Signametrics Corporation SMU2055 Operator's Manual

Operator's Manual

Model SMU2055 6½ Digit USB Digital Multimeter

Signametrics Corporation

April, 2010

Compatible with Rev 1.62 Hardware

CAUTION

In no event shall Signametrics or its Representatives be held liable for any consequential damages whatsoever

(including, without limitation, damages for loss of business profits, business interruption, loss of business

information, or other loss) arising from of the use of or inability to use Signametrics products, even if Signametrics

Corporation has been advised of the possibility of such damages. Because some States do not allow the exclusion or

limitation of liability for consequential damages, the above limitations may not be applicable to you.

2008 Signametrics Corp. Printed in the USA. All rights reserved. Contents of this publication must not be

reproduced in any form without the permission of Signametrics Corporation.

Signametrics 2

TABLE OF CONTENTS

1.0 INTRODUCTION .................................................................................................................................................6

1.1 SAFETY CONSIDERATIONS.......................................................................................................................... 6

1.2 MINIMUM REQUIREMENTS .........................................................................................................................6

1.3 FEATURE SET .............................................................................................................................................6

2.0 SPECIFICATIONS ...............................................................................................................................................7

2.1 DC VOLTAGE MEASUREMENT ...................................................................................................................7

2.2 DC CURRENT MEASUREMENT....................................................................................................................8

2.3 RESISTANCE MEASUREMENTS....................................................................................................................8

2.3.1 2-wire.......................................................................................................................................8

2.3.2 4-wire.......................................................................................................................................8

2.4 AC VOLTAGE MEASUREMENTS..................................................................................................................8

2.4.1 AC Voltage True RMS Measurement.......................................................................................9

2.4.2 AC Volts Accuracy...................................................................................................................9

2.5 AC CURRENT MEASUREMENT, TRUE RMS..............................................................................................10

2.6 DIODE TEST FUNCTION ............................................................................................................................10

2.7 MEASUREMENT RATES CONTROL ............................................................................................................11

2.8 ACCURACY NOTES ...................................................................................................................................11

2.9 OTHER SPECIFICATIONS ...........................................................................................................................12

2.10 ACCESSORIES .........................................................................................................................................13

3.0 GETTING STARTED.........................................................................................................................................14

3.1 SETTING THE DMM..................................................................................................................................14

3.2 INSTALLING THE SOFTWARE.....................................................................................................................14

3.3 INSTALLING THE DMM MODULE .............................................................................................................14

3.4 CALIBRATION FILE ................................................................................................................................... 14

3.5 DMM INPUT TERMINALS .........................................................................................................................15

3.6 DMM REAR PANEL..................................................................................................................................15

3.7 STARTING THE CONTROL PANEL ..............................................................................................................16

3.8 USING THE CONTROL PANEL .................................................................................................................... 16

4.0 DMM OPERATION AND MEASUREMENT TUTORIAL........................................................................... 18

4.1 VOLTAGE MEASUREMENT........................................................................................................................ 18

4.1.1 DC Voltage Measurements ....................................................................................................18

4.1.2 True RMS AC Voltage Measurements ...................................................................................18

4.2 CURRENT MEASUREMENTS ......................................................................................................................18

4.2.1 Improving DC Current Measurements ..................................................................................19

4.3 RESISTANCE MEASUREMENTS..................................................................................................................19

4.3.1 2-Wire Ohm Measurements ...................................................................................................19

4.3.2 4-Wire Ohm Measurements ...................................................................................................19

4.3.3 Effects of Thermo-Voltaic Offset............................................................................................20

4.4 DIODE CHARACTERIZATION .....................................................................................................................20

5.0 WINDOWS INTERFACE..................................................................................................................................21

5.1 DISTRIBUTION FILES ................................................................................................................................21

5.2 USING THE SMU2060 DRIVER SET WITH C++ OR SIMILAR SOFTWARE...................................................22

5.3 VISUAL BASIC FRONT PANEL APPLICATION.............................................................................................23

5.3.1 Visual Basic Simple Application............................................................................................23

5.4 WINDOWS DLL DEFAULT MODES AND PARAMETERS.............................................................................. 24

5.5 USING THE DLL WITH LABWINDOWS/CVI........................................................................................... 24

5.6 WINDOWS COMMAND LANGUAGE ...........................................................................................................24

DMMCalibrate................................................................................................................................25

DMMCleanRelay ............................................................................................................................25

DMMClearMinMax ........................................................................................................................26

3 Signametrics

DMMCloseUSB...............................................................................................................................26

DMMDelay .....................................................................................................................................27

DMMErrString................................................................................................................................27

DMMGetBusInfo.............................................................................................................................28

DMMGetCalDate............................................................................................................................29

DMMGetdB.....................................................................................................................................29

DMMGetdBStr................................................................................................................................30

DMMGetDevLocation.....................................................................................................................30

DMMGetDeviation ......................................................................................................................... 30

DMMGetDeviatStr..........................................................................................................................31

DMMGetDiffMnMxStr....................................................................................................................31

DMMGetFunction...........................................................................................................................32

DMMGetGrdVer.............................................................................................................................32

DMMGetHwVer..............................................................................................................................33

DMMGetHwOption.........................................................................................................................33

DMMGetID.....................................................................................................................................34

DMMGetManDate..........................................................................................................................35

DMMGetMax..................................................................................................................................35

DMMGetMaxStr .............................................................................................................................36

DMMGetMin...................................................................................................................................36

DMMGetMinStr..............................................................................................................................37

DMMGetNumDevices.....................................................................................................................37

DMMGetRange...............................................................................................................................38

DMMGetRate..................................................................................................................................38

DMMGetSupplyV............................................................................................................................39

DMMGetStoredReading .................................................................................................................39

DMMGetType .................................................................................................................................40

DMMGetVer ...................................................................................................................................40

DMMInit .........................................................................................................................................41

DMMIsAutoRange ..........................................................................................................................41

DMMIsInitialized............................................................................................................................42

DMMIsRelative...............................................................................................................................42

DMMOpenUSB...............................................................................................................................43

DMMRead.......................................................................................................................................43

DMMReadNorm..............................................................................................................................44

DMMReadNsamples.......................................................................................................................45

DMMReadStr..................................................................................................................... .............45

DMMSetAutoRange ........................................................................................................................46

DMMSetFunction............................................................................................................................46

DMMSetRange................................................................................................................................47

DMMSetRate...................................................................................................................................48

DMMSetRelative.............................................................................................................................49

DMMTerminate...............................................................................................................................49

5.7 CALIBRATION SERVICE COMMANDS.........................................................................................................49

AC_zero ..........................................................................................................................................50

DMMLoadCalFile...........................................................................................................................50

SetGain............................................................................................................................................51

GetGain...........................................................................................................................................51

GetOffset.........................................................................................................................................52

SetFcomp ........................................................................................................................................53

SetOffset..........................................................................................................................................53

Linearize_AD..................................................................................................................................54

Read_ADcounts ..............................................................................................................................54

5.8 MAINTANANCE COMMANDS.....................................................................................................................55

GrdXingTest ....................................................................................................................................55

