The SIG Messerschmitt Bf-109 ARF is a sport scale model, not

necessarily based on any particular full-scale variant. The

covering is printed with color and markings representing typical

German aircraft of the era, including details such as panel lines

and national markings. The builder can add unit markings and

other details of his own choice to make a convincing replica of this

great German warplane.

The recent and rapid development of super-efficient brushless

electric motors and lithium polymer batteries have made electric

powered aircraft, such as the Bf-109, a practical reality. Our

prototype Bf-109 models have proven to be outstanding R/C

aircraft, both in terms of looks and performance. We have flown

our own prototypes a great deal and can report that they are solid

flying models with honest flight characteristics. When powered

with an appropriately sized brushless outrunner motor swinging

the recommended propeller, the airplane will have a wide speed

range and be capable of some very nice scale fighter plane type

aerobatics. While the SIG Bf-109 ARF is a comfor table model to

fly, we do

not recommend it for a first R/C model. But we can and

do recommend the Bf-109 as your first electric warbird.

This assembly manual will guide you through each assembly step

in detail and is further enhanced with photos that visually assist

you with each step. It is important that you follow the provided

construction sequence to achieve the best results.

Reference Material:

SIG Manufacturing Company, Inc. wishes to gratefully

acknowledge the excellent reference materials listed below:

• http://en.wikipedia.org/wiki/Messerschmitt Bf 109

• http://www.axishistory.com/index.php?id=1154

• "The Great Planes", by James Gilbert, Published by Grossett &

Dunlap, 1970

Specifications: Imperial Metric

Wing Span: 48 in. 1219 mm

Wing Area: 396 sq. in. 25.52 dm

2

Length: 42.5 in. 1079 mm

Flying Weight: 60 oz. 1700 g

Wing Loading: 21.8 oz./sq.ft. 66.6 g/dm

2

Motor: Brushless, 300 to 400 watt

ESC Required: Brushless type to suit motor & battery pack

Battery Pack

Required: 3-Stack 3300 mAh Lithium Polymer Pack Typical

Radio Required: 4 Channel w/ Hitec 2-HS55 and 2-HS81

servos or equivalent

Order Number: SIGRC102ARF

ITEMS REQUIRED TO COMPLETE THIS KIT:

• Radio System - 4-channels, with 4 micro servos (Hitec HS-55 &

HS-81 used & shown in this manual)

• Appropriate servo extensions

(see Radio Systems section for specifics)

• Brushless Motor (see Power System section for recommendations)

• Brushless Speed Control (see Power System section for recommendations)

• Lithium Polymer Battery Pack (see Power System section for

recommendations)

• Propeller (see Power System section for recommendations)

• Motor mounting bolts, sized for your par ticular motor

• Dremel

®

Tool with a variety of sanding bits

• An assortment of screwdrivers

R

1

Messerschmitt Bf-109 ARF ASSEMBLY MANUAL

INTRODUCTION:

The prototype, Messerschmitt Model 109, first took to the air in

mid-September of 1935 and its performance was nothing short of

spectacular! Small, powerful, and fast, Willy Messerschmitt's

Model 109 surely had a date with destiny.

Based on many of the design concepts of the earlier Model 108

Taifun, the Model 109 was exceptionally well constructed and

aerodynamically clean. The concept behind the 109 was to place

the smallest and cleanest airframe possible behind the most

powerful engine available at the time. This resulted in an aircraft

that had many positive attributes, as well as a few negatives. One

of these negatives was the weight of the airplane versus its

relatively small wing. This created a high wing loading, especially

in comparison to its eventual foes . In an attempt to keep the weight

as low as possible, the retractable landing gear pivoted outward

toward the wingtips, keeping the main wing spar weight down. But

as a result, the splayed, close-tracked landing gear would plague

the design for the rest of its operational life. All of this aside, the

Model 109 can truly be called one of the first modern fighter

aircraft of the era.

The Bf-109 was ultimately manufactured in greater numbers than

any other aircraft in history - over 30,000 units between 1939 and

1945. It was manufactured in Germany, Czechoslovakia, and

Spain. To keep the airplane competitive in combat, it went through

many modifications and remained the Luftwaffe's primary fighter

aircraft throughout WWII. Used in a wide variety of combat

missions, the Bf-109 served as an air superiority fighter, a bomber

escort, an interceptor, a ground attack aircraft, and in high-speed

reconnaissance missions. But in its primary role as an air

superiority fighter, the Bf-109 was truly a formidable aircraft. In

fact, at one time or another, every top scoring Ger man fighter ace

flew Bf-109's. Notably, Erich Har tmann, with a combat record of

352 enemy aircraft shot down, always flew a Bf-109, refusing to fly

any other aircraft.

In historical terms, the Bf-109 will always be best remembered for

its role in the Battle of Britain, forever being compared to its

closest adversary of the time, the Supermarine Spitfire. While

these comparisons rage on to this day, it's fair to say that both of

these fine aircraft were among the best of their day.

• Pliers - needle nose and flat nose types

• Wire cutters

• A selection of glues - thin, medium, and thick SIG CA,

SIG Epoxy Glue (5 and 30 minute types) and

SIG Super-Weld white glue

• Fine point CA applicator tips

• Drill with assorted small drill bits

• Pin vise for small diameter drill bits

• Small T-pins

• Sandpaper

• Hobby knife with sharp #11 blades

• Scissors

• Covering iron and trim seal tool

• Paper towels

RADIO SYSTEMS:

The SIG Bf-109 ARF requires the use of a four-channel radio

system and four micro servos. Due to limited space in the wing

bays for aileron servos, we used and can recommend the Hitec

HS-55 (2 required) for this purpose. We used and can recommend

Hitec HS-81 servo for the fuselage-mounted elevator and r udder

servos. These little servos fit into the fuselage tray perfectly and

provide plenty of torque. A sub micro receiver is not mandatory but

smaller receivers like the Hitec Electron 6 do offer great reliability

and considerably lighter weight over larger, standard type

receivers.

Ser

vo Extensions: In order to connect the ailerons ser vos to the

receiver, two 6" ser vo extensions and one standard Y-har ness will

be required. Note that in our radio installation, we leave the "Y"

harness plugged into the receiver, plugging the two aileron servo

extensions into it whenever the wing is attached.

POWER SYSTEMS:

Motor

s: The Bf-109 has been designed to fly with brushless

motors in the 300 to 400 watt range. We have used and can

certainly recommend the fine Himax range of brushless motors for

your own Bf-109 model. W e ha v e tested this airplane with both the

Himax #HC3516-1130 (300 watt) and HC3522-0990 (400 watt)

brushless motors with great results.

Electr

onic Speed Controls (ESC): We suggest using a 35 amp

ESC for 300 watt motors or a 45 amp ESC for 400 watt motors.

Pr

opellers: We suggest using an APC 10 x 7E propeller with

either the 300 or 400 watt motors or an APC 11 x 7E, used only

with the 400 watt motor

Batter

y Packs:We suggest using a 3S 3300 mAh Lithium Polymer

battery pack. Note that this pack fits perfectly in the Bf-109 battery

tray.

Batter

y Charger: Use a charger designed specifically for

lithium polymer batteries! Using any other type of battery

charger for lithium polymer batteries can be extremely

dangerous.

COVERING MATERIAL:

The Bf-109 ARF has been professionally covered in SIG

AEROKOTE

®

iron-on plastic covering material. This covering is a

tough, lightweight, and heat shrinkable material. The camouflage

patterns, national markings, and other detail and panel lines have

been printed on the outer surface of the covering, giving a very

realistic overall look to the model. The inks used in the printing

process are quite durable and bond to the covering film extremely

well. Normal handling and flying conditions should have little, if any

effect on the printed finish. However, carefully note that certain

solvents can and will soften the ink, allowing it to be rubbed off.

The following is a short list of cleaners and solvents that can and

cannot be used on the printed finish of your model:

Use

Do Not Use

Windex®Window Cleaner CA Debonder

SIG Model Magic Cleaner Acetone

Hexane Alcohol

Dope Thinner

If in doubt of the suitability of a cleaner or chemical to use on your

model, always test it first, choosing an inconspicuous location on

the model. In addition to the above, carefully note that excessive

heat from typical covering tools, such as heat guns, covering irons

and trim seal tools, may also soften and remove the ink finish.

Work only with temperatures set at 250

O

F or less. Whenever

working on the covering with a heat iron, we strongly suggest that

you first cover the shoe of the iron with a soft cotton cloth, such as

an old T-shirt.

Your Bf-109 ARF kit was built and covered in a part of the world

that has a great deal of humidity. You may therefore notice that

after the covered parts have been removed from their plastic bags,

that some wrinkles may appear after 24 to 48 hours. This is

perfectly normal and is the result of the wood losing humidity and

dimensionally shrinking.

If wrinkles appear in the covering, they are easy to remove, using

a little heat. Because of the ink printing, it is not

advisable to rub a

hot iron over the surfaces to be tightened. If proper precautions

are taken, a heat gun will do the job quickly. First, locate and

inspect all the seams where the covering overlaps like at the

leading and trailing edges of the wing and tail surfaces and the top

and bottom of the fuselage. Seal these overlaps down with a trim

iron (set to about 220

O

F to 240OF) by applying the iron to the seam

overlap for a few seconds without moving the iron, then lift the iron

to move to the next location and repeat. Do this until you are sure

that all the seams are secure before proceeding with the heat gun.

Protect these seams with wet paper towel strips while you shrink

the loose areas with the heat gun. Use caution to never use any

more heat than necessary to get the covering to shrink.

COMPLETE KIT PARTS LIST:

The following is a complete list of all parts contained in this kit.

Before beginning assembly, we suggest that you take the time to

inventory the parts in your kit, using the provided check-off boxes

(❑). Carefully note that the CA type hinges for the rudder,

elevators, and ailerons are in place in their appropriate locations

but are not glued in place. All parts are covered in pre-printed

AeroKote

®

with green and blue-gray camouflage colors with panel

lines and other details except where noted.

❑ Bag #1 Ver tical fin and rudder, 2 CA hinges installed but not

glued, leading edge of rudder at the bottom drilled and

routed to receive the tail wheel wire.

❑ Bag #2 Stabilizer and elevator, 4 CA hinges installed but not

glued, elevator joiner wire installed but not glued.

2

3

❑ Bag #3 Full Span Wing, ailerons installed with 3 CA hinges on

each but not glued, aileron servo hatches installed

with 4 ea T2 x 6 mm PWA screws

❑ Bag #4 Fuselage with top hatch/cockpit installed and retained

by magnets, motor mount/battery tray installed, two

plastic pushrod tubes installed, blind nuts for wing hold

down bolts installed, servo tray installed.

❑ Bag #5 Clear Canopy with frame painted on, 4 holes drilled for

mounting screws.

❑ Sub bag 4 ea. T2 x 6 mm PWA screws

❑ Bag #6 Fiberglass cowl - painted yellow.

❑ Sub bag 4 ea. T2 x 12 mm PWA screws

❑ Bag #7 Wire Pushrod bag

❑ 2 ea.

1.25 mm dia.x 597 mm

with "Z" bend on one end

❑ 2 ea.

