Signature Kitchen Suite SKSCF1801P, SKSCF2401P, SKSCR3001P, SKSCW241RP, SKSCF3001P Installation Manual

...

ENGLISH FRANÇAIS ESPAÑOL

Integrated Refrigeration Installation Guide

BUILT-IN REFRIGERATION

SKSCF1801P

SKSCF2401P

SKSCF3001P

SKSCW181RP

MFL67410814_Rev.06

SKSCR2401P

SKSCR3001P

SKSCW241RP

www.signaturekitchensuite.com

Copyright © 2017 - 2018 Signature Kitchen Suite. All Rights Reserved.

2

Table of Contents

SAFETY INSTRUCTIONS ............................. 3

Before Installation ......................................... 6

Choosing the Install Location ....................... 6

Installation options ....................................... 9

Dimensions and Clearances

–

SKSCF1801P – 18" INTEGRATED

FREEZER COLUMN

SKSCW181RP – 18" INTEGRATED

WINE COLUMN .......................................... 10

SKSCF2401P – 24" INTEGRATED

FREEZER COLUMN

SKSCR2401P – 24" INTEGRATED

REFRIGERATOR COLUMN

SKSCW241RP – 24" INTEGRATED

WINE COLUMN .......................................... 12

SKSCF3001P – 30" INTEGRATED

FREEZER COLUMN

SKSCR3001P – 30" INTEGRATED

REFRIGERATOR COLUMN ....................... 14

Custom Panels

–

SKSCF1801P – 18" INTEGRATED

FREEZER COLUMN

SKSCW181RP – 18" INTEGRATED

WINE COLUMN .......................................... 16

SKSCF2401P – 24" INTEGRATED

FREEZER COLUMN

SKSCR2401P – 24" INTEGRATED

REFRIGERATOR COLUMN

SKSCW241RP – 24" INTEGRATED

WINE COLUMN ......................................... 18

SKSCF3001P – 30" INTEGRATED

FREEZER COLUMN

SKSCR3001P – 30" INTEGRATED

REFRIGERATOR COLUMN ....................... 20

Required Accessories and Tools ................ 22

Installation .................................................. 23

Unpacking ...................................................... 24

Moving the Appliance .................................... 25

Special Circumstances .................................. 25

Product Dimensions ...................................... 26

A

Installing the Anti-tip Brackets

Protecting Edges of Enclosure

Installing Appliance in Enclosure

B

Aligning and Leveling the Appliance

Attaching the Appliance to the Enclosure

Attaching the Toe Kick Panel

C

Installing Door Panels

Adjusting Door Panels

Installing Door Trim

Attaching Air Separator

Special Installations

–

Optional Frame Kit Accessory

Adjusting the Door Spring

Adjusting the Door Stop

Water Filter Bypass

Reversing the Door

Side-by-Side Flush Installation

Preparing to Connect the Water Line

..................................

..................................

......................................

.................................

......................................

......................................

.......................

.....................

..................

.............

........................

......................

............................

...............................

.....................

............

......

29

30

31

32

34

35

37

38

38

39

39

40

40

40

41

45

47

Connecting the Water Line

Attaching the Badge

.....................................

...........................

47

48

SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

This guide contains many important safety messages.

Always read and obey all safety messages.

This is the safety alert symbol. It alerts you to safety messages that inform you of hazards

that can kill or hurt you or others or cause damage to the product.

All safety messages will be preceded by the safety alert symbol and the hazard signal word

WARNING, or CAUTION. These words mean:

3

ENGLISH

WARNING

CAUTION

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and

tell you what can happen if the instructions are not followed.

You may be killed or seriously injured if you don’t follow instructions.

Indicates an imminently hazardous situation which, if not avoided, may

result in minor or moderate injury, or product damage.

WARNING

TIP-OVER HAZARD

Use two or more people to move and install the refrigerator.

To prevent the refrigerator from tipping over, install anti-tip brackets

(provided). Failure to follow the refrigerator installation instructions

can result in serious injury or death.

WARNING

the product, basic safety precautions should be followed, including the

following. Read all instructions before using this appliance.

Installation

• These products are not designed to be used as freestanding units. Doing so will result in a

risk of tipover, personal injury, and product or property damage.

• Do not install the refrigerator near a gas stove, water heater or other source of ignition that

may possibly leak gas. Do not install product in direct sunlight. Install the product in a wellventilated area.

the product. Do not block the front air inlet. Failure to follow these instructions may cause

product malfunction.

• Enclosure must be constructed of materials which are strong enough to avoid damage

during installation and frequent use.

4

• Cabinet materials must be able to withstand the heat and humidity produced during product

operation and use without twisting or deforming.

bending. The product must be level both horizontally and vertically.

• Keep children away from area during installation.

• Do not use an extension cord or power strip with this product.

• Do not install the refrigerator in a damp location or where it will be exposed to running water.

Deterioration of the insulation on electrical parts may result, causing risk of electric shock.

• Connect to potable water only. Non-potable water can cause health risks.

• If connected to a circuit protected by fuses, use time delay fuse.

Electrical Connection

Use a dedicated outlet.

Plug in the power plug with the power cord facing downward.

When installing or moving the refrigerator, be careful not to roll over or damage the

power cord. Do not squeeze or crush the cord or plug when pushing the refrigerator in.

Do not allow the power cord to be bent, crushed, or damaged. Do not run the power

Do not extend or modify the length of the power cord.

Turn off the power before cleaning or moving the refrigerator.

• Failure to do so may cause electric shock or injury.

• Press the POWER button for 3 seconds to turn off the power at display panel.

Do not pull out the cord or touch the power plug with wet hands.

Doing so may cause electric shock or injury.

Remove water or dust from the power plug and insert it securely into the wall socket.

Do not unplug the refrigerator by pulling on the cord.

Do not use the power cord or the power plug if it is damaged or if the outlet is damaged.

Wait for 5 minutes or longer when reconnecting the plug or turning the power back on.

Give the compressor time to cycle before restarting.

5

If the supply cord is damaged, it must be replaced by the manufacturer or its service

CAUTION

Do not remove the cover of the automatic ice dispenser.

The internal mechanism of the icemaker can cause injury if handled.

Do not stick your hands under the refrigerator.

Sharp edges, fans, and wires may cause an injury

Save these instructions for the local inspector's use.

Observe all governing codes and ordinances.

Installer: Leave these instructions with the consumer.

Consumer: Keep these instructions with the owner's manual for future reference.

ENGLISH

General

electrical power and grounding must comply with local codes and ordinances and be made by

licensed personnel when required. In the absence of a local code:

• In the U.S.A., in accordance with the National Electric Code, ANSI/NFPA70 – latest edition/State

and Municipal codes and/or local codes.

• In Canada, in accordance with the Canadian Electric Code C22.1 – latest edition/Provincial and

Municipal codes and/or local codes.

Appliance is very heavy:

Refrigerator 30" approx. 386 Ibs/175 kg

Refrigerator 24" approx. 324 Ibs/147 kg

Freezer 30" approx. 403 Ibs/183 kg

Freezer 24" approx. 346 Ibs/157 kg

Freezer 18" approx. 304 Ibs/138 kg

Wine 18" approx. 306 lbs/139 kg

Wine 24" approx. 357 lbs/162 kg

6

Before Installation

WARNING

Do not store or install the appliance where it will be exposed to:

• outside weather

• water damage

• temperatures under 32°F (0°C)

Choosing the Install Location

Temperature and Humidity

The appliance should be installed in a dry, well ventilated area.

The ambient temperature should stay between 55 °F(13 °C) and 110 °F (43 °C), to avoid

malfunctions.

Do not install product where it will be exposed to direct sunlight or near a heat source, such as an

oven or radiator.

Anti-tip Devices

WARNING: Tip Hazard

• The appliance is very heavy and may tip over if the door is opened before the appliance is

securely installed.

• Install the supplied anti-tip brackets to prevent the appliance from tipping. The safest method of

installing the appliance in a stable position is to use the supplied anti-tip devices.

• Do not open the appliance door unless it is still on the pallet or the anti-tip brackets are engaged.

If the enclosure is sturdy enough, attaching the appliance to the upper and side walls of the

wall. If in doubt, contact an architect or structural engineer.

Enclosure

7

• The panel above the appliance must be made from a solid material (not MDF) that is at

least 5/8" (16 mm) thick.

• The front 4 inches (100 mm) of the interior surface (furniture return) will be visible when

• Above all, the enclosure cannot be out of square. Use a spirit level or measure the

diagonals of the opening to make sure corners are square.

• The appliance is attached at the sides and the top to either the enclosure or to adjacent

cabinets. Make sure the enclosure or the adjacent cabinets are securely connected to the

Floor

WARNING

performance.

ENGLISH

• Do not install the appliance on a platform or raised structure.

• The structure underneath the appliance must be able to support the weight of the appliance

• For best performance and to avoid leakage, level the appliance.

Electrical Requirements

WARNING

Electrical Shock Hazard

• Plug into a grounded 3 prong outlet.

• Do not remove ground prong.

• Do not use an adapter.

• Do not use an extension cord.

Follow all state and local codes or NEC.

The appliance comes with a UL listed 3 wire power supply cord.

The appliance requires a 3-wire receptacle.

The receptacle must be installed by a licensed electrician only.

8

Grounding

This appliance must be grounded. In the event of a malfunction or breakdown, grounding will

reduce the risk of electric shock by providing a path of least resistance for the electric current.

WARNING: Improper connection of the equipment grounding conductor may result in electric

if you are in doubt as to whether the appliance has been properly grounded.

NOTE

Some local regulations may require a separate ground. In such cases, the required ground

wire, clamp and screw are available as a separate accessory and must be purchased

separately.

Never ground the appliance to plastic plumbing lines, gas lines or water pipes.

Water Connection

CAUTION

• Connect the appliance to potable water only.

• A cold water connection is required for operation of the automatic ice maker. The water pressure

must be between 20 and 120 psi. (1.38-8.27).

• The installation must comply with local plumbing regulations.

• A separate shut-off valve must be installed for the appliance water connection.

• Do not use a self-piercing valve.

• Do not install the shutoff valve for the water behind the appliance. The shutoff valve must be

easily accessible.

• Install the water connection in the area shown in the diagram under Dimensions and Clearances.

