing Signal Alarm On/Off (sec. 10.4H):

Missing signal alarm is always enabled (factory default sec. 9.1) even if the option contact is selected to be a different function.

• Option Contact - Missing Signal Alarm (sec. 7B): The missing signal alarm represents a missing sensor signal after batch

Current Output:

Batch Completion

Current Output:

Valve Control

This function is designed to completely disable the missing signal alarm, if desired. NOTE: If disabled, the batch contact is

NOT affected and will NOT signal the operator or stop the running batch if there is a problem.

• Current Output - Batch Completion (sec. 8A): In advanced mode, the current output

functions identical to the simple operation mode. See the simple operation mode explanation

above.

Batch running...

0%

valve

20 mA

4 mA

100%

valve

• Current Output - Valve Control (sec. 8B): This function is designed for use with a George Fischer electric

actuator with PE 22P positioner for preventing overflow or minimizing water hammer. When a batch starts, the

current output is held at 20 mA, forcing the PE 22P positioner to the full open valve position. Near batch end, the output gradually ramps downward

to slow the flowrate, then drops to 4 mA closing the valve and ending the batch. Front keypad and remote START, STOP, and

Current Output:

End of Batch

RESUME inputs also control the output (sec. 5). A STOP command any time during a batch

sequence will force the output to 4 mA and close the PE 22P positioner. (Note: for optimum

performance, the batch process should last at least 1 minute!)

Batch running...

0%

0 mA

100%

20 mA

500ms

• Current Output - End of Batch (sec. 8C): This function is designed to trigger a second 5600 batch controller's

remote START input for a second batching stage. When the batch starts, the current output remains at 0 mA until the end of the batch, then jumps to

20 mA for 500 milliseconds. The 500 millisecond current pulse triggers the second 5600's remote START terminal to start the second batch stage.

4 of 12

ÐSIGNET 5600 Batch Controller

Loading...

Loading...