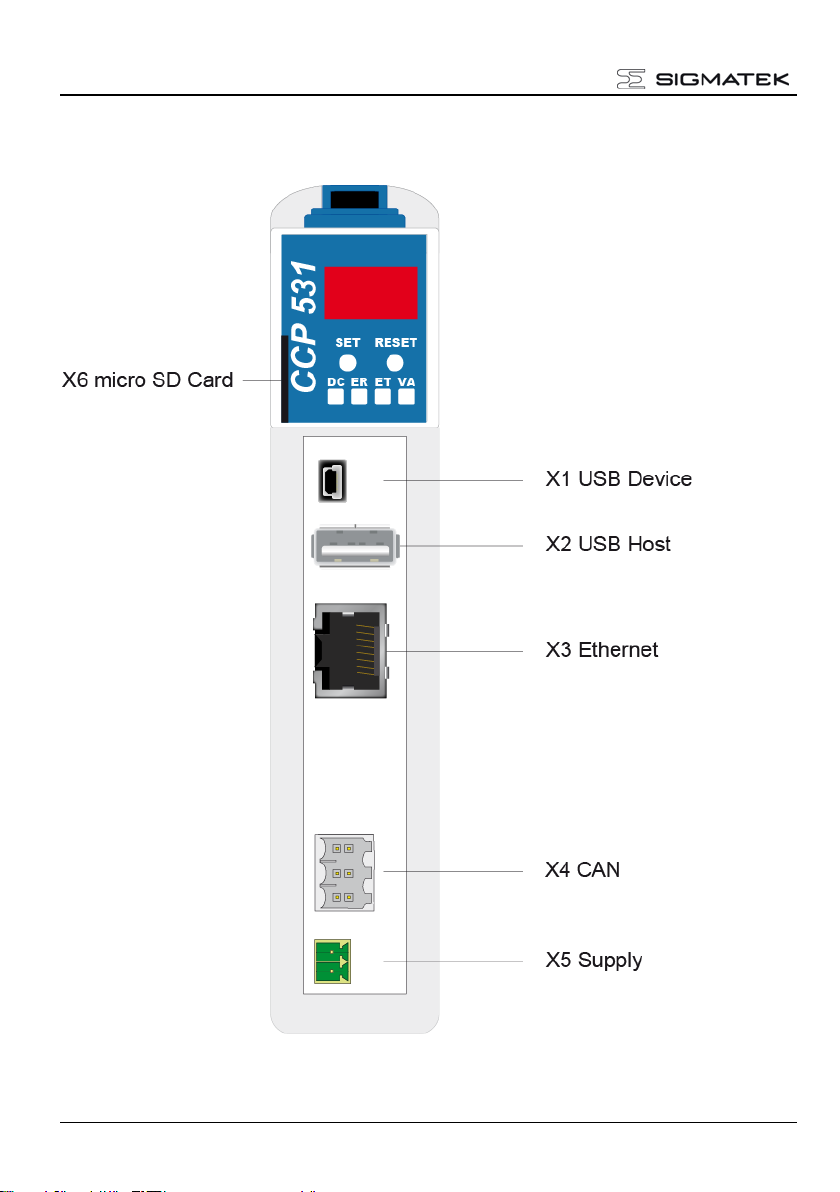

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 1

C-DIAS Processor Module CCP 531

The CCP 531 processor module runs the control program and

thereby represents an essential component of an automation

system. The internal DC/DC converter powers all modules on a

C-DIAS module carrier.

The CAN bus, an Ethernet interface or the USB device (Mini

USB) can be used as the online interface connection.

A 7-segment display and 2 status LEDs provide information on

the actual status of the CPU.

For program updates, the integrated USB Host interface can be

used (USB stick, keyboard). With help from the exchangeable

SD card, the entire control program can be easily exchanged.

The CCP 531 processor module is designed to be mounted in

the control cabinet.

Compatibility

Completely PC-compatible. The CCP 531 works with standard PC BIOS and therefore no

SIGMATEK-specific BIOS is needed; the LASAL operating system in provided.

C-DIAS PROCESSOR MODULE CCP 531

Page 2 12.04.2017

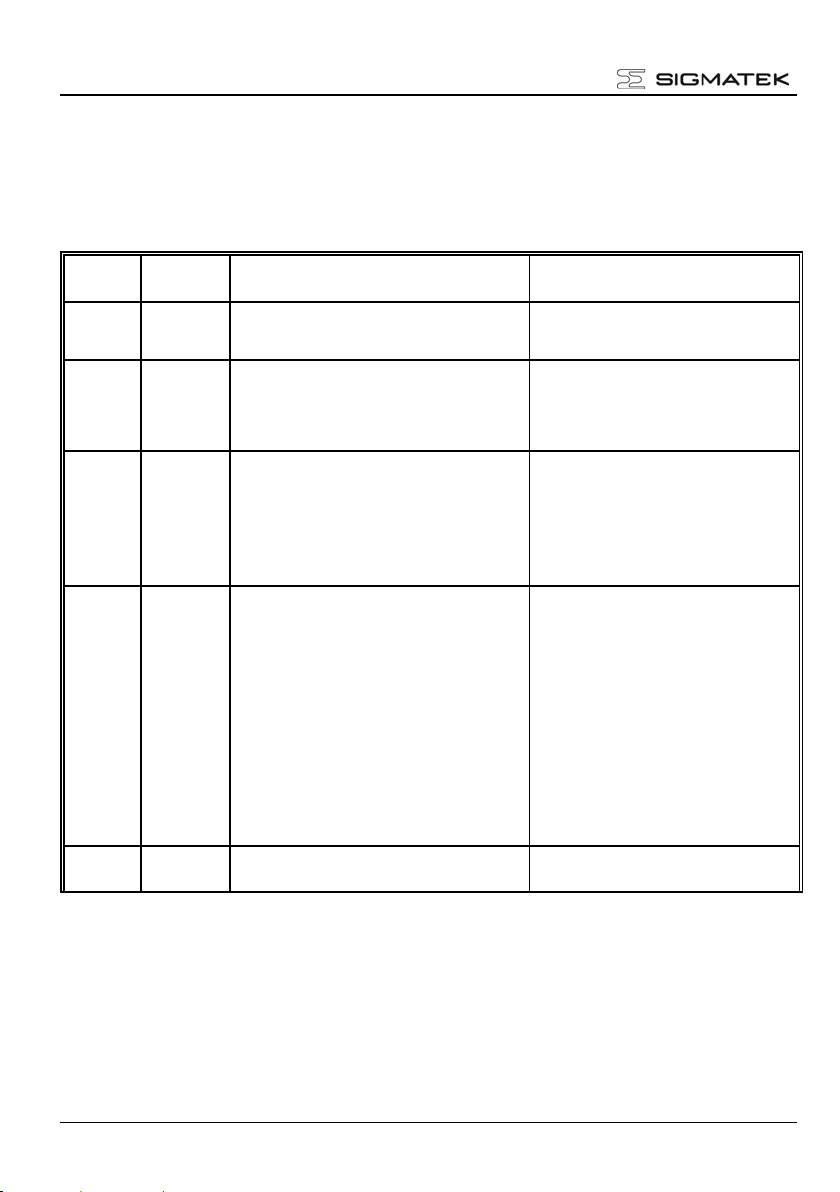

Technical Data

Performance data

Processor

EDGE-Technology X86 compatible

16-bit data bus

Clock frequency

500 MHz

Addressable I/O/P modules

CAN bus: 32

C-DIAS bus: 8

Internal I/O

No

Internal cache

32-kbyte L1 Cache

256-kbyte L2 Cache

BIOS

AMI

Internal program and data memory

(DDR2 RAM)

