Operator's Manual

Model SM2060 7½ Digit Digital PCI Multimeter

Model SMX2060 7½ Digit Digital PXI Multimeter

Model SM2064 7½ Digit High Work Load PCI Digital Multimeter

Model SMX2064 7½ Digit High Work Load PXI Digital Multimeter

Signametrics Corporation

February 2005

Rev 1.1

CAUTION

In no event shall Signametrics or its Representatives are liable for any consequential damages whatsoever

(including, without limitation, damages for loss of business profits, business interruption, loss of business

information, or other loss) arising out of the use of or inability to use Signametrics products, even if Signametrics

has been advised of the possibility of such damages. Because some states do not allow the exclusion or limitation of

liability for consequential damages, the above limitations may not apply to you.

© 2004 Signametrics Corp. Printed in the USA. All rights reserved. Contents of this publication must not be

reproduced in any form without the permission of Signametrics Corporation.

Signametrics 2

TABLE OF CONTENTS

1.0 INTRODUCTION.................................................................................................................................................8

1.1 S

AFETY CONSIDERATIONS

1.2 M

INIMUM REQUIREMENTS

1.3 F

EATURE SET

2.0 SPECIFICATIONS.............................................................................................................................................10

2.1 DC V

2.2 DC C

2.3 R

2.4 AC V

2.5 AC C

2.6 L

2.7 RTD T

2.8 T

2.9 A

2.10 T

2.11 T

2.12 M

2.13 S

2.14 A

2.15 O

OLTAGE MEASUREMENT

URRENT MEASUREMENT

ESISTANCE MEASUREMENTS

2.3.1 2-wire.....................................................................................................................................11

2.3.2 4-wire.....................................................................................................................................11

2.3.3 6-wire Guarded Resistance Measurement (SM2064)............................................................11

2.3.4 Extended Resistance Measurements (SM2064) .....................................................................12

OLTAGE MEASUREMENTS

2.4.1 AC Voltage True RMS Measurement.....................................................................................12

2.4.2 AC Peak-to-Peak Measurement (SM2064)............................................................................14

2.4.3 AC Crest Factor Measurement (SM2064) .............................................................................15

2.4.4 AC Median Value Measurement (SM2064)...........................................................................15

URRENT MEASUREMENT

EAKAGE MEASUREMENT

HERMOCOUPLE TEMPERATURE MEASUREMENT

DDITIONAL COMPONENT MEASUREMENT CAPABILITY

2.9.1 Diode Characterization .........................................................................................................17

2.9.2 Capacitance, Ramp Method (SM2064)..................................................................................17

2.9.3 Capacitance, In-Circuit Method (SM2064)..........................................................................19

2.9.4 Inductance Measurement (SM2064)......................................................................................19

IME MEASUREMENTS

2.10.1 Threshold DAC ....................................................................................................................19

2.10.2 Frequency and Period Measurement...................................................................................20

2.10.3 Duty Cycle Measurement.....................................................................................................20

2.10.4 Pulse Width..........................................................................................................................20

2.10.5 Totalizer...............................................................................................................................21

RIGGER FUNCTIONS

2.11.1 External Hardware Trigger (at DIN-7 connector) ..............................................................21

2.11.2 Analog Threshold Trigger....................................................................................................21

2.11.3 Delayed Hardware Trigger..................................................................................................21

EASUREMENT APERTURE AND READ INTERVAL

OURCE FUNCTIONS

2.13.1 DC Voltage Source ..............................................................................................................24

2.13.2 AC Voltage Source...............................................................................................................24

2.13.3 DC Current Source..............................................................................................................24

CCURACY NOTES

THER SPECIFICATIONS

.............................................................................................................................................9

EMPERATURE MEASUREMENT

..........................................................................................................................8

.........................................................................................................................9

.................................................................................................................10

.................................................................................................................10

..................................................................................................................11

...............................................................................................................12

, T

RUE

RMS .............................................................................................15

(SM2064) ......................................................................................................16

(SM2064) .....................................................................................16

(SM2064) ...................................................................17

..........................................................................17

...........................................................................................................................19

.............................................................................................................................21

..................................................................................21

(SMX2064)...........................................................................................................23

.................................................................................................................................24

.........................................................................................................................25

3.0 GETTING STARTED.........................................................................................................................................27

3.1 S

ETTING THE

3.2 I

NSTALLING THE

3.3 I

NSTALLING THE SOFTWARE

3.4 DMM I

3.5 S

TARTING THE CONTROL PANEL

3.6 U

SING THE CONTROL PANEL

4.0 DMM OPERATION AND MEASUREMENT TUTORIAL...........................................................................32

DMM .................................................................................................................................27

DMM M

NPUT CONNECTORS

ODULE

.............................................................................................................27

....................................................................................................................27

......................................................................................................................28

..............................................................................................................29

....................................................................................................................30

3 Signametrics

4.1 V

OLTAGE MEASUREMENT

4.1.1 DC Voltage Measurements ....................................................................................................32

4.1.2 True RMS AC Voltage Measurements ...................................................................................32

4.1.3 AC Peak-to-Peak and Crest Factor (SM2064)......................................................................33

4.1.4 AC Median Value Measurement (SM2064)...........................................................................33

4.2 C

URRENT MEASUREMENTS

4.2.1 Extended DC Current Measurements (SM2064) ...................................................................34

4.2.2 Improving DC Current Measurements ..................................................................................34

4.2.3 DC Current Measurements at a specific voltage...................................................................34

4.3 R

ESISTANCE MEASUREMENTS

4.3.1 2-Wire Ohm Measurements ...................................................................................................35

4.3.2 4-Wire Ohm Measurements ...................................................................................................35

4.3.3 Using Offset Ohms function (SM2064)..................................................................................36

4.3.4 6-wire Guarded Resistance Measurement (SM2064)............................................................36

4.3.5 Extended Resistance Measurements (SM2064) .....................................................................37

4.3.6 Effects of Thermo-Voltaic Offset ............................................................................................38

4.3.7 Guarding High Value Resistance Measurements (SM2064) .................................................39

4.4 L

EAKAGE MEASUREMENTS

4.5 M

EASUREMENT TIMING

4.5.1 Aperture.................................................................................................................................40

4.5.2 Read Interval..........................................................................................................................40

4.6 RTD T

4.7 I

4.8 D

4.9 C

4.10 IN-C

4.11 I

4.12 C

4.13 T

4.14 F

4.15 S

4.16 I

4.17 M

4.18 U

EMPERATURE MEASUREMENT

NTERNAL TEMPERATURE

IODE CHARACTERIZATION

APACITANCE MEASUREMENT

IRCUIT CAPACITANCE MEASUREMENT

NDUCTANCE MEASUREMENT

HARACTERISTIC IMPEDANCE MEASUREMENT

RIGGER OPERATION

4.13.1 External Hardware Trigger.................................................................................................44

4.13.2 Analog Threshold Trigger....................................................................................................45

4.13.3 Software Generated Triggered Operations..........................................................................45

REQUENCY AND TIME MEASUREMENTS

4.14.1 Threshold DAC ....................................................................................................................47

4.14.2 Frequency and Period Measurements .................................................................................48

4.14.3 Duty Cycle Measurement.....................................................................................................48

4.14.4 Pulse Width..........................................................................................................................48

4.14.5 Totalizer Event Counter.......................................................................................................48

OURCING FUNCTIONS

4.15.1 DC Voltage Source ..............................................................................................................49

4.15.2 AC Voltage Source...............................................................................................................50

4.15.3 DC Current Source..............................................................................................................51

4.15.4 Source Current - Measure Voltage......................................................................................51

NTERFACING TO THE

4.16.1 Triggering the SM2060 DMM’s...........................................................................................51

4.16.2 Multiplexing with the SM2060 DMM’s................................................................................52

4.16.3 Interface Commands and Timing .........................................................................................52

EASURING TEMPERATURE WITH THERMOCOUPLES

SING THE

PXI

BUS TRIGGER FACILITIES

4.18.1 Selecting PXI Trigger Outputs.............................................................................................53

4.18.2 Selecting PXI Trigger Inputs ...............................................................................................54

........................................................................................................................32

......................................................................................................................33

..................................................................................................................35

(SM2064)..................................................................................................... 39

...........................................................................................................................40

(SM2064) .......................................................................................................42

.....................................................................................................................42

(SM2064) ...............................................................................................43

(SM2064) ............................................................................................... 44

.............................................................................................................................44

(SM2064)..........................................................................................................49

SM4040

SERIES RELAY SCANNERS

(SM2064) .....................................................................................42

(SM2064) ..........................................................................43

(SM2064)..................................................................... 44

...............................................................................................47

......................................................................51

.............................................................................53

(SMX2064)..........................................................................53

5.0 WINDOWS INTERFACE..................................................................................................................................55

5.1 D

ISTRIBUTION FILES

5.2 U

SING THE

5.3 V

ISUAL BASIC FRONT PANEL APPLICATION

5.4 W

INDOWS

SM2060 D

5.2.1 Multiple Card Operations under Windows............................................................................57

5.3.1 Visual Basic Simple Application............................................................................................59

DLL D

EFAULT MODES AND PARAMETERS

Signametrics 4

................................................................................................................................55

RIVER WITH

C++

OR SIMILAR SOFTWARE

.............................................................................................58

............................................................57

.............................................................................60

5.5 U

SING THE

5.6 W

INDOWS COMMAND LANGUAGE

SM2060 DLL

DMMArmAnalogTrigger ................................................................................................................60

DMMArmTrigger............................................................................................................................62

DMMBurstBuffRead .......................................................................................................................63

DMMBurstRead..............................................................................................................................64

DMMCalibrate................................................................................................................................65

DMMCleanRelay ............................................................................................................................66

DMMClearBuffer............................................................................................................................67

DMMClearMinMax ........................................................................................................................67

DMMClosePCI ...............................................................................................................................68

DMMDelay .....................................................................................................................................68

DMMDelayedTrigger .....................................................................................................................69

DMMDisableTrimDAC...................................................................................................................70

DMMDisArmTrigger ......................................................................................................................70

DMMDutyCycleStr .........................................................................................................................71

DMMErrString................................................................................................................................71

DMMFrequencyStr.........................................................................................................................72

DMMGetACCapsR .........................................................................................................................73

DMMGetAperture...........................................................................................................................73

DMMGetBufferSize.........................................................................................................................74

DMMGetBusInfo.............................................................................................................................74

DMMGetCalDate............................................................................................................................75

DMMGetdB.....................................................................................................................................76

DMMGetdBStr................................................................................................................................76

DMMGetCJTemp............................................................................................................................77

DMMGetDeviation .........................................................................................................................77

DMMGetDeviatStr..........................................................................................................................78

DMMGetFuncRange.......................................................................................................................78

DMMGetFunction...........................................................................................................................79

DMMGetGrdVer.............................................................................................................................79

DMMGetHwVer..............................................................................................................................80

DMMGetID.....................................................................................................................................80

DMMGetManDate..........................................................................................................................81

DMMGetMax..................................................................................................................................82

DMMGetMaxStr .............................................................................................................................82

DMMGetMin...................................................................................................................................83

DMMGetMinStr.............................................................................................................................. 83

DMMGetRange...............................................................................................................................84

DMMGetReadInterval ....................................................................................................................85

DMMGetSourceFreq ......................................................................................................................85

DMMGetTCType.............................................................................................................................86

DMMGetTriggerInfo.......................................................................................................................86

DMMGetType .................................................................................................................................87

DMMGetVer ...................................................................................................................................87

DMMInit .........................................................................................................................................88

DMMIsAutoRange ..........................................................................................................................88

DMMIsInitialized............................................................................................................................89

DMMIsRelative...............................................................................................................................89

DMMOpenPCI................................................................................................................................90

DMMOpenCalACCaps...................................................................................................................90

DMMOpenTerminalCal..................................................................................................................91

DMMPeriodStr ...............................................................................................................................92

DMMPolledRead ............................................................................................................................92

DMMPolledReadCmd.....................................................................................................................93

DMMPolledReadStr........................................................................................................................94

DMMQuickInit................................................................................................................................94

DMMRead.......................................................................................................................................95

DMMReadBuffer.............................................................................................................................96

DMMReadBufferStr........................................................................................................................97

WITH LABWINDOWS

...........................................................................................................60

/CVI®............................................................................60

5 Signametrics

DMMReadCJTemp .........................................................................................................................97

DMMReadCrestFactor ...................................................................................................................98

DMMReadDutyCycle......................................................................................................................99

DMMReadFrequency......................................................................................................................99

DMMReadInductorQ....................................................................................................................100

DMMReadMeasurement...............................................................................................................101

DMMReadMedian......................................................................................................................... 101

DMMReadNorm............................................................................................................................102

DMMReadPeakToPeak.................................................................................................................102

DMMReadPeriod..........................................................................................................................103

DMMReadStr................................................................................................................................104

DMMReadTotalizer ......................................................................................................................105

DMMReadWidth...........................................................................................................................105

DMMReady...................................................................................................................................106

DMMSetACCapsDelay .................................................................................................................106

DMMSetACCapsLevel..................................................................................................................107

DMMSetACVSource .....................................................................................................................107

DMMSetAperture..........................................................................................................................108

DMMSetAutoRange ......................................................................................................................109

DMMSetBuffTrigRead ..................................................................................................................109

DMMSetCapsAveSamp.................................................................................................................110

DMMSetCJTemp...........................................................................................................................111

DMMSetCompThreshold ..............................................................................................................112

DMMSetCounterRng..................................................................................................................... 112

DMMSetDCISource......................................................................................................................113

DMMSetDCVSource.....................................................................................................................114

DMMSetFastRMS.........................................................................................................................115

DMMSetFuncRange......................................................................................................................115

DMMSetFunction..........................................................................................................................116

DMMSetInductFreq......................................................................................................................116

DMMSetOffsetOhms.....................................................................................................................117

DMMSetPXITrigger......................................................................................................................117

DMMSetRange..............................................................................................................................118

DMMSetReadInterval...................................................................................................................119

DMMSetReference........................................................................................................................119

DMMSetRelative...........................................................................................................................120

DMMSetRTD ................................................................................................................................121

DMMSetSensorParams.................................................................................................................122

DMMSetSourceMode....................................................................................................................122

DMMSetSync ................................................................................................................................123

DMMSetTCType ........................................................................................................................... 124

DMMSetTempUnits....................................................................................................................... 124

DMMSetTrigPolarity....................................................................................................................125

DMMSetTrigRead.........................................................................................................................125

DMMSetTrimDAC ........................................................................................................................126

DMMStartTotalizer.......................................................................................................................127

DMMStopTotalizer .......................................................................................................................128

DMMTerminate.............................................................................................................................128

DMMTrigger.................................................................................................................................129

DMMTriggerBurst........................................................................................................................ 130

DMMWidthStr...............................................................................................................................131

5.7 C

ALIBRATION SERVICE COMMANDS

AC_zero ........................................................................................................................................133

DMMLoadCalFile.........................................................................................................................133

GetGain.........................................................................................................................................134

GetOffset.......................................................................................................................................134

SetFcomp ......................................................................................................................................135

SetOffset........................................................................................................................................136

Linearize_AD................................................................................................................................136

Read_ADcounts ............................................................................................................................137

......................................................................................................133

Signametrics 6

5.8 M

AINTANANCE COMMANDS

GrdXingTest ..................................................................................................................................138

5.7 E

RROR CODES

5.8 W

ARNING CODES

..................................................................................................................138

........................................................................................................................................138

...................................................................................................................................139

6.0 MAINTENANCE ..............................................................................................................................................139

6.1 P

ERFORMANCE TESTS

6.2 DC V

6.3 R

6.4 R

6.5 AC V

6.6 DC C

6.7 AC C

N

OTE

6.8 C

6.8 I

6.9 F

6.10 C

OLTAGE TEST

ESISTANCE TEST

ESISTANCE TEST

OLTAGE TEST

URRENT TEST

URRENT TEST

: S

OME RANGES APPLY TO

APACITANCE TEST

NDUCTANCE TEST

REQUENCY COUNTER TEST

ALIBRATION

............................................................................................................................141

................................................................................................................................141

, 2-

WIRE

.....................................................................................................................142

, 4-

WIRE

.....................................................................................................................143

................................................................................................................................144

................................................................................................................................145

................................................................................................................................146

2064

ONLY

. P

(SM2064

(SM2064

LEASE REFER TO CHAPTER

ONLY

) ....................................................................................................147

ONLY

) ...................................................................................................... 148

( SM2064

ONLY

) ......................................................................................149

2.0 (S

PECIFICATION

). .................146

.......................................................................................................................................150

7.0 WARRANTY AND SERVICE.........................................................................................................................152

8.0 ACCESSORIES.................................................................................................................................................152

7 Signametrics

1.0 Introduction

Congratulations! You have purchased a Personal Computer (PC) Plug-in instrument with analog and systems

performance that rivals the best, all-in-one box, instruments. The SM2060 and SMX2064 Digital Multimeters

(DMM’s) are easy to setup and use, have sophisticated analog and digital circuitry to provide very repeatable

measurements, and are protected to handle any unexpected situations your measurement environment may

encounter. To get years of reliable service from these DMM’s, please take a few moments and review this manual

before installing and using this precision instrument.

