Signature Control Systems 810 Series, 8124US, 8124IT, 8124FR, 8124PT Installation And Programming Manual

...

9954664

9

www.SIgnatureControlSystems.com

©2014 Signature Control Systems, Inc.

Peoria, IL 61615

ence regulations of the Canadian Department of Communications.

noise emissions from digital apparatus set out in the radio interfer-

NOTE: This digital apparatus does not exceed the Class B limits for radio

CANADIAN RADIO INTERFERENCE REGULATIONS

8800 N. Allen Rd.

DC 20402. Stock No. 004-000-00345-4.

his booklet is available from the U.S. Government Printing Office, Washington,

T

“How to Identify and Resolve Radio-TV Interference Problems”

prepared by the Federal Communications Commission helpful:

technician for additional suggestions. The user may find the following booklet

If necessary, the user should consult the dealer or an experienced radio/television

on different branch circuits

Plug the controller into a different outlet so that the controller and receiver are

Move the controller away from the receiver

Relocate the controller with respect to the receiver

eorient the receiving antenna

R

may change without notice.

our products, features and specifications in this manual

NOTE: In our efforts to continually improve and update

following measures:

on, the user is encouraged to try to correct the interference by one or more of the

or television reception, which can be determined by turning the controller off and

occur in a particular installation. If this controller does cause interference to radio

residential installation. However, there is no guarantee that interference will not

on our website at www.SignatureControlSystems.com

Department toll-free at 1-866-4SIGNATURE, or by visiting us

EZ Indoor 8100 Series, please call our Technical Services

If you have questions, problems or comments on your new

which are designed to provide reasonable protection against such interference in a

device in accordance with the specifications in Subpart J of Part 15 of FCC Rules,

been type tested and found to comply with the limits for a Class B computing

er’s instructions, may cause interference to radio and television reception. It has

if not installed and used properly, that is, in strict accordance with the manufactur-

This electronic irrigation controller generates and uses radio frequency energy and

FCC RULES

Installation and Programming Guide

For EZ Indoor Models:

• 8124US

• 8124IT

• 8124FR

• 8124PT

• 8124ES

• 8124AU

• 8126US

• 8126IT

• 8126FR

• 8126PT

IGNATURE CONTROL SYSTEMS, INC LIMITED WARRANTY AND DISCLAIMER: TURF PRODUCTS

S

1

) Signature Control Systems, Inc. [“SCS”] warrants to the owner (the “Buyer”) that all new products, as featured in the current Signature Turf

Catalog at date of purchase will be free from original defects in materials and workmanship for the time periods described below, provided they

a

re used for approved purposes under manufacturer’s recommended specifications.

2

) This warranty is given expressly and in place of all other expressed or implied warranties of merchantability and fitness for a particular purpose.

T

his is the only warranty made by Signature Control Systems, Inc for Turf products. This warranty gives you specific legal rights and you may

have other rights which vary from state to state.

3) During the warranty period, SCS will repair or replace, at SCS’s sole discretion, any part to be found defective with prior written authorization.

Buyers remedy is limited solely to the replacement or repair of the defective parts.

4

) This warranty does not apply (i) to Acts of God including without limitation, lightning and flooding; or (ii) to products not manufactured by SCS

w

hen used in conjunction with SCS products; or (iii) where equipment is used, or installation is performed in any manner contrary to SCS’s

specifications and instructions, nor where equipment is altered or modified.

5

) Signature Control Systems, Inc. reserves the right to redesign, alter or modify its products at anytime and does not, and will not,

a

ssume any liability with respect to obsolete inventory arising there from.

6) Neither SCS or its affiliates are liable for any indirect, incidental or consequential damages in connection with the use of equipment, including

but not limited to: vegetation loss, the cost of substitute equipment or services required during periods of malfunction or resulting non-use,

property damage or personal injury resulting from installer’s actions, whether negligent or otherwise.

7

) No agent or representative of SCS, nor of any distributor, retailer, lessor or installer of the system, has any express or implied authority to make

a

ny representation, promise, guarantee or warranty not stated here. SCS disclaims any warranty of merchantability or fitness for a particular

purpose, or any other warranties that extend beyond those described here.

8) Some states do not allow the exclusion of incidental or consequential damages, so the above exclusion may not apply to you. All implied

warranties, including those of merchantability and fitness for use, are limited to the duration of this express warranty.