64 Mbytes

Internal remnant data memory

512 Kbytes

(1)

Internal storage device

512 Mbytes microSD card (12-104-531)

1-Gbyte microSD card (12-104-531-1)

Interface connections

1 x USB Host 2.0 (full speed 12 MBit/s)

1 x USB Device 1.1

1 x Ethernet

1 x CAN

1 x C-DIAS

Data buffer

Yes

Status display

Yes

Status LEDs

Yes

Real-time clock

Yes (buffering approximately 10 days)

(1)

See chapter “Note on SRAM Behavior”

c

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 3

Electrical requirements

Supply voltage

+18 – 30 V DC

Supply voltage (UL)

18 – 30 V DC (Class 2)

Current consumption of (+24 V)

power supply

Typically 150 mA

Maximum 500 mA

Current consumption of (+24 V)

power supply (UL)

Maximum 500 mA

Starting current

For a very short time (~20 ms) : 30 A

Power supply on the C-DIAS bus

Supplied by the CCP 531

Current load on C-DIAS bus

(power supply for I/O/P modules).

Maximum 1.2 A

Only US and Canada:

Use class 2 power supply only!

Seulement Etats-Unis et Canada:

Utilisez alimentation de la classe 2 uniquement!

Standard configuration

Ethernet 1

IP: 10.10.150.1

Subnet-Mask: 255.0.0.0

CAN bus

Station: 00

Baudrate: 01 = 500 kBaud

Problems can arise if a control is connected to an IP network, which contains mod-

ules that do not run a SIGMATEK operating system. With such devices, Ethernet

packets could be sent to the control with such a high frequency (i.e. broadcasts),

that the high interrupt load could cause a real-time runtime error or runtime error. By

configuring the packet filter (Firewall or Router) accordingly however, it is possible

to connect a network with SIGMATEK hardware to a third party network without trig-

gering the error mentioned above.

Des problèmes peuvent survenir si un automate est connecté à un réseau IP con-

tenant des modules qui ne fonctionnent pas sous un système d'exploitation

SIGMATEK. Avec de tels dispositifs, les paquets Ethernet peuvent être envoyés à

l’automate avec une fréquence tellement élevée (càd. diffusion), que les interrup-

tions ainsi générées peuvent provoquer une erreur d'exécution. En configurant

d’une façon appropriée le filtre de paquets (pare-feu ou un routeur) il est toutefois

possible de connecter un réseau avec le matériel SIGMATEK à un réseau tiers sans

déclencher l'erreur mentionnée ci-dessus.

C-DIAS PROCESSOR MODULE CCP 531

Page 4 12.04.2017

Miscellaneous

Article number

12-104-531 (512 Mbytes microSD card)

12-104-531-1 (1-Gbyte microSD card)

Hardware version

1.x

Project back-up

Internally on the microSD card

Standard

UL508 (E247993)

Environmental conditions

Storage temperature

-10 ... +85 °C

Operating temperature

0 ... +60 °C

Humidity

10 – 90 %, uncondensed

EMV stability

According to EN 61000-6-2 (industrial area)

Shock resistance

EN 60068-2-27

150 m/s²

Protection Type

EN 60529

IP20

Protection Type (UL)

open type device

Pollution degree

2

c

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 5

Mechanical Dimensions

104.10 (dimensioning incl. covers)