1.25 mm dia. x 98 mm

with "Z" bend on one end

❑ Bag #8 Tail Wheel Assembly with 25 mm dia.Wheel

❑ Bag #9

Green covering material for repairs, 2 ea. 110 mm x 30 mm

❑ Bag #10 Control Horn bag

❑ 4 ea. Control hor ns

❑ 4 ea. Backing plates

❑ 4 ea. Pushrod connectors with set screws

❑ 4 ea. Metal keeper washers

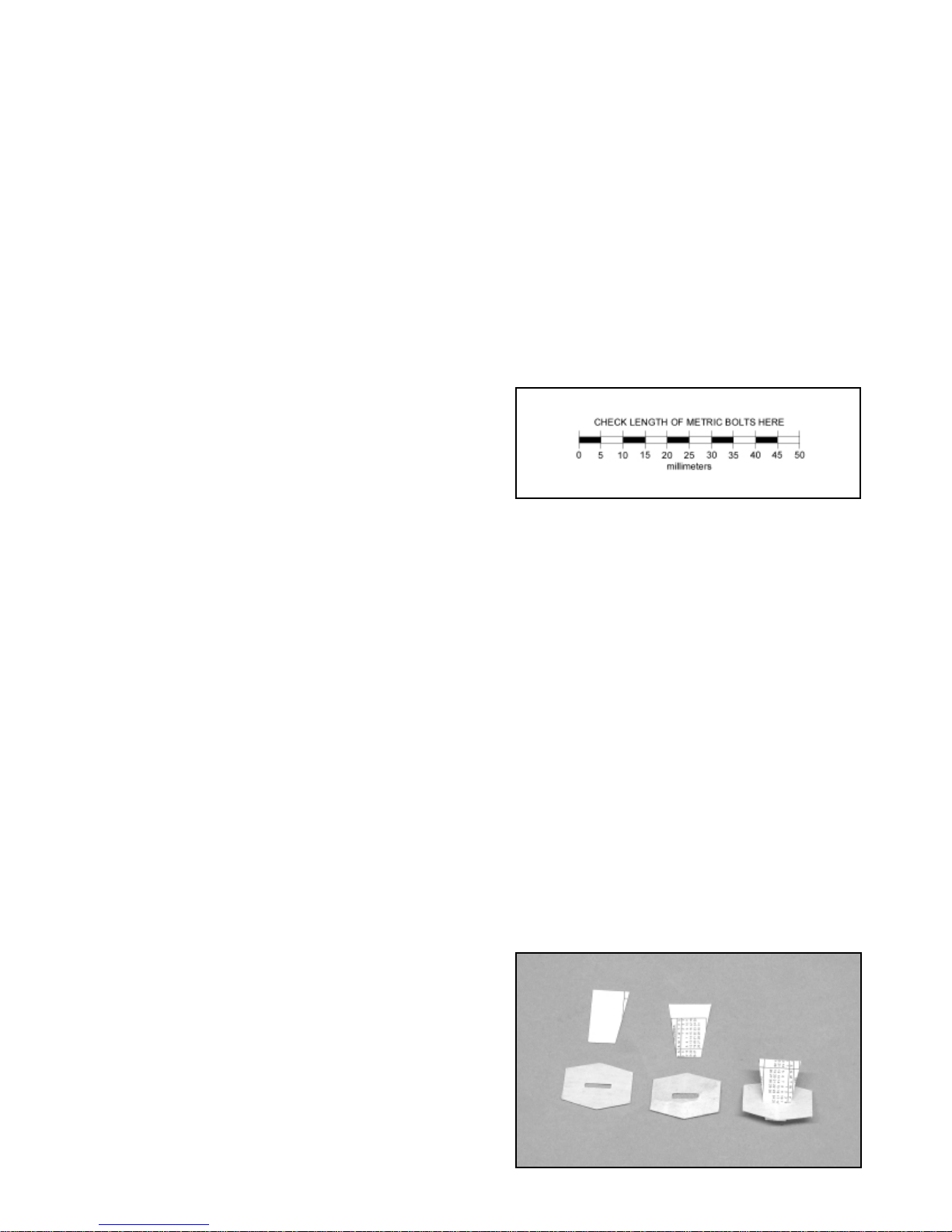

❑ 8 ea. M2 x 20 mm bolts

❑ Bag #11 Accessory Bag with 2 ea. Plywood landing gear doors

painted gray, drilled for mounting bolts and air scoop

for fuselage.

❑ Sub bag ❑ 4 ea. Metal straps to retain landing

gear doors

❑ 8 ea. M2 x 8 mm bolts

❑ 8 ea. M2 nuts

❑ 8 ea. M2 washers

❑ Bag #12 ❑ 2 ea. plywood washers, 24 mm dia. - painted gray

one side.

❑ 2 ea. M4 x 30 mm plastic wing hold down bolts

❑ Bag #13 Spinner Bag with yellow painted plastic spinner cone

❑ 1 ea. 72 mm dia. x 4.5 mm plywood backplate

❑ 2 ea. 20 mm dia. x 2mm plywood washers for

spacers

❑ Bag #14 ❑ 2 ea. Painted plastic wing radiator covers

❑ Bag #15 ❑ 4 ea. 8 mm square x 12 mm hardwood for wing

servo mounts

❑ Bag #16 Tail Brace Bag - all parts painted gray

❑ 2 ea. 2 mm dia. x 94 mm wire threaded M2 on one

end and an eyelet bent on the opposite end

❑ 2 ea. M2 R/C metal R/C links

❑ 2 ea. M2 knurled lock nuts

❑ Sub bag ❑ 2 ea. Metal tabs, drilled two places

and bent in center

❑ 2 ea. T2 x 6 mm PWA screws

❑ 2 ea. T2 x 8 mm PWA screws

❑ 2 ea. 3 mm ID x 6 mm silicone tube

keepers

❑ Bag #17 Main Landing Gear Bag

❑ 2 ea. 4 mm dia. Wire landing gear wires -

pre-bent

❑ 2 ea. 63 mm dia. Light foam wheels

❑ Sub bag ❑ 4 ea. Plastic retaining straps

❑ 8 ea. T3 x 8 mm PWA screws

❑ 2 ea. 4.1 mm ID wheel collars

with set screws

❑ 2 ea. 4 mm ID plastic bushings

NOTE: In this manual, all references to "right" or "left" refer to your

right or left, as if you were seated in the cockpit looking forward.

WING ASSEMBLY:

The following parts will be required for this assembly sequence:

❑ Wing

❑ 4 ea. ser vo mounting blocks from Bag 15

❑ 2 ea.

Hitec HS-55 or similar sized aileron servos - not included

❑ 2 ea. 6" ser vo wire extensions - not included

❑ Bag #10 2 ea. Control hor ns

2 ea. Backing plates

2 ea. Pushrod connectors with set screws

2 ea. Metal keepers,

4 ea. M2 x 20 mm bolts

❑ Bag #12 2 ea. Painted plywood wing bolt washers

2 ea. M4 x 30 mm nylon wing bolts

❑ Bag #7 2 ea. .048 x 3-7/8 (98 mm)

wire pushrods with Z-bend

❑ Bag #11 2 ea. Landing gear doors with hardware

❑ Bag #14 Radiator covers

❑ Bag #17 Landing gear wires with mounting hardware

❑ 1) As noted above, the hinges for the ailerons are not yet

glued. The first step is to remove the left and right ailerons and the

hinges from the wing. The hinges have a die-cut center slot that

can be used to accurately place and center the hinge equally into

4

can be used to accurately place and center the hinge equally into

both the wing panel and the aileron. To do this, use a business

card and a pair of scissors to cut some "wedges". These should

be wide enough at the top so as to not pass through the hinge slot

cut-out. Insert each hinge in place into the wing panel up to the

cardboard wedge.

Now, slip the aileron onto each hinge, pressing it fully in place.

Center the aileron, leaving equal spacing between each end of the

aileron and the wing.

❑ 2) Flex the aileron down a 1/2" or so to expose the center of

the hinge and use a piece of masking tape to hold it in this

position. Remove the wedge from one of the hinges and apply

three drops of thin CA to each exposed side of the hinge. Repeat

this operation until all the hinges on this side of the wing are glued.

IMPOR

TANT: - Be careful to avoid getting glue on the covering.

Solvents such as CA debonder will also remove the ink on the

covering.

❑ 3) Remove the tape holding the flexed aileron, returning it to

the neutral position. Turn the wing over and flex the aileron down

about 1/2", again exposing the center of the hinges. Use another

piece of tape to hold the aileron in this position. Repeat the same

gluing process on each hinge - 3 small drops of thin CA on each

exposed side of each hinge. Remove the tape holding the aileron

and return it to the neutral position. Hold the wing up to the light

and look through the gap between the aileron and the wing for any

excess glue that may have accumulated in the gap. Inserting a

slip of paper into the hinge gap, on each side of the hinges, will

wick out any excess CA glue . Hinge the opposite aileron using the

same procedure.

Note that it typically takes a little time for CA glue to fully "wick" its

way across the surface of the hinge and surrounding wood. Allow

about 10 minutes or so before flexing the ailerons. After sufficient

time has passed, firmly flex each aileron briskly up and down to

create free and easy movement. We also suggest pulling on the

aileron at each hinge location, making sure each hinge is firmly in

place.

❑ 4) Remove the four screws from each corner of both aileron

servo covers on the bottom of the wing. With the aileron ser vo

covers out of the way, remove the covering from the slot that has

been cut for the servo arms.

❑ 5) Install straight servo arms onto two HS-55 servos, orienting

the arms at 90

O

to the servo body. Note that these extra arms

come with the servos and are about 1-7/32" long, end to end.