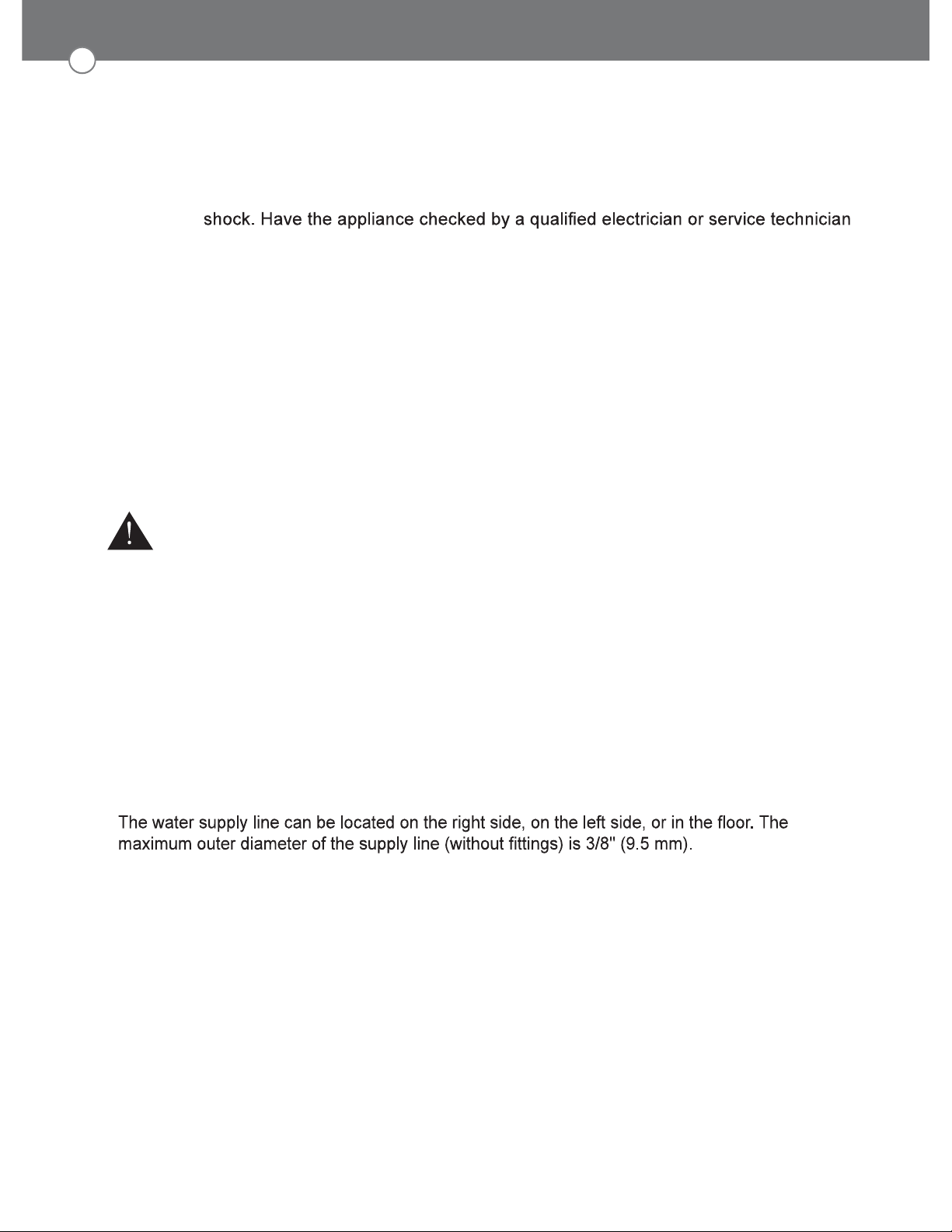

Installation options

There are many different installation options.

These are limited only by the design of the kitchen.

Individual Appliance

OK OK X

Side-by-Side (Pair)

OK X X X

9

ENGLISH

Individual Appliances with Partition

Minimum thickness of the partition 5/8” (16 mm)

OK OK OK

OK

OK

10

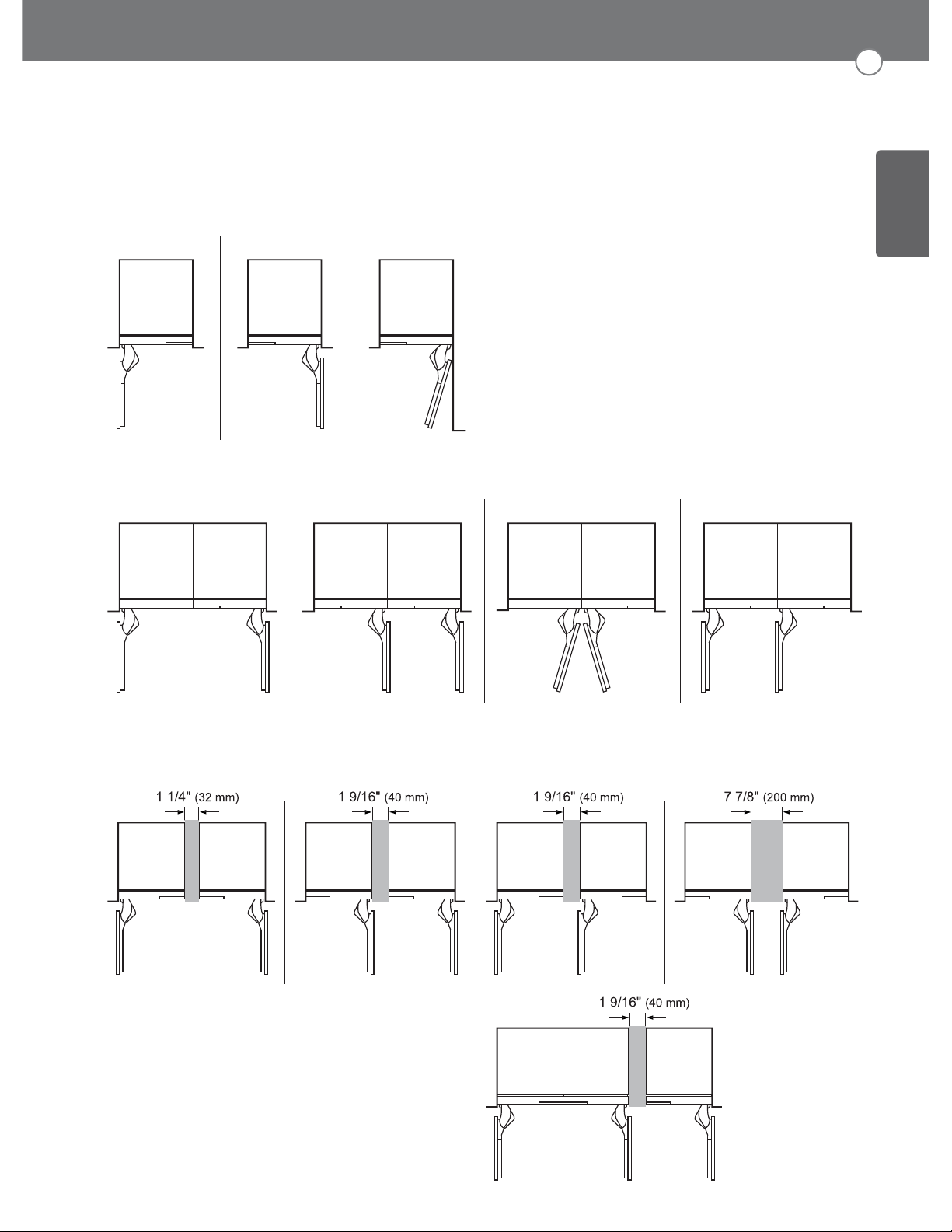

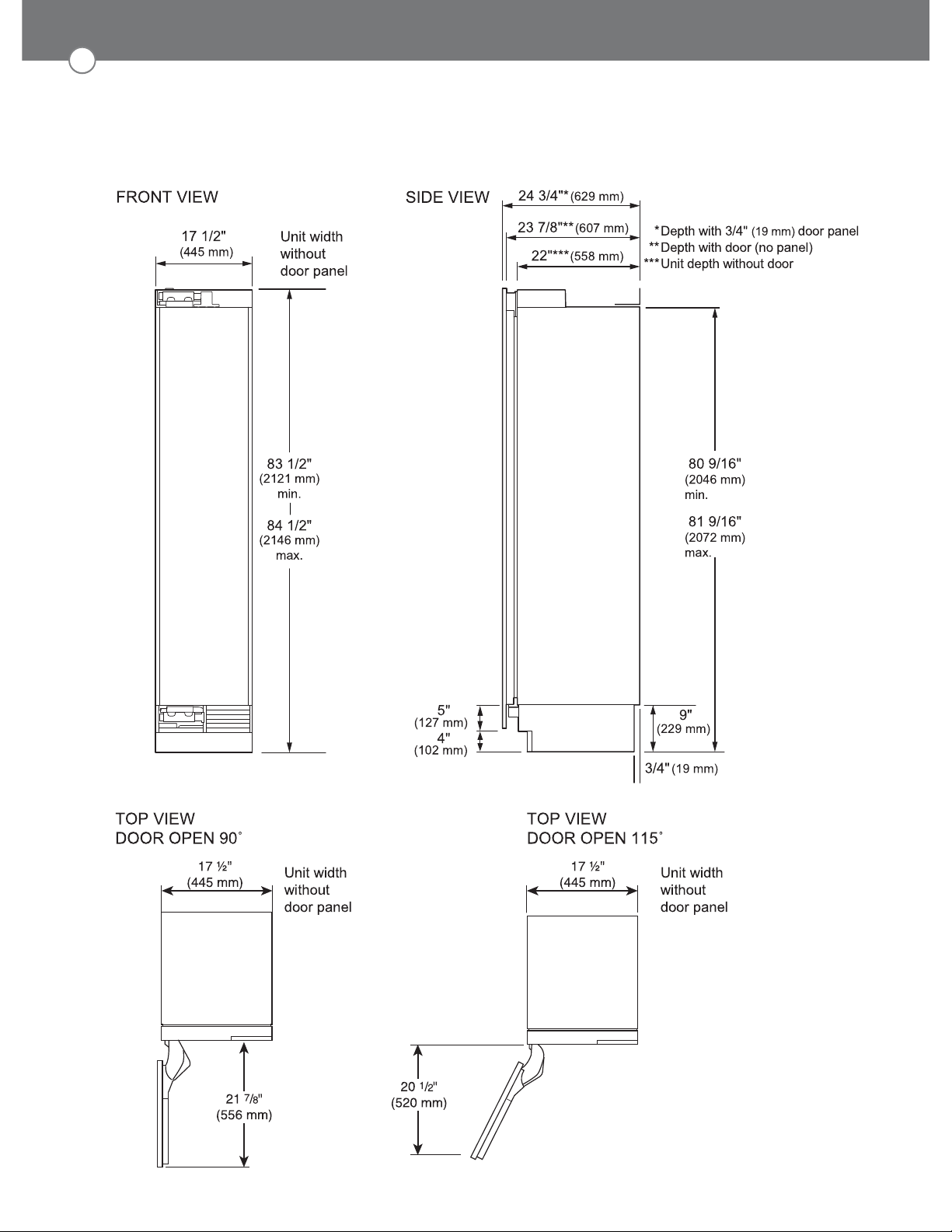

SKSCF1801P – 18" INTEGRATED FREEZER COLUMN

SKSCW181RP – 18" INTEGRATED WINE COLUMN

CUTOUT DIMENSIONS – FLUSH OR PROUD INSTALLATION, SINGLE COLUMN

NOTE

(635 mm) depth adjacent cabinets.

Proud – With a 24" (610 mm) depth cutout, the front face of the freezer/wine column extends

approximately 3/4" (19 mm) beyond 24" (610 mm) depth adjacent cabinets.

sides and the top of the cutout opening. The shaded area will be visible after installation.

ELECTRICAL

A 115V, 60Hz, 15 or 20 amp power supply is required. An individual, properly grounded branch

circuit or circuit breaker is recommended. Install a properly grounded 3-prong electrical

receptacle recessed into the back wall. Electrical must be located on rear wall as shown.

Note: GFI (ground fault interrupter) is not recommended.

WATER LINE

A cold water supply is required for automatic icemaker operation.

The water pressure must be between 20 and 120 psi.

Tubing should be long enough to extend to the front of the freezer. Allow enough tubing to

accommodate a bend leading into the water line connection.

Install a shut-off valve between the icemaker water valve and the cold water supply in the home.

INSTALLATION CLEARANCES

SKSCF1801P SKSCW181RP

11

ENGLISH

NOTE

Door Swing Clearances

The installation must allow for clearances to adjacent walls or cabinets. This freezer/wine column is

equipped with a 2-position door stop.

The factory-set 115° door swing can be adjusted to 90° if clearance to adjacent cabinets or walls is

restricted.

Door Handle Clearances

The door handle depth must be added to the dimension where noted to determine the total

clearance required from adjacent cabinets or walls. This clearance will vary depending on the custom

handle used. When using Signature Kitchen Suite handles or the Signature Kitchen Suite stainless

steel door panel kit with handles (optional accessories), the door handle clearance with the door

open 115° is 11" (279 mm).