WrCalFileToStore...........................................................................................................................55

WrCalStoreToFile...........................................................................................................................56

5.9 ERROR CODES ..........................................................................................................................................57

5.10 WARNING CODES ...................................................................................................................................57

5.11 PARAMETER LIST ...................................................................................................................................58

Signametrics 4

5.11.1 Measurement and Source Functions....................................................................................58

5.11.2 Range Values .......................................................................................................................58

5.11.3 Measurement Rate parameters ............................................................................................59

6 CALIBRATION .....................................................................................................................................................60

7.0 WARRANTY AND SERVICE...........................................................................................................................62

8.0 ACCESSORIES...................................................................................................................................................62

5 Signametrics

1.0 Introduction

Congratulations! You have purchased a USB Digital Multimeter. The SMU2055 Digital Multimeter (DMM) has

sophisticated analog and digital circuitry to provide repeatable measurements, and its protected to handle any

unexpected situations your measurement environment may encounter. Your new DMM is easy to setup and use. To

get years of reliable service from your DMM, please take a few moments to review this manual before installing and

using this precision instrument.

This manual describes the SMU2055 USB module.

1.1 Safety Considerations

Safety Considerations

The SMU2055 DMM is capable of measuring up to 240 VDC or 240 VAC across the Volt HI and LO

terminals, and can also measure common mode signals that "float" the DMM above EARTH ground by up

to 300 VDC or 250 VAC. When making common mode measurements, the majority of the circuits inside

the DMM are set to the common mode voltage. These voltages can be lethal and may KILL!

The DMM comes installed in a plastic chassis with 4 components (bottom, top, front and back) that must

not be removed due to performance as well as safety reasons. Removal of these shields and/or

improper assembly of the shields can expose lethal voltages. The plastic screws are required for safety

reasons.

Warning

Check to see that all measurement wires are separated from the USB communication cable. If

measurement wires come into contact with the USB cable, this may apply measurement voltages to

your computer, causing personal injury and/or damage to your computer!

When making any measurements above 50 VDC or 40 VAC, use only approved Safety Test Leads

such as Signametrics Basic Test Leads or Deluxe Test Leads, offered as optional accessories with the

Signametrics DMM’s.

1.2 Minimum Requirements

The SMU2055 DMMs are precision modules that are compatible with any USB 2.0 or higher computer port. A

mouse must be installed when controlling the DMM from the Windows Control Panel. The SMU2055 comes with

a Windows' DLL, for operation with Windows Version 95/98/Me/2000/XP, Vista and LINUX.

1.3 Feature Set

The SMU2055 is a traditional 6-1/2 digit DMM and can be used as a general purpose DMM. Signametrics also

offers the high precision 7-1/2 digit USB DMM, the SMU2060, which adds capacitance measurements, triggered

operation and a high resolution frequency counter. If your requirements call for a High Workload, then the Multi

Function SMU2064 will probably fit the ticket with its timing measurements, inductance, sourcing and higher

speed. The SMU2064 specialized measurements can replace costly instruments and thus shrinking the size and cost

of a test system.

Signametrics 6

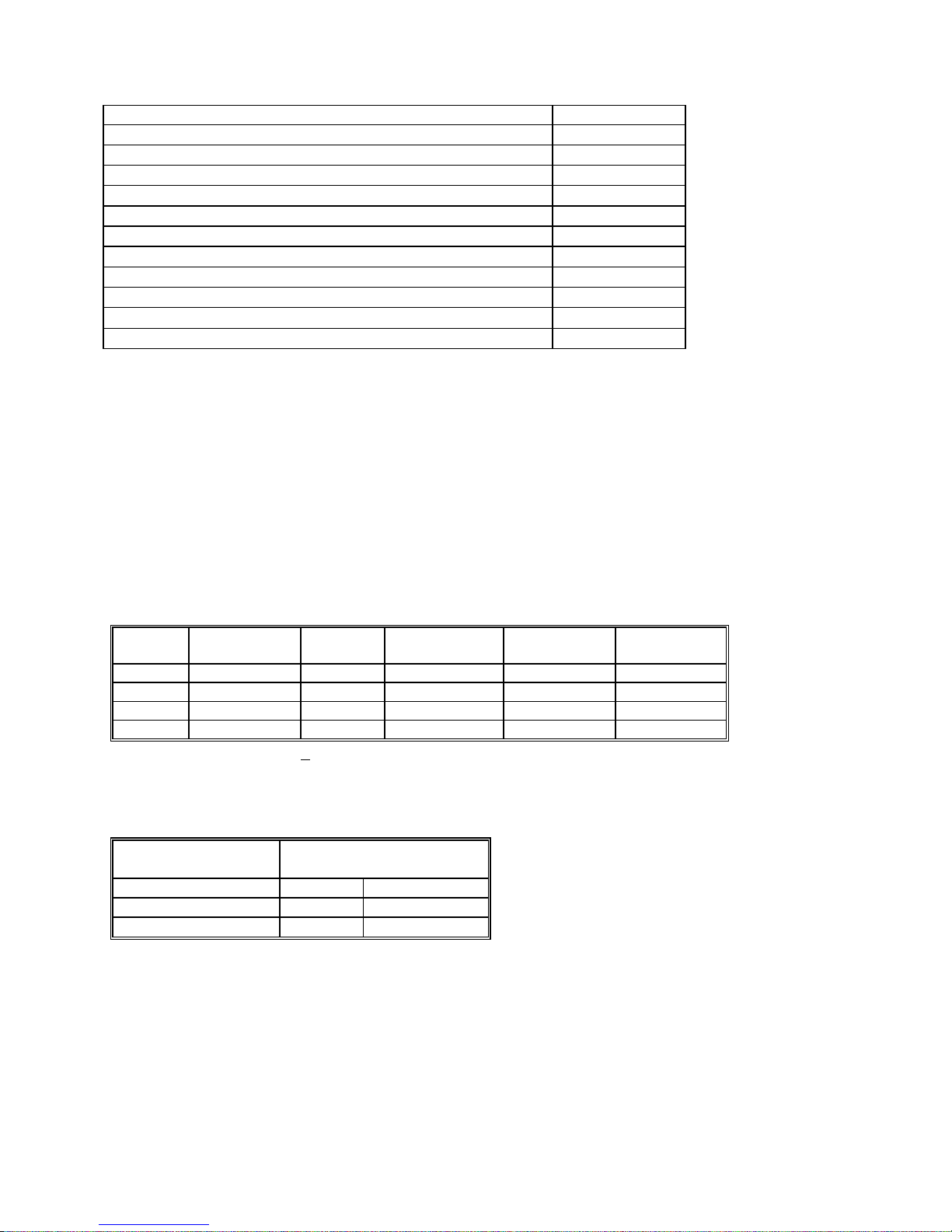

SMU2055 basic features:

Function SMU2055 DMM

Volts DC; four ranges, 240mV to 240V

Volts AC; TRMS; four ranges, 240mV to 240V

2-Wire Ohms, six ranges 240 to 24 M

4-Wire Ohms, six ranges 240 to 24 M

DC current, four ranges 2.4 mA to 2.4 A

AC current, four ranges 2.4 mA to 2.4 A

Diode V/I Five ranges, 100 A to 1mA

Auto range, Relative

Min/Max, dB and percent deviation functions

High Dynamic range; ±2,400,000 counts

Measurement rate selectable: 0.5 to250 readings/s

2.0 Specifications

The following specifications are based on both, verification of large number of units as well as

mathematical evaluation. The specifications should be considered for the specified environment.

