LIL’ RASCAL ARF ASSEMBLY MANUAL

INTRODUCTION:

Congratulations on your purchase of the SIG Lil’ Rascal ARF kit!

The SIG Rascal series have become popular with modelers

because their classic looks and good flying characteristics. SIG is

pleased to now offer this same fine design in this unique 180 class

size. The Lil’Rascal ARF not only retains the great characteristics

of the original but is also small enough to take almost anywhere,

completely assembled and ready to fly! Unlike most other small

electric powered models, the Lil’Rascal has a really nice po wer-toweight ratio, allowing it to handle much higher wind conditions.

Your Lil’ Rascal ARF has been expertly covered with Oracover

®

.

This covering material is tough and light weight and is easily

repairable. This kit has been specifically engineered to make

assembly fast and simple when following the detailed instructions

in this manual.

The Lil’ Rascal ARF is very light and therefore well matched to the

included electric 180 class motor and geardrive unit. This power

system swings the supplied 6 x 4 prop with amazing power and

efficiency. There are quite a few micro electronic speed controllers

(ESC) that will work well in this model, in the 4-10 Amp range. The

ESC unit shown in this manual is the MAXX Products MX-9104

ESC. This is a very small, light weight 4 Amp unit that handles

5-7 cell battery packs and includes a battery elimination circuit

(BEC), doing away with the need for a separate receiver battery.

This unit is available from MAXX Products, already pre-wired with

the appropriate JST connectors.

To maximize the performance of the motor/geardrive unit used in

this model, we suggest using a 7-cell 300 mAh Ni-MH (2/3 AAA

size) battery pack, in a “folded” configuration. Properly charged,

this pack delivers excellent power and great duration for the Lil’

Rascal model. To derive the maximum capacity and performance

from your battery pack, it is essential to use the correct battery

charger. We use and highly recommend a charger that is designed

for charging NiMH cells, such as the Astro Flight #115D unit. This

charger is an AC/DC type, allowing you to charge packs either at

home or from your car’s 12-volt batter y at the field. It is also a

“Peak Delta” charger, assuring a maximum battery pack charge

every time. Using this charger, at a 1 Amp charge rate, our packs

take about 15 minutes to fully charge. Having at least two battery

packs will allow you to fly almost continuously.

The assembly and flying of this model will only be successful if you

follow these instructions carefully. Deviating from these

instructions has the potential to cause problems later in the

assembly process or during flight. The successful assembly and

flying of this model is your responsibility so take your time and

enjoy your Lil’Rascal.

RADIO EQUIPMENT:

The Lil’ Rascal ARF gets its performance from many factors, such

as its light weight and generous wing area. These combine to

produce a very favorable wing loading, allowing the model to take

advantage of the 180 motor/geardrive unit. Since this model is

factory built and covered, you can only realistically control the

finished, ready-to-fly weight by choosing the most appropriate

radio equipment for a model of this size. In short, the performance

of the Lil’Rascal will be reflected in the equipment that you choose.

In flight tests of the Lil’ Rascal, we used the Hitec™ #HS-55

servos. However, any brand of servo that is in the same size and

torque range as the HS-55 servo will work just fine. For example,

one of our test models used the MAXX Products MX-50 units and

they performed perfectly. In general, the servo torque proper ties

for the Lil’Rascal ARF model should be in the 9 – 14 in./oz. area.

Only small or “micro”receivers should be used in this model due to

weight and size constraints. We prefer to use dual conversion

receivers, such as the Hitec™ Electron 6, the FMA M5, etc. Single

conversion receivers can also be used as long as y ou are a w are of

the potential for interference from other transmitters. When we

used the Hitec™ Electron 6 receiver, we carefully removed the

plastic case, thus saving another 7 grams (about 1/4 oz.) in weight.

As mentioned earlier, you will also need a 4-10 Amp electronic

speed controller (ESC) to control the throttle function. Your

ESC should be pre-wired with JST connectors in order to connect

properly with the motor connector.

In general, choose your airborne radio equipment carefully. As

with any airplane, especially electric powered models, excess

weight is to be avoided. Maximum performance can only be

achieved with light weight components.