9

) Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

10) STANDARD PRODUCTS LIMITED 1-YEAR WARRANTY: All SCS products are covered by this warranty for a period of one year from the date

of supply except as noted below:

a) Signature Turf Gear Drive Rotors, Spray-Heads & Valves: Five (5) years; from original sale date.

b) Signature Turf & Satellite Controllers: Two (2) years; from original sale date.

c) Repairs & Refurbished Components: Balance of product warranty or three (3) months, from repair date, whichever occurs first, on

materials and labor only.

d) Brass Quick Coupler Valve Bodies: Five (5) years; from original sale date.

e) Solenoid Coils: One (1) year; from original sale date.

11) TECHNICAL ADVICE: SCS warranties as hereinabove set forth shall not be enlarged, diminished or affected by, and no obligation or liability

shall arise or grow out of, SCS rendering of technical advice or service in connection with Buyer's order or the products furnished.

12) QUESTIONS: If you have any questions concerning the warranty or its application, please email your question to info@scsmail.com or write to:

Signature Control Systems, Inc

Turf Division

8800 N. Allen Rd.

Peoria, Illinois 61615

U.S.A.

Attention: Customer Service.

13) CLAIMED DEFECTIVE MERCHANDISE POLICY. Products returned to the retailer or distributor and claimed defective must be inspected by an

authorized SCS representative to determine warranty compliance. If approval is granted, products will be repaired or replaced, or a credit

memorandum covering the net purchase price will be issued.

14) In the event of a defect: If a defect arises in a Signature product or part within the warranty period, you should contact your Signature retailer,

distributor, or Signature Control Systems, Inc. at www.signaturecontrolsystems.com or one of the following locations:

WORLD

HEADQUARTERS

16485 Laguna Canyon Rd.,

Suite 130,

Irvine • California • 92618

Tel: 949.580.3640

Fax: 949.580.3645

U S A To l l F r e e : 8 88 . 6 3 5 . 7 6 6 8

15) SERVICE TIME-LINE: Signature may, at its option, require that product or part be returned to a Signature service point or your retailer or

distributor. Signature will determine whether the claimed defect is covered by the warranty. If covered, the product will be repaired or replaced.

Please allow 4 to 6 weeks for completion of repairs or replacement and return of the product or part. If a product or part is replaced, the

replacement is warranted only for the remainder of the original product or part warranty period.

MANUFACTURING

FACILITY

8800 N. Allen Rd.,

Peoria

Illinois • 61615

Tel: 949.580.3640

Fax: 949.580.3645

EUROPE & MIDDLE EAST

5 rue de la Vallee Yart

78640 Saint Germain de la Grange

France

Tel: +33.13.489.9056

Fax: +33.13.489.6025

REGIONAL OFFICES

ASIA Shenzhen • Guangdon Province • 518131

Tel: (86) 136.00419465 • Fax: (86) 755.83275012

SOUTH AMERICA Roodepoort • South Africa

Office & Mobile: +27 82 553 9093 • Fax: 086 670 6318

AUSTRALIA Glen Osmond 5064 • South Australia

Tel: +61 (0) 417 862 269 • Fax +61 (0) 8 8338 2021

M

E

Gua

T

e

l/

SOUTH

S

ant

Tel/Fax:

X

ICO,

najua

to

Fax: +

iago

•

+56

CE

NTRAL

•

M

e

xico

52 (461) 614.2322

AM

E

RI

CA

Chile

229.556220

AM

E

RICA

• 8126ES

EATURES

F

Signature exclusive SELECT&ADJUST programming

•

Two independent programs

•

Three start times per program (6 total starts)

•

Stacking start times

•

Three scheduling options to suit the needs of plant material or to

•

omply with watering restrictions (days of the week, 1-30 day

c

nterval, true odd/even)

i

Will accept Normally Closed Rain Sensor

•

eap year compatible-automatically includes Feb 29th every four years

L

•

Manual Test Feature

•

Programmable run times from one minute to 6 hours

•

Self reseting polyswitch for short-circuit protection

•

NSTALLATION INSTRUCTIONS

I

The EZ Pro Jr. Indoor 8100 Series can be easily mounted indoors. Find a

location near a 120V receptacle (230/240V for IT, FR, PT & ES models).

Install the EZ Indoor near eye level if possible. Install the top screw in

he wall and adjust the depth for a snug fit when the controller is

t

uspended on the screw. Remove the wiring skirt and suspend the

s

ontroller on the first mounting screw and insert and tighten the other 2

c

crews through the lower hole

s

nchors as necessary).

a

Low Voltage Wiring

ow voltage output cables should be enclosed in conduit affixed near the

L

ontroller. (For field connection, AC wires must have an insulation rated at

c

5° C minimum). Conduit should be secured near the case (follow local codes).