It is important to note that a specified range for a DMM is expressed as a numeric value indicating the

highest absolute measurement that can be displayed using that range. The lowest value that can be

detected is expressed by the corresponding resolution for the range.

2.1 DC Voltage Measurement

Input Characteristics

Input Resistance 240 mV, 2.4 V Ranges: >10 G, with typical leakage of 50pA

Input Resistance 24 V, 240 V Ranges: 10.00 M

Accuracy ± (% of reading + Volts) [1]

Range Full Scale

6-½ Digits

240 mV 240.0000 mV

2.4 V 2.400000 V

24 V 24.00000 V

240 V 240.0000 V

[1] With reading rate set to < 2/sec, and within one hour from Self Calibration (S-Cal).

For resolution at higher measurement rates, see the following table. Use this table for DC Volts, DC

Current and Resistance measurements.

Maximum reading rate

1 / second 6-1/2 22 bits

27/second 6 20 bits

250 / second 5-1/2 18 bits

DCV Noise Rejection Normal Mode Rejection, at 50, 60, or 400 Hz ± 0.5%, is better than 95 dB

for Rates of 6rps and lower. Common Mode Rejection (with 1 k lead imbalance) is better than 120

dB for these conditions.

Resolution 24 hours

23C 1C

100 V 0.003 + 2 V 0.005 + 3 V 0.007 + 3.5 V

1 V 0.003 + 3 V 0.004 + 4 V 0.005 + 10 V

10 V 0.004 + 200 V 0.005 + 250 V 0.007 + 300 V

100 V

0.004 + 600 V 0.005 + 800 V

Digits of Resolution

90 Days

23C 5C

One Year 23C

5C

0.007 + 1 mV

7 Signametrics

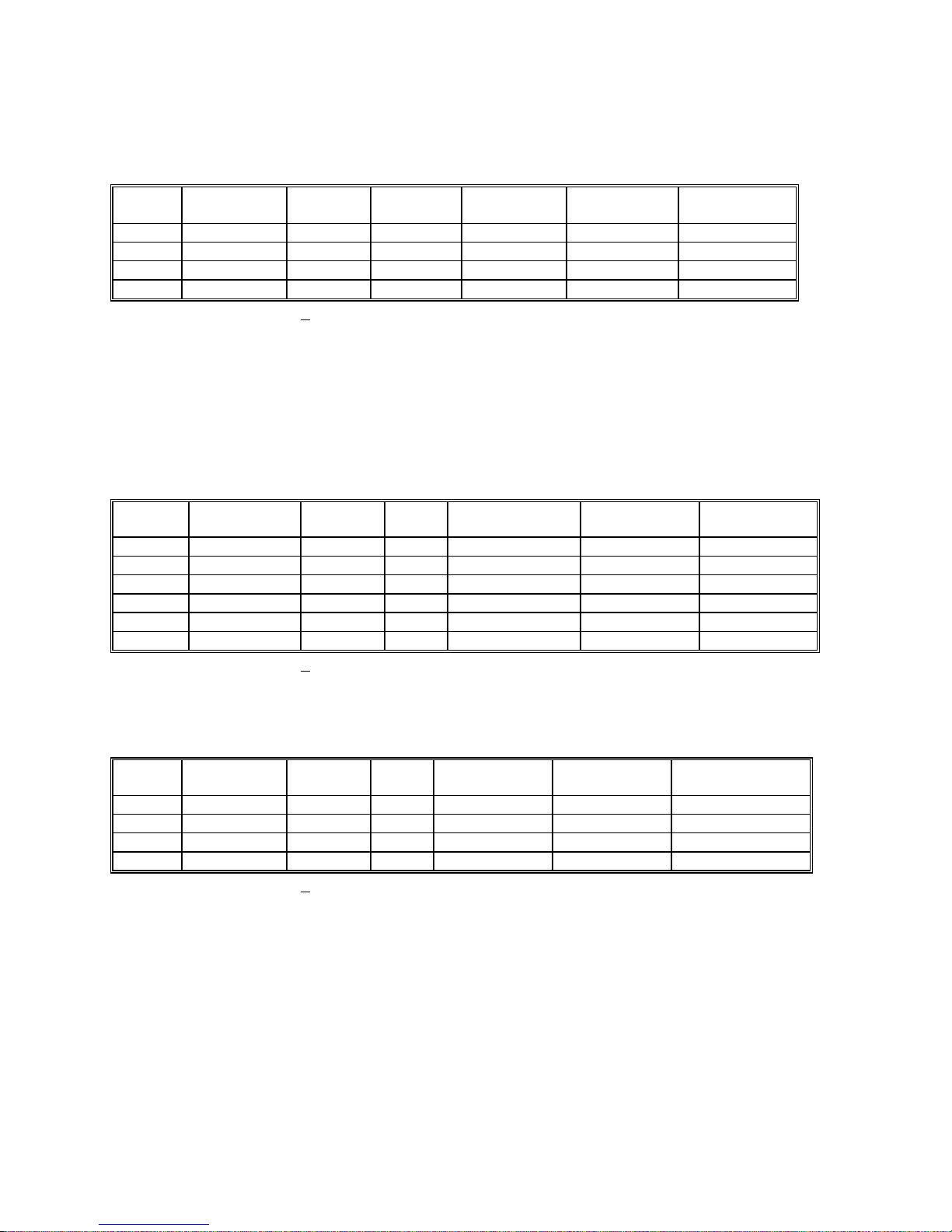

2.2 DC Current Measurement

Input Characteristics

Number of built-in shunts Two

Currents greater than 2.4A require external shunt

Protected with 2.5A Fast blow fuse

Accuracy ± (% of reading + Amps) [1]

Range Full Scale

Reading

2.4 mA 2.40000 mA

24 mA 24.0000 mA

240 mA 240.000 mA

2.4 A 2.40000 A

Resolution Max Burden

Voltage

10 A

100 A

1 A

10 A

25mV

250mV

55mV

520mV

24 hours

23C 5C

0.05 + 300 A 0.06 + 700 A 0.07 + 1 A

0.05 + 350 A 0.065 + 800 A 0.08 + 1 A

0.05 + 50 A 0.055 + 60 A 0.065 + 80 A

0.3 + 60 A 0.4 + 70 A 0.45 + 90 A

90 Days

23C 5C

One Year 23C

5C

[1] With reading rate set to < 2/sec, and within one hour from Zero (Relative control).