This manual describes the SM2060 and SM2064 DMM’s. The SMX2060 is identical to the SM2060 and the

SMX2064 is identical to the SM2064. The only difference is the bus type. The SM206X is a PCI module, while the

SMX206X is a PXI/cPCI module.

Note: In this manual, all references made to the "SM2060" are applicable to the SMX2060, and references to the

“SM2064” are applicable to the SMX2064. References to “DMM” apply to the SM2060, SMX2060, SM2064 and

SMX2064. Features unique to the SM2064 will be identified as such.

1.1 Safety Considerations

Safety Considerations

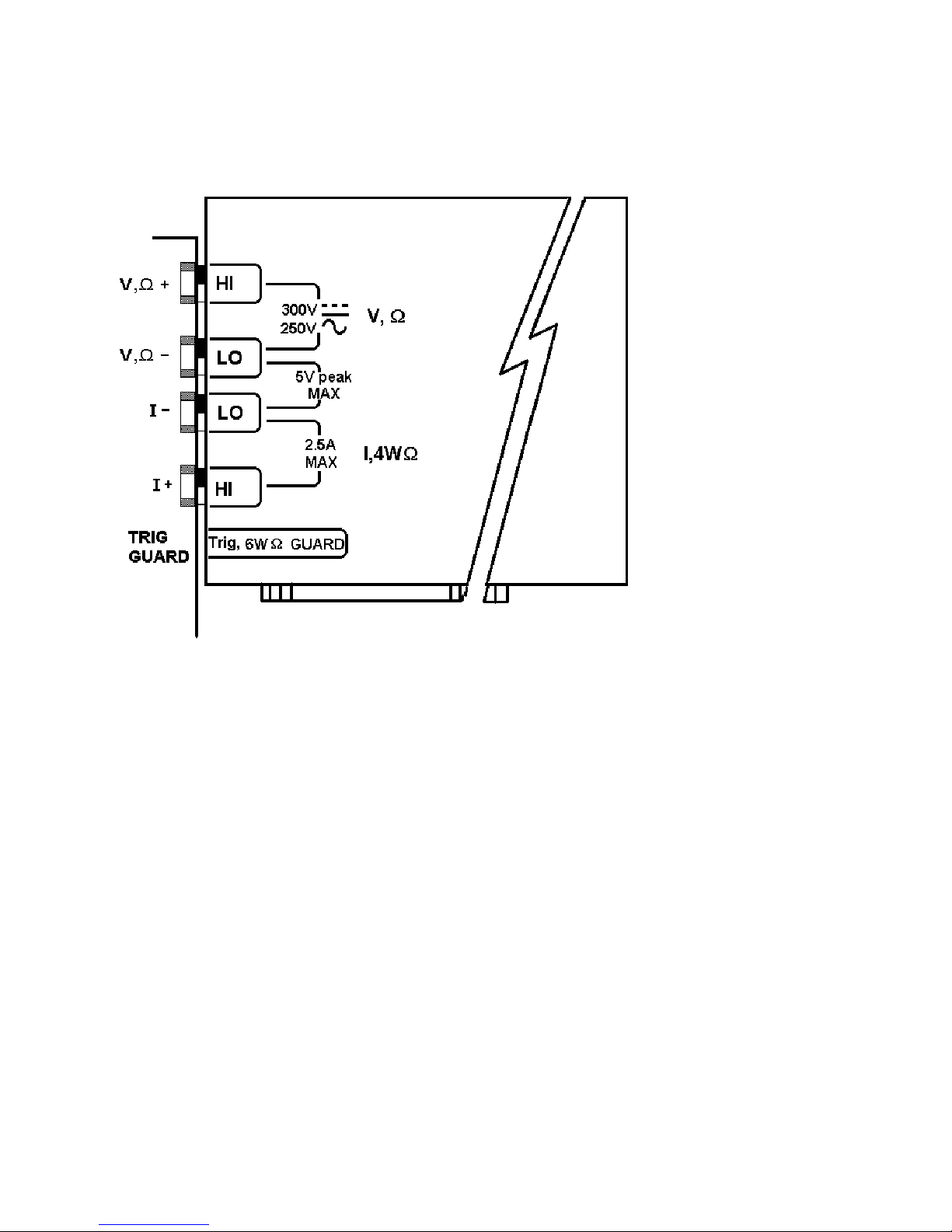

The SM2060 series of DMM’s is capable of measuring up to 300 VDC or 250 VAC across the Volt HI

and LO terminals, and can also measure common mode signals that "float" the DMM above EARTH

ground by up to 300 VDC or 250 VAC. When making common mode measurements, the majority of the

circuits inside the DMM are at the common mode voltage. These voltages can be lethal and can KILL!

During and after installing your DMM, check to see that there are no wires or ribbon cables from

your PC trapped inside the DMM.

The DMM comes installed with four shields (bottom, top and two edge strips) that must not be removed

for performance as well as safety reasons. Removal of these shields and/or improper assembly of the

shields can result in lethal voltages occurring within your PC. Be sure to check your installation before

closing the cover on your personal computer.

Warning

Check to see that no loose wires or ribbon cables infringe upon any of the internal circuits of the

DMM, as this may apply measurement voltages to your computer, causing electrocution and/or

damage to your computer!

To avoid shock hazard, install the DMM only into a computer that has its power connector

connected to a power receptacle with an earth safety ground.

When making any measurements above 50 VDC or 40 VAC, only use Safety Test Leads. Examples

of these are the Signametrics Basic Test Leads and Deluxe Test Leads, offered as an accessory with the

Signametrics DMM’s.

Signametrics 8

1.2 Minimum Requirements

The SM2060 series of system DMM’s are precision plug-in modules that are compatible with IBM type personal

computers (PCs), PXI and cPCI chassis. It requires as a minimum a Pentiums computer. They require a half-length

expansion slot on the PCI bus or 3U PXI slot. A mouse must be installed when controlling the DMM from the

Windows Control Panel. The SM2060 comes with a Windows' DLL, for operation with Windows' Version

95/98/Me/2000/XP and NT4.0.

1.3 Feature Set

The base unit, the SM2060, has traditional 7-1/2 digit features and it can be used as a general purpose DMM, where

accuracy and speed are important. The High Workload Multi Function SM2064 adds timing, capacitance,

inductance, sourcing and a lot more speed. With its specialized measurements, it can replace some costly

instruments, shrinking the size and cost of a test system.