12

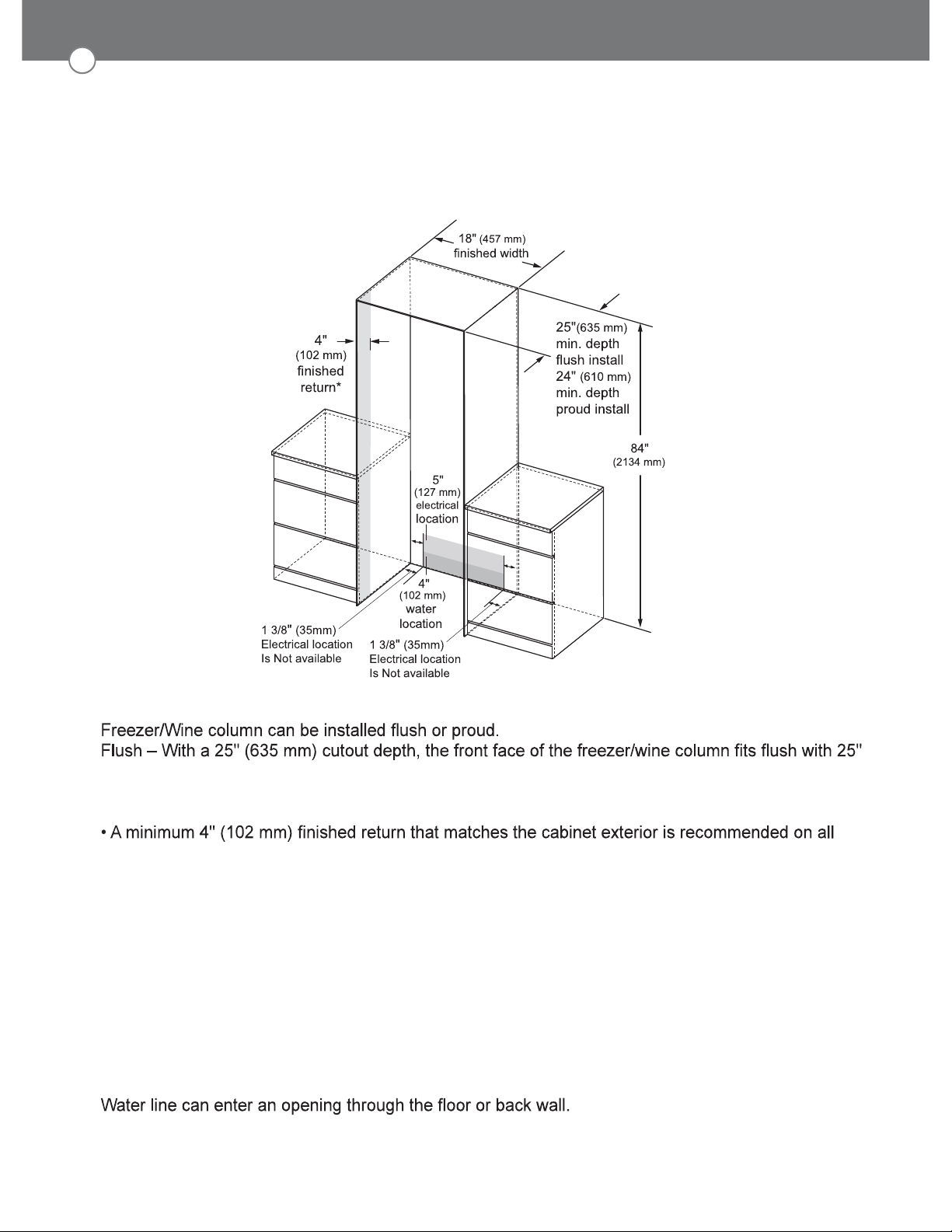

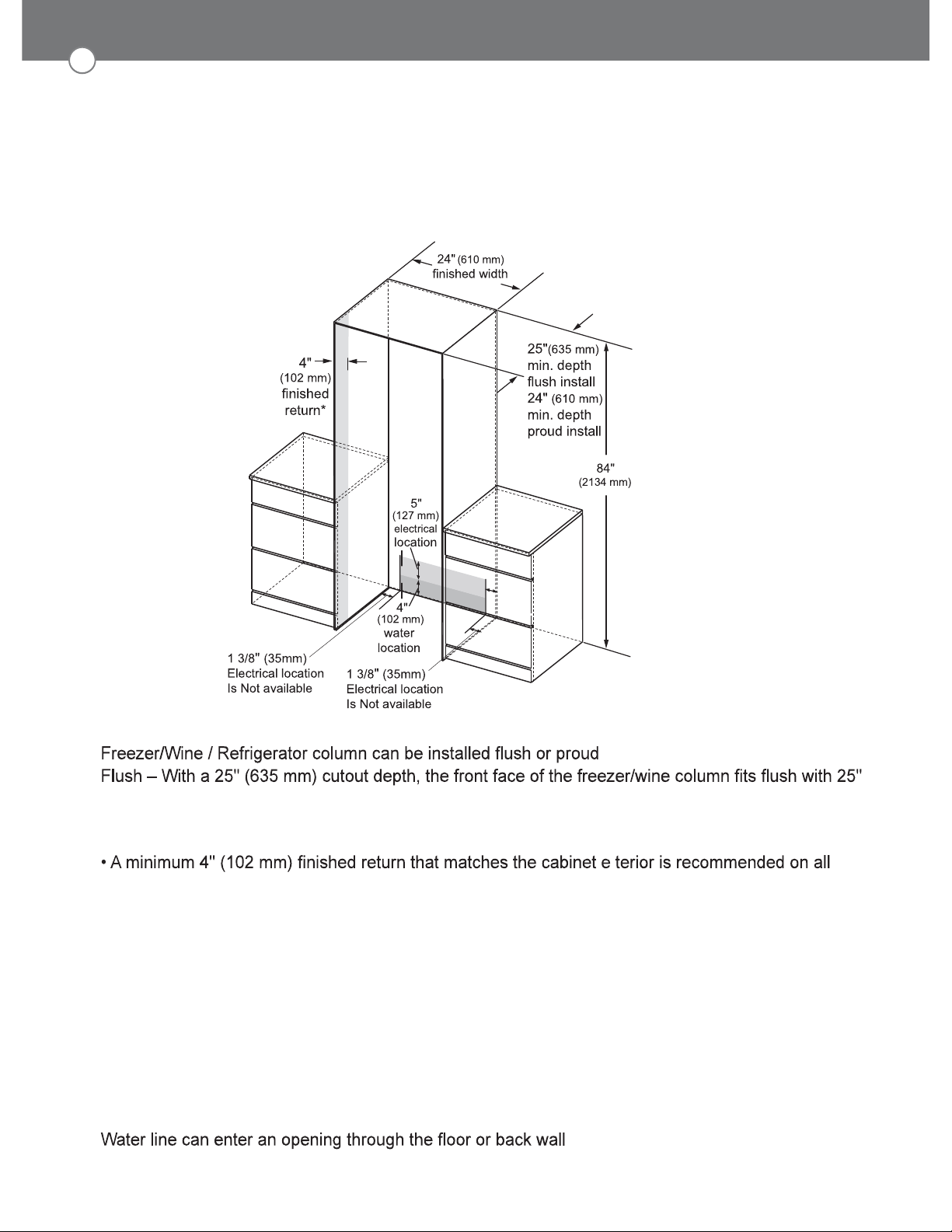

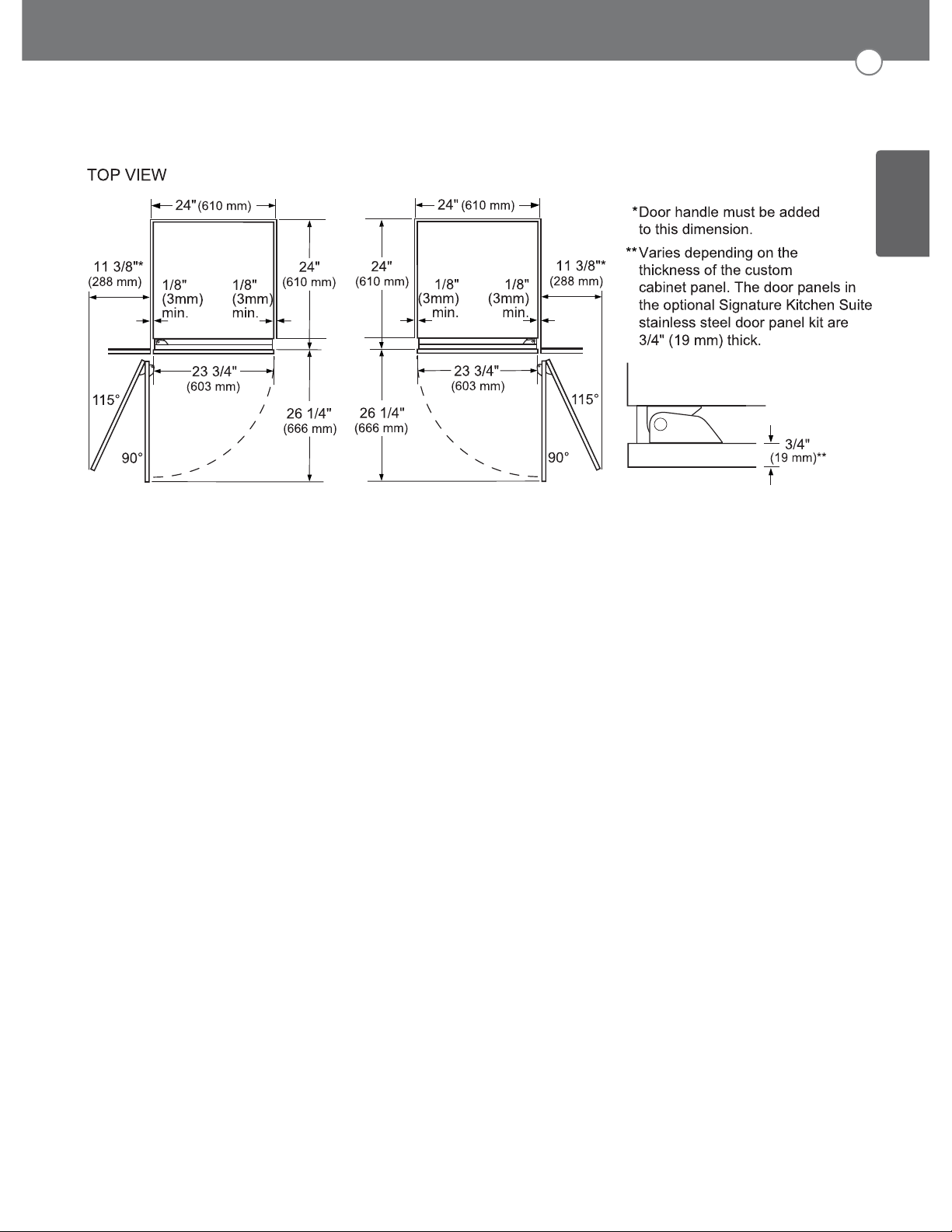

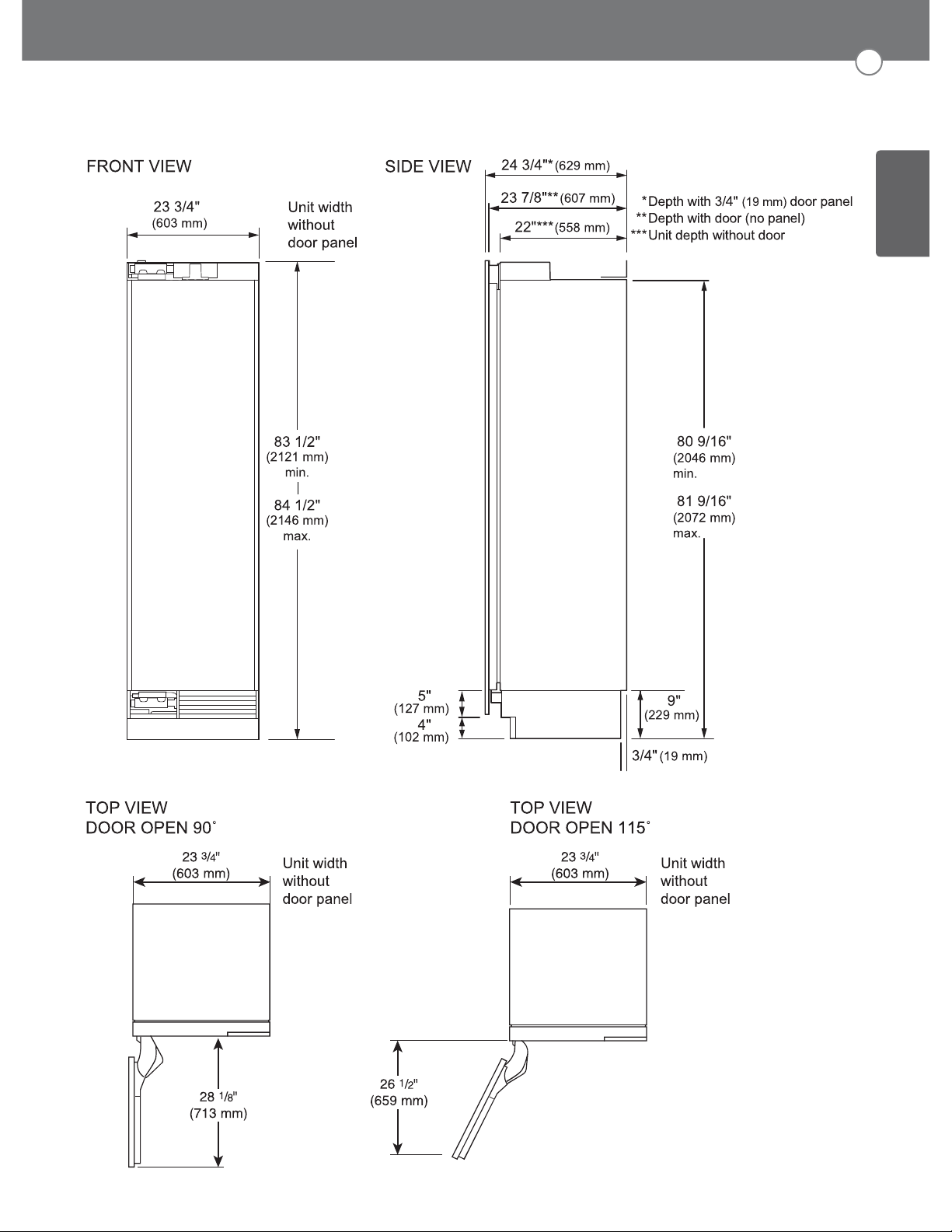

SKSCF2401P – 24" INTEGRATED FREEZER COLUMN

SKSCR2401P – 24" INTEGRATED REFRIGERATOR COLUMN

SKSCW241RP – 24" INTEGRATED WINE COLUMN

CUTOUT DIMENSIONS – FLUSH OR PROUD INSTALLATION, SINGLE COLUMN

NOTE

(635 mm) depth adjacent cabinets.

Proud – With a 24" (610 mm) depth cutout, the front face of the freezer/wine column extends

approximately 3/4" (19 mm) beyond 24" (610 mm) depth adjacent cabinets.

sides and the top of the cutout opening. The shaded area will be visible after installation.

ELECTRICAL

A 115V, 60Hz, 15 or 20 amp power supply is required. An individual, properly grounded branch

circuit or circuit breaker is recommended. Install a properly grounded 3-prong electrical

receptacle recessed into the back wall. Electrical must be located on rear wall as shown.

Note: GFI (ground fault interrupter) is not recommended.

WATER LINE

A cold water supply is required for automatic icemaker operation.

The water pressure must be between 20 and 120 psi.

Tubing should be long enough to extend to the front of the freezer. Allow enough tubing to

accommodate a bend leading into the water line connection.

Install a shut-off valve between the icemaker water valve and the cold water supply in the home.

INSTALLATION CLEARANCES

SKSCF2401P SKSCR2401P

13

ENGLISH

SKSCW241RP

NOTE

Door Swing Clearances

• The installation must allow for clearances to adjacent walls or cabinets. The appliances are

equipped with 2-position door stops.

• The factory-set 115° door swing can be adjusted to 90° if clearance to adjacent cabinets or walls is

restricted.

Door Handle Clearances

The door handle depth must be added to the dimension where noted to determine the total clearance

required from adjacent cabinets or walls. This clearance will vary depending on the custom handle

used. When using Signature Kitchen Suite handles or the Signature Kitchen Suite stainless steel

door panel kit with handles (optional accessories), the door handle clearance with the door open

115° is 14" (356 mm).