2.3 Resistance Measurements

Characteristics

Number of current sources Five

Maximum Test Voltage 2.4V

2.3.1 2-wire

Accuracy ± (% of reading + ) [1]

Range Full Scale

6 ½ Digits

240 240.0000 100

2.4 k 2.400000 k 1 m

24 k 24.00000 k 10 m 100 A 0.003 + 300 m 0.004 + 330 m 0.007 + 350 m

240 k 240.0000 k 100 m 10 A 0.008 + 3.2 0.012 + 4 0.02 + 5

2.4 M 2.400000 M 1 1 A 0.02 + 40 0.03 + 50 0.04 + 70

24 M 24.0000 M 100

Resolution Source

current

1 mA

1 mA

100 nA

24 hours

23C 1C

0.004 + 4.5 m [2] 0.005 + 5 m [2] 0.008 + 6 m [2]

0.0025 + 28 m 0.004 + 32 m 0.007 + 33 m

0.2 + 400 0. 3 + 500 0.4 + 600

90 Days

23C 5C

One Year

23C 5C

[1] With reading rate set to < 2/sec, and within one hour from Self Calibration (S-Cal).

[2] Use of S-Cal and Relative to improve measurement floor.

2.3.2 4-wire

Accuracy ± (% of reading + ) [1]

Range

[3]

240 240.0000 100

2.4 k 2.400000 k 1 m

24 k 24.00000 k 10 m 100 A 0.003 + 300 m 0.004 + 330 m 0.007 + 350 m

240 k 240.0000 k 100 m 10 A 0.008 + 3.2 0.012 + 4 0.02 + 5

[1] With reading rate set to < 2/sec, and within one hour from Self Calibration (S-Cal).

[2] Use of Relative to facilitate indicated floor.

[3] The 2.4MΩ and 24MΩ ranges are functional but not specified for 4-Wire operations.

Full Scale

6 ½ Digits

Resolution Source

current

1 mA

1 mA

24 hours

23C 1C

0.004 + 3 m [2] 0.005 + 4 m [2] 0.008 + 5 m [2]

0.0025 + 28 m 0.004+ 32 m 0.007 + 33 m

90 Days

23C 5C

One Year

23C 5C

2.4 AC Voltage Measurements

Input Characteristics

Input Resistance 1 M, shunted by < 300 pF

Max. Crest Factor 4 at Full Scale, increasing to 7 at Lowest Specified Voltage

AC coupled Specified range: 10 Hz to 200 kHz

Typical Settling time < 0.5 sec to within 0.1% of final value

Common Mode rejection: at 50Hz to 60Hz, 1 k imbalance in either lead, is better than 60 dB.

Signametrics 8

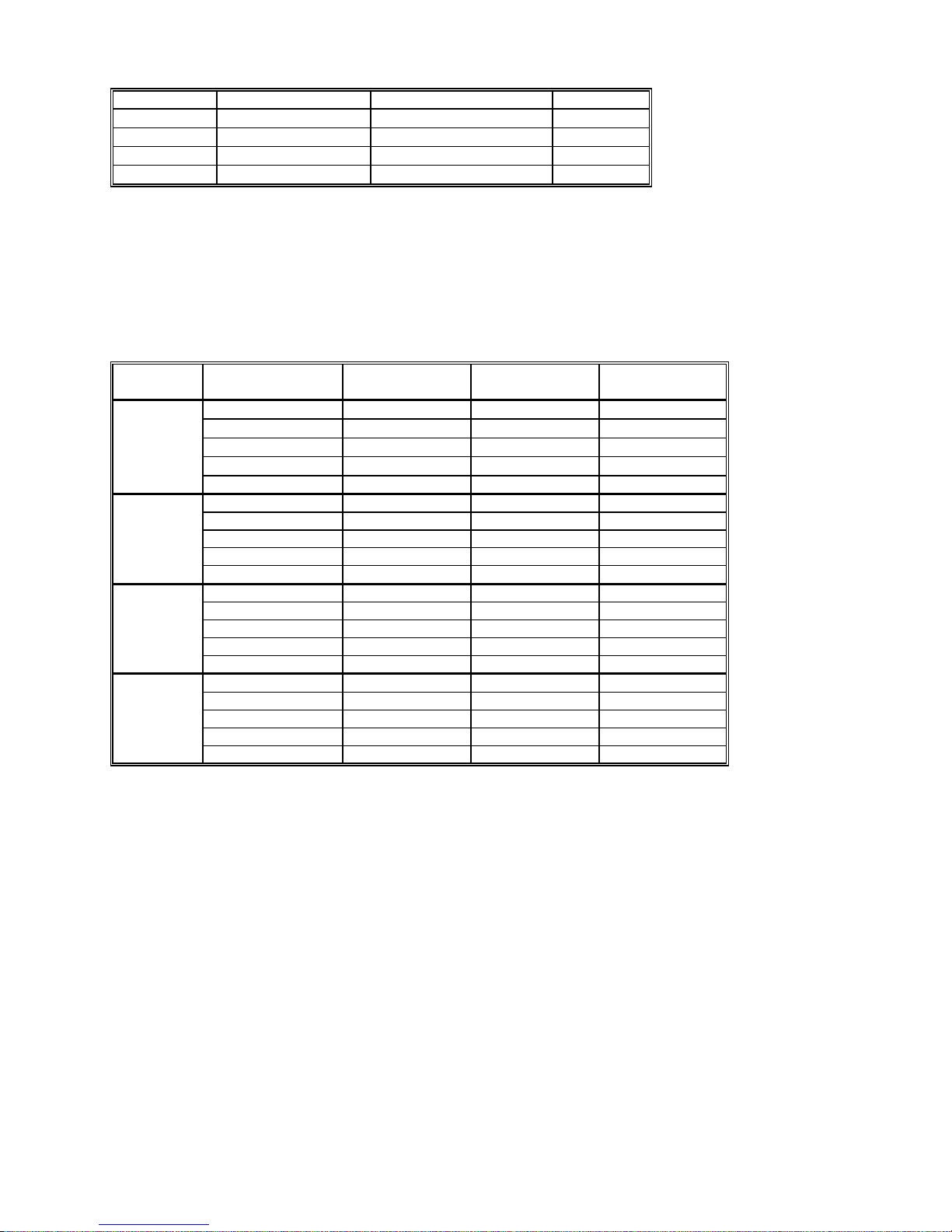

2.4.1 AC Voltage True RMS Measurement

Range [1] Full Scale 6-½ Digits Lowest specified Voltage Resolution

240 mV 240.0000 mV 5 mV

2.4 V 2.400000 V 20 mV

24 V 24.00000 V 200 mV

240 V 240.0000 V 2 V

[1] Signal is limited to 8x106 Volt Hz Product. For example, the largest frequency input at 250 V is 32

kHz, or 8x10

6

Volt x Hz.

100 V

1 V

10 V

100 V

2.4.2 AC Volts Accuracy

Settles to rated accuracy within 0.5 seconds for signals >50% of scale.

May take up to 2s to settle to rated accuracy for signals < 5% of scale.