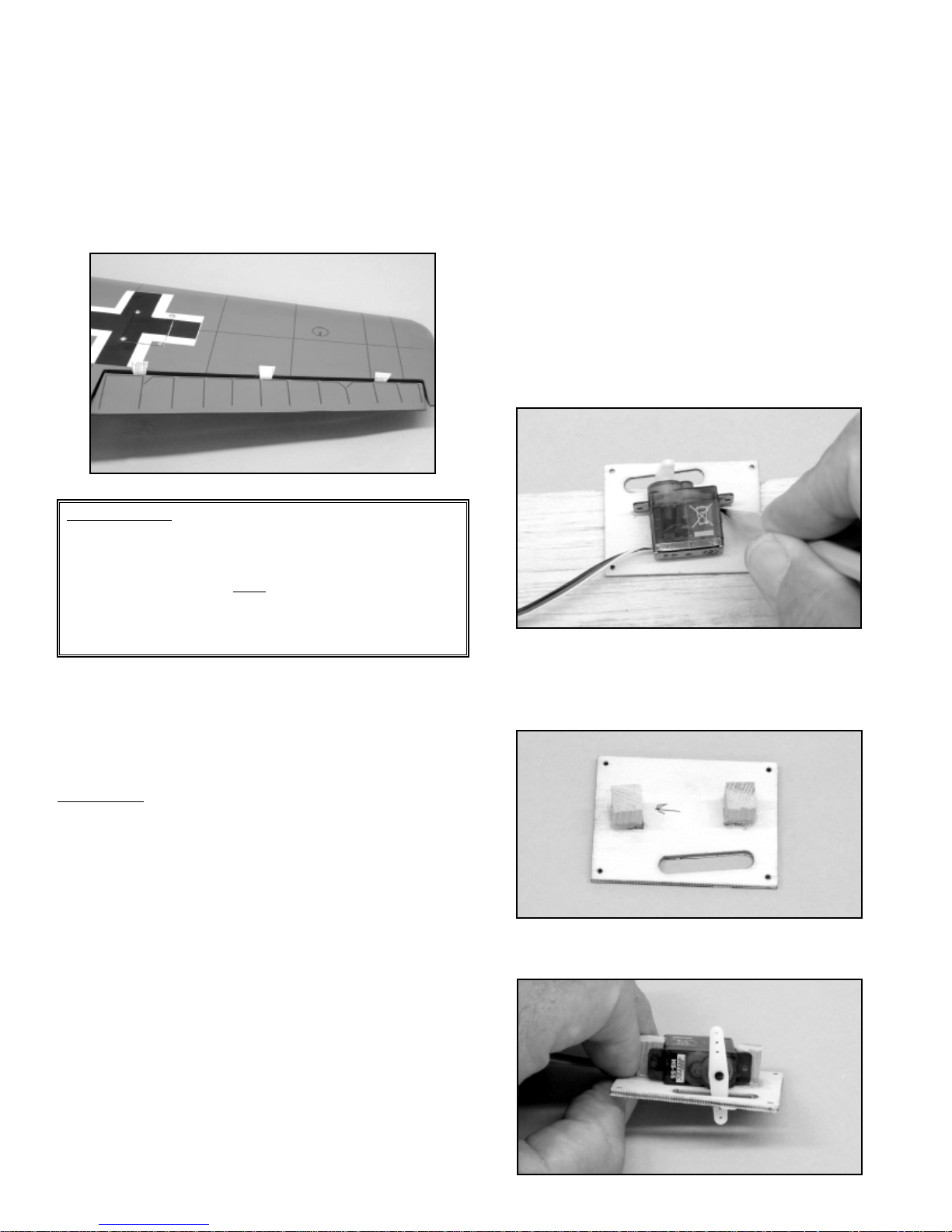

❑ 6) Lay the servo onto the inside surface of the aileron hatch,

positioning the servo arm centered in the slot, with the servo body

within the borders of the hatch. Hold the servo in this position and

use a pencil to mark where the bottom of the servo mounting lugs

and sides of the servo case meet. This marks position of the two

wooden servo mounts.

❑ 7) Locate the four 8 mm square x 12 mm long hardwood

blocks from bag #15. These are glued on end, to the servo hatch,

at the location marks just made. 5-minute epoxy or thick CA glue

works well for this purpose. Allow the glue to fully set.

❑ 8) Place the servo back onto the hatch between the two

mounting blocks. Use a sharp pencil to mar k the servo mounting

Important Note: When installing CA type hinges, more is not

better! Applying excess thin CA glue to this type of hinge does

nothing more than stiffen it, potentially causing the hinge to

crack and break. If you have followed these instr uctions, each

hinge will have a total of 6 small

drops of thin CA glue on each

side. This is the correct amount of adhesive for the pur pose.

Using a fine tip applicator for this purpose is strongly advised

and recommended.

5

hole locations onto the mounting blocks.

Remove the servo and drill pilot holes for the servo mounting

screws into the wood mounting blocks, using a #60 (1 mm) bit.

Use the mounting screws that came with your servo to secure the

servo to the mounting blocks.

Repeat this same procedure with the remaining aileron servo and

servo hatch.

❑ 9) In this step, the servo arms will be centered onto the servo

output shaft. First, remove the ser vo output arm retaining screws

and remove the servo output arms. Connect the two aileron

servos leads into a standard "Y" harness. Plug the "Y" harness

into the receiver. Tur n your transmitter on and center the aileron

trim to neutral. Connect the receiver to a 4.8v battery pack. With

the system now on and working, reattach the two servo output

arms onto the two aileron servos, with the arms at 90

O

(or as close

to 90

O

as possible) and reinstall the output arm retaining screws

into each servo. If your radio system has "sub trim" capability, use

this feature to further center the output arms at 90

O

to the servo

body and centered within the servo hatch slot. Once the output

arms are both centered, cut off the opposite, unused end of each

arm. This ensures that the arm will not contact the covering on the

inside top of the wing when the servo tray is installed. Turn the

radio system off and unplug the servo leads from the "Y" harness.

❑ 10) Connect a 6" ser vo lead extension onto each aileron servo

lead. We always suggest securing these extensions at the

connectors, using a length of heat shrink tubing. This ensures that

the connection remains secure.

❑ 11) On the top surface of the wing, near the center joint, you will

be able to feel the location of two 1/2" diameter holes through the

covering. These are the exit holes for the aileron servo leads. Use

a sharp #11 blade to remove the covering from these holes. You

should then be able to see a small stick tack-glued to the inside top

sheeting with a string attached to it. This is the pull string, used to

pull the aileron servo leads through the wing ribs.

❑ 12) Inside the aileron ser vo bay in each wing panel, the other

end of this string is attached to a small tack-glued stick. Break this

stick loose and unwind the string from the stick. This end of the

string is secured firmly to the connector end of the servo extension

lead (we like to tie this string tightly to the connector). With the

string in place to the connector, feed the connector and string into

the servo bay while gently pulling on the string at the exit hole in

the center of the wing. Start the connector down through the holes

in the wing ribs. Lightly pull back and forth until the connector

moves through one rib and up to another . Keep doing this until the

connector appears at the exit hole. Pull the connector up through

the hole and temporarily tape it to the wing surface. Now, mount

the servo hatch and servo in place to the bottom of each wing

panel, using the provided screws, removed earlier. Repeat this

procedure with the opposite servo hatch and wing panel.

❑ 13) With both servo leads now through their respective exit

holes on the top center of the wing, remove the strings and plug

each lead into a standard "Y" harness. Again, we suggest

securing these connections with short lengths of heat shrink

tubing.

❑ 14) The aileron control horns are now installed onto the bottom

surfaces of each aileron. The vertical center arm of the control

horn is located 1-1/2" from the inboard from the end of the aileron,

with its four hole locations lined up with the hinge line. Hold the

control horn in this position and use a sharp pencil to mark the two

control horn mounting hole locations onto the surface of the

aileron.

At the two marks just made, use a #46 (2 mm) dia. bit to drill two

clearance holes completely through the aileron, 90

O

perpendicular

MODELER’S TIP: It happens to all of us now and then; the

factory installed servo lead string disappears into the wing! No

problem. Simply pull the string completely out of the wing and

attach a small weight, such as a metal nut or even a small split

shot sinker, to one end of the string. Insert the weighted end of

the string into the servo opening and start it down the holes that

are just behind the spars. With the wing on end and the center

of the wing below the servo well, gently shake the wing while

feeding the in the weighted string, listening for the weight to

drop through to the next rib. When the center section is

reached, turn the wing upside down and shake the weight out

of the hole and you're back in business!

trailing edge. These two lines are used to align the radiators. The

black painted inlet side of these covers faces forward towards the

leading edge, with the front of the cover even with the rectangle

and the inside edge of the cover on the chordwise line. You may

need to slightly trim the rear outboard corner of the cover to keep

it from hanging over the trailing edge. We suggest using medium

or thick CA glue to attach these covers in place, being careful to

not use excessive glue that might smear the outer surface of the

cover or the cover ing itself.

❑ 18) Use a sharp #11 blade and hobby knife to no w open the two

wing hold down bolt holes at the trailing edge of the wing center

section. Use medium or thick CA glue to glue the two painted

plywood washers in place, centered over the two bolt holes in the

wing.

MAIN LANDING GEAR INSTALLATION:

This assembly sequence assumes that the optional main landing

gear and related parts will be installed. Note that if you intend to

fly your Bf-109 model without

landing gear, you can then proceed

to the Motor Installation section. The following parts will be

required for the following assembly steps.

The parts for the main gear are found in these bags:

❑ Bag #17: 2 ea. 4 mm wire landing gear legs

2 ea. 63 mm dia. main wheels

4 ea. plastic retaining straps

8 ea. T3 x 8 mm PWA screws

2 ea. 4.1 mm ID wheel collars with setscrews

2 ea. 4 mm ID plastic bushings

❑ Bag #11: 2 ea. plywood landing gear doors

4 ea. metal straps

8 ea. M2 x 8 mm bolts

8 ea. M2 nuts

8 ea. M2 washers

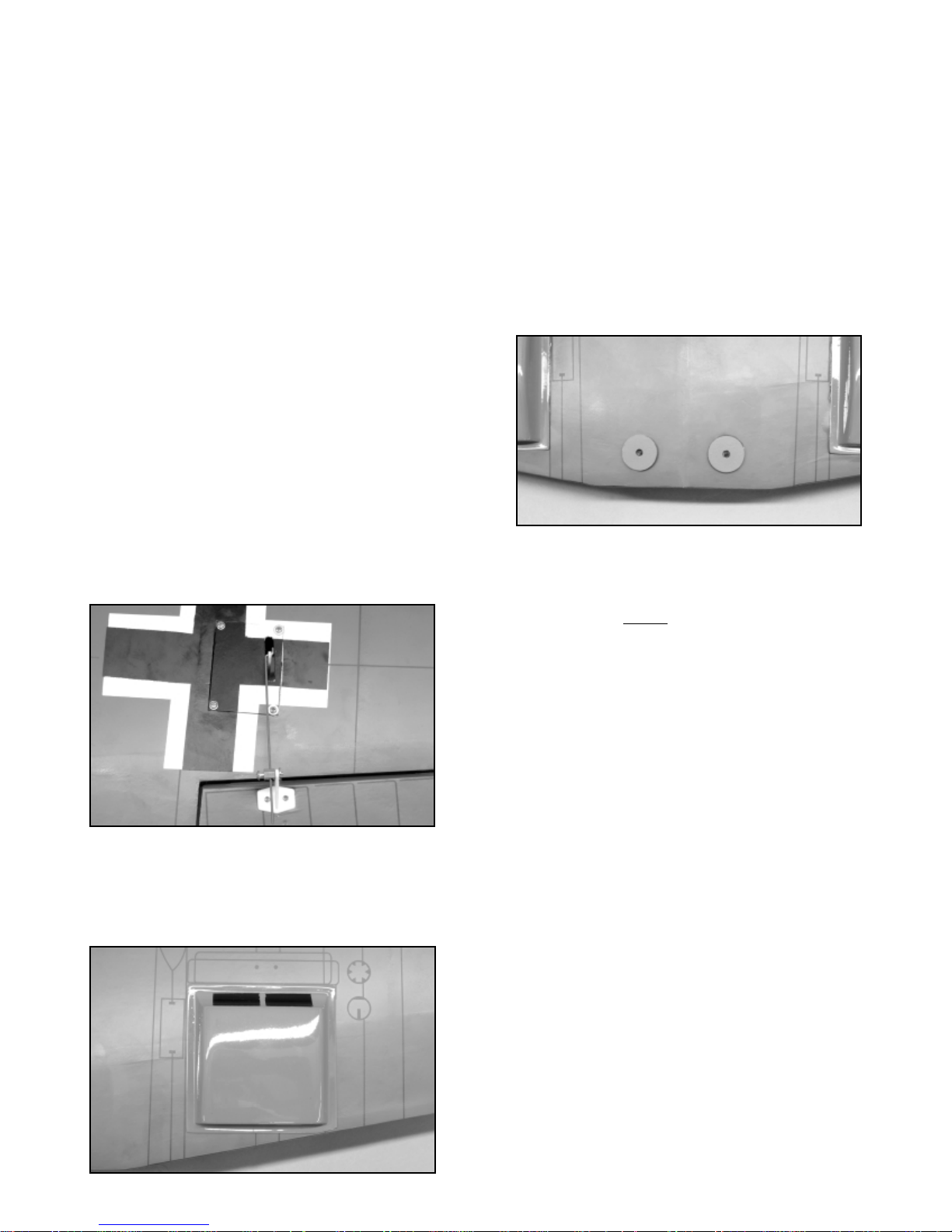

❑ 1) As received, the wing structure includes two slotted

hardwood main landing gear mounting blocks, built into the bottom

surfaces. These blocks are used to mount and secure the main

landing gear wire forms.

