Page 1

———————————————

Centrifuge

4-15C

Operating Manual

Page 2

Page 3

Dear customer,

Congratulations for purchasing a SIGMA laboratory centrifuge. You have selected a device

which combines many advantages.

A wide spectrum of programming options and an electronic operation control allow a troublefree use of the centrifuge. With its 3-phase drive, maintenance-free, quiet operation without

any carbon dust pollution is guaranteed.

Your device is equipped with user-friendly options which make the operation and standard

settings easier for you. Built-in error-detecting functions keep the user from entering incorrect

values and check the complete operation.

A special advantage is the storage capacity the centrifuge offers. The instrument has a

program memory which can store up to 50 data sets and is capable of keeping the last run

program in its memory for an unlimited amount of time allowing the program to be restarted

at any time - even if the centrifuge was turned off in between. All important operation

parameters can be seen at a glance.

The settings are executed via the knob in the control panel which has a coated surface

protecting the device against moisture and dust. In addition, the interior of the centrifuge is

also easy to clean. We are able to offer you a device that combines functional variety with

practical applications.

We thank you for your confidence and wish you a successful application of the centrifuge.

SIGMA Laborzentrifugen GmbH

P.O. Box 1713 - 37507 Osterode/Germany

Phone 05522/5007-0 - Fax 05522/500712

Internet: www.sigma-zentrifugen.de

eMail: info@sigma-zentrifugen.de

SIGMA Service-Tel. 05522/5007-25

Operating Manual SIGMA 4-15C, page 3 of 95

03/06

Page 4

Page 5

Konformitä tserklä rung

(73/23/EWG; 89/336/EWG; 98/37/EWG)

Statement of Conformity

(73/23/CEE; 89/336/CEE; 98/37/CEE)

Déclaration de conformité

(73/23/CEE; 89/336/CEE; 98/37/CEE)

Die nachfolgend bezeichnete Maschine wurde in Ü bereinstimmung mit den Richtlinien

73/23/EWG; 89/336/EWG und 98/37/EWG hergestellt und geprüft.

The following machine is manufactured and tested in compliance with directions 73/23/CEE;

89/336/CEE and 98/37/CEE.

La machine désignée ci-dessous est produit et examiné conforme aux directives 73/23/CEE;

89/336/CEE et 98/37/CEE

Bezeichnung der Maschine: Laborzentrifuge

Machine: Laboratory Centrifuge

Désignation de la machine: Centrifugeuse de laboratoire

Maschinentyp : 4 - 15

Type:

Type de la machine:

Bestell Nr. : 10750, 10751, 10752, 10753, 10730, 10731, 10732

Part No.: 10733

Réf. usine:

Normen: EN 61010-2-020

Standards: EN 61000-3-2 ; EN 61000-3-3

Normes : EN 61326

Sigma Laborzentrifugen

An der Unteren Sö se 50

D-37520 Osterode

01.02.2002 Geschä ftsführer

Managing Director

Directeur Gérant

........................................................................

Fabr. Nr. Serial No. Numé ro de fabrique

Konformitätserklärung dreisprachig 4-15 20020201.DOC

Operating Manual SIGMA 4-15C, page 5 of 95

03/06

Page 6

Page 7

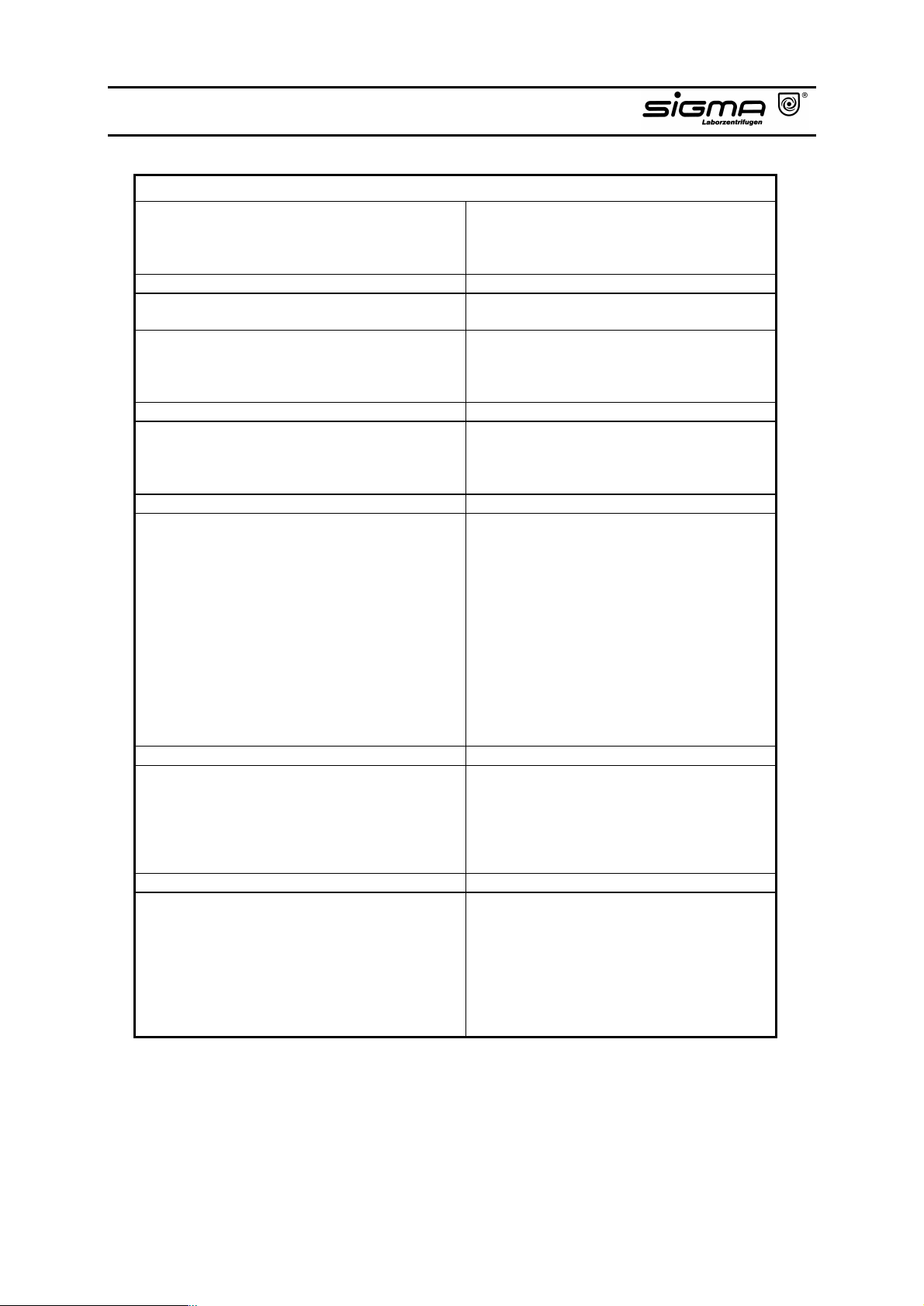

General Information

1.1 Technical data

1.2 Suitable accessories

1.3 Scope of supply

1.4 Standards and regulations

1.5 Safety instructions

1.6 Symbol table

Description of the Centrifuge

2.1 General outlay

2.2 Construction and constructive safety measures

2.3 Drive

2.4 Operation and display

2.5 Electronic control

2.6 Safety devices

2.6.1 Lid lock, cover closing device

2.6.2 Imbalance monitoring system

2.6.3 Rotor monitoring

2.6.4 Standstill monitoring

2.6.5 System check

2.6.6 Ground wire check

Installation and Start-up

3.1 Unpacking of the centrifuge

3.1.1 Transport safety device

3.2 Installation

3.2.1 Site

3.2.2 Connection/Fuse

3.2.3 Fuses / emergency circuit breaker on site

3.3 Installation of rotors and accessories

3.3.1 Fastening of angle rotors with hermetically sealed lid

3.4 Initial start-up

3.4.1 Switching on of the centrifuge

3.4.2 Opening lid

3.4.3 Installation of a rotor

Operating Manual SIGMA 4-15C, page 7 of 95

03/06

Page 8

Operating Elements

4.1 Operating panel

4.1.1 Start-key

4.1.2 Stop-key

4.1.3 Lid-key

4.1.4 Knob

4.2 Display

4.2.1 Set

4.2.2 Speed

4.2.3 Relative Centrifugal Force (RCF)

4.2.4 Time

4.2.5 Program

4.2.6 Rotor

4.2.7 Parameters

4.2.7.1 Acceleration

4.2.7.2 Deceleration

4.2.7.3 Radius

4.2.7.4 Density

4.2.7.5 Start delay

4.2.7.6 Automatic lid opening after end of run

4.2.8 Configuration

Operation

5.1 Selection, display and alteration of program parameters

5.1.1 Selection and alteration of the parameters and activation of the start

delay and the automatic lid opening after end of run

5.1.2 Selection and alteration of the rotor part number

5.1.3 Alteration of the parameter values during the centrifuge run

5.1.4 Alteration of the configuration

5.1.4.1 Curves

5.1.4.2 Creation of curves for variable accelerations and decelerations

5.1.4.3 Alteration of existing curves

5.1.5 Alteration of the contrast

5.1.6 Imbalance monitoring

5.1.7 Shortrun and faststop

Programming

6.1 Load, save and delete programs

6.1.1 Load a program

6.1.2 Save a program

6.1.3 Delete a program

Operating Manual SIGMA 4-15C, page 8 of 95

03/06

Page 9

Notes for Centrifugation

7.1 Practical notes for centrifugation

7.2 Forbidden centrifuging operations

Care and Maintenance

8.1 Care and cleaning of centrifuge

8.2 Care and cleaning of accessories

8.3 Rotor pins

8.4 Glass breakage

8.5 not applicable

8.6 Sterilization and disinfection of rotor chamber and accessories

8.6.1 Autoclaving

8.7 Checks by operator

Appendix

9.1 Slope of the specified curves, linear curves

9.2 Quadratic curves

9.3 Entry limitations

9.4 Mathematical relations

9.4.1 Relative Centrifugal Force (RCF)

9.4.2 Density

9.5 Error correction

9.5.1 Centrifuge cannot be started

9.5.2 Centrifuge decelerates during operation

9.5.3 Lid cannot be opened/closed

9.5.4 Emergency lid release

9.5.5 Problems with the centrifuge?

9.6 Error codes

9.7 Speed-RCF-diagram

9.8 Declaration of decontamination/Return declaration

9.9 Form program data

9.10 Leaflet

Operating Manual SIGMA 4-15C, page 9 of 95

03/06

Page 10

Page 11

1.1 Technical Data

Manufactuer: S I G M A

Laborzentrifugen GmbH

D-37520 Osterode

Germany

Type: 4-15C

Electr. connection:

Protection class:

Power consumption (kVA):

Rated power (kW):

Max. current (A):

Power data:

Max. speed (rpm):

Max. capacity (l):

Max. gravitational field (x g):

Max. kin. energy (Nm):

Further parameters

Time range:

Programs:

Acceleration curves:

Deceleration curves:

Radius:

Rotor part no.:

Dimensions:

Depth (mm):

Width (mm):

Height (mm):

Weight (kg):

EMC (acc. to EN 55011):

Noise level (dBA):

Notes of user:

Serial number:

Supply date:

Inventory number:

Location:

Responsibility:

The figures are valid for an ambient temperature of 23 °C +/- 2 °C and nominal voltage +/- 5 %.

