Page 1

Integrated Mixed-Signal Solutions

PRODUCT DATA SHEET

STMP35xx

D-Major™Audio System on Chip

with USB 2.0, LCD, Voice Record and Battery Charger

Third Generation Audio Decoder

Version 1.06 July 16, 2004

Host Processor

(Optional)

Rechargeable

Battery

LED/LCD Screen

FM Tuner

9

0

9

4

9

8

1

0

2

1

0

6

Hi-Speed USB

Microphone

Voice Record

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

5-35xx-D1-1.06-071604

Flash Memory

Hard Drive

Buttons/Switches

SDRAM

Headphones

CD Pickup

Copyright © 2004 SigmaTel, Inc.

All rights reserved.

SigmaTel, Inc. makes no warranty fo r t he use of i ts pr od uc ts, a ssu mes no res po nsi bil ity fo r a ny err or s wh ich may app ea r in t his document,

and makes no commitment to update the information contained herein. SigmaTel reserves the right to change or discontinue this product at

any time, without notice. There are no express or implied licenses granted hereunder to design or fabricate any integrated circuits based on

information in this document.

The following are trademarks of SigmaTel, Inc., and may be used to identify SigmaTel products only: SigmaTel, the SigmaTel Logo, C Major,

D Major and Go-Chip. Other products and company names contained herein may be trademarks of their respective owners.

Page 2

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

1. TABLE OF CONTENTS

1. TABLE OF CONTENTS .....................................................................................................................2

2. PRODUCT OVERVIEW .....................................................................................................................3

3. CHARACTERISTICS/SPECIFICATIONS ........................................................................................ 21

4. DSP CORE .......................................................................................................................................25

5. ON-CHIP MEMORY SUBSYSTEM ..................................................................................................30

6. CHIP WIDE PROGRAMMABLE CONTROL REGISTERS .............................................................38

7. INTERRUPT SUBSYSTEM ..............................................................................................................49

8. USB CONTROLLER ........................................................................................................................60

9. INTEGRATED USB 2.0 PHY (HS,FS) .............................................................................................79

10. PARALLEL EXTERNAL MEMORY CONTROLLER (EMC) .......................................................103

11. GENERAL PURPOSE FLASH CONTROLLER ..........................................................................118

12. FLASH ECC ACCELERATOR ....................................................................................................134

13. FILTER COPROCESSOR (FILCO) .............................................................................................154

14. PULSE WIDTH MODULATOR (PWM) CONTROLLER .............................................................. 185

2

C INTERFACE ...........................................................................................................................196

15. I

16. ENHANCED SPI INTERFACE .....................................................................................................209

17. SPI INTERFACE ..........................................................................................................................217

18. TIMERS ........................................................................................................................................220

19. SDRAM INTERFACE ...................................................................................................................227

20. SWIZZLE ..................................................................................................................................... 239

21. REAL-TIME CLOCK/ALARM/WATCHDOG RESET & PERSISTENT BITS .............................. 248

2

S SERIAL AUDIO INTERFACE ................................................................................................259

22. I

23. GENERAL PURPOSE INPUT/OUTPUT (GPIO) .........................................................................266

24. DAC ..............................................................................................................................................276

25. ADC ..............................................................................................................................................286

26. MIXER ..........................................................................................................................................297

27. HEADPHONE DRIVER ................................................................................................................310

28. LOW RESOLUTION ADC ............................................................................................................315

29. BOOT MODES .............................................................................................................................329

30. DC-DC CONVERTER ..................................................................................................................339

31. PIN DESCRIPTION .....................................................................................................................377

32. PACKAGE DRAWINGS ...............................................................................................................389

33. STMP35XX FAMILY MEMBER PART NUMBERS & ORDERING INFORMATION ...................391

34. INDEX OF REGISTERS ...............................................................................................................393

ADDITIONAL SUPPORT

Additional product and company information can be obt ained by goin g to the SigmaTel website at:www.sigmatel.com

available for authorized customers at: extranet.

2 5-35xx-D1-1.06-071604

. Additional product and design information is

sigmatel.com

Page 3

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

2. PRODUCT OVERVIEW

2.1. Features

• Decodes MP3 and WMA and is upgradeable to other digital music formats

• Supports WMA Digital Rights Management (DRM) and other security schemes

• Includes on-chip read only unique ID for digital rights management algorithms

• USB High Speed Device Interface (up to 480Mb/s transfers)

• Enables file transfer and firmware upgrade using USB Mass Storage Class

• Both Windows and Macintosh drivers available

• Integrated USB High S peed PHY

• Direct connection to USB 5V power for operation and battery charging

• 96K Words (288K Bytes) of on-chip RAM

• Hardware support for flexible external storage options

• NAND Flash, MMC, Secure Digital, SmartMedia, CompactFlash

• Five byte address support for new 1Gb/die (128KB block) NAND Flash

• MLC NAND Flash support

• 1.8V NAND Interface Support

• 16 bit wide NAND support

• Hardware

• SDRAM

• ATA/IDE Hard Disk digital devices.

• Optimized for very long battery life

• 50 hours of operation on a single AA battery

• Flexible, efficient on-chip DC-DC converter

• Flexible battery configurations, including 1xAA, 1xAAA, 2xAA, 2xAAA, LiIon

• Pulse frequency modulation mode for low standby power

• Energy saving dynamic power management

• Typical off current is 250µ

• More than 1 year battery life in “off” mode on one AA Alkaline battery

• Integrated battery charger for LiIon and NiMH

• Battery temperature sensor support for safest charging protocols

• Real time clock with alarm function wakes up from powerdown/standby modes

• High quality integrated audio mixed signal sub-system

• <0.05% THD direct drive headphone amplifier

– Eliminates DC blocking capacitors

– Including anti-pop and short-circuit protection

• High performance 18-bit Σ∆ technology stereo D/A and A/D converters

• Full analog mixer configuration

• Line-in to Headphone/Line-out SNR >90 dB

• Two an alog line-level input s: Line1 In (stereo), Line2 In ( stereo, 144-pin p ackage)

• Mic(mono) input with integrated pre-amp and microphone biasing circuit

• Volume control

• GPIO, button I/O controls, and LCD/LED Disp lay Compatible Inter face

• Pulse Width Modulators for EL backlights

• Integrated 75MHz DSP with Filter Coprocessor for power optimization

• Optimized for audio applications

• Field upgradeable firmware

accelerated ECC off-loads DSP bit error correction

A (crystal oscillator & real time clock only)

5-35xx-D1-1.06-071604 3

Page 4

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

• Integrated Development Environment, SDK, and debugger

• Application and support libraries

• Bass and Treble control; configurable multiple band EQ control

• Voice record in ADPCM format (upgradable to other formats)

• FM tuner input and control support

• Optional interface to a host chip/processor for cell phone & PDA applications, etc.

• Application notes, reference schematics, sample PCB layouts are available.