COVERING MATERIAL:

Your Lil’ Rascal ARF has been covered using Oracover

®

. This

material is world famous for its ease in application, light weight,

and consistent color. If you live in a dry climate, you may notice

some wrinkles develop in the covering after you remove the

covered parts from their plastic bags. This is perfectly normal in

low humidity. The model was covered in a part of the world where

the relative humidity is high and some of this moisture is retained

in the balsa wood. When the covered parts are exposed to drier

humidity conditions, the retained moisture will evaporate causing

1

R

the wood to dimensionally “shrink”in the process. In turn, this may

cause some relaxing of the covering. However, this is easily taken

care of using a small heat iron, such as a small “trim seal”type unit.

When using a larger iron, we suggest using a “sock” of thin cloth

over the shoe to avoid scratches. The iron should be set to about

280

O

- 300OF. Use the heated iron over the wrinkle to lightly shrink

the material – do not press on it. Then lightly iron it back down to

the wood. The use of a heat gun is not recommended since the

parts are really too small. Avoid contact with the plastic windows

and windshield because the heat will distort the plastic.

Over-heating the covering seams may cause them to shr ink too

much and possibly expose the wood beneath. For this reason, we

don’t suggest using a heat gun. A typical hobby type covering iron

will work just fine on a model of this size. A small “trim seal” iron

is perfect for controlling the heat applied to a specific area. Using

such an iron also minimizes the possibility of warping the thin

parts.

For part number reference, your Lil’Rascal is covered in Oracover

®

film with the following part numbers: #10 White, and #21-29

Transparent Red, or #21-59 Transparent Blue.

REQUIRED TOOLS:

For proper assembly, we suggest you have the following tools and

materials available:

• A selection of glues - SIG Thin and Thick CA

and SIG Kwik-Set 5-Minute Epoxy

• CA applicator tips - fine

• Screwdriver Assor tment

• Pliers - Needle Nose and Flat Nose

• Wire Cutters

• Pin Vise for small diameter drill bits

• Small T-pins

• Sandpaper

• Hobby Knife with sharp #11 blades

• P aper Towels

• Small W eights

FUSELAGE:

The fuselage is essentially complete with the wire rudder and

elevator pushrods already in place. All that is required is the

installation of the rudder and elevator servos and connecting the

servo output arms to the “Z” bends on the pushrods. For this step

you will need the two required servos and the mounting screws

that came with them. Remove the servo output arm retaining

screws and the output arms from the two servos.