(Allowable ambient temperature +4 °C - +40 ° C; max. humidity 80 %.)

Subject to technical alterations.

see nameplate

I

1,5

1,2

6,5 (230 V/50 Hz) respectively

13,0 (120 V/60 Hz)

13 500

2

20 376

50 487

9 h, 59 min/continuous operation

50 No. 1 - 50

10 linear No. 0 - 9

10 quadratic No. 10 - 19

10 freely programmable

No. 20 - 29

9 linear No. 1 - 9

1 brakeless No. 0

10 quadratic No. 10 - 19

10 freely programmable

No. 20 – 29

max./min. s. 1.2

s. chapter 1.2

685

490

405

82 kg

Class B

75 (at max. speed)

.....................................................

.....................................................

.....................................................

.....................................................

.....................................................

Operating Manual SIGMA 4-15C, page 11 of 95

03/06

Page 12

Page 13

1.2 Accessories Suitable for SIGMA 4-15C

Part No.

11150 Swing-out rotor for 4 buckets 13215, 13220,

13220 Bucket , aluminium, for microtitre plates,

13221 Bucket , aluminium, for microtitre plates,

13231 Bucket, aluminium, for 1 pointed bottom

13175 Adapter for pointed bottom bottle 15175,

13233 Bucket, aluminium, for 50 RIA-tubes Ø 12.5

13234 Bucket, aluminium, for 4 tubes 100 ml,

13235 Bucket, aluminium, for 7 culture tubes

Description

13221, 13231, 13234, 13235, 13236, 13350

max. allowed data with rotor 11150:

radius edge 16.6 cm,

radius max. 16.0 cm,

radius min. 11.3 cm,

max. plate height 54 mm

max. allowed data with rotor 11150:

radius edge 16.6 cm,

radius max. 16.0 cm,

radius min. 10.0 cm,

max. plate height 56 mm, incl. plate holder

17979

bottle 150 or 200 ml e.g. 15175, approx.

Ø 61.5 x 140 mm, incl. adapter 13175,

suitable for 11150, max. radius 19.0 cm,

min. radius 8.7 cm,

suitable for 13231, 17347

x 70 - 90 mm, e.g. 15060, suitable for 11150

Ø 45 x 100 mm, e.g. 15100, 15102, 15103,

15106, incl. rubber cushion 16051, suitable

for 11150, max. radius 17.8 cm, min. radius

7.8 cm

50 ml 15151, suitable for 11150, max. radius

19.0 cm, min. radius 9.3 cm

Max. speed

(rpm)

4 100

4 500

4 500

4 300

4 500

Max.

gravitational

field (x g)

3 120

3 007

2 124

3 758

3 622

2 264

4 302

3 680

4 302

Operating Manual SIGMA 4-15C, page 13 of 95

03/06

Page 14

Part No.

13236 Bucket, aluminium, for 12 culture tubes

13350 Round bucket, aluminium, with thread, incl.

17134 Aluminium sealing cap for 13350

17135 Polysulfone sealing cap, clear, for 13350

17350 Round carrier for 24 reaction vials 0.5-

17351 Round carrier for 12 Monovettes, max.

17352 Round carrier for 25 RIA-tubes 5 ml, max.

17353 Round carrier for 16 reaction vials 1.5-

17354 Round carrier for 16 glass tubes 7 ml, max.

17355 Round carrier for 12 tubes with screw cap

17356 Round carrier for 16 Vacutainer/hemolyse/

Description

15 ml 15115, suitable for 11150, max. radius

18.8 cm, min. radius 9.6 cm

O-ring 482840, for the 500 ml bottles 15500,

15501 and for the round carriers ∅ 85 mm

17350 up to 17402, sealable with caps

17134, 17135, suitable for 11150, max.

radius 19.0 cm, min. radius 8.7 cm

0.75 ml, ∅ 7.9/10 x 28/31 mm, e.g. 15005,

polypropylene

∅ 15.5/18 x 50 - 75 mm, polypropylene

∅ 12.5 x 65 - 80 mm, e.g. 15060,

polypropylene

2.2 ml, max. ∅ 11 mm, e.g. 15008, 15040,

polypropylene

∅ 12.5 x 85 - 115 mm, e.g. 15007, 15027,

polypropylene

10-12 ml, max. ∅ 16.2/19 x 65 x 90 mm, e.g.

13026 plus 17126, 15000, 15010, 15039,

polypropylene

RIA-tubes 5-6 ml, max. ∅ 13.5/17.5 x 70 -

90 mm, polypropylene

Max. speed

(rpm)

4 500

4 500

Max.

gravitational

field (x g)

4 246

4 302

Operating Manual SIGMA 4-15C, page 14 of 95

03/06

Page 15

Part No.

17358 Round carrier for 12 tubes 10-15 ml, max.

17359 Round carrier for 9 culture tubes 15 ml,

17360 Round carrier for 10 culture tubes 15 ml,

17362 Round carrier for 5 sterilin tubes 30 ml,

17370 Round carrier for 5 tubes 25-30 ml, max.

17375 Round carrier for 3 tubes 50 ml, max.

17376 Round carrier for 4 tubes with screw cap

17377 Round carrier for 4 culture tubes 50 ml

17378 Round carrier for 4 culture tubes 50 ml with

17385 Round carrier for 1 tube with screw cap

Description

∅ 17.2/19.5 x 90 - 115 mm, e.g. 15015,

15020, 15022, 15023, 15024 and Monovettes

9 ml and 10 ml, polypropylene

max. ∅ cap 23 mm, e.g. 15115, Greiner or

Corning tubes, polypropylene

max. ∅ cap 22 mm, e.g. 15115, Greiner or

Corning tubes, polypropylene

graduated up to 20 ml, with skirt, incl. cap,

max. ∅ 25/31 x 65 - 95 mm, polypropylene,

see www.bibby-sterilin.co.uk, no. 03008

∅ 25.4/29 x 85 - 115 mm, e.g. 15025, 15026,

15029, 15030, 15032, 15033, polypropylene

∅ 35/38 x 90 - 110 mm, e.g. 15049, 15050,

15056, polypropylene

40-50 ml, max. ∅ 29/34 x 85 - 110 mm, e.g.

13055 plus 17054, 15051, 15052, 15054,

polypropylene

15151, polypropylene

skirt, polypropylene

78-85 ml, max. ∅ 38/40 x 85 - 115 mm, e.g.

13085 plus 17185, 15074, 15075, 15076,

15080, polypropylene

Max. speed

(rpm)

Max.

gravitational

field (x g)

Operating Manual SIGMA 4-15C, page 15 of 95

03/06

Page 16

Part No.

17390 Round carrier incl. rubber cushion 16051

17395 Round carrier for 1 bottle with screw cap

17400 Round carrier for 1 bottle with screw cap

17401 Round carrier incl. rubber cushion 16250

17402 Round carrier for 1 tube with pointed

17347 Round carrier for 1 bottle with screw cap

13215 Rectangular bucket, aluminium, sealable

11156 Swing-out rotor for 6 buckets for the

11140 Swing-out rotor for 4 buckets for the

Description

for 1 tube 100 ml, max. ∅ 45/50 x 85 -

110 mm, e.g. 15100, 15102, 15103, 15106,

polypropylene

125 ml, max. ∅ 51 x 90 - 115 mm, e.g. 15125,

polypropylene

200 ml, max. ∅ 57 x 90 - 115 mm, e.g. 15202,

15203, polypropylene

for 1 round bottom tube 175-250 ml, max.

∅ 57.5 x 90 - 137 mm, e.g. 15201, 15206,

15250, 15251, 15254, polypropylene

bottom 150-250 ml, max. Ø 60 x 120 -

140 mm, polypropylene

250 ml, max. Ø 61.5 x 90 - 125 mm, e.g.

13255, 15247, 15248, 15249 and for 15175

with adapter 13175 (suitable for bucket

13350 without screw cap 17135),

polypropylene

with cap 17112, for the system of

rectangular carriers, max. tube length

115 mm, suitable for rotor 11150, max.

radius 18.2 cm, min. radius 8.8 cm

following accessories,

data with 13115: max. radius 18.2 cm, min.

radius 9.5 cm

data with 13127: max. radius 19.1 cm, min.

radius 9.7 cm

following accessories

Max. speed

(rpm)

4 500

4 500

4 500

5 000

Max.

gravitational

field (x g)

4 120

4 120

4 324

4 668/4 416

Operating Manual SIGMA 4-15C, page 16 of 95

03/06

Page 17

Part No.

13115 Rectangular bucket, aluminium, suitable for

13127 Rectangular bucket, aluminium, incl.

18000 Rectangular carrier, undrilled, for tubes 85 -

18002 Rectangular carrier for 20 reaction vials

18003 Upper part for 18002 for 20 reaction vials

18005 Rectangular carrier for 20 RIA-tubes 5 ml,

18007 Rectangular carrier for 20 glass tubes 7 ml,

18009 Rectangular carrier for 20 hemolyse tubes,

18010 Rectangular carrier for 12 tubes with screw

18012 Rectangular carrier for 12 Vacutainer-tubes

18015 Rectangular carrier for 12 tubes 10-15 ml,

Description

the system of rectangular carriers, max.

tube length 110 mm

polysulfone sealing cap 17112, suitable for

the system of rectangular carriers, max.

tube length 115 mm

110 mm, polyallomer

1.5-2.2 ml, max. ∅ 11 mm, e.g. 15008, 15040,

polypropylene

1.5-2.2 ml, max. ∅ 11 mm, e.g. 15008, 15040

(can be used together with 18002),

polypropylene

max. ∅ 12.2 x 60 - 75 mm, flat and round

bottom, e.g. 15060, polyallomer

max. ∅ 12.3 x 80 - 105 mm, flat and round

bottom, e.g. 15007, 15027, polyallomer

max. ∅ 12.8 x 70 - 90 mm, polypropylene

cap 10-12 ml, max. ∅ 16.8/17.5 x 60 - 85

mm, e.g. 13026 plus 17126, 15000, 15010,

15039, polyallomer

∅ 13.5/18 x 65 - 90 mm, polypropylene

max. ∅ 17 x 90 - 105 mm, e.g. 15015, 15020,

15022, 15023, 15024, polyallomer

Max. speed

(rpm)

5 000

5 000

Max.

gravitational

field (x g)

4 416

4 668

Operating Manual SIGMA 4-15C, page 17 of 95

03/06

Page 18

Part No.