• Offered in 100-pin TQFP, and 144-pin fpBGA packages

• Backward pin and firmware compatible with STM P3 4 10

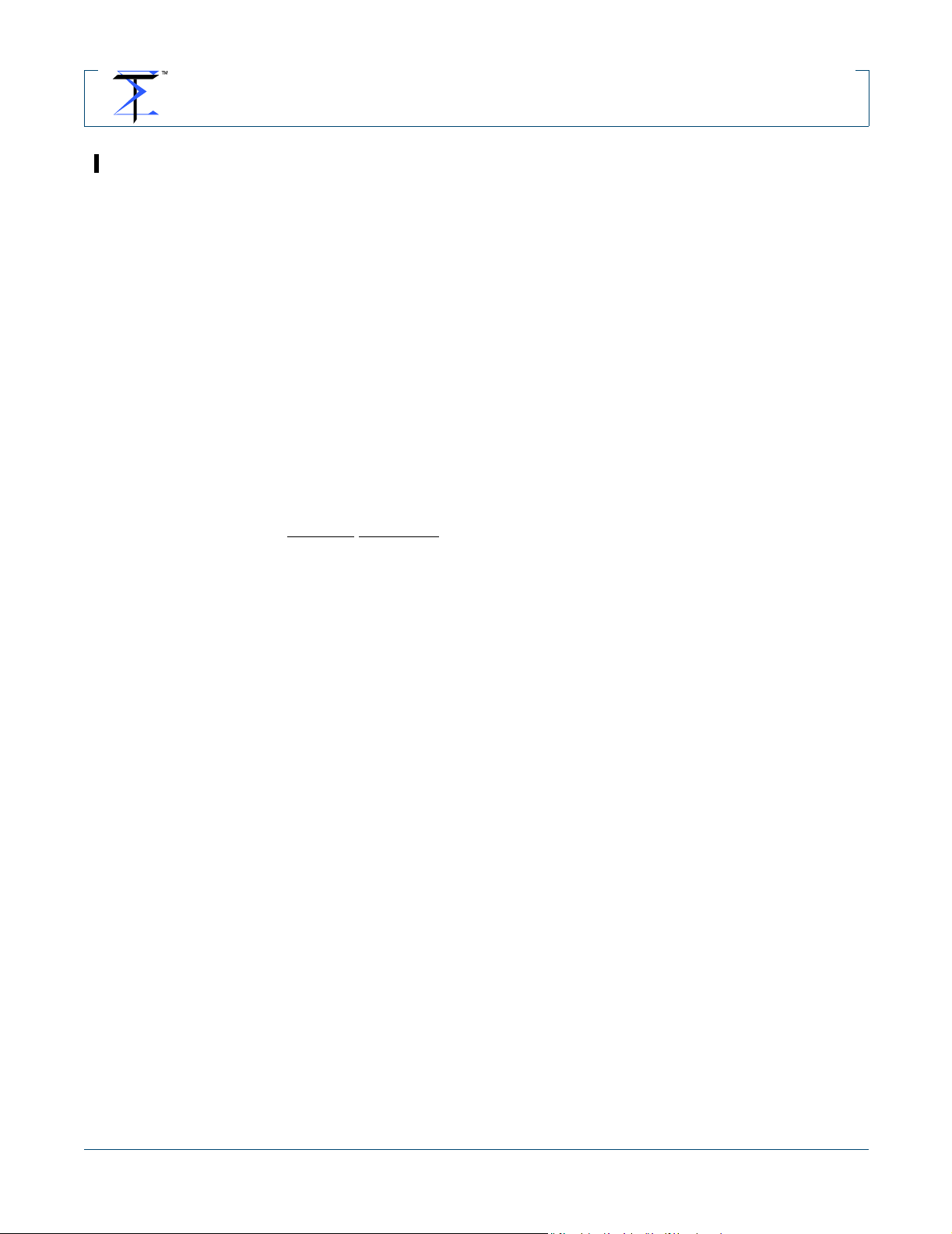

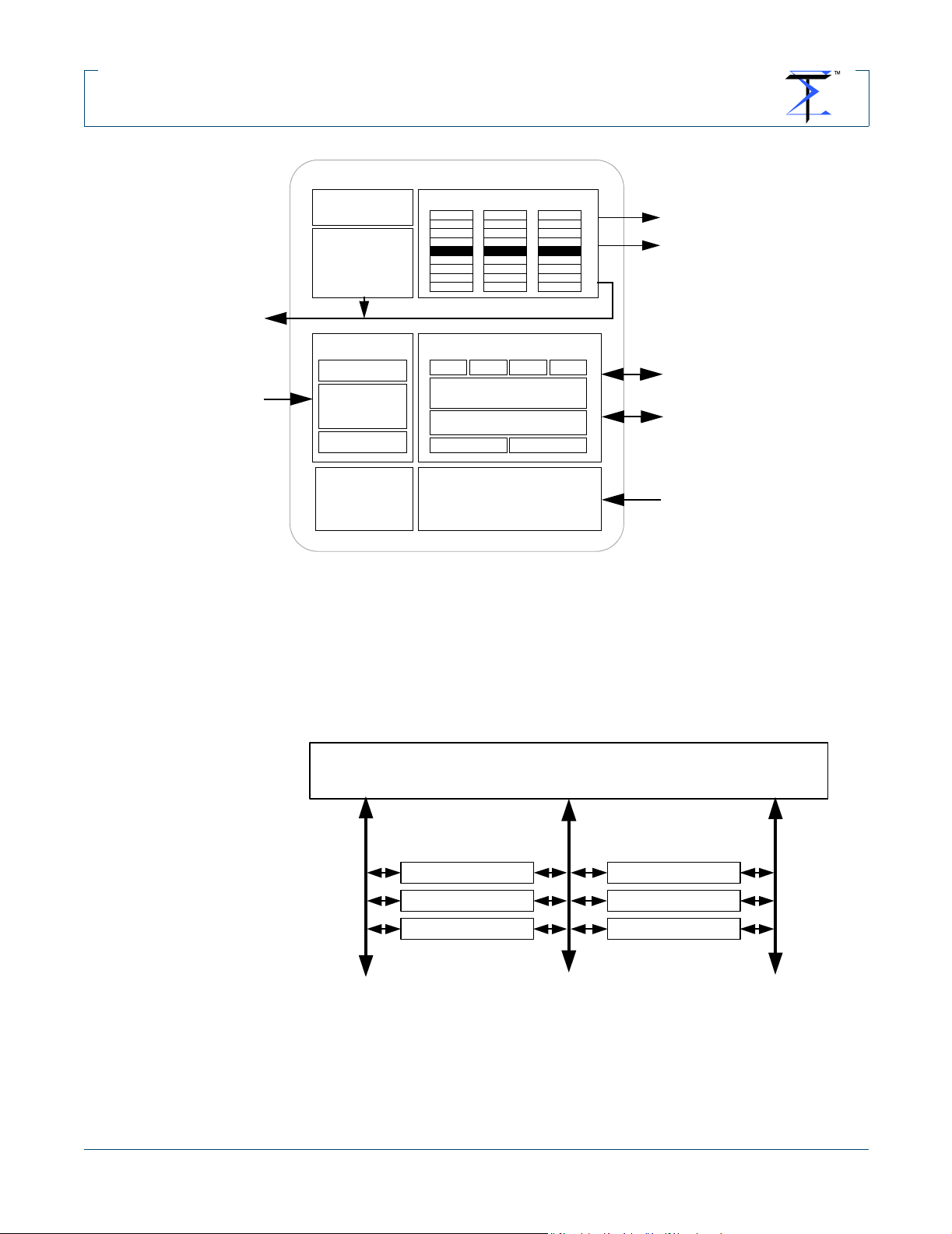

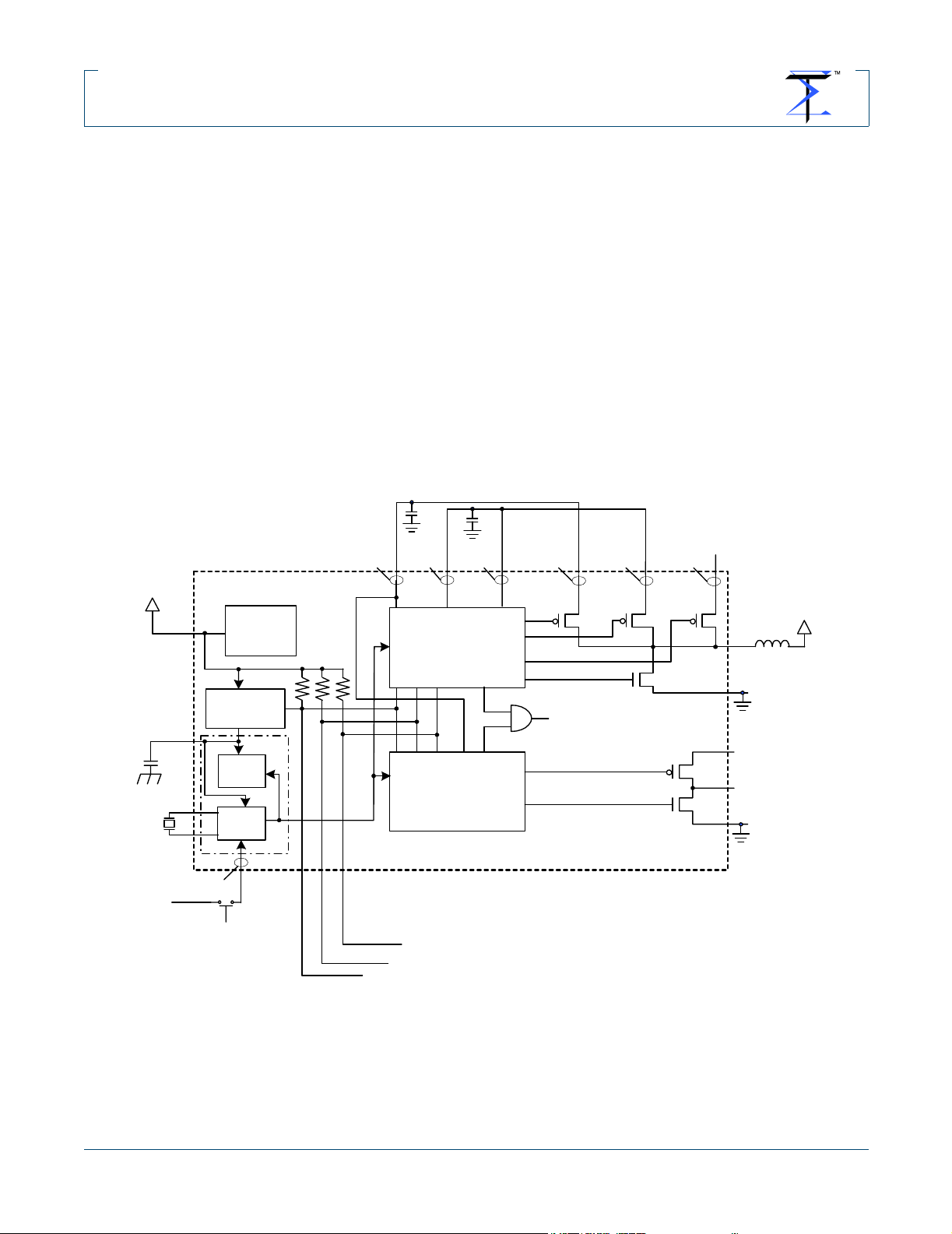

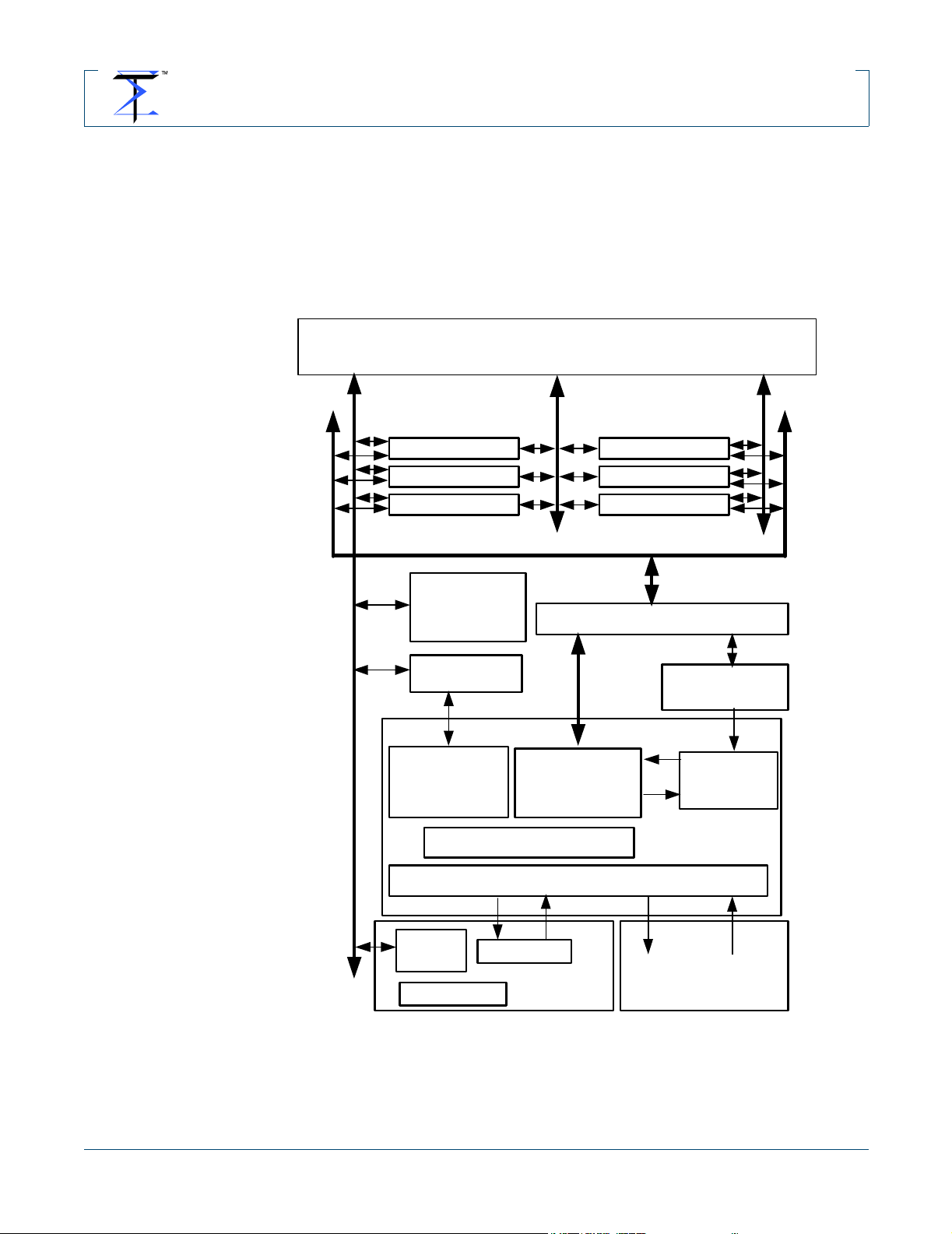

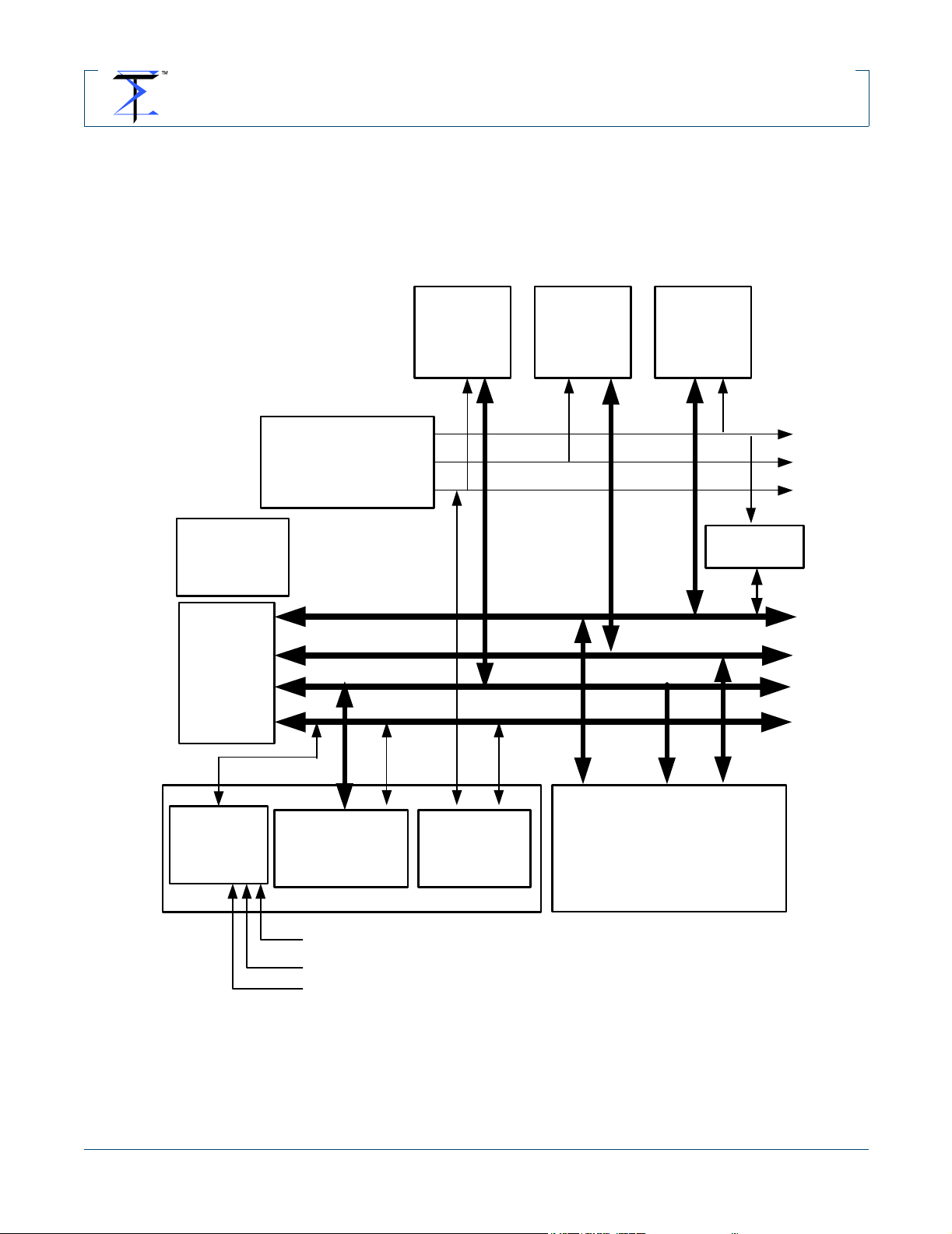

2.2. STMP35xx Block Diagram

9

0

9

4

9

8

1

0

2

1

0

6

Hard Drive

LED/LCD

Buttons/

Switches

E.L. Backlight

MMC/SD

Card

I2C

Peripherals

SmartMedia

CompactFlash

NOR Fla sh

NAND Flash

MLC Flash

SDRAM

Pin 1

Synchronization

Synchronization

GPIO Interface

I/O Pin Multiplexer

General Purpose Input/Output

14 mm

CD Control

IDE Interface

Interface

I2 S & CD

I2S CD

Interface

I2C Interface

Pulse Width

SPI Interface

SPI Interface

SPI Interface

I2C Interface

I2C Interface

Flash/IDE

EMC

Interface

SDRAM

SDRAM

Interface

Interface

USB High Speed

USB Full Speed

USB PHY

USB

(HS & FS)

USB 2. 0

USB

Device

24-bit

DSP

On-Chip ROM

On-Chip ROM

16K x 24bits

8K x 24bits

Inte rrupt Control, Timers,

Interrupt Control, Timers, Bit

Bit Manipulation Unit,

Manipulation Unit, RTC, Trace

Trace Debug Unit

Debug Unit, Reed-Solomon

Memory Bus

Peri p he ral Bus

DSP

On-Chip RAM

On-Chi p RAM

96K x 24bits

96K x 24bits

Microphone

Filter &

ECC

USB

engines

DAC

DAC

ADC

ADC

Low

DCDC

Resolution

Converter

ADC x3

Rechargable Battery

Figure 1. Chip Block Diagram

FM Radio

Mic in

Amp

DAC

Temperature

FM in

Low

Battery

Resoluti

Charger

on ADC

10 mm

STMP35xx

Line in

Σ

Σ

DCDC

DCDC

Converter

Converter

Input

5V

Headphone Amplifier

RTC,

ALARM,

PLL

PLL,

xtal

XTAL

Crystal

Pin A1

Headphone Amplifier

Headphones

Cap-less

Direct Drive

10 mm

14 mm

100-pin TQFP

For additional package measurements, please see 32. “PACKAGE DRAWINGS” on page 389.

Figure 2. Chip Package Photos

4 5-35xx-D1-1.06-071604

144-pin fpBGA

Page 5

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

2.3. Description

SigmaTel's STMP35xx is a third generation single-chip highly-integrated digital music

system solution for devices such as digital audio players, PDAs, voice recorders, MP3encode recorders, and cell phones. It includes a high performance DSP, 288KBytes of

on-chip SRAM, and a USB 2.0 interface (including High speed 480Mb/second transfers)

for downloading music and uploading voice and MP3 recordings. The chip also includes

a mixer, DAC, ADC and provides interfaces to IDE Hard Drives, CD-DSPs, Flash memory, LCD/LEDs, button & switch inputs, headphone driver, FM tuner input & controls and

a microphone. The chip’s highly programmable architecture supports MP3, WMA, and

other digital audio standards. WMA digital rights management and other security

schemes are also supported. For devices like PDAs and cell phones, the STMP35xx

can act as a slave chip to a host chip/processor.

The DAC includes a headphone driver to directly drive low impedance headphones. The

ADC includes inputs for both microphone and analog audio in to support voice recording &

FM radio integration and MP3 encode features. Si gmaTel's propr ietary Sig ma-De lta ( Σ∆)

technology achieves a DAC SNR in excess of 90 dB for high-quality audio playback.

The STMP35xx has low power consumption to allow long battery life and includes an

efficient flexible on-chip DC-DC converter that allows many different battery configurations, including 1xAA, 1xAAA, 2xAA, 2xAAA and LiIon. Th e chip inclu des a n inte grat ed

intelligent charger for NiMH and LiIon batteries. In addition, the single-chip design and

low pin count enables very small digital audio devices to be designed.

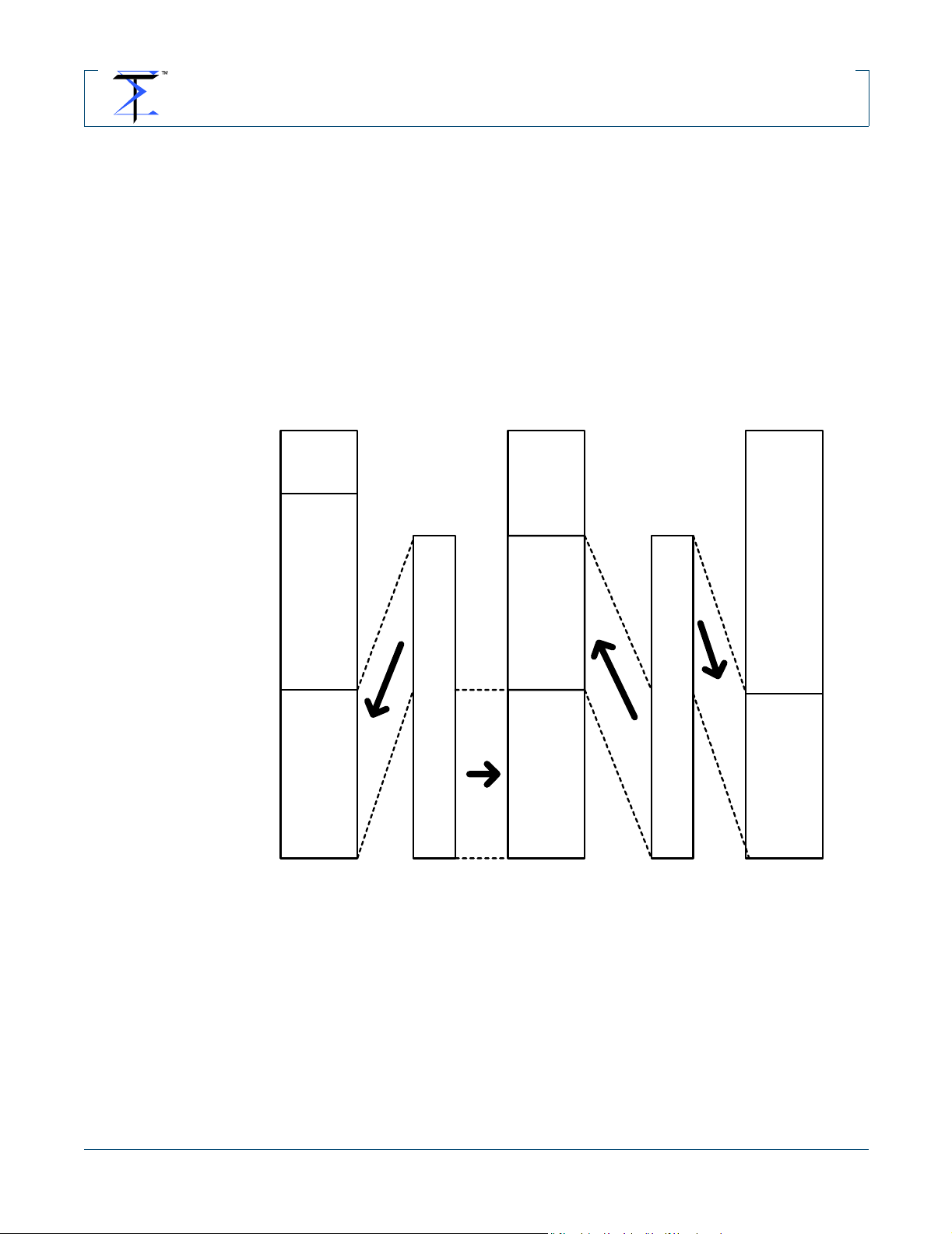

2.3.1. DSP Core

The on-chip DSP core is modeled exactly after the Motorola DSP56004. It supports

the identical instruction set, registers, addressing modes, etc., as the DSP56000

family of digital signal processors. Figure 3 shows a high level view of the DSP core.

This architecture is highly optimized for battery operated audio applications. Its 24bit intrinsic data size provides sufficient precision for high quality audio algorithms

while minimizing the number of register and data path signals that must be toggled

for any operation. The term “WORD”, as used in this data sheet, refers to a 24-bit

unit of storage unless otherwise noted.

The functionality that defines the on-chip DSP, is the memory map, interrupt processing, and peripherals it offers.

The integrated DSP comprises three execution units, an interrupt controller and a

debug interface. It connects to the rest of the STMP35xx chip via thr ee memory busses, a set of interrupt input signals and various reset and clock inputs. It implements

a 3 memory space Harvard architecture, simultaneously referencing an X data element, a Y data element and a program element. These references are conveyed

over the program or “P” bus, the X b us and the Y bus. Ea ch bus c omprises a 24 bit

wide data path and a 16 bit address bus. Program accessible I/O registers reside in

the top 4K word addresses on the X-bus. The DSP architecture has special programmed I/O support for the to p 64 words of this space bu t Sigm aTel has extended

this space to the top 4K words, i.e. addresses $F000 through $FFFF, inclusive.

The DSP Core also implements the OnCE debugger that is the norm for this DSP

architecture. The OnCE interface connects to an external debugger over four I/O

signal pins on the STMP35xx.

Using an industry standard instruction set architecture and debugger interface for

the integrated DSP means that development tools and debuggers are in the highly

evolved and stable portion of their life cycle. In addition, it means that system devel-

5-35xx-D1-1.06-071604 5

Page 6

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

DSP Core

Address to

X space

Address to

Y space

Data to/from

X space

Data to/from

Y space

Interrupts

To/from

P space

Debug Interface

Program

Address

Generator

ProgramDecoder

Instruction Latch

Decoder

&

State Machines

Registered Control

Bit Manipulation

Unit

Address

R0

R1

R2

R3

R4

R5

R6

R7

DATA ALU

X0 X1

A

Generation Unit

N0

N1

N2

N3

N4

N5

N6

N7

M0

M1

M2

M3

M4

M5

M6

M7

Y0 Y1

x

+

B

Interrupt

Controller

Figure 3. DSP Core at a Glance

opers with experience developing on this DSP can be found. The Sigma Tel sof twar e

developers kit (SDK) provides an excellent integrated development environment

with an assembler, C compiler, debugger and other re quisite tools.