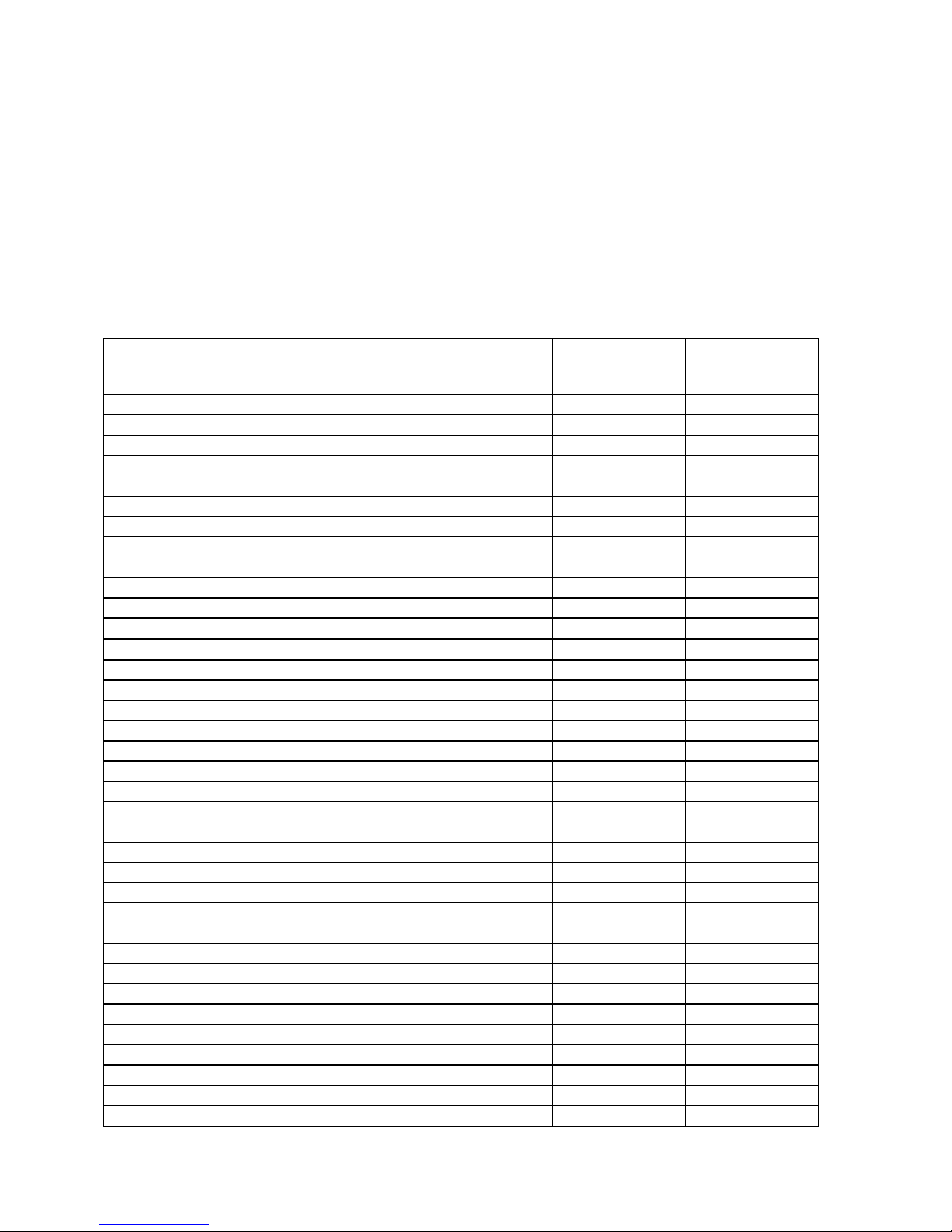

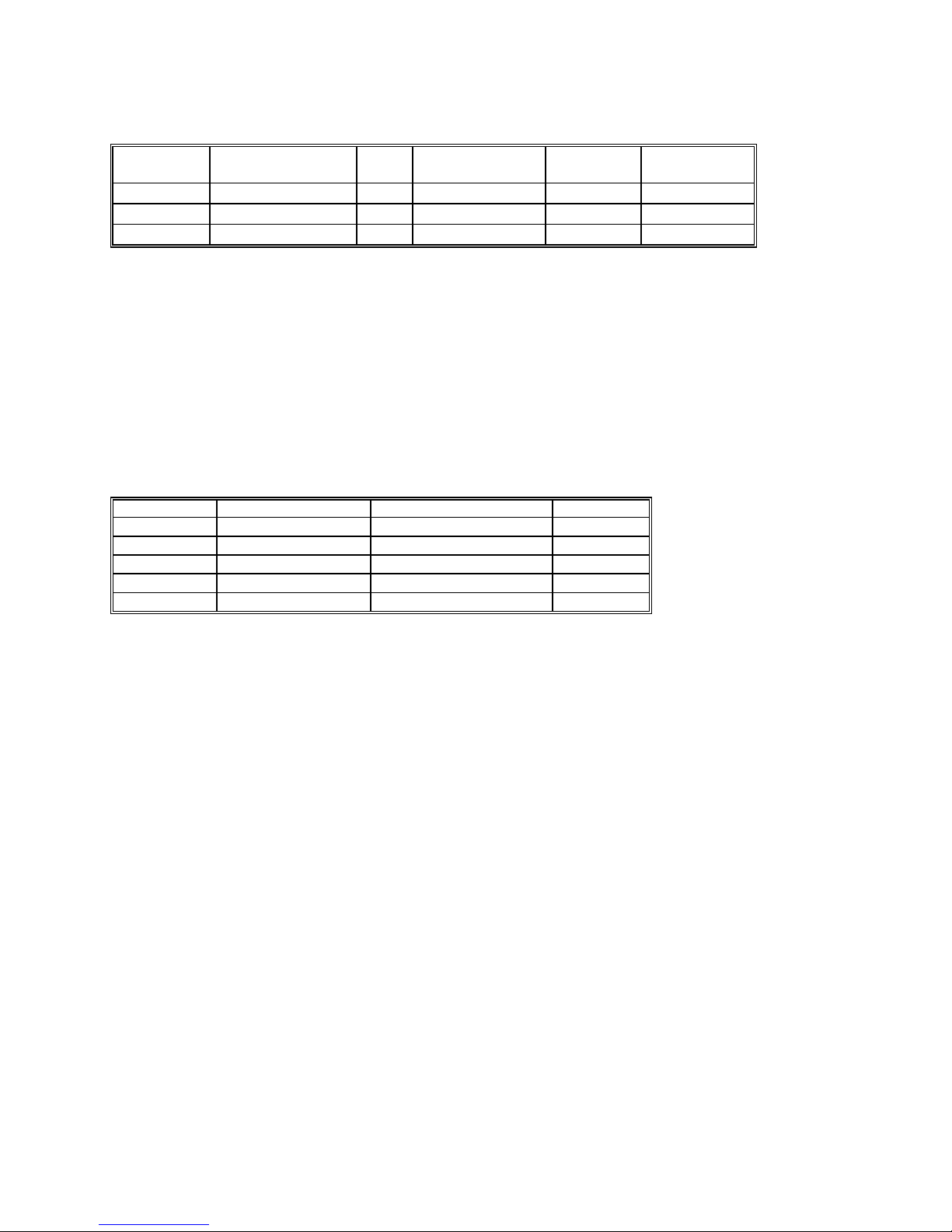

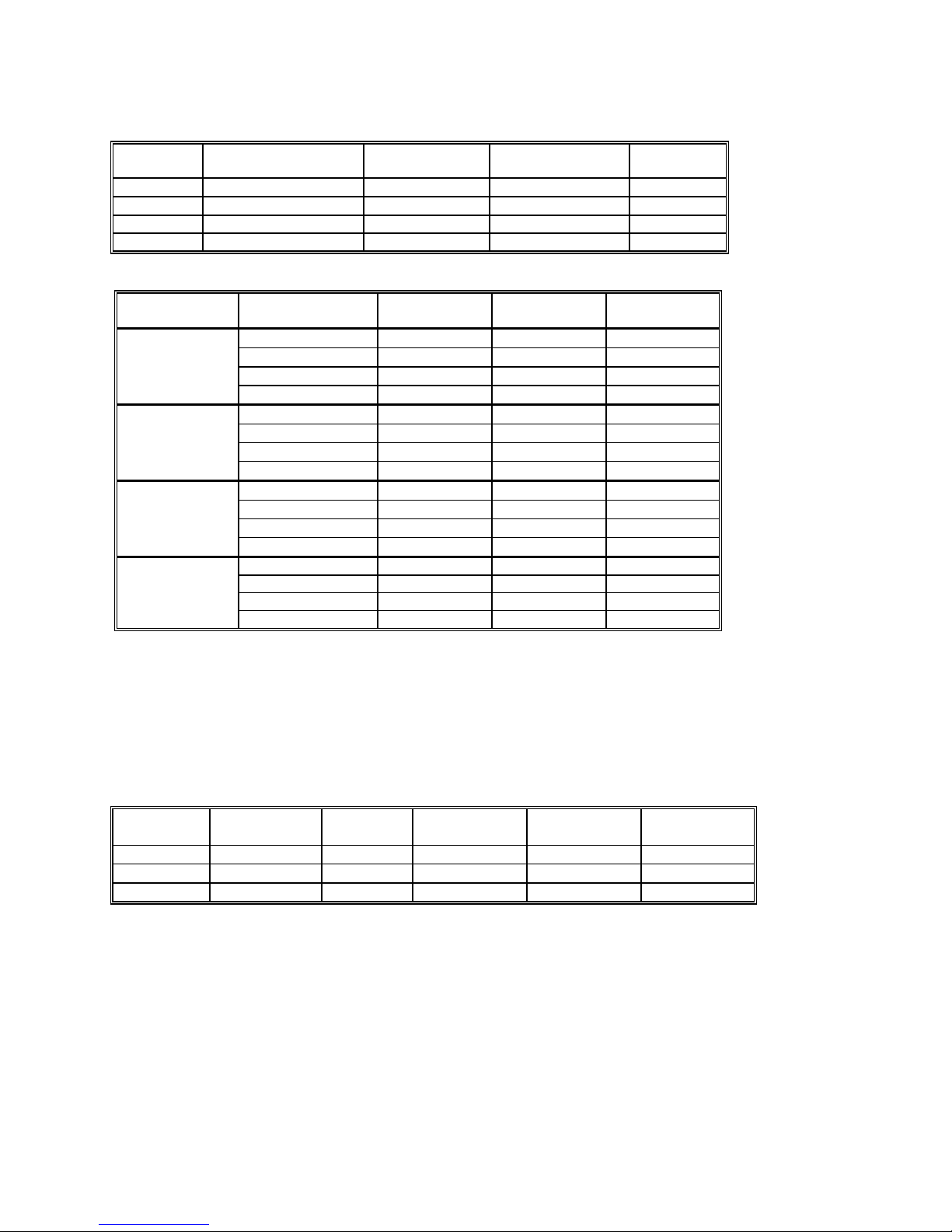

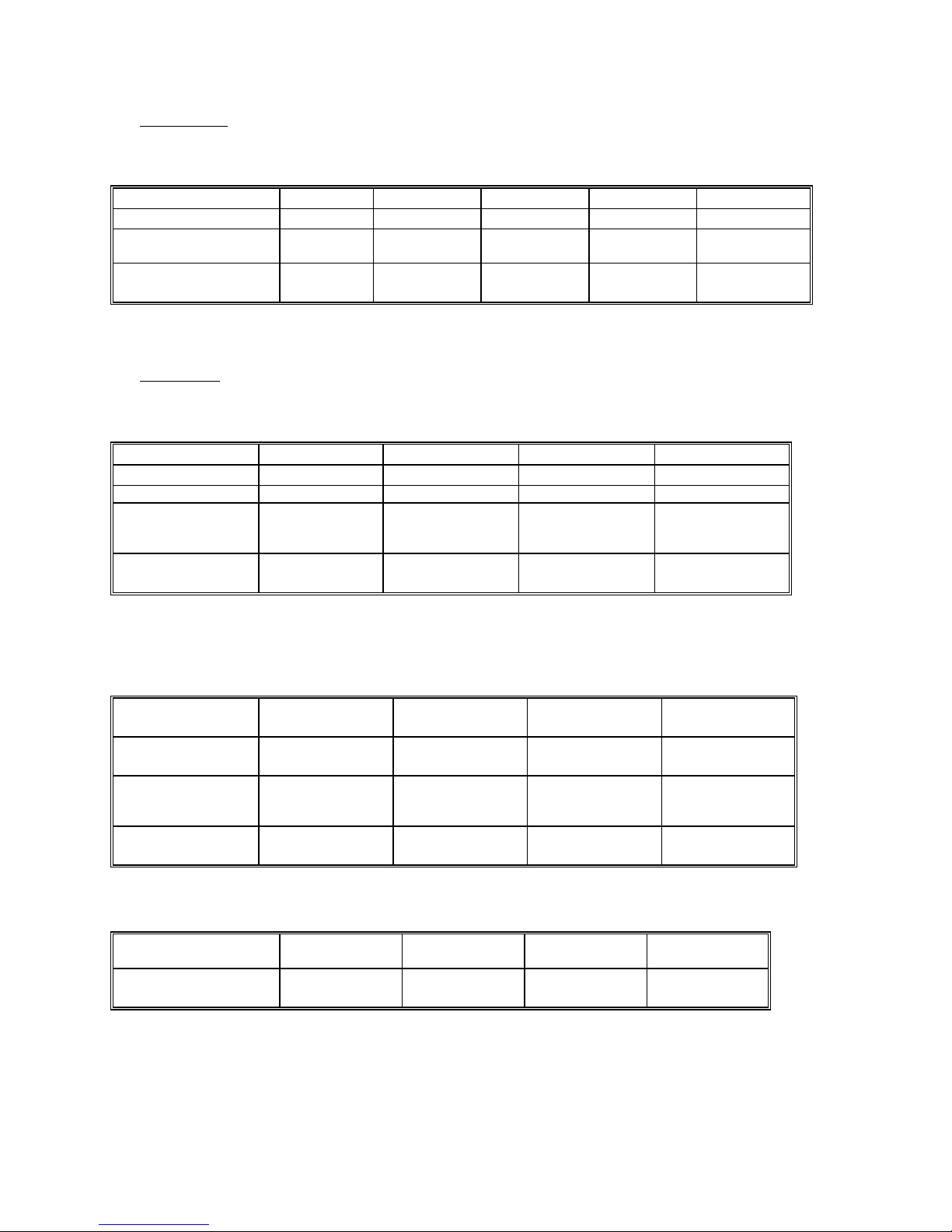

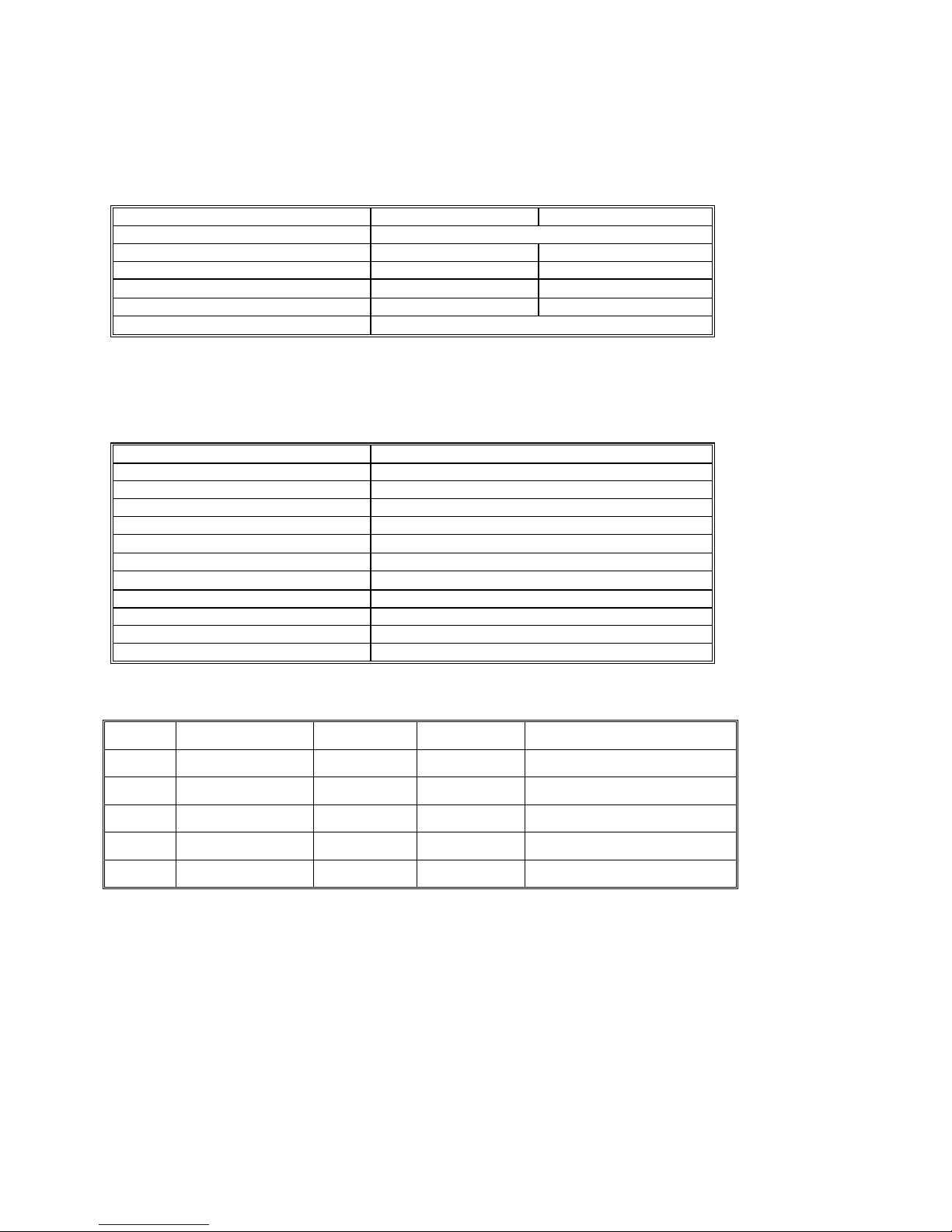

SM2060 and SM2064 7½ Digit DMM’s feature table:

Function SM/SMX2060

DMM

DCV five ranges 240mV to 330V

ACV five ranges 240mV to 330V

2-Wire Ohms, six ranges 240 Ω to 24 MΩ √ √

4-Wire Ohms, six ranges 240 Ω to 24 MΩ √ √

DC current, four ranges 2.4 mA to 2.4 A

AC current, four ranges 2.4 mA to 2.4 A

Diode V/I characteristics at 100 ηA to 1mA √ √ (plus 10mA)

Auto range, Relative

Min/Max, dB and percent deviation functions

On board measurement buffer

External and threshold trigger

Thermocouples type;

High Dynamic range; +24,000,000 counts

Frequency / Period measurement

Measurement rate: 0.2 to 1,400/sec

Measurement rate: to 20,000/sec

Capacitance, ramp type, eight ranges, 1 nF to 10 mF

Capacitance, In-Circuit method five ranges, 24nF to 2.4mF

Inductance, six ranges 33 µH to 3.3 H

Internal DMM temperature sensor

Offset Ohms

Temperature types pt385, 3911, 3916, 3926, Copper, variable Ro

Pulse width, pos./neg., & duty cycle

Totalizer/event counter

Variable threshold DAC; all timing measure.

Peak to Peak, Crest factor, Median

Six wire Ohms (with force/sense)

DCV source to ±10.0 V

ACV source 0 to 20 V pk-pk, 2 Hz to 75 KHz

DC current source, 1 nA to 12.5 mA

Leakage measurement to ±10.0V three ranges 240nA, 2.4uA, 25uA

Expanded ranges

2-Wire Ohms two additional ranges 24 Ω and 240 MΩ

4-Wire Ohms additional range 24 Ω

Resistance with V&I limits (to 10GΩ)

DC Current four additional ranges 240nA, 2.4µA, 24µA, 240µA

B, E, J, K, N, R, S, T

√ √

√ √

√ √

√ √

√ √

√ √

√ √

√ √

√ √

√ √

√ √

√ √

SM/SMX2064

High Workload

DMM

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

9 Signametrics

2.0 Specifications

The following specifications are based on both, verification of large number of units as well as

mathematical evaluation. They should be considered under the environment specified.

It is important to note that a DMM specified range is expressed as a numeric value indicating the highest

absolute voltage that can be measured. The lowest value that can be detected is expressed by the

corresponding resolution for the range.

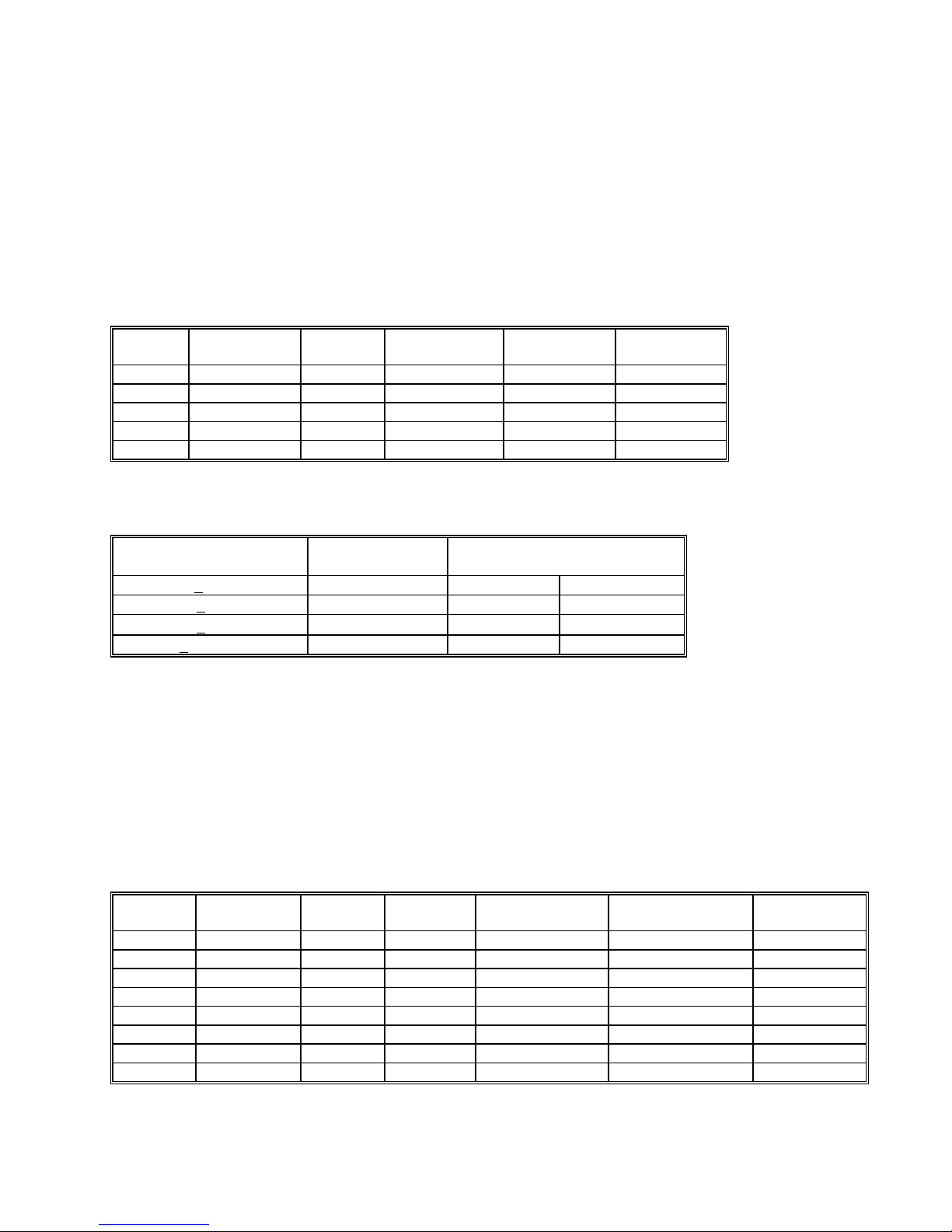

2.1 DC Voltage Measurement

Input Characteristics

• Input Resistance 240 mV, 2.4 V Ranges: >10 GΩ, with typical leakage of 50pA

• Input Resistance 24 V, 240 V, 330V Ranges: 10.00 MΩ

Accuracy ± (% of reading + Volts) [1]

Range Full Scale

7-½ Digits

240 mV 240.00000 mV

2.4 V 2.4000000 V

24 V 24.000000 V

240 V 240.00000 V

330 V

330.00000 V

Resolution 24 hours

23°C ± 1°C

10 ηV 0.003 + 1 µV 0.004 + 1.5 µV 0.005 + 2 µV

100 ηV 0.002 + 3 µV 0.0025 + 5 µV 0.003 + 10 µV

1 µV 0.003 + 150 µV 0.004 + 250 µV 0.005 + 300 µV

10 µV

0.004 + 200 µV 0.005 + 300 µV

10 µV

0.005 + 250 µV 0.01+ 400 µV

90 Days

23°C ± 5°C

One Year 23°C

± 5°C

0.006 + 0.5 mV

0.015 + 0.7 mV

[1] With Aperture set to 0.5 Sec, and within one hour from Self Calibration (S-Cal).

For resolution at smaller Apertures, see the following table. Use this table for DC Volts, DC current

and Resistance measurements.