18016 Rectangular carrier for 4 culture tubes

18017 Rectangular carrier for 10 tubes 15 ml and

18025 Rectangular carrier for 5 glass tubes 25 ml,

18022 Rectangular carrier for 4 sterilin tubes

18030 Rectangular carrier for 5 tubes with screw

18050 Rectangular carrier for 2 tubes 50 ml, max.

18051 Rectangular carrier for 2 tubes with screw

18052 Rectangular carrier for 2 culture tubes

18053 Rectangular carrier for 2 culture tubes

18085 Rectangular carrier for 1 tube with screw

Description

15 ml 15115, polypropylene

tubes with cap, max. ∅ 17.2/18 x 80 -

112 mm, e.g. Monovettes 9 ml and 10 ml,

polypropylene

max. ∅ 24 x 85 - 105 mm, e.g. 15025, 15026,

polyallomer

30 ml, graduated up to 20 ml, with skirt,

incl. cap, max. ∅ 25/31 x 65 - 95 mm,

polypropylene, see www.bibby-sterilin.co.uk,

no. 03008

cap 27-30 ml, max. ∅ 25.4/27.5 x 80 -

110 mm, e.g. 15029, 15030, 15032,

polypropylene

∅ 35/38 x 85 - 110 mm, e.g. 15049, 15050,

15056, polyallomer

cap 40-50 ml, max. ∅ 29/35 x 80 - 110 mm,

e.g. 13055 plus 17054, 15051, 15052, 15054,

polypropylene

50 ml 15151, polypropylene

50 ml with skirt, max. ∅ 29.5/38 x 85 -

118 mm, polypropylene

cap 78-85 ml, max. ∅ 38/40 x 85 - 112 mm,

e.g. 13085 plus 17185, 15074, 15075, 15076,

15080, polyallomer

Max. speed

(rpm)

Max.

gravitational

field (x g)

Operating Manual SIGMA 4-15C, page 18 of 95

03/06

Page 19

Part No.

18100 Rectangular carrier for 1 tube 100 ml, max.

18105 Rectangular carrier for 20 RIA-tubes 5 ml,

18107 Rectangular carrier for 20 glass tubes 7 ml,

18115 Rectangular carrier for 12 tubes 10-15 ml,

18125 Rectangular carrier for 1 bottle with screw

18200 Rectangular carrier for 1 bottle with screw

13201 Round bucket for 1 glass tube 200 ml

11141 Swing-out rotor 48 x 15 ml complete,

11157 Swing-out rotor 72 x 15 ml complete,

Description

∅ 45.5/48 x 85 - 110 mm, e.g. 15100, 15102,

15103, 15106, polyallomer

max. ∅ 12.2 x 60 - 75 mm, flat and round

bottom, e.g. 15060, decantable, polyallomer

max. ∅ 12.3 x 80 - 105 mm, flat and round

bottom, e.g. 15007, 15027, decantable,

polyallomer

max. ∅ 17 x 90 - 105 mm, e.g. 15015, 15020,

15022, 15023, 15024, decantable,

polyallomer

cap 125 ml, max. ∅ 51 x 90 - 115 mm, e.g.

15125, polypropylene

cap 200 ml, max. ∅ 57 x 90 - 115 mm, e.g.

15202, 15203, polypropylene

15201, 15206, incl. rubber cushion 16250,

sealable with aluminium cap 17121

consisting of rotor 11140, 4 rectangular

buckets 13115, 4 carriers 18015 and

48 polystyrene tubes 15020, max. radius

15.7 cm, min. radius 6.1 cm

consisting of rotor 11156, 6 rectangular

buckets 13115, 6 carriers 18015 and 72

polystyrene tubes 15020, max. radius

18.2 cm, min. radius 9.5 cm

Max. speed

(rpm)

5 000

4 500

Max.

gravitational

field (x g)

4 416

4 120

Operating Manual SIGMA 4-15C, page 19 of 95

03/06

Page 20

Part No.

11144 Swing-out rotor for microtiter plates, incl.

11118 Swing-out rotor for microtiter plates, incl.

17108 Rectangular sealing cap, polysulfone, clear,

17978 Plate holder for bucket 13218

12165 Angle rotor 6 x 78-85 ml for sealed tubes,

12166 Angle rotor 8 x 40-50 ml for sealed tubes,

12172 Angle rotor 12 x 27-30 ml for sealed tubes,

12168 Angle rotor 20 x 10-12 ml for sealed tubes,

12130 Angle rotor 30 x 1.5-2.2 ml for reaction

Description

2 buckets 13145 and plate holder 17977,

radius edge 12.85 cm,

radius max. 10.7 cm

radius min. 6.3 cm,

max. plate height 64 mm

2 buckets 13218 and plate holder 17978,

radius edge 15.15 cm,

radius max. 13.8 cm

radius min. 5.8 cm,

max. plate height 80 mm,

buckets sealable with cap 17108

incl. 4 clips 17118, for bucket 13218

e.g. 13085 plus 17185, 15074, 15075, 15076,

15080, incl. hermetic aluminium lid, max.

radius 9.8 cm, min. radius 2.7 cm, angle 25°

e.g. 13055 plus 17054, 15051, 15052, 15054,

incl. hermetic aluminium lid, max. radius

9.6 cm, min. radius 3.3 cm, angle 25°

e.g. 15029, 15030, 15032, incl. hermetic

aluminium lid, max. radius 11.0 cm, min.

radius 5.1 cm, angle 30°

e.g. 13026 plus 17126, 15000, 15010, 15039,

incl. hermetic aluminium lid, max. radius

9.8 cm, min. radius 5.8 cm, angle 25°

vials, e.g. 15008, 15040, incl. hermetic

aluminium lid, max. radius 10.0 cm, min.

radius 6.7 cm, angle 45°

Max. speed

(rpm)

5 000

5 500

12 500

12 500

12 500

12 500

13 500

Max.

gravitational

field (x g)

3 592

2 991

1 761

5 124

4 667

1 961

17 119

16 770

19 216

17 119

20 376

Operating Manual SIGMA 4-15C, page 20 of 95

03/06

Page 21

Part No.

11148 Swing-out rotor 32 x 1.5-2.2 ml, incl. 8

12200 Angle rotor 100 x 1.5-2.2 ml for reaction

12169 Angle rotor for 8 culture tubes 50 ml, e.g.

13060 Adapter for 1 culture tube 15 ml 15115,

12170 Angle rotor for 12 culture tubes 15 ml, e.g.

12256 Angle rotor for 6 bottles 250 ml, e.g. 13255,

Adapters, tubes and steel tubes

13000 Adapter , POM, for reaction vials 0.25-

13002 Adapter, POM, for reaction vials 0.5-0.75 ml,

13021 Adapter for PCR-tube 0.2 ml, Ø 5.85/6.95 x

Description

buckets, for reaction vials, e.g. 15008,

15040, incl. hermetic aluminium lid, max.

radius 8.4 cm, min. radius 4.4 cm

vials, e.g. 15008, 15040, incl. aluminium lid

17824, 2 lines, max. radius 16.3/15.18 cm,

min. radius 13.11/11.9 cm

15151, incl. hermetic aluminium lid, max.

radius 10.4 cm, min. radius 4.3 cm,

angle 25°

suitable for 12169, polypropylene

15115, incl. hermetic aluminium lid, max.

radius 10.0 cm, min. radius 4.6 cm,

angle 25°

15247, 15249, incl. aluminium lid 17801,

max. radius 14.5 cm, min. radius 3.9 cm,

angle 30°

0.4 ml 15014, suitable for 11148, 12130,

12200, 17353, 18002, 18003

15005, ∅ 7.9/10 x 28/31 mm suitable for

11148, 12130, 12200, 17353, 18002, 18003

20/23.4 mm, suitable for 11148, 12130,

12200, 17353, 18002, 18003

Max. speed

(rpm)

12 000

9 000

12 500

12 500

8 000

Max.

gravitational

field (x g)

13 523

14 761/13 747

18 168

17 469

10 375

Operating Manual SIGMA 4-15C, page 21 of 95

03/06

Page 22

Part No.

13079 Bottom adapter for 1 tube 40-42 ml 15051,

13080 Adapter for 1 culture tube 50 ml 15151,

13081 Adapter for 1 culture tube 15 ml 15115,

13082

13083

13084

15005

15008 Reaction vials 1.5 ml, 1 pack contains

15040 Reaction vials 2.2 ml, 1 pack contains

15014 Reaction vials 0.4 ml (Beckman system),

15060

13026

Description

15052, 15054, suitable for 12169,

polypropylene

suitable for 12165, polypropylene

suitable for 12165, polypropylene

Adapter for 1 tube 40-50 ml, max. ∅ 28.8 x

105 - 110 mm, e.g. 13055, 15051, 15052,

15054, suitable for 12165, polypropylene

Adapter for 1 tube 27-30 ml, max. ∅ 25.5 x

90 - 110 mm, e.g. 15029, 15030, 15032,

suitable for 12165, polypropylene

Adapter for 2 tubes 10-12 ml, max. ∅

16/17.5 x 75 x 90 mm, e.g. 15000, 15010,

15039, suitable for 12165, polypropylene

Reaction vials 0.5 ml, ∅ 7.9/10 x 28/31 mm,

1 pack contains 100 pcs., suitable for

13002, 17350

100 pcs., suitable for 11148, 12130, 12200,

17353, 18002, 18003

100 pcs., suitable for 11148, 12130, 12200,

17353, 18002, 18003

polypropylene, 1 pack contains 100 pcs.,

suitable for 13000

Polystyrene tube 5 ml (RIA-tube), ∅ 12 x

75 mm, suitable for 13233, 17352, 17356,

18005, 18009, 18105

Stainless steel tube 10 ml, ∅ 15.7 x 76 mm,

closeable with cap 17126, suitable for

12168, 17355, 18010

Operating Manual SIGMA 4-15C, page 22 of 95

03/06

Page 23

Part No.

17126 Stainless steel sealing cap for 13026

15000

15010 ditto, polycarbonate

15039 ditto, polypropylene

15020

15021 Polypropylene stopper for 15020, 15023

15023

15115 Falcon tube with screw cap 15 ml, pointed

15029

15030 Polycarbonate tube with screw cap 30 ml,

15032 Polypropylene tube with screw cap 27 ml,

15049

13055 Stainless steel tube 50 ml, sealable with

17054 Stainless steel sealing cap for 13055

Description

Teflon tube with screw cap 12 ml, ∅ 16.1 x

81.1 mm, suitable for 12168, 13084, 17355,

18010

Polystyrene tube 15 ml, ∅ 17 x 100 mm,

suitable for 17358, 18015, 18115

Polypropylene tube 15 ml, ∅ 17 x 100 mm,

suitable for 17358, 18015, 18115

bottom, polypropylene, suitable for 12170,

13060, 13081, 13236, 17359, 17360, 18016

Teflon tube with screw cap 28 ml, ∅ 25.3 x

96 mm, suitable for 12172, 13083, 17370,

18030

∅ 25.3 x 98 mm, suitable for 12172, 13083,

17370, 18030

∅ 25.3 x 97 mm, suitable for 12172, 13083,

17370, 18030

Polycarbonate tube 50 ml, ∅ 34 x 100 mm,

graduated 0 - 50 ml in steps of 1 ml,

suitable for 17375, 18050

cap 17054, ∅ 29 x 101.5 mm, suitable for

12166, 13082, 17376, 18051

Operating Manual SIGMA 4-15C, page 23 of 95

03/06

Page 24

Part No.