7

ield wiring is best accomplished with the AC disconnected from the unit.

F

rovided in the case (pre-drilled or use

p

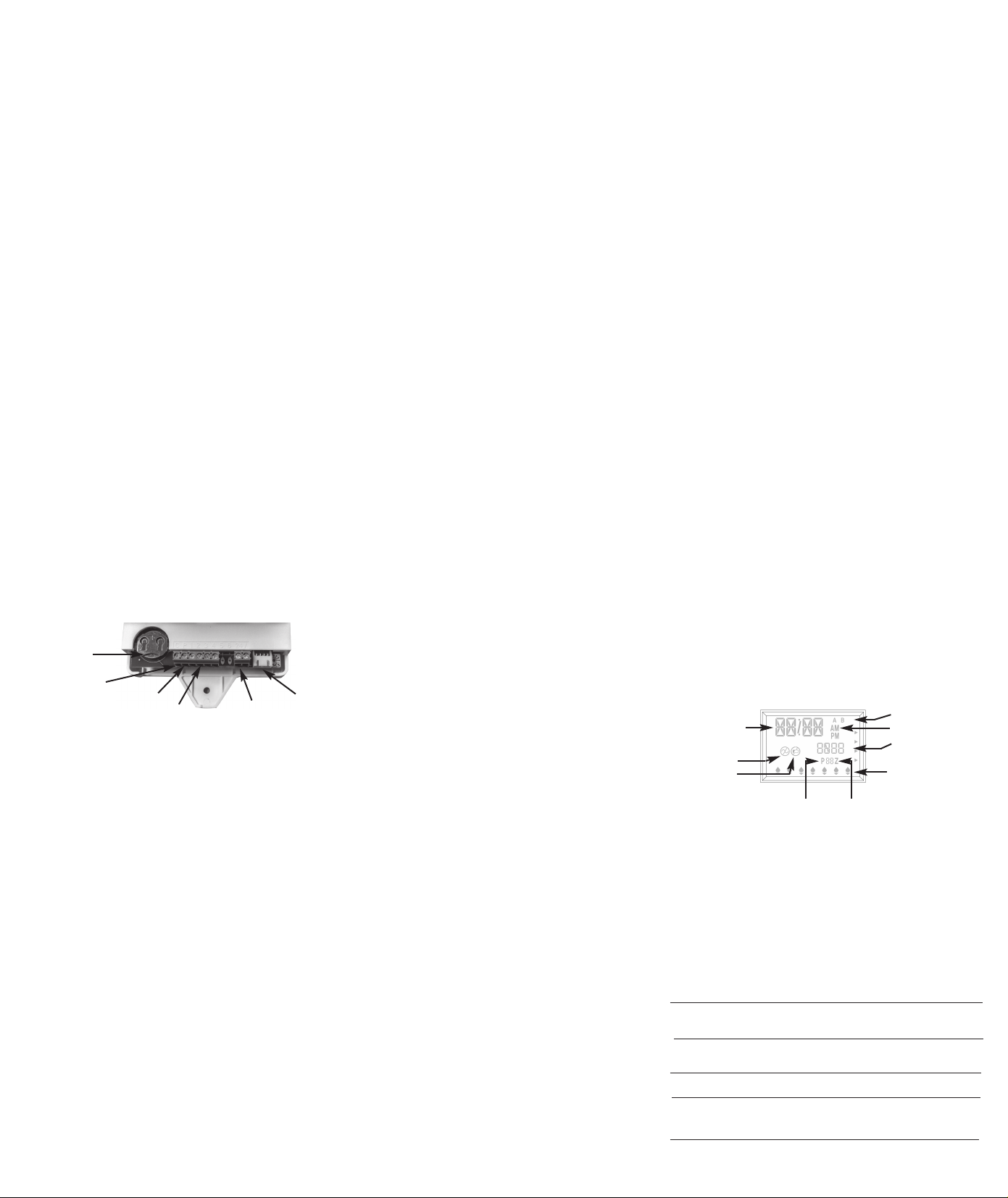

Terminal Strip: All zone & pump wire connections made inside the EZ

Indoor utilize screw type connectors that require a small screwdriver.