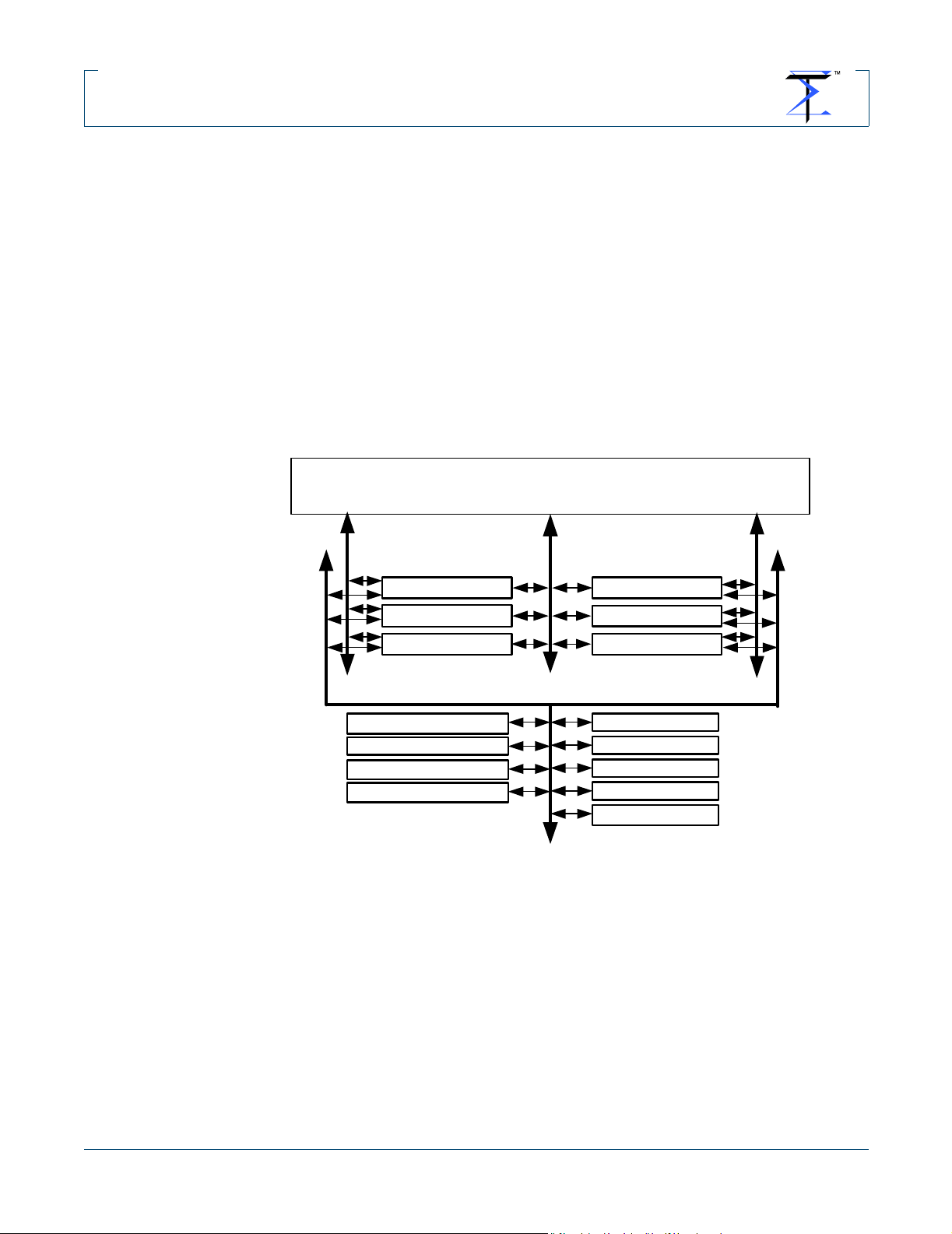

2.3.2. On-chip RAM and ROM

The STMP35xx includes 96K words of on-chip RAM. This amounts to 2.25Mbits of

on-chip SRAM in six 16K Word blocks. The RAM is split into two 48K word banks

with one bank attached to the X bus and one attached to the Y bus. The P bus is

X-BUS

16KW or d S RAM

16KW or d S RAM

16KW or d S RAM

Figure 4. 6 x 16K Word On-chip SRAM Blocks

connected to both RAM banks so that program space can be allocated from the

same two banks that hold X and Y data values. An adjustable switching mechanism

DSP CORE

P-BUS

Y-BUS

16KWord SRAM

16KWord SRAM

16KWord SRAM

6 5-35xx-D1-1.06-071604

Page 7

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

is provided so that a portion of the X bus RAM or Y bus RAM can be allocated to the

P bus in units of 8K words from 0K to the full 64K words.

A typical application will allocate a portion of the X bus RAM and another portion of

the Y bus RAM to the P bus. In normal operation, this switching mechanism will

present a contiguous block of RAM beginning at location zero in the P bus address

space, or P:$0000 as it is written in assembler syntax

Suppose we allocate 24K Words from the X bus RAM to the P bus and another 24K

Words from the Y bus RAM to the P Bus. This gives us 24K Words of X RAM, 24K

Words of Y RAM and 48K Words of P RAM fo r o ur ap plication . All 96K Words of onchip SRAM are allocated, as shown in Figure 5.

$FFFF

$F000

$6000

$5FFF

X

Address

Space

PIO

Regs.

No

SRAM

24K

Words

X

RAM

$BFFF

48K Words Physical SRAM

$C000

P

Address

Space

on-chip

ROM

24K

Words

from

Y

RAM

24K

Words

from

X

RAM

$BFFF

48K Words Physical SRAM

Y

Address

Space

No

SRAM

$5FFF

24K

Words

Y

RAM

$0000

Figure 5. On-Chip RAM Allocation Example

The STMP35xx contains an on-chip 16K Word ROM which holds the Bootstrap

code. At power-on time, the first instruction executed by the DSP comes from this

ROM. Power-on reset causes the on-chip ROM to be placed at P:$0000. The reset

interrupt vector is located at P:$0000, thus the first instructions executed come from

this ROM. Software in this ROM offers a large number of BOOT configuration

options, including manufacturing boot modes for “burn-in” and “tester” operation.

Other boot modes are responsible for loading app lication code from off-chip into the

on-chip RAM. Off chip sources for application bootstrapping include:

• External NAND FLASH

• Host (PC) controlled bootstrapping using USB,

5-35xx-D1-1.06-071604 7

Page 8

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

• Host (PC) controlled bootstrapping using I2C slave.

2

•I

C Master transfers from serial EEPROM

Once the on-chip boot code has loaded the application code into on-chip RAM, it

can relocate the 16K Word on-chip ROM to the very top of the P address sp ace, se e

Figure 5. “On-Chip RAM Allocation Example” on page 7. The on-chip ROM can be

disabled entirely so that all 64K words of P space is available for on-chip RAM.

The on-chip boot code includes a firmware recovery mod e. If the de vice fails to bo ot

from NAND flash, for example, the device will boot from a PC host connected to its

USB port. This firmware recovery m ode can be invoked at anytime by holding the

PSWITCH or “play” button for at least five seconds during power up.

The on-chip RAM serves as one end of all DMA transfers, e.g either the source or

destination. Every SRAM block has three potential accessors: P-BUS, DMA-BUS,

and its respective X-BUS or Y-BUS. A number of the integrated peripheral controllers use a distributed DMA implementation to transfer data to or from on-chip

SRAM.

DSP CORE

X-BUS

16KWord SRAM

16KWord SRAM

16KWord SRAM

DMA-BUS

Exter nal Flash/I DE

External SDRAM

USB

FLASH ECC

Figure 6. On-Chip RAM & Distributed DMA

In this distributed DMA architecture, all of the peripheral controllers that use DMA

share a common DMA address and data bus path to and from on-chip RAM. Each

peripheral controller implements its own a ddress ge nerator. Address generation can

be highly sequential as in the case of the D/A converter or fairly random as in the

case of the USB controller. Thus each device that uses the distributed DMA will

have at least one base address register (HW_xxxBAR) and various address modifying registers. Most of the distributed DMA devices implement some form of circular

buffering in their addressing modes. There is a centralized arbiter that selects wh ich

of the distributed DMA peripheral co ntrollers has access to the DMA bus on any

given clock cycle.

P-BUS

Y-BUS

16KWord SRAM

16KWord SRAM

16KWord SRAM

CD

D/A

A/D

Trace Buffer

Filter Coproc.

8 5-35xx-D1-1.06-071604

Page 9

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

With a DSP core clock of 65MHz, a single block of on-chip RAM can provide 65MHz

times 3 bytes or 195 MByte/second of bandwidth. There are four 24 bit data busses

connected to the on-chip SRAM blocks. Furthermore, each SRAM block is single

ported and has its own independent address and data busses. Thanks to the arbitration logic in this memory subsystem, all four busses (P, X, Y, DMA) can be made

to cycle on every clock. Thus the peak bandwidth available from the on-chip RAM is

four times 195 MByte/second or 780 MByte/second.

Of course, there are times when more than one data bus needs to transfer into or

out of the same SRAM block. When conflicts occur, the arbiter will “stall” the DSP for

one (or more) clock(s) to resolve the conflict.

The reader should not be surprised to see devices like A/D or D/A converters using

DMA transfers. Some readers may be surprised to learn that external FLASH and

external SDRAM are only accessible via the DMA. Th e external memories are not

mapped into the “load/store” space of the DSP’s instruction set.

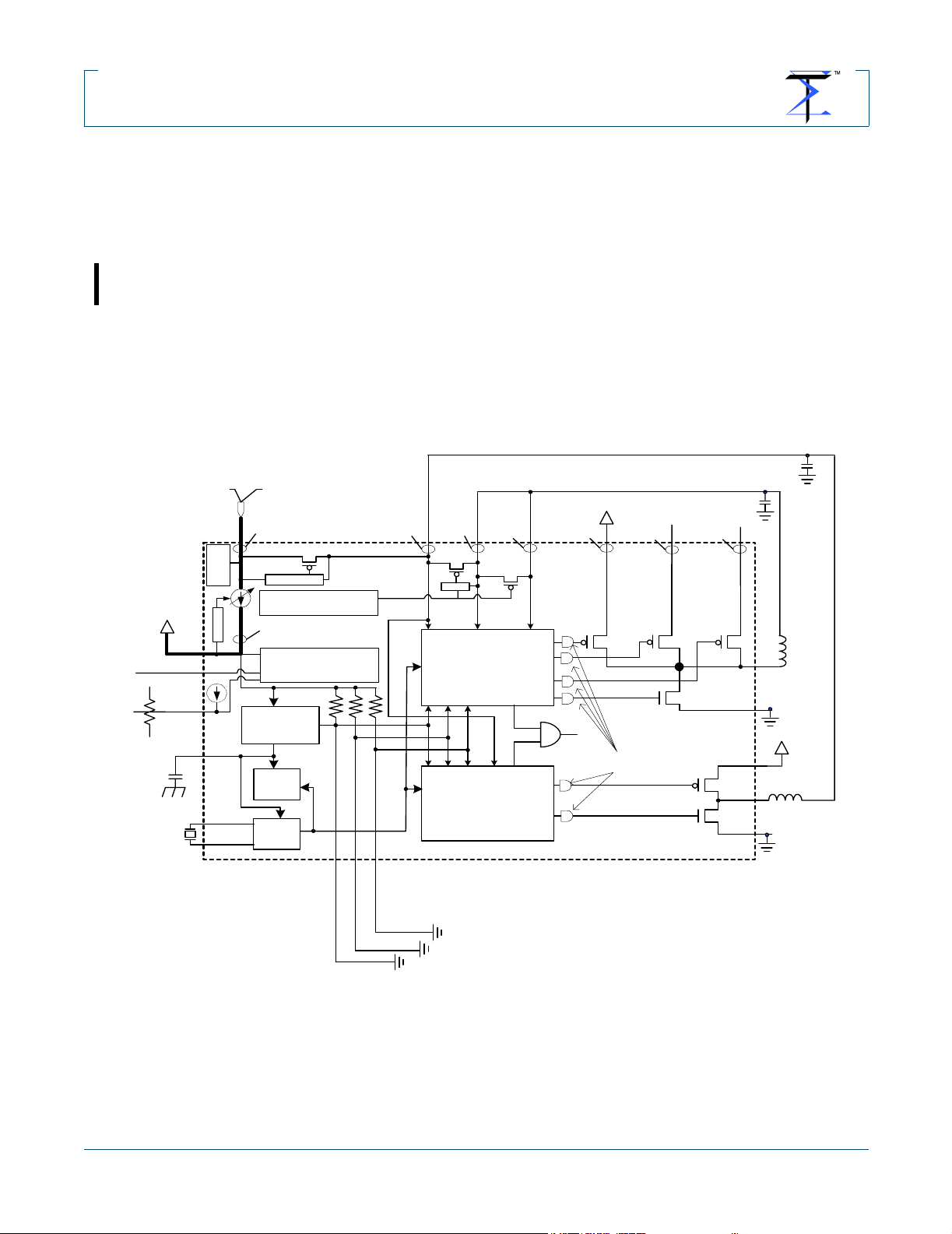

2.3.3. Power Subsystem

The STMP35xx contains a sophisticated pow er subsystem inc luding two inte grated

DC to DC converters to produce a very cost effective product with flexible battery

configurations. In addition, it contains power monitoring circuits for battery brownout

detection as well as system overload br ownout detection. The chip also contains

detection circuits for battery installation and removal. It manages power state

changes caused by battery changes or from monitoring the on/off power switch circuit.

The chip has two programmable integrated DC-DC converters that can be used to

provide power for the device as well as the entire application. The converters can be

configured to operate from standard battery chemistries in the range of 0.9-4.2 volts

including alkaline cells, NiMH, LiIon etc. These converters use off chip reactive components (L/C) in a pulse width or frequency modulated DC to DC converter.

The DC to DC converter circuit consists of the of f-ch ip reactive component s, an integrated controller and integrated low resistance FET switches. The DC-DC converter

#1, as shown in Figure 7, has one n-channel FET and three independently controlled p-channel FETs generating three independent channels of separately controlled voltages. For the case shown, the battery is a sin gle AA alkaline battery in the

range 0.9 to 1.5 volts. DC-DC converter # 1 is used to “boost” this input voltage to

3.3 volts for use in driving the I/O VDD rail and two separate 1.8 volt sour ces for

driving the analog VDD rail and the digital VDD rail. This case is shown in the first

row of Table 1, “Flexible Battery Config urations,” on page 11. Other rows show different configurations supported by the DC to DC converters. For example, when th e

battery chemistry provides an input voltage that is higher than that desired for the

I/O rail, digital rail or analog rail, then the DC to DC converte rs can opera te in “buck”

mode which provides a regulated output that is lower than its input.

One obvious use for the DCDC converter is in boosting the output of a nearly

depleted alkaline battery delivering 0.9 volts up to th e re gula te d 3. 3 vo lt I/O rail voltage and the regulated 1.8 volt digital and core rails. The DCDC converter can also

be used to lower the voltage of a 4.2 v olt LiIon b attery down to the 1.8V digital core

and analog rails. Table 1, “Flexible Battery Configurations,” on page 11 shows various battery configurations that can be sup po rt ed .

1

1.Note VddA3 == VddHP, VddA4== VddPLL. The analog power pair formerly known, in the STMP3410,

as VddA2 and VssA2 have been redefined for the STMP35xx as Vdd5V and LRADC2.

5-35xx-D1-1.06-071604 9

Page 10

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

In addition, the DCDC converter can regulate these voltages to lower the standard

core and I/O values to extend the battery life. Recall that energy consumed in a

CMOS AC circuit is proportional to V

These program controlled reductions in operating voltage are used in various SigmaTel software applications to provide very long battery life products. The

STMP35xx also contains a silicon speed sensor so that each device can tailor its

operating voltage to the minimum required for safe operation as constrained by its

individual silicon process parameters and junction temperature.

The DC to DC converters control the power up sequence of the device and hold the

rest of the chip in reset until the power supplies have stabilized at the correct voltages. The power up sequence begins when the battery is connected to the BATT

pin. As shown in Figure 7, the crystal oscillator will begin running as soon as the battery is connected and the pswitch is asserted. The crystal oscillator and the real

time clock (RTC) can be programmed to continue to operate even when the player

is in the off state. The crystal oscillator and RTC are the only drains on the battery in

the off state and designed for very small energy consumption. The RTC module

includes an alarm function that can be used to “wake-up” the DC to DC converters

which will then wake up the rest of the system.

2

so this reduction can be quite significant.

battery

BATT

VddXTAL

Resolution

Regulator

VddXTAL=BATT

RTC

XTAL

OSC

Pswitch

Power Button

VddA

1/2/3

DC-DC

(boost mode)

DC-DC

* only available on 144-pin package

DCDC_VddIO

Low

ADC

VddIO

1/2/3*/4*

DCDC_mod2

DCDC_mod0*

DCDC_mod1*

VddD

1/2/3

#1 Control System

#2 Control System

NC

NC

NC

Figure 7. Lowest Cost 1xAA 100-pin Configuration

DCDC_VddD

DSP_RESET

medium V (2 Alkaline/NimH)

or hi V LiIon Applications

DCDC_VddA*

1

NC

battery

DCDC_Batt

DCDC_Gnd

NC

DCDC2_Vout*

NC

DCDC2_Batt*

DCDC2_Gnd*

The power down sequence is also controlled by the DC to DC converters. When a

power down event is detected, they return the player to the power off state. In the

power off state with non-LiIon chemistries, the I/O Vdd rail is connected to the Battery and the internal VddD and VddA rails are pulled down to ground to minimize

10 5-35xx-D1-1.06-071604

Page 11

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

leakage currents. For LiIon mode, the I/O Vdd rail is connected to ground instead of

connecting to BATT.