On the bottom of the wing center section, about 2-1/4" (57 mm)

back from the wing leading edge, you will be able to feel the two

slots that will hold the main landing gear legs. Press firmly on

these slot locations with your finger, moving back and forth on the

surface of the wing until you can see where the edges of these

slots are. Once the slots are located, use a shar p #11 blade to

carefully slit the covering from one end of the slot to the other.

Repeat this with the opposite landing gear slot.

to its bottom surface. Repeat this process on the opposite aileron.

Use the four M2 x 20 mm bolts and the two plastic control horn

backing plate to now mount each aileron horn to the bottom of

each aileron with the backing plates on top of each aileron to

engage the bolt ends. Cut off the excess bolt ends and file smooth.

❑ 15) Install a pushrod connector, pointing towards the center of

the wing, into the outermost hole in the control horn and secure it

with a metal keeper washer, pressed in place over the stub end.

Repeat this process with the remaining pushrod keeper and

keeper washer.

❑ 16) Insert the Z-bend end of the .049" dia.x 3-78" (1.25 mm dia.

x 98 mm) aileron pushrods into the outermost hole of the aileron

servo arms. Note that these holes may need to be slightly

enlarged to fit the wire diameter. Slide the opposite, unbent end of

the pushrod into the hole in the pushrod keepers on the aileron

control horns. Again, connect the aileron "Y" harness into the

aileron receptacle in the receiver. Turn the transmitter on and

connect a 4.8V battery pack into the receiver. With the aileron

servos now working, make sure the trims are at neutral and then

tape the ailerons in neutral to the wing. Now firmly tighten the

setscrews in the pushrod keepers to lock the pushrods in place.

Remove the tape from the ailerons and wing. Move the aileron

stick on the transmitter to move the ailerons. Viewed from the rear

trailing edge of the wing, the right aileron should move up when the

aileron stick is moved to the right. If this aileron movement is

wrong, reverse the aileron channel in your transmitter. Once

satisfied, disconnect the aileron "Y" harness and battery pack from

the receiver and turn off the transmitter.

❑ 17) The two plastic wing radiator covers (Bag #14) are now

glued in place onto the bottom of each wing panel. Notice that

there are lines printed chordwise on the bottom covering that are

about 3-11/16" (94 mm) out from the center of the wing. A

rectangle intersects this line about 4-7/16" (113 mm) forward of the

6

freely with just a small amount of left and right "play". Once in

position, firmly tighten the setscrew in the wheel collar. Repeat this

process with the remaining wheel.

The wing assembly is now complete and ready to use. Set it aside

for now.

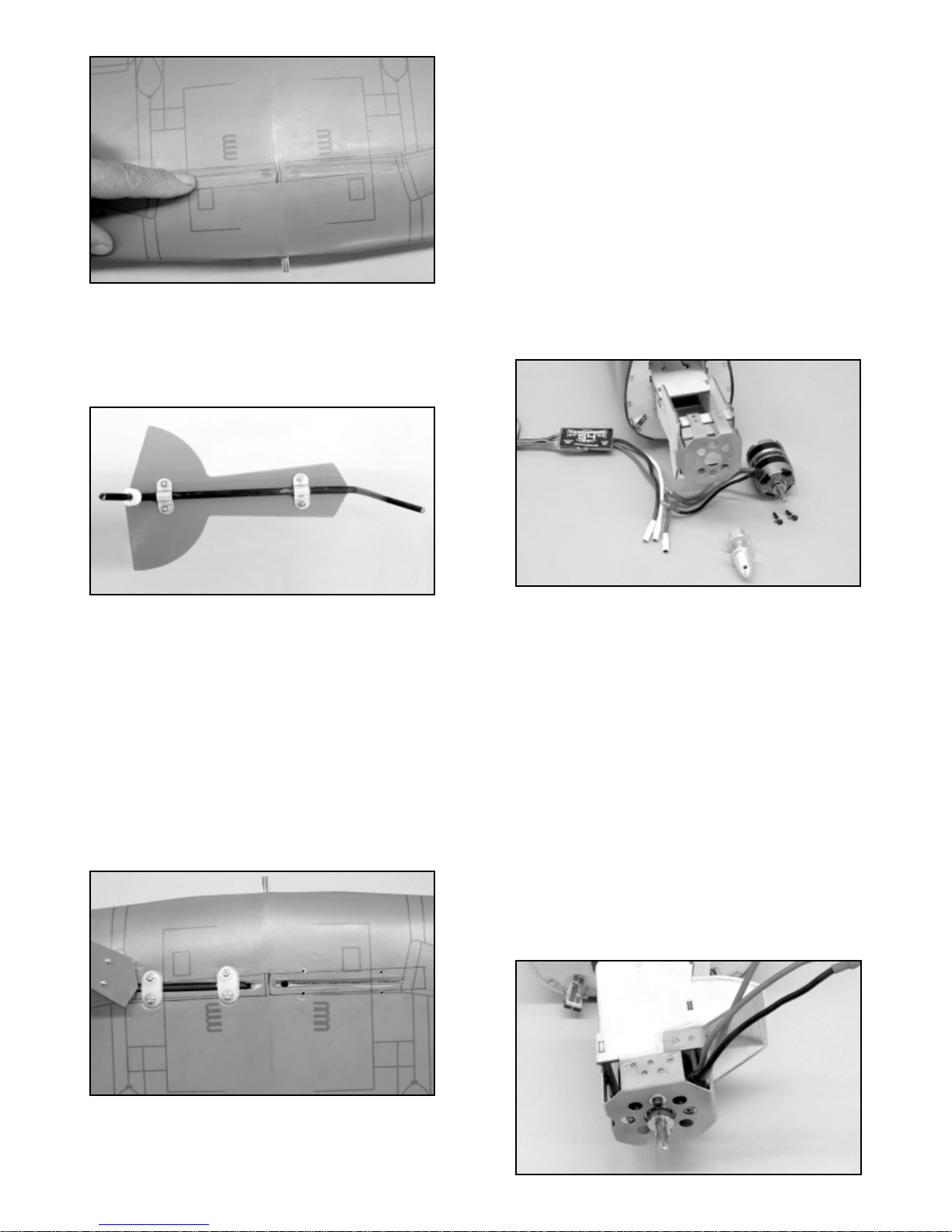

MOTOR, RECEIVER, & ESC INSTALLATION:

The following parts are not included in your kit. These will be

required for the following assembly steps:

❑ Motor of choice

❑ Mounting bolts & washers for your specific motor

❑ Prop adaptor for your specific motor shaft

❑ Electronic speed control (ESC)

❑ Receiver

❑ 3" or 4" of Velcro

®

for mounting the receiver & ESC

Note: The metal motor mount in the Bf-109 has been designed to

accommodate the front mounting of most 35 mm diameter motors.

The small holes give a general location for the tapped holes

in the front of your motor. Enlarge or slot them as needed

to accommodate your specific motor. We have used Himax

HC3516-1130 and HC3522-0990 motors with the proper speed

controls, props, and 3S1P LiPo 3300 mAh batteries in the

prototypes and have been very satisfied with the performance and

duration of these setups. We will show the HC3522-0990 in this

manual as a typical motor installation.

❑ 1) Feed the motor wires through one of the openings next to

the front motor mount plate and position the motor up to the back

side of the front mounting plate. Bolt the motor to the mounting

plate using the appropriate bolts and washers for your specific

motor. We always suggest using a non-permanent thread-locking

compound for these bolts, such as Loctite

®

"Blue". This simple

precaution works very well to keep these bolts in place under

vibration.

7

❑ 2) Attach the gear doors to the inside of the gear legs using

the metal clips, M2 x 8 mm bolts, M2 nuts, and M2 washers. Note

that the bottom edges of these doors are made with two distinct

angles. The more highly angled edge should be oriented toward

the rear of the wing to providing better ground clearance.

❑ 3) Insert the wires into the landing gear blocks in the wing, with

the legs and doors offset to the front leading edge of the wing. The

wheel axles should be close to the leading edge when viewed from

above and aligned with each other in a straight line or a slight toe

in position. It might be necessary to slightly "tweek" the axle wires

to achieve alignment. If so, do this now.

❑ 4) Once satisfied with the axle alignment, secure both landing

gear wires into the wing bottom using the four plastic retaining

straps, as shown. Hold the strap in place and mark its two hole

locations onto the surface of the wing. Use a 3/32" dia. bit to drill

pilot holes for the mounting screws. Repeat this process for the

remaining landing gear straps. Secure the straps in place with

T3 x 8 mm PWA screws.

5) The main wheels are now installed and secured. Slide a

plastic bushing over the axle wire, all the way to the bend. Slide

the main wheel in place onto the axle, followed by the wheel collar.

The wheel collar should be positioned to allow the wheel to turn

RUDDER & ELEVATOR SERVO INSTALLATION:

As mentioned earlier, the rudder and elevator ser vos do not need

to be the sub-micro type used for the aileron servos. We used

Hitec HS-81 servos in our Bf-109 prototypes to take advantage of

their higher torque.

In the following steps you will need the following parts:

❑ 2 ea. 1.25 mm dia. x 597 mm wire pushrods

❑ 2 ea. Rudder & elevator servos (not included)

❑ 1) From the kit contents, locate the tw o 1.25 mm dia.x 597 mm

wire pushrods. Note that these pushrods are supplied with a "Z"

bend at one end - this is the end that will attach to the servo

output arm. From the canopy/hatch opening in the fuselage, insert

the straight ends of the pushrods all the way into the two guide

tubes behind the servo tray. Straighten these pushrods as needed

to get smooth and easy travel.

Note:

The pushrod guide tubes cross within the fuselage so that

the pushrod for the elevator exits the left side of the fuselage while

the servo is on the right side of the servo tray and the rudder is just

the opposite.

❑ 2) Prepare the two servos for installation by first inserting the

rubber grommets and eyelets - supplied with the servos - into the

mounting lugs at each end. Remove the servo arm retaining screw

from each servo and then the servo arms.

❑ 3) Place the servos into the top of the servo tray. Slide the

servo to the outside of the servo tray opening and hold it there.

Use a pencil to mark the servo mounting hole locations onto the

servo tray. Repeat this process with the remaining servo . Remove

the servos from the tray and use a 1/16" dia. (1.5 mm) bit to drill

pilot holes at the mounting marks just made. Reinstall the ser vos

and secure them to the tray using the mounting screws that came

with them. Note that the output ends of these two servos are

towards the front of the fuselage.

❑ 4) With the servos now mounted, check the relationship

between the two servo output arms when they are in place on the

servos. If there is any interference, then you will have to select or

modify servo arms that will not contact or interfere with each other

during the operation of the servos. Remove the servo arms, then

fit the "Z" bend ends of the pushrods onto the selected servo

output arms and place the arms back onto the servos with the

connected drive arms at 90

O

to the servo body as shown.