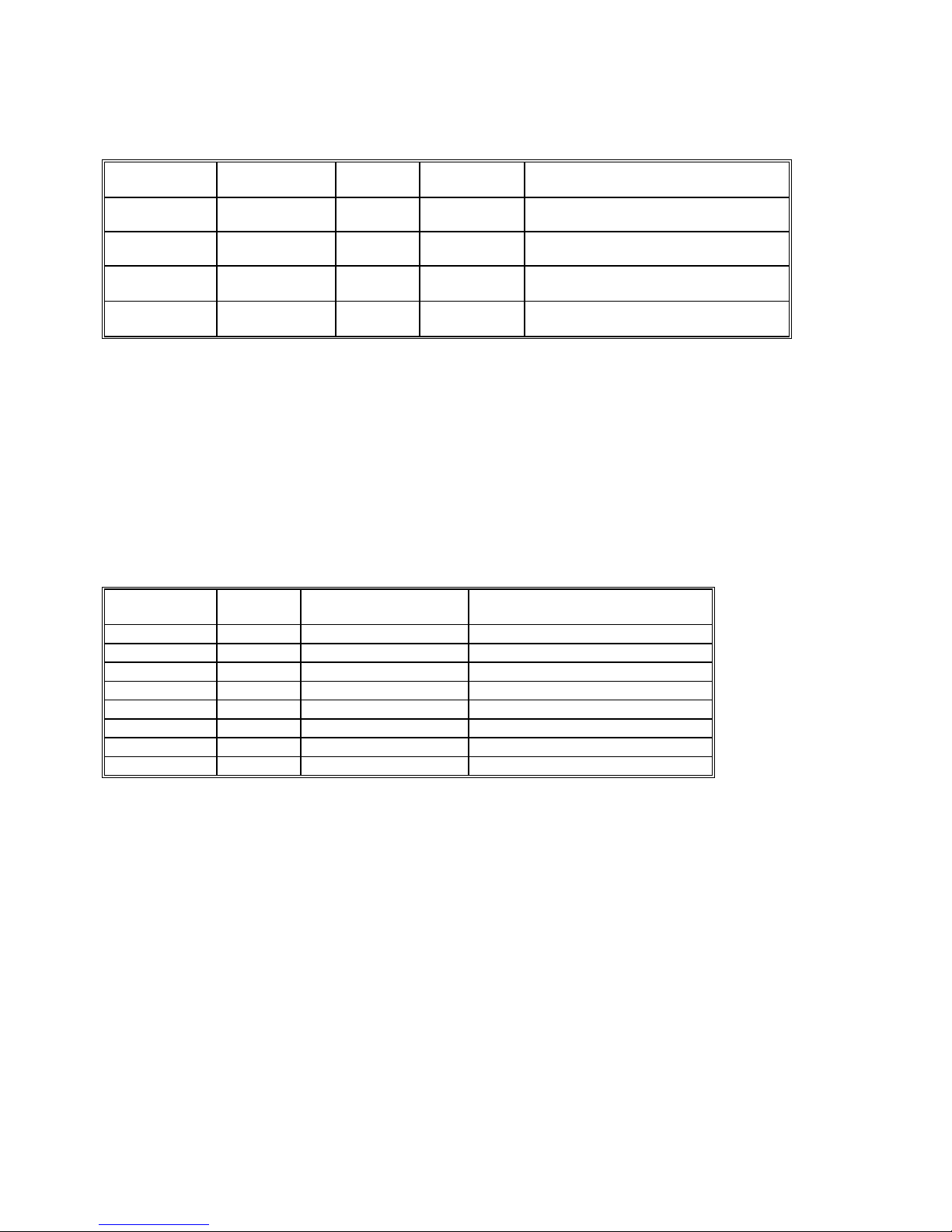

Measurement Aperture

SM2060, SM2064

Maximum reading

rate

Resolution

0.5 s < Aperture 2 / second 7-1/2 digits 25 bits

10 ms < Aperture 100 / second 6-1/2 digits 22 bits

625µs < Aperture

1200 / second 5-1/2 digits 18 bits

2.5us < Aperture [2] 20,000 / second [2] 4-1/2 digits 14 bits

[2] Available only with the SM2064.

DCV Noise Rejection Normal Mode Rejection, at 50, 60, or 400 Hz ± 0.5%, is better than 95 dB

for apertures of 0.160s and higher. Common Mode Rejection (with 1 kΩ lead imbalance) is better

than 120 dB for these conditions.

2.2 DC Current Measurement

Input Characteristics

• Number of shunts Five in SM2064, two in the SM2060

• Protected with 2.5A Fast blow fuse

Accuracy ± (% of reading + Amps) [1]

Range Full Scale

6-½ Digits

240 ηA [2] 240.0000 ηA

2.4 µA [2] 2.400000 µA

24 µA [2] 24.00000 µA

240 µA [2] 240.000 µA 10 ηA

2.4 mA 2.40000 mA

24 mA 24.0000 mA

240 mA 240.000 mA

2.4 A 2.40000 A

Resolution Max Burden

Voltage

0.1 pA

1 pA

10 pA

10 ηA

100 ηA

1 µA

10 µA

100 µV

100 µV

100 µV

2.5mV

25mV

250mV

55mV

520mV

24 hours

23°C ± 5°C

0.07 + 40pA 0.1 + 45pA 0.17 + 60pA

0.05 + 70pA 0.08 + 90pA 0.21 + 150pA

0.05 + 400pA 0.08 + 600pA 0.13 + 0.8nA

0.052 + 200 ηA 0.07 + 300 ηA 0.1 + 400 ηA

0.05 + 300 ηA 0.06 + 400 ηA 0.07 + 550 ηA

0.05 + 350 ηA 0.065 + 450 ηA 0.08 + 550 ηA

0.05 + 50 µA 0.055 + 60 µA 0.065 + 80 µA

0.3 + 60 µA 0.4 + 70 µA 0.45 + 90 µA

90 Days

23°C ± 5°C

[1] With Aperture set to 0.96 Sec, and within one hour from Zero (Relative control).

[2] Available only with the SM2064.

One Year 23°C

± 5°C

Signametrics 10

2.3 Resistance Measurements

2.3.1 2-wire

Accuracy ± (% of reading + Ω) [1]

Range [4] Full Scale

7 ½ Digits

24 Ω[3] 24.000000 Ω 1 µΩ

240 Ω 240.00000 Ω 10 µΩ

2.4 kΩ 2.4000000 kΩ 100 µΩ

24 kΩ 24.000000 kΩ 1 mΩ 100 µA 0.0025 + 300 mΩ 0.004 + 330 mΩ 0.006 + 350 mΩ

240 kΩ 240.00000 kΩ 10 mΩ 10 µA 0.0055 + 3.2 Ω 0.006 + 4 Ω 0.007 + 5 Ω

2.4 MΩ 2.4000000 MΩ 100 mΩ 1 µA 0.018 + 40 Ω 0.03 + 50 Ω 0.04 + 70 Ω

24 MΩ 24.0000 MΩ 100 Ω

240 MΩ[3] 240.000 MΩ 1 kΩ

Resolution Source

current

10 mA

1 mA

1 mA

100 nA

10 nA

24 hours

23°C ± 1°C

0.0038 + 1.4 mΩ [2] 0.005 + 1.6 mΩ [2] 0.008 + 2 mΩ [2]

0.0037 + 4.5 mΩ [2] 0.0046 + 5 mΩ [2] 0.007 + 6 mΩ [2]

0.0023 + 28 mΩ 0.004 + 32 mΩ 0.006 + 33 mΩ

0.12 + 400 Ω 0.13 + 500 Ω 0.2 + 600 Ω

0.8 + 20 kΩ 1.0 + 30 kΩ 1.3 + 50 kΩ

90 Days

23°C ± 5°C

One Year

23°C ± 5°C

[1] With Aperture set to 0.5 Sec, and within one hour from Self Calibration (S-Cal).

[2] Use of S-Cal and Relative to improve measurement floor.

[3] Ranges are only available with the SM2064.

Ω

[4] Test voltages are 2.4V max with the exception of the 24

and 240 Ω ranges 240 mV.

2.3.2 4-wire

Accuracy ± (% of reading + Ω) [1]

Range [4] Full Scale

7 ½ Digits

24 Ω [3] 24.000000 Ω 1 µΩ

240 Ω 240.00000 Ω 10 µΩ

2.4 kΩ 2.4000000 kΩ 100 µΩ

24 kΩ 24.000000 kΩ 1 mΩ 100 µA 0.0025 + 300 mΩ 0.004 + 330 mΩ 0.006 + 350 mΩ

240 kΩ 240.00000 kΩ 10 mΩ 10 µA 0.0055 + 3.2 Ω 0.007 + 4 Ω 0.007 + 5 Ω

2.4 MΩ 2.4000000 MΩ 100 mΩ 1 µA 0.018 + 40 Ω 0.03 + 50 Ω 0.04 + 70 Ω

24 MΩ 24.0000 MΩ 100 Ω

Resolution Source

current

10 mA

1 mA

1 mA

100 nA

24 hours

23°C ± 1°C

0.0038 + 0.7 mΩ [2] 0.005 + 0.8 mΩ [2] 0.008 + 1 mΩ [2]

0.0037 + 3 mΩ [2] 0.0046 + 4 mΩ [2] 0.007 + 5 mΩ [2]

0.0023 + 28 mΩ 0.004 + 32 mΩ 0.006 + 33 mΩ

0.12 + 400 Ω 0.13 + 500 Ω 0.2 + 600 Ω

90 Days

23°C ± 5°C

One Year

23°C ± 5°C

[1] With Aperture set to 0.5 Sec, and within one hour from Self Calibration (S-Cal).

[2] Use of Relative to facilitate indicated floor (adder part of spec).

[3] 24 Ω range only available with SM2064.

Ω

[4] Test voltages are 2.4V max with the exception of the 24

and 240 Ω ranges 240 mV.

2.3.3 6-wire Guarded Resistance Measurement (SM2064)

This is an in-circuit forced guard measurement method, as implemented in ICT testers. Add this typical additional

error to the above specification.

Range Guard forced current

24 Ω [3]

240 Ω

2.4 kΩ

24 kΩ 100 µA 0.03 + 1 Ω

240 kΩ 10 µA 0.35 + 10 Ω

24 MΩ 1 µA 0.85 + 1000 Ω

[1] This table should be used in conjunction with the 2-wire and 4-wire table above.

10 mA

1 mA

1 mA

Accuracy ± (% of reading + Ω)

One Year 23°C ± 5°C [1]

0.3 + 4 mΩ

0.003 + 20 mΩ

0.005 + 100 mΩ

11 Signametrics

2.3.4 Extended Resistance Measurements (SM2064)

Characteristics

• Test Voltage Adjustable between -10V and +10V in 5mV steps

Accuracy ± (% of reading + Amps) [1]

Range

400kΩ

4MΩ

40MΩ

Measurement range

1kΩ to 100MΩ

10kΩ to 1GΩ

100kΩ to 10GΩ

Resol

ution

10Ω

100Ω

1kΩ

Current Limit [3] 90 Days

25µA

2.5µA

250nA

23°C ± 5°C

0.2 +

50Ω

0.3 +

350Ω

0.4 +

3kΩ

One Year 23°C

± 5°C

0.33 + 90Ω

0.43 +

0.55 + 4.5kΩ

550Ω

[1] With Aperture set to 0.5 Sec, and within one hour from Zero (Relative control).

[2] Multiply “% of reading” by 1/Voltage Source for applied voltages below 1V

[3] Limit is reached when the test current exceeds the Current Limit, or it is below 0.04% of

this value.

2.4 AC Voltage Measurements

Input Characteristics

• Input Resistance 1 MΩ, shunted by < 300 pF, all ranges

• Max. Crest Factor 4 at Full Scale, increasing to 7 at Lowest Specified Voltage

• AC coupled Specified range: 10 Hz to 100 kHz

• Typical Settling time < 0.5 sec to within 0.1% of final value

• Typical Settling time Fast RMS < 0.05 sec to within 0.1% of final value

2.4.1 AC Voltage True RMS Measurement

Range Full Scale 7-½ Digits Lowest specified Voltage Resolution

240 mV 240.0000 mV 5 mV [1]

2.4 V 2.400000 V 10 mV

24 V 24.00000 V 100 mV

240 V 240.0000 V 1 V

330 V

[1] Between 5 mV and 10 mV, add 100 µV additional errors to the accuracy table below.

[2] Signal is limited to 8x10

32 kHz, or 8x10

6

330.0000 V 2 V

6

Volt Hz Product. For example, the largest frequency input at 250 V is

Volt x Hz.

100 ηV

1 µV

10 µV

100 µV

100 µV

Signametrics 12

AC Volts Accuracy with Fast RMS disabled (default).

With Fast RMS disabled, settling time to rated accuracy is within 0.5 s.

Accuracy ± (% of reading + Volts) [1]

Range Frequency 24 hours

23°C ± 1°C

240 mV

2.4 V

24 V

240 V

330 V

10 Hz - 20 Hz

20 Hz - 47 Hz

47 Hz - 10 kHz

10 kHz - 50 kHz

50 kHz - 100 kHz

10 Hz - 20 Hz 3.0 + 2 mV 3.1 + 2.2 mV 3.2 + 2.5 mV

20 Hz - 47 Hz 0.93 + 1.3 mV 0.96 + 1.5 mV 1.0 + 1.7 mV

47 Hz - 10 kHz 0.05 + 1 mV 0.055 + 1.1 mV 0.065 + 1.2 mV

10 kHz - 50 kHz 0.62 + 1.2 mV 0.65 + 1.3 mV 0.70 + 1.5 mV

50 kHz - 100 kHz 5.1 + 1.5 mV 5.2 + 1.7 mV 5.3 + 2 mV

10 Hz - 20 Hz 3.0 + 14 mV 3.1 + 16 mV 3.3 + 20 mV

20 Hz - 47 Hz 0.93 + 12 mV 0.96 + 14 mV 1.0 + 16 mV

47 Hz - 10 kHz 0.06 + 10 mV 0.065 + 11 mV 0.073 + 13 mV

10 kHz - 50 kHz 0.31 + 18 mV 0.33 + 21 mV 0.35 + 25 mV

50 kHz - 100 kHz 2.0 + 30 mV 2.2 + 35 mV 2.4 + 40 mV

10 Hz - 20 Hz 3.0 + 140 mV 3.1 + 160 mV 3.3 + 200 mV

20 Hz - 47 Hz 0.93 + 120 mV 0.96 + 130 mV 1.0 + 150 mV

47 Hz - 10 kHz 0.04 + 100 mV 0.045 + 110 mV 0.06 + 130 mV

10 kHz - 50 kHz 0.32 + 150 mV 0.4 + 170 mV 0.45 + 200 mV

50 kHz - 100 kHz 2.5 + 200 mV 2.8 + 240 mV 3.2 + 300 mV

10 Hz - 20 Hz 3.0 + 200 mV 3.1 + 160 mV 3.3 + 200 mV

20 Hz - 47 Hz 1.0 + 180 mV 1.1 + 200 mV 1.1 + 250 mV

47 Hz - 10 kHz 0.05 + 150 mV 0.07 + 200 mV 0.08 + 230 mV

10 kHz - 50 kHz 0.34 + 200 mV 0.45 + 250 mV 0.5 + 300 mV

50 kHz - 100 kHz 2.5 + 270 mV 2.8 + 350 mV 3.2 + 400 mV

3.0 + 350 µV 3.1 + 380 µV 3.2 + 430 µV

0.92 + 150 µV 0.93 + 170 µV 0.95 + 200 µV

0.13 + 100 µV 0.14 + 110 µV 0.15 + 120 µV

0.55 + 160 µV 0.6 + 200 µV 0.63 + 230 µV

5.3 + 350 µV 5.4 + 370 µV 5.6 + 400 µV

90 Days

23°C ± 5°C

One Year

23°C ± 5°C

ACV Noise Rejection Common Mode rejection, for 50 Hz or 60 Hz with 1 kΩ imbalance in either lead, is better

than 60 dB.

AC Volts Accuracy with Fast RMS enabled.

13 Signametrics

Fast RMS settles to rated accuracy within 50ms.