14

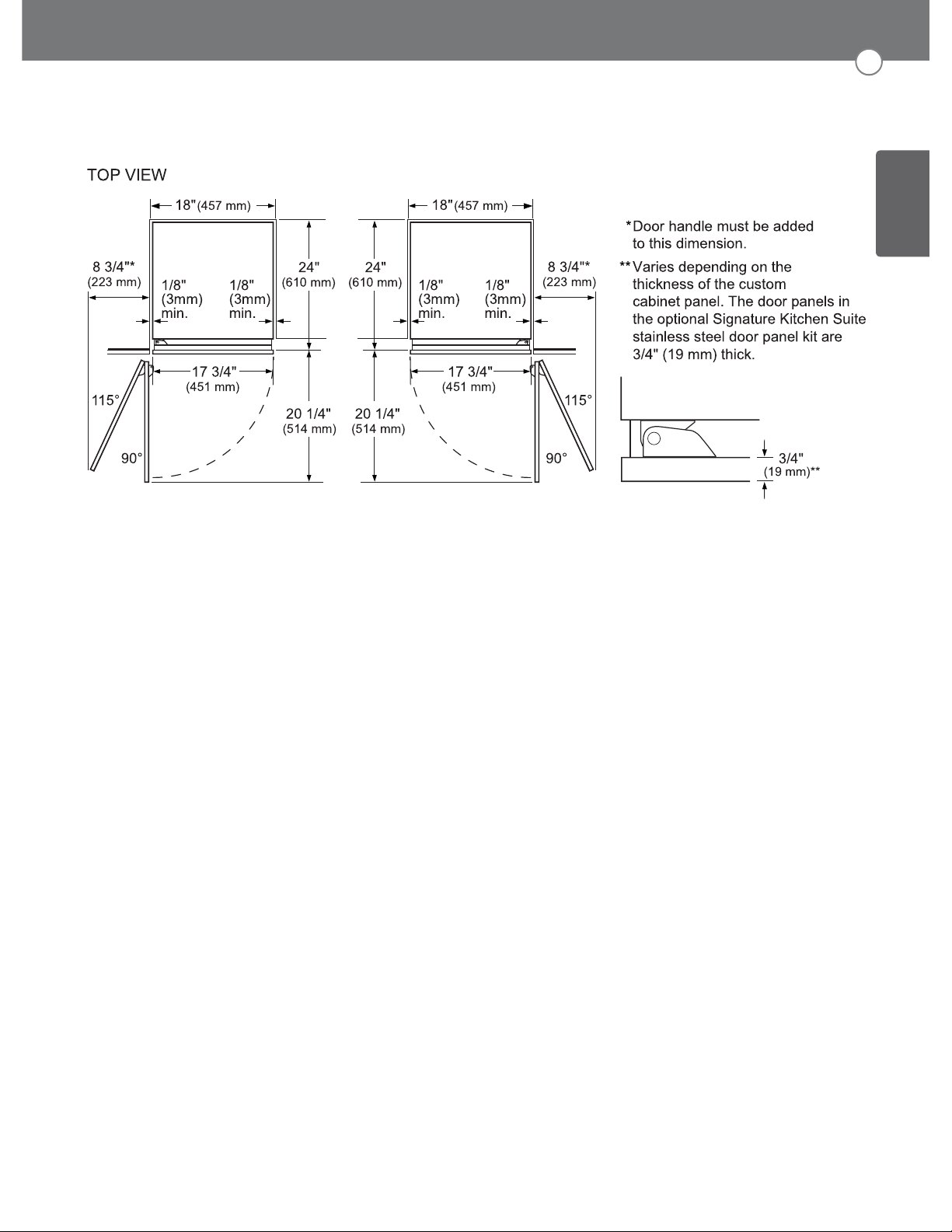

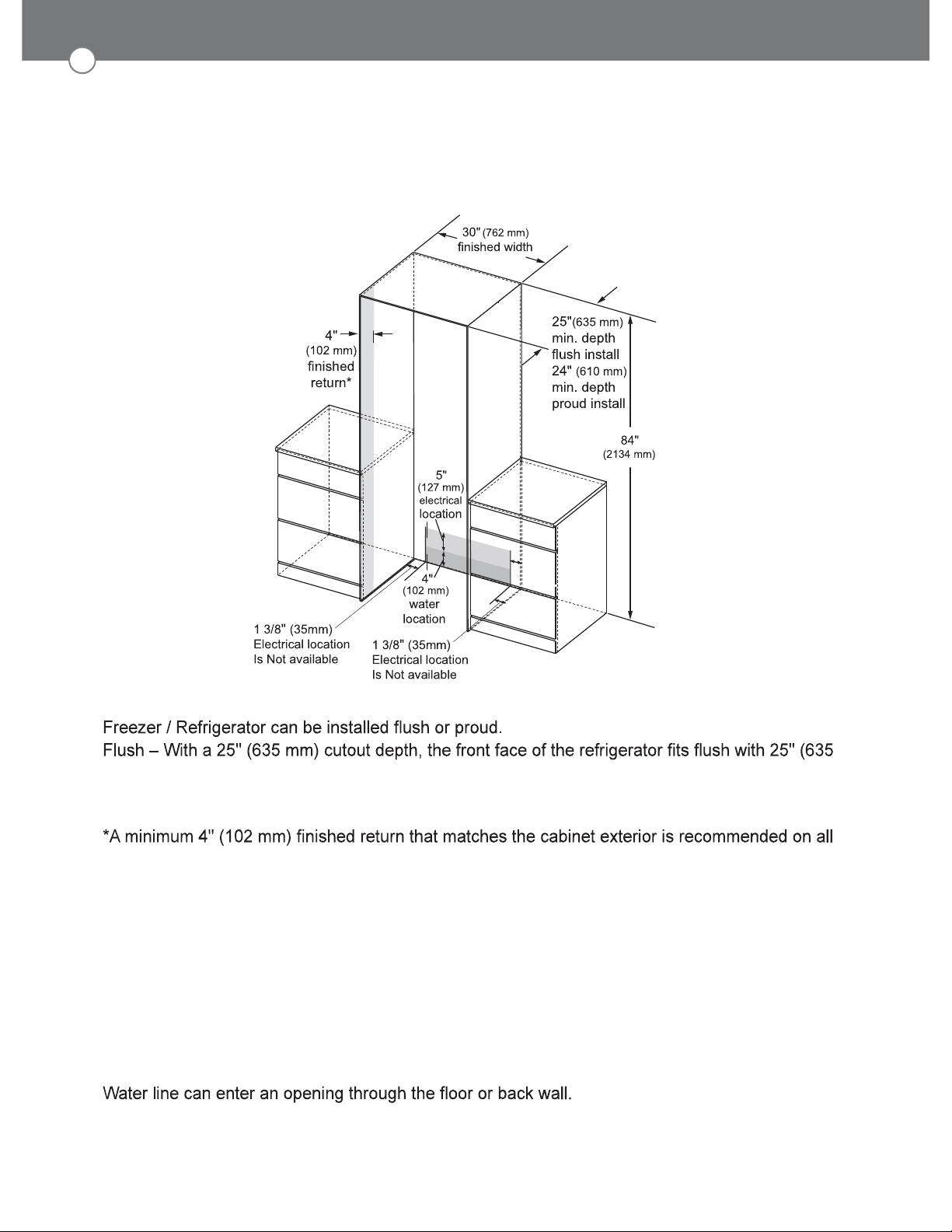

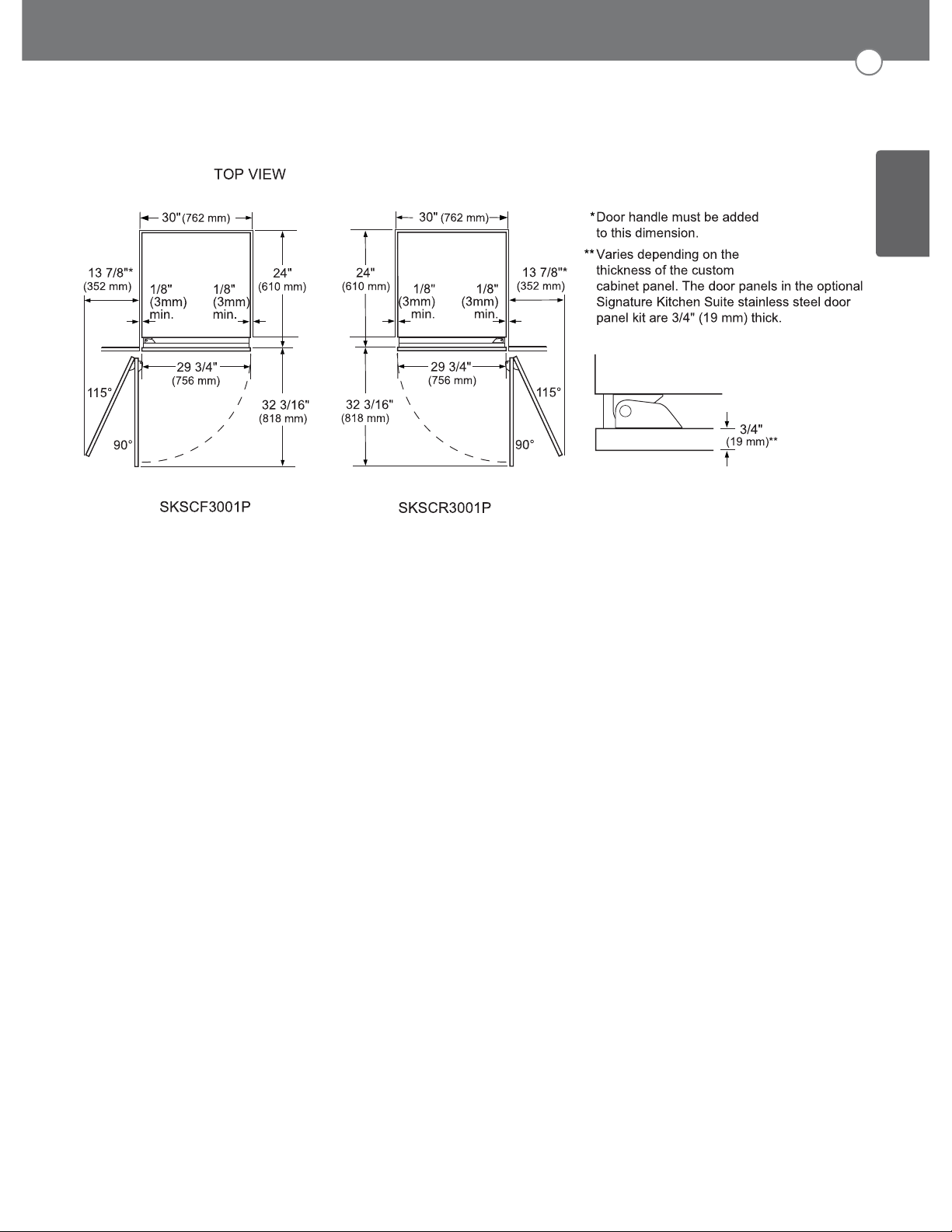

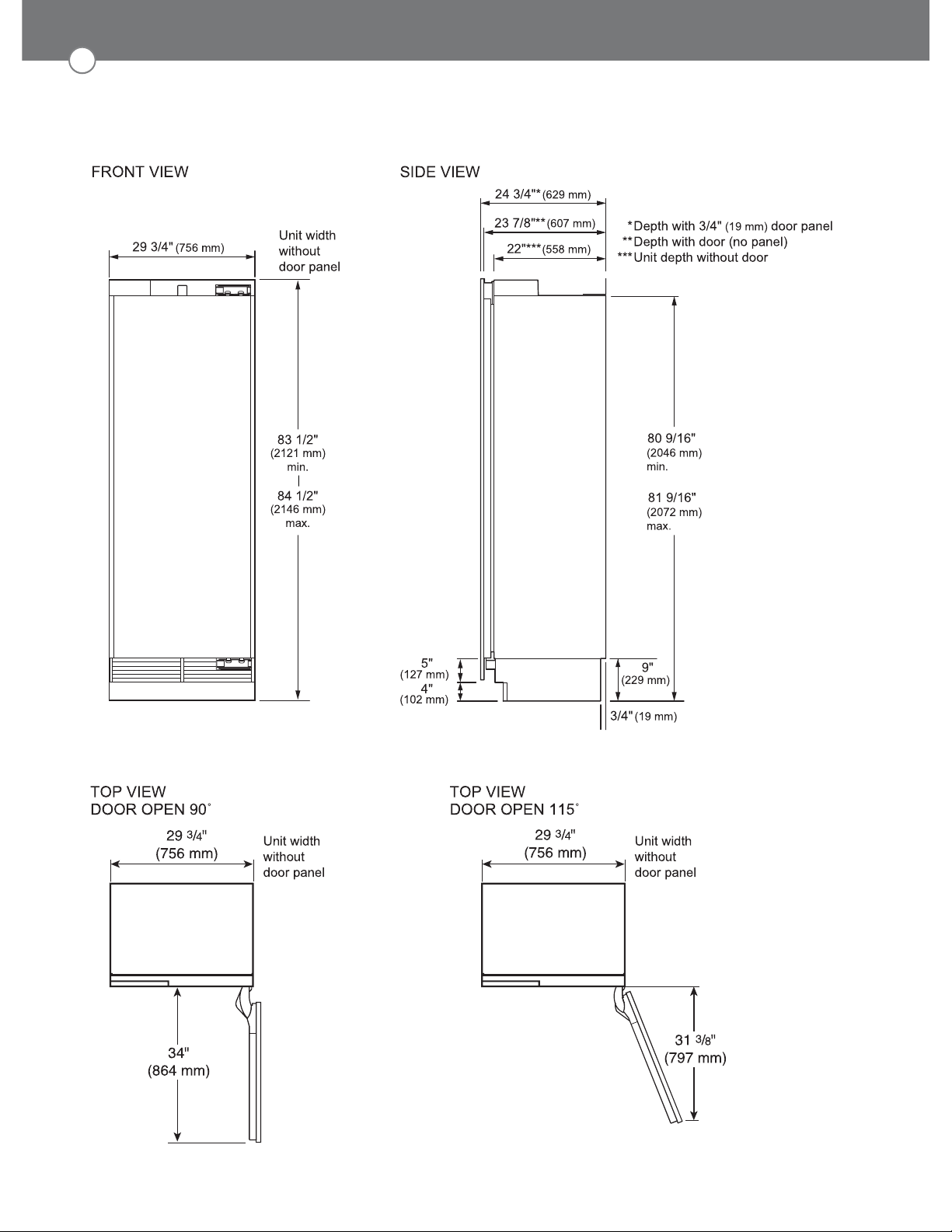

SKSCF3001P – 30" INTEGRATED FREEZER COLUMN

SKSCR3001P – 30" INTEGRATED REFRIGERATOR COLUMN

CUTOUT DIMENSIONS – FLUSH OR PROUD INSTALLATION, SINGLE COLUMN

NOTE

mm) depth adjacent cabinets.

Proud – With a 24" (610 mm) depth cutout, the front face of the refrigerator extends approximately

3/4" (19 mm) beyond 24" (610 mm) depth adjacent cabinets.

sides and the top of the cutout opening. The shaded area will be visible after installation.

ELECTRICAL

A 115V, 60Hz, 15 or 20 amp power supply is required. An individual properly grounded branch

circuit or circuit breaker is recommended. Install a properly grounded 3-prong electrical

receptacle recessed into the back wall. Electrical must be located on rear wall as shown.

Note: GFI (ground fault interrupter) is not recommended.

WATER LINE

The water pressure must be between 20 and 120 psi.

Tubing should be long enough to extend to the front of the refrigerator. Allow enough tubing to

accommodate a bend leading into the water line connection.

Install a shut-off valve between the water valve and cold water supply in the home.

INSTALLATION CLEARANCES

15

ENGLISH

NOTE

Door Swing Clearances

The installation must allow for clearances to adjacent walls or cabinets. This freezer / refrigerator

is equipped with a 2-position door stop. The factory-set 115° door swing can be adjusted to 90° if

clearance to adjacent cabinets or walls is restricted.

Door Handle Clearances

The door handle depth must be added to the dimension where noted to determine the total

clearances required from adjacent cabinets or walls. This clearance will vary depending on the

custom handle used. When using Signature Kitchen Suite handles or the Signature Kitchen Suite

stainless steel door panel kit with handles (optional accessories), the door handle clearance with the

door open 115° is 16" (406 mm).

16

SKSCF1801P – 18" INTEGRATED FREEZER COLUMN