Accuracy ± (% of reading + Volts) [1]

Range Frequency 24 hours

23C 1C

240 mV

2.4 V

24 V

240 V

10 Hz - 20 Hz

20 Hz - 47 Hz

47 Hz – 10 kHz

10 kHz – 50 kHz

50 kHz - 100 kHz 2 + 0.6 mV 2.1 + 0.8 mV 2.2+ 1 mV

10 Hz - 20 Hz 3 + 2 mV 3.3 + 2.2 mV 3.5 + 2.5 mV

20 Hz - 47 Hz 0.45 + 1.3 mV 0.47 + 1.5 mV 0.5 + 1.7 mV

47 Hz – 10 kHz 0.07 + 1 mV 0.075 + 1.1 mV 0.08 + 1.2 mV

10 kHz – 50 kHz 0.35 + 2 mV 0.37 + 2.3 mV 0.4 + 2.5 mV

50 kHz - 100 kHz 2+ 2.5 mV 2.1 + 2.8 mV 2.2 + 5 mV

10 Hz - 20 Hz 4 + 25 mV 4.3 + 16 mV 4.5 + 35 mV

20 Hz - 47 Hz 0.50 + 20 mV 0.55 + 25 mV 0.65 + 30 mV

47 Hz – 10 kHz 0.07 + 15 mV 0.075 + 20 mV 0.085 + 23 mV

10 kHz – 50 kHz 0.2 + 25 mV 0.25 + 30 mV 0.3 + 35 mV

50 kHz - 100 kHz 1.5 + 35 mV 1.6 + 28 mV 1.7 + 50 mV

10 Hz - 20 Hz 3 + 250 mV 3.1 + 350 mV 3.3 + 400 mV

20 Hz - 47 Hz 0.45 + 230 mV 0.+ 300 mV 0.+ 350 mV

47 Hz – 10 kHz 0.07 + 180 mV 0.075 + 220 mV 0.08 + 250 mV

10 kHz – 50 kHz 0.28 + 250 mV 0.29 + 300 mV 0.55 + 350 mV

50 kHz - 100 kHz 1.5 + 350 mV 1.6 + 400 mV 1.8 + 500 mV

3 + 300 V 3.4 + 500 V

0.45 + 150 V 0.47 + 170 V

0.13 + 100 V 0.14 + 110 V

0.3 + 180 V 0.35 + 220 V

[1] With reading rate set to ≤ 2/sec

ACV Noise Rejection Common Mode rejection, for 50 Hz or 60 Hz with 1 k imbalance in either lead, is better

than 60 dB.

Specs in red indicate change from last manual release.

90 Days

23C 5C

One Year

23C 5C

3.6 + 0.6 mV

0.5 + 0.35 mV

0.16 + 0.25 mV

0.4 + 0.35 mV

9 Signametrics

2.5 AC Current Measurement, True RMS

Input Characteristics

Crest Factor 4 at Full Scale

Number of built-in shunts Two

Currents greater than 2.4A require external shunt

Protected with 2.5A Fast blow fuse

2.5.1 AC Current True RMS Measurement

Range Full Scale 6 1/2 Digits Lowest Specified

Current

2.4 mA 2.400000 mA

24 mA 24.00000 mA

240 mA 240.0000 mA 3 mA 55mV 100 nA

2.4 A 2.400000 A 30 mA 520mV 1 uA

60 A

300 A

Accuracy ± (% of reading + Amps)

Range Frequency [1] 24 hours

23C 1C

2.4 mA

24 mA

240 mA

2.4 A

10 Hz - 20 Hz

20 Hz - 47 Hz

47 Hz - 1 kHz

1 kHz - 10 kHz

10 Hz - 20 Hz

20 Hz - 47 Hz

47 Hz - 1 kHz

1 kHz - 10 kHz

10 Hz - 20 Hz

20 Hz - 47 Hz

47 Hz - 1 kHz

1 kHz - 10 kHz

10 Hz - 20 Hz 1.8 + 4 mA 2.5 + 4.5 mA 2.7 + 5 mA

20 Hz - 47 Hz 0.66 + 4 mA 0.8 + 6 mA 0.9 + 6 mA

47 Hz - 1 kHz 0.3 + 3.8mA 0.33 + 3.8 mA 0.35 + 4 mA

1 kHz - 10 kHz 0.4 + 4mA 0.45 + 4.5 mA 0.5 + 5 mA

3.8 + 4 A 2.7 + 4 A 2.9 + 4 A

0.9 + 4 A 0.9 + 4 A 1.0 + 4 A

0.04 + 1.5 A 0.08 + 3 A 0.12 + 4 A

0.12 + 4 A 0.14 + 4 A 0.22 + 4 A

1.8 + 30 A 2.6 + 30 A 2.8 + 30 A

0.6 + 30 A 0.9 + 30 A 1.0 + 30 A

0.07 + 10 A 0.15 + 20 A 0.16 + 30 A

0.21 + 30 A 0.3 + 40 A 0.4 + 40 A

1.8 + 400 A 2.7 + 400 A 2.8 + 400 A

0.6 + 400 A 0.9 + 400 A 1.0 + 400 A

0.1 + 100 A 0.17 + 180 A 0.2 + 220 A

0.3 + 300 A 0.35 + 350 A 0.4 + 400 A

Maximum Burden

Voltage (RMS)

25mV 1 nA

250mV 10 nA

90 Days

23C 10C

One Year

23C 10C

Resolution

2.6 Diode Test Function

Test Currents Five

Current sources voltage compliance 4 V

Accuracy ± (% of reading + Volts) [1]

Range Full Scale

5-½ Digits

0.1 A 0.022 + 15 V

1 A 0.018 + 12 V

10 A 0.015 + 10 V

100 A 0.014 + 8 V

1 mA

2.40000 V

[1] With measurement rate set to 2rps or lower rate

Signametrics 10

Resolution

One Year 23C 10C

10 V

0.014 + 8 V

2.7 Measurement Rates Control

Use DMMSetRate() using the following codes.

Symbol Code

(Readings/sec)

0.5 RATE_p5 0

1 RATE_1 1

2 RATE_2 2

3 RATE_3 3

7 RATE_7 7

14 RATE_14 14

27 RATE_27 27

50 RATE_50 50

90 RATE_90 90

170 RATE_170 170

250 RATE_250 250

Power line Rejection Rate

50Hz 60Hz 400Hz

2.8 Accuracy Notes

Important: all accuracy specifications for DCV, Resistance, DCI, ACV, and ACI apply for the time periods shown

in the respective specification tables. To meet these specifications, Self Calibration must be performed once a day or

as indicated in the specification table. This is a simple software operation that takes a few seconds. It can be

performed by calling Windows command DMMCal(), or selecting S-Cal in the Control Panel.

These products are capable of continuous measurement as well as data transfer rates of up to 250 readings per

second (rps). In general, to achieve 6-1/2 Digits of resolution, the rate should be set to 2rps or lower.

Since the DMM is powered via a USB calbe (AM/BM 6’ cable), it is important to make sure it gets the

required 5V supply. Using the right USB cable is very important. Make sure this cable has a 24 AWG

wires for power supply, indicated by marking on the cable such as 28/1P + 24/2C. Be aware that there are

a lot of cables which are marked 28/1P + 28/2C. These have high resistance, and will not be adequate.

Another issue can be with powered USB hubs. Some of the lower quality units can have upwords of 8V

rather than the required 5V +/-5%. On initialization (DMMInint) the DMM measures its internal supply

voltage and returnes an error or warning code if the power is inadequate. See DMMGetSupplyV function.