Accuracy ± (% of reading + Volts) [1]

Range Frequency 24 hours

23°C ± 1°C

240 mV

2.4 V

24 V

240 V

330 V

350 Hz - 800 Hz

800 Hz - 10 kHz

10 kHz - 50 kHz

50 kHz - 100 kHz

350 Hz - 800 Hz 0.93 + 1.3 mV 0.96 + 1.5 mV 1.0 + 1.7 mV

800 Hz - 10 kHz 0.068 + 1 mV 0.075 + 1.1 mV 0.08 + 1.2 mV

10 kHz - 50 kHz 0.62 + 1.2 mV 0.65 + 1.3 mV 0.70 + 1.5 mV

50 kHz - 100 kHz 5.1 + 1.5 mV 5.2 + 1.7 mV 5.3 + 2 mV

350 Hz - 800 Hz 0.93 + 12 mV 0.96 + 14 mV 1.0 + 16 mV

800 Hz - 10 kHz 0.065 + 10 mV 0.068 + 11 mV 0.073 + 13 mV

10 kHz - 50 kHz 0.31 + 18 mV 0.33 + 21 mV 0.35 + 25 mV

50 kHz - 100 kHz 2.0 + 30 mV 2.2 + 35 mV 2.4 + 40 mV

350 Hz - 800 Hz 0.93 + 120 mV 0.96 + 130 mV 1.0 + 150 mV

800 Hz - 10 kHz 0.062 + 100 mV 0.065 + 110 mV 0.08 + 130 mV

10 kHz - 50 kHz 0.32 + 150 mV 0.4 + 170 mV 0.45 + 200 mV

50 kHz - 100 kHz 2.5 + 200 mV 2.8 + 240 mV 3.2 + 300 mV

350 Hz - 800 Hz 1.0 + 180 mV 1.1 + 200 mV 1.1 + 250 mV

800 Hz - 10 kHz 0.065 + 150 mV 0.07 + 200 mV 0.08 + 230 mV

10 kHz - 50 kHz 0.34 + 200 mV 0.45 + 250 mV 0.5 + 300 mV

50 kHz - 100 kHz 2.5 + 270 mV 2.8 + 350 mV 3.2 + 400 mV

0.6 + 150 µV 0.65 + 170 µV 0.7 + 200 µV

0.13 + 100 µV 0.14 + 110 µV 0.15 + 120 µV

0.55 + 160 µV 0.6 + 200 µV 0.63 + 230 µV

5.3 + 350 µV 5.4 + 370 µV 5.6 + 400 µV

90 Days

23°C ± 5°C

One Year

23°C ± 5°C

AC Volts Accuracy with Slow RMS (default).

Settles to rated accuracy within 1X to 10X signal period, settable by user.

Range Frequency 24 hours

23°C ± 1°C

240 mV

2.4 V

24 V

240 V

330 V

0.5 Hz - 10 Hz

10 Hz - 20 Hz

20 Hz - 60 Hz

60 kHz - 200 Hz

0.5 Hz - 10 Hz 0.2 + 2 mV 0.25 + 2.2 mV 0.3 + 2.5 mV

10 Hz - 20 Hz 0.3 + 1.3 mV 0.35 + 1.5 mV 1.0 + 1.7 mV

20 Hz - 60 Hz 0.5 + 1 mV 0.55 + 1.1 mV 0.65 + 1.2 mV

60 kHz - 200 Hz 0.62 + 1.2 mV 0.65 + 1.3 mV 0.70 + 1.5 mV

0.5 Hz - 10 Hz 3.0 + 14 mV 3.1 + 16 mV 3.3 + 20 mV

10 Hz - 20 Hz 0.93 + 12 mV 0.96 + 14 mV 1.0 + 16 mV

20 Hz - 60 Hz 0.06 + 10 mV 0.065 + 11 mV 0.073 + 13 mV

60 kHz - 200 Hz 0.31 + 18 mV 0.33 + 21 mV 0.35 + 25 mV

0.5 Hz - 10 Hz 3.0 + 140 mV 3.1 + 160 mV 3.3 + 200 mV

10 Hz - 20 Hz 0.93 + 120 mV 0.96 + 130 mV 1.0 + 150 mV

20 Hz - 60 Hz 0.04 + 100 mV 0.045 + 110 mV 0.06 + 130 mV

60 kHz - 200 Hz 0.32 + 150 mV 0.4 + 170 mV 0.45 + 200 mV

0.5 Hz - 10 Hz 3.0 + 200 mV 3.1 + 160 mV 3.3 + 200 mV

10 Hz - 20 Hz 1.0 + 180 mV 1.1 + 200 mV 1.1 + 250 mV

20 Hz - 60 Hz 0.05 + 150 mV 0.07 + 200 mV 0.08 + 230 mV

60 kHz - 200 Hz 0.34 + 200 mV 0.45 + 250 mV 0.5 + 300 mV

0.25 + 100 µV 0.3 + 200 µV 0.35 + 300 µV

0.3 + 150 µV 0.35 + 170 µV 0.4 + 200 µV

0.13 + 100 µV 0.14 + 110 µV 0.15 + 120 µV

0.55 + 160 µV 0.6 + 200 µV 0.63 + 230 µV

2.4.2 AC Peak-to-Peak Measurement (SM2064)

• Measures the peak-to-peak value of a repetitive waveform.

Signametrics 14

90 Days

23°C ± 5°C

One Year

23°C ± 5°C

ACV

Range

240 mV 0.1 V 1.9 V 1 mV

2.4 V 1.0 V 16 V 10 mV 0.5 ± 40 mV

24 V 10 V 190 V 100 mV 0.5 ± 700 mV

240 V 100 V 850 V 1 V 0.55 ± 6 V

[1] Signal frequency range 30 Hz to 60 kHz.

2.4.3 AC Crest Factor Measurement (SM2064)

•

Measures the crest factor (CF) of a repetitive waveform

Lowest specified

input voltage

(Vp-p)

Full Scale

reading (Vp-p)

Resolution

Typical Accuracy 23°C ± 5°C

One Year [1]

0.5 ± 3 mV

ACV

Range

240 mV 0.1 V 1.9 V 0.01

2.4 V 1.0 V 16 V 0.01 2.1 ±0.1

24 V 10 V 190 V 0.01 2.0 ±0.1

240 V 100 V 700 V 0.01 2.0 ±0.1

330 V 100 V 850 V 0.01 2.0 ±0.1

[1] Crest factor measurement requires signal frequency of 30 Hz to 60 kHz.

2.4.4 AC Median Value Measurement (SM2064)

• Measures the mid-point between the positive and negative peaks of a repetitive waveform

• Used to determine the Threshold DAC setting for optimal frequency and timing measurements

ACV

Range

240 mV 0.08 V

2.4 V 0.80 V

24 V 8 V

240 V 80 V

330 V 80 V

[1] Median measurements require a repetitive signal with frequency range of 30 Hz to 30 KHz.

Lowest specified

input voltage

(Vp-p)

Lowest specified input

voltage (Vp-p)

Highest specified input

voltages (Vp-p)

Full Scale

reading

±0.95 V

±9.5 V

±95.0 V

±350.0 V

±350.0 V

Resolution

1 mV

10 mV 3% ±160 mV

100 mV 3% ±1.4 V

1 V 3% ±12 V

1 V 3% ±12 V

Resolution

Typical Accuracy 23°C ± 5°C

One Year [1]

2.2 ±0.3

Typical Accuracy 23°C ± 5°C One Year [1]

2.0% ±17 mV

2.5 AC Current Measurement, True RMS

15 Signametrics

Input Characteristics

• Crest Factor 4 at Full Scale, increasing to 10 at Lowest Specified Current

• Protected with 2.5 A

Fast Blow fuse

Range Full Scale 6 1/2 Digits Lowest Specified

Current

2.4 mA 2.400000 mA

24 mA 24.00000 mA

240 mA 240.0000 mA 3 mA 55mV 100 nA

2.4 A 2.400000 A 30 mA 520mV 1 uA

60 µA

300 µA

Accuracy ± (% of reading + Amps)

Range Frequency [1] 24 hours

23°C ± 1°C

2.4 mA

24 mA

240 mA

2.4 A

10 Hz - 20 Hz

20 Hz - 47 Hz

47 Hz - 1 kHz

1 kHz - 10 kHz

10 Hz - 20 Hz

20 Hz - 47 Hz

47 Hz - 1 kHz

1 kHz - 10 kHz

10 Hz - 20 Hz

20 Hz - 47 Hz

47 Hz - 1 kHz

1 kHz - 10 kHz

10 Hz - 20 Hz 1.8 + 4 mA 2.5 + 4.5 mA 2.7 + 5 mA

20 Hz - 47 Hz 0.66 + 4 mA 0.8 + 6 mA 0.9 + 6 mA

47 Hz - 1 kHz 0.3 + 3.8mA 0.33 + 3.8 mA 0.35 + 4 mA

1 kHz - 10 kHz 0.4 + 4mA 0.45 + 4.5 mA 0.5 + 5 mA

3.8 + 4 µA 2.7 + 4 µA 2.9 + 4 µA

0.9 + 4 µA 0.9 + 4 µA 1.0 + 4 µA

0.04 + 1.5 µA 0.08 + 3 µA 0.12 + 4 µA

0.12 + 4 µA 0.14 + 4 µA 0.22 + 4 µA

1.8 + 30 µA 2.6 + 30 µA 2.8 + 30 µA

0.6 + 30 µA 0.9 + 30 µA 1.0 + 30 µA

0.07 + 10 µA 0.15 + 20 µA 0.16 + 30 µA

0.21 + 30 µA 0.3 + 40 µA 0.4 + 40 µA

1.8 + 400 µA 2.7 + 400 µA 2.8 + 400 µA

0.6 + 400 µA 0.9 + 400 µA 1.0 + 400 µA

0.1 + 100 µA 0.17 + 180 µA 0.2 + 220 µA

0.3 + 300 µA 0.35 + 350 µA 0.4 + 400 µA

[1] All AC Current ranges have typical measurement capability of at least 20 kHz.

Maximum Burden

Voltage (RMS)

25mV 1 nA

250mV 10 nA

Resolution

90 Days

23°C ± 10°C

One Year

23°C ± 10°C

2.6 Leakage Measurement (SM2064)

Characteristics

µ

• Burden Voltage: < 100

• Test Voltage: Adjustable between -10V to +10V in 5mV steps

Accuracy ± (% of reading + Amps) [1]

Range Full Scale

6-½ Digits

240 ηA 240.0000 ηA

2.4 µA 2.400000 µA

24 µA 24.00000 µA

[1] With Aperture set to 0.5 Sec, and within one hour from Zero (Relative control).

V

Resolution 24 hours

23°C ± 5°C

0.1 pA 0.15 + 50pA 0.2 + 65pA 0.17 + 100pA

1 pA 0.1 + 350pA 0.15 + 500pA 0.2 + 600pA

10 pA 0.08 + 3nA 0.12 + 4nA 0.18 + 2nA

90 Days

23°C ± 5°C

One Year 23°C

± 5°C

2.7 RTD Temperature Measurement (SM2064)

Signametrics 16

• Ro: Variable from 10

Ω

to 10 kΩ

• Measurement Method: 4-Wire

• Temperature units: Selectable

o

C or oF

RTD Type

pt385, pt3911,

pt3916, pt3926

pt385, pt3911,

pt3916, pt3926

Cu (Copper)

Cu (Copper)

Ro (Ω)

100, 200 Ω 0.01°C -150 to 650°C ±0.06°C

500, 1 kΩ 0.01°C -150 to 650°C ±0.03°C

Less than 12 Ω 0.01°C -100 to 200°C ±0.18°C for temperatures ≤ 20°C, ±0.05°C

Higher than 90 Ω 0.01°C -100 to 200°C ±0.10°C for temperatures ≤ 20°C, ±0.05°C

[1] With Aperture of 0.5s and higher, using a 4-wire RTD. Measurement accuracy does not include

RTD probe error.

Resolution Temperature

range

Temperature Accuracy 23°C ± 5°C [1]

One Year

otherwise

otherwise

2.8 Thermocouple Temperature Measurement (SM2064)

• Cold Junction Compensation: By Sensor measurement or S/W setting.

• Cold Junction Temperature range: 0

o

C

• Cold Junction Sensor: Use SMX40T or SM40T Isothermal unit, or define sensor equation

to 50

o

C

• Isothermal Block compatibility: SM4022, SM4042, SMX4032, SM40T, SMX40T

• Temperature units: Selectable

o

C or oF

TC Type Resolution Maximum Temperature

[2]

B

E

J

K

N

R

S

T

0.01°C 2200°C ±0.38 °C

0.01°C 1200°C ±0.035 °C

0.01°C 2000°C ±0.06 °C

0.01°C 3000°C ±0.07 °C

0.01°C 3000°C ±0.10 °C

0.01°C 2700°C ±0.25 °C

0.01°C 3500°C ±0.35 °C

0.01°C 550°C ±0.06 °C

[1] With Aperture of 0.5s and higher. Measurement accuracy does not include Thermocouple error.

[2] DMM Linearization temperature range may be greater than that of the Thermocouple device.

Temperature Accuracy 23°C ± 5°C [1]

One Year

2.9 Additional Component Measurement Capability

2.9.1 Diode Characterization

• Available DC current values 100 ηA, 1 µA, 10 µA, 100 µA and 1 mA.

• SM2064 add variable current of 10 ηA to 12.5 mA

• Typical Current Value Uncertainty 1%

• Typical Voltage Value Uncertainty 0.02%

•

Maximum diode voltage compliance 4 V

2.9.2 Capacitance, Ramp Method (SM2064)

Accuracy ± (% of reading + Farads) [1]

17 Signametrics

Range Full Scale

Reading

1,200 pF 1,199.9 pF 0.1 pF 1.5 ± 0.25 pF

12 ηF 11.999 ηF

120 ηF 119.99 ηF

1.2 µF 1.1999 µF

12 µF 11.999 µF 1 ηF

120 µF 119.99 µF 10 ηF

1.2 mF 1.1999 mF

12 mF 50.000 mF

Resolution One Year

23°C ± 5°C

1 pF 1.2 ± 5 pF

10 pF 1.0

100 pF 1.0

100 ηF

1 µF

1.0

1.0

1.2

2

[1] Within one hour of zero, using Relative control. Accuracy is specified for values higher than 5% of the selected

range with the exception of the 1,200 pF range.

This Measurement is independent of set Aperture and Read Interval. If desired, the DMMSetCapsAveSamp()

function may be used to control measurement parameters. It is provided

the application, trading off accuracy for speed.

Measurement time will vary as function of the set parameters, selected range and measured capacitance. The following are

measurement times associated with the default parameters, as range is selected.

Range Input Measurement Time Measurement Rate (rps)

1,200 pF 5% of Scale

1,200 pF Full Scale

12 ηF

12 ηF

120 ηF

120 ηF

1.2 µF

1.2 µF

12 µF

12 µF

120 µF

120 µF

1.2 mF 5% of Scale

1.2 mF Full Scale

12 mF 5% of Scale

12 mF Full Scale

5% of Scale

Full Scale

5% of Scale

Full Scale

5% of Scale

Full Scale

5% of Scale

Full Scale

5% of Scale

Full Scale

19.5 ms 51.3

52.3 ms 19.1

70.0 ms 14.3

118ms 8.5

8.9 ms 112.4

127 ms 7.9

15.6 ms 64.1

175 ms 5.7

14.1 ms 70.9

480 ms 2.1

17.3 ms 57.8

50.3 ms 19.9

52.6 ms 19.0

151.5 ms 6.6

52.8 ms 18.9

170 ms 5.9

means to fine tune the measurement timing for

Signametrics 18

2.9.3 Capacitance, In-Circuit Method (SM2064)

• Adjustable Peak Voltages Stimulus 100mV to 1.3V

• Minimum Parallel Load Resistance 100Ω

Accuracy ± (% of reading + Farads) [1]

Range Full Scale

3-½ Digits

24 ηF 23.99 ηF

240 ηF 239.9 ηF

2.4 µF 2.399 µF

24 µF 23.99 µF 10 ηF

240 µF 239.9 µF 100 ηF

2.4 mF 2.399 mF

24 mF 23.99 mF

Resolution One Year

23°C ± 5°C [2]

10 pF 2.7 ± 100 pF

100 pF 2.5 ± 500 pF

1000 pF

1 µF

10 µF

2.5 ± 5 ηF

[1] Within one hour of zero, using Relative control, and Caps Open-Cal operation

η

[2] Accuracy is specified for values higher than 5% of the selected range with the exception of the 2.4

F range.

Capacitance Measurement time is independent of set Aperture and Read Interval. It depends on range, and

capacitance

.

2.9.4 Inductance Measurement (SM2064)

Range Test frequency Full Scale

4 ½ Digits

24 µH

240 µH

2.4 mH 4 kHz 3.3000 mH

24 mH 1.5 kHz 33.000 mH

240 mH 1 kHz 330.00 mH

2.4 H 100 Hz 3.3000 H

75 kHz

50 kHz

33.000 µH 1 ηH 3.0% + 500 ηH

330.00 µH 10 ηH 2.0% + 3 µH

[1] Within one hour of zero, and Open Terminal Calibration.