The terminal strips in the controller accept 14 AWG (1.6mm) wire or

maller. (See figure 1)

s

onnecting Master Valve or Pump-Start Relay

C

he EZ Indoor is equipped with a shared circuit to operate either a pumpstart

T

elay or a master valve. Connect one wire from the pump-start relay to

r

COM (common) on terminal strip, the other to P(pump/master valve)

on the terminal strip. Refer to the pump-start relay manufacturer’s

instructions for specific installation details. (See figure 1)

Connecting Rain/Moisture Sensor

The EZ Indoor is able to operate a sensor with normally-closed leads. To

install a sensor, insert one lead from the sensor to the Common terminal

& the other lead to the Field Common wires. Refer to the sensor

manufacturer’s instructions for specific installation details. (See figure 1)

Connecting the Transformer

120 VAC in United States, Canada and Mexico; 230 VAC in Europe, and

240 VAC in Australia and South Africa

NOTE: Refer to and follow local codes if different from these instructions.

CAUTION: Disconnect 120V power (230/240V for IT, FR, PT & ES models)

Connect the AC Power cable to the right side of the terminal strips and

route the cable through the slot provided in the case. Attach the wiring

skirt to the unit. Plug the AC power adaptor into the nearest receptacle.

FIGURE

1

Battery CR2032

Common

Pump / Master Valve

Station Terminals

Power

Smart Water Port

PROGRAMMING INSTRUCTIONS

Programming Overview

Before programming the EZ Indoor, it may be helpful to become familiar

with some general programming guidelines:

• If a segment(s) on the LCD is flashing, it means that it can be changed

by the using the adjust keys.

When using keys, hold the button three seconds to start a fast scroll.

•

• Be sure the appropriate program letter is displayed when you are

programming; program changes are specific to the program letter

displayed on the LCD.

• There is no “ENTER” key. Key-presses and dial settings are stored

automatically for you.

• If you make a programming change while a program is running, the

program terminates immediately. The new program starts at the next

start time scheduled.

When not running, the controller displays the current time and the current day.

•

• During manual operations, there is a 5-second delay before the

operation begins. During this time, you can change your settings.

Each time you make a change, the delay resets to 5 seconds.

• MANUAL procedures only operate with the Program dial set in the

AUTO or MANUAL positions.

• To reset, remove battery and power down the unit.

Front Panel Layout

Looking at the front panel, you see a large LCD, 4 rubber buttons and one

large rotary dial.The rubber buttons are marked SELECT and ADJUST and

are the core of Signature’s exclusive SELECT&ADJUST programming. The

keys are identified with ‘+’ or ‘–’ for increasing or decreasing the

segment you’re working on.

SELECT&ADJUST works on the principle that you first SELECT what you

want to set, and ADJUST the variables of what you selected. For example,

if you want a run time of 10 minutes on zone 5, you would use the

SELECT keys to select zone 5 and, once on zone 5, you would use the

ADJUST keys to set the run time to 10 minutes. There are instances when

only SELECT or only ADJUST are required. They will be explained in this

guide where appropriate.

the display will increase or decrease one unit. Hold the ‘+’ or ‘–’ key

NOTE: Every time the ‘+’ or ‘–’ key is pressed,

for three seconds to initiate a fast scroll. NOTE: Please refer to the

Technical Data section for an explanation of the LCD segments.

ROGRAMMING INSTRUCTIONS

P

et Time of Day, Date & Current Day of Week

S

Turn the large dial to the DATE/TIME position. Press SELECT to select between

ours, minutes, and 12/24 hour mode. Press ADJUST to scroll to the correct

h

ime or adjust between 12/24 mode. ‘A.M.’ will not appear on the LCD when in

t

.M. mode; ‘P.M.’ will appear on the LCD when in P.M. mode. Press SELECT

A

keys to select between day, month and year positions. Press ADJUST keys to

croll to the current date. The correct day of the week will automatically show

s

n LCD screen when today’s date is adjusted. The EZ Indoor controller is leap

o

ear compliant.

y

elect Zones and Set Their Run Times

S

zone run time determines the duration a zone will run. Turn the large

A

dial to the RUN TIME A or B position. Press SELECT to choose the zone

you want for the selected program (A or B). With the zone number

isplayed on the LCD, press ADJUST to adjust the RUN TIME for that

d

one. RUN TIMES can be set from 1 minute to 6 hours. Continue

z

selecting zones and adjusting their run times until you have all the zones

you want in the selected program.

fter the last zone and before the first zone, a RUN TIME summation is

A

rovided. This is useful for determining the total run time for a program.

p

The LCD displays the letters “ALL” and a total RUN TIME is displayed.