SKSCW181RP – 18" INTEGRATED WINE COLUMN

3/4" (19 MM) CUSTOM PANEL DIMENSIONS – FLUSH INSTALLATION

Freezer/Refrigerator Column

Wine Column

NOTES

Trimmed units are designed to be customized with decorative panels. Field-installed 3/4" (19 mm)

custom door panels are required.

For custom panels: Use templates provided with units to pre-drill holes for mounting panel brackets

(provided with unit). Adjustment screws and instructions also provided with units.

Maximum total door panel weight for 30" column is 64 lb.

Maximum total door panel weight for 24" column is 53 lb.

Maximum total door panel weight for 18" column is 44 lb.

DESIGN TIPS

4" (102 mm) will be visible on the interior sides of the cutout. It is recommended that the

the optional frame kit may be used.

If using custom panels, a custom toe kick is required.

Door Handles: Handles are not included with the units.

Custom handles are required for installation. Brushed aluminum handles are available as an optional

accessory.

17

ENGLISH

OPTIONAL ACCESSORIES – FLUSH OR PROUD INSTALLATION

SKSPK180CS/SKSPK185CS – STAINLESS STEEL PANEL

KIT FOR 18" FREEZER COLUMN

SKSWK185RS/SKSWK185LS – STAINLESS STEEL PANEL

KIT FOR 18” WINE COLUMN

This unit can be installed with an optional stainless steel

panel kit. The freezer column kit is reversible and can be

used in both right hand and left hand door swing installations.

The wine column panel kits are not reversible.

SKSFK800CS – FRAME KIT

This unit can be installed in a 24" (610 mm) deep cutout with

an optional frame kit. The kit includes two 80" (2032 mm)

brushed aluminum side trim pieces. Each trim piece is 5"

(127 mm) deep with a 1/8" (3 mm) front face.

HANDLES FOR USE WITH CUSTOM PANELS

SKSHK310HS – 31 11/16" (805 mm) Medium Brushed

Aluminum Handle

SKSHK480HS – 48" (1219 mm) Long Brushed Aluminum

Handle

SKSPK180CS

SKSPK185CS

SKSWK185LS SKSWK185RS

DESIGN TIPS

mm) cutout depth installation or in a proud 24" (610 mm)

cutout depth installation.

replacement installations where the existing cutout is 24"

(610 mm) deep.

