Signal Dynamics Switch Cubes, LINX User Manual

1

Contents

Introduction Page 2

Instrumentation Page 7

Operation / Function Page 9

Programming Page 18

Appendix Page 21

All Rights Reserved. Reproduction by any means, electronic or mechanical

including photocopying, recording or by any information storage and retrieval

system or translation in whole or in part is not permitted without written

authorization from Signal Dynamics Corporation.

Copyright © Signal Dynamics Corporation.

Installation Page 3

Wire Diagram Page 22

Warranty Page 24

2

LINX™ Network Bus Electrical System

System Overview:

Simpler, easier installation and comprehensive rider information; these

are the some of the basic advantages of the LINX™ Network Bus

Wiring System. As you read this manual you will realize the significant

improvements and advanced features that this system provides over

conventional wiring harnesses. Additionally, updates, knowledge base

and Q&A for this system will be updated and posted on the LINX™

web-site as they occur at www.SignalDynamics.com/LINX.

How does LINX™ work?

LINX™ is a serial data communication network for connecting the

various electrical functions of the motorcycle over a single network

cable, eliminating complex electrical wiring, confusion and errors while

wiring or troubleshooting the electrical system.

LINX™ System

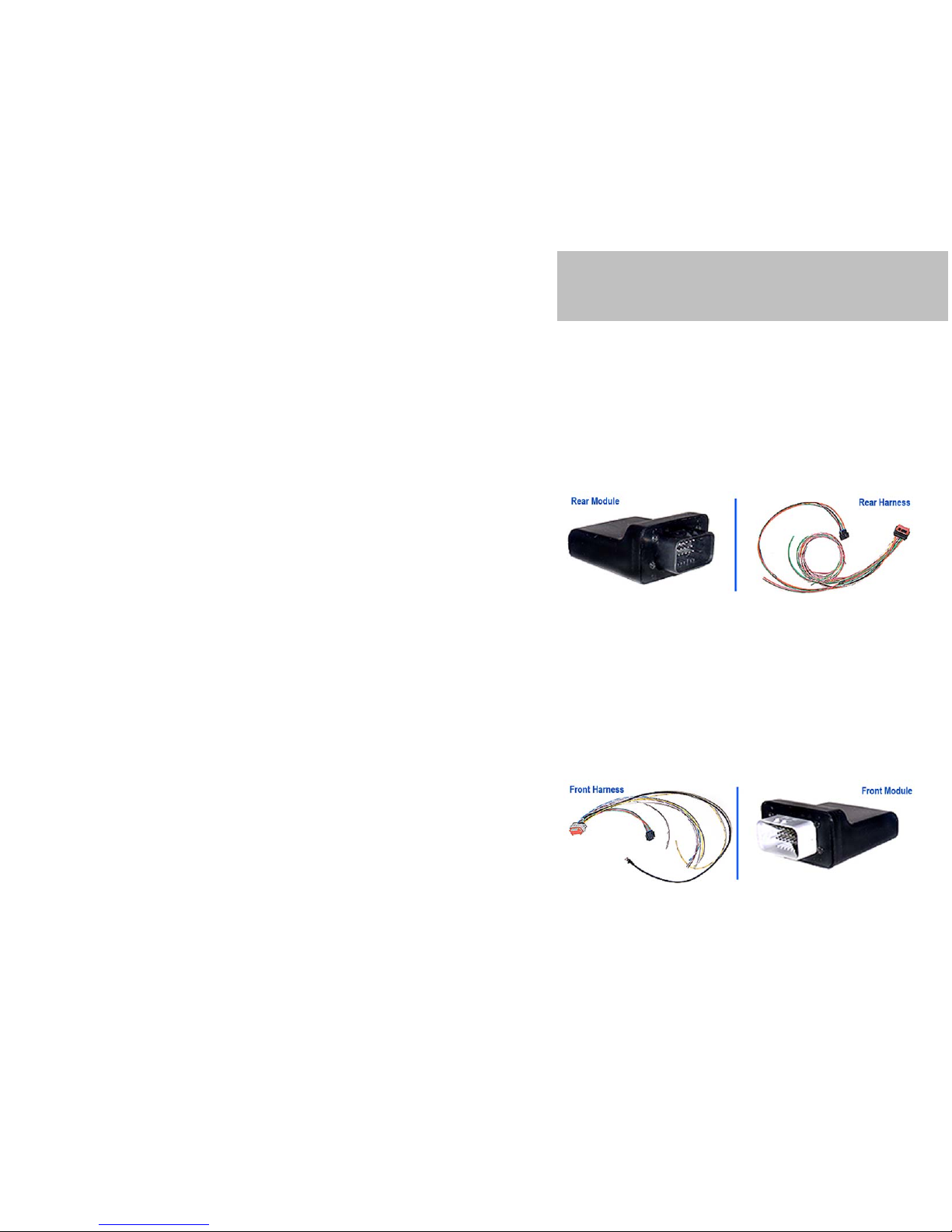

The LINX™ system is composed of: three communication modules, two

handle bar switches, and two wiring harnesses. These modules when

connected with the network cables, communicate with each other,

transfer information and self-check themselves for proper operation. If a

problem does develop, a written text message is displayed on the Liquid

Crystal Display (LCD) module. The system is designed to be simple, yet

provide more practical and useful information to the user.

Introduction

3

Locating Rear Module

The rear module is identified by its’ Black Connector, and should be

located in an area that is close to the battery and Starter Solenoid, and

also central to all of the devices it connects to. The module is splash

proof, but should be mounted in an area that has some protection from

water and heat. Under the seat on the battery box is usually a good

location. The module mounts with the enclosed double sided tape.

Locating Front Module

The front module is identified by it’s Grey Connector, and should be

located in an area that is central to all of the devices it connects to.

Under the gas tank, or in the headlight housing are two common

locations. The module is splash proof, but should be mounted in an area

that has some protection from water and heat. Once the two modules are

mounted the 4 wires that connect them should be connected. A 4 pin

connector is included, but these wires can be cut or extended as needed.

The module mounts with the enclosed double sided tape.

Installation

4

Installing switch cubes

The switch cubes are designed to fit a 1” handlebar, and connect to the

front brake switch, and clutch switch (optional). Installing the switch

cubes involves drilling a hole in the handlebar where the switch cube

will be located, and another where the wires will connect to the display

module. These wires come with the ends already crimped on, but they