The time displayed is a summation of all the RUN TIMES for the selected

rogram. (ex. A program has a run time of 5 minutes on zone 1; 12

p

inutes on zone 2; and 6 minutes on zone 4. The display at this position

m

displays ALL and a run time of 23 minutes).

et Start Times

S

START TIME is the time of day a program will start running. The EZ

A

Indoor allows three start times per program (only 1 start time needed if

atering once a day). Turn the large dial to the START TIME A or B position.

w

ress SELECT to select the start time you want to set (1, 2, or 3). Press

P

DJUST to set the time of day the program will start. Repeat as needed.

A

To delete a start time, select the position between 11:59pm and 12:00am.

The --:-- will appear indicating there is no start time.

Start Time Stacking

The EZ Indoor will stack start times if your program watering times overlap

nother start time. The additional start time will begin when the first

a

ycle finishes.

c

et the Watering Schedule

S

WATER DAYS, or daily, lets you choose which days of the week you

•

want to water (i.e., Monday, Wednesday, Friday only).

• ODD/EVEN tells the controller to water on either the odd or even

days of the month (i.e., the controller will water on the 31st and the

1st when an ODD schedule is chosen).

• INTERVAL waters every X number of days (from 1 to 30 days) (i.e.,

water every 3 days, waters every 10 days, etc.). A value of 1 in an

interval schedule means to water every day. When using the interval

option, you have the flexibility to tell the controller what day to start

the interval program on (up to 30 days out).

The LCD will display the currently scheduled program (default is all

WATER DAYS.) The SELECT keys will scroll the LCD display through each

of the scheduling positions WATER DAYS, ODD, EVEN, INTERVAL, and

INTERVAL START DATE. A scheduling option is chosen after you press a

button, either SELECT or ADJUST. The old schedule is replaced with the

new one. It’s easy to program a schedule with the following procedures.

Set Water Days Scheduling Option

Turn the large dial to the SCHEDULE A or B position. Use the SELECT till

the raindrops appear above the days of the week. Press the ADJUST ‘+’

button to select that day for watering or press ADJUST ‘–’ for nonwatering days. A flashing indicator appears over the day you’re about to

set. Raindrops appear over selected days to water. The indicator

automatically moves one day to the right after an ADJUST ‘+’ or ‘–’ key

press. Continue selecting or deselecting the days you want the controller

to water until you have your 7-day calendar set.

NOTE: Programming a WATER DAYS schedule deletes any other

schedule for the selected program.

Set Odd/Even Day Scheduling Option

Turn the large dial to the SCHEDULE A or B position. The last scheduling

option chosen for the current program appears on the LCD. To set either

an ODD or an EVEN schedule press the SELECT button till an arrow

appears on the LCD next to the appropriate schedule (ODD or EVEN).

A DATE must be set for odd/even watering). The SELECT buttons act as

toggle keys and will toggle between odd or even.

NOTE: Programming an ODD/EVEN schedule deletes any other

schedule for the selected program.

Set Interval Scheduling Option

Turn the large dial to the SCHEDULE A or B position. The last scheduling

option chosen for the current program appears on the LCD. Press

SELECT to scroll to the interval days position. An arrow will appear on

the LCD next to INT (Interval). Use the ADJUST to choose interval days

between watering (1-30). The date displayed is day one of the interval

schedule (Today’s date if one has been set). A DATE must be set for

odd/even watering. To change day 1 date use SELECT to go to the

interval start date position. As needed, change the date for day one of the

interval schedule with ADJUST (can only be set up to 30 days out).

NOTE: Programming an INTERVAL schedule deletes any other

schedule for the selected program.

PROGRAM REVIEW

To review the current program, turn the large dial to the setting you wish

to review (i.e., turn the large dial to TIME to review the time set for the

controller). When you need to view different zones or run times (1, 2, 3),

use the SELECT buttons only.

PROGRAMMING INSTRUCTIONS - OFF MODE

Turning the Controller Off

Turn the MODE dial to the OFF position. This suspends all watering

operations (including manual/test procedures) from operating. The clock

continues to maintain the current time and date and your program(s) is

retained until you want to run your program(s) again. To run your

program, turn the MODE dial back to the AUTO position.

dvanced Features Water Budget

A

Set % WATER BUDGET changes the duration of run times in a program

y the percentage entered 0 - 200% (i.e., a 10 minute run time at 50%

b

water budget will run 5 minutes). This feature is useful when changes

n weather occur. If it is unusually dry, you may want to extend your

i

run time for each zone in a program. With % Water Budget, you can

hange one number, and all run times in the program are adjusted.

c

Turn the large dial to the % WATER BUDGET position. A % symbol will

ppear on the LCD to let you know you are working on the % Water

a

udget amount. Press ADJUST to choose the desired percentage

B

mount. If % WATER BUDGET is set for 110% or greater, the EZ Indoor.

a

ill split the run time in half to reduce runoff. Half of the calculated run

w

time will operate for each zone in that program, followed by the second

alf of the run time for each zone.

h

NOTE: % WATER BUDGET is changeable by program. If you have

rogramming in A, and B, you must enter two water budget values if

p

you want every program to be changed.