18

SKSCF2401P – 24" INTEGRATED FREEZER COLUMN

SKSCR2401P – 24" INTEGRATED REFRIGERATOR COLUMN

SKSCW241RP – 24" INTEGRATED WINE COLUMN

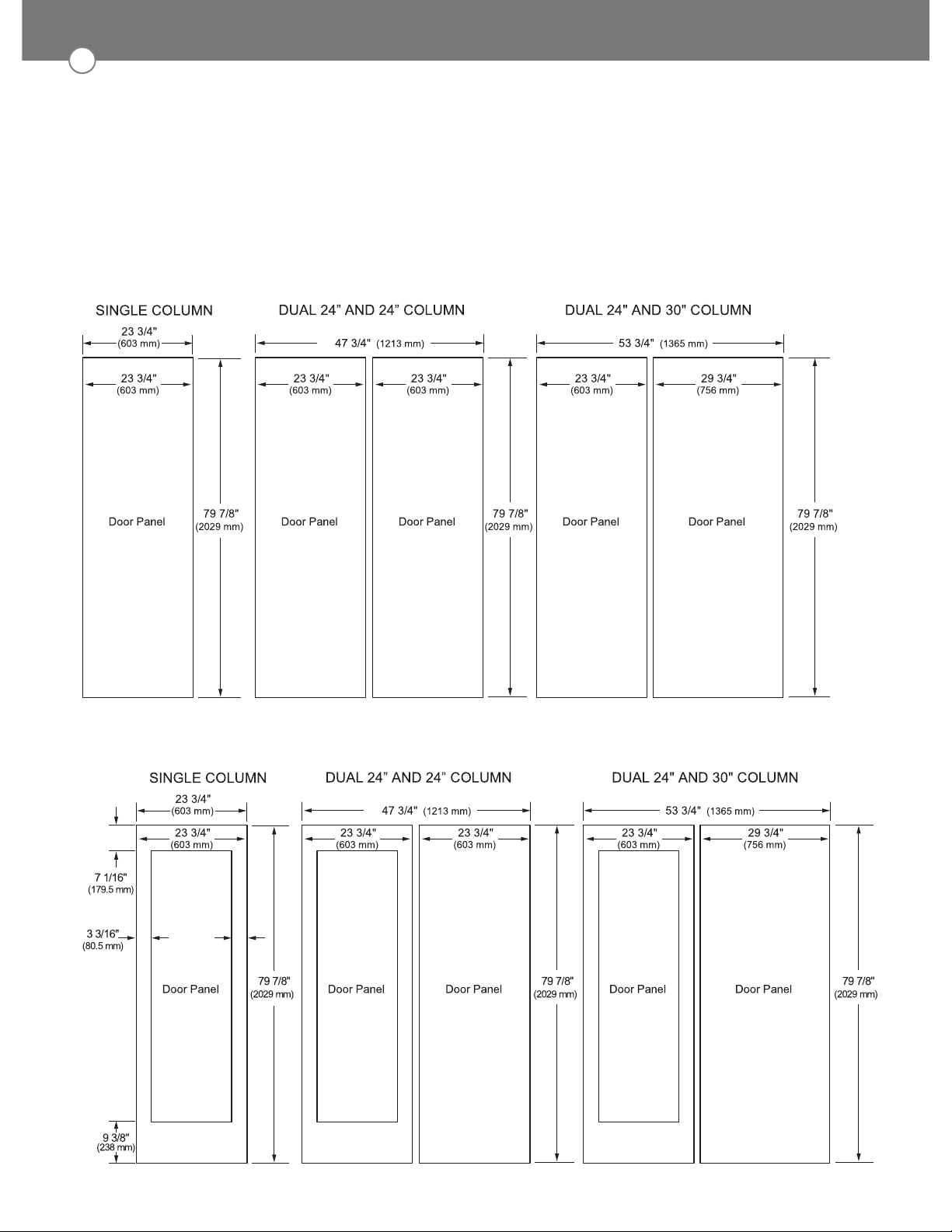

3/4" (19 MM) CUSTOM PANEL DIMENSIONS – FLUSH INSTALLATION

Freezer/Refrigerator Column

Wine Column

NOTES

Trimmed units are designed to be customized with decorative panels. Field-installed 3/4" (19 mm)

custom door panels are required.

For custom panels: Use templates provided with units to pre-drill holes for mounting panel brackets

(provided with unit). Adjustment screws and instructions also provided with units.

Maximum total door panel weight for 30" column is 64 lb.

Maximum total door panel weight for 24" column is 53 lb.

Maximum total door panel weight for 18" column is 44 lb.

DESIGN TIPS

4" (102 mm) will be visible on the interior sides of the cutout. It is recommended that the

the optional frame kit may be used.

If using custom panels, a custom toe kick is required.

Door Handles: Handles are not included with the units.

Custom handles are required for installation. Brushed aluminum handles are available as an optional

accessory.

19

ENGLISH

OPTIONAL ACCESSORIES – FLUSH OR PROUD INSTALLATION

SKSPK240CS/SKSPK245CS – STAINLESS STEEL PANEL

KIT FOR 24" FREEZER / REFRIGERATOR COLUMN

SKSWK245RS/SKSWK245LS – STAINLESS STEEL PANEL

KIT FOR 24" WINE COLUMN

This unit can be installed with an optional stainless steel

panel kit. The freezer/refrigerator column kit is reversible

and can be used in both right hand and left hand door swing

installations. The wine column panel kits are not reversible.

SKSFK800CS – FRAME KIT

This unit can be installed in a 24" (610 mm) deep cutout with

an optional frame kit. The kit includes two 80" (2032 mm)

brushed aluminum side trim pieces. Each trim piece is 5"

(127 mm) deep with a 1/8" (3 mm) front face.

HANDLES FOR USE WITH CUSTOM PANELS

SKSHK310HS – 31 11/16" (805 mm) Medium Brushed

Aluminum Handle

SKSHK480HS – 48" (1219 mm) Long Brushed Aluminum

Handle

SKSPK240CS

SKSPK245CS

DESIGN TIPS

SKSWK245LS SKSWK245RS

mm) cutout depth installation or in a proud 24" (610 mm)

cutout depth installation.

replacement installations where the existing cutout is 24"

(610 mm) deep.

20

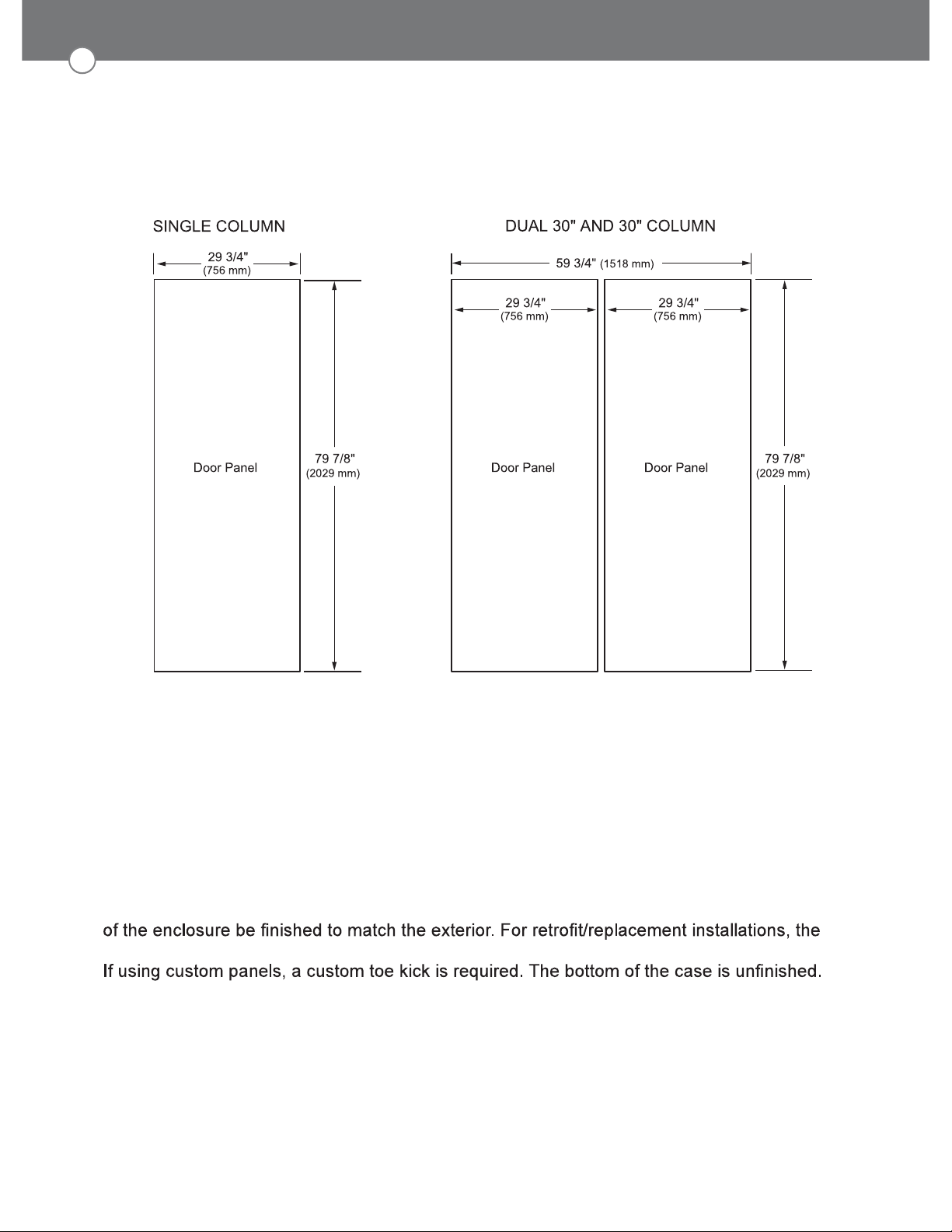

SKSCF3001P – 30" INTEGRATED FREEZER COLUMN

SKSCR3001P – 30" INTEGRATED REFRIGERATOR COLUMN

3/4" (19 MM) CUSTOM PANEL DIMENSIONS – FLUSH INSTALLATION

NOTES

Trimmed units are designed to be customized with decorative panels. Field-installed 3/4" (19 mm)

custom door panels are required.

For custom panels: Use templates provided with units to pre-drill holes for mounting panel brackets

(provided with unit). Adjustment screws and instructions also provided with units.

Maximum total door panel weight for 30" column is 64 lb.

Maximum total door panel weight for 24" column is 53 lb.

Maximum total door panel weight for 18" column is 44 lb.

DESIGN TIPS

4" (102 mm) will be visible on the interior sides of the cutout. It is recommended that the interior

optional frame kit may be used.

Door Handles: Handles are not included with the units. Custom handles are required for installation.

Brushed aluminum handles are available as an optional accessory.

OPTIONAL ACCESSORIES – FLUSH OR PROUD INSTALLATION

21

SKSPK300CS/SKSPK305CS – STAINLESS STEEL PANEL KIT FOR

30" FREEZER / REFRIGERATOR COLUMN

This unit can be installed with an optional stainless steel panel kit.

The kit includes one door panel, one toe kick and one handle. This

kit is reversible and can be used in both right hand and left hand door

swing installations.

SKSFK800CS – FRAME KIT

This unit can be installed in a 24" (610 mm) deep cutout with an

optional frame kit. The kit includes two 80" (2032 mm) brushed

aluminum side trim pieces. Each trim piece is 5" (127 mm) deep with

a 1/8" (3 mm) front face.