can be cut off and easily re-crimped in the event you need to fish the

wire through a small hole (see crimping instructions). After the hole is

drilled and the wire fished through, simply plug the connector into the

switch, and connect the two wires on the right side to the brake switch,

and the two wires on the left side to the clutch (optional). It is

recommended that an electrical grease (not included) be used on the

connector and socket to help prevent corrosion from moisture. Last

insert the switch into the housing, and install the four screws through the

back side of the saddle clamp.

Installation

5

Installing the Display Module

The display module can be mounted either above or below the handlebar

by attaching the backing plate mounting tab to a handlebar clamp (not

included). The wires from the switch cubes will come out of the

handlebars, into the display housing, and plug into the appropriate

connector. The data wire from the front module is routed to the display

module and plugged into the appropriate connector. The data wire comes

with the end already crimped on, but it can be cut off and easily recrimped in the event you need to fish the wire through a small hole, or

shorten it (see crimping instructions). It is recommended that electrical

grease (not included) be used on the data cable and socket to help

prevent corrosion from moisture. Be sure to plug the cables into the

correct sockets as the unit can be damaged from improper installation.

They are labeled “L” & “R” (for Left & Right handlebar switches) and

“C” for Front Module.

Installation

6

To Replace the Connector End on a Cable.

1. Strip about 1” of the outer insulation with an RJ-45

stripper/crimping tool, the inner insulation does not need to be

stripped. These tools are commonly used to crimp computer

network cables, and are avalible at most electronic stores.

2. Insert the wires into the low profile connector. Be sure the blue wire

is to your left with the clip of the connector away from you, and the

connector pointing up.

3. Insert the connector into the crimper, and crimp. Be careful no to

push the connector too far into the crimper as the low profile

connectors do not have a stop to position the connector at the

correct position. Also be sure the wires are all of the way into the

connector when you make the crimp. It is a good idea to crimp the

connector twice to be sure that all of the conductor pins have

pierced the wires.

Installation

7

Display Module:

When the system is powered-on, a self-test will run and if any faults are

noted, they will be displayed. After this, the logo will be displayed for 3

seconds, and then the module will enter the operational mode. The

following items will be displayed on the screen in the operational mode:

Information & Icons on LCD Screens:

• Speed (in MPH or KPH).

• Engine RPM (digital readout and bar graph).

• Clock.

• High Beam “ON” Icon.

• Bike in “Neutral” Icon.

• Information Window (one of the following)

• Turn Signal Left / Right

• Hazard Flasher On.

• Run / Kill Status.

• Text information window: (toggles between the following with the

# key on the right handlebar switch).

• Odometer

• Trip 1 (Reset by pressing the # key for 3 seconds)

• Trip 2 (Reset by pressing the # key for 3 seconds)

Instrumentation

Loading...

Loading...