24.90

129

109.2

C-DIAS PROCESSOR MODULE CCP 531

Page 6 12.04.2017

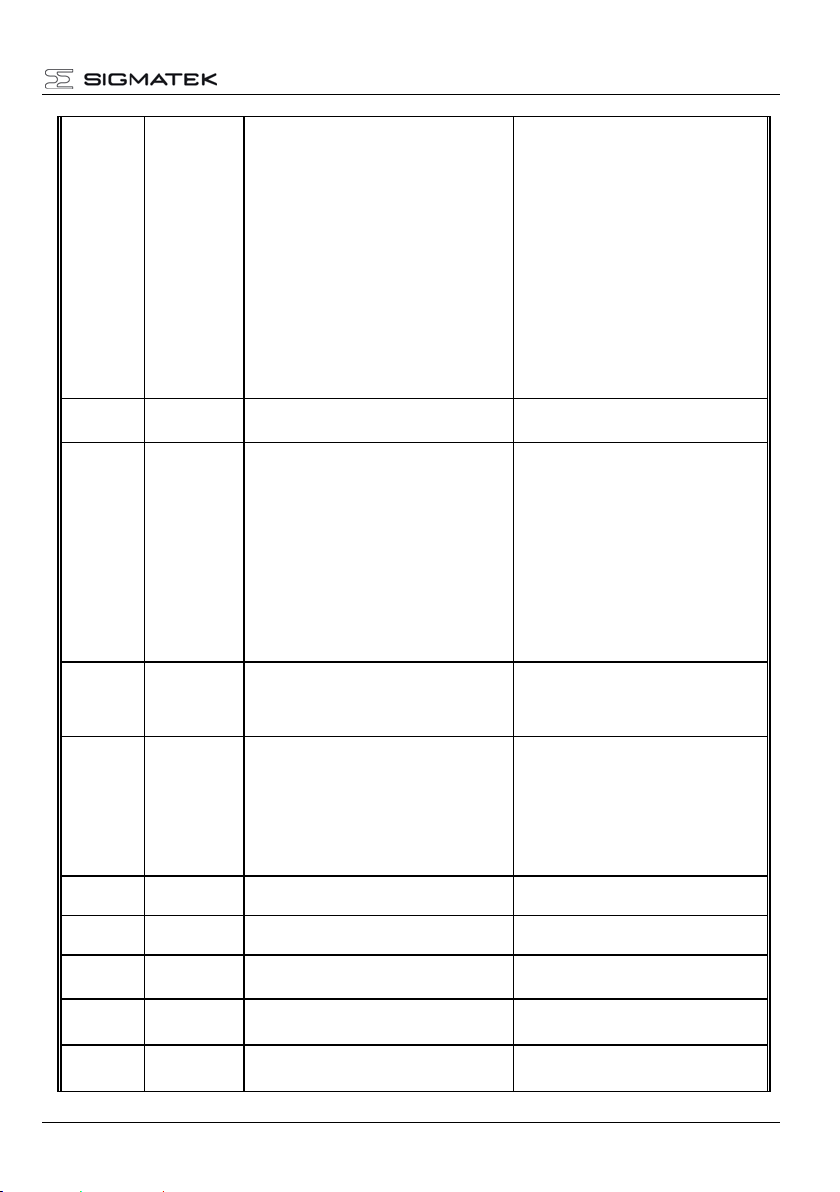

Connector Layout

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 7

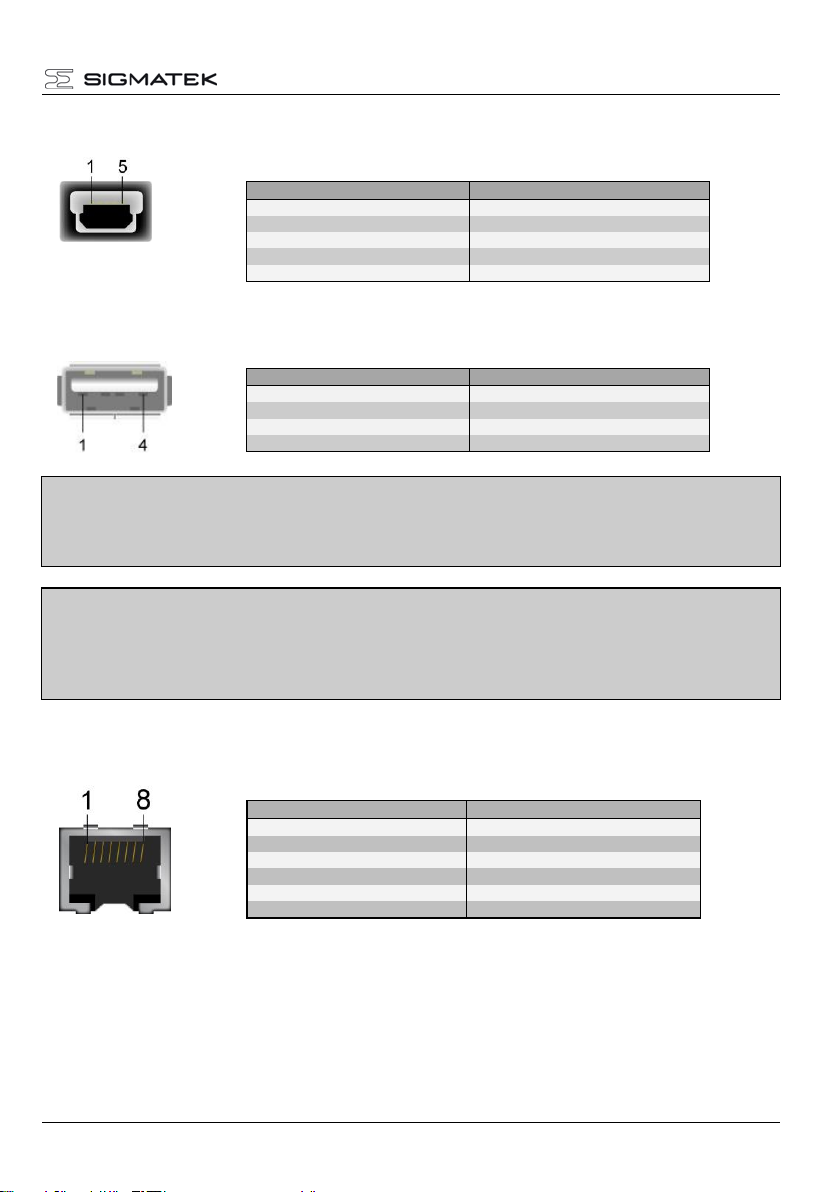

X1: USB Device 1.1

n.c. = do not use

X2: USB Host 2.0

It should be noted that many of the USB devices on the market do not comply with

USB specifications; this can lead to device malfunctions. It is also possible that

these devices will not be detected at the USB port or function correctly. Therefore, it

is recommended that every USB stick be tested before actual use.

Il faut souligner que la plupart des périphériques USB sur le marché ne sont pas

conformes aux spécifications USB, ce qui peut entraîner des dysfonctionnements de

l'appareil. Il est également possible que ces dispositifs ne seront pas détectés par le

port USB ou qu’ils ne fonctionnent pas correctement. Par conséquent, il est recom-

mandé que chaque clé USB soit testée avant l'utilisation sur l’automate.

X3: Ethernet

Pin

Function

1

+5 V 2 D- 3 D+ 4 n.c. 5 GND

Pin

Function

1

+5 V 2 D- 3 D+ 4 GND

Pin

Function

1

TX+ 2 TX- 3 RX+

4 - 5

n.c. 6 RX-

7 - 8

-

a

C-DIAS PROCESSOR MODULE CCP 531

Page 8 12.04.2017

X4: CAN-Bus

X5: Power plug

X6: microSD Card

It is recommended that only storage media provided by SIGMATEK

(CompactFlash cards, microSD cards etc.) be used.

Order number for the 512-Mbyte EDGE microSD card: 12-630-051

Order number for the 1-Gbyte EDGE microSD card: 12-630-101

The number of read and write actions have a significant influence on the

lifespan of the storage media.

Il est recommandé de n’utiliser que les supports de stockage approuvés par SIG-

MATEK (compact flash, microSD, etc.).

Numéro de commande pour la carte microSD 512 Mo Edge est le: 12-630-051

Numéro de commande pour la carte microSD 1 Go Edge est le: 12-630-101

Le nombre de cycles de lecture et d'écriture a l’influence notable sur la durée de

vie des supports de stockage.

Pin

Function

1

CAN A (CAN LOW)

2

CAN B (High)

3

CAN A (CAN LOW)

4

CAN B (High)

5

GND 6 n.c.