❑ 2) Working through the fuselage wing saddle opening, feed

the motor wires from your ESC forward into the nose, under the

battery tray, until they exit below the motor. Plug the motor wires

into the corresponding wires from ESC and then, slide the excess

wiring back under the battery tray. Make sure to arrange these

wires so that they do not contact the motor.

❑ 3) The ESC is now secured to the bottom of the battery tray,

ahead of wing. W e suggest using Velcro

®

for this purpose. With the

ESC now in place, feed the ESC battery connector wire along the

side of the battery tray, up to the top of the tray.

❑ 4) The receiver is now installed into the fuselage on the

bottom rear surface of the battery tray. Again, we suggest using a

length of Velcro

®

for this purpose. Insert the ESC receiver lead into

its appropriate throttle receptacle in the receiver. Using your

transmitter and flight battery, connect the battery to the ESC

battery connector and test the motor throttle function. Also, make

sure the motor is turning in the correct direction. Disconnect the

flight battery and turn off the transmitter.

8

spinner backplate in its running position, allowing the cowl to be

accurately mounted to the fuselage.

❑ 3) Position the front of the cowl to contact the spacers on the

back of the spinner backplate and then, center the cowl to the

backplate in both top and side views. Use tape to hold the cowl to

the backplate in this centered position. Use a few more pieces of

tape to hold the cowl to the fuselage at its back edges. The cowl

should now be firmly and accurately in position. Using a #60 (.040"

dia.) bit, drill four pilot holes through the plywood pads beneath the

four pre-drilled holes in the cowl.

❑ 4) With a screwdriver, install the four cowl mounting screws

through the holes in the cowl and into the plywood pads. Tighten

the screws just enough to place the washer head in contact with

the cowl - no more. Remove the pieces of tape, the propeller nut,

the propeller, and the plywood backplate. Remove the 1/16"

spacers from the rear of the backplate and lightly sand the

backplate smooth.

MOUNTING THE T AIL SURF ACES:

In the following steps you will need the following par ts:

❑ Bag #1 Vertical fin and rudder assembly

❑ Bag #2 Horizontal stabilizer and elevator assembly

❑ Bag #12 2 ea. M4 x 30 mm Nylon wing bolts

❑ 1) Remove the elevators, rudder, and hinges from the tail

surfaces. Insert the vertical fin into its slot at the top rear of the

fuselage. It should bottom out on the built in platform at the bottom

of the slot. The trailing edge of the fin should be in perfect

alignment with the vertical tailpost of the fuselage - slide it forward

or back until it is aligned. Next, use a sharp, soft pencil to mark

both sides of the fin where it meets the fuselage at the slot.

Remove the fin from the fuselage and use a sharp #11 blade to

The servos are now tested using the radio system. Connect the

appropriate rudder and elevator servo leads into the receiver, tur n

on the transmitter, and connect the flight battery to the ESC lead.

Make sure the rudder and elevator trims are at neutral. Test the

servos with the transmitter for proper movement and the alignment

of the servo arms at neutral. If necessary, reposition the output

arms to align them at 90

O

to the servo body at neutral. With arms

now positioned correctly, reinstall the servo output arm retaining

screws. Unplug the flight battery and turn off the transmitter.

MOUNTING THE COWL:

In the following steps you will need the following par ts:

❑ Fuselage with motor mounted

❑ Prop adaptor part for your specific motor

❑ Flight propeller.

❑ Bag #6 Sub bag containing four (4) T2 x 12 mm PWA

cowl mounting screws

❑ Bag #13 1 ea. Plywood spinner back plate

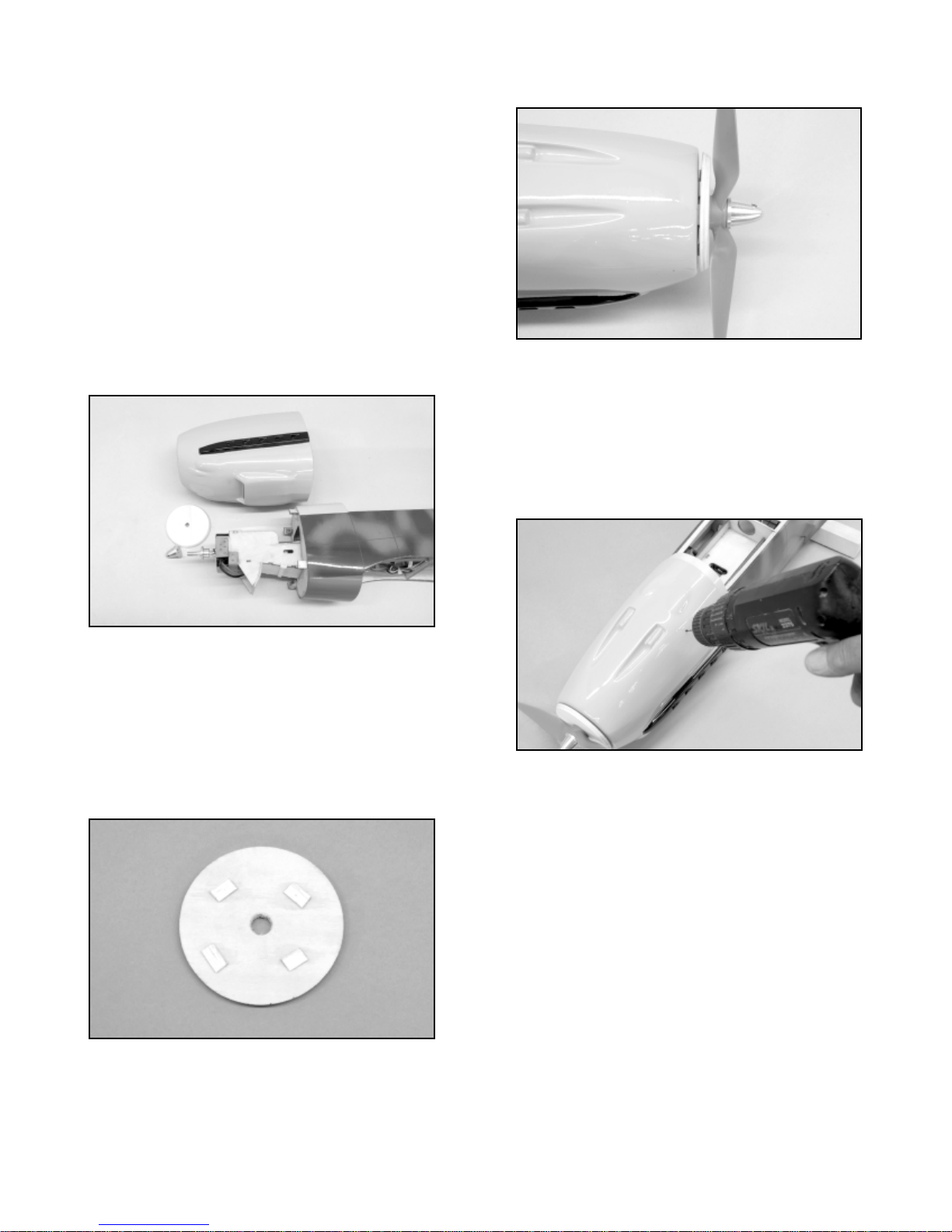

❑ 1) Mount prop adaptor on the motor output shaft and secure it

in place. The provided plywood spinner backplate has a center

hole diameter of 6 mm (just under 1/4"). This hole will likely have

to be opened up to fit onto your propeller adaptor. Do this now.

After establishing a good concentric fit, remove the plywood

backplate from the adaptor. Tack glue four (4) 1/16" (1.5 mm) thick

spacers to the back surface of the backplate , as shown. These will

properly locate the cowl in relationship to the spinner. These

spacers will be removed shortly.

❑ 2) Slide the cowl in place onto the front of the fuselage,

moving it back until the front of the cowl is slightly behind the face

of the prop adaptor. Slip the spinner backplate onto the prop

adaptor shaft with the 1/16" spacers towards the cowl. Place the

propeller in position onto the prop adaptor shaft and tighten it

in place with a propeller nut. This set-up should now have the

9

❑ 4) The two elevator halves are now joined. We suggest using

15-minute epoxy for this step. Apply glue to the two joiner slots at

the inboard leading edge ends of each stabilizer half. Use a small

diameter piece of wire or a pin to also apply glue into the joiner

holes in each elevator half. Press the wire elevator joiner in place

into each elevator half and quickly remove any excess glue. Place

the elevator assembly on a flat wor k surface, protected with wax

paper. Use a straightedge to align the elevator leading edges with

each other, as shown. Allow the glue to fully cure before handling.

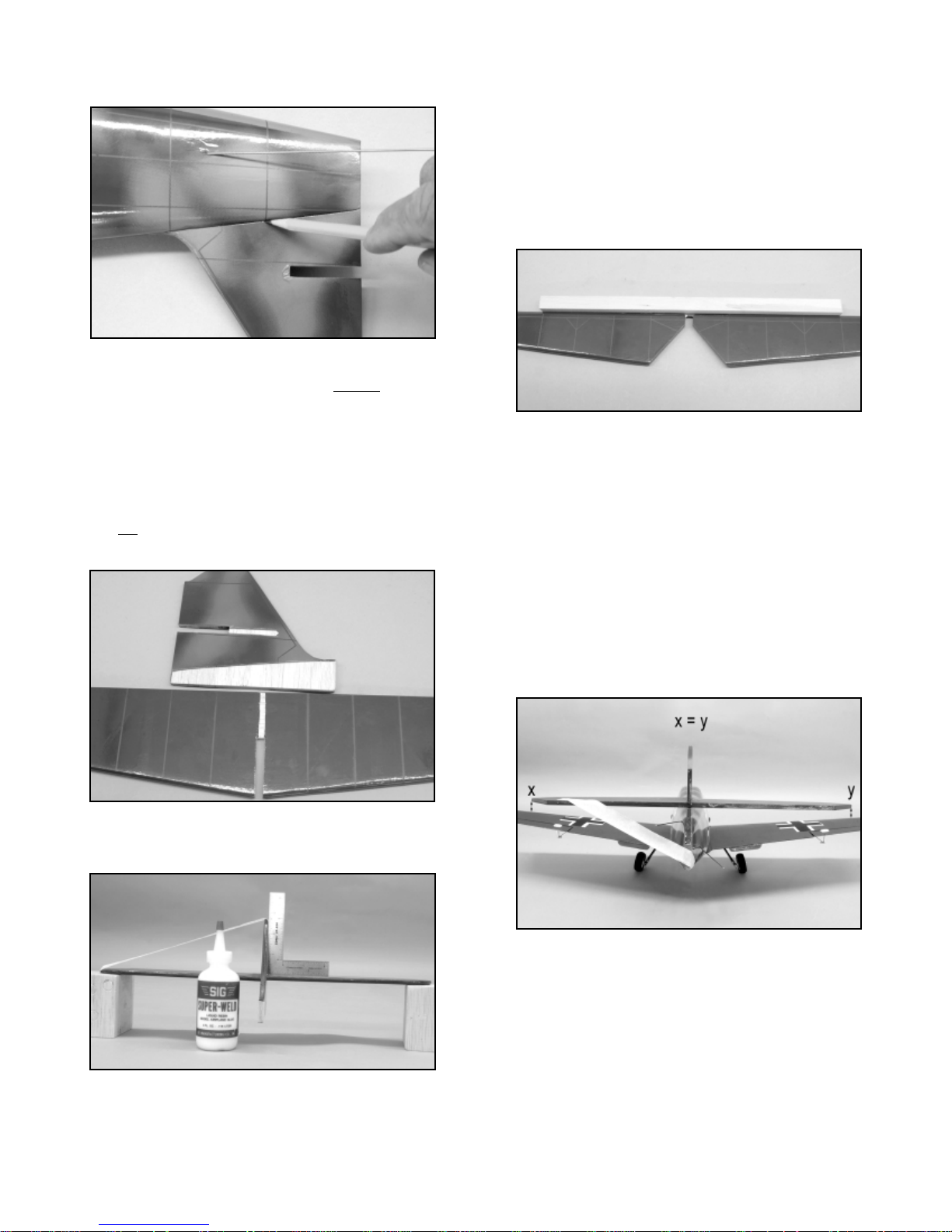

❑ 5) In preparation for accurately gluing the tail group to the

fuselage, first mount the wing to the fuselage using the two

M4 x 30 mm nylon wing bolts.