11 Signametrics

2.9 Other Specifications

Temperature Coefficient Less than 0.1 x accuracy specification below 18C and over

Hardware Interface Single USB/cPCI 3U slot

Overload Protection (voltage inputs) 250 VDC, 250 VAC

Isolation 300 VDC, 250 VAC from Earth Ground

Maximum Input (Volt x Hertz) 8x106 Volt x Hz normal mode input (across Voltage HI &

1x106 Volt x Hz Common Mode input (from Voltage HI or

Safety Designed to IEC 1010-1, Installation Category II.

Calibration Calibrations are performed by Signametrics in a computer at

Temperature Range Operating -10C to 65C

Temperature Range Storage -40C to 85C

Size Single 3U USB or CompactPCI slot

Power +5 volts, 200 mA maximum

Note: Signametrics reserves the right to make changes in materials, specifications, product functionality, or

accessories without notice.

28C

LO).

LO relative to Earth Ground).

23C internal temperature rise. All calibration constants are

stored in an onboard memory and in a text file.

Signametrics 12

2.10 Accessories

Several accessories are available for the SM2060 series DMMs, which can be purchased directly from Signametrics

Corp, or from one of its approved distributors or representatives. Some of the accessories available:

DMM Probes SM-PRB ($15.70)

6 ft. USB 2.0 AM/BM cable SMU-CBL6ft

3 ft. USB 2.0 AM/BM cable SMU-CBL3ft

10 ft. USB 2.0 AM/BM cable SMU-CBL10ft

DMM Probe kit SM-PRK ($38.50)

Deluxe Probe kit SM-PRD ($95.00).

Shielded SMT Tweezers Probes SM-PRSMT ($24.90).

Multi Stacking Double Banana shielded cable 36” SM-CBL36 ($39.00).

Multi Stacking Double Banana shielded cable 48” SM-CBL48 ($43.00).

Lab View VI’s library SM204x.llb (free).

Linux Driver kit (free).

Extended 3 Year warrantee (calibration not included) $120.00 for SM2055.

13 Signametrics

3.0 Getting Started

After unpacking the DMM, please inspect for any shipping damage that may have occurred, and report

any claims to your transportation carrier.

The package includes the Digital Multimeter; Installation CD, a Floppy Disk containing the calibration

and verification records, 6’ USB cable and Certificate of Calibration.

3.1 Setting the DMM

The DMM is provided with plug-and-play installation software, and does not require any switch settings,

or other adjustments prior to installation.

3.2 Installing the Software.

Before connecting the DMM Hardware, it is necessary to install the DMM software. Insert the

Signametrics Product Installation CD into your CD drive. A menu will appear automatically on most

computers. Otherwise, double-click on the autorun.exe file in the root directory of the Installation CD.

A menu will appear, allowing you to choose which Signametrics product to install. Select the product

you would like to install, "SMU2055/2060/2064 USB DMMs". A Software Setup Wizard will begin.

Follow the installation process, selecting which components you would like installed, and where they

should be installed. The Hardware Driver and the Front Panel are required components to run and test the

product. On the last page of the wizard, click Install.

After the software has been installed, The Signametrics USB Driver Wizard will appear. Click "next". A

windows message may appear asking if you are sure you wish to install this driver. Continue the

installation. Afterwards, you should now see a screen that indicates the drivers have been sucsessfully

installed on this computer.

3.3 Installing the DMM Module

Warning

To avoid shock hazard, install the DMM only into a personal computer that has its power line connector

connected to an AC receptacle with an Earth Safety ground.

Use extreme care when plugging the DMM module(s) into a USB port on your computer. Make sure no

cable is connected to the front panel of the DMM while you plug it into the USB port.

Connect the SMU2055/2060/2064 to one of the USB ports on your computer. On Windows 2000, XP, or

Vista a "Found New Hardware" Wizard dialog box should appear. On Windows 7, the drivers may

automatically be detected and installed without a Found New Hardware Wizard Appearing.

The Wizard asks "Can Windows connect to Windows Update to search for software?" Select "No, not

this time" and click on "Next". Select "Install the software automatically" and click on "Next". Windows

should be able to find the drivers automatically since they were copied to the system (section 3.2).

Windows may double check whether you want to install the software. If this is the case, click "Continue

Anyways". The Wizard should say "The wizard has finished installing software for: [multimeter product

name]". Click "Finish" to complete the installation.

3.4 Calibration File

The SM60CAL.DAT file supplied with your DMM has a unique calibration record for that DMM (See

"Calibration" at the end of this manual.). In most cases, the installation of the calibration file is handled

automatically by the DMM software.

Signametrics 14

A copy

of the calibration file resides on an EEProm on the DMM and is copied to your computer the first

time you use the instrument. A backup copy of the calibration file is included on a diskette that comes

with the DMM.

The default location of the Calibration File is “C:\SM60CAL.DAT”. If your system uses multiple

DMMs, the software will append the Calibration Records of each DMM into a single SM60CAL.DAT

file. The SM60CAL.DAT file is a text file, and can be opened using a text editor such as Notepad, should

it be necessary.

3.5 DMM Input Terminals

Before using the DMM, please take a few moments and review this section to understand where the

voltage, current, or resistance and other inputs and outputs should be applied. This section contains

important information concerning voltage and current limits. Do not exceed these limits, as

personal injury or damage to the instrument, your computer or application may result.

Figure 3-1. The DMM input connectors consist of four Banana jacks.

V, 2 + This is the positive terminal for all Volts, 2-Wire Resistance and diode test. When in 4-Wire

resistance measurement mode, it serves as the positive terminal of the current source. The maximum

input across V, 2 + and V, 2 - is 240 VDC or 240 VAC.

V, 2 - This is the negative terminal for all Volts, 2-Wire Resistance and diode test. When in 4-Wire

resistance measurement mode, it serves as the negative terminal of the current source. Do not float this

terminal or any other DMM terminal more than 240 VDC or 240 VAC above Earth Ground.

I , 4+ This is the positive terminal for all Current measurements. While in 4-Wire resistance

measurement mode it is the high sense. The maximum input across I, 4 + and I, 4 - is 2.5 A. Do not

apply more than 5 V peak across the I,4+ and I,4- terminals.

I,4 - This is the negative terminal for Current measurements. While in 4-Wire resistance measurement

mode it serves as the low sense. The maximum input across I, 4W + and I, 4W - is 2.5 A. Do not

apply more than 5 V peak across these two terminals.

The I,4 - Current function is protected by a 2.5 A, 250 V Fast Blow fuse (PCT type).