Pin

Function

1

+24 V supply

2

GND

Pin

Function

1

DAT2

2

CD/DAT3

3

CMD 4 +3V3 5 Clk 6 GND 7 DAT0 8 DAT1

1

1 2

65

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 9

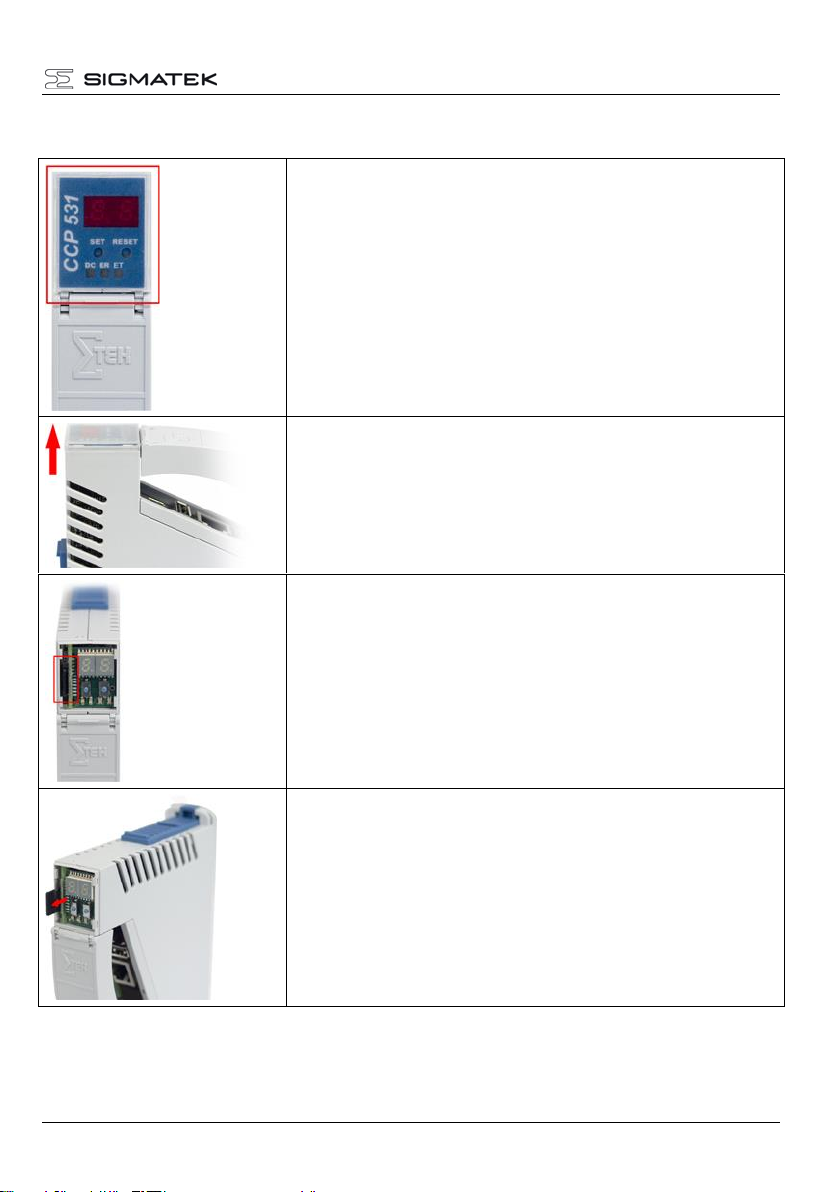

Exchanging the microSD card

The microSD card is located under the LED cover.

To exchange the microSD card, carefully lift the LED cover.

The microSD card is located on the left side and can be

disengaged by lightly pressing on the card itself.

Remove the microSD card.

C-DIAS PROCESSOR MODULE CCP 531

Page 10 12.04.2017

Connector

Type

Wire Size

Max. drive torque

X1

USB Type Mini-B

- - X2

USB Type A

- - X3

RJ 45 - -

X4

B2L 3.5/6

0.13 - 1.0 mm2

28 - 18 AWG (UL/CSA)

Cage Clamp

X5

FK-MCP 1.5/ 2-ST-3.5

0.14 - 1.5 mm2

28 - 16 AWG (UL/cUL)

Cage Clamp

MC 1.5/ 2-ST-3.5

0.13 - 1.0 mm2,

30 - 16 AWG (UL),

28 - 16 AWG (CSA)

0.22 - 0.25 Nm

Applicable connectors

USB Device: 5-pin, type Mini-B

USB Host: 4-pin, type A

Ethernet: 8-pin, RJ45

CAN Bus: 6-pin Weidmüller plug, B2L3,5/6

Supply: 2-pin Phoenix plug with screw terminal technology MC 1.5/ 2-ST-3.5

2-pin Phoenix plug with spring terminal FK-MCP 1.5/ 2-ST-3.5

The complete C-DIAS CKL 017 connector set with spring terminals is available from

Sigmatek under the article number 12-600-017.

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 11

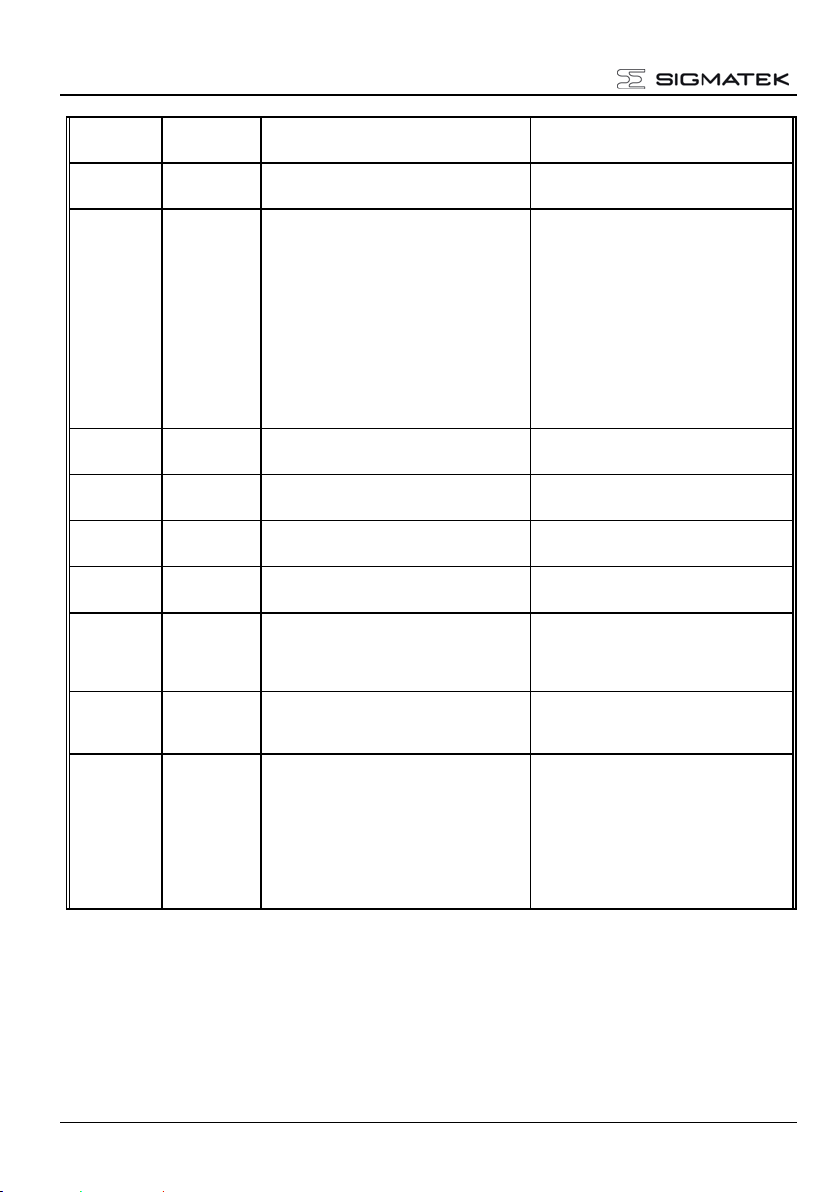

Status Displays

Ethernet

LED

Color

Description

Active

Yellow

Lights when data is exchanged over Ethernet

Link

Green

Lights when the connection between the two PHYs is established

Control

LED

Color

Description

ERROR

Red

Lights when an error occurs (defective USV)

DCOK

Green

Lights when the power supply is OK

C-DIAS PROCESSOR MODULE CCP 531

Page 12 12.04.2017

Display

The CCP 531 processor module has a 2-digit decimal display (7 segment display) for the

following functions:

- When configuring the processor module, the parameters are shown in the display.

- If an error occurs while running the program or no valid user program is found, the dis-

play shows an error message. Thereby, "Er" (error) and the error code are displayed alternatingly. The same error code is also shown in the LASAL status line.

- While running the program, the display can be used to show digits using the system

variable _cpuDisplay. Valid values are 0 to 255; values over 99, however, are not shown

and the display remains dark.

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 13

CAN Bus Setup

This section explains how to configure a CAN bus correctly. The following parameters must

first be set: Station number and data transfer rate.

CAN bus station number

Each CAN bus station is assigned its own station number. With this station number, data

can be exchanged with other stations connected to the bus. Up to 31 stations can be installed in a CAN bus system. However, each station number can only be assigned once.