15051

15052 Polypropylene tube with screw cap 42 ml,

15054 Polycarbonate tube with screw cap 40 ml,

15151 Culture tube with screw cap 50 ml, pointed

13085 Stainless steel tube 85 ml, sealable with

17185 Stainless steel sealing cap for 13085

15074 Polycarbonate tube with special screw cap

15075 Polycarbonate tube with screw cap 82 ml,

15076 Polypropylene tube with screw cap 78 ml,

15080

15102

15103 ditto, polycarbonate, graduated 2 - 100 ml

15125 Polypropylene bottle with screw cap 125

Description

Teflon tube with screw cap 42 ml, ∅ 28.5

x 107 mm, suitable for 12166, 13082, 17376,

18051

∅ 28.8 x 107 mm, suitable for 12166, 13082,

17376, 18051

∅ 28.8 x 107 mm, suitable for 12166, 13082,

17376, 18051

bottom, polypropylene, suitable for 12169,

13080, 13235, 17377, 18052

cap 17185, ∅ 38/40 x 100/107 mm, suitable

for 12165, 17385, 18085

made of aluminium with seal for high

speeds 72 ml, ∅ 38 x 109 mm, suitable for

12165, 17385, 18085

∅ 38 x 112 mm, suitable for 12165, 17385,

18085

∅ 38 x 112 mm, suitable for 12165, 17385,

18085

Polyflor tube with screw cap 81 ml, ∅ 38 x

112 mm, suitable for 12165, 17385, 18085

Polypropylene tube 100 ml, ∅ 45 x 100 mm,

suitable for 13234. 17390, 18100

in steps of 2 ml

ml, ∅ 51 x 99 mm, suitable for 17395, 18125

Operating Manual SIGMA 4-15C, page 24 of 95

03/06

Page 25

Part No.

15175 Polypropylene bottle with pointed bottom

15202 Polypropylene bottle with screw cap

15203 Polycarbonate bottle with screw cap

13255 Stainless steel bottle 250 ml, sealable with

17256 Stainless steel sealing cap for 13255

15247 Teflon bottle with screw cap 250 ml, Ø 61.4

15248 Polycarbonate bottle with screw cap 250

15249 ditto, polypropylene

15500 Polycarbonate bottle 500 ml, incl. screw

15501 ditto, polypropylene

Glass tubes

15007

15027 ditto, graduated 0 - 5.5 ml in steps of 0.1 ml

15015

15024 ditto, graduated 0 - 10 ml in steps of 0.1 ml

Description

200 ml, Ø 61.5 x 139 mm, graduated up to

175 ml (N-3143-0175), suitable for 13231

with 13175, 17347 with 13175

190 ml, ∅ 56 x 112 mm, suitable for 17400,

18200

200 ml, ∅ 56 x 113 mm, suitable for 17400,

18200

cap 17256, Ø 61.4 x 125 mm, suitable for

12256, 17347

x 122 mm, suitable for 12256, 17347

ml, Ø 61.4 x 125 mm, suitable for 12256,

17347

cap, Ø 85 x 135 mm, suitable for 13350

Glass tube 7 ml, ∅ 12 x 100 mm, suitable

for 17354, 18007, 18107

Glass tube 10 - 12 ml, ∅ 16 x 100 mm,

suitable for 17358, 18015, 18115

Operating Manual SIGMA 4-15C, page 25 of 95

03/06

Page 26

Part No.

15022

15025

15026 ditto, graduated 5 - 25 ml in steps of 1 ml

15033

15050

15056 ditto, graduated 4 - 50 ml in steps of 1 ml

15100

15106 ditto, graduated 1 - 100 ml in steps of 1 ml

15201 Glass tube 200 ml, Ø 56 x 112 mm, suitable

15206 ditto, graduated 15 - 175 ml in steps of 5 ml

15250 Glass tube 230 ml, Ø 56 x 135 mm, suitable

15254 ditto, graduated 15 - 200 ml in steps of 5 ml

Further accessories

16018 Rubber adapter for 15 ml glass tube 15022,

16019 Rubber adapter for 15 ml glass tube 15022,

16030 Rubber adapter for 30 ml glass tube 15033,

Description

Special glass tube 15 ml, ∅ 17 x 110 mm,

suitable for 12166 with 16018 and for 12165,

with 16019, max. permitted speed 7 000 rpm

Glass tube 25 ml, ∅ 24 x 100 mm, suitable

for 17365, 18025

Special glass tube 30 ml, ∅ 24 x 105 mm,

suitable for 12166 with 16030 and for 12165

with 16031, max. permitted speed 7 000 rpm

Glass tube 50 ml, ∅ 34 x 100 ml, suitable for

17375, 18050

Glass tube 100 ml, ∅ 44 x 100 mm, suitable

for 17390, 18100

for 13201, 17401

for 17401

suitable for 12166

suitable for 12165

suitable for 12166

Operating Manual SIGMA 4-15C, page 26 of 95

03/06

Page 27

Part No.

16031 Rubber adapter for 30 ml glass tube 15033,

16906 Rubber plate for 18025

16907 ditto, only for 18050

16908

16909 Rubber plate for rectangular carriers

16250 Rubber cushion for 13201

17112 Rectangular polysulfone sealing cap, clear,

17118 Sealing clip for caps 17108, 17112

17801 Lid for rotor 12256

17919 Table for centrifuge made of varnished

17913 Fasteners for table 17919

Further accessories are available on request.

Description

suitable for 12165

ditto, only for 18100

incl. 2 clips 17118, for 13215 and spare for

13127

sheet steel with 2 doors and space for

accessories, movable on lock-type castors,

dimensions: w 490, d 635, h 490 mm

Maximum speed for tubes

Some tubes, e.g. centrifuges glass tubes, microtubes, culture tubes, Teflon tubes and

especially high volume tubes can be used in our rotors, buckets and adapters at

higher speeds than their breaking limit. We recommend to always fill up the tubes and

to follow the recommendations of the manufacturer.

Operating Manual SIGMA 4-15C, page 27 of 95

03/06

Page 28

Operating Manual SIGMA 4-15C, page 28 of 95

03/06

Page 29

1.3 Scope of Supply

The following belongs to the centrifuge:

1 Rotor wrench SW 13 Part No. 930 102

1 Square wrench “Emergency lid release“ Part No. 80 054

1 Tube grease for rotor trunnion pins Part No. 70 284

20 ml slushing oil Part No. 70 104

Documentation:

1 Short operating instructions

1 Operating Manual

1 "Rotor and Accessories, Operation and Use"

1 EU-Statement of Conformity

1 Equipment Decontamination Certificate

Accessories according to your order, our order confirmation and our delivery

note.

Rotor Part No. Rotor No.

....................... .....................

....................... .....................

....................... .....................

....................... .....................

....................... .....................

....................... .....................

....................... .....................

1.4 Standards and Regulations

Please refer to the enclosed EU-Statement of Conformity.

Operating Manual SIGMA 4-15C, page 29 of 95

03/06

Page 30

1.5 Safety Instructions

regarding operation of centrifuges with rotors of different max. speed, e.g. angle

rotors and swing-out rotors.

According to the German trade association regulation BGR500 chapter 2.11

part 3 the owner of the instrument is advised to take care of the following points:

1. According to BGR500 the owner has to provide operating instructions based

on those of the manufacturer and to inform the employees accordingly.

2. For safety reasons these operating instructions must clearly state that the

max. speed engraved on the rotor and/or the bucket and the max. allowable

filling quantity must not be exceeded.

3. If the density of the material exceeds 1.2 g/cm3, the max. speed of the centrifuge must be reduced.

4. Operation of the centrifuge in hazardous locations is not allowed.

5. During operation the centrifuge must not be moved. Leaning against or resting

on the centrifuge is not allowed.

6. Do not spin explosive or highly inflammable materials.

7. Substances which could damage the material of the centrifuge, the rotors or

the buckets anyhow must not be centrifuged or only under consideration of

special safety measures. Infectious, toxic, pathogene or radioactive substances must be centrifuged in certified rotors only.

8. Keep a clearance of at least 30 cm around the centrifuge. Dangerous materials of any kind must not be put down or stored in that area.

9. Attention!

Keep your hand away from the danger zone when closing the centrifuge lid.

Risk of bruising!

10.Attention!

Defective lid relieving devices could cause the centrifuge lid to fall down

(contact Service). Risk of bruising!

Operating Manual SIGMA 4-15C, page 30 of 95

03/06

Page 31

1.6 Symbol Table

International symbols used for the centrifuge:

Symbol Title

Gefä hrliche elektrische Spannung

Achtung, Bedienungsanleitung beachten

Ein (Netzverbindung)

I

Aus (Netzverbindung)

O

Schutzleiteranschluß

Erde

Netzstecker ziehen

Vorsicht Quetschgefahr

Drehrichtungspfeil

→

Heiße Oberflä che

Dangerous voltage

Courant haute tension

Attention, consult accompanying documents

Attention, consulter les documents joints

On (Power)

Marche (mise sous tension)

Off (Power)

Arrê t (mise hors tension)

Protective earth (ground)

Liaison à la terre

Earth (ground)

Terre

Unplug mains plug

Tirer la fiche de prise

Caution! Risk of bruising

Attention! Danger de blessure

Arrow direction of rotation

Flèche sens de rotation

Hot surface

Surface chaude

Operating Manual SIGMA 4-15C, page 31 of 95

03/06

Page 32

2.1 General Outlay

The new generation of SIGMA laboratory centrifuges is equipped with two

microprocessors which guarantee independently the control of the rotor

recognition and the overspeed signal. A further optimization and increase of the

instrument’s safety could be maintained. The long-life asynchronous motor is

silent and brushless. The problem of carbon brush change is no longer existent,

and as there is no carbon dust pollution, operation in clean rooms is possible if

the appropriate accessories are used.

2.2 Construction and Constructive Safety Measures

The centrifuge is built into a sheet steel housing. The armoured chamber, the

sheet steel lid, the motorized lid lock device and the hinge system are providing

optimum safety. At the back the lid is secured by solid hinges and at the front

twice by a motorized lid lock. Due to these elements there is a solid safety case

around the rotor chamber.

The centrifuge stands on elastic feet.

2.3 Drive

The drive motor is a well dimensioned asynchronous motor.

2.4 Operation and Display

The grafical LCD display is hermetically sealed. A single knob only allows any

data input. The backlit display indicates any operating status and guides the

operator through the wide range of applications.

Option:

A connection for a serial interface is possible so that an external personal computer with printer can be connected for control or recording.