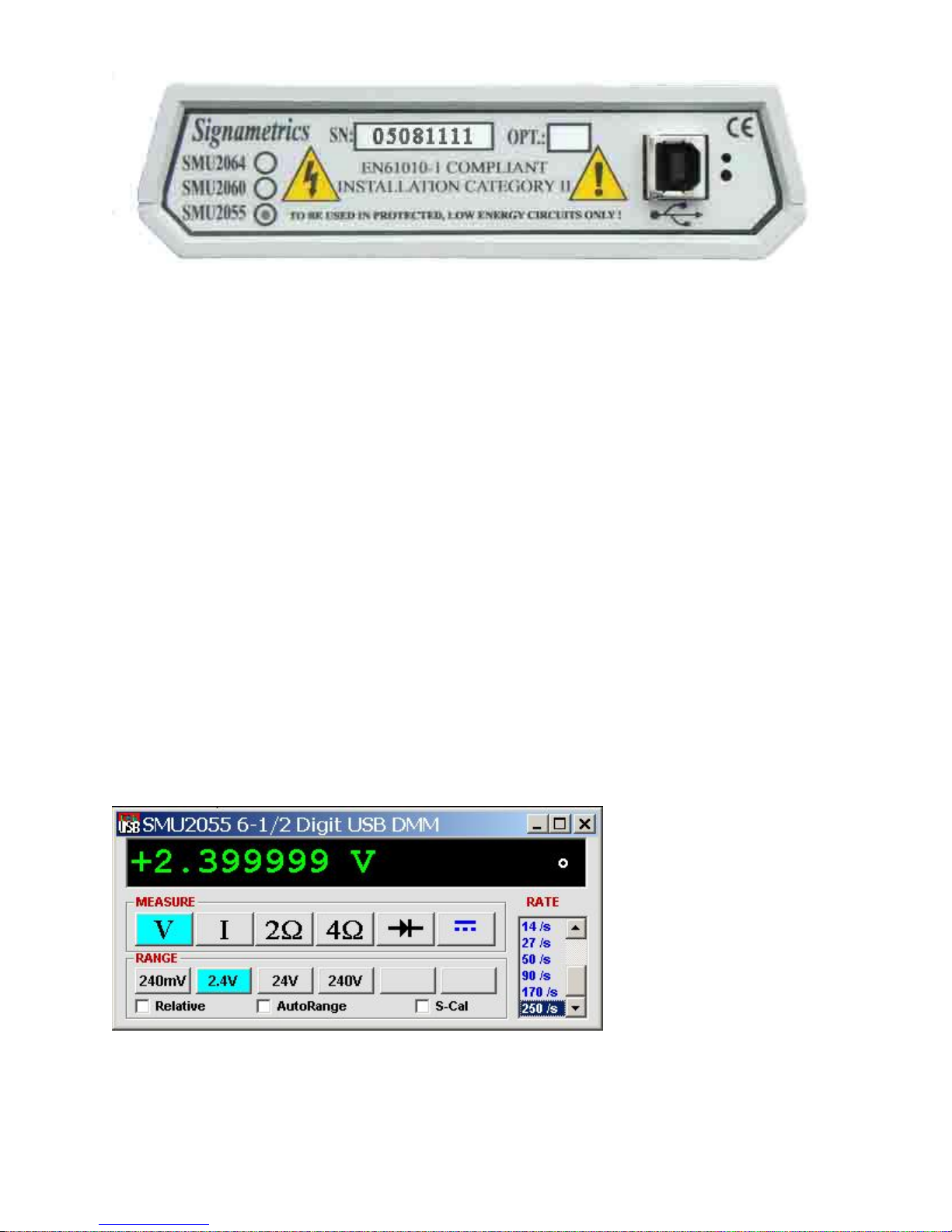

3.6 DMM Rear Panel

The rear panel includes various compliance and warning text and graphics, the unit serial number, its

modle number and the installed options. The USB connector provides for both, compueter interface and

power to run the DMM..

15 Signametrics

Figure 3-2. The Rear panel has the USB BF type connector. Compatible with BM cable.

3.7 Starting the Control Panel

You can verify the installation and gain familiarity with the DMM by exercising its measurement

functions using the Windows based Control Panel. To run the control panel, StartSMU2060 Series

MultimetersSMU2064 Multimeter. If you do not hear the relays click, it is most likely due to an

installation error. Another possible source for an error is that the SM60CAL.DAT file does not

correspond to the installed DMM.

When the DMM is started for the first time, it takes a few extra seconds to extract its calibration data from

the on-board memory, and write it to the calibration file C:\SM60CAL.DAT

The Control Panel is operated with a mouse. All functions are accessed using the left mouse button.

When the DMM is operated at very slow reading rates, you may have to hold down the left mouse button

longer than usual for the program to acknowledge the mouse click.

Note: The SMU2055 front panelstarts up in DCV, and 240 V range. If the DMM is operated in

Autorange, with an open input, it will switch between the 2.4V and 24V ranges every few seconds, as a

range change occurs. This is perfectly normal wth high end DMM’s such as the SM2055. This

phenomenon is caused by the virtually infinite input impedance of the 2.4V DC range. On these ranges,

an open input will read whatever charge is associated with the signal conditioning of the DMM. As this

electrical charge changes, the SM2055 will change ranges, causing the range switching. This is normal.

3.8 Using the Control Panel

Figure 3-2. The Control Panel. The two main groups include Measurement Function and Range buttons.

The Range buttons are context sensitive such that only “240m, 2.4, 24 and 240 appear when in a Voltage

Measurement Function is selected, and 2.4m, 24m, 240m and 2.4 appear when a Current Measurement

Function is selected, etc.

Signametrics 16

Note: All of the controls described below correspond to their respective software function, which can be

invoked within your control software or as objects in a visual programming environment. The software

command language provides a powerful set of capabilities. Some of the functions are not included in the

control panel, but are in the software.

DC/AC This function switches between DC and AC. This is applicable for the Voltage and Current

DMM functions.

Relative This is the Relative function. When activated, the last reading is stored and subtracted from all

subsequent readings. This is a very important function when making low-level DCV measurements, or in

2W. For example, when using 2W, you can null out lead resistance by shorting the leads together and

clicking on Relative. When making low level DC voltage measurements (e.g., in the V region), first

apply a copper short to the V, + & - input terminals, allow the reading to stabilize for a few seconds,

and click on Relative. This will correct for any internal offsets. The Relative button can also be used in

the Percent and dB deviation displays (shown below), which are activated using the T

ools in the top

menu.

Rate Box: Controls the DMM Measurement rate. As rate decreases, the measurement noise decreases.

Also consider the power line frequency (50/60 Hz) of operation when setting it, as certain rates have

better noise rejection at either 50 or 60 Hz. (See “Specifications” for details.). When measuring VAC

values, there is no point setting the Rate to a value greater than 2rps.

Range: Can be set to Autorange or manual by clicking on the appropriate range in the lower part of the

Windows panel. Autoranging is best used for bench top application. Autorange is not recommended

for automated test applications due to the uncertainty of the DMM range, as well as the extra time for

range changes. Locking a range is highly recommended when operating in an automated test system,

especially to speed up measurements. Another reason to lock a range is to control the input impedance in

DCV. The 240 mV and 2.4 V ranges have virtually infinite input impedance, while the 24 V and 240 V

ranges have 10 M input impedance.