CAN bus data transfer rate

The data transfer rate (baud rate) for the CAN bus can be set. However, the longer the

length of the bus, the smaller the transfer rate that must be selected.

Value

Baud rate

Maximum length

00

615 kBit/s

60 m

01

500 kbit/s

80 m

02

250 kBit/s

160 m

03

125 kBit/s

320 m

04

100 kBit/s

400 m

05

50 kBit/s

800 m

06

20 kBit/s

1200 m

07

1 Mbit / s

30 m

These values are valid for the following cable: 120 , Twisted Pair.

NOTE: the following is valid for the CAN bus protocol: 1 kBit/s = 1 kBaud.

C-DIAS PROCESSOR MODULE CCP 531

Page 14 12.04.2017

Configuration of the Process Module

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 15

To enter the mode for setting changes, press and hold the SET button while the C-IPC is

booting.

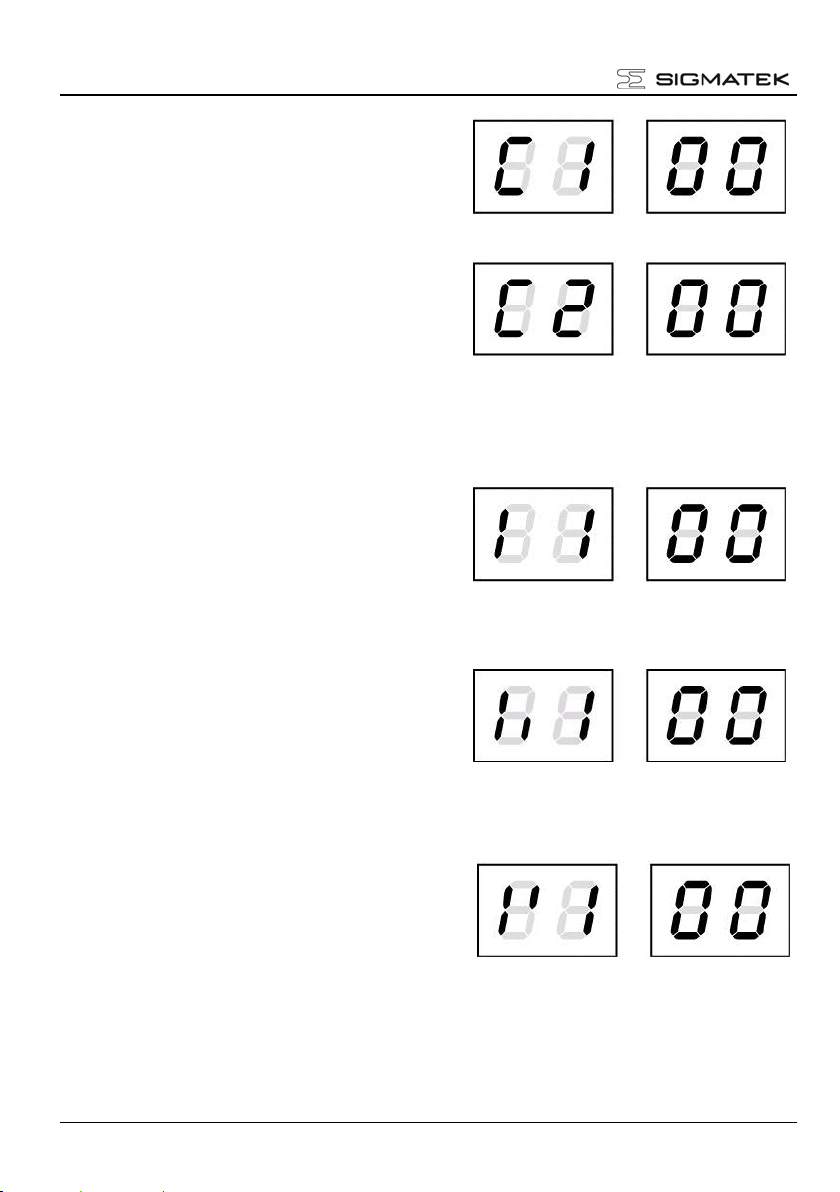

When the following appears in the display:

the SET button can be released.

After releasing the SET button, the first menu appears in the display.

With several short presses of the SET button, it is possible to switch through the various

menu points. By pressing the SET button for approximately 1.5 s, the menu is accessed

and the setting can be changed with short presses.

Once the desired changes are made, press the SET button for about 5 seconds to end the

process. If the changes are to be discarded, press the RESET button to restart the C-IPC.

The settings for the IP address, subnet mask and gateway are hexadecimal, whereas in

the left and right digits, 0 - F must be entered separately. The switch occurs when the SET

button is pressed for about 1.5 s.

The values from AUTOEXEC.LSL are used as the standard settings; changes are written

back to this file. Before this, the original content of the file is written to AUTOEXEC.BAK.