HANDLES FOR USE WITH CUSTOM PANELS

SKSHK310HS – 31 11/16" (805 mm) Medium Brushed Aluminum

Handle

SKSHK480HS – 48" (1219 mm) Long Brushed Aluminum Handle

DESIGN TIPS

cutout depth installation or in a proud 24" (610 mm) cutout depth

installation.

ENGLISH

SKSPK300CS

SKSPK305CS

installations where the existing cutout is 24" (610 mm) deep.

22

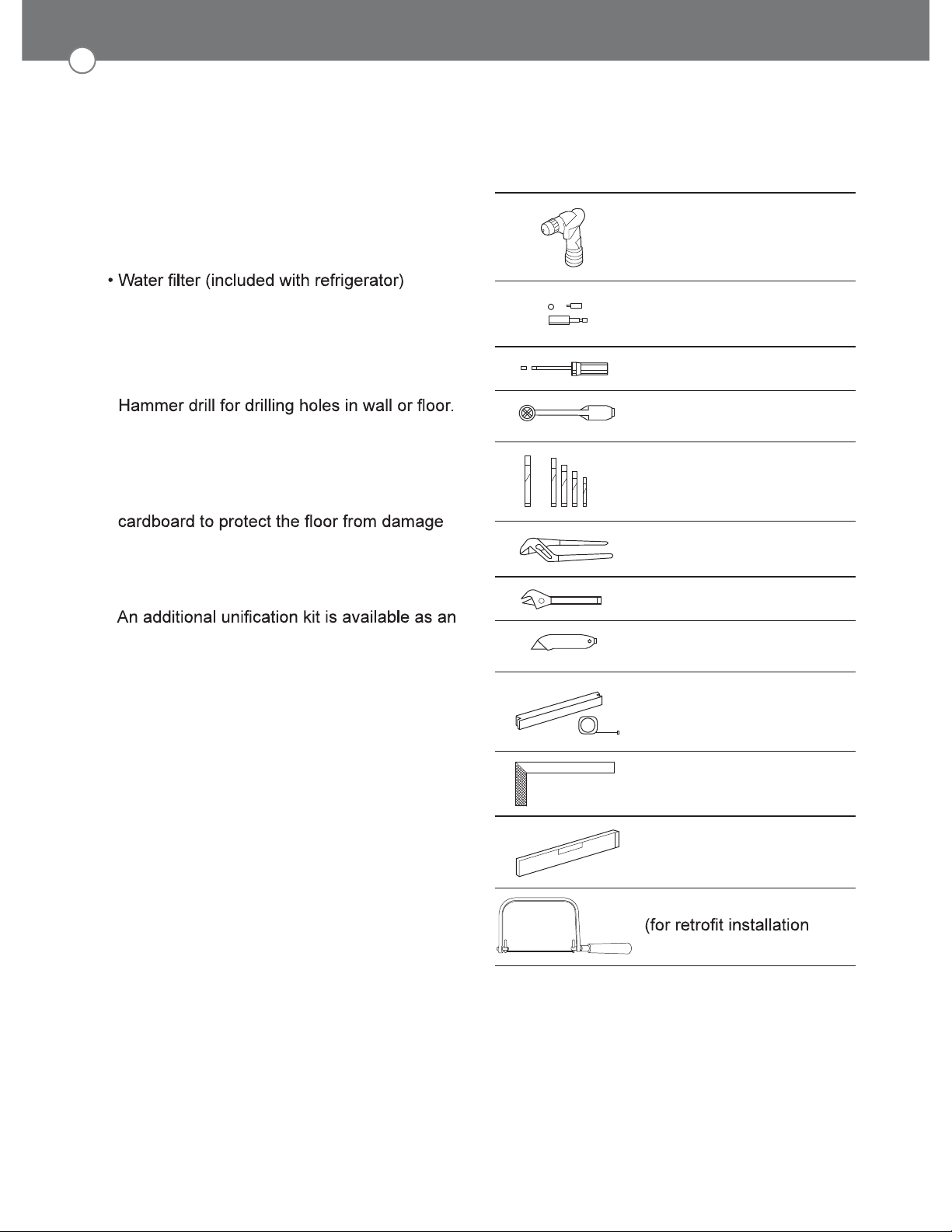

Required Accessories and Tools

Supplied Accessories

Installation instructions

•

•

Operating instructions

•

Installation kit

Other

•

Stepladder

•

Dolly, hand truck

•

•

Drill bits in various sizes and suitable for

materials

•

Wood screws in different sizes

•

Thin plywood sheet, particle board or

Suitable material for covering and protecting

•

furniture (e.g. protective sheets)

Adhesive tape

•

•

accessory (part number SKSFJ800P) from

Signature Kitchen Suite.

Tools

Cordiess screwdriver

Torx bit T20, T30

and magnetic holder

Torx screwdriver T20, T30

6/16"(10 mm) hex nut

driver

Various drill bits

Multigrip pliers

Adjustable wrench

Cutter with adustable

blade

Metal tape measure, folding rule

Square

Level, length 2" (60 cm)

and 4'(1.2 m)

saw to cut top trim pieces

only)

Installation

The following installation instructions describe the installation steps for various appliance

types:

• Refrigerator units with water dispenser

• Freezer units with ice maker

The diagrams may be a general representation of your appliance.

Particular reference is made to special installation steps for individual appliance types.

23

ENGLISH

24

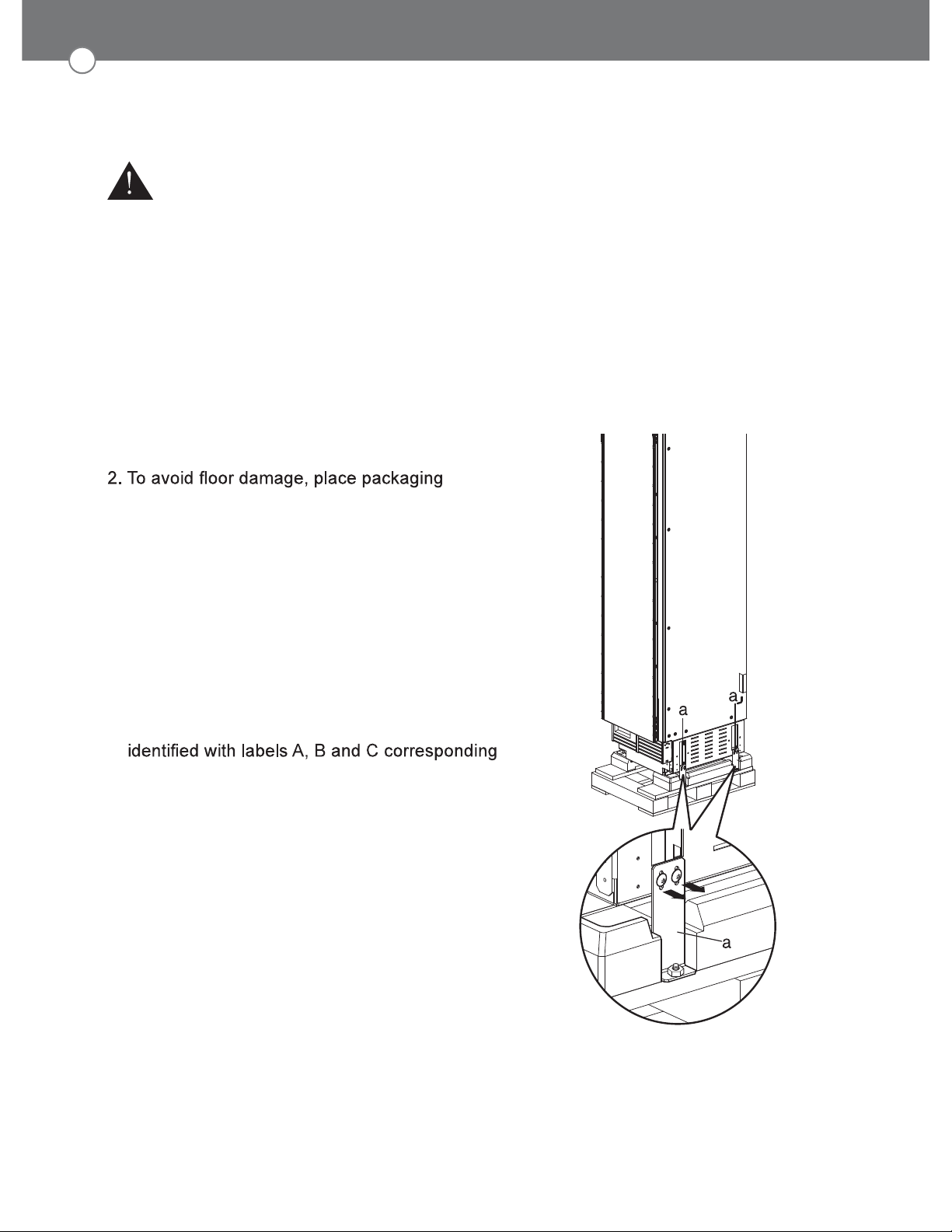

Unpacking

WARNING

To avoid serious injury or product damage:

• DO NOT open appliance door unless the product is secured against tipping.

• The appliance is very heavy and is prone to tipping if not secured.

• To avoid injury, use 2 or more people and proper lifting techniques when lifting or moving

the appliance.

Check appliance for damage in transit.

Do not install the appliance if it is visibly damaged.

If in doubt, contact your dealer.

1. Remove the packaging carton, being careful not

to damage the surface of the appliance.

cardboard or plywood under the appliance.

3. Remove accessories on the sides and

underneath the appliance.

NOTE:

To avoid damaging parts, do not remove the

protective shipping materials inside the appliance

until the installation is complete.

4. Installation Preparation

Unpack installation materials and accessories.

To simplify installation, the packages are

to the manual sections.

CAUTION:

Appliance is very heavy. Use two or more people

when lifting or moving the appliance.

5. Remove shipping brackets (a) and lift the

appliance off the pallet.