Operating Manual SIGMA 4-15C, page 32 of 95

03/06

Page 33

2.5 Electronic Control

The electronics controlled by two microprocessors allows extensive adaptations

of the centrifuge to the different tasks. The following parameters can be

programmed and displayed among others:

− Speed (by activation of FINE steps of 1 or 10 rpm possible)

− RCF in steps of 1 or 10 x g

− Time preselection (9 h, 59 min max.), in steps of 1 min or 1 sec

− Continuous operation

− Short-time operation

− Fixed deceleration and acceleration curves

− Free creation of deceleration and acceleration curves

− Saving, recalling and alteration of programs

− Input and measurement of the time integral

− Start delay

− Continuous self-monitoring and recognition of errors which are displayed and

saved for service

2.6 Safety Devices

Apart from the passive safety devices due to the instrument's mechanical design

there are the following active precautions for your safety:

2.6.1 Lid Lock, Cover Closing Device

The centrifuge can only be started when the power switch is switched to "ON“

and when the lid is correctly closed. After closing the lid the motorized lid locks

are automatically locked. Attention! Please do not leave your fingers between

lid and upper edge of the centrifuge housing when closing the lid. The lid

can only be opened when the rotor has completely stopped. If the lid is opened

by the emergency release during operation, the centrifuge will immediately switch

off and decelerate brakeless up to standstill of the rotor. If the lid is open, the

drive is completely separated from the mains supply, that means starting of the

centrifuge is impossible (refer to chapter 9.5.4 "Emergency lid release").

2.6.2 Imbalance Monitoring System

In the event that uneven loading leads to imbalance, the drive is switched off and

an imbalance warning message is displayed.

Operating Manual SIGMA 4-15C, page 33 of 95

03/06

Page 34

2.6.3 Rotor Monitoring

During programming the rotor part no. and if required the bucket part no. must be

entered. Two microprocessors check, if the entered speed or the gravitational

field is allowed for the rotor. Input errors are impossible (refer to point 9.3 "Entry

limitations"). After starting, during the start-up phase, the computer additionally

checks the identification of the rotor.

Attention: Please take care to enter the correct bucket part no. as the max.

allowable speed could be exceeded by entering an incorrect bucket. This is

not allowed.

If the rotor doesn`t correspond to the programmed rotor no., STOP is carried out

and an error message is displayed. Restarting the centrifuge is only possible

after reset and when the correct rotor number has been selected.

2.6.4 Standstill Monitoring

Opening of the centrifuge lid is only possible, if the rotor is at standstill. This

standstill is checked by the computer and also by an additional hardware circuit.

2.6.5 System Check

An internal system check monitors data transmission and the sensor signals with

regard to plausibility. In the event of an error, malfunctions are recognized with

utmost sensitivity, displayed as error message together with an error number,

and saved for service.

2.6.6 Ground Wire Check

For ground wire check there is a ground screw at the rear panel of the centrifuge.

A ground wire check can be carried out using an appropriate measuring

instrument.

Operating Manual SIGMA 4-15C, page 34 of 95

03/06

Page 35

3.1 Unpacking of the Centrifuge

Open case. Take out the box containing accessories. Remove packaging

material. Lift centrifuge upwards with a lifting device or with several persons.

When lifting or carrying the centrifuge please always reach under the instrument

from the side.

Attention: The instrument is heavy!

Please keep case for possible transport of centrifuge later.

3.1.1 Transport Safety Device

The SIGMA 4-15C has a transport safety device which must be removed before

start-up. The transport safety device blocks the drive system.

The transport safety device screws are accessible from the outer underside.

Lift the left or front side of the centrifuge to put a suitable object – for example a

block of wood- between the table and the bottom of the centrifuge.

Attention: Danger of injuries!

The star grip transport safety device screws become apparent. Unscrew by hand

and totally remove.

After that, line centrifuge up and continue start-up.

The transport safety device screws should be stored for possible despatch

(service, repairs).

Operating Manual SIGMA 4-15C, page 35 of 95

03/06

Page 36

3.2 Installation

3.2.1 Site

All energy consumed by the centrifuge is converted into heat and emitted into the

ambient air. Therefore, sufficient ventilation is important. The air-ducts in the unit

must be open. Also, the centrifuge shouldn`t be positioned near radiators and

should not be directly exposed to sunshine.

A clearance of at least 30 cm around the centrifuge is necessary.

For normal operation the ambient temperature should not fall below 10 °C and

not exceed 35 °C. The max. humidity of air is 80 %. During transport from cold to

warmer places water will condensate inside the centrifuge. It is important that

there is enough time for drying before the centrifuge can be started again.

3.2.2 Connection/Fuse

The operating voltage on the name plate must correspond to the local supply

voltage!

SIGMA laboratory centrifuges are units of safety class I, DIN VDE 0700, and include a three wire power cord 2,5 m long with shockproof right angle plug. The

instrument has thermal fuses. In case of a disconnection through the thermal

fuses, allow a cool-down phase of two minutes, after which they could be

reactivated by a switch.

3.2.3 Fuses / Emergency Circuit Breaker on Site

The centrifuges must be protected typically with at least 16 A slow acting fuses.

An emergency circuit breaker to cut the power to the centrifuge in the event of a

malfunction is required on site. This switch should be located away from the

centrifuge, preferably outside the room where the centrifuge is used or at the exit

of this room.

Operating Manual SIGMA 4-15C, page 36 of 95

03/06

Page 37

3.3 Installation of Rotors and Accessories

1. Open centrifuge lid by pressing Lid-key.

2. Unscrew rotor tie-down screw from motor shaft (anticlockwise).

3. Lower the rotor straight down onto the motor shaft.

4. Tighten the tie-down screw (clockwise) with the rotor wrench so that the disc

spring is pressed together.

Fastening torque: 1-6/1-15/2-5/1-15K/2-16/2-16K/2-16KC: approx. 5 Nm

3-16/3-16K/3-18K/3K 30: approx. 7,5 Nm

4-15/4K15/6-15/6K15: approx. 10 Nm

In the event of frequent use the tie-down screw must be loosened by some

turns and fastened again. This should be done once a day or after approx.

20 cycles (please refer to chapter 5.1.4 “Alteration of the Configuration“

– Cycles). This ensures a proper connection between rotor and shaft (please

refer to chapter 8.2 "Care and cleaning of accessories" as well).

5. Fill all positions of swing-out

rotors with buckets. Make

sure that all buckets are

inserted correctly.

6. Use only appropriate vessels

for the rotor (please refer to

chapter 1.2 "Suitable accessories" as well).

7. Fill vessels external to the centrifuge.

8. Put or screw on covers of vessels.

9. Opposite places of the rotors must always be loaded with same accessories

and same filling.

10. Attention when using microtiter rotors: It is important not to run the plate

holders without plates inserted.

11. In angle rotors the plastic vessels must always be totally filled to avoid cracks

of vessels and leakages or loosening of the caps in case of partial filling.

Attention, follow the special comments of chapter 1.5.

allowed not allowed

Universal grease

Operating Manual SIGMA 4-15C, page 37 of 95

03/06

Page 38

12. Attention: The centrifuge will absorb smaller differences in weight when

loading the rotors. But it is recommended to balance the vessels as

accurately as possible in order to ensure a run with minimal vibrations.

Should the centrifuge be operated with very uneven load, the imbalance

monitoring will switch off the drive. An imbalance warning would be displayed.

13. Rotors with lid should always be run with their lid. The rotor lid is tightened by

hand. Correct fastening must be ensured. Attention: The lid screw serves

for fastening of the lid onto the rotor only, not for fastening of the rotor

onto the drive! Before installation of the lid, the correct fastening of the rotor

fixing screw must always be checked using a wrench.

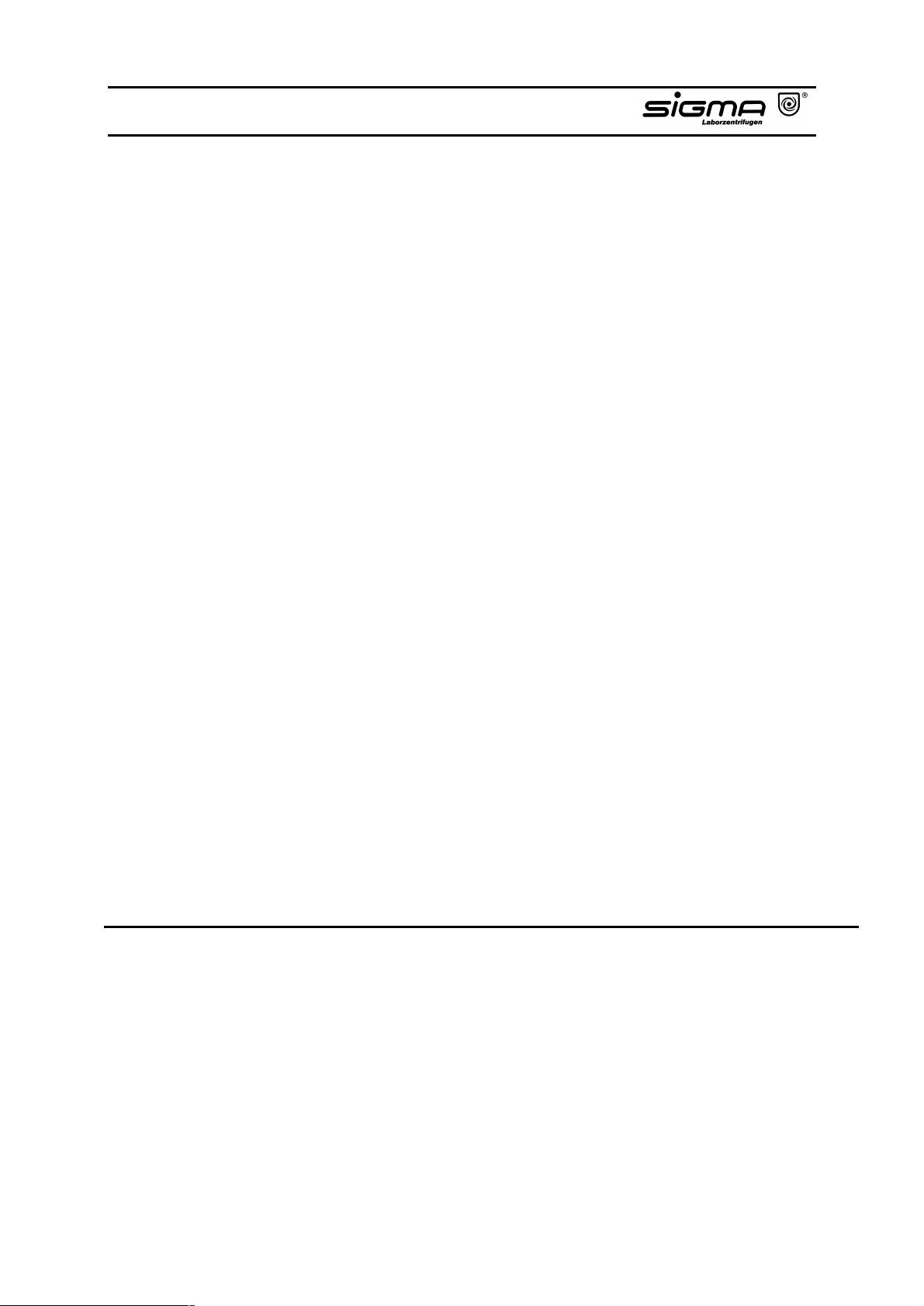

3.3.1 Fastening of Angle Rotors with Hermetically Sealed Lid

(Please refer to drawing on next page.)