a

C-DIAS PROCESSOR MODULE CCP 531

Page 16 12.04.2017

C1 ... CAN PLC station

00 – 30 ... Station number

C2 ... CAN PLC baud rate

00 ... 615.000

01 … 500.000

02 … 250.000

03 … 125.000

04 … 100.000

05 … 50.000

06 … 20.000

07 … 1.000.000

I1, I2, I3, I4 IP address I1.I2.I3.I4,

Hexadecimal

00 – FF respectively

S1,S2,S3,S4 Subnet Mask S1.S2.S3.S4, hexadecimal

00 – FF respectively

G1,G2,G3,G4 Gateway G1,G2.G3.G4, hexadecimal

00 – FF respectively

a

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 17

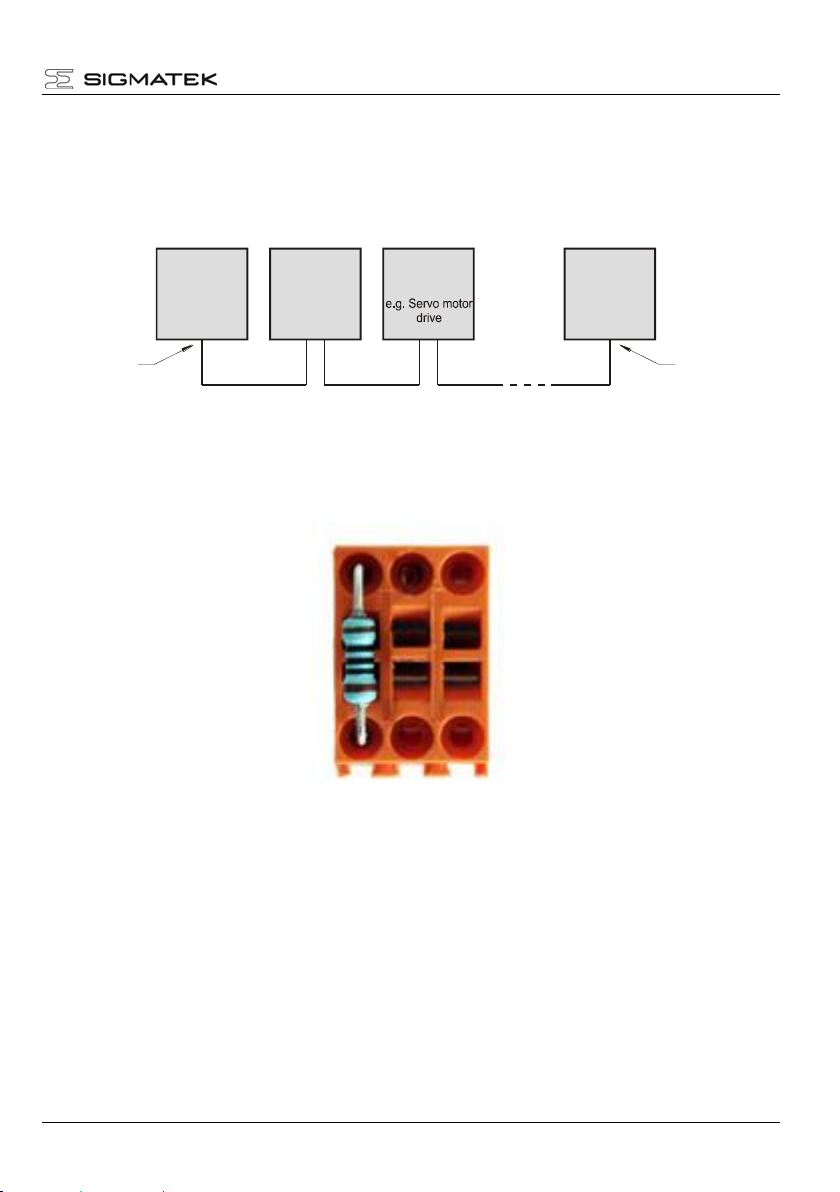

CAN Bus Termination

In a CAN bus system, both end modules must be terminated. This is necessary to avoid

transmission errors caused by reflections in the line.

Device 1 Device 2 Device 3 Device n

e.g. CPU

DCP 080

e.g. Terminal

ET 081

CAN-Bus-Connections

CAN-Bustermination on

terminal module

D-SUB-plug

with terminating

resistors

e.g. Terminal

ET 805

If the CCP 531 processor module is an end module, it can be terminated by placing a 150Ohm resistor between CAN-A (Low) and CAN-B (High).

1 x 150-Ohm resistor

C-DIAS PROCESSOR MODULE CCP 531

Page 18 12.04.2017

Wiring and Mounting Instructions

Earth Connection

The CCP 531 must be connected to earth over the mounting on the back wall of the control

cabinet or over the earth terminal provided (C-DIAS module carrier). It is important to create a low-ohm earth connection, only then can error-free operation be guaranteed. The

earth connection should have the maximum cross section and the largest electrical surface

possible.

Any noise signals that reach the CCP 531 over external cables must be filtered out over

the earth connection. With a large (electrical) surface, high frequency noise can also be

well dissipated.

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 19

Shielding

The wiring for the CAN bus and Ethernet must be shielded. The low-ohm shielding is either

connected at the entry to the control cabinet or directly before the CCP 531 processor

module over a large surface (cable grommets, grounding clamps)!

Noise signals can therefore be prohibited from reaching the electronics and affecting the

function.

ESD Protection

Before any device is connected to or disconnected from the CCP 531, the potential with

ground should be equalized (by touching the control cabinet or earth terminal). Static electricity (from clothing, footwear) can therefore be reduced.

Working with and on the CCP 531

Valid operating and safety guidelines for personal safety must always be observed.

With installation /initial start-up / product maintenance, the relevant measures for ESD

protection must be taken.

(For example: the employees must ground themselves before they start working with and on the

product.

