SIGE SE1020W Datasheet

Applications

Gigabit-Ethernet systems, test equipment

and modules

OC-24 fibre optic modules and line

termination

Fibre Channel optical systems

Features

Single +3.3 V power supply

Power dissipation = 110 mW (typ)

Input noise current = 180 nA rms when used

with a 0.7 pF detector

Transimpedance gain = 4.0 kΩ into a 50 Ω

load (differential)

On-chip automatic gain control gives input

current overload of 2.6 mA pk and max

output voltage swing of 300 mV pk-pk

Differential 50 Ω outputs

Bandwidth (-3 dB) = 1.2 GHz

Wide data rate range = 50 Mb/s to 1.25 Gb/s

Constant photodiode reverse bias voltage =

1.5 V (anode to input, cathode to VCC)

Minimal external components, supply

decoupling only

Operating junction temperature range =

-40°C to +125°C

Ordering Information

SE1020W

1.25 Gb/s Transimpedance Amplifier

Product Preview

Product Description

SiGe Semiconductor offers a portfolio of optical

networking ICs for use in high-performance

optical transmitter and receiver functions, from

155 Mb/s up to 12.5 Gb/s.

SiGe Semiconductor’s SE1020W is a fully

integrated, silicon bipolar transimpedance

amplifier; providing wideband, low noise

preamplification of signal current from a

photodetector. It features differential outputs and

incorporates an automatic gain control

mechanism to increase dynamic range, allowing

input signals up to 2.6 mA peak. A decoupling

capacitor on the supply is the only external

circuitry required. A system block diagram is

shown after the functional description, on page 3.