1. Screw rotor lid (2) onto rotor and tighten it.

2. Lower rotor with lid (2) onto motor shaft.

3. Put rotor tie-down screw (1) onto motor shaft and tighten using the wrench.

4. The rotor can be run without lid (2) as well.

5. The rotor and lid seals (3) must be greased after cleaning.

6. Special instructions for the use of hermetically sealed rotors:

All rotors can be installed or removed with closed lid after loosening the rotor

tie-down screw. All rotors are autoclavable (refer to chapter 8.6 "Sterilization

and disinfection of rotor chamber and accessories").

To increase life of rotors and seals the rotors must be cleaned with slushing

oil and the seals and thread areas with vaseline or grease after cleaning.

Attention!

Please follow the special comments of chapter 1.5.

Operating Manual SIGMA 4-15C, page 38 of 95

03/06

Page 39

Operating Manual SIGMA 4-15C, page 39 of 95

03/06

Page 40

3.4 Initial Start-Up

Attention!

Before initial start-up please take care that your centrifuge is orderly installed

(refer to chapter 3.2 "Installation").

3.4.1 Switching on of the Centrifuge

Press mains switch (at the back of the centrifuge). When power is applied the

first time, default values will be displayed:

− The command panel illuminates.

− The speed display indicates "2000".

− The time display indicates "2“.

− The program display indicates "--", i.e.

- the centrifuge will accelerate to 2000 rpm,

- the centrifuge operation is terminated after 2 minutes,

- no program number has been allocated so far.

3.4.2 Opening Lid

Press Lid-key

− The lid opens.

3.4.3 Installation of a Rotor

Put a rotor onto the shaft and fasten it by screwing the rotor tie-down screw

clockwise onto the drive shaft. Please use the supplied rotor wrench (refer to

chapter 3.3 "Installation of rotor and accessories"). Please pay attention to the

fact that during tightening the disc spring of the rotor tie-down screw is pressed

together and the screw is tightened.

Operating Manual SIGMA 4-15C, page 40 of 95

03/06

Page 41

4.1 Operating Panel

Operating panel

The centrifuge can be operated via the operating panel. Keys can be pressed

when their LED is on.

Operating Manual SIGMA 4-15C, page 41 of 95

03/06

Page 42

4.1.1 Start-key

This key can be used for the following:

• starting centrifuge operation,

• terminating a previously started deceleration process and restarting

centrifuge,

• shifting into short-run at preselected speed. Pressing Start-key continuously

for longer than one second leads to acceleration to the maximum speed with

the maximum acceleration curve and after release deceleration with the

maximum deceleration curve.

The centrifuge can be started when

• the lid is closed

• the Start-key is illuminated.

4.1.2 Stop-key

This key can be used

• to early terminate a run: The centrifuge decelerates with the preset curve to a

complete stop. Deceleration can be terminated by pressing the Start-key

again.

• to carry out a faststop: Push Start-key for longer than one second. The

centrifuge decelerates with the maximum deceleration curve.

4.1.3 Lid-key

This key is used to open the lid. This can only be executed if

• the centrifuge has come to a complete stop

• the Lid-key is illuminated.

4.1.4 Knob

This knob can be used for selecting and alterating parameters and figures/

numbers.

Operating Manual SIGMA 4-15C, page 42 of 95

03/06

Page 43

4.2 Display

Default values

4.2.1 Set

If this area is illuminated, you are in the change mode which you can exit by

pressing the knob (here in combination with the speed).

4.2.2 Speed

Speed

In the upper section of the area the set speed of the centrifuge is displayed.

Underneath is the actual speed. The maximum speed values are rotor

dependent.

4.2.3 Relative Centrifugal Force (RCF)

RCF

The relative centrifugal force is the acceleration which the sample is exposed to.

The set value of this parameter is in the upper section of this area, underneath is

the actual value. The maximal RCF-values are rotor dependent.

(Refer to chapter 9.4 "Mathematical relations")

Operating Manual SIGMA 4-15C, page 43 of 95

03/06

Page 44

4.2.4 Time

Time

The set run time is displayed in the upper section of this area, underneath the

remaining run time is displayed. Time is defined as the period from the start of

the centrifuge to the beginning of deceleration, maximum value is 9 h 59 min.

The set time is underlined (here: 2 minutes).

The set value is indicated in hours, minutes, and seconds. The actual value has

the same units as the set value and is displayed in hours : minutes or in minutes :

seconds if the set value is below 10 minutes.

h:m

m:s

If the highest possible time of 9 h 59 min is exceeded or below the minium

adjustable time range, continuous operation is activated. The word "HOLD" is

displayed instead of the set value. After the start of a continuous run, the elapsed

time is displayed instead of the remaining run time. By entering a specific run

time the continuous mode is deactivated. It can be terminated by pressing the

Stop-key as well.

Continuous run

Operating Manual SIGMA 4-15C, page 44 of 95

03/06

Page 45

4.2.5 Program (PROG)

Program

In this area the number of the actual program is displayed. If the program is not

saved yet, "--" is displayed.

By activating this area you are able to load stored programs without calling the

selection list.

The program used last is automatically loaded after restarting.

Program Selection List ( )

Program selection list

The area marked with arrows for the program selection list presents the view of

the programs already saved. Storage space for fifty programs - No. 1 – 50 - from

which you can select and load a program is at your disposal. The actual loaded

program is indicated by "--".

Operating Manual SIGMA 4-15C, page 45 of 95

03/06

Page 46

4.2.6 Rotor (here: 11150/13215)

Rotor

In this area the actually selected rotor or a rotor/bucket combination are

displayed.

Rotor Selection List ( )

Rotor selection list

The area marked with arrows for the rotor selection list offers all available rotors

which can be selected via the knob.

4.2.7 Parameters (PARA)

Parameters

If this area has been selected, parameters can be changed and the start delay

and the automatic lid opening after end of run can be activated or deactivated.

Operating Manual SIGMA 4-15C, page 46 of 95

03/06

Page 47

4.2.7.1 Acceleration

Acceleration

The acceleration number selects an acceleration curve which the centrifuge will

follow. Two different versions are available:

0 - 9 linear

10 - 19 quadratic up to 1000 rpm, then linear

Their shape is further explained in chapter 9.1 "Slope of the specified curves,

linear curves" and 9.2 "Quadratic curves".

4.2.7.2 Deceleration

Deceleration

The deceleration number selects a deceleration curve that decelerates the

centrifuge down to standstill. The deceleration curves are inverted images of the

acceleration and are labelled with identical numbers. Curve no. 0 represents

brakeless deceleration.

4.2.7.3 Radius

Radius

The set radius will determine the displayed RCF-value. If the radius is not

changed, the max. RCF-value will be displayed.

Operating Manual SIGMA 4-15C, page 47 of 95

03/06

Page 48

4.2.7.4 Density

Density

If the density of a sample exceeds 1.2 g/cm3, the maximum final speed will

reduce (refer to chapter 9.4.2 “Density”). A value between 1.2 and 9.9 g/cm3 is

possible.

4.2.7.5 Start Delay

With this function a start delay can be set.

4.2.7.6 Automatic Lid Opening after End of Run

If this parameter has been set the lid will automatically open after standstill of the

rotor.

Operating Manual SIGMA 4-15C, page 48 of 95

03/06

Page 49

4.2.8 Configuration

Configuration

Selection of configuration (CONFIG) opens a menu where Code, Language,

Screen, Fine, Buzzer, Sensor, Info, Reset and the creation of freely

programmable curves can be chosen. Furthermore, the cycles and run times of

the individual rotors can be read.

Operating Manual SIGMA 4-15C, page 49 of 95

03/06

Page 50

5.1 Selection, Display and Alteration of Program Parameters

The value of each area can be changed as follows:

• This display shows the default values. No area is inverted.

Default values

• One area can be activated by pressing the knob once. It is then inverted.

Being in the selection mode now, you can select other areas by turning the

knob.

• Activate a selected area by pressing the knob. You are now in the alteration

mode, "SET" and the selected area are inverted.

• Select the new value of the selected area by turning the knob.

• Confirm the entry by pressing the knob. You then leave the alteration mode.

"SET" and the selected area are deactivated. The alteration mode is left

automatically after 20 seconds. The areas are no longer inverted, the actual

values are taken over.

• Now, you can select other areas by turning the knob or you can operate the

start key. Then, the centrifuge starts with the selected values.

Notice:

All entry limits are automatically checked. When reaching a limit, the counting

operation is stopped (refer to chapter 9.3 "Entry limitations").