S_Cal: This function is the System Calibration that corrects for internal gain, scale factor and zero

errors. The DMM does this by alternatively selecting its local DC reference and a zero input. It is

required at least once every day to meet the accuracy specifications. It is recommended that you also

perform this function whenever the external environment changes (e.g. the temperature in your work

environment changes by more than 5C. This function takes a few seconds to perform. Disconnect all

leads to the DMM before doing this operation. Keep in mind that this is not a substitute for periodic

calibration, which must be performed with external standards.

17 Signametrics

4.0 DMM Operation and Measurement Tutorial

Most of the measurement functions are accessible from the Windows Control Panel (Figure above). All of

the functions are included in the Windows DLL driver library. To gain familiarity with the DMM, run the

Windows ‘SETUP.EXE’ to install the software, then run the DMM, as described in the previous section.

This section describes in detail the DMM’s operation and measurement practices for best performance.

4.1 Voltage Measurement

Measures from 0.1 V to 240 VDC or VAC. Use the V, 2+ and V, 2- terminals, being certain to

always leave the I,4+ and I,4- terminals disconnected. Use the AC/DC button on the Control Panel

to switch between AC and DC.

Making Voltage Measurements is straightforward. The following tips will allow you to make the most

accurate voltage measurements.

4.1.1 DC Voltage Measurements

When making very low-level DCV measurements (<1 mV), you should first place a copper wire shorting

plug across the V, 2 + and V, 2 - terminals and perform Relative operation to eliminate zero errors.

A common source of error can come from your test leads, which can introduce several Volts of error due

to thermal voltages. To minimize thermal voltaic effects, after handling the test leads; you should wait a

few seconds before making measurements. Signametrics offers several high quality probes that are

optimal for low-level measurements.

Note: The front panel powers up in 2rps, DCV, 240 V range. If the DMM is operated in Autorange, with

an open input, The DMM will keep changing ranges. This is perfectly normal with ultra high impedance

DMM’. The virtually infinite input impedance of the 240 mV and 2.4 V DCV ranges causes this

phenomenon. On these ranges, an open input will read whatever charge is associated with the signal

conditioning of the DMM. As this electrical charge accumulates, the DMM will change ranges.

4.1.2 True RMS AC Voltage Measurements

ACV is specified for signals greater than 1mV, from 10 Hz to 50 kHz. The ACV function is AC coupled,

and measures the true RMS value of the waveform. As with virtually all true-RMS measuring

meters, the DMM may not read a perfect zero with a shorted input. This is normal.

ACV measurements, if possible, should have the NEUTRAL or GROUND attached to the V,2 -

terminal. This prevents any “Common Mode” problems from occurring (Common Mode refers to

floating the DMM V,2- above Earth Ground.) Common Mode problems can result in noisy readings,

or even cause the PC to hang-up under high V X Hz input conditions. In many systems, grounding the

source to be measured at Earth Ground (being certain to avoid any ground loops) can give better results.

The settling time and low frequency limits of the RMS functions (AC Voltage and current) are effected

by both, the value of the input as a percentage of range, and the frequency of the signal.

Take into account the amount of time it takes for the RMS circuit to settle. With a setteling time of 0.5s,

you may use a measurement rate of 2 readings/s and take two readings. The first will provide the 0.5s to

settele, and the second will make a stable reading. Do not average since the first reading will introduce an

error.

For improved accuracy and stability while measuring low frequency signals, the measurement time

(1/rate) should be at least ten (10) times the period of the measured signal.

4.2 Current Measurements

The DMM measures AC and DC currents between 100 A and 2.5 A. Use the +I, 4W terminals, being

certain to always leave all other terminals disconnected. Use the AC/DC button to switch between AC

and DC. The AC current is an AC coupled True RMS measurement function. See figure 4-2 for

connection.

Signametrics 18

The Current functions are protected with a 2.5 A, 250 V fuse internal to the DMM. The 2.4mA and 24mA

ranges utilize a 10 shunt, while the 240mA and 2.4A ranges use a 0.1 shunt. In addition to the shunt

resistors, there is some additional parasitic resistance in the current measurement path associated with the

fuse and the internal wiring. The maximum burden voltage is about 250mV.

Warning! Applying voltages greater than 35 V to the I+, I- terminals can cause personal injury and/or

damage to your DMM! Think before applying any inputs to these terminals!

4.2.1 Improving DC Current Measurements

When making sensitive DC current measurements disconnect all terminals not associated with the

measurement. User the Relative function while in the desired DC current range to zero out any residual

error. Using the S-Cal (DMMCalibrate ()) prior to activating Relative will improve accuracy further.

Although the DMM is designed to withstand up-to 2.4A indefinitely, be aware that excessive heat may be

generated when measuring higher AC or DC currents. If allowed to rise this heat may adversely effect

subsequent measurements. In consideration with this effect, it is recommended that whenever practical,

higher current measurements be limited to short time intervals.

4.3 Resistance Measurements

The key for stable and accurate Resistance measurements, with low test voltage, is in the number of

current sources used. This DMM uses five. The V, 2 + provides the positive terminal and the V, 2-

negative terminal of the current source. The DMM measures resistance by forcing a current, and

measuring a voltage, which the DMM converts and displays as a resistance value. Most measurements

can be made in the 2-wire mode. The 4-wire ohms is used to make low value resistance measurements.

All resistance measurement modes are susceptible to Thermo-Voltaic (Thermal EMF) errors. See section

4.3.5 for details.

4.3.1 2-Wire Ohm Measurements

In the 2-Wire resistance measurement the DMM sources current and measure resuting voltage. The DMM

measure Resistance using six ranges; 240 to 24 M. Use the V,2+, V,2- terminals for this function.

Disconnect the I,2+ and I,2- terminals in order to reduce error due to leakage and noise, as well as

better safety.

If the resistor to be measured is less than 24 k, you may null out any lead resistance errors by first

shorting the ends of the V,2+ and V,2- test leads together and performing a Relative operation

(DMMSetRelative under program control). Making measurements above 200 k, you should consider

shielded or twisted leads to minimize noise pickup. Further improvement can be achieved using guarding

(section 4.3.5).

It is a good idea to be aware of the test voltages, particularly when measuring a circuite that includes

semiconductors. To reduce this voltage, select a higher resistance range (lower current). For instance,

measuring 10k resistor using the 24k range (100uA), results in 1V test voltage, which will turn on

semiconductor junctions, resulting in lower resistance reading. To avoid this error, select the 240k range

(10uA), which will result in 100mV and will read the 10k a lot more accurately (see section 2.3 for

resistance ranges vs. current). For characterizing semiconductor part types, use the Diode measurement

function.

For applications requiring voltage and current controlled resistance measurements, use the SMU2064,

which has Extended Resistance Measurement function as well as active guarding.

4.3.2 4-Wire Ohm Measurements

4-wire Ohms measurements are advantageous for making measurements below 200 k, eliminating lead

resistance errors. The V,2+ and V,2- terminals apply a current source stimulus to the resistance, and

the I,4+ and I,4- Input terminals are the sense inputs. The Source + and Sense + leads are connected

to one side of the resistor, and the Source - and Sense - leads are connected to the other side. Both Sense

leads should be closest to the body of the resistor. See Figure 4-3.

19 Signametrics

Loading...

Loading...