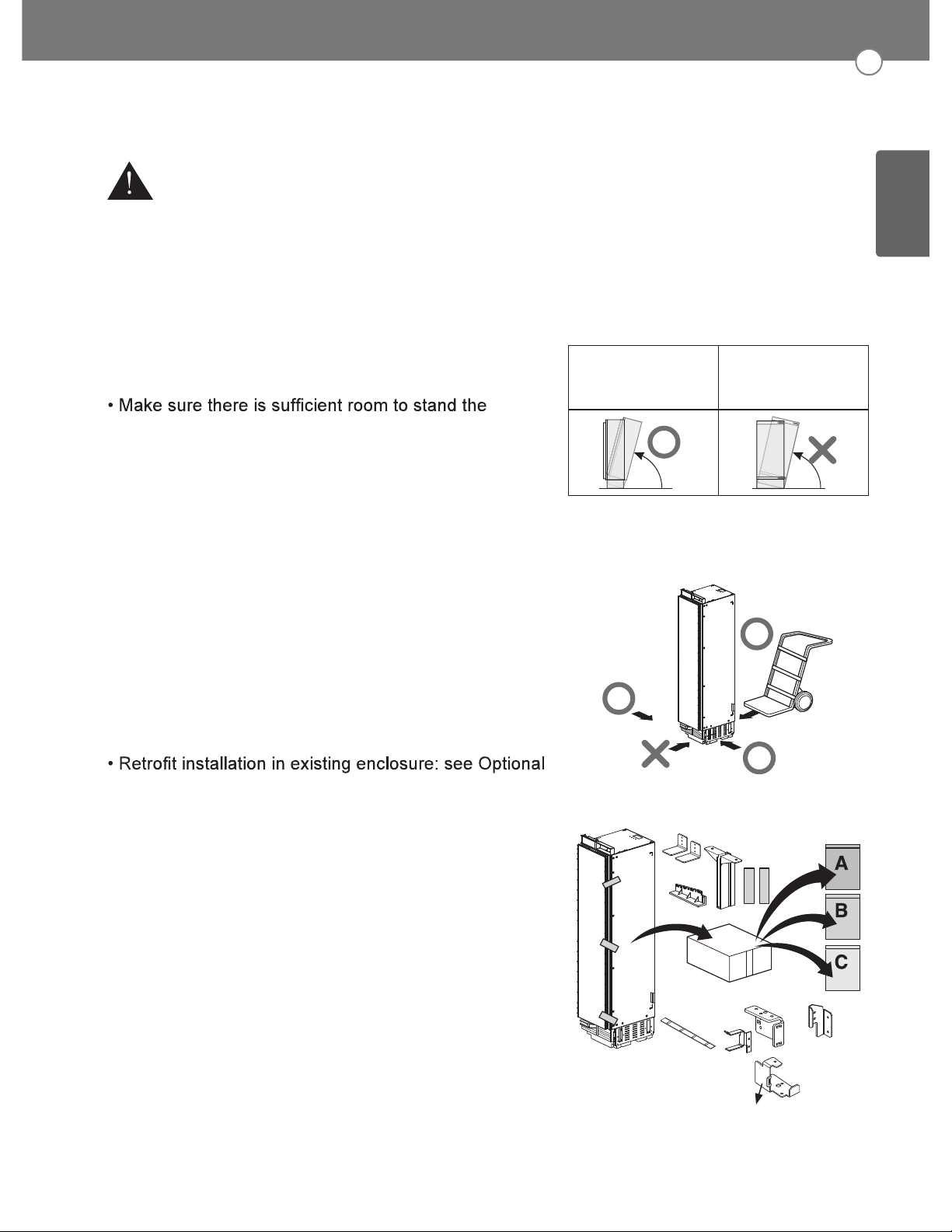

Moving the Appliance

WARNING

• To avoid injury, use 2 or more people and observe proper lifting techniques when lifting or

moving the appliance.

• If the appliance cannot be transported in an upright position, transport it horizontally.

To avoid product damage:

25

ENGLISH

• Do not tilt the appliance toward the sides or lay it on its

sides.

appliance upright before doing so.

• Use a dolly, lift truck or hand cart to transport the

appliance.

• Transport from the rear side of the appliance ONLY.

• Secure the appliance during transport to prevent it

from tipping.

Special Circumstances

Before proceeding with your installation, check if any

of the following special circumstances apply to your

installation. If so, follow the relevant instructions in the

Special Installations section before continuing the

installation.

Frame Kit Accessory section.

• Reversing door swing: see Door Reversal section.

• Side-by-Side installation of 2 appliances: see Side-bySide Installation section.

Raise up via

appliance rear

Do not raise up

from appliance

side

(* Wine Column only.)

26

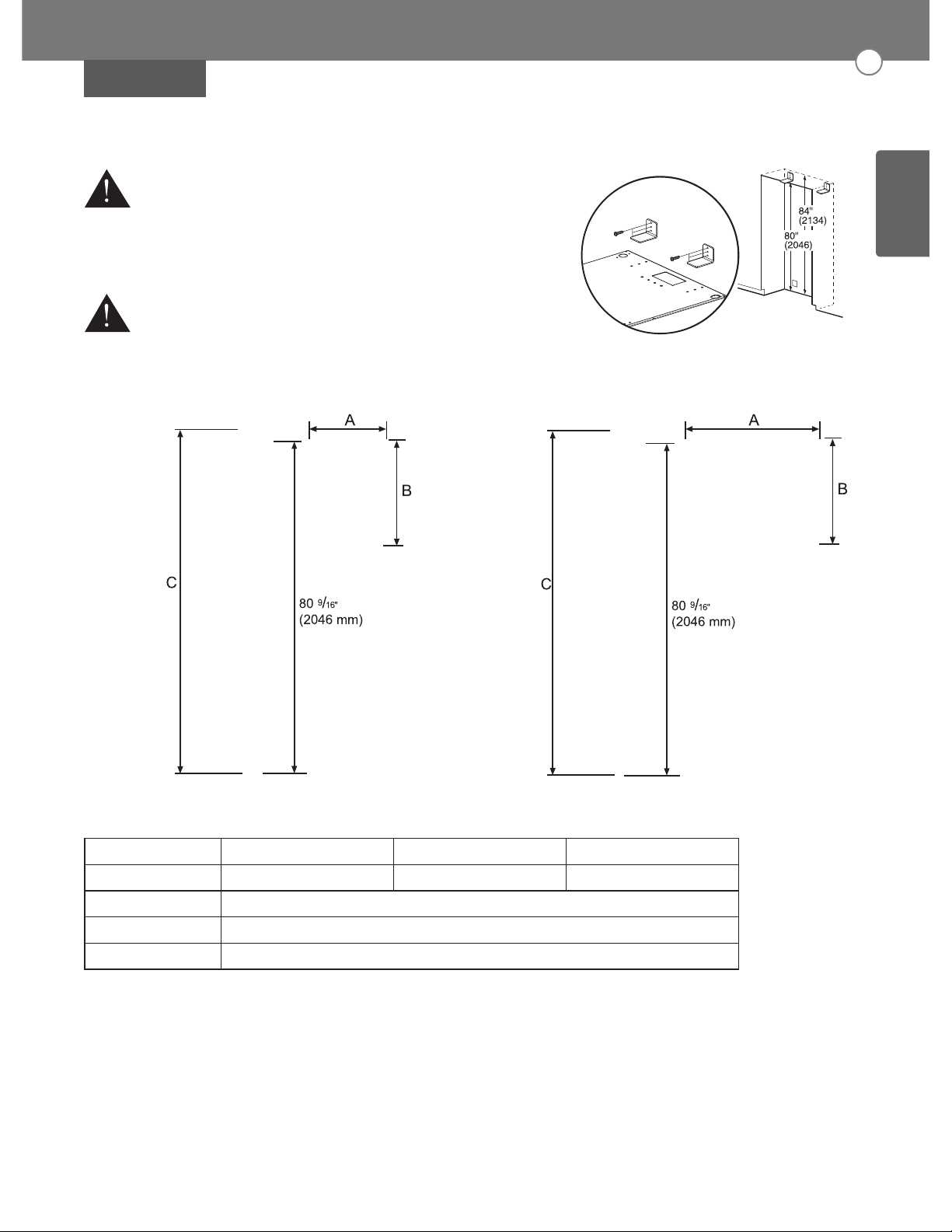

Product Dimensions

18" Freezer / Wine Column

24" Freezer / Refrigerator / Wine Column

27

ENGLISH

28

30" Freezer / Refrigerator Column

A

Installing the Anti-tip Brackets

WARNING

To avoid injury or damage, check for electrical wires or

plumbing in walls before drilling or installing screws.

CAUTION

To avoid injury, observe all safety practices during

installation, including wearing safety glasses and other

safety apparel.

29

ENGLISH

18" Unit 24" Unit 30" Unit

A (Width) 17 ½" (445 mm) 23 3/4" (603 mm) 29 3/4" (756 mm)

B (Depth) 23 7/8"(607 mm)

C (Height) 83 ½"(2121 mm)

D (Back height) 80 9/16"(2046 mm)

30

NOTE:

2 anti-tip-brackets are required for each appliance.

The anti-tip-brackets must overlap a minimum of 2 1/8"

(54 mm) over the appliance to secure the appliance.

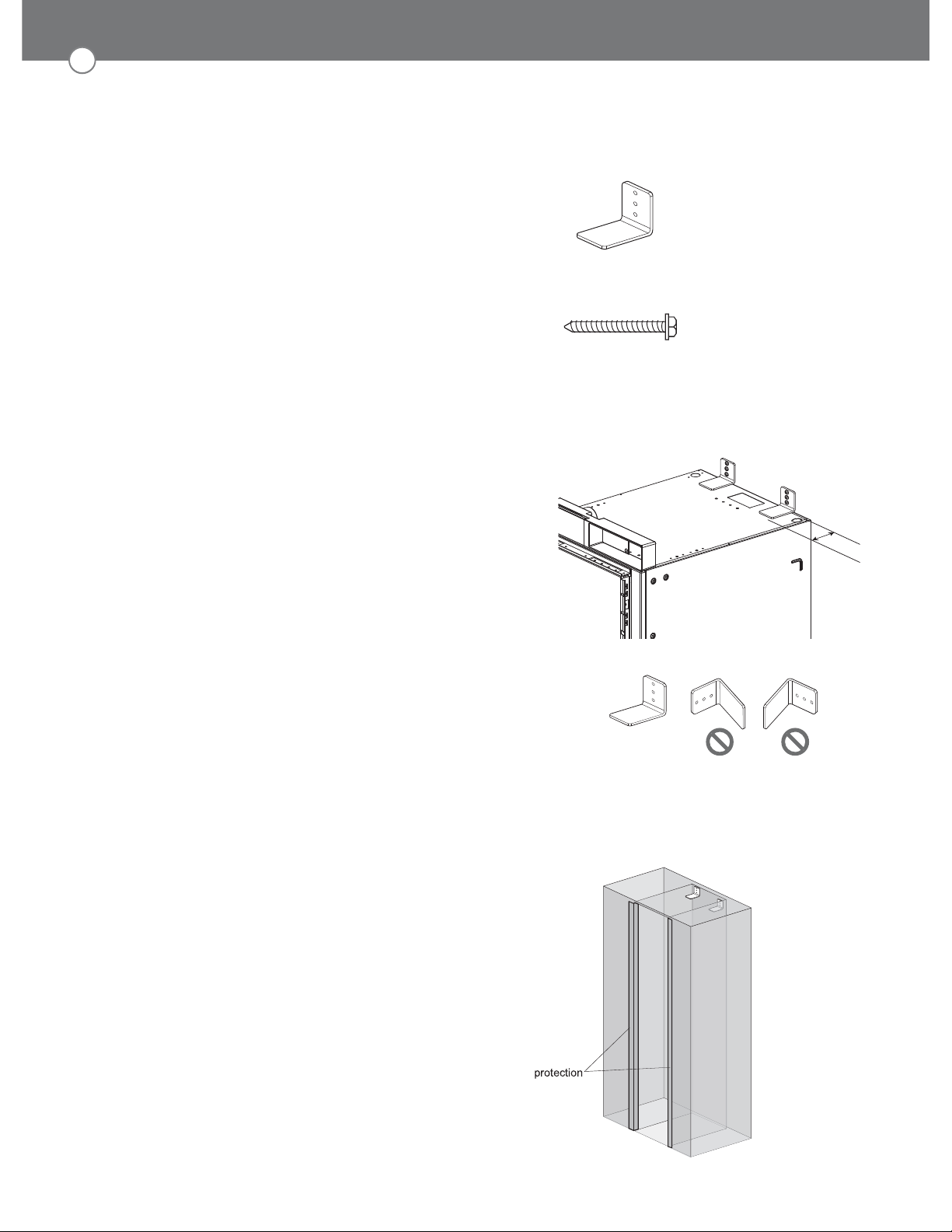

Anti-tip brackets (2)

1. Install the anti-tip brackets at the rear of the enclosure,

locating the brackets based on stud locations and

product and enclosure dimensions.

2. Make sure the anti-tip brackets are securely attached

to a stud or other weight-bearing structure.

Do not attach brackets to drywall, cinder block, or

uncured concrete.

To ensure safety, at least one bracket must be

attached to a stud. Attach brackets to studs wherever

possible within the enclosure. Use a minimum of 3

screws or bolts to attach each bracket.

Brackets must be attached as shown at right. The brackets

could fail to prevent tipover of the unit if installed in an

alternate orientation.

Concrete / Wood wall

5X45 6X (Hex)

>2

(54 mm)

1

/8"

Protecting Edges of Enclosure

To protect the front edges of the enclosure, tape thin

cardboard or some other protective material around the

edges.

Loading...

Loading...