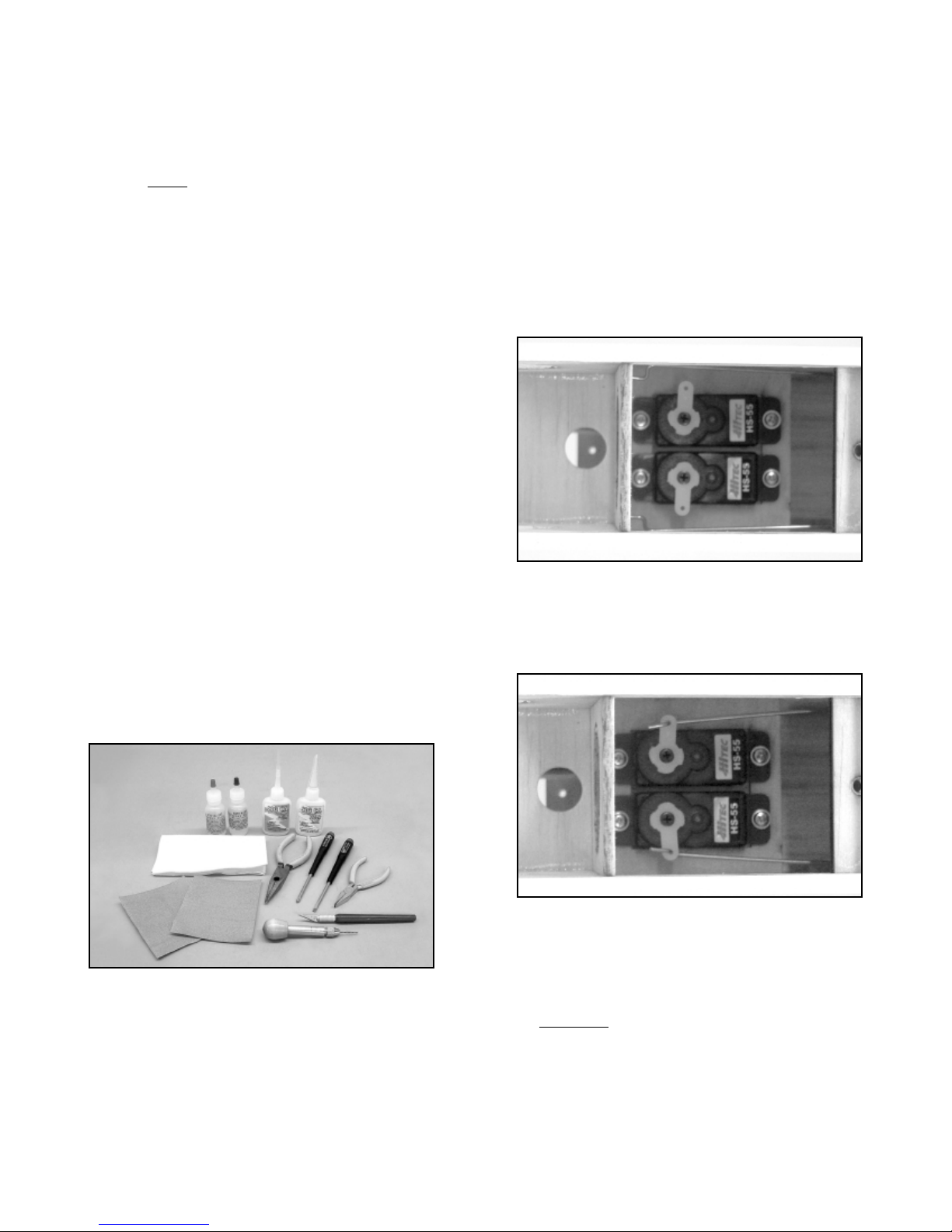

The rudder and elevator servos are now installed into the fuselage,

from the top. First remove the battery hatch from the bottom of the

fuselage. Position the servos in place into the servo tray. Drill

small pilot holes for each servo screw using a pin vise and small

drill bit - we used a .040” (#60) drill bit for these pilot holes. Use a

small Phillips screwdriver to install the servo mounting screws all

the way. Now remove the screws and the two ser vos. Apply a

single drop of Thin CA glue to each screw hole and allow the glue

to set. Re-install the servos and their mounting screws into the

servo tray. From the bottom battery tray opening, route the two

servo leads out of the servo compartment and up through the rear

hole in the receiver mounting tray.

Test fit the two servo output arms onto each servo, positioned at

90

O

to the servo body. If these ar ms interfere with each other, trim

them accordingly.

Remove the servo arms. Attach the wire elevator and rudder

pushrods to the ends of each output arm. Place the arms back

onto the servo output shafts and re-install the output arm screws do not tighten these yet because they may have to be repositioned

when the radio system is tested and centered.

MOUNTING THE T AIL GROUP:

❑ 1) From the kit contents locate the horizontal stabilizer and

elevator and the ver tical fin and r udder. Also locate the two white

plastic control horns. NOTE: As received, the elevator and rudder

are only tempor

arily attached to the stabilizer and fin with unglued

CA hinges in the pre-cut slots. Remove the elevators from the

stabilizer and the rudder from the fin. Also remove the hinges from

them.

2

❑ 2) Before hinging the elevators to the stabilizer, glue the white

plastic elevator control horn in place, using Thick CA glue. Apply

a small amount of glue to the two “spikes”on the base of the horn

and a small amount of glue to the base itself. With the three small

holes in the control horn facing forward, firmly press the horn

into the two pre-drilled holes at the leading edge of the elevator

assembly, until the base bottoms out on the elevator surface . If any

glue oozes out onto the covering, it can be quickly removed with

SIG CA Debonder.

❑ 3) The elevator assembly is now hinged to the horizontal

stabilizer. Insert the four (4) CA hinges half way into the pre-cut

hinge slots in the leading edge of the elevators. Once the hinges

are in place, use a small T-pin through the center of each hinge to

keep them from being pushed back any further into the elevators.

Insert the exposed ends of the hinges into the pre-cut slots in the

horizontal stabilizer - NOTE: Properly in place, the elevator

horn will be on the left

side of the stabilizer. Move the elevator

assembly left or right as needed to center it with the horizontal

stabilizer. Use a piece of tape to hold the elevators in the full

“down” position. Remove the pin from one of the hinges and use

Thin CA glue, with a fine applicator tip, to apply 2-3 drops to the

exposed center of the hinge. Remove the pin from the next hinge

and again, apply 2-3 drops of glue to the exposed center of the

hinge. Repeat this process with the remaining two hinges.