DVANCED FEATURES - AUTO MODE

A

The EZ Indoor incorporates a manual/test procedure for checking the

unction of the controller or allowing you to bypass the current program

f

to water immediately. The following section will show you how to set up

he controller to run a zone manually.

t

OTE: All test procedures are run with the dial in the MANUAL position.

N

f necessary, you can return the dial to the AUTO position while a manual

I

est is in progress. This allows you the ability to walk away from the

t

controller after setting up a manual/test procedure and not have to come

ack to reset the controller to AUTO.

b

NOTE: Manual or automatic watering will not work if a rain sensor is

nstalled and it has suspended watering. If watering is required you will

i

need to bypass the rain sensor.

un a Zone Manually

R

Turn the large dial to the MANUAL position. The default of zone 01 and

0:10 minutes will be flashing (recall that this means you can change

0

them). Press SELECT to select the zone number that you want to run. Press

DJUST to set the run time for the selected zone. The controller will delay

A

5 seconds before starting the zone. After the zone starts you can return the

ial to the AUTO position and the controller will finish the manual test.

d

ADVANCED FEATURES - AUTO MODE

The EZ Indoor incorporates Signature’s ManualAdvance feature in the

ANUAL procedure. ManualAdvance allows you to cease the currently

M

running zone and immediately advance to any new zone you select. With

the MANUAL or CYCLE procedure running a zone, Press SELECT to

advance to a new zone. The last entered run time will be displayed.

Press ADJUST to enter a new run time for the new zone (the controller

will delay 5 seconds before starting the new zone).

NOTE: Once the zone has started running, the run time cannot be

adjusted without deselecting and reselecting the zone.

TECHNICAL DATA

1. Transformer: 24 VAC internal transformer; 20 VA, .67A for zones and

logic. The transformer can run a pump or master valve and one zone

valve, maximum.

2. Sensor Operation: Sensors must have normally closed

connections (leads)and must be wired between the timer common

terminal and the field com wire.

3. Zone Lines: The EZ Indoor will operate a maximum of two (2)

solenoids concurrently, providing one is the pump/master valve.

4. Temperature Range: Operating: -20° to +55° C (23° to 131°

Fahrenheit). Storage: -30° to +85° C (-22° to 185° Fahrenheit)

5. Display

T

ime, Date, Start Time,

R

un Time, Basic Date,

W

ater Budget Month

No AC symbol

Low battery warning

Su M T W Th F S

Problem Indicator

6. Battery: CR2032 coin cell.

7. Case Dimensions (approx.): 6" H x 4 1/2" W x 2" D

8. Reset Procedures: To reset the controller to factory defaults, remove battery

& remove power. In the event of a lock-up, follow the same procedure.

9. Default Settings (12 hour mode)

• 12:00 A.M. • Tuesday • Date is 01/01 2008

• No Run Times (zone 01, —:—)

• No Start Times (start number 01, —:—)

• Every day watering schedule

• 5 second delay between zones

10. Fuse: An electronic poly-switch is incorporated on the interconnect

PCB of,the controller. This type of circuit breaker does not require resetting

or replacement by the user.

Zone #; # of zones

Program letter A or B

AM PM indicator

Odd

Year, Interval Days, Zone number

Even

Interval

Event

Water days; Day of week

TROUBLESHOOTING/SERVICE

SYMPTOM

No output to zone,

pump, master valve

Controller not responding

to any dial/key press

No output to a single zone

No output to any

zone wire

If overwatering

POSSIBLE CAUSE

• AC disconnected

• Unit needs reset

• Wiring issues or bad solenoid

• Broken on disconnected common

• RS wired into common wire is

open or disconnected

• Too many start times

SOLUTION

• Check AC source,

• Remove battery and

power down

• Check wiring &/or solenoid

• Check common wire

• Check start times-only

1 needed

Loading...

Loading...