Type Package Remark

SE1020W Bare Die None

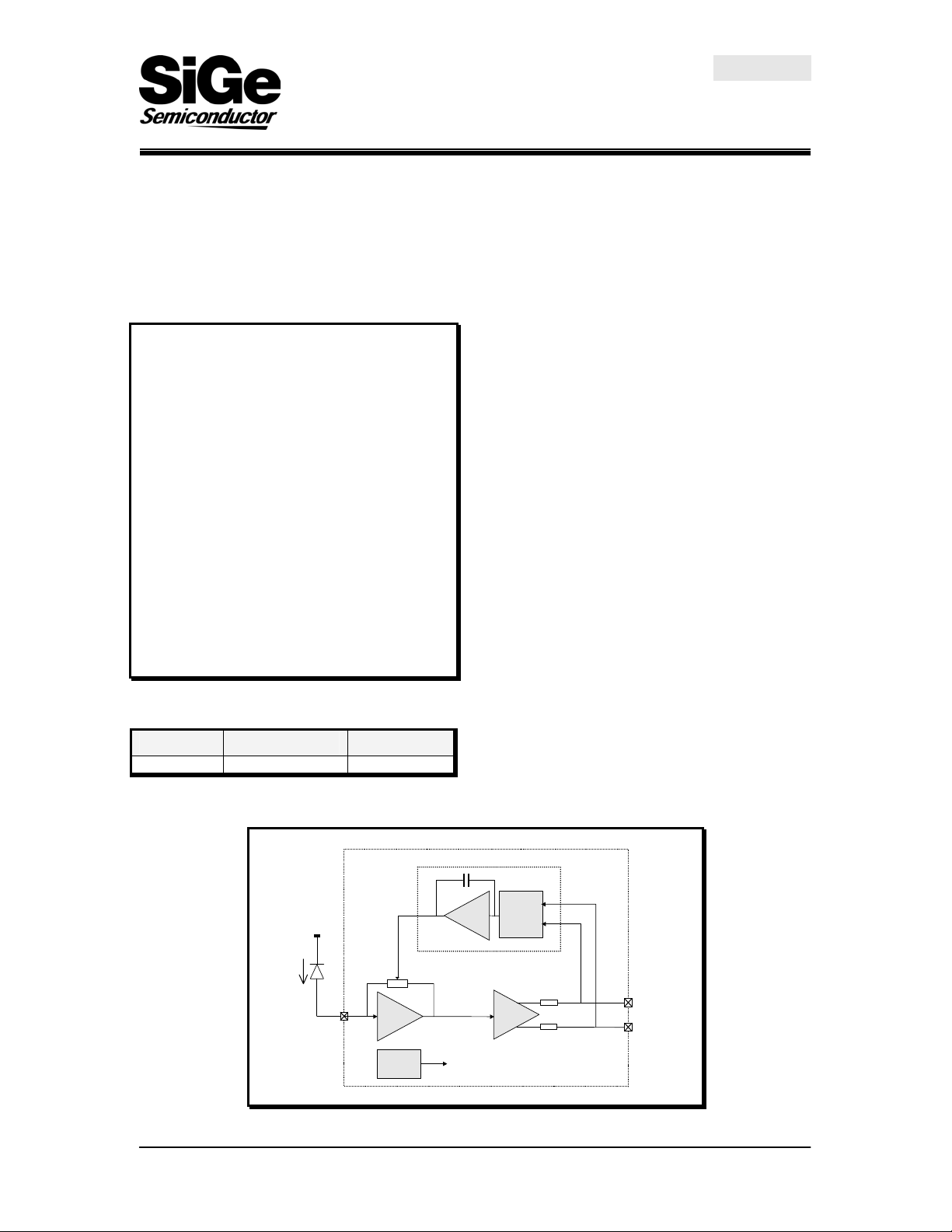

Functional Block Diagram

VCC or +ve suppl y

Input

Current

TZ_IN

SE1020

TzAmp

1.25 Gb/s

R

f

Tz Amp

Bandgap

Reference

Automatic Gain Control

Integr ator

42-DST-01 Rev 1.3 May 27/02 Confidential 1 of 7

Rectifi er

Output

Driver

Ω

50

Ω

50

OUTP

OUTN

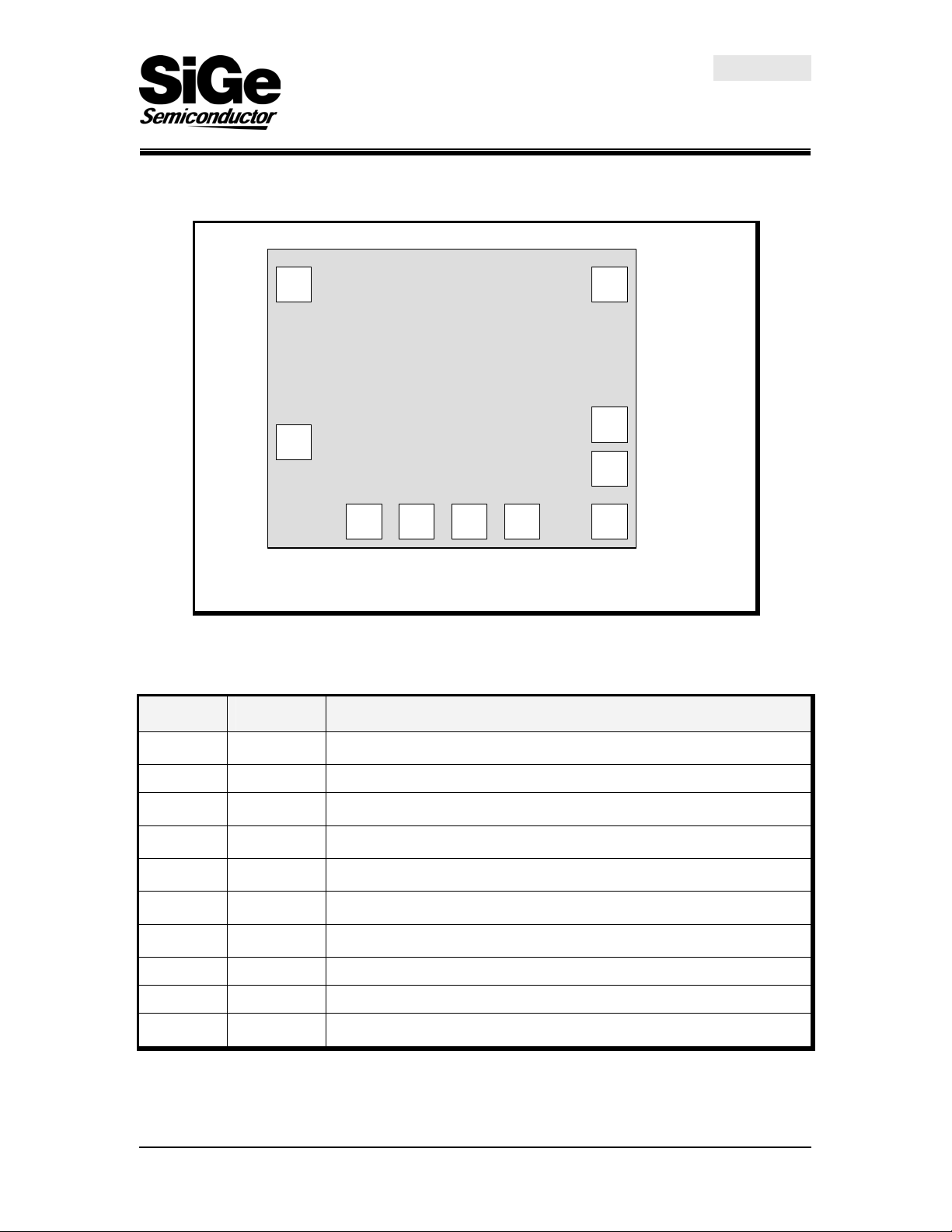

Bondpad Diagram

SE1020W

1.25 Gb/s Transimpedance Amplifier

Product Preview

VCC

1

Top

View

TZ_IN

2

6 5 4 3

Bondpad Description

Pad No. Name Description

1 VCC

2 TZ_IN Input pad (connect to photodetector anode).

3 VEE2

4 VEE1

5 VEE1

6 VEE1

7 VCC

8 OUTN Negative differential voltage output.

Positive supply (+3.3 V), pads 1, 7 & 10 are connected on chip. Only one

pad needs to be bonded.

Negative supply (0V) – Note this is separate ground for the input stage,

which is AC coupled on chip. There is no DC current through this pad.

Negative supply (0V), pads 4, 5 & 6 are connected on chip. Only one pad

needs to be bonded.

Negative supply (0V), pads 4, 5 & 6 are connected on chip. Only one pad

needs to be bonded.

Negative supply (0V), pads 4, 5 & 6 are connected on chip. Only one pad

needs to be bonded.

Positive supply (+3.3 V), pads 1, 7 & 10 are connected on chip. Only one

pad needs to be bonded.

10

VCC

9

OUTP

8

OUTN

7

VCC VEE2 VEE1 VEE1 VEE1

9 OUTP Positive differential voltage output.

10 VCC

Positive supply (+3.3 V), pads 1, 7 & 10 are connected on chip. Only one

pad needs to be bonded.

42-DST-01 Rev 1.3 May 27/02 Confidential 2 of 7

Functional Description

Amplifier front-end

The transimpedance front-end amplifies an input

current from a photodetector, at pin TZ_IN, to

produce an output voltage with the feedback

resistor Rf determining the level of amplification

(see the functional block diagram on page 1). An

automatic gain control loop varies this resistor, to

ensure that the output from the front-end does

not saturate the output driver stage that follows.

This gain control allows input signals of up to

2.6 mA peak.

The input pin TZ_IN is biased at 1.5 V below the

supply voltage VCC, allowing a photodetector to

have a constant reverse bias by connecting the

cathode to 3.3 V. This enables full single rail

operation.

The front-end stage has its own supply ground

connection (VEE2) to achieve optimum noise

performance and maintain integrity of the highspeed signal path. The front-end shares the VCC