Remove the tape holding the elevator in the down position,

allowing it to center itself with the stabilizer . Turn the stabilizer over

and again, use a piece of tape to pull and hold the elevators in the

full “up” position. Apply 2-3 drops of glue to each exposed hinge

center and remove the tape. Allow about 10 minutes for the glue

to fully wick its way into the hinges.

After the glue has set, firmly flex the elevators full up and down to

free their movement, removing any “stiffness” to their action.

❑ 4) The horizontal stabilizer/elevator assembly is now glued to

the fuselage. To allow a little time to work and properly align the

stabilizer, use SIG 5-Minute Epoxy for this step.

Begin by first mounting the wing to the fuselage using the

provided 4-40 nylon bolt. Place the model onto a flat surface that

lets you view it directly from the front. Prop-up the rear of the

fuselage with scrap wood to allow the tail wire to clear the surface.

Mix and apply a small amount of epoxy glue to the exposed wood

on fuselage stabilizer saddle area. Carefully place the stabilizer on

the fuselage saddle area, centering it as close as you can. Wipe

off excess glue using alcohol and towel. Use a small weight to hold

the stabilizer firmly to the fuselage. View the model from the front

to see if the stabilizer is squarely in place in relationship to the

wing/fuselage, without tilting to one side or the other. Make any

adjustments needed to hold the stabilizer in this correct position.

Now view the stabilizer from the top to make sure it is in place with

its trailing edge square to the fuselage. Allow the epoxy to cure

completely.

❑ 5) The vertical fin - without the r

udder hinged in place - is now

glued to the top of the stabilizer, again using SIG 5-Minute epoxy.

First, trial-fit the fin into the slot in the top of the stabilizer, without

3

X

X = X

O

O

90

90

X

X

X

any glue. If needed, trim the bottom fin tab to allow full contact of

the fin base to the top of the stabilizer and the fuselage. Have the

wing mounted to the fuselage and sitting on a flat surface to allow

easy viewing from the front. Prop-up the rear of fuselage to clear

tail wire. Mix and apply a small amount of glue to the bottom edge

of the fin and the sides of the locating tab. Carefully press the fin

into place. Wipe off any excess epoxy using alcohol and towel.

Viewing the model from the front, make sure that the fin is 90

O

to

the horizontal stabilizer. Viewing the model from the side, the

trailing edge of the fin should line-up with the very rear of the

fuselage. Use tape to hold the fin in place and let the glue set.

After the glue sets remove the tape and the wing from the

fuselage.

❑ 6) Prepare the rudder for hinging by first installing the

remaining white plastic control horn on its lower r

ight side, in the

two pre-drilled holes. Apply a small amount of Thick CA glue to

the “spikes” on the horn’s base and a small amount of glue on the

base itself. Press the horn firmly into the two holes until its base

bottoms out on the surface of the rudder.

Using the three (3) remaining CA hinges, insert them half way into

the rudder. As you did with the elevator hinges, use a T-pin through

each hinge at the center. Inser t the exposed hinge ends into the

slots in the fin and fuselage. Make sure the rudder clears the fin

at the top and aligns with the fuselage at the bottom. Use a piece

of tape to hold the rudder in the full “right” position. Remove the

pin from one of the hinges and use Thin CA glue to apply 2-3

drops at the exposed center of the hinge. Repeat this process with

the remaining two hinges. Remove the tape holding the rudder,

allowing it to return to its neutral position. Use a piece of tape to

hold the rudder in the full “left” position and again apply 2-3 drops

of glue to each exposed hinge center. Remove the tape and allow

about 10 minutes for the glue to set. Fir mly flex the hinged rudder

back and forth until its movement is free and easy.

LANDING GEAR:

❑ 1) Locate the 2 main wheels, 2 wheel pants – 1 left, 1 right,

2 plastic retaining pads, and the pre-bent wire landing gear.

❑ 2) Look at the landing gear and the wheel pants. Understand

that when assembled, the wheel pants face forward while the

V-bend shape at the top center of the landing gear wire points to

the back of the fuselage.

❑ 3) Insert the wire landing gear axle wire just into the hole in the

plastic wheel pant, the side with the molded wire recess. Slip one

of the wheels into the wheel pant and feed the wire axle through

the wheel axle hole. Once the wire is through the wheel, you can

feed it through the hole in the outer side of the wheel pant.

❑ 4) Locate one of the square plastic retaining pads. Use sand

paper to rough up one side. Apply a small amount of Thick CA

glue to the roughened side of the pad and place it, centered over

the wire landing gear, against the wheel pant surf ace. Hold in position until the CA sets. Repeat this process to finish the remaining

wheel pant/wheel assembly.