In addition to the various voltage detectors, a power up or p ower down eve nt can be

signaled by the special power switch circuitry in the DC to DC converters. A simple

resistor network and momentary contact push button switch is sufficient for player

on/off control.

There is a special three channel low resolution A/D converter on-chip to help with

battery based applications. One channel is dedicated to measuring the voltage on

the BATT pin and is used to monitor the battery condition to estimate its remaining

life. All low resolution channel also have digital trip point comparator functions that

can be used to generate inter rupts to the DSP. The trip point can be program matically set at one of 512 levels for battery b rown out detect ion on the Battery LRADC

or for threshold detection on the other two LRADCs. NOTE: ONLY the battery can

be connected directly to the BATT pin for correct operation of the device, thus the

battery channel of the low resolution A/D converter is not available for any other purpose. The second and third low resolution A/D converters are uncommitted and

available for application use. An optional current source can be enabled to either the

second or third LRADC pin to support external temperature sensors with minimal

external components.

In addition, the DC to DC converters have comparators to monitor their output voltages. They can report “brownout” conditions resulting from over dr awing their power

capabilities. These conditions are reported either on a normal interrupt level or as a

non-maskable interrupt (NMI).

The device contains an integrated PLL which is referenced to the 24.0MHz crystal

oscillator. It can generate clock sources from 39.6MHz to 120.0MHz in steps of

1.2MHz. It includes a post divide stage for the dig ital cloc k fro m a div ide by one to a

divide by 2048. With the PLL turned off and the post divider set to 2048, one can

achieve a low power 11.7KHz operating point.

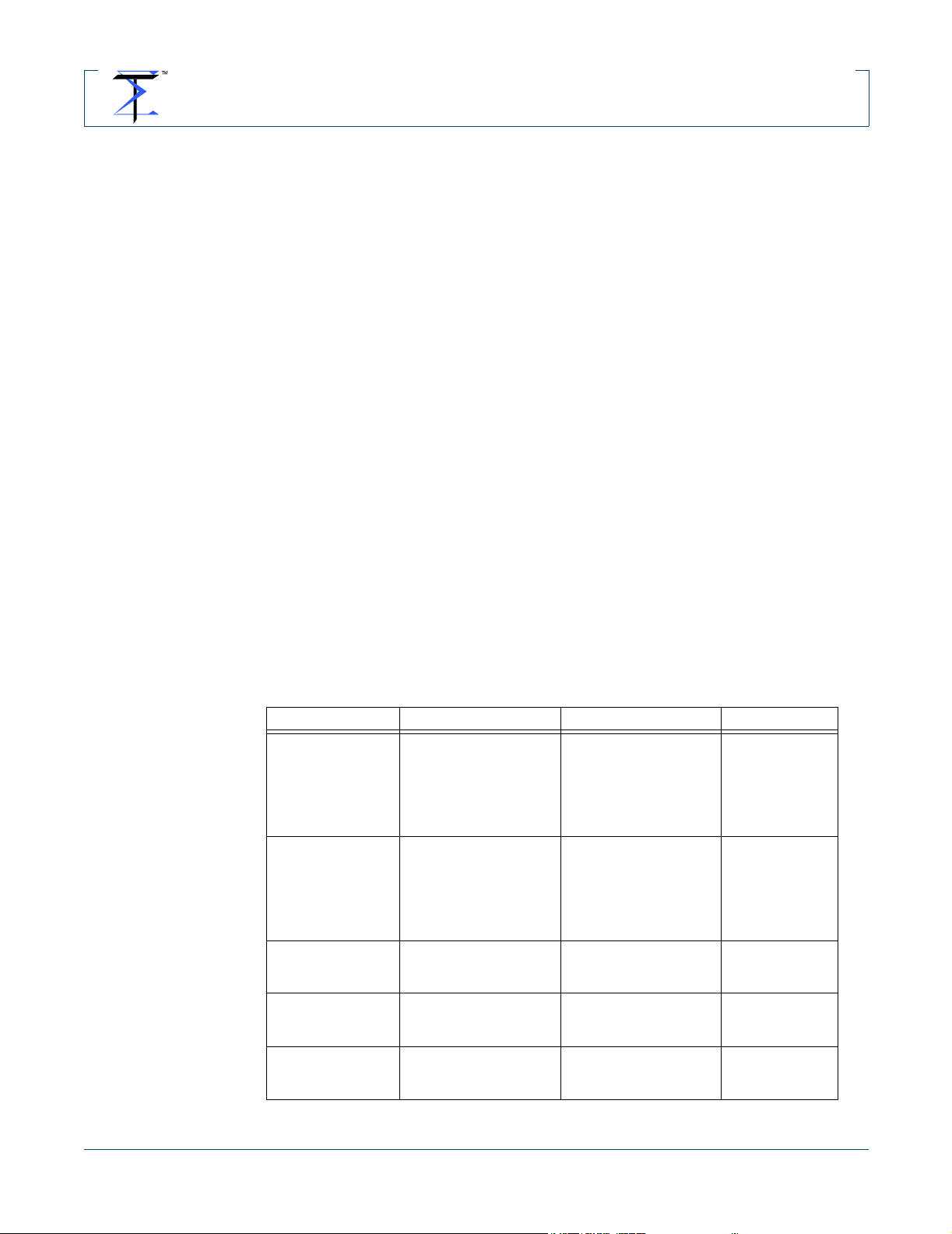

POWER SOURCE VDD I/O VDD D VDD A

1 Alkaline or 1 NiMH

(0.9V-1.5V)

1 Alkaline or 1 NiMH

(0.9V-1.5V)

LiIon, (3.0-3.6V) LiIon Battery DCDC1

2 Alkaline or 2 NiMH

(1.8V-3.0V)

LiIon (3.3V-4.2V) DCDC2

DCDC1

DCDC_VddIO

Boost

3.3V

DCDC1

DCDC_VddIO

Boost

3.3V

DCDC2

Boost

3.3V

Buck

3.3V

Table 1. Flexible Battery Configurations

DCDC1

DCDC_VddD

Boost

1.8V

DCDC1

DCDC_VddD

Boost

1.8V

lowest cost (shared

passives & 100-pin)

Buck

1.8V

DCDC1

Buck

1.8v

DCDC1

Buck

1.8V

DCDC1

DCDC_VddA

Boost

1.8V

better noise floor

(144-pin)

DCDC1

DCDC_VddD

Boost

1.8V

DCDC1

Buck

1.8V

DCDC1

Buck

1.8V

DCDC1

Buck

1.8V

5-35xx-D1-1.06-071604 11

Page 12

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

There is an integrated watchdog reset timer available for automatic recovery from

catastrophic software errors. If programmed by software, this circuit will generate a

reset sequence if its timer is ever allowed to reach zero. Normally functio ning s oftware will reload the watchdog count before expiration of the count. The maximum

delay until a watchdog reset is greater than four hours.

2.3.4. Battery Charger

The STMP35xx integrates support for LiIon charging protocols in USB or AC line

attached environments. When the 5 V source is detected on the VDD5V pin the

power management system autom atically reconfigures to use the integr ated linear

regulators to supply the core and I/O rails. Software can then enable the integrated

current source to provide battery charge current, as shown by the bold path in Figure 8. The variable current sources tappers of the charge current as it approaches

the maximum LiIon battery voltage. Software can then take over to control the final

“topping-off” algorithm, as desired.

USB Vbus 5v Line 5V input

>4.35V

VDD5V

5V

detect

Linear Reg.

battery

Charge Current Path

BATT

LRADC1

LRADC2

Temp.

VddXTAL

V Sense

Low Resolution AD C

Regulator

VddXTAL=BATT

RTC

XTAL

OSC

linear charger

controller

3 Channel

DCDC_mod2

DCDC_mod1*

VddIO

1/2/3*/4*

DCDC_mod0*

VddD

1/2/3

Linear

#1 Control System

#2 Control System

VddA

1/2/3

DCDC_VddIO

DC-DC

(boost mode)

DC-DC

* only available on 14 4-pi n p ac kages

battery

DCDC_VddD

DSP_RESET

disabled during linear

battery charge

NC

DCDC_VddA*

NC

DCDC_Batt

DCDC_Gnd

DCDC2_Vout*

DCDC2_Batt*

DCDC 2_G nd*

MODE = 000, for LiIon, both converters in buck mode

battery

Figure 8. Integrated LiIon Battery Charger

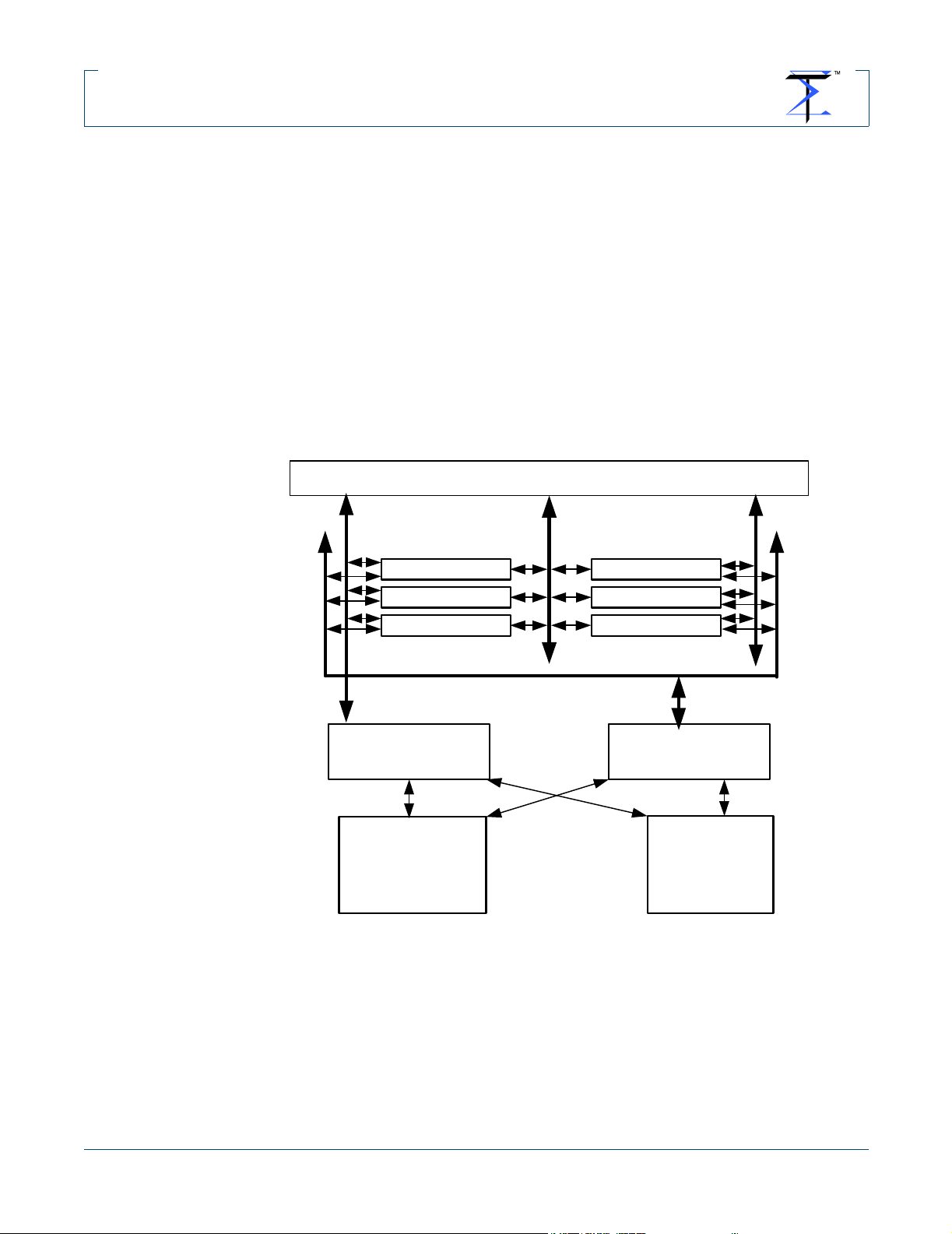

2.3.5. USB Interface

The chip includes a Universal Serial Bus (USB) version 2. 0 controller and integrated

UTMI PHY. The STMP35xx device interface can be attached to USB 2.0 hosts and

12 5-35xx-D1-1.06-071604

Page 13

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

hubs running in the USB 2.0 High Speed mode at 480Mbit/second. It can be

attached to USB 2.0 Full Speed interfaces at 12Mbit/second. Of course, the USB

2.0 Full Speed mode allows the STMP35xx to attach to USB 1.1 compliant hosts

and hubs.

The USB interface is used to download digital music data or program code into

external memory and to upload voice recordings or MP3 encoded recordings from

external memory to the PC. Program updates can also be loaded into the flash

memory area using the USB interface.

DSP CORE

X-BUS

16KWord SRAM

16KWord SRAM

16KWord SRAM

DMA-BUS

USB System

Programmable

Registers

Bus Interface

USB Controller

Programmable

Registers

P-BUS

End Point

Controller

Protocol Lay er

Y-BUS

16KWord SRAM

16KWord SRAM

16KWord SRAM

USB DMA Interface

USB Config

State Machine

End

Point

Info

ARC USB 2.0

Device Controller

Serial Interf ac e E ngine

PHY

Regs.

480MHz PLL

Figure 9. USB Interface Block Diagram

The Universal Serial Bus (USB) is a cable bus that supports data exchange

between a host computer and a wide range of simultaneously accessible peripherals. The attached peripherals share USB bandwidth through a host-scheduled,

5-35xx-D1-1.06-071604 13

USB Xcvr

Integrated

USB 2.0 PHY

External USB 2.0

UTMI PHY

Page 14

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

token based protocol. The bus allows peripherals to be attached, configured, used

and detached while the host and other peripherals are in operation.

The USB subsystem is designed to make efficient use of system resources within

the SMTP35xx. It contains a random access DMA engine that reduces the interrupt

load on the DSP and reduces the total bus bandwid th that must be dedicate d to servicing the eight on-chip physical endpoints

It is a dynamically configured port which can suppor t up to 6 general use physical

endpoints and 8 logical endpoints, each of which may be configured for bulk, interrupt or isochronous transfers. The USB configuration information is read from onchip memory via the USB controller’s DMA.

Figure 9 shows a block diagram of the USB controller. This device makes extensive

use of the DMA to read and write the multiple buffers associated with all of the endpoints that it can have open at one time

2.3.6. External Memory Interfaces.

DSP CORE

X-BUS

16KWord SRAM

16KWord SRAM

16KWord SRAM

DMA-BUS

EMC

Programmable

Registers

EMC

NAND Flash/

SmartMedia

State Machine

Figure 10. External Memory Controller

The chip includes an external memory controller that has two major functional

modes: SmartMedia/NAND and CompactFlash. The SmartMedia/NAND flash interface provides a state machine that provides all of the logic necessary to perform

DMA functions between on-chip RAM and the flash. The CompactFlash interface

supports the CompactFlash M emory mode. This mode can be used to communicate

with standard CompactFlash (CF) devices such as CF Flash and the IBM MicroDrive. The CF Memory mode can be used to communicate with standard

ATA/ATAPI devices like CD-ROM and hard drives

P-BUS

16KWord SRAM

16KWord SRAM

16KWord SRAM

EMC

DMA Engine

EMC

Compact Flash

State Machine

Y-BUS

14 5-35xx-D1-1.06-071604

Page 15

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

The external memory controller can be described as three fairly independent

devices in one: a SmartMedia/NAN D flash interfac e based on th e STMP3410 flash

controller, a CompactFlash/NOR flash/IDE interface, and a new general purpose

flash state machine that can support the new 1Gb/die NAND flash devices with

128KByte block erase modes. These interfaces share the same device pins, some

registers and the DMA engine.

The interfaces use memory mapped registers to setup and control the transactions.

Data is always sent through DMA – there are no data registers that correspond to

the interface data bus. Transactions are always started with a kick bit. The interface

sets up the control lines and transfers data to/from the internal RAM. Once the

transaction is complete the interface signals the DSP with either a polled flag or an

interrupt.

2.3.7. Hardware Acceleration for ECC for Robust External Storage

The forward error correction module is used to provide STMP35xx applications with

a reliable interface to various storage media, especially storage media that would

otherwise have unacceptable bit error r at es . T he ECC m od ule co m pr ise s two different error correcting code proces so rs:

• 1-bit correcting Samsung SSFDC (Hamming-code) encoder/decoder.

• 4-symbol correcting (9-bits/symbol) Reed-Solomon encoder/decoder.

The 1-bit hamming code is defined by Samsung for use with all SSSFDC compliant

NAND flash memories. This code is capable of correcting a single incorrect bit over

the block for which the ECC is valid (256 bytes per page).

The purpose of the Reed-Solomon decoder is to process a coded block (data block

followed by “parity” check data) to determine if there is an error and, if there are

errors, where they are located and how to correct them. The purpose of the ReedSolomon encoder is to read a block of 503-symbols from RAM, calculate and

append 8-parity symbols to form a 512-symbol RS-codeword.

The Hamming code error corrector is strong enoug h to detect two bit s in erro r in 256

bytes and to correct 1-bit/256 byte errors. Both of these error correction

encoder/decoders use DMA transfers to move data to and from on-chip RAM completely in parallel with the DSP performing other useful work.