[2] Accuracy is specified for values greater than 5% of the selected range.

Resolution

100 ηH 1.5% + 25 µH

1 µH 1.5% + 200 µH

10 µH

100 µH

Accuracy 23°C ± 5°C

One Year [2]

2.5 + 3 mH

3 + 35 mH

2.10 Time Measurements

2.10.1 Threshold DAC

• The Threshold DAC is used for selecting a detection level, providing optimal frequency and

timing measurements even at extreme duty cycle values.

± (% of setting + volts)

Selected VAC

range [1]

240 mV -1.0 V to +1.0 V 0.5 mV 1.900 V 0.2% + 4 mV

2.4 V -10.0 V to +10.0 V 5.0 mV 19.00 V 0.2% + 40 mV

24 V -100.0 V to 100.0 V 50 mV 190.0 V 0.2% + 0.4 V

240 V -400 V to 400 V 500 V 850.0 V 0.2% + 4 V

[1] This table should be used in conjunction with the AC volts section above.

Threshold range (DC

level)

Threshold

DAC

resolution

Highest allowed input

Vp-p

Typical one year setting

uncertainty

19 Signametrics

2.10.2 Frequency and Period Measurement

ACV Mode

•

Input Impedance 1 MΩ with < 300 pF

Frequency Range 2 Hz - 100 Hz 100 Hz-1 kHz 1 kHz-10 kHz 10 kHz-100 kHz 100 kHz-300 kHz

Resolution 1 mHz 10 mHz 100 mHz 1 Hz 1 Hz

Uncertainty is ±0.002% of

reading ± adder shown

Input Signal Range [1] 10% - 200%

[

1] Input RMS voltage required for a valid reading. Do not exceed 250 V RMS input. For example, 10% -200%

4 mHz 20 mHz 200 mHz 2 Hz 5 Hz

of range

of range indicates that in the 240 mVAC range, the input voltage should be 24 mV to 660 mV RMS.

ACI Mode

•

Input Impedance 10 Ω in the 3 mA and 30 mA ranges, 0.1 Ω in the 330 mA and 2.5 A ranges.

Frequency Range 2 Hz - 100 Hz 100 Hz-1 kHz 1 kHz-10 kHz 10 kHz-500 kHz

Resolution 1 mHz 10 mHz 100 mHz 1 Hz

Uncertainty 0.01% ±4 mHz 0.01% ±20 mHz 0.01% ±200 mHz 0.01% ±2 Hz

Input Signal Range,

2.4 mA, 240mA Ranges

[1]

Input Signal Range,

24 mA, 2.4 A ranges

10% -500%

of range

50% -100%

of range

10% - 200%

of range

10% - 500%

of range

50% - 100%

of range

10% -200%

of range

10% -500%

50% - 100%

of range

of range

10% - 200%

of range

45% -200%

of range

10% - 500%

of range

50% - 100%

of range

[1] Input current required to give a valid reading. For example, 10% -500% of range indicates that in the 3.3 mA

range, the input current should be 0.33 mA to 16.5 mA.

2.10.3 Duty Cycle Measurement

Frequency Range 2 Hz to 100 Hz 100 Hz to 1 kHz 1 kHz to 10 kHz 10 kHz to 100 kHz

Resolution 0.02% 0.2% 2% 20%

Typical Uncertainty is

±0.03% of reading ±

adder shown

Full scale reading 100.00 % 100.00 % 100.00 % 100.00 %

0.03% 0.3% 3% 20%

2.10.4 Pulse Width

Polarity Frequency range Resolution Width range Typical

Positive or negative pulse

widths

2 Hz to 100 kHz

1 µs 2 µs to 1 s 0.01 +/- 4 µs

± (% of reading + sec)

Uncertainty

Signametrics 20

2.10.5 Totalizer

(s)

• Active edge polarity: Positive or negative transition

• Maximum count: 10^9

•

Allowed rate: 1 to 30,000 events per second

Uses Threshold DAC

•

2.11 Trigger Functions

2.11.1 External Hardware Trigger (at DIN-7 connector)

Trigger Input voltage level range +3 V to +15 V activates the trigger.

Trigger Pulse Width

Minimum trigger input current 1 mA

Internal Reading Buffer Circular; 80 or 120 readings depending on resolution.

Isolation of trigger input ±50 V from analog DMM inputs, and from chassis

Minimum = 1/Aperture + 50µS

earth ground.

2.11.2 Analog Threshold Trigger

• Trigger point: Selectable positive or negative transition of set threshold.

• Buffer type: Circular

• Captures up to 120 post-trigger readings for apertures

• Captures up to 80 post-trigger readings for apertures > 625uSec.

•

Aperture range: 160ms to 625

•

Read Interval

• User selects number of post-trigger readings.

• The number of pre-trigger readings: buffer size – post-trigger count.

• The number of cycles the circular filled, and the trigger point are retrievable.

range

: 1/Aperture to 65ms

µS (to 2.5µS with SM2064)

< 625uSec.

2.11.3 Delayed Hardware Trigger

This function allows time for the signal to settle after a trigger has occurred.

It allows readings to be delayed up to 65mSec with 1

It allows readings to be delayed up to 1s with 2

µs resolutions.

µSec resolution

.

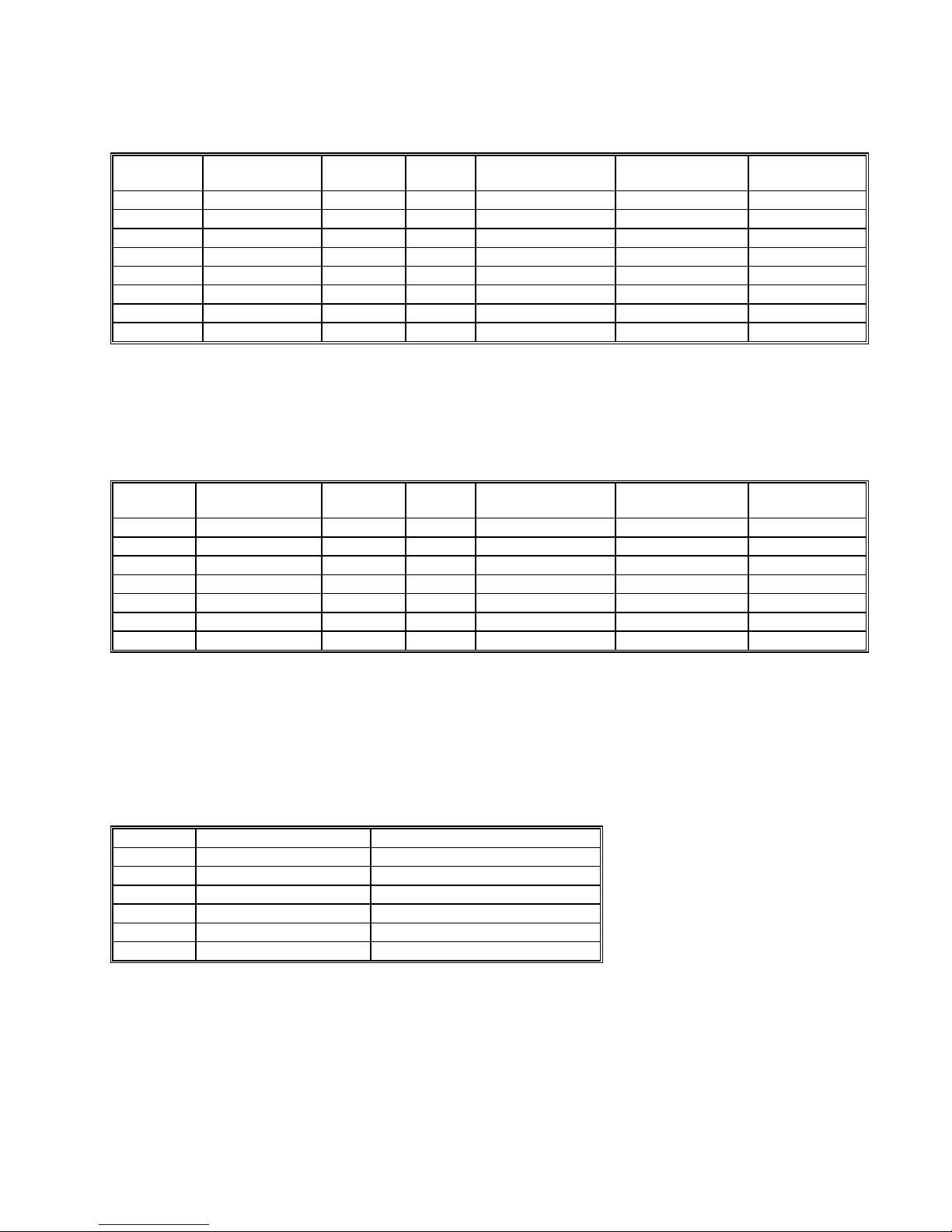

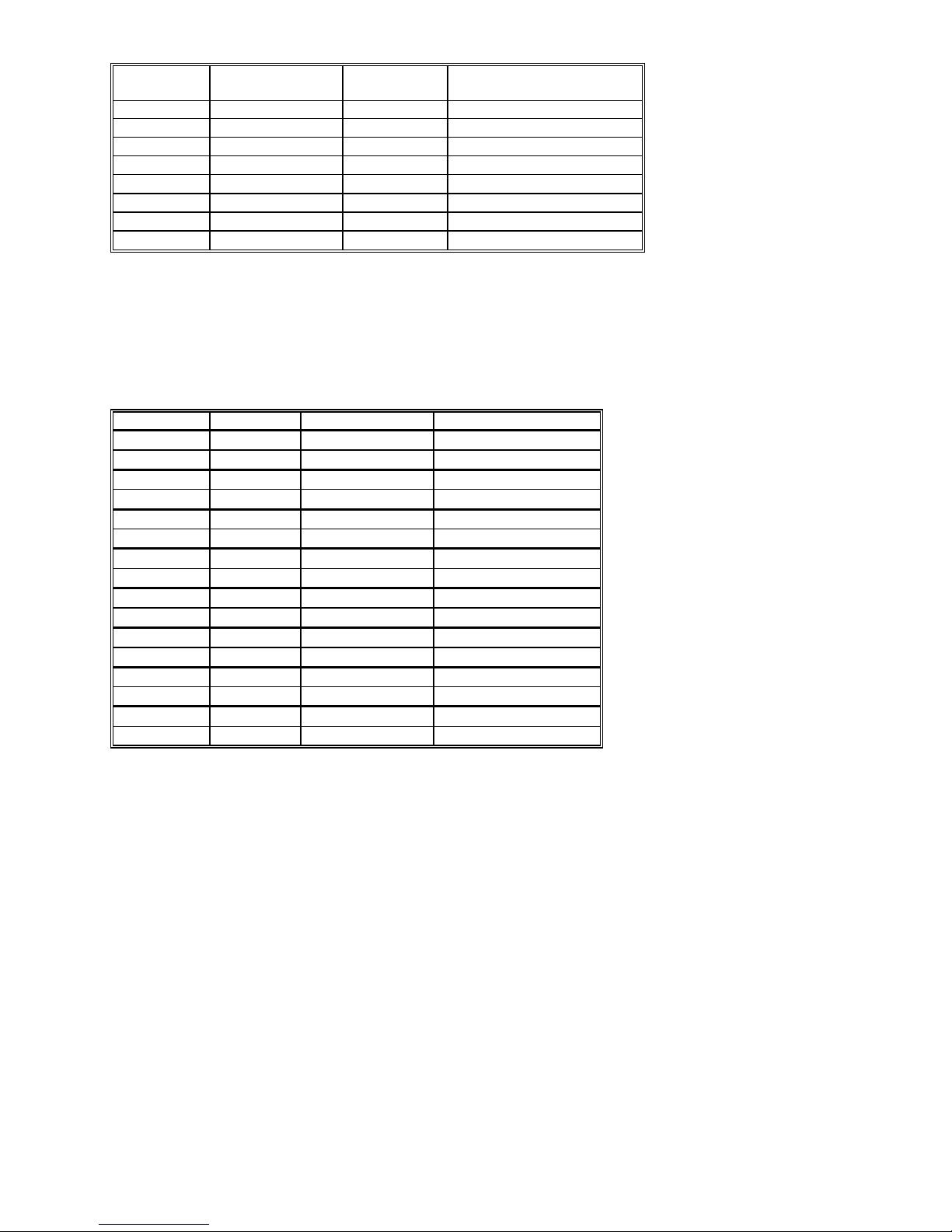

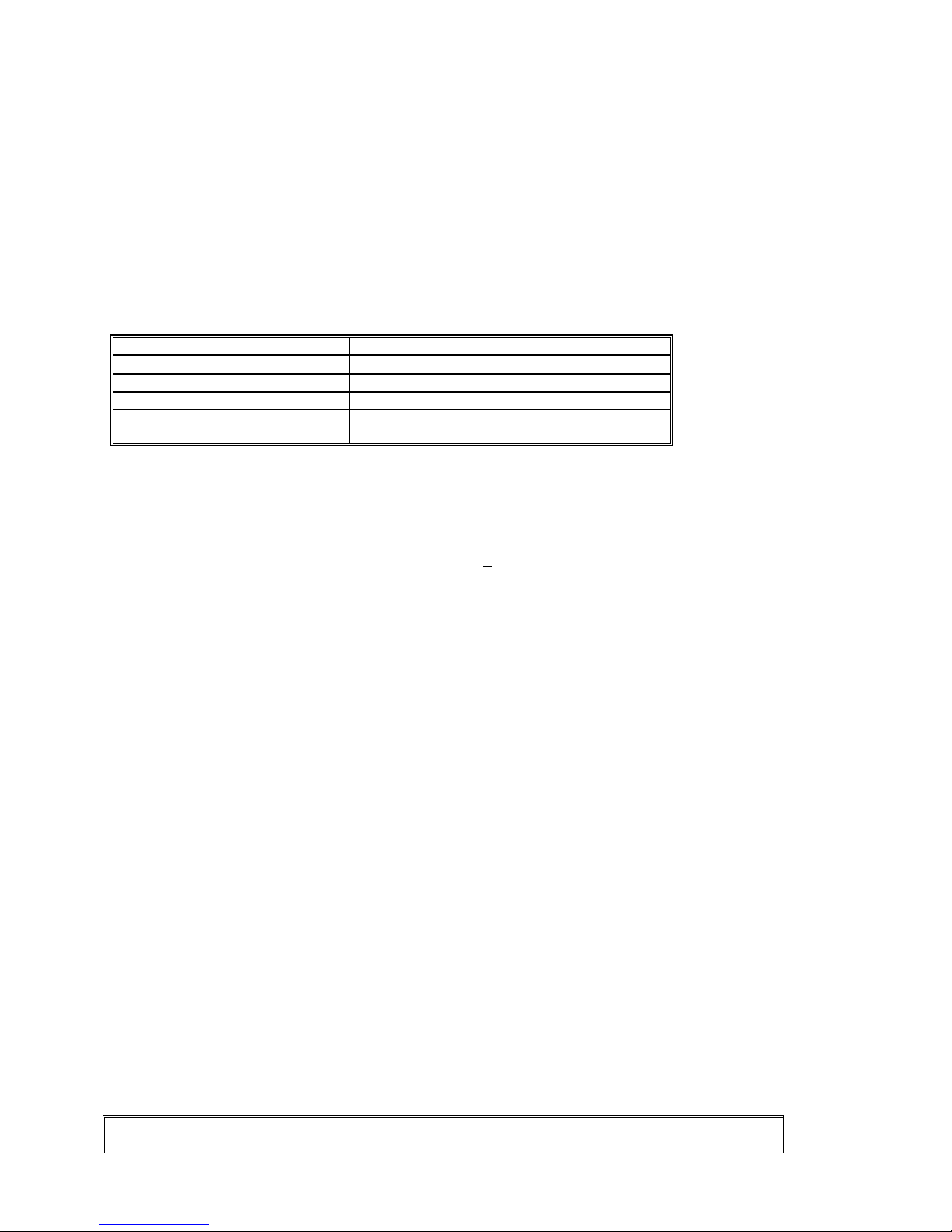

2.12 Measurement Aperture and Read Interval

Both Aperture and The Read Interval may be set. The range of values depend on the DMM model and its

mode of operation. For example, when using the internal buffer such as in External Trigger mode, the

Read Interval can be set smaller than in Command/Response operation. The time involved in processing

the measurement command and the post processing and transmission of the measurement results

constitute an overhead, which limits the minimum Read Interval to a value that is greater than the

Aperture. Setting it to zero (default) results in the fastest measurement rates at the selected Aperture. The

faster SM2064 has lower overhead and therefore a shorter minimum Read Interval than the SM2060. For

instance, with Aperture set to 625us and Read Interval set to zero, in command/response operation the

SM2060 measurement rate is about 1,090/s while that of the SM2064 is 1,370/s. This indicates overhead

of about 300µs for the SM2060 and 100µs for the SM2064.