Without using any glue, slip the fin/stabilizer assembly into the fin

slot at the top rear of the fuselage. With the airplane on a flat

surface and with the tail raised to approximately level, stand back

and sight the model from the rear. What you want to see is the

horizontal stabilizer perfectly level with the wings and the vertical

fin sitting at 90

O

upright. If the stabilizer tilts one way or the other,

lightly sand the bare wood on the bottom of the fin on the side that

is low , until the stabilizer aligns properly. Once satisfied with the fit

and alignment, remove the fin/stabilizer assembly from the

fuselage.

❑ 6) Lightly coat the bare wood gluing surfaces on both sides of

the fin with SIG Super-Weld white glue. Then, lightly coat both

sides of the fin slot in the fuselage, again with white glue. Carefully

slide the fin into the fuselage slot and wipe off any excess glue with

a wet paper towel. As before, check, and then, double check the

alignment. The trailing edge of the fin is in alignment with the

fuselage tail post, the horizontal stabilizer is perfectly level with the

wings and the vertical fin is sitting at 90

O

. If needed, a strip of

masking tape can be used to hold proper alignment while the glue

dries.

Once the glue has dried, remove the wing from the fuselage.

carefully cut the covering about 1/32" below the line just drawn.

Remove the cover ing, exposing the wood.

❑ 2) Insert the stabilizer into the slot in the vertical fin until the

trailing edge of the stabilizer is about 1/16" f

orward of the trailing

edge of the fin. Again, use a sharp, soft pencil to mark the top and

bottom stabilizer intersection lines onto each side of the vertical fin

and the top and bottom of the stabilizer, where it intersects the

rudder. Remove the stabilizer. Use a shar p #11 blade to carefully

remove the covering from each side of the fin and stabilizer,

between the two lines - make these cut lines about 1/32" inside of

the drawn lines and use only enough pressure to cut through the

covering, not

the wood. Remove the cover ing to expose the wood

beneath.

❑ 3) The vertical fin and horizontal stabilizer are now glued

together, accurately squared to one another, as shown. We highly

recommend the use of SIG Super-Weld white glue for this step

because it allows a little working time, dries clear, and provides a

very strong bond. If needed, a strip of tape works well to hold

these parts in the properly squared position.

10

the plastic control horn backplate to secure the control horn in

place. Cut-off the excess bolt ends and file smooth.

❑ 3) The rudder control horn is now installed onto the bottom

right side of the rudder. As shown, the control horn is positioned

1-1/8" up from the bottom leading edge of the rudder, with the four

R/C link holes in line with the leading edge of the rudder. Hold the

horn in this position and use a pencil to mark the two mounting

hole locations onto the rudder. Again, use a #46 bit to dr ill two

mounting holes through the rudder at the marks just made. Use

the two remaining M2 x 20 mm bolts and the plastic control horn

backplate to secure the horn in place. Cut off the excess bolt ends

and file smooth.

❑ 4) The elevators are now hinged to the horizontal stabilizer.

The hinging method is the same as described earlier for the

ailerons. Use card wedges to center the hinges and remember to

use a fine-tip applicator on your thin CA bottle to keep from getting

any excess glue on the cover ing.

❑ 5) The rudder can now be hinged in place to the vertical fin

and fuselage. Note that the bottom hinge slot entry location in the

tailpost of the fuselage should be opened a little more to accept the

tail wheel bearing diameter. As we did with the rudder, use a short

length of scrap wire to lightly force this area open, to accept about

one half of the bearing diameter when the rudder is fully in place.

We also found that the bottom hinge slot needs to be opened up a

little more to accept the thickness of the brass hinge. This can be

easily done with a #11 blade or even a #27 X-acto saw blade.

Using the two remaining CA hinges, trial fit the rudder fully in place,

making sure it has free movement. Make any adjustments

necessary to achieve this. Once satisfied with the fit and

movement, remove the rudder, leaving the CA hinges in the

vertical fin. Carefully apply a thin coat of Vasoline

®

to the tail wheel

bearing area to protect it from excess glue. The brass tail wheel

hinge is glued in place using 15-minute epoxy. First, place two of

the card wedges into the center CA hinge slots. Next, lightly coat

both sides of the brass hinge half with epoxy glue. Use a piece of

business card to now work some epoxy glue into the fuselage

hinge slot, cleaning up any excess. Now, insert the brass hinge

half partially into its slot in the fuselage and engage the two CA

hinges into their slots in the rudder. Press the rudder in place to

the fuselage and fin.

The two rudder CA hinges can now be glued in place using the

same method described earlier during the hinging of the ailerons.

Allow time for the CA glue to fully wick across the surface of the

HINGING THE CONTROL SURFACES:

The following steps will require the following par ts:

❑ Rudder & elevator with CA hinges - 6 hinges total

❑ Bag #8 - Tail Wheel assembly

❑ Bag #10 - 2 ea. Control horns

2 ea. Control horn backing plates

2 ea. Pushrod connectors

2 ea. Connector keepers

4 ea. M2 x 20 mm bolts

❑ 1) The steerable tail wheel assembly is now installed into the

bottom leading edge of the rudder. Note that this assembly is also

the bottom hinge for the rudder. Because of this, a little extra

clearance must be made to accept the brass tail wheel bearing.

The rudder has been factory slotted for the brass hinge. The

leading edge of this slot should be opened up a little more to

accept at least one half of the bearing. We did this with a scrap

piece of wire that was about the diameter of the bearing. Simply

press this wire firmly into the slot area, forcing it to open a bit more.

Trial-fit the tail wheel assembly in place to check the bearing fit.

Once the bearing fits freely, the tail wheel assembly/hinge can be

glued in place to the rudder. We suggest first coating the bearing

area only with some Vasoline

®

to protect it from accepting glue and

locking up. Use 15-minute epoxy to glue the tail wheel assembly

and hinge into the bottom of the rudder. Carefully remove any

excess glue and allow the glue to fully cure.

❑ 2) The elevator control horn is now installed onto the bottom of

the left elevator half. As shown, the center of the control hor n is

located 1-3/16" outboard of the inner elevator trim line. In top view,

locate the control horn at this position, with its four vertical R/C link

holes in line with the leading edge. Hold the control horn in this

position and mark its two mounting holes onto the surface of the

elevator. Use a #46 (.081" dia.) bit to dr ill two holes through the

elevator at the marks just made. Use two M2 x 20 mm bolts and

11

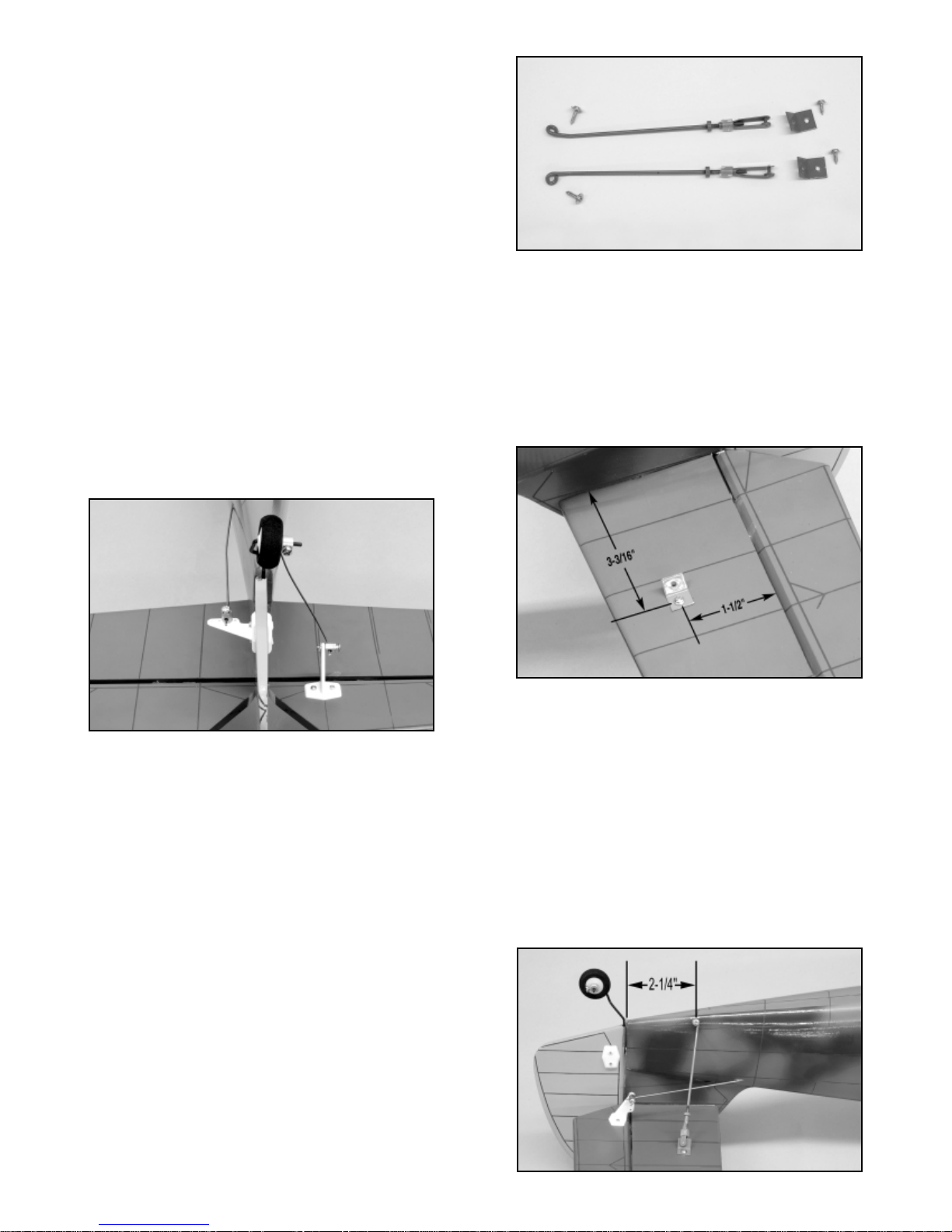

❑ 1) Mark the location of the metal mounting tabs on the bottom

of the stabilizer. Measure 3-3/16" (81 mm) from the side of the fin

on each side. This should be about the center of the hardwood rib

in the stabilizer. From the elevator hinge line, measure 1-1/2"

(38 mm) forward. The intersection of these two marks is the

mounting location for the metal mounting tab. Use a sharpened

awl to puncture the covering and a little of the hardwood rib. Use

two T2 x 6 mm PWA screws to mount the two metal tabs to the

bottom of the stabilizer, as shown.