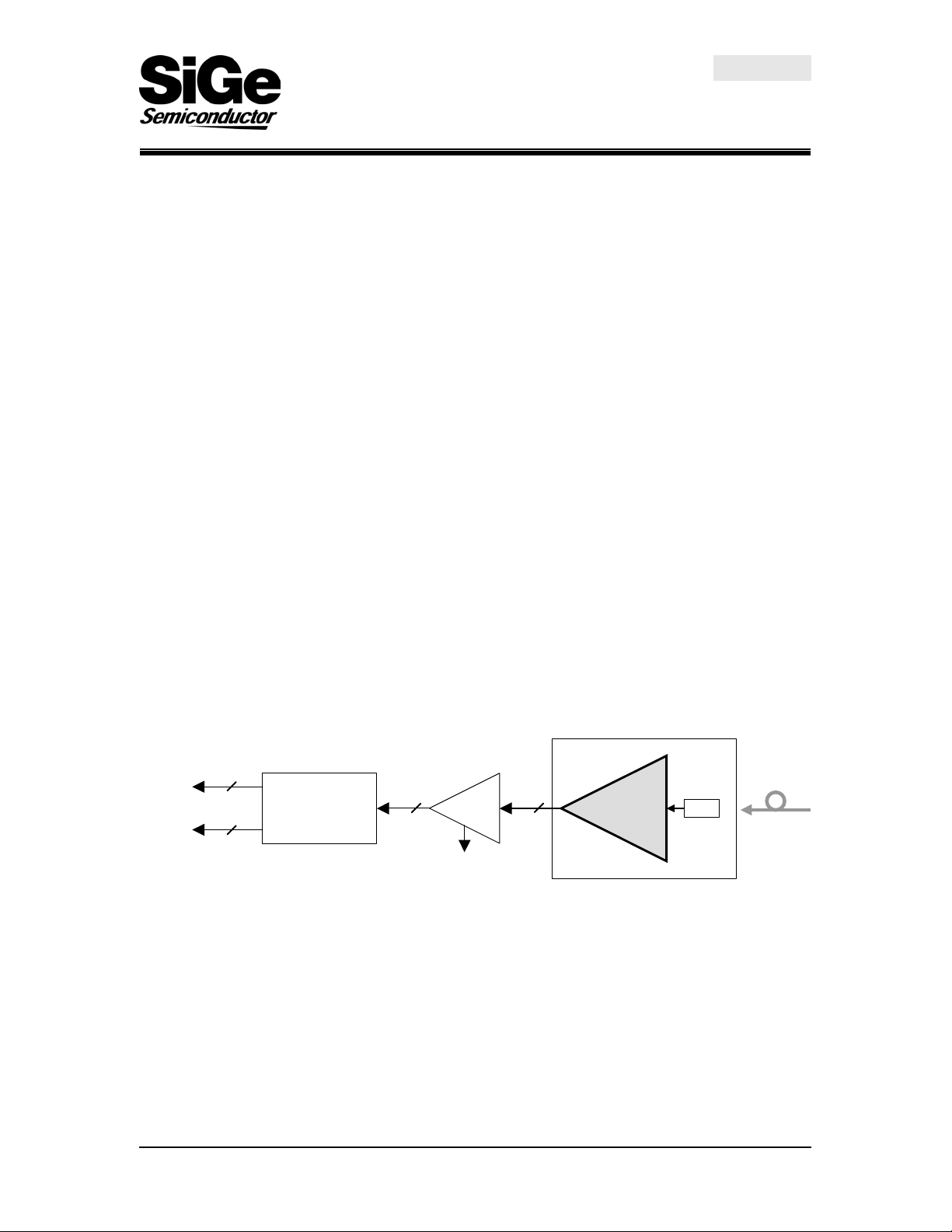

System Block Diagram

1.25 GHz

1.25 Gb/s

2

Clock

Clock & Data

Recovery

2

Data

Amplifier

2

AGC

SE1230

LOS

SE1020W

1.25 Gb/s Transimpedance Amplifier

Product Preview

(+3.3 V) connection with the remainder of the

circuitry, which has a separate ground (VEE1).

Output driver stage

The output driver acts as a buffer stage, capable

of swinging up to 300 mVpk-pk differential into a

100 Ω load. The small output swings allow ease

of use with low voltage post amplifiers (e.g. 3.3 V

parts). Increasing optical input level gives a

positive-going output signal on the OUTP pin.

Automatic Gain Control (AGC)

The AGC circuit monitors the voltages from the

output driver and compares them to an internal

reference level produced via the on-chip bandgap

reference circuit. When this level is exceeded, the

gain of the front-end is reduced by controlling the

feedback resistor Rf.

A long time-constant integrator is used within the

control loop of the AGC with a typical low

frequency cut-off of 10 kHz.

Receiver Module

2

SE1020W

TZ

Amplifier

PIN

42-DST-01 Rev 1.3 May 27/02 Confidential 3 of 7

Loading...

Loading...