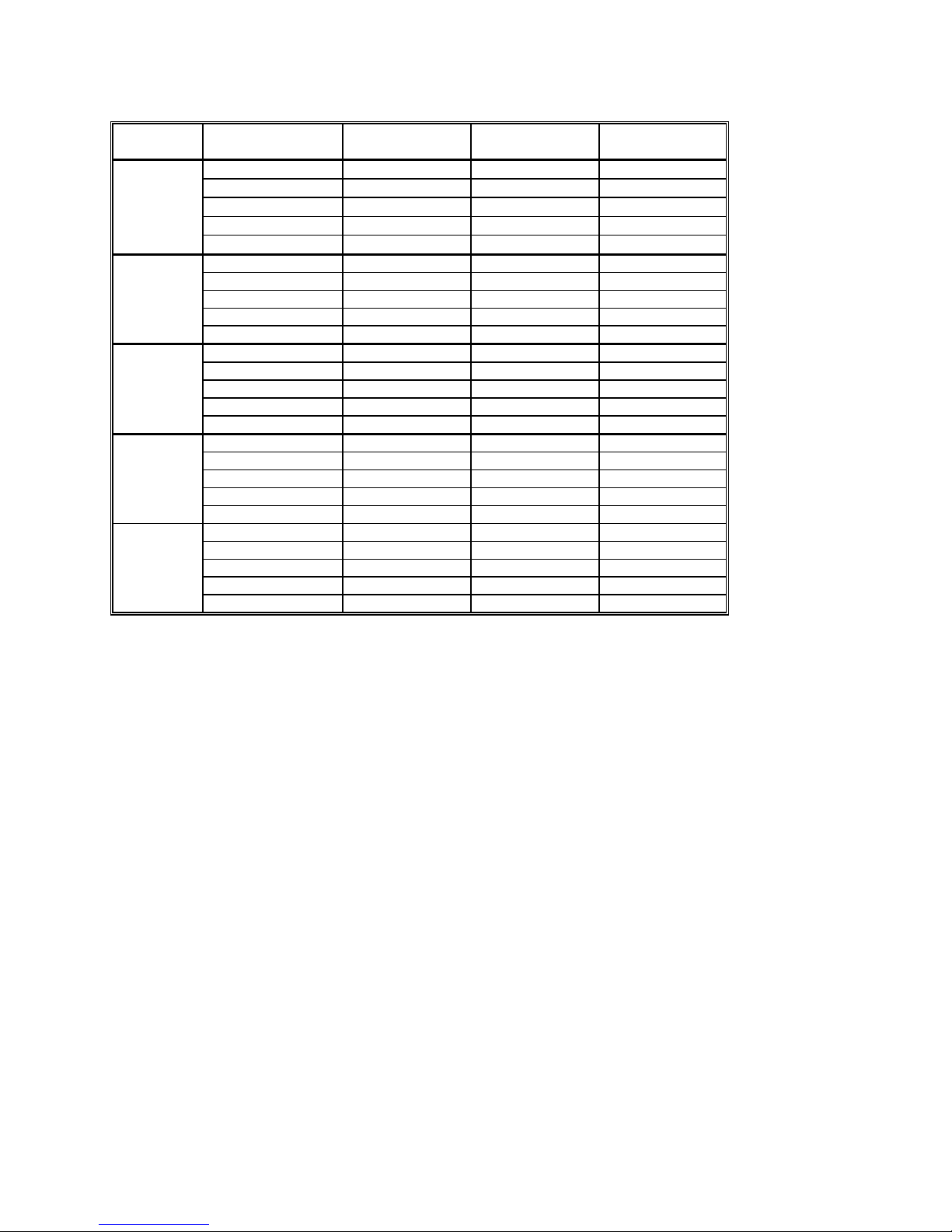

The SM2064 has 31 A/D apertures available, ranging from 5 Seconds to 2.5µS

available measurement apertures and the corresponding minimum read intervals and measurement rates.

Power Line Rejection Command/Response

mode min. Read

21 Signametrics

. The following table contains all

H/W Trigger mode min. Read

Interval

/ max meas. Rate

Interval(s) / max meas.

(Hz)

rate(Hz)

Aperture 60Hz 50Hz 400Hz

5.1200s [1]

5.0666s [1]

√ √ √

√

2.08s [1]

2.0s [1]

1.06666s [1]

√ √ √

√

960ms [1]

533.33ms [1]

√

480ms [1]

266.666ms [1]

160.0ms

133.33ms

√

√ √ √

√

80.00ms

66.6667ms

√

40.00ms

33.333ms

√

20.00ms

16.6667ms

√

5.0677s / 0.2 N/A

√ √

1.067s / 1 N/A

√ √

533.6ms / 2 N/A

√ √

268ms / 4 N/A

134ms / 8 133.5 ms / 8

√ √

67.2ms / 15 66.713 ms / 15

√ √

33.643ms / 29.72 33.38 ms / 30

√ √

16.77ms / 59.6 16.89 ms / 59

5.121s / 0.2 N/A

2.081s / 0.5 N/A

2.001s / 0.5 N/A

0.9605s / 1 N/A

480.2ms / 2 N/A

166ms / 6 160.3 ms / 6

80.4ms / 13 80.2 ms / 13

40.4ms / 25 40.32 ms / 24.8

20.098ms / 49.76 20.33 ms / 50

10ms 10.094ms / 99 10.25 ms / 97

8.333ms 8.422ms / 119 8.503 ms / 115

5ms 5.109ms / 195 5.187 ms / 185

4.16667ms 4.265ms / 234 4.274 ms / 220

2.5ms 2.598ms / 385 2.614 ms / 350

2.0833ms 2.177ms / 458 2.216 ms / 410

1.25ms 1.344ms / 744 1.380 ms / 625

1.0417ms 1.133ms / 880 1.158 ms / 864

625µS

520.83µS

312.5µS

260.42µS

130.21µS

2.5µS

719µs / 1,390 728 µs / 1,370

617µs / 1,625 622 µs / 1,610

410µs / 2,445 414 µs / 2,445

355µs / 2,825 358 µs / 2,825

223µs / 4,475 217 µs / 4,660

47µs / 21,600 45 µs / 22,200

[1] Not available with any of the Triggered modes.

Signametrics 22

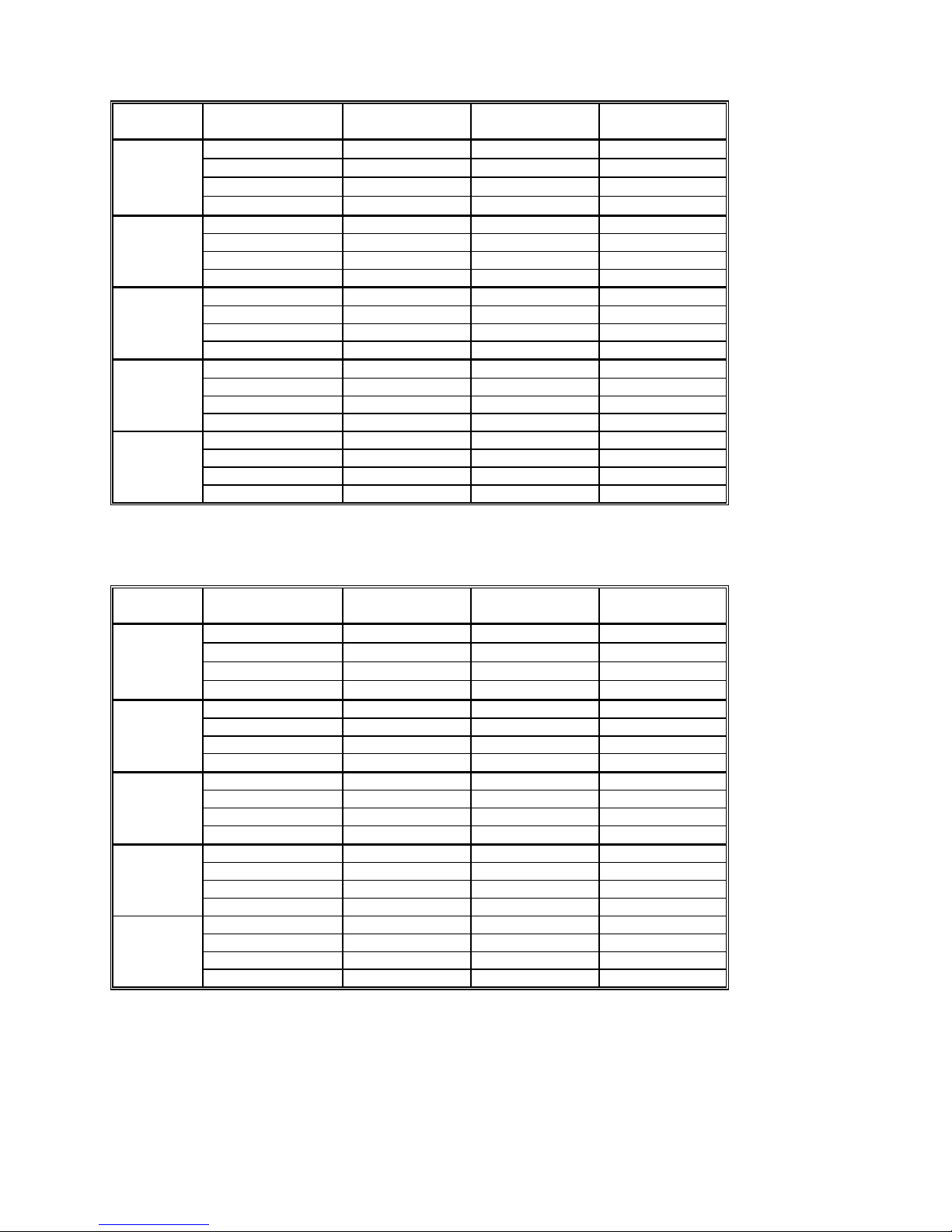

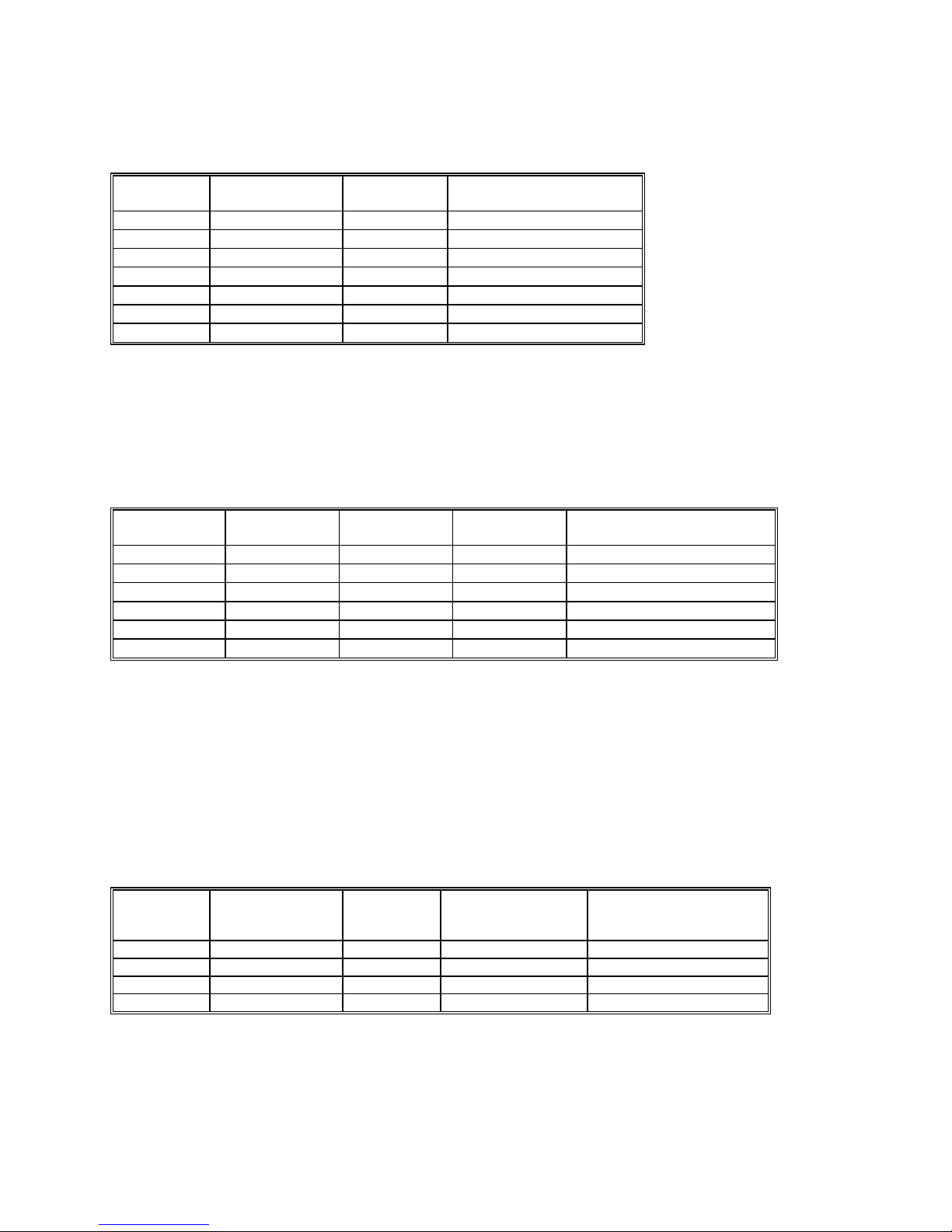

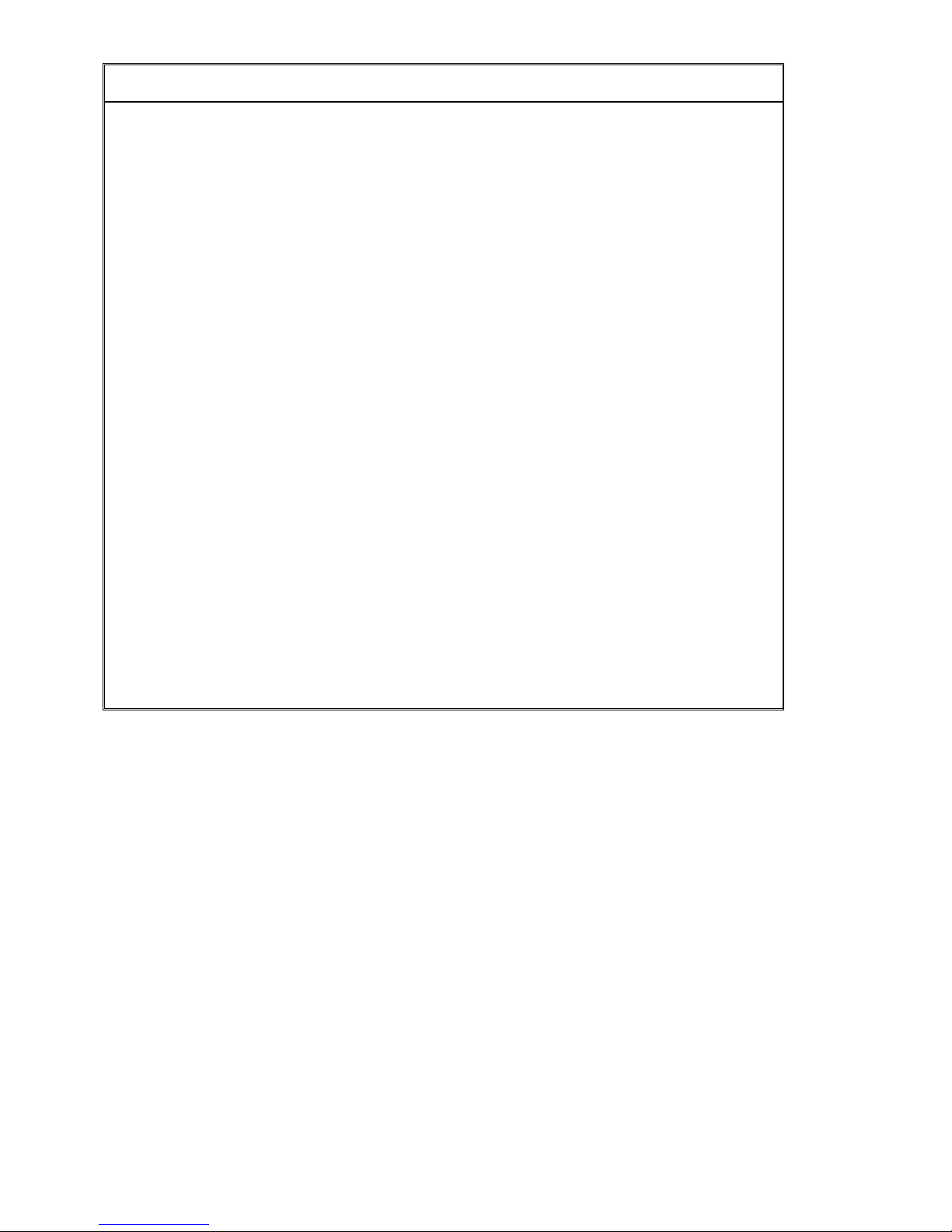

The SM2060 has are 26 A/D apertures available, ranging from 5 Seconds to 625uSec. The following

table contains all available measurement apertures corresponding minimum read intervals and

measurement rates.