❑ 2) Adjust the two braces for length. They should both be 4"

(101 mm) long, measured from the pin of the R/C link to the

center of the bent eye at the opposite end. Lock this setting with

the knurled lock nut.

❑ 3) On the bottom rear of the fuselage, measure 2-1/4" (56 mm)

forward from the rudder hinge line and make a mark on each side.

This is where the eye of the brace will be mounted to the fuselage.

Clip the R/C link to the tab on the stabilizer and position the eye of

the brace wire even with the 2-1/4" mark. Use a sharpened awl to

puncture the covering and wood at the center of the eye. Use two

T2 x 8 mm PWA screws to mount the braces to the bottom of the

fuselage. Remove the screws and s wing the braces out of the w a y.

12

hinges and surrounding wood. Once sufficient time has passed,

move the rudder briskly left and right to free up its movement.

❑ 6) The pushrod connections are now made between the

elevators and rudder and their corresponding servos. Starting with

the elevator pushrod, slide a pushrod connector onto the elevator

pushrod wire. Now, install the pushrod connector stub into the last

outer hole in the elevator control horn and secure it to the horn with

the metal cup washer. Repeat this procedure for the rudder

pushrod, installing the pushrod connector stub into the second

inboard hole in the rudder control horn, as shown.

Turn on your transmitter and power up the receiver with your flight

battery pack. Once again, check the rudder and elevator trims,

making sure they are at neutral settings. Hold the elevators in the

neutral position to the horizontal stabilizer, using a couple of small

pieces of tape applied to the outboard hinge lines. With the

elevators now locked in neutral, use a screwdriver to firmly tighten

the setscrew in the elevator pushrod connector. Remove the tape

holding the elevators. Moving to the rudder, again use a piece of

tape to hold the rudder in neutral to the vertical fin. With the

rudder now locked in this position, use a screwdriver to firmly

tighten the setscrew in the rudder pushrod connector. Remove the

tape holding the rudder.

Use the transmitter to now test the movement of both the elevators

and rudder. If the movement of either of these surfaces in the

wrong direction, use the servo reversing function to change the

movement and, if necessary, re-center the surfaces to achieve a

neutral setting.

❑ 7) The excess pushrod wire behind the pushrod connectors

can now be cut off, leaving about 3/16" of wire for any later final

flight trimming purposes.

INST ALLING THE T AIL BRACES:

For these steps you will need the following par ts:

❑ Bag #16 2 ea. 2 mm x 94 mm wire tail braces - M2 threads

at one end, bent "eye" at the other end 1 left, 1 right

2 ea. Tail brace mounting tabs - pre-bent

and drilled

2 ea. R/C Links with silicone keepers

2 ea. Knurled lock nuts

2 ea. T2 x 6 mm PWA screws

2 ea. T2 x 8 mm PWA screws

If desired, a functional, scale-like antenna mast can be made using

a 3" (75 mm) length of scrap nylon pushrod tubing, pre-painted

either in gray or flat black. Drill a pilot hole for this antenna mast,

1/2" behind the top rear edge of the canopy, centered on the top of

the fuselage. The antenna mast is now glued into the drilled hole

using 5-minute epoxy glue. The receiver antenna can now be

routed up through the antenna mast tube and extended back to the

top leading edge of the vertical fin where it can be secured with a

small bead-head pin.

Many of us enjoy seeing a pilot figure in the cockpit of our models.

In the case of the Bf-109, this simple addition looks great and

provides a sense of scale and realism to the finished airplane. Our

pilot figure started life as a Williams Bros. 1/6th scale Standard

Pilot figure. After assembling it, we, then, cut down the figure to fit

within the cockpit area. Then, we used plastic paints to add color

and finish to the pilot. We mounted him in place and remounted

the canopy.

Use a fine applicator tip and thin CA to place a drop of glue into the

screw holes in the fuselage to "harden" them. Reinstall the braces

and screws.

FINAL DETAILS:

The canopy is now mounted in place ov er the cockpit. From the kit

parts, locate the canopy and the four T2 x 6 mm PWA mounting

screws. In top view, the canopy is centered over the cockpit with

approximately 1/8" of its rear edge extending back past the rear

surface of the slanted cockpit/fuselage f ormer . Use small pieces of

tape to hold the canopy in this position. Use the four T-2 x 6 mm

PWA screws; threaded through the provided holes in the canopy,

to secure the canopy in this final mounted position. Remove the

tape holding the canopy, and then, remove the four mounting

screws. We suggest using a fine tip applicator with thin CA to

harden each of the screw holes. A single small drop of thin CA

glue, applied directly into each hole will provide hardened threads

for secure mounting.

The simulated supercharger air scoop (Bag #11), located on the

left side of the cowl is now glued in place with the lower front

corner of the scoop 1-1/2" (38 mm) ahead of the back edge of the

cowl and 3/8" (9.5 mm) above the exhaust manifold. T o mount this

part, we used thick CA glue, sparingly applied to the bottom

surface of the air scoop.

If desired, typical plastic paints can be used to add a little more

detail and realism to the cowl. The two machine gun troughs on

top of the cowl can be painted flat gray to simulate gunpowder

staining. The molded gun barrels can be painted flat black. The

two exhaust manifolds can be painted a smoky gray to simulate

burning exhaust.

13

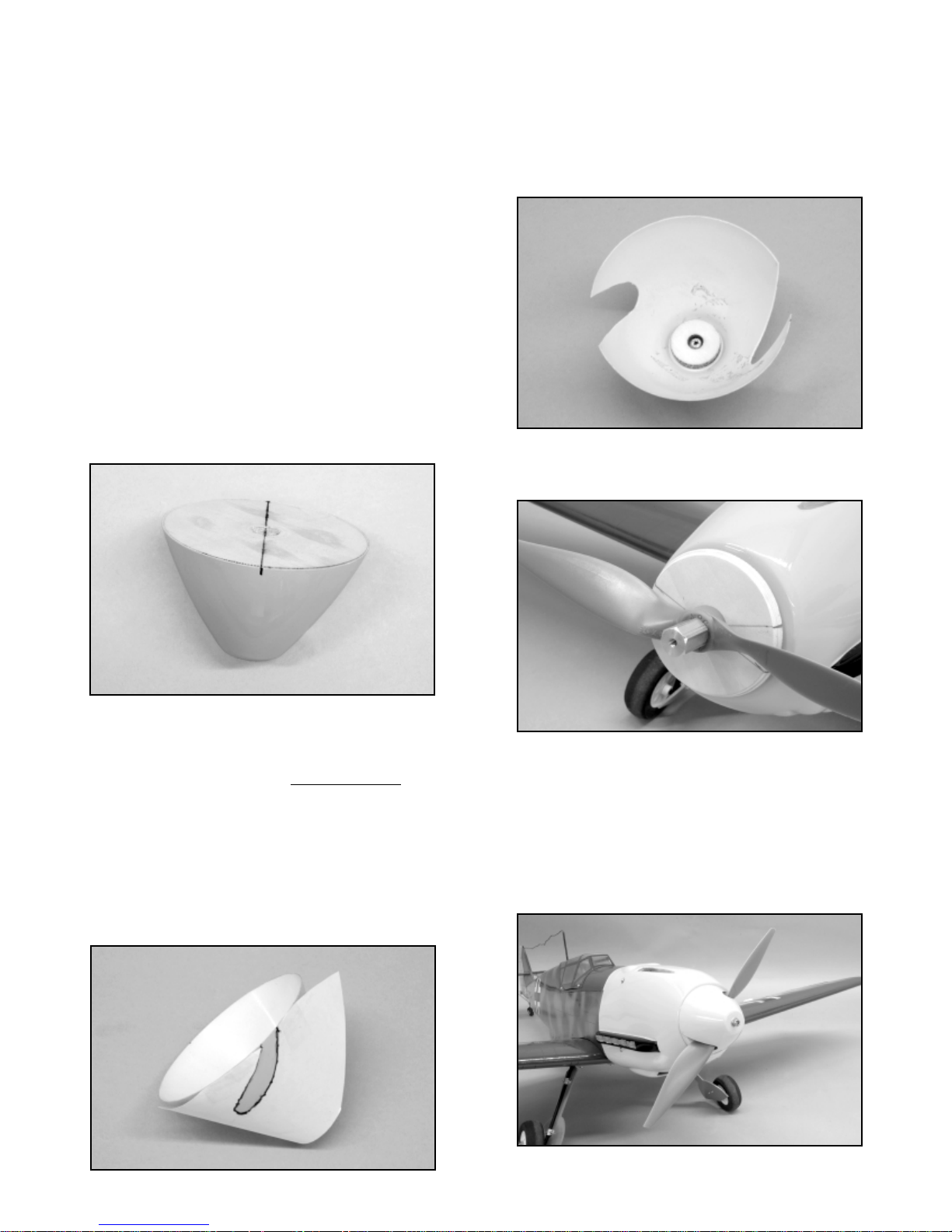

PREP ARING THE SPINNER:

The plastic spinner cone supplied with this kit has a unique shape,

peculiar to the Bf-109 and is supplied uncut. This is to allow the

builder to use it for a 2 or 3 bladed prop for either flying or display.

Finishing this spinner is not difficult but does require some care.

Note that mounting this spinner requires an adapter nut that

threads onto the shaft of your particular motor at one end and is

tapped for an 8-32 bolt on the opposite end. C.B. Associates

makes these adapter nuts in any size that you will need. You will

also need an 8-32 x 3/4" socket head bolt and a several #8

washers for use as spacers.

For the following steps, locate Bag #13 containing the spinner

parts.

❑ 1) To locate the cutout locations for the blades of a two bladed

propeller, start by drawing a straight line across the bac k surf ace of

the plywood spinner backplate, exactly through the center of the

prop shaft hole. On a flat surface, place and hold the spinner over

the backplate and use a pencil to transfer the two opposing edge

marks onto the back edge of the spinner cone.

Note: If you want to use a three-bladed propeller, use a compass

to make three pencil marks at 120

O

apart.

❑ 2) Cut out the propeller template f

ound on page 16. Align the

leading edge of the template with one of the marks on the edge of

the cone. Tape the template in position and trace the outline of

the blade cutout onto the cone. Move the template over to

the opposite mark, tape it in place and use pencil to trace the

remaining blade cutout outline. The prop blade cutouts are now

made in the spinner. To mak e this relativ ely easy and accur ate , we

used a Dremel

®

Tool with a highly tapered sanding bit, followed by

sandpaper to smooth the edges.

14

❑ 3) Use thick CA glue or 5-minute epoxy to glue the tw o 20 mm

dia. plywood washers together with their center holes aligned.

Glue the laminated 20 mm washer assembly to the inside flat nose

of the plastic spinner, aligning the center hole with the molded

"dimple" on the inside of the spinner. Use thick CA glue or

5-minute epoxy. After the glue sets, use a #19 (.166 dia.) bit to drill

through the front center of the spinner, at the dimple mark.

❑ 4) Place the spinner backplate on the motor shaft and then,

the propeller. Tighten these parts in place with the adaptor nut.

Insert an 8-32 x 3/4" bolt into the front of the cone and place about

4 washers on the bolt on the inside of the spinner.Thread the bolt

into the adapter nut and adjust the number of washers on the bolt

until the skirt of the cone is just even with the bottom of the

plywood backplate when the bolt is tightened down. This spacing

will remain the same as long as you replace the prop with an

identical prop. Changing brands and/or sizes of props will more

than likely change the required amount of shims.