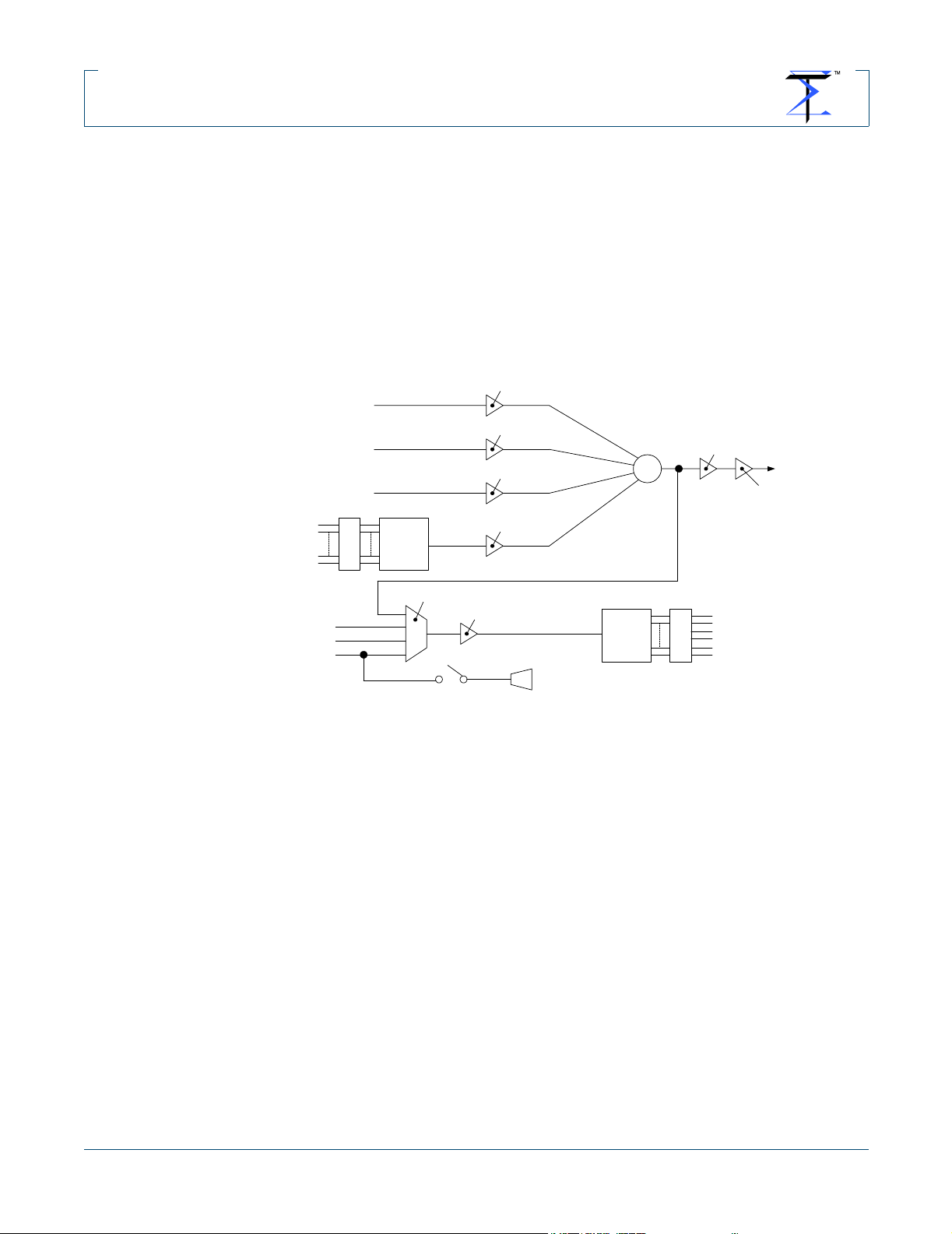

2.3.8. Mixed Signal Audio Subsystem

The STMP35xx contains an integrated high quality mixed signal audio subsystem,

including high quality sigma delta D/A and A/D converters. The D/A is of course the

mainstay of the Audio Decoder/Player product application while the A/D is used for

Voice Record and MP3 Encode applications.

The chip includes a low noise headphone driver that allows it to directly drive low

impedance (8Ω or 16Ω) headphones. The direct drive, or “cap-less” mode removes

the need for large expensive DC blocking capacitors in the headphone circuit. The

headphone power amplifier can detect headphone shorts and report them via the

DSP interrupt system. A digitally programmable master volume control allows user

control of the headphone volume. Annoying clicks and pops are eliminated by zero

crossing updates in the volume/mute circuits and by headphone driver startup and

shutdown circuits.

There is an integrated analog mixer that drives the master volume control programmable gain amplifier. The chip provides for two stereo line level inputs and a mono

microphone input. The microphone circuit has a mono to stereo programmable gain

5-35xx-D1-1.06-071604 15

Page 16

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

pre-amp and an optional microphone bias generator. The line inputs have programmable gain/attenuation and balance capability. The integrated sigma delta DAC has

a programmable gain/attenuation analog amplifier. The programmable gain/attenuation stage outputs from all three stereo inputs and from the DAC are mixed together

to drive the master volume control. There is an analog mux in front of the ADC that

can select any of the three input sources or the mixer output. The se lected source is

then sent to the ADC Gain stage and from there to the ADC. The mixer can be independently powered down. In this configuration, the mixer is bypassed so that the

DAC can still play audio through the headphone driver saving power consumption

and improving the SNR and THD performance.

Line 1 In Gain

LINEIN

Mixer

Master

Volume

Headphone

Driver

FROM

DAC

DMA

MICIN

FMIN

EN

DAC

CLK

Mic In Gain

FM In Gain

DAC Gain

+ OUTPUT

ADC Input Mux

LINEIN

FMIN

MICIN

ADC GAIN

Figure 11. Mixed Signal Audio Elements

2.3.9. Filter Coprocessor

A filter coprocessor has been added to the STMP35xx to reduce th e DSP load associated with filter calculations. Additional enhancements in the ADC and DAC buffer

management have greatly reduced the DSP work load as compared with

STMP3410 based applications. The concomitant reduction in DSP overhead yields

more available MIPS for more intensive software applications or allows the reduction in clock frequency/voltage and thereby dramatically extends the battery life.

The filter coprocessor is a DMA based engine that overlaps execution with the DSP.

2.3.10. IDE/ATA Hard Drive Interface

The external memory controller interface supports the attachment of an ATA/IDE

hard drive device. This is particularly useful for one inch 2GByte hard drive and 2.5

inch 10GByte hard drive MP3 players. Hard drive and external SDRAM configurations are supported in the same application, i.e. large blocks of hard drive data can

be copied to SDRAM leaving the hard drive unused for most of the MP3 play time.

Mic Bias

ADC

CLK

EN

TO

ADC

DMA

2.3.11. SDRAM Interface

The STMP35xx contains an SDRAM controller that can be used to connect external

SDRAM memory chips. The controller is designed to work with 8 bit wide memory

16 5-35xx-D1-1.06-071604

Page 17

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

systems. It supports SDRAM products from the 64Mbit, 128Mbit and 256MBit

JEDEC families. SDRAM memory systems as small as 8MBytes can be configured.

SDRAM memory subsystem are useful for applications that include CD-ROM or IDE

hard drives.

2.3.12. Serial Peripheral Control Interface and I2C

The chip contains a four wire SPI bus. It can act as a master for this bus to control

other chips in the system, such as EEPROMs. It can also act as a slave on this bus

to allow a host processor to communicate with the STMP35xx. The STMP35xx

includes an enhanced SPI interface that provides DMA transfer supp ort. In addition,

the chip contains a two wire SMB/I

master on the SMB interface.

2.3.13. LCD/LED and GPIO

The STMP35xx contains 85 GPIO pins in the 144-pin p ackage. Most digita l pins that

are available for specific functions, e.g. SDRAM interface are also available as

GPIO pins if they are not otherwise used in a particular application.

Most LCD and LED displays can be directly controlled from the GPIO interface.

2

C bus interface. It can act as either a slave or

2.3.14. PULSE WIDTH MODULATOR (PWM) CONTROLLER

The STMP35xx contains four PWM output controllers that can be used in place of

GPIO pins. Applications include LED brightness control and high voltage genera tors

for electroluminescent lamp (E.L.) display back lights. Independent output control of

each phase allows zero, one or hi-Z to be independently selected for the active and

inactive phases. Individual outputs can be run in lock step with guaranteed nonoverlapping portions for differential drive applications.

The controller does not use the DMA. Initial values of Period, Active, and Inactive

widths are set for each desired chan nel. The outputs are selected by phase and

then the desired PWM channels are simultaneously enabled. This effectively

launches the PWM outputs to autonomously drive their loads without further DSP

intervention.

Each PWM channel has a dedicated internal 12 bit counter which increments once

for each divided clock period presented from the clock divider. The internal counter

resets when it reaches the value stored in the channel control registers. The Active

flip flop is set to one when the internal counter reaches the value stored in a register .

It remains high until the internal counter exceeds the value stored in another register. These two value define the starting and ending points for the logically “active”

portion of the waveform. The actual state on the output for each phase, e.g. active

or inactive, is completely controlled by the active and inactive state values in the

channel control registers and can be: HIGH, LOW, or TRI-STATE.

5-35xx-D1-1.06-071604 17

Page 18

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

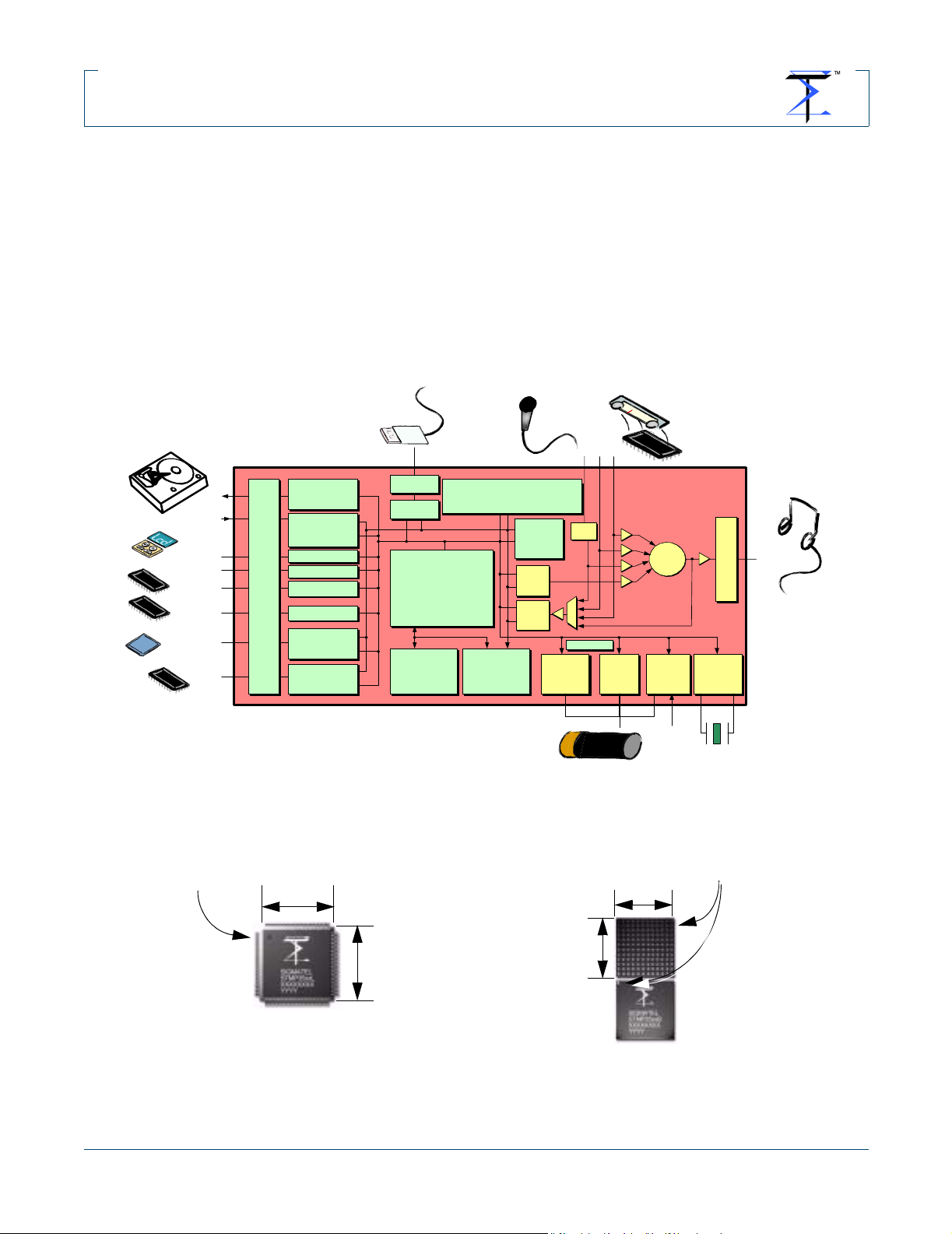

2.4. STMP35xx Family Members

The STMP35xx is available in a number of ordering options whose function content

is represented in Figure 12, also see 33. “STMP35xx FAMILY MEMBER PART

NUMBERS & ORDERING INFORMATION” on page 391..

STMP3550

‡

STMP3501

STMP350 2

MP3

WMA

LED/LCD Interface

USB Mass Storage

Voice Record

†

FM Tuner

Headphone Amp

& Driver

20-25 Hour

Battery Life

1xAA, 1xAAA Batt.

USB 2.0 (Full Speed)

SLC, MLC NAND

100-pin TQFP

†

STMP3505

STMP3506

MP3

WMA, WMA w/DRM

‡

MP3 Encode

LED/LCD Interface

EL Backlight

USB Mass Storage

RTC [Janus DRM]

Voice Record

FM Tuner

Headphone Amp

& Driver

50 Hour

Battery Life

1,2xAA, 1,2xAAA,

LiIon batteries

USB 2.0 (Full Speed)

SLC, MLC NAND

100-pin TQFP

144-pin BGA

‡

STMP3510

STMP3520

MP3

WMA, WMA w/DRM

‡

MP3 Encode

LED/LCD Interface

EL Backlight

USB Mass Storage

RTC [Janus DRM]

Voice Reco rd

FM Tuner

Headphone Amp

& Driver

50 Hour

Battery Life

1,2xAA, 1,2xAAA ,

LiIon batteries

High-Speed USB 2.0

SLC, MLC NAND

100-pin TQFP

144-pin BGA

‡

STMP3560

MP3

WMA, WMA w/DRM

‡

MP3 Encode

LED/LCD Interface

EL Backlight

USB Mass Storage

SDRAM Interface

RTC [Janus DRM]

Voice Record

FM Tuner

Headphone Am p

& Driver

50 Hour

Battery L ife

1,2xAA, 1,2xAAA,

LiIon batteries

High-Speed USB 2.0

Battery Charging

SLC, MLC NAND

100-pin TQFP

144-pin BGA

Figure 12. STMP35xx Family Members

18 5-35xx-D1-1.06-071604

Page 19

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

2.5. Signal Pin Sharing Among Various Application Configurations

A large number of the chips I/.O pins are shared between various functions. The

exact conflicts can be found in Table 491, “Pin Definition Table,” on page 377.

SDRAM

EMC NAND & SmartMedia

EMC CompactFlash Memory & A TA/IDE

EMC NAND & SmartMedia #2 #1

EMC CompactFlash memory & ATA/IDE #2 #1

SDRAM #1 #1

CapLess Mode Headphone #3

Line In 1 #3

Table 2. Pin Sharing Constraints by Subsystem

NOTES:

#1: The EMC and SDRAM interfaces share a number of pins, including addr ess and

data busses. While precluding exactly simultaneous accesses, careful attention to

chip selects and controller programing allows them to be used within the same

application, e.g. reading CompactFlash in IDE mode and writing SDRAM for H DD

MP3 player applications. Recommendation: use driver level mutual exclusion semaphores.

#2: Within the EMC devices, conflicts can occur between shared pins in the

NAND/SmartMedia interface and the CompactFlash interface. Use driver level

mutual exclusion semaphores.

#3: Capless headphone mode common amplifier output shares a pin with the analog line 1 Right input. In addition, the headphone common mode sense input shares

a pin with analog line 1 Left input. Only one of these uses can be designed into a

specific application.

Line In 1)

CapLess Mode Headphone

2.6. Additional Documentation

Additional documentation and information is available from SigmaTel, including an

extensive software development kit (SDK), application notes, reference schematics,

sample PCB board layouts, sample bill of materials, etc.

It is specifically recommended that the reader refer to the peripheral device include

files from the SDK. These files provide constant declarations for address offsets to

the registers defined in the following sections. Note that the name of each programmable register defined in this data sheet corresponds to a C language #define or

assembly language equate of the exact same name. In addition, these files contain

5-35xx-D1-1.06-071604 19

Page 20

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

declarations that allow symbolic access to the individual bit fields within these registers. User programs can include all of these peripheral include files by simply including the file hw_equ.inc into their assembly files and hw_equ.h into their C files.