Operating Manual SIGMA 4-15C, page 50 of 95

03/06

Page 51

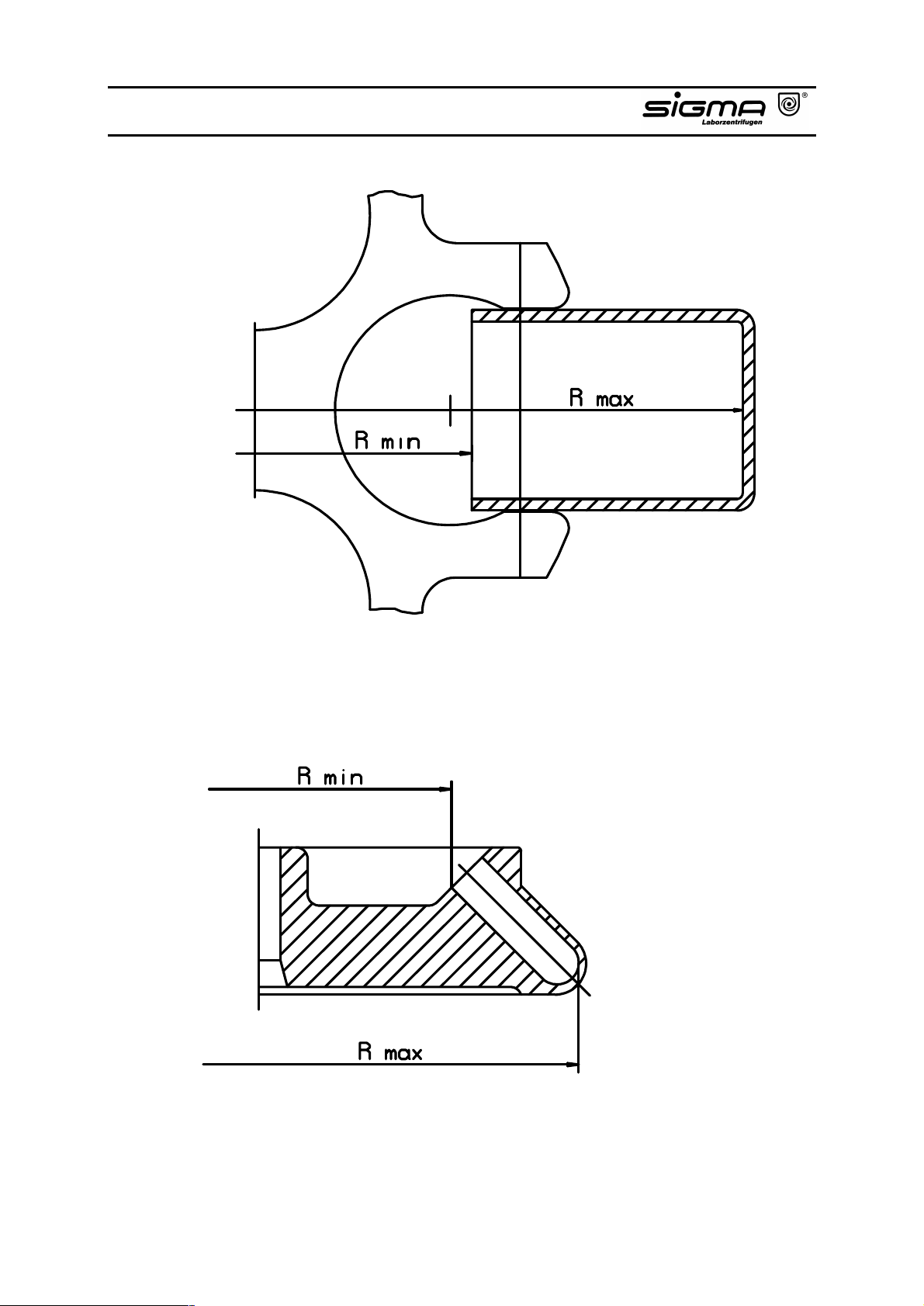

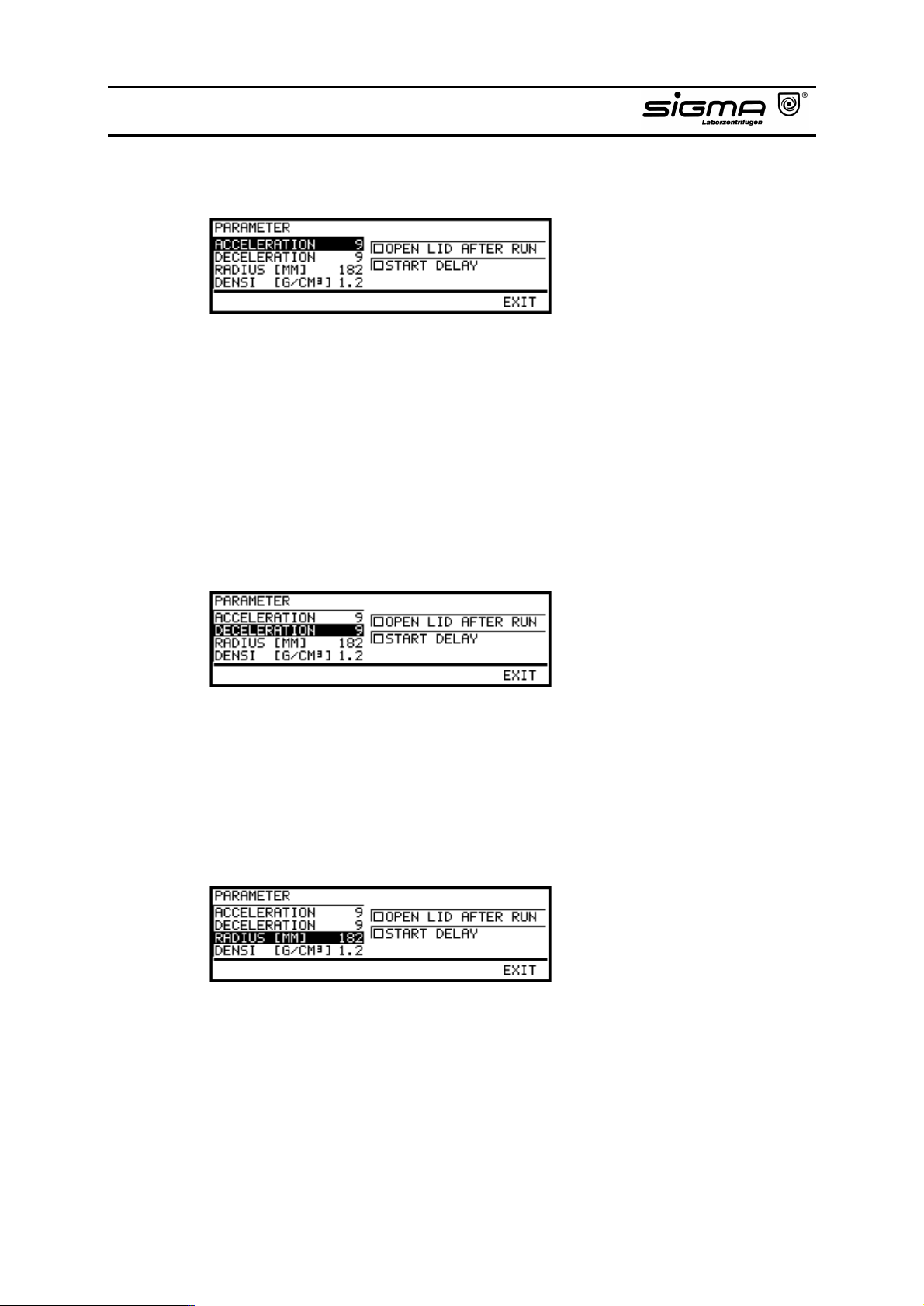

5.1.1 Selection and Alteration of the Parameters and Activation of the

Start Delay and the Automatic Lid Opening after End of Run

Selection and alteration of the parameters

• Select the area "Parameters" (PARA) by turning the knob (selection mode)

and confirm by pressing the knob.

• The parameters to be changed, e.g. acceleration, deceleration, radius, density

and the start delay and automatic lid opening after end of run can be selected

(here: acceleration).

• Confirm the selected parameter by pressing the knob (here: acceleration). The

parameter is activated. Select the desired acceleration curve by turning the

knob.

Deceleration, radius and density are changed in the same way.

Operating Manual SIGMA 4-15C, page 51 of 95

03/06

Page 52

Activation of the start delay and/or the automatic lid opening after end of run

• Select ”START DELAY” by turning the knob.

• Activate the “START DELAY” by pressing the knob.

• Select time delay (here: 10 seconds) by turning and confirm by pressing the

knob.

• Change the set time by turning the knob and deactivate the start delay by

pressing the knob.

The automatic lid opening after end of run is activated or deactivated in the same

way.

Operating Manual SIGMA 4-15C, page 52 of 95

03/06

Page 53

5.1.2 Selection and Alteration of the Rotor Part Number

• Select the area of the rotor selection list ( ) by turning the knob.

• After pressing the knob, you get a view over all available rotor types.

Rotor selection list

• Select the number of the actual rotor/bucket combination by turning the knob

and confirm the entry by pressing the knob.

Attention: Please take care that the correct rotor/bucket combination is

entered as otherwise the max. allowable speed could be exceeded. This

is not allowed.

Operating Manual SIGMA 4-15C, page 53 of 95

03/06

Page 54

5.1.3 Alteration of Program Parameters during the Centrifuge Run

During the run, the following values can be altered.

• Speed

• RCF

• Run time

• Switching into the continuous run mode/time mode

• Acceleration curve

• Deceleration curve

• Start delay

Alter the Set values as usual by activating the Alteration mode (refer to chapter

5.1 "Selection, Display and Alteration of Program Parameters").

You cannot change:

• Rotor

• Program

• Radius

• Density

The following functions can be activated/deactivated:

• Start delay

• Automatic lid opening after end of run

Operating Manual SIGMA 4-15C, page 54 of 95

03/06

Page 55

5.1.4 Alteration of the Configuration

In the configuration mode, several background functions can be changedand

data can be read.

• Select the configuration mode by turning the knob.

• After pressing the knob, the configuration menu appears.

• Select by turning the knob the desired area and activate the function by

pressing the knob.

• CODE: Protection of specific functions by a code, deactivation of the protection and

changing of the code

• LANGUAGE: Selection of the language of the operation

• SCREEN: Magnification of the speed or the RCF display

• FINE: In this function it is possible to preselect the set speed in steps of 1 or 10

min-1. The set time can be preselected in steps of 1 min or 1 sec. Exeption:

Curve input in 1/10 sek.

• CYCLES: For each bucket/rotor combination cycles and run time are stored. The data

of the used rotors are displayed.

• BUZZER: An acoustic signal can be activated for a preselected time after termination

of a run or in the event of an imbalance or an error message. In the event

of "IMBALANCE" or "ERROR" the acoustic signal is already activated.

• SENSOR: The sensor menu displays different signals. In case of a failure of the

instrument this makes the diagnosis of errors and their fast repair through

the service easier. Values can neither be entered nor altered.

Operating Manual SIGMA 4-15C, page 55 of 95

03/06

Page 56

• INFO: The Info menu displays information like the type of centrifuge and the

EPROM version, the number of cycles, the total run time and the software

version and date. In case of a failure of the instrument this helps to find

reasons for the fault. Values can neither be entered nor altered.

• RESET: The "Reset"-function offers the possibility to delete all programs,

parameters and configurations to get the original settings again.

• CURVES: Creation of user defined accelerations and decelerations.

The procedure of alteration of the basic functions shall be explained by an example

(Alteration of the screen).

• You can choose between three display versions:

- RCF and speed at normal size

- Speed magnified -Zoom- (no RCF display)

- RCF magnified -Zoom- (no speed display)

• Select the configuration mode by turning the knob.

• After pressing the knob the configuration menu appears.

• Select "SCREEN" by turning the knob.

Operating Manual SIGMA 4-15C, page 56 of 95

03/06

Page 57

• By pressing the knob you get into the screen menu. The screen marked with a

cross is activated. If you want to select the screen "SPEED - (ZOOM)" you

proceed as follows:

• Select "SPEED - (ZOOM)" by turning the knob.

• Activate the Speed-Zoom-screen by pressing the knob.

• Select "EXIT" by turning the knob. Confirm it by pressing the knob. You get

into the configuration menu again.

Operating Manual SIGMA 4-15C, page 57 of 95

03/06

Page 58

• By pressing the knob you return to the main display. The areas "SPEED" and

"TIME" are displayed magnified. The area "RCF" disappears.

Operating Manual SIGMA 4-15C, page 58 of 95

03/06

Page 59

5.1.4.1 Curves

With the “curve function” user defined accelerations and decelerations can be

created. Curve numbers 20 – 29 are available. The intervals no. 1 – 10 of each

curve consist of fix points which are defined by time and speed. In the event that

the speed of one interval is higher than the set speed for the run, the curve speed

can be limited or allowed or starting can be prohibited.

CUT ⇒

Speed in one interval is automatically limited to the set speed for

the run.

ADMIT ⇒

CANCEL ⇒

Chosen speed in one interval is allowed.

A stop occurs. Starting is not possible without to a change of the

curve speed in one interval.