CENTER OF GRAVITY:

Establishing the Center of Gravity (C.G.) for this or any R/C model

aircraft is critical to its ultimate success in the air. And determining

the proper C.G. location becomes even more important with

15

smaller models. While the Bf-109 is a solid, predictable airplane to

fly, it is, none-the-less, a warbird type aircraft and is less tolerant to

improper C.G. locations than other model types.

Start by installing the battery pack that you will be using to power

the airplane. Slide the pack as far forward in the battery tray as

possible and secure it in this position to keep it from shifting while

you are working with the model. Attach the cockpit/hatch over the

battery compartment.

The correct C.G.location for this model is exactly 2-1/2" (63.5 mm)

behind the leading edge, at the fuselage/wing location. Use two

pieces of masking tape, applied onto each side of the top surface

of the wing, where it meets the fuselage wing saddle. Bolt the wing

in place to the fuselage and use a ruler to measure and mark the

2-1/2" location onto the tape, immediately next to the fuselage.

With the airplane now assembled with the battery pack in place, it

is ready for balancing. The best way to do this is to place the model

onto a balancing fixture upside down. Locate the balancing fixture

at the two 2-1/2" marks on each side of the wing, next to the

fuselage sides. If the model is properly balanced, it will be

suspended perfectly level. If the nose hangs down, the air plane is

nose heavy and conversely, if the tail hangs down, the model is tail

heavy. A slightly nose heavy model is certainly the lesser of two

evils. However, a tail heavy condition m

ust be remedied before

flying the airplane.

If your model balances a little nose heavy, the battery pack can be

shifted a little aft to correct the problem. If the model balances in

a tail heavy condition, then, it is likely necessary to modify the

existing battery tray, allowing the flight battery to be shifted even

further forward. As shown with our Himax 400 watt motor

installation, we were able to modify the battery tray, allowing the

battery pack to slide a full 1-1/4" further forward.

Modeler’s Note: A standard 2-3/4" dia. yellow nylon spinner,

such as a SIG # SIGSP2755, can be used to make a nice

looking alternative spinner, by simply cutting off 1/2" from the tip

of the spinner cone.

Once this cut has been made, the cut line should be rounded

off, giving the appearance of the scale opening for the cannon

muzzle. To do this, we used a bolt and a nut as an arbor and

then, installed the end of the bolt in a drill press. With the

spinner turning, sandpaper was used to uniformly and neatly

round off the opening.

The finished spinner should look like the photo.

16

Again, as shown, the battery pack, in place in the battery tray, now

sits directly behind the motor with a piece of scrap 1/4" balsa in

place to keep it from shifting. This "fix" works well when using

lighter motors and is far superior to adding weight to achieve

proper balance.

Once you have achieved the proper 2-1/2" C.G.location by shifting

the battery as needed, mark and note the battery location onto the

battery tray to ensure that it is installed and retained in the proper

position, every time the model is flown.

CONTROL MOVEMENTS:

The Bf-109 is a fighter plane and as such, is designed to be

responsive to your control inputs. It is very important to set your

model up to these recommended throws, for the first flight, to a v oid

any nasty surprises, especially on elevator. Set the throws as

close to these specifications as possible mechanically by moving

the linkages in or out on the servo arms and control horns, then

fine tune these throws with the adjustments available in the

transmitter.

Recommended Initial Contr

ol Movements:

ELEVATORS: 1/2" (12 mm) up and down

AILERONS: 3/8" (9.5 mm) up and down

RUDDER: 7/8" (22.25 mm) left and right

FLYING:

If you have carefully followed this assembly manual, you should

have no real problem test flying your Bf-109. We suggest

choosing a calm day for the first flights. Such conditions always

help in correctly evaluating the flight perfor mance of the model.

If you have built your Bf-109 model without landing gear, the

requirement is, of course, to hand-launch the airplane. The

hand-launch can be done by a friend and, with a little experience,

you can also learn to launch the model by yourself. To properly

hand-launch a low-wing model like the Bf-109, the fuselage is

firmly gripped just behind the wings. The airplane should be briskly

launched straight ahead, directly into the wind, with the wings level

and the motor at high throttle. The launch should be aimed

directly at the horizon - ne

ver hand-launch the model with the nose

up!

If you have built your Bf-109 model with the landing gear, then of

course, the airplane can be taken off from the ground. Ar m the

motor and test the flight controls for correct movement. Hold up

elevator and taxi the model to get a feel for how it handles on the

ground. Make sure you have positive left and right turning ability.

If you don't, make any adjustments needed to achieve positive

ground control. Once you are satisfied with the taxi tests, line the

model up with the center of the runway with the nose pointed

directly into the wind. Hold a little up elevator and smoothly

advance the throttle - do not

throw the throttle fully open all at once!

The model should roll forward smoothly, tailwheel on the ground.

As is typical of this type of airplane, you will need to be ready with

some right rudder as you slowly release the up elevator and allow

the tail to rise. Allow the speed to build until a slight application of

up elevator breaks it free from the runwa y. Do not try to force it into

the air before it is ready to fly.

Once the airplane is airborne, maintain a straight outward flight

path, climbing at a shallow angle, until a safe maneuvering altitude

is reached. If the model requires trim input, fly to a reasonable

altitude before attempting to make any changes. Make your

control inputs smooth and avoid jerking the sticks. At trimming

altitude, bring the throttle back to about a 2/3rds setting for cruise

speed and then, begin fine-tuning any required trims. What you

want to achieve is a straight and level flight path without

transmitter corrections.

Once you're comfortable with the way the model is flying, make a

few circuits around the field, getting a feel for the controls. If the

airplane is properly trimmed, it should demonstrate smooth flight

characteristics, without any jumpiness or over sensitivity. At

altitude, try an axial roll. Next, try another roll in the opposite

direction. The Bf-109 should roll smoothly in each direction. Next,

try a simple inside loop. Choose your entry heading and go to full

throttle. Pull up smoothly until the airplane is inverted, then back

off the throttle as it comes down the backside of the loop.

Consecutive loops are easily done using the same technique. This

maintains a steady airspeed and conserves battery power. Still at

cruise speed and reasonable altitude, roll the model inverted. A

properly balanced model will take very little down elevator to

maintain inverted flight.

By now, you should be getting comfortable with the handling of

your Bf-109. Fly the airplane up to a safe altitude, flying directly

into the prevailing wind. Throttle back the motor to become

familiar with the slow flight characteristics of the model. Still at a

lower throttle setting, make a few dummy landing approaches,

Spinner Template

17

including the required turns. What you're looking for is a

comfortable landing speed. Now, try a fe w po wer-on and po wer-off

stalls. Again, you're looking for the speed at which the model stalls

and also for the type of stall that will occur. All of this is great

information to have when you are setting up your first landing.

After making a few high-speed strafing passes over your field, it's

likely time to set-up your Bf-109 for a landing.

We always suggest that you make your landings using a standard

approach. Enter the downwind leg at about 50' in the air, throttled

back just enough to allow the airplane to very gradually sink. Make

the base turn, followed by the final turn, lined up with the center of

the runway. Keep a little power on the model, while keeping the

nose just slightly down. Fly to the touch down location until the

model is a foot or so off the ground. Start easing off of the throttle,

allowing the airplane to touch down on the main wheels. Allow the

tail wheel to settle to the ground and let the model finish its rollout

to a stop. Hold full up elevator and taxi bac k to the pits . With some

experience, you'll be making ver y nice landings every time.

With the first flight now in your logbook, it is time to completely

check ever ything in and on the model that may have come loose

or needs attention. In our long experience with model aircraft,

we've learned that anything that might come loose or needs

attention, will show up within the first few flights. Do yourself a

favor and check everything now. The second flight should be even

more fun because you now have a tr immed model.

MAINT AINING YOUR Bf-109:

Getting into the habit of routinely performing maintenance and

inspection of your Bf-109 will keep it looking good and flying good

for a long time. Full scale airplanes receive this kind of routine

treatment and fly safely for years. Your R/C model aircraft should

receive the same treatment.

After each flying session take the time to completely clean your

model. If you are used to cleaning up glow powered models, you

should really enjoy how easy it is to clean up an electric model! W e

use and suggest fresh, good quality paper towels and a silicone

free cleaner for degreasing and polishing. SIG makes one of the

best cleaners for this purpose - Pure Magic Airplane Cleaner.

Clean the airplane until it shines including the prop and spinner.

At home take a little time to completely inspect the airplane,

looking for loose bolts, screws , co vering seams, etc. Anything that

you find wrong - immediatel

y fix it! Inspect the fuselage radio

compartment carefully. Check each servo, looking for loose

linkages, missing screws, etc. Check each R/C link for integrity

and to make sure the keepers are in place. Check all the control

horns and servo arms to be sure they are firmly attached to the

control surfaces.

Finally, after each flying session you should monitor the charge on

your radio system, charging it as needed. If several days pass

before you fly again, top off the charge bef ore flying again. Be sure

that the radio is fully charged before heading out to the flying field

again.

Good luck and good flying.........

Messerschmitt Bf-109 Log Book

Date of first flight:

Comments:

18

LIMIT OF LIABILITY

The craftsmanship, attention to detail and actions of the builder/flyer of this model airplane kit will

ultimately determine the airworthiness, flight performance, and safety of the finished model. SIG MFG. CO.’s

obligation shall be to replace those parts of the kit proven to be defective or missing. The user shall

determine the suitability of the product for his or her intended use and shall assume all risk and liability in

connection therewith.

CUSTOMER SERVICE

SIG MANUFACTURING COMPANY, INC. is committed to your success in both assembling and flying the

MESSERSCHMITT Bf-109 ARF kit. Should you encounter any problem building this kit, or disco ver any missing or damaged parts, please feel free to contact us by mail or telephone.

SIG MANUFACTURING COMPANY, INC.

P.O. Box 520

401-7 South Front Street

Montezuma, IA 50171-0520 USA

PHONE: 1-641-623-5154

FAX: 1-641-623-3922

SIG WEB SITE: www.sigmfg.com

SIG E-MAIL: mail@sigmfg.com

WARNING! THIS IS NOT A TOY!

Flying machines of any form, either model-size or full-size, are not toys! Because of the speeds that

airplanes must achieve in order to fly, they are capable of causing serious bodily harm and property

damage if they crash. IT IS YOUR RESPONSIBILITY AND YOURS ALONE to assemble this model

airplane correctly according to the plans and instructions, to ground test the finished model before each flight

to make sure it is completely airworthy, and to always fly your model in a safe location and in a safe

manner. The first test flights should only be made by an experienced R/C flyer, familiar with high

performance R/C aircraft.

The governing body for radio-control model airplanes in the United States is the ACADEMY OF MODEL

AERONAUTICS, commonly called the AMA. The AMA SAFETY CODE provides guidelines for the saf e operation of R/C model airplanes. While AMA membership is not necessar ily mandatory, it is required by most

R/C flying clubs in the U.S.and provides you with important liability insurance in case your R/C model should

ever cause serious property damage or personal injury to someone else. For more information,

contact:

ACADEMY OF MODEL AERONAUTICS

5161 East Memorial Drive

Muncie, IN 47302

Telephone: (765) 287-1256

AMA WEB SITE: modelaircraft.org

Loading...

Loading...