20 5-35xx-D1-1.06-071604

Page 21

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

3. CHARACTERISTICS/SPECIFICATIONS

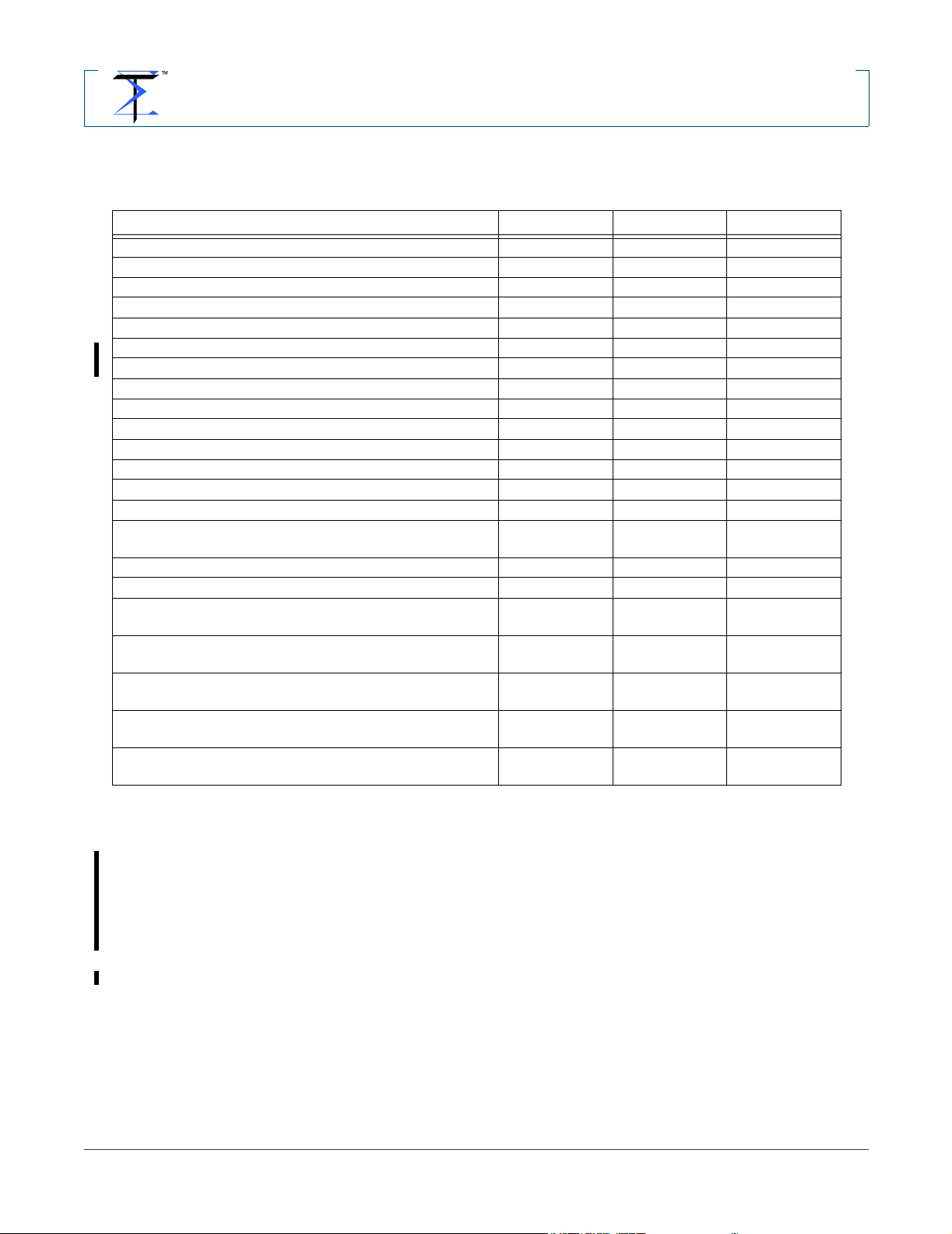

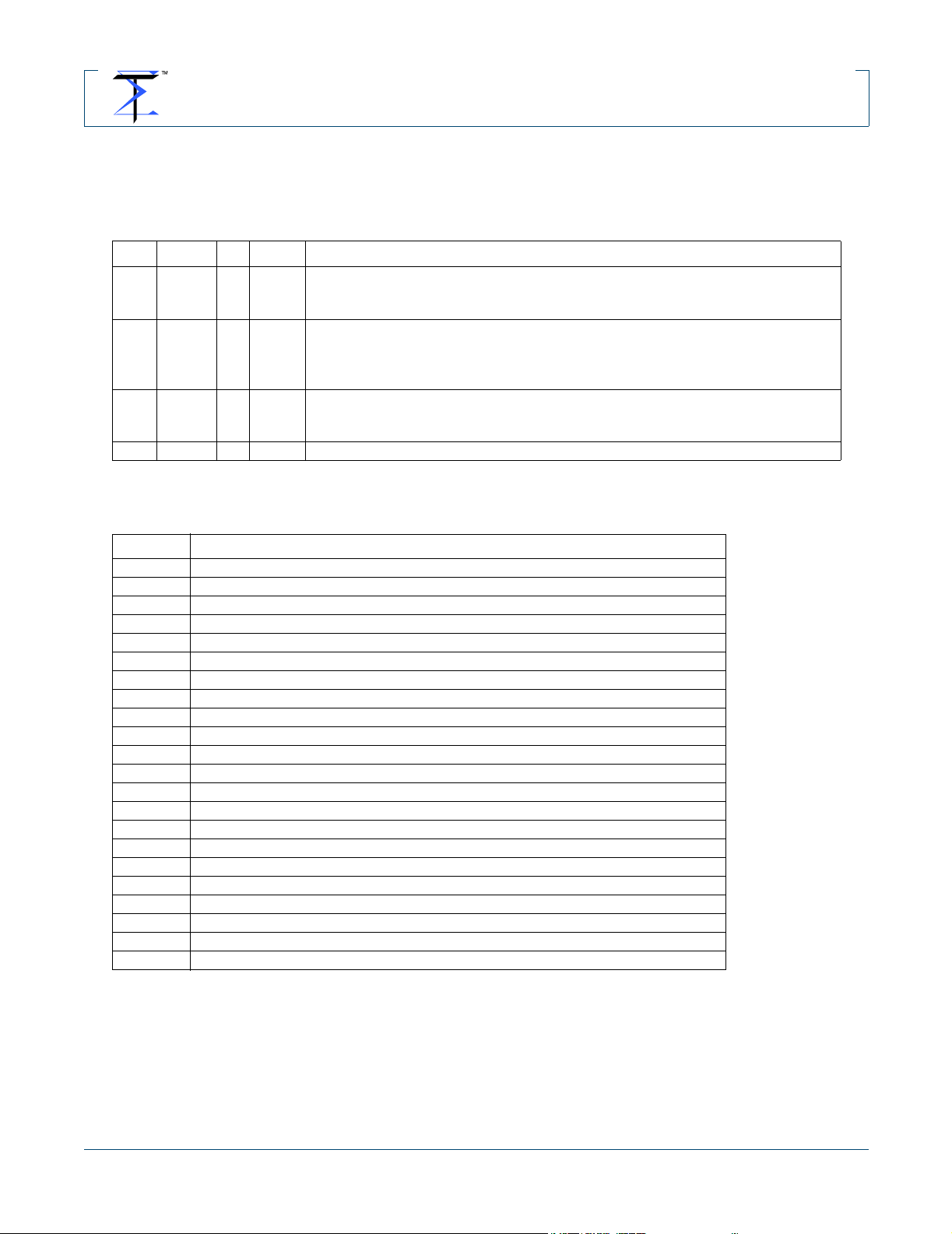

3.1. Absolute Maximum Ratings

PARAMETER MIN MAX UNITS

Ambient operating temperature (Note 1) -10 70 °C

Storage temperature -40 125 °C

Battery Pin (BATT) DCDCMODE 000, 001, 010,011 -0.3 4.2 V

Battery Pin (BATT) DCDCMODE 101,111 -0.3 1.98 V

5 Volt Source Pin (VDD5V) -0.3 5.25 V

PSWITCH DCDCMODE 101,111 -0.3 VddIO V

PSWITCH DCDCMODE 000,001,010,011(Note 2). -0.3 BATT V

Analog supply voltage (VddA1, 2, VddHP, VddPLL) Digital Supply 1.98 V

Digital supply voltage (VddD1, 2, 3) -0.3 Analog Supply V

I/O Supply (VddIO1, 2, 3, 4) -0.3 3.63 V

DCDC converter #1 (DCDC_VddD) -0.3 VddD Rail V

DCDC converter #1 (DCDC_VddA) -0.3 VddA Rail V

DCDC converter #1 (DCDC_VddIO) DCDC Mode 000 -0.3 4.2V V

DCDC converter #1 (DCDC_VddIO) all other DCDC Modes -0.3 3.6V V

DCDC converter #1 (DCDC_Batt) -0.3 max (VddIO,

BATT)

DCDC converter #2 (DCDC2_Vout) DCDC Mode 000 -0.3 4.2 V

DCDC converter #2 (DCDC2_Vout) all other DCDC Modes -0.3 3.6 V

Input voltage on any DCDC MODE input pin relative to

ground (DCDCMOD) (Note 3)

Input voltage on any digital I/0 pin relative to ground (DIO3)

(Note 3)

Input voltage on any digital I/O pin in 1.8V mode relative to

ground (DIO18) (Note 3)

Input voltage on USB D+, D- pins relative to ground (USBIO)

(Note 3)

Input voltage on any analog pin relative to ground (AIO)

(Note 3)

Table 3. Absolute Maximum Ratings

Note: 1. Contact SigmaTel for extended temperature range options. In most systems designs, battery

-0.3 BATT V

-0.3 VDDIO+0.3 V

-0.3 VDDD+0.3 V

-0.3 3.6 V

-0.3 VDDA+0.3 V

and display specifications will limit the operating range to well within these specifications.

2. The maximum voltage limit on the PSWITCH pin can be achieved in DCDCMODE 000, 001, 010, and

011 by connecting the power switch to battery. A 20kohm resistor is placed between the switch and the

PSWITCH pin to limit the current into the pin. In DCDCMODE 111 and 101, the power switch is tied to

VDDIO and a 20kohm resistor is placed between the switch and the PSWITCH pin to limit the current

into the pin. The ESD protection diode limits the input voltage to an acceptable level as long as a 20kohm

resistor is placed in series with PSWITCH pin to limit the current.

3. Pin sets for DCDCMODE, DIO3, DIO18, and AIO are defined in the pin list, see Table 491. “Pin Definition

Table” on page 377.

V

5-35xx-D1-1.06-071604 21

Page 22

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

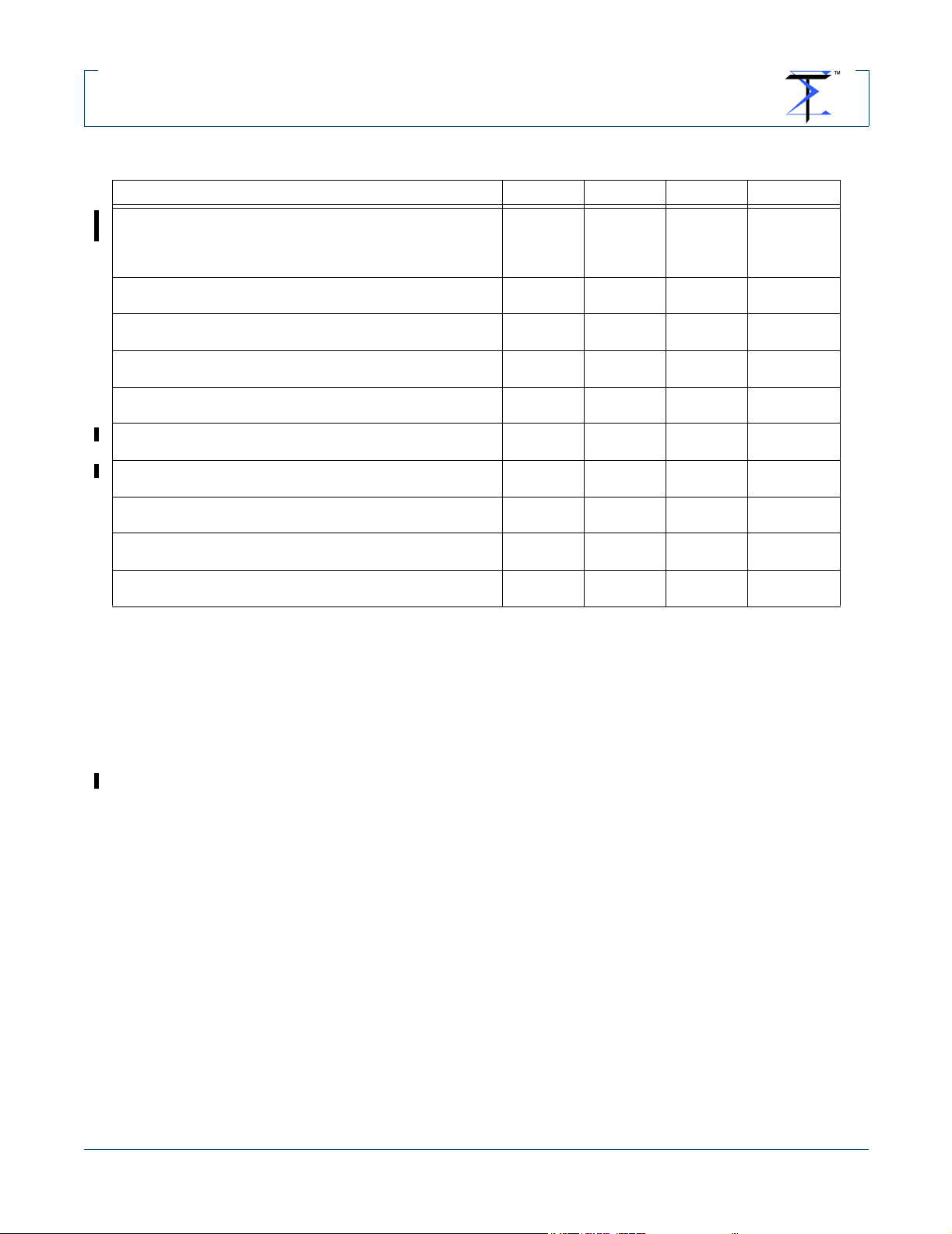

D-Major™Audio System on Chip

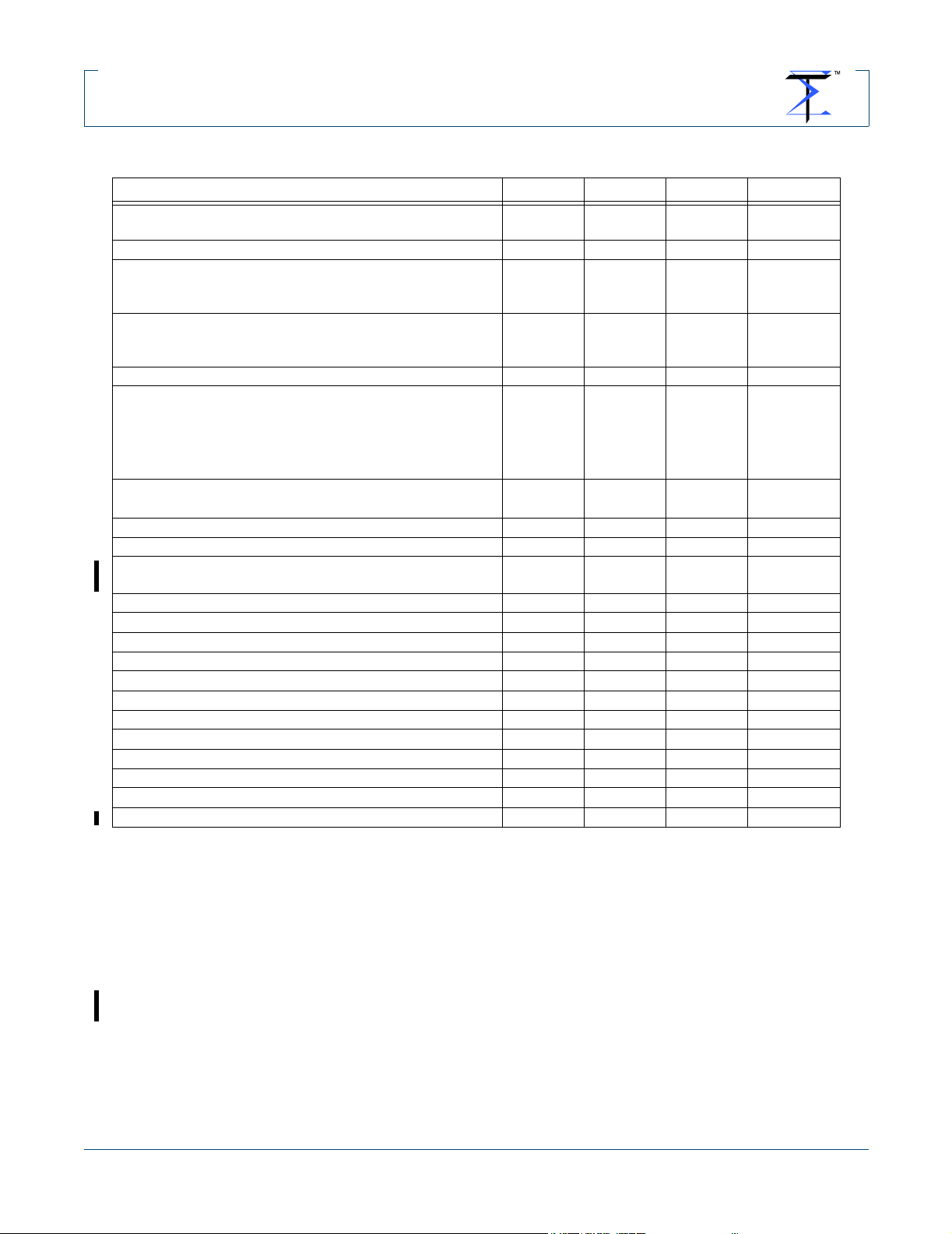

3.2. Recommended Operating Conditions

PARAMETER MIN TYP MAX UNITS

Digital core supply voltage – VddD1, VddD2, VddD3 (Note 4)

Specification dependent on DSP frequency

Digital I/O supply voltage – VddIO1, VddIO2 2.9 3.0 3.6 V

Analog supply voltage – VddA(VddA1, VddA2, VddA3) for

player type applications where the mixer is powered down.