❑ 5) Attach the assembled landing gear to the fuselage bottom

using the two M2 x 6MM screws supplied. Insert the screws

through the metal brackets and into the two pre-drilled holes. Use

a small Phillips screwdriver to secure the landing gear to the

fuselage.

RADIO INSTALLATION:

For the following steps you will need your micro receiver, a

micro 4-10 Amp ESC with the proper connectors, your charged

transmitter, and a charged battery pack.

4

MODELERS TIP: A real problem with smaller R/C models is

the typical length of the receiver antenna. These are often 30”

to 36” long and therefore leave a great deal of their length

hanging off the rear of a small model, such as the Lil’ Rascal.

Because the antenna should never be cut, the only other way

is to shorten its length using a “bobbin”. We have used this

technique with our own Lil’ Rascal models with excellent

results.

❑ 1) Mount the receiver to the built-in receiv er tra y in the fuselage ,

ahead of the servo compartment. The easiest and lightest way to

mount the receiver is to use a 1”square piece of Velcro

®

tape. The

receiver is mounted between the forward and rear wir ing access

holes in the receiver tray. Position the receiver with its servo

connectors toward the rear of the fuselage cabin.

Earlier, you routed the rudder and elevator ser vo leads up through

the rear hole in the receiver tray. Connect these two leads to the

appropriate rudder and elevator positions in your receiver. The

receiver antenna is routed down through the forward hole in the

receiver tray, into the lower battery compartment. If you used an

antenna bobbin as earlier described, use a piece of tape to hold it

in place against the fuselage side and route the rest of its length

back up through the rear hole in the receiver tray.

❑ 2) To route the antenna out of the fuselage, drill a small 3/64”

dia. hole through the right fuselage side, just below the wing

saddle and just in front of the fuselage former separating the servo

and receiver compartments. Pull the antenna through this hole.

To hold the antenna in place at the rear of the fuselage, use a pair

of needle nose pliers to make a small hook, with a loop at one end

- a piece of straight pin works great. Glue the hook to the rear of

the fuselage, beneath the stabilizer, using a little thick CA. Use a

small rubber band to attach the antenna to the wire hook to hold it

tight.

❑ 3) The electronic speed controller (ESC) is connected to the

motor using a JST connector and simply floats free in the nose of

the fuselage. DO NOT wrap the ESC in foam, plastic, etc. It can

get warm during operation and must be fully exposed to allow it to

stay relatively cool. The receiver connector on the ESC is routed

up through the front hole in the receiver tray and plugged into the

receiver’s throttle position.

❑ 4) The battery pack is mounted to the bottom of the receiver

tray, using the supplied Velcro

®

tape. This makes the battery pack

easy to remove for charging between flights.

The airborne radio system can now be tested for proper operation

– note that the propeller and spinner are NOT yet installed. Note

that in the interest of minimizing weight and in consideration of the

small amount of available space, this installation does not include

an “on/off” switch. Turning the airborne radio system on or off is

simply done by plugging the battery pack into and out of the ESC

battery connector.

a) Make sure your transmitter rudder and elevator trims are in

neutral and that the throttle stick is in the full “low throttle” position.

Turn on your transmitter.

b) Make very sure of the correct polar ity of the connectors and

plug your charged battery pack into the correct battery connector

on the ESC unit.

c) You should now be able to move the rudder and elevator

controls to check for the correct direction of their movement. You

should now also be able to mov e the throttle stick to w ard the “high”

position and the motor should run. NOTE: Some ESC units must

first be “armed” by movement of the throttle stick – read the

manufacturer’s directions for this information.

d) With the system now working, you must check the rudder

and elevator servos for correct movement. Use the servoreversing feature on your radio system, if needed, to make the

servo move in the correct direction.

e) Reposition the servo output arms on the servos as close to

90

O

to the servo case as possible. Reinstall the servo output arm

screws in both servos.

5

The “bobbin” itself is nothing more than a piece of

3/32” x 1/2” x 3/4 ” balsawood. From the receiver, measure the

antenna out to 4-1/2”– no closer. This is the point to start

wrapping the antenna wire around the bobbin. Do not cross

the wrapped antenna wire, simply lay it neatly next to each

strand. Wrapping the antenna wire 12 to 14 times around this

size bobbin, shortens its overall length by about 11”. Hold the

now-wrapped antenna wire to the bobbin with a length of clear

tape. Now when you install the receiver into the fuselage, you

will have a much more reasonable length of antenna wire to

work with at the rear.