For interval no. 1 a linear (LIN) or quadratic (QUAD) acceleration can be chosen.

All further accelerations are linear.

Furthermore, run profiles can be created. The following conditions must be

fulfilled:

- The max. preset final speed of one interval corresponds to the set speed of

the run.

- The total time corresponds to the set time of the run.

- The final speed of the last interval is 0.

Operating Manual SIGMA 4-15C, page 59 of 95

03/06

Page 60

5.1.4.2 Creation of Curves for Variable Accelerations and

Decelerations

• Select the configuration mode by turning the knob.

• After pressing the knob the configuration menu appears.

• Select "CURVES" by turning the knob.

• After pressing the knob the curve menue appears.

Operating Manual SIGMA 4-15C, page 60 of 95

03/06

Page 61

• Select “0:00:00” by turning the knob. You are now creating interval no. 1.

Activate “0:00:00” by pressing the knob.

• Set the time by turning the knob.

• Save the time value in interval no. 1 by pressing the knob.

• Select “SPEED” by turning the knob.

Operating Manual SIGMA 4-15C, page 61 of 95

03/06

Page 62

• Activate speed value “0” of interval no. 1 by pressing the knob.

• Change the speed value by turning the knob. The created curve with the max.

curve speed appears.

• After pressing and turning the knob the time value of interval no. 2 appears.

• Activate “0:00:00” of the second interval by pressing the knob.

• Set the time by turning the knob. The extended curve appears.

Operating Manual SIGMA 4-15C, page 62 of 95

03/06

Page 63

• Save the time value no. 2 by pressing the knob.

• Select “SPEED” by turning the knob.

• Activate the speed value “0” by pressing the knob.

• Change the speed value by turning the knob.

• After pressing and turning the knob the time value of interval no. 3 appears.

Operating Manual SIGMA 4-15C, page 63 of 95

03/06

Page 64

• Activate “0:00:00” of the third interval by pressing the knob.

• Set the time by turning the knob. The extended curve appears.

• Save the time value no. 3 by pressing the knob.

Operating Manual SIGMA 4-15C, page 64 of 95

03/06

Page 65

• Select “SPEED” by turning the knob.

• Activate “0” by pressing the knob.

• Change the speed value by turning the knob. The curve appears and can be

programmed as acceleration or deceleration curve under no. 20.

• Select “EXIT” by pressing and turning the knob and leave the curve mode by

pressing the knob again.

• The created curve no. 20 is saved and can be recalled when programming

the parameters.

Operating Manual SIGMA 4-15C, page 65 of 95

03/06

Page 66

5.1.4.3 Alteration of Existing Curves

After activation of the area “CURVES” in the configuration menu you can

analogous to the procedure discribed in 5.1.4.2 select already existing curves

and alter them.

5.1.5 Alteration of the Contrast

If you press the knob for longer than a second, a dialogue window appears. Now

you can select the contrast by turning the knob. By pressing the knob again, you

confirm the entry, the new contrast remains.

5.1.6 Imbalance Monitoring

An imbalance dialogue window indicates an excessive imbalance during

operation.

Run cannot be continued (imbalance > cut-off limit). Run is terminated with max.

deceleration.

Reason:

Improper loading or malfunction during operation (e.g. glass breakage) resulting

in an uneven run.

Note!

Additional information and a detailed description of errors and their correction is

given in chapter 9.5 “Error correction“.

Operating Manual SIGMA 4-15C, page 66 of 95

03/06

Page 67

5.1.7 Shortrun and Faststop

• Shortrun

By pressing the Start-key continuously the shortrun function is activated. The

instrument accelerates to the maximum speed with the maximum acceleration

curve and after release decelerates with the maximum deceleration curve until

standstill.

• Faststop

Pressing the Stop-key during operation for longer than a second leads to

maximum deceleration until standstill.

Operating Manual SIGMA 4-15C, page 67 of 95

03/06

Page 68

6.1 Load, Save and Delete Programs

What is considered a program?

A program contains all data that are required for a centrifuge run.

The advantage is that special sedimentation results can be repeated under equal

conditions without a change of data caused by entry errors.

Programs can be loaded, operated, altered, and deleted any time.

All programs can be protected against unauthorized use by a personal Code.

6.1.1 Load a Program

There are two possibilities of loading a program:

1. Loading by program number

• Select the program area (“PROG --“) by turning the knob, and activate it by

pressing the knob.

Activated program area

• By turning the knob, all programs saved and the actual program ("--") appear

one after the other.

Changed program

• Load desired program by pressing the knob.

Operating Manual SIGMA 4-15C, page 68 of 95

03/06

Page 69

2. Loading from the list of programs

• Select the program selection list ( ) by turning the knob and activate this area

by pressing the knob. You are able to see all programs in the memory, "--"

indicates the actual program.

Program selection list

• Select the program you want to load by turning the knob. After pressing the

knob a dialogue window appears. Select the instruction "LOAD" and confirm it

by pressing the knob.

Dialogue window

Operating Manual SIGMA 4-15C, page 69 of 95

03/06

Page 70

6.1.2 Save a Program

If you want to save an actual program:

• Select the program selection ( ) list by turning the knob and activate it by

pressing the knob to get a view over all programs in the memory and the free

positions in the list.

Program selection list

• Select the desired program position in the list by turning the knob.

• After pressing the knob a dialogue window appears. Select "SAVE" and

confirm it by pressing the knob.

Dialogue window

Operating Manual SIGMA 4-15C, page 70 of 95

03/06

Page 71

6.1.3 Delete a Program

If you want to delete a program from the list:

• Select the program selection list ( ) by turning the knob and activate this area

by pressing the knob to see the list of programs.

Program selection list

• Select the program you want to delete by turning the knob.

• A dialogue window appears after pressing the knob. Select "DELETE" and

confirm it by pressing the knob.

Dialogue window

Operating Manual SIGMA 4-15C, page 71 of 95

03/06

Page 72

7.1 Practical Notes for Centrifugation

1. Locate centrifuge horizontally on a level surface.

2. Ensure safe location.

3. Keep at least 30 cm free space around the centrifuge.

4. Provide for sufficient ventilation.

5. Tighten rotor firmly onto motor shaft.

6. Avoid imbalance.

7. Load opposite buckets with same

accessories.

8. Centrifugation with low capacity:

The vessels should be placed symmetrically so that the buckets and

their suspensions are loaded evenly.

Loading an inner or outer position of

the bucket only is not allowed (see

illustration). Even angle rotors should

be loaded symmetrically to same

weight.

Centrifugation with different tubes:

Working with different tube sizes is

possible. Opposite places must be

loaded with the same vessels (see

illustration).

9. Load all positions of swing-out

rotors.

10. Load vessels outside the centrifuge.

11. Please pay attention to the max. speed of

glass tubes. At speeds over 4 000 rpm there is an increased breaking glass

hazard.

12. Fill vessels carefully to same weight. Imbalances would result in increased

wear of bearings.

13. Grease joints of buckets and rotor pins in swing-out rotors.

14. Use perfect accessories only.

15. Avoid corrosion to accessories by careful maintenance.

Operating Manual SIGMA 4-15C, page 72 of 95

03/06

Page 73

16. Spin infectious material in sealed rotors and buckets only.

17. Do not spin explosive or highly imflammable materials.

18. Record all program data, refer to forms of appendix chapter 9.8.

19. When centrifuging substances with a density > 1,2 g/cm3 the allowable max.

speed must be reduced (refer to chapter 9.4.2 "Density").

Operating Manual SIGMA 4-15C, page 73 of 95

03/06

Page 74

7.2 Forbidden Centrifuging Operations

1. Operation of not carefully installed centrifuge.

2. Operation without front or back panels.

3. Operation by non authorized personnel.

4. Operation with rotor not installed properly (refer to chapter 3.3).

5. Operation with incompletely loaded drum rotor, swing-out rotor or angle rotor

with interchangeable buckets.

A rotor must always be loaded completely, empty places are not allowed!

Opposite buckets or carriers may nevertheless be empty. Mixed loading is

allowed, if opposite places are loaded with same buckets and carriers of

same weight.

6. Operation with overloaded rotors.

he load for a rotor is limited by its design and the max. speed (see

rotor/bucket engraving) and must not be exceeded. The rotors are intended

for liquids of max. homogeneous density of 1.2 g/cm

speed. If liquids of higher density are used, the speed must be reduced

accordingly (refer to chapter 9.4 "Mathematical relations").

7. Operation with rotors, buckets and carriers showing corrosion or other

defects.

8. Operation of very corrosive substances which can cause damages to material

and affect the mechanical strength of rotors, buckets and carriers.

9. Operation of rotors and accessories not allowed by the manufacturer. The

use of poor commodity goods is not recommended. At high speeds breaking

glass or bursting vessels can cause dangerous imbalances.

10. Operation in hazardous locations.

11. Operation with vessels of improper size.

12. Centrifugation of improper material.

13. Operation with partially filled plastic tubes in high-speed angle rotors.

14. Lifting or moving of the centrifuge during operation. Leaning against or resting

on the centrifuge is not allowed.

15. Do not place potential dangerous material - eg. glass vessels containing

liquids - near the centrifuge.

3

if centrifuged at max.

Operating Manual SIGMA 4-15C, page 74 of 95

03/06

Page 75

16. Attention: Do not open cover and/or reach into rotor chamber unless the rotor

is at standstill. Never attempt to override the lid interlock system while the

rotor is spinning.

17. Such materials are prohibited which chemically interact vigorously.

18. Do not spin explosive or inflammable materials.

19. Substances which could damage the material of the centrifuge, the rotors or

the buckets must not be centrifuged. Infectious, toxic, pathogene or

radioactive substances must be centrifuged in certified rotors and vessels

only and all necessary safety precautions are taken.

Operating Manual SIGMA 4-15C, page 75 of 95

03/06

Page 76

8.1 Care and Cleaning of the Centrifuge

Please use water-soluble, mild detergents for cleaning. Avoid corroding and

aggressive substances. Do not use alkaline solutions or solvents or agents with

abrasive particles. Before using detergents or decontamination agents which had

not been recommended by us, the user has to contact us to make sure that such

procedure would not damage the centrifuge.

Remove product particles from the rotor chamber using a cloth or paper towl. It is

recommended to open the cover when the centrifuge is not in use so that

moisture can evaporate. Increased wear of the motor bearings will thus be

avoided. If there is the risk of toxic, radioactive or pathogene

contamination, special safety measures must be kept.

Operating Manual SIGMA 4-15C, page 76 of 95

03/06

Page 77

8.2 Care and Cleaning of Accessories

For care of accessories special safety measures must be considered as these

are measures ensuring operational safety at the same time.

Buckets, trunnions and also synthetic buckets are produced exactly in order to

withstand the permanent high stress with high gravitational fields.

Chemical reactions as well as stress-corrosion (combination of oscillating pressure and chemical reaction) can affect or destroy the metals. Hardly detectable

cracks on the surface expand and weaken the material without visible signs.

When detecting a visible damage of the surface, a crack, a mark or any other