Specification dependent on maximum output power

Analog supply voltage – VddA(VddA1, VddA2, VddA3) for FM

or Voice Record type applications which utilize the mixer.

Specification dependent on maximum output power

Battery startup input voltage in 1xAA or 1xAAA mode 0.9 - - V

Full Scale Input Voltage:

Line Inputs (Note 5) - 0.6 - Vrms

Mic Input

With 20 dB boost

Without 20 dB boost

Full Scale Output Voltage with 16Ω load:

Headphone/Line Outputs (VddA = 1.8 V) - 0.54 - Vrms

Headphone/Line Outputs (VddA = 1.38 V) - 0.42 - Vrms

Crosstalk between output channels (16Ω loads at 1Khz) - -75 - dB

THD+N (16Ω headphone at 1 Khz) except STMP3501

(Note 9)

THD+N (10KΩ load at 1 Khz) -87 dB

THD+N (16Ω headphone at 1 Khz) for STMP3501 -64 dB

Analog line input resistance (Note 6) - 25 - kΩ

Microphone input resistance - 10 0 - kΩ

Analog output resistance - - <1 Ω

DAC SNR Idle Channel (Note 7) - 96 - dB

DAC -60dB dynamic range (Note 7) 92 94 - dB

ADC SNR Idle Channel (Note 7) 90 dB

ADC -60dB dynamic range (Note 7) 90 dB

Line SNR (Note 7) except STMP3501 92 94 - dB

Line SNR (Note 7) for STMP3501 87 89 - dB

Standby Current (Note 8) 150 200 uA

Table 4. Recommended Operating Conditions

Note: 4. Recommended operating voltages for DCLK can be found in Table 5 In all cases, design must allow for

board and bypass design variations.

5. At 1.38VddA max input is 0.45Vrms

6. Input resistance changes with volume setting: 10KΩ at +12dB, 25KΩ at 0dB, 50KΩ at -34.5dB

7. Measured “A weighted” over a 20 Hz to a 20 kHz bandwidth, relative to full scale output voltage (1.8V)

8. The chip consumes current when in the “OFF” mode to keep the crystal oscillator and the real time clock

running. With a typical 2850mAh AA battery, the standby current would take more than 1 year to drain the

battery fully . It also is possible to design a system that disables the crystal oscillator and real time clock to

achieve a much lower OFF current.

9. The BGA package reduces THD performance by approximately 4dB.

1.35 - Analog

Supply

Digital

Supply

1.45 - 1.98 V

-

--70-66dB

-1.98V

- Vrms

0.06

0.6

V

22 5-35xx-D1-1.06-071604

Page 23

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

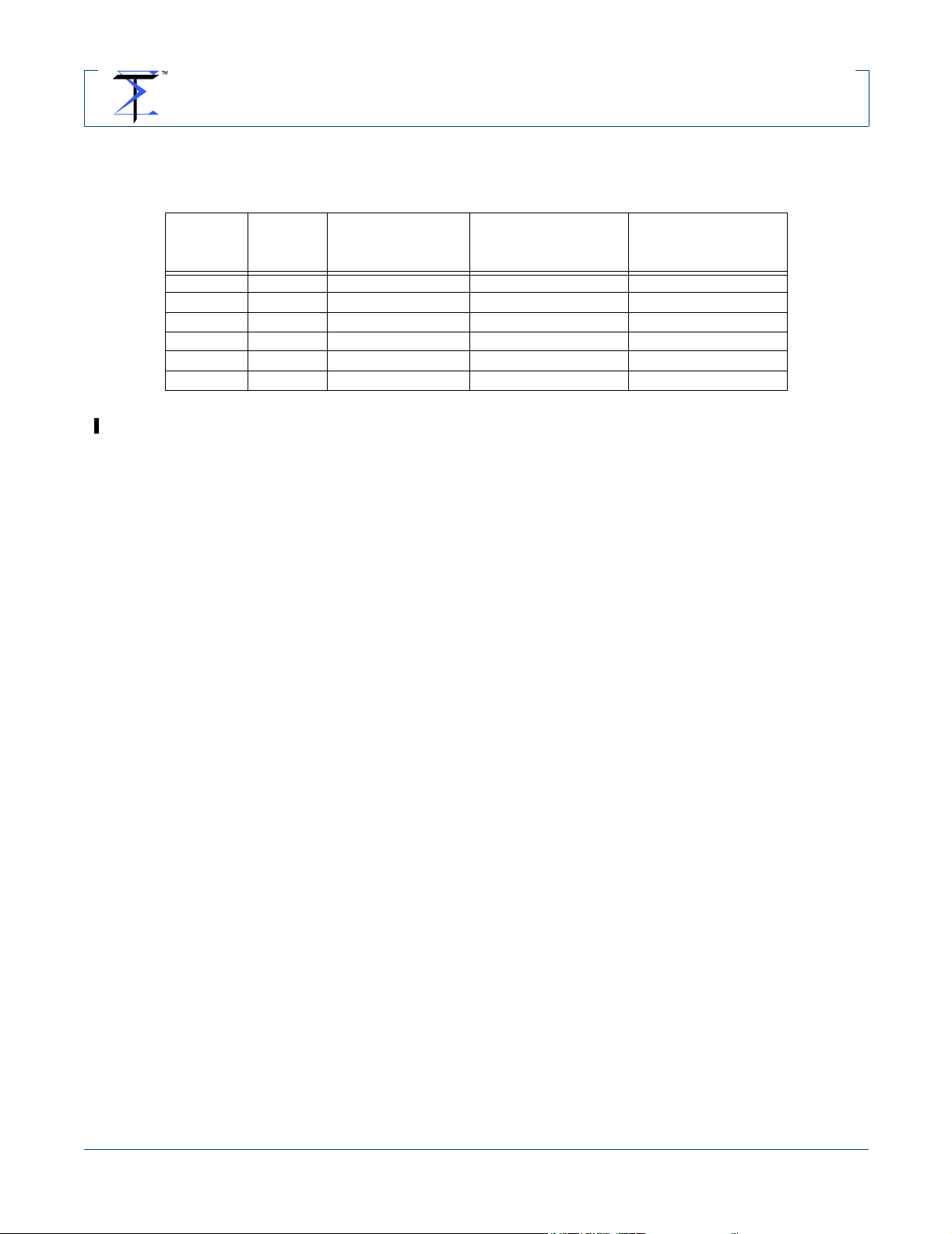

The following table can be used to select a proper setting for VddD and VddD

brownout voltages based on standar d analysis of worst case design and characterization data.

MAX

DCLK

TARGET

75.6MHz 1.92 V 11100 1.85 V 11010

69.6MHz 1.82 V 11001 1.76 V 10111

64.8MHz 1.73 V 10110 1.66 V 10100

60.0MHz 1.63 V 10011 1.54 V 10000

48.0MHz 1.4 V 01100 1.34 V 01010

39.6MHz 1.37 V 01011 1.28 V 01000

Min.

VddD

Table 5. Recommended Operating Conditions for sp ecific dclk targets

HW_DCDC_VDDD_

VOLTAGE_LEVEL

Corresponding

VddD

Brownout Voltage

HW_DCDC_VDDD_

BROWNOUT_LEVEL

.

5-35xx-D1-1.06-071604 23

Page 24

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

3.3. DC Characteristics

PARAMETER MIN TYP MAX UNITS

Power Dissipation, VddD = 1.37 V, VddA = 1.37 V, VddIO =

3.05 V DCDC mode = 2-Channel Boost, DCLK = 36 MHz on

PLL, USB off, Application = MP3 Play, minimum power

configuration selected.

V

(DIO3) - Input high voltage for DIO3 digital I/O pin set, in

iH

3.3 Volt mode.

V

(DIO3) - Input low voltage for DIO3 digital I/O pin set in 3.3

IL

Volt mode.

V

(DIO18) - Input high voltage for DIO18 digital I/O pin set in

IH

1.8 Volt mode.

(DIO18) - Input low voltage for DIO18 digital I/O pin set in

V

IL

1.8 Volt mode.

V

(DIO3) - Output high voltage for DIO3 digital I/O pin set in

OH

3.3 Volt mode, 4mA mode.

V

(DIO3) - Output high voltage for DIO3 digital I/O pin set in

OH

3.3 Volt mode, 8mA mode.

(DIO3) - Output low voltage for DIO3 digital I/O pin set in

V

OL

3.3 Volt mode.

V

(DIO18) - Output high voltage for DIO18 digital I/O pin

OH

set in 1.8 Volt mode.

V

(DIO18) - Output low voltage for DIO18 digital I/O pin set

OL

in 1.8 Volt mode.

Table 6. DC Characteristics

2.0 V

0.7*VddD V

0.8*VddIO V

0.8*VddIO V

VddD - 0.4 V

80 mW

0.8 V

0.3*VddD V

0.4 V

0.4 V

3.4. Restrictions on Approved Usage of SigmaTel Parts

SigmaTel Products are not designed or intended for use in life support appliances,

or systems where malfunction of a SigmaTel product can reasonably be expected to

result in personal injury or death nor are they intended for use in any application

where malfunction of a SigmaTel product can reasonably be expected to result in

environmental or other subsequent damage.

24 5-35xx-D1-1.06-071604

Page 25

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

4. DSP CORE

The on-chip DSP core is modeled exactly after the Motorola DSP56004. It supports

the identical instruction set, registers, addressing modes, etc., as the DSP56000

family of digital signal processors. Figure 13 shows the DSP architecture.The DSP

core is a general-purpose 24-bit DSP especially suited to high fidelity digital audio

applications for very low power/energy environments.

OnCE

Debugger

Interface

Data

Bus

Switch

ADDRESS

GENERATION

UNIT

ON-CHIP

PROGRAM

RAM/ROM

XAB

YAB

PAB

XDB

YDB

PDB

GDB

ON-CHIP

Y

RAM

ON-CHIP

X

RAM

Peripherals

PROGRAM

Interrupt

Controller

5-35xx-D1-1.06-071604 25

PROGRAM

DECODE

CONTROLLER

Mode GPIO bits

IVL[6:0],IRQA, IRQB, NMI

RESET

Figure 13. DSP Architecture

PROGRAM

ADDRESS

GENERATOR

DATA ALU

24 x 24 +56 --> 56-bit M AC

Two 56 bit Accumulators

Page 26

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

The central components are:

• Data Busses (XD,YD,PD)

• Address Busses (XA,YA,PA)

• Data Arithmetic Logic Unit (Data ALU)

• Address Generation Unit (AGU)

• Program Control Unit (PCU)

• On-Chip Program ROM

• On-Chip X,Y,P RAM

• On-Chip Emulation circuitry

The DSP is organized around the registers of three independent e xecution unit s: the

PCU, the AGU and the data ALU. Data movement between the execution units

occurs over four bidirectional 24-bit buss es: the X data bus (XDB), the Y data bus

(YDB), the program data bus (PDB) and the global data bus (GDB). Certain instruc tions treat the X and Y data buses as one 48-bit data by concatenating them. Data

transfers between the data ALU and the X data memory or Y data memory occu r

over the XDB and YDB respectively.

The bus structure supports general register-to-register, register-to-memory, and

memory-to-register data movement. It can transfer up to two 24-bit words or one 56bit word in the same instruction cycle.

Transfers between busses occur in the internal bus switch. The internal bus switch,

which is similar to a switch matrix, can connect any two internal busses without adding pipeline delays. Thus greatly simplifying the programming model.

The bit manipulation unit is located in the bus switch so that it can access each

memory space. The bit manipulation un it performs bit operations on memory locations, address registers, control registers and data regi sters over the XDB, YDB and

GDB.

The data ALU performs all of the arithmetic and logical operations on data operands. It consists of four 24 bit input registers, two 48-bit accumulators and two 8-bit

accumulator extension registers, an accumulator shifter, two data bus shifter/limiter

circuits, and a parallel single cycle, non-pipelined multiply-accumulator (MAC) unit.

The address generation unit (AGU) performs all of the ad dress storage and address

generation computations necessary to indirectly address data operands in memory.

It operates in parallel with other DSP resources to minimize address generation

overhead and keep the su pply of da ta operand s fed to the da ta ALU. The A GU has

two identical address arithmetic units that can generate two 16-bit addresses every

instruction cycle. Each of the arithmetic units can perform one of three types of

address arithmetic: linear, modulo and reverse-carry.

The program control unit performs instruction prefetch, instruction decode, hardware DO loop control, and interrupt/exception processing. It consists of three components: the program address generator, the program decode controller, and the

program interrupt controller. It contains a 15-level by 32 bit system stack memory

and the following directly addressable registers: the program counter (PC), loop

address (LA), loop counter (LC), status register (SR), and the operating mode register (OMR).

The DSP core responds to 7 interrupt vector level inputs (IVL[6:0], two peripheral

interrupts (IRQA, IRQB) and a non-maskable interrupt (NMI).