a

C-DIAS PROCESSOR MODULE CCP 531

Page 20 12.04.2017

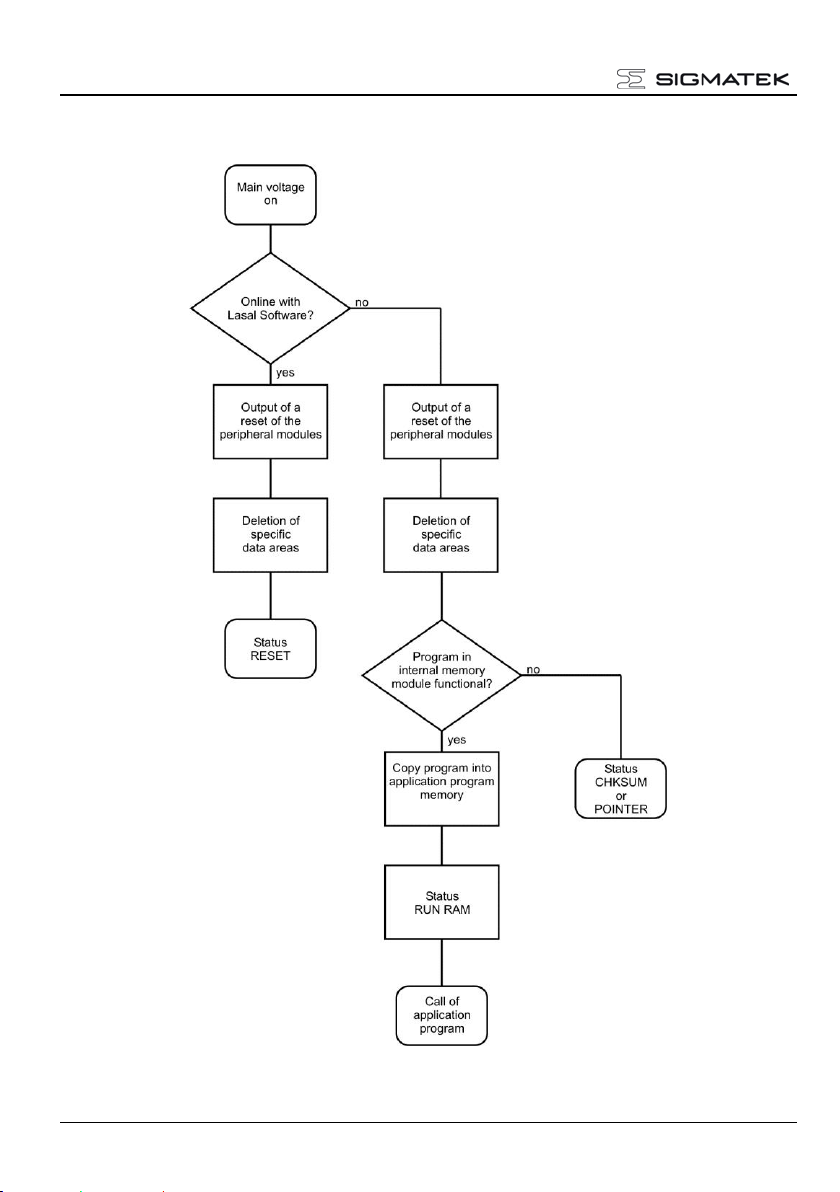

Process Diagram

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 21

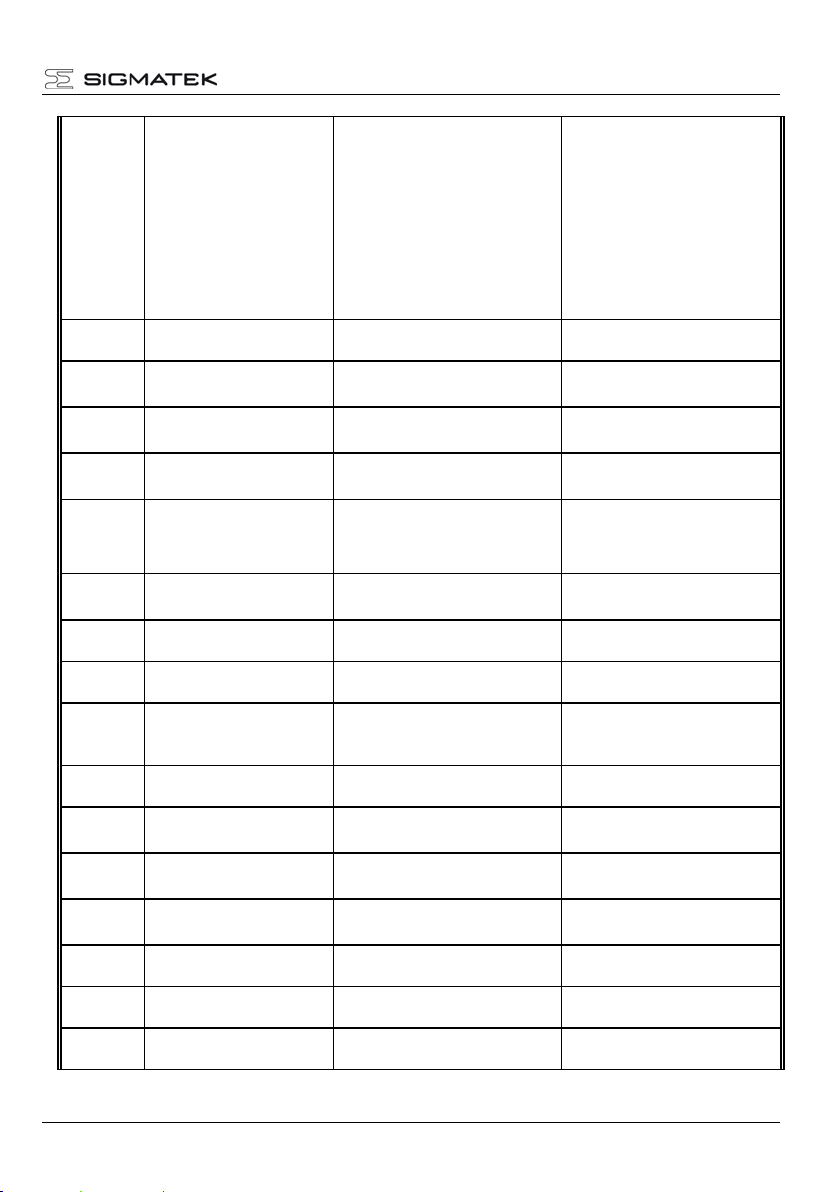

System Boot Checkpoints

The checkpoints are shown on the 7-segment display before the LASAL CLASS software

status and error messages. Since this involves checkpoints, it should be interpreted as

errors when the system stops at a checkpoint.

Number

Meaning

Cause/solution

88

Display during system start.

If the status does not change, the oper-

ating system or application cannot be

started. This may be for different

reasons.

- The operating system is not fully booted

- Check operating system/boot medium

- Boot medium not inserted

- Boot medium defective

- No operating system on the boot medium

- BIOS self-test error

- RAM, CPU, BIOS, etc.

Unlisted messages are an indication of a hardware defect.

C-DIAS PROCESSOR MODULE CCP 531

Page 22 12.04.2017

Status and Error Messages

Status and error messages are shown in the status test of the LASAL CLASS software. If

the CPU has a status display, the status or error number is also show here as well.

POINTER or CHKSUM messages can also be shown on the terminal screen.

Number

Message

Definition

Cause/solution

00

RUN RAM

The user program is currently running in RAM.

The display is not affected.

01

RUN ROM

The user program in the program memory

module was loaded into the RAM and is

currently being run.

The display is not affected.

02

RUNTIME

The total duration of all cyclic objects exceeds

the maximum time; the time can be configured

using 2 system variables:

-Runtime: time remaining

-SWRuntime: pre-selected value for the

runtime counter

03

POINTER

Incorrect program pointers were detected

before running the user program

Possible Causes:

- The program memory module is miss-

ing, not programmed or defect.

- The program in the user program

memory (RAM) is not executable.

- The user program is overwriting a

software error

Solution:

- Reprogram the memory module, if the

error reoccurs exchange the module.

- Correct programming error

04

CHKSUM

An invalid checksum was detected before

running the user program.

Cause/solution: s. POINTER

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 23

05

Watchdog

The program was interrupted through the

watchdog logic.

Possible Causes:

- User program interrupts blocked

over a longer period of time (STI

command forgotten)

- Programming error in a hardware

interrupt.

- INB, OUTB, INW, OUTW instruc-

tions used incorrectly.

- The processor is defect.

Solution:

- Correct programming error.

- Exchange CPU.

06

GENERAL

ERROR

General error

07

PROM DEFECT

An error has occurred while programming

the memory module.

Cause:

- The program memory module is

defect.

- The user program is too large.

- The program memory module is

missing.

Solution:

- Exchange the program memory

module

08

Reset

The CPU has received the reset signal

and is waiting for further instructions.

The user program is not processed.

09

WD DEFEKT

The hardware monitoring circuit (watchdog logic) is defect.

After power-up, the CPU checks the

watchdog logic function. If an error

occurs during this test, the CPU deliberately enters an infinite loop from which no

further instructions are accepted.

Solution: Exchange CPU.

10

STOP

11

PROG BUSYS

12

PROGRAM

LENGTH

13

PROG END

The memory module was successfully

completed.

14

PROG MEMO

The CPU is currently programming the

memory module.

C-DIAS PROCESSOR MODULE CCP 531

Page 24 12.04.2017

15

STOP BRKPT

The CPU was stopped by a breakpoint in

the program.

16

CPU STOP

The CPU was stopped by the PG software (F6 HALT in status test).

17

INT ERROR

The CPU has triggered a false interrupt

and stopped the user program or has

encountered an unknown instruction

while running the program.

Cause:

- A nonexistent operating system was

used.

- Stack error (uneven number of PUSH

and POP instructions).

- The user program was interrupted by

a software error.

Solution:

18

SINGLE

STEP

The CPU is in single step mode and is

waiting for further instructions.

19

Ready

A module or project has been sent to the

CPU and it is ready to run the program.

20

LOAD

The program has stopped and is receiving a module or project.

21

UNZUL.

Modul

The CPU has received a module, which

does not belong to the project.

22

MEMORY

FULL

The operating system memory /Heap) is

too small. No more memory could be

reserved, when an internal or interface

function was called from the application.

23

NOT LINKED

When starting the CPU, a missing

module or a module that does not belong

to the project was detected.

24

DIV BY 0

A division error has occurred.

Possible Causes:

- Division by 0.

- The result of a division does not fit in

the result register.

Solution:

- Correct programming error.

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 25

25

DIAS ERROR

An error has occurred while

accessing a DIAS module.

Possible Causes:

- An attempt is made to access

a nonexistent DIAS module.

- DIAS bus error.

Solution:

- Check the DIAS bus

- Check the termination resis-

tors.

26

WAIT

The CPU is busy.

27

OP PROG

The operating system is currently

being reprogrammed.