Power Line Rejection Command/Response

mode min. Read

Interval(s) / max meas.

rate(Hz)

Aperture 60Hz 50Hz 400Hz

5.1200s [1]

5.0666s [1]

2.08s [1]

2.0s [1]

1.06666s [1]

960ms [1]

533.33ms [1]

480ms [1]

266.666ms [1]

160.0ms

133.33ms

80.00ms

66.6667ms

40.00ms

33.333ms

20.00ms

16.6667ms

10ms 10.36ms / 97 10.25 ms / 97

8.333ms 8.68ms / 115 8.503 ms / 115

5ms 5.36ms / 185 5.187 ms / 185

4.16667ms 4.52ms / 220 4.274 ms / 220

2.5ms 2.86ms / 350 2.614 ms / 350

2.0833ms 2.44ms / 410 2.216 ms / 410

1.25ms 1.6ms / 625 1.380 ms / 625

1.0417ms 1.39ms / 719 1.158 ms / 864

625µS

[1] Not available with any of the Triggered modes.

Precise control of the measurement timing and line frequency rejection can be accomplished by controlling the Read

Interval and Aperture. Line rejection is dictated by the Aperture, and the duration of measurement is controlled with

Read Interval

Read Interval can be programmed in

√ √ √

√

√ √ √

√

√

√

√ √ √

√

√

√

√

5.0677s / 0.2 N/A

√ √

1.067s / 1 N/A

√ √

533.6ms / 2 N/A

√ √

268ms / 4 N/A

134ms / 8 133.5 ms / 8

√ √

67.2ms / 15 66.713 ms / 15

√ √

33.7ms / 30 33.38 ms / 30

√ √

16.9ms / 59 16.89 ms / 59

.

µs increments for values up to 65ms

5.121s / 0.2 N/A

2.081s / 0.5 N/A

2.001s / 0.5 N/A

0.9605s / 1 N/A

480.2ms / 2 N/A

166ms / 6 160.3 ms / 6

80.4ms / 13 80.2 ms / 13

40.4ms / 25 40.32 ms / 24.8

20.35ms / 50 20.33 ms / 50

917µs / 1,090 728 µs / 1,370

H/W Trigger mode min. Read

Interval(s) / max meas. Rate

(Hz)

, and in 20µs increments to 1 second.

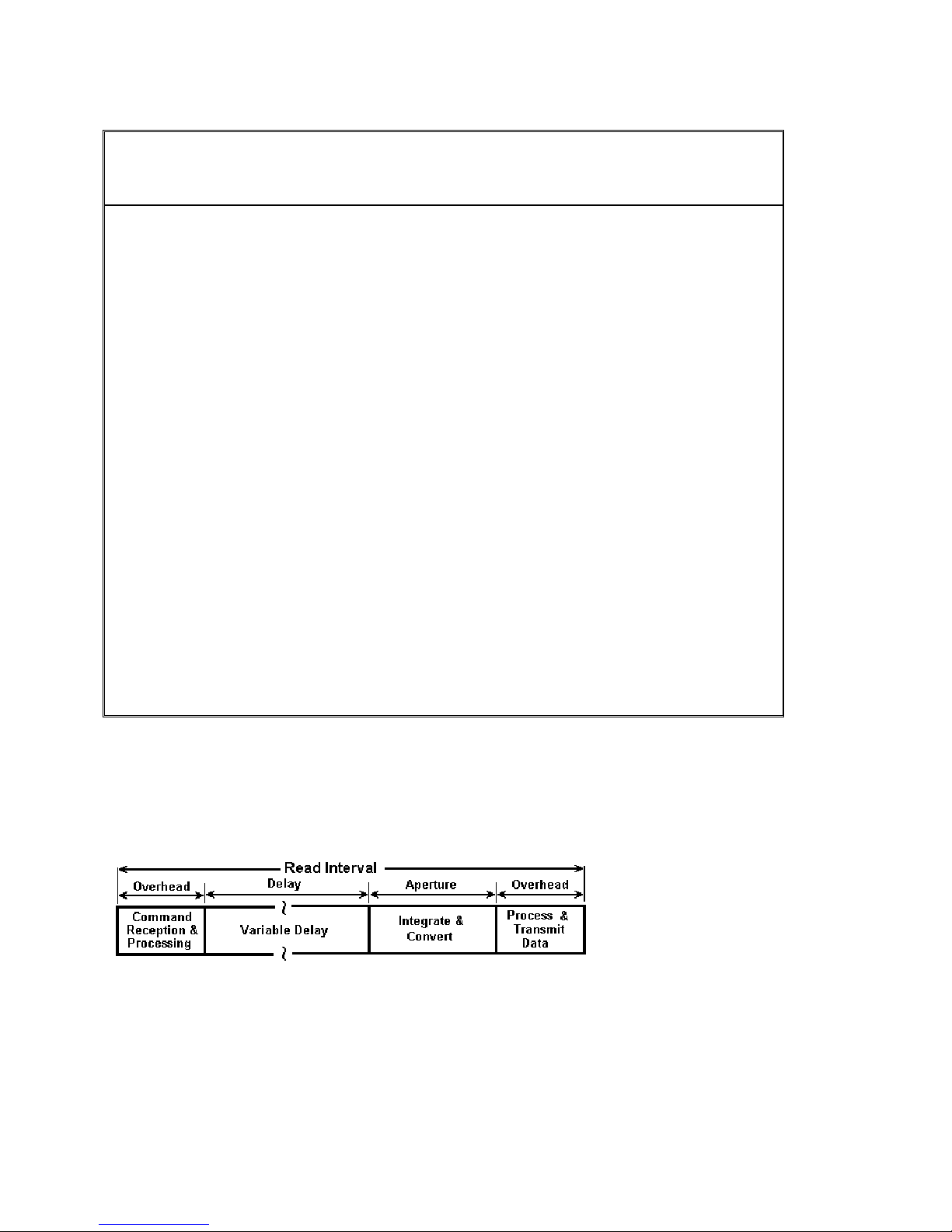

Figure 2-1: Time frame of a single measurement.

.13 Source Functions (SMX2064)

2

23 Signametrics

•• Isolated to 300 V DC from the Chassis

Current can be paralleled with multiple SM

•

Voltage can be pu

t in series with multiple SMX2064s

X2064s

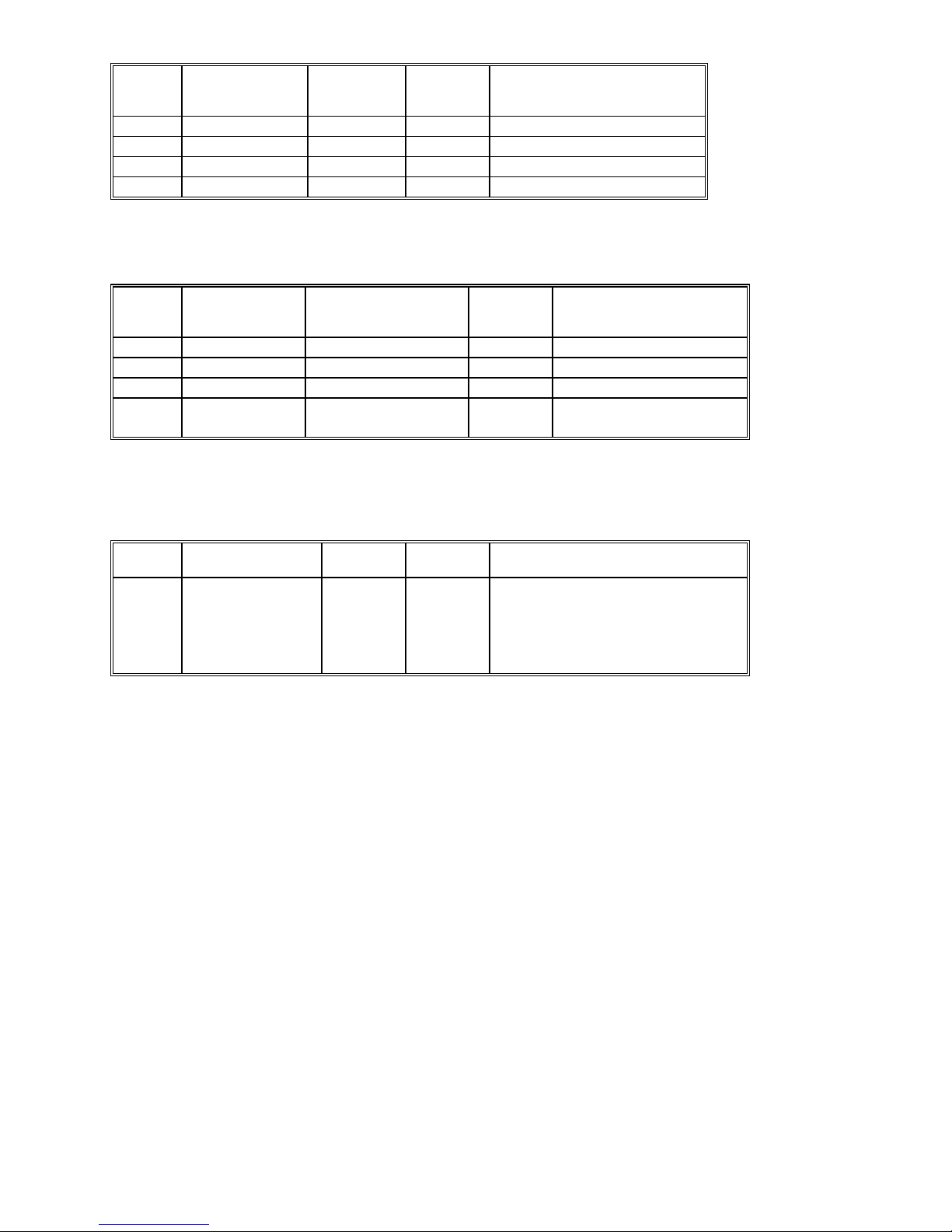

2.13.1 D

Output Voltage range -10.000 V to +10.000 V

Typical Current source/sink at 5V output 5 mA 5 mA

DAC resolution 18 bits 12 bits

Accuracy 23°C ± 10°C One Year 0.015% ± 350 µV

Typical settling time 3 S (rate set to 2/s) 1 ms

Typical source resistance

[1] An Aperture 3ms or higher is required for the clos e. set to 13 ed loop mod

C Voltage Source

Parameter Closed Loop [1] Open Loop

1.0% ± 35 mV

250 Ω

2.13.2 AC Voltage Sourc

The AC Voltage source has two ranges. 900 m

generating 5 mV t 9.3V while 0 o n generate 300mV to 7.2V RMS.

Parameter Specification

Ranges 900mV and 8V

Output Voltage, sine wave 30mV to 7.2 V RMS (0.14 to 20.0V peak-to-peak)

DAC resolution 12 bits

Typical Current Drive at 3.5V RMS 3 mA RMS

Accuracy 18 C to 2

Typical settling time (f-out > 40 Hz) 0.5 s

Typical source resistance

Frequency range / resolution 10 Hz to 100 kHz / 10 mHz

SFDR (spurious free dynamic range) 60dBc

THD (total harmonic distortion) 59dBc

Frequency stability 100 ppm ± 10 mHz

[1] 166ms er Aperture is for prop ed loop mo

°

8°C One Yea

or high required er clos de.

the higher range ca

r

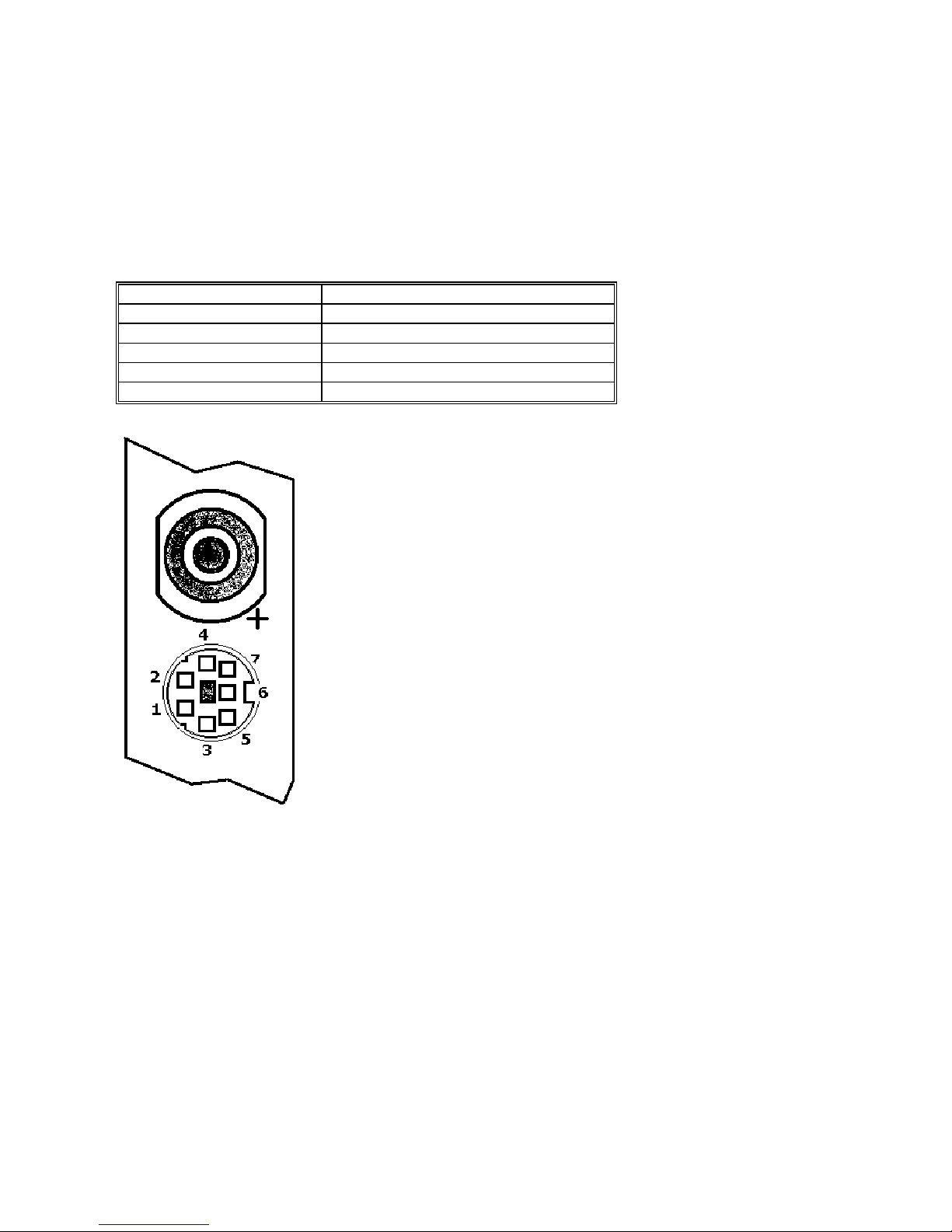

e