26 5-35xx-D1-1.06-071604

Page 27

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

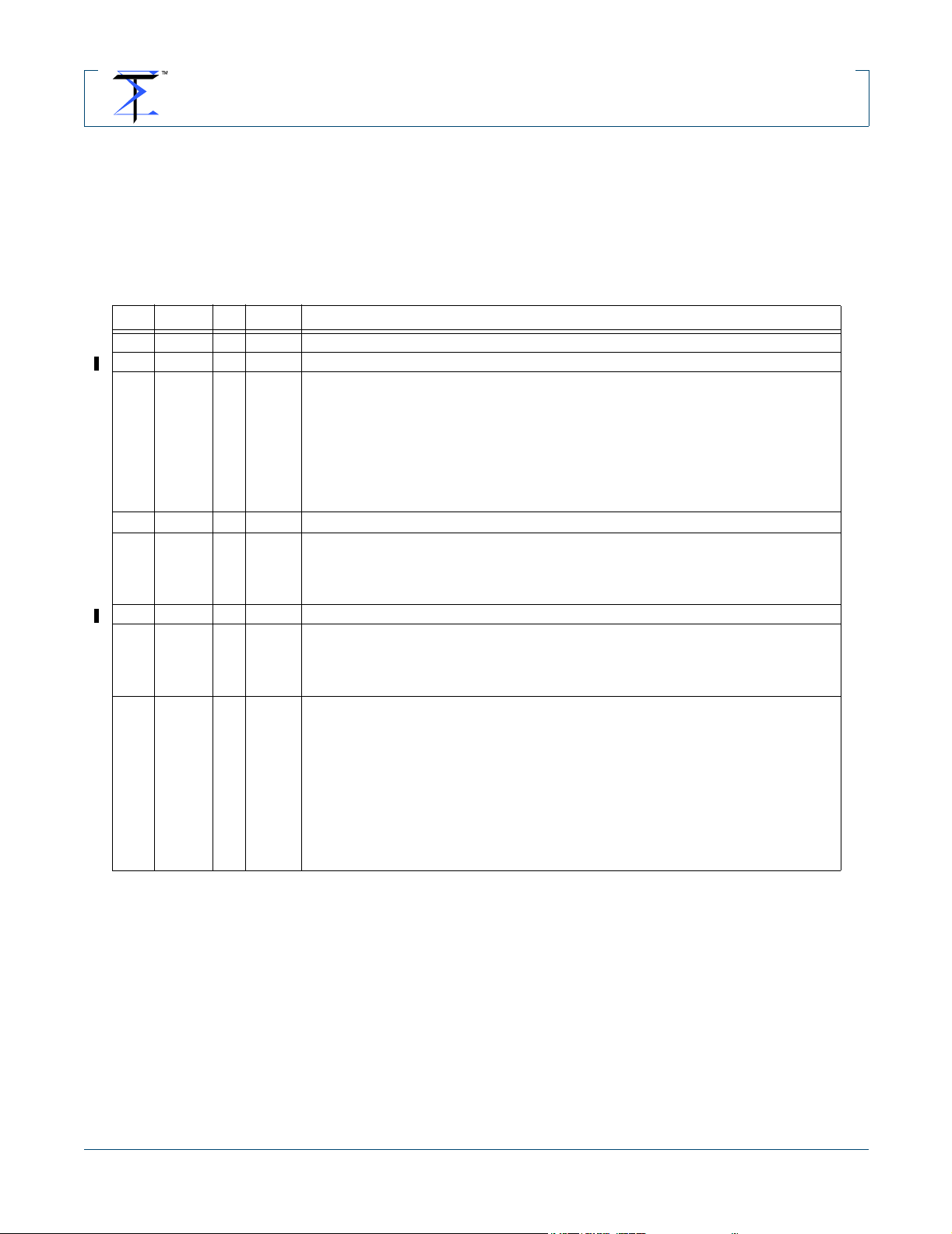

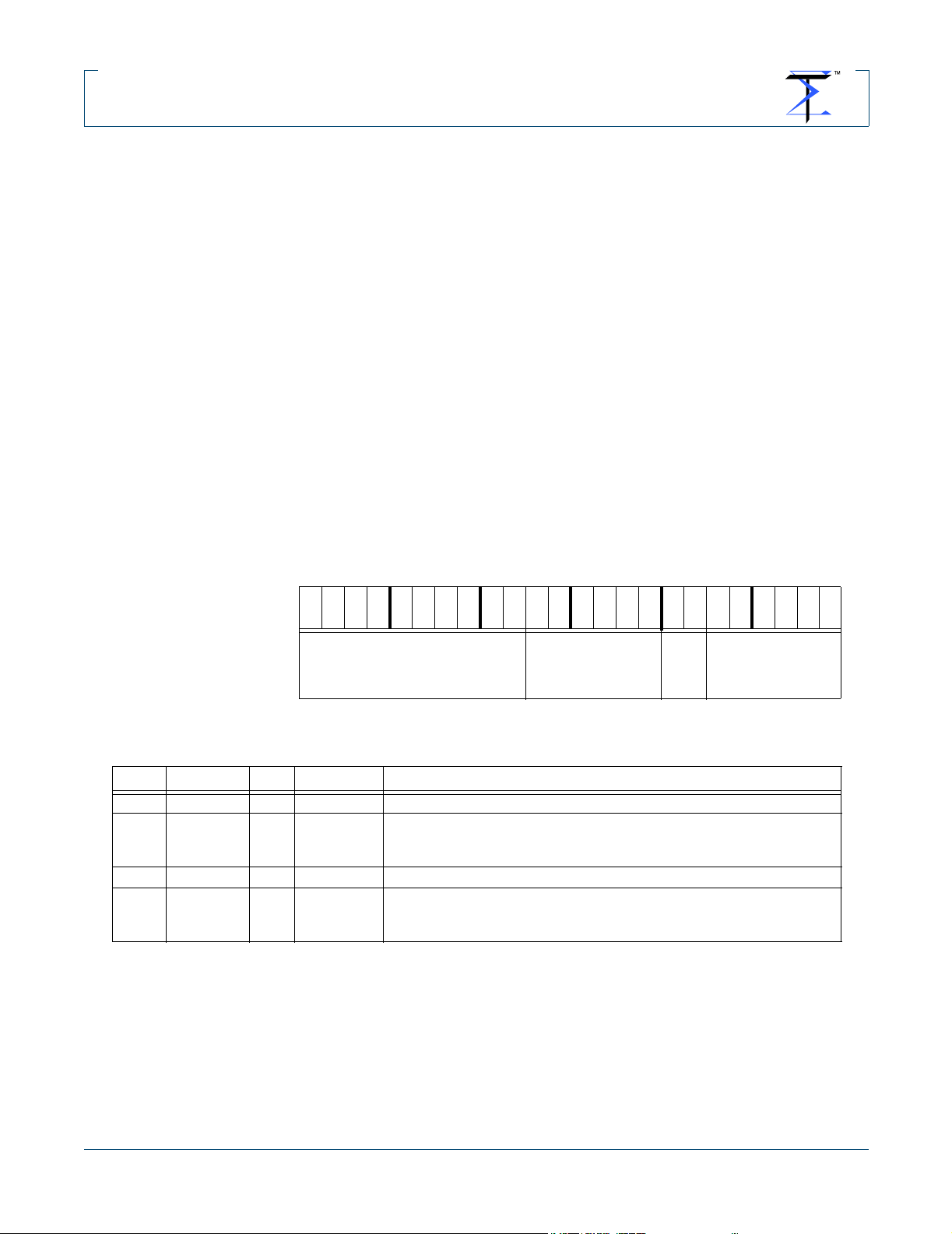

4.1. Operating Mode Register

The organization of the operating mode register is shown below. The operating

mode register determines chip configuration including boot modes, and memory

configuration. The HW_OMR is a core register that is accessible by special DSP

instructions. It therefore has no address.

HW_OMR SPECIAL

BITS LABEL RW RESET DEFINITION

23:8 RSRVD R0 Reserved – Must be written with 0.

7 RSRVD R 0 Reserved – Must be written with 0.

6 SD RW 0 Stop Delay – This bit is exported from the core as an output. It can be used when

waking up from the STOP low power standby mode. If this bit is set, then when an

IRQA interrupt occurs to wake up the core from the STOP state, the clock control

circuitry will wait a time period (e.g. 65536 clock cycles) before allowing the clocks

back in to the DSP core. This can be used, for example, to restabilize a PLL clock

oscillator. If this bit has a zero value, then the clocks will be allowed back into the core

immediately after the occurrence of the IRQA interrupt, thus implementing a “warm

boot” from the STOP low power standby state.

5 RSRVD R 0 Reserved – Must be written with 0.

4 MC RW GP0 Operating Mode C – This bit is used to configure the boot mode for the STMP35xx.

When the hardware reset is active, this bit samples the state of GP0 pin. Once the

boot code executes, it can check the state of this bit in order to make decisions about

what type of boot mode to perform.

3:2 RSRVD R 0 Reserved – Must be written with 0.

1 MB RW GP1 Operating Mode B – This bit is used to configure the boot mode for theSTMP35xx.

When the hardware reset is active, this bit samples the state of the GP1 pin. Once the

boot code executes, it can check the state of this bit in order to make decisions about

what type of boot mode to perform.

0 MA RW 1 Operating Mode A – This bit is used to choose between Boot ROM and Program

Memory for instruction fetches and read accesses. When this bit is set, as it is after

hardware reset, the Boot ROM space is activated and any fetches or read accesses to

the P: space will refer to the on-chip ROM. When this bit is a zero, the Program RAM

Memory space is enabled instead of the Boot ROM memory space and any fetch or

read access to P: space will refer to the on-chip RAM. Writes to P: space always

access the program RAM regardless of the state of the MA bit. It is not possible to

write to the program ROM. This bit affects ROM access in region P:$0000 through

P:$3FFF. Accesses to the high mapped region of ROM, P:$C000 through P:$FFFF is

controlled by HW_RAM_ROM_CFG_PROMIE.

Table 7. Operating Mode Register Description

4.2. General Debug Register

The HW_GDBR Register is also mapped into the X Peripheral I/O space. This register is used as a gateway between the DSP and the Debug port. For instance, when

displaying the states of the internal registers and memory of the DSP core, the DSP

moves the data to this register and the data is then shifted out the OnCE_DSO pin.

The HW_GDBR register operation is controlled automatically by the emulator and

the debug circuitry within the core. An added feature of the Debug Unit is that the

emulator cannot access the debug unit unless a write to the HW_GDBR Register is

executed by the DSP (normally in the boot code).

5-35xx-D1-1.06-071604 27

Page 28

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

K

N

STMP35xx

D-Major™Audio System on Chip

HW_GDBR X:$FFFC

23222120191817161514131211100908070605040302010

VALUE

Table 8. HW_GDBR

BITS LABEL RW RESET DEFINITION

23:0 VALUE RW 0 Value to be read by the debugger or debugger value to be read by a DSP instruction

from the debugger.

Table 9. General Debug Register (GDBR)

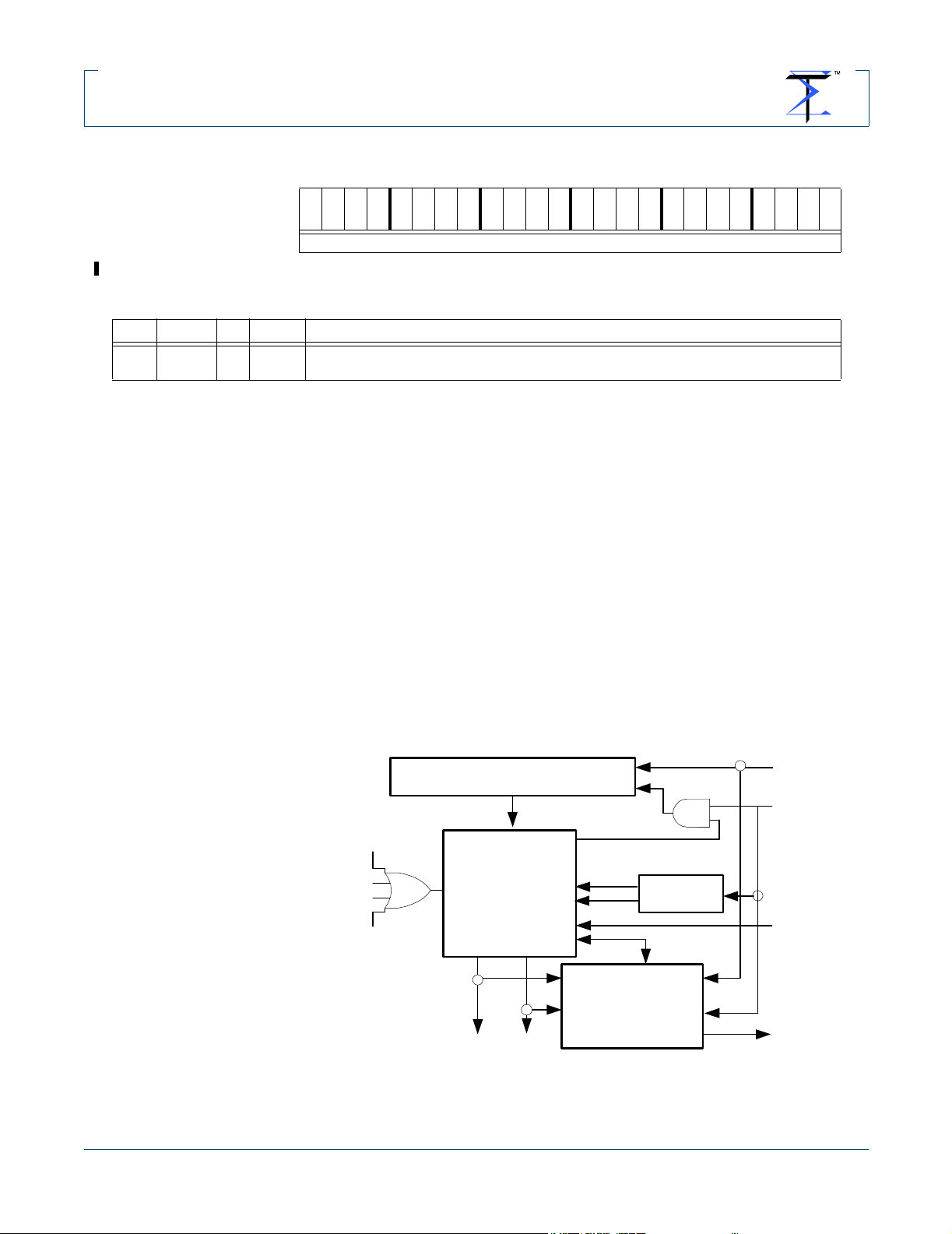

4.3. OnCE (On-Chip Emulator) Debug Interface

The DSP on-chip emulation (OnCE) circuitry provides a sophisticated debugging

tool that allows simple, inexpensive, and speed independent access to the processor’s internal registers, memories and peripherals. OnCE provides software engineers with access to the internal state including the addresses of the last five

instructions and provides the ability to modify that state, and single step the processor. OnCE capabilities are accessed through a four pin interface

1. Debug Serial input (OnCE_DSI)

2. Debug Serial Clock (OnCE_DSK)

3. Debug Serial Output (OnCE_DSO)

4. Debug Request Input (OnCE_DRN)

The OnCE controller and serial interface consists of the following blocks: OnCE

command register, bit counter, OnCE decoder and the status/control register. For a

block diagram, see Figure 14. “OnCE Interface Block Diagram” on page 28.

0

OnCE COMMAND REGISTER

ISBKPT

ISDR

ISTRACE

ISSWDBG

Figure 14. OnCE Interface Block Diagram

28 5-35xx-D1-1.06-071604

OnCE

DECODER

REG

READ

WRITE

REG

bit 7

Bit Counter

bit 23

Status and Control

Register

OnCE_DSI

OnCE_DS

OnCE_DR

OnCE_DSO

Page 29

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

The OnCE Command Register is an 8 bit shift register that receives the serial data

from the OnCE_DSI pin. It holds the 8 bit commands to be used as input for the

OnCE controller.

OnCE Command Register

BITS LABEL RW RESET DEFINITION

7 RW RW The read/write bit specifies the direction of the data transfer. For zero, write the data

associated with the command into the register specified in the RS field. For one, read

the data contained in the register specified in the RS field.

6 GO RW If the GO bit is set, the chip will execute the instruction which resides in the PIL

register. To execute the instruction, the processor leaves the debug mode, and the

status is reflected on the OS0,OS1 pins. The processor will return to the debug mode

immediately after executing the instruction.

5 EX RW If the Exit Command bit is set, the processor will leave the debug mode and resume

normal operation. The Exit command is executed only if the Go command was issued

and the operation is a write to OPDBR or a read/write to” No Register Selected”.

4:0 RS RW Register Select field

Table 10. OnCE Command Register

The Register Select field (RS[4:0]) selects one of 32 OnCE debug registers to be

read or written.

RS[4:0] REGISTER SELECTED

00000 OnCE Status and Control Register

00001 Memory Breakpoint register

00010 Reserved

00011 Trace Counter

0010X Reserved

00110 Memory Upper Limit

00111 Memory Lower Limit

01000 GDB Register NOTE: this register can be read or written by the DSP instructions

01001 PDB Register

01010 PAB Register for Fetch

01011 PIL register, next instruction from debugger comes from here

01100 Clear Memory Breakpoint Counter

01101 Reserved

01110 Clear Trace Counter

01111 Reserved

10000 Reserved

10001 Program Address Bus FIFO and Increment Counter

10010 Reserved

10011 PAB Register for Decode

101XX Reserved

11XX0 Reserved

11111 No Register Selected

Table 11. OnCE Register Selects

5-35xx-D1-1.06-071604 29

Page 30

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

5. ON-CHIP MEMORY SUBSYSTEM

The chip includes 96 kwords of on-chip RAM (96k x 24 bits = 2.25 Mbits) that is

used for program and data storage, and 16 K word s of on-chip ROM (16K x 24 b it s =

384kbits) that is used for the code that boots the device (see Section 20 for more

details on boot modes and the contents of the on-chip ROM). The on-chip ROM is

mapped at the address range P:$0000-$3FFF at reset, it can also be configured to

be mapped at address range P:$CFFF-$FFFF, or it can be disabled.

The on-chip RAM is organized into two banks of 48K words each, called PXRAM

and PYRAM. PXRAM can be mapped into the DSP P memory space, starting at

P:$0000, or into the DSP X memory space, starting at X:$0000. PYRAM can be

mapped into the DSP P memory space, starting immediately after the end of the

PXRAM memory, or into the DSP Y memory space, starting at Y:$0000. Both

PXRAM and PYRAM memory can be allocated to the DSP P, X or Y memory

spaces in 8K word increments, from a minimum of 0K word s to all available memo ry.

The memory configuration is controlled by the PX & PY Memory Configuration registers documented below. There are no hardware safeguards against improper programming of these registers. It is possible to allocate less than all of the on-chip

RAM, unallocated memory will then be invisible to the DSP.

5.1. PXRAM Configuration Register

HW_PXCFG X:$FFE8

23222120191817161514131211100908070605040302010

PXXSIZE

Table 12. HW_PXCFG

BITS LABEL RW RESET DEFINITION

23:14 RSRVD R0 Reserved – Must be written with 0.

13:8 PXXSIZE RW 011000 Number of kwords of PXRAM that is mapped in the DSP X memory

space. Initialize 24KW to X RAM. This six bit field represents 1K

increments of RAM. It must be allocated in 8K word chunks.

7:6 RSRVD R0 Reserved – Must be written with 0.

5:0 PXPSIZE RW 011000 Number of kwords of PXRAM that is mapped in the DSP P memory

space. Initialize 24KW to Y RAM. This six bit field represents 1K

increments of RAM. It must be allocated in 8K word chunks.

Table 13. PXRAM Configuration Register Description

PXPSIZE

0

30 5-35xx-D1-1.06-071604

Page 31

OFFICIAL PRODUCT DOCUMENTATION 8/10/04

STMP35xx

D-Major™Audio System on Chip

5.2. PYRAM Configuration Register

HW_PYCFG X:$FFE9

23222120191817161514131211100908070605040302010

0

PYYSIZE

Table 14. HW_PYCFG

BITS LABEL RW RESET DEFINITION

23:14 RSRVD R0 Reserved – Must be written with 0.

13:8 PYYSIZE RW 011000 Number of kwords of PYRAM that is mapped in the DSP Y memory

space. Initialized to 24KW Y RAM.This six bit field represents 1K

increments of RAM. It must be allocated in 8K word chunks.

7:6 RSRVD R0 Reserved – Must be written with 0.

5:0 PYPSIZE RW 011000 Number of kwords of PYRAM that is mapped in the DSP P memory

space. Initialized to 24KW to P RAM. This six bit field represents 1K

increments of RAM. It must be allocated in 8K word chunks.

Table 15. PYRAM Configuration Register Description

PYPSIZE

The PXRAM bank is accessible to DSP P space accesses, DSP X space accesses,

and DMA accesses. The PYRAM bank is accessible to DSP P space accesses,

DSP Y space accesses, and DMA accesses. PXRAM & PYRAM are made up of 3

physical blocks of 16K words each for a total of 48K words each. Since the allocation of on-chip RAM to DSP P space, X space, & Y space is in 8K Word increments,

it is possible for a single physical memory block in the PXRAM bank to be accessed

by the DSP P, DSP X, and DMA busses at the same time, similarly for the PYRAM

bank. When this happens, the memory interface control logic steals one or more

clock cycles from the DSP to allow all of the accesses to complete in separate clock

cycles. In case of conflict, DMA accesses take priority over DSP accesses, and DSP

program accesses take priority over DSP data accesses.

It is possible to eliminate cycle steals because of DSP P space and DSP X or Y conflicts by allocating PXRAM & PYRAM in increments of 16K words, this means that

each physical memory block is allocated to DSP P , X or Y sp ace. It is not possible to

eliminate the cycle steal that happens because a DMA access conflicts with a DSP

access to memory. In order to allow the programmer to monitor total number of