28

OP INSTALLED

The operating system has been

reinstalled.

29

OS TOO LONG

The operating system cannot be

loaded; too little memory.

30

NO OPERATING SYSTEM

Boot loader message.

No operating system found in

RAM.

31

SEARCH FOR OS

The boot loader is searching for

the operating system in RAM.

32

NO DEVICE

33

UNUSED CODE

34

MEM ERROR

The operating system loaded does

not match the hardware configuration.

35

MAX IO

36

MODULE LOAD ERROR

The LASAL Module or project

cannot be loaded.

37

GENERELLER BS-FEHLER

A general error has occurred while

loading the operating system.

38

APPLMEM ERROR

An error has occurred in the

application memory (user heap).

39

OFFLINE

40

APPL LOAD

41

APPL SAVE

C-DIAS PROCESSOR MODULE CCP 531

Page 26 12.04.2017

46

APPL-LOAD-ERROR

An error has occurred while

loading the application.

47

APPL-SAVE-ERROR

An error has occurred while

attempting to save the application.

50

ACCESS-EXCEPTIONERROR

Read or write access of a restricted memory area. (I.e. writing to the

NULL pointer).

51

BOUND EXCEEDED

An exception error caused by

exceeding the memory limits

52

PRIVILEDGED INSTRUCTION

An unauthorized instruction for the

current CPU level was given. For

example, setting the segment

register.

53

FLOATING POINT ERROR

An error has occurred during a

floating-point operation.

60

DIAS-RISC-ERROR

Error from the Intelligent DIASMaster.

64

INTERNAL ERROR

An internal error has occurred, all

applications are stopped.

Restart; report error to Sigmatek.

65

FILE ERROR

An error has occurred during a file

operation.

66

DEBUG ASSERTION

FAILED

Internal error.

Restart; report error to Sigmatek.

67

REALTIME RUNTIME

The total duration of all real-time

objects exceeds the maximum

time; the time cannot be configured.

2 ms for 386 CPUs

1 ms for all other CPUs

Starting from Version 1.1.7

68

BACKGROUND RUNTIME

The total time for all background

objects exceed the maximum time;

the time can be configured using

two system variables:

-BTRuntime: time remaining

-SWBTRuntime: pre-selected

value for the runtime counter

70

C-DIAS ERROR

An error occurred in connection

with a C-DIAS module.

Cause:

- The reason for this error is

documented in the log file

Solution:

- Depends on the cause

a

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 27

75

SRAM ERROR

Only EDGE CPUs

An error occurred while initializing,

reading or writing SRAM data.

Possible causes:

- - SRAM configured incorrect-

ly

- - SD card formatted incor-

rectly

- - SD card removed

Solution:

- - evaluate log file

(Event00.log)

- - check configuration

- - format SD card as EDGE

medium with Lasal Class 2

- check SD card

95

USER DEFINED 0

User-definable code.

96

USER DEFINED 1

User-definable code.

97

USER DEFINED 2

User-definable code.

98

USER DEFINED 3

User-definable code.

99

USER DEFINED 4

User-definable code.

100

C_INIT

Initialization start; the configuration is

run.

101

C_RUNRAM

The LASAL project was successfully

started from RAM.

102

C_RUNROM

The LASAL project was successfully

started from ROM.

103

C_RUNTIME

104

C_READY

The CPU is ready for operation.

105

C_OK

The CPU is ready for operation.

106

C_UNKNOWN_CID

An unknown class from a stand-along or

embedded object: unknown base class.

107

C_UNKNOWN_CONSTR

The operating system class cannot be

created; the operating system is probably wrong.

108

C_UNKNOWN_OBJECT

Reference to an unknown object in an

interpreter program, creation of more

than one DCC080 object.

109

C_UNKNOWN_CHNL

The hardware module number is greater

than 60.

C-DIAS PROCESSOR MODULE CCP 531

Page 28 12.04.2017

110

C_WRONG_CONNECT

No connection to the required channels.

111

C_WRONG_ATTR

Wrong server attribute.

112

C_SYNTAX_ERROR

No specific error, recompile all and

reload project components.

113

C_NO_FILE_OPEN

An attempt was made to open an

unknown table.

114

C_OUTOF_NEAR

Memory allocation error

115

C_OUT OF_FAR

Memory allocation error

116

C_INCOMAPTIBLE

An object with the same name exists

but has another class.

117

C_COMPATIBLE

An object with the same name and

class exists but must be updated.

224

LINKING

The application is currently linking.

225

LINKING ERROR

An error has occurred while linking. An

error messaged is generated in the

LASAL status window.

226

LINKING DONE

Linking is complete.

230

OP BURN

The operating system is currently

being burned into the Flash memory.

231

OP BURN FAIL

An error has occurred while burning

the operating system.

232

OP INSTALL

The operating system is currently

being installed.

240

USV-WAIT

The power supply was disconnected;

the UPS is active.

241

Reboot

The operating system is restarted.

242

LSL SAVE

243

LSL LOAD

252

CONTINUE

253

PRERUN

The application is started.

254

PRERESET

The application is ended.

255

CONNECTION BREAK

For unlisted error messages, please contact SIGMATEK.

C-DIAS PROCESSOR MODULE CCP 531

12.04.2017 Page 29

Application exceptions

SRAM and IRQ routines

Writing remnant data during interrupt routines is not allowed and leads to a system crash.

SRAM and consistency of changed data

If more than 32 different sectors are changed (512 bytes each) shortly before shutting

down the voltage supply while the user program is writing to the microSD card, this can

sometimes lead to partial loss of remnant data.

The file system does not support safe writing through SRAM

If files are stored, modified or written on the microSD card from the user program, these

files must always be stored with a fixed maximum size. Since changes in size and the simultaneous shutdown of the voltage supply can corrupt the file system, a later change in the

file size is not allowed.

Data Breakpoint

This CPU does not support the data breakpoint is a feature.

C-DIAS PROCESSOR MODULE CCP 531

Page 30 12.04.2017

Note on SRAM Behavior

Because the SRAM (remnant memory) is emulated via the microSD card, there are two

different mechanisms for saving SRAM data to the microSD card:

1. Cyclic writing when data is changed (default)

2. Writing only in the event of PowerFail with a backup time buffered through the

hardware (starting with version 01.02.195)

The advantage of cyclic writing is that in the event of a severe system crash, it's possible to

reference an image of the SRAM data that with the standard settings, is a maximum of 1

minute older than the last change. With extensive use, the amount and frequency of SRAM

data changes from the user program can have a massive effect on the microSD card

lifespan.

Detailed information regarding the SRAM behavior and the corresponding settings can be

found in the LASAL OS documentation, in the chapter “SRAM”.

In the LASAL CLASS project, seldom changed value settings in retentive servers as well

as RamEx and StringRam objects, can be converted to file storage. Should existing objects

be converted from SRAM to File, the loader version 02.02.140 or higher and the RamEx

and StringRam classes of the Tools library version 01.02.033 or higher must be used.

If the user program runs cyclic writing processes in files, the tool “Flash Media Lifetime

Calculation” included in LASAL CLASS can be used to determine the effects of the opera-

tions mentioned above on the flash media. This allows the lifespan of the media to be calculated for different, configurable writing scenarios.

Loading...

Loading...