What will this procedure do to the range of your receiver? The

answer is that you will lose some amount of range but not

enough to effect the overall safe operation of the model. This

is because a small R/C model is rarely flown to extreme

distances for the simple reason that you can no longer see it.

Since you would nev er do this, some loss of r ange is more than

acceptable for a small model.

f) Now make sure the motor shaft is moving in the correct

direction. When viewing the fuselage from the rear to the front -as if you were sitting in the cockpit -- the motor shaft should turn

clockwise when throttle is applied.

e) At this point, the servo output arms should now be centered,

the servos should be moving in the correct directions and the

motor should be turning in the correct rotation.

❑ 5) The wire pushrods are now connected to the rudder and

elevator control horns. First turn on the transmitter and then plug

the charged battery pack into the ESC connector. Use small

pieces of tape to hold the rudder and elevators in the neutral

position to the vertical fin and the horizontal stabilizer.

❑ 6) Locate the two (2) white plastic pushrod keepers from the kit

contents. Slide one of these keepers onto the wire rudder

pushrod, sliding it all the way to the fuselage side. Now hold the

pushrod wire against the side of the rudder control horn and use a

fine tip marker pen to mark the exact position of the rudder horns

hole on the wire.

Use a pair of pliers to firmly hold the pushrod wire exactly at the

mark just made and bend the wire straight down at a 90

O

angle.

The excess pushrod wire is now removed, leaving about 1/4” of its

length to pass through the control horn hole – use a good pair of

wire cutters to do this. The bent end of the pushrod wire is now

inserted into the hole in the control horn. Slide the plastic pushrod

retainer out to the control horn and press its tab end over the

exposed wire on the opposite side of the control horn.

❑ 7) Using the same technique described above, bend, cut,

and secure the elevator pushrod to the elevator control horn remember to first slide the remaining white plastic pushrod keeper

onto the pushrod wire.

❑ 8) Remove the pieces of tape holding the rudder and elevator

in the neutral position. Now test the action of the rudder and

elevators with your transmitter. If necessary, use the rudder and

elevator trims to adjust the surfaces back to neutral.

❑ 9) The suggested initial control throws are now set for the

rudder and elevator. Most modern radio systems allow you to set

the total movement of the servos directly from the transmitter. This

is usually referred to as EPA, or end point adjustment. You can use

this feature to now adjust the control mov ements f or the rudder and

elevators. The following control movements are recommended for

initial flights. These measurements are taken at the widest part of

the elevators and rudder, at their trailing edges. Later, when you

are more comfortable with the Lil’ Rascal ARF and how it flies,

these control throws can be increased to suit your needs.

RECOMMENDED INITIAL CONTROL THROWS:

Rudder: 1/2” left and 1/2” right

Elevator: 1/2” up and 1/2” down

MOUNTING THE PROPELLER AND SPINNER:

IMPORTANT NOTE: The propeller and spinner assembly

supplied in this kit was expressly designed for use with electric

power systems. These components are not designed for use with

internal combustion engines. Under no circumstances should

these units be used with internal combustion engines because

they may fail and cause ser ious damage.

❑ 1) Locate the propeller and spinner assembly from the kit

contents. These are the black nylon propeller, the white plastic

spinner cone, the spinner backplate, the threaded aluminum collet,

the propeller nut & washer, and the spinner bolt.

❑ 2) Press the aluminum collet firmly onto the motor output shaft

at the front of the fuselage until it bottoms out. Slide the spinner

backplate onto the threaded end of the collet, as far back as it will

go. Slide the propeller onto the collet, back to the backplate. Install

the washer onto the collet and thread the nut onto the collet

threads. Align the propeller between the recesses in the spinner

6

backplate and lightly tighten the nut with finger pressure to hold

the propeller to the backplate. Place the spinner cone in place,

aligning the ridges in its edges with the recesses in the backplate.

Adjust the propeller position as needed to allow the spinner cone

fit in place into the backplate. Remove the spinner cone and use

a small wrench to tighten the propeller nut firmly to the backplate.

This also pulls the collet into the backplate, securing it to the motor

shaft. Place the spinner cone back in place, pressing its locating

ridges into the recesses in the backplate and secure it to the collet

with the spinner bolt.

❑ 3) IMPORTANT: With the propeller now mounted to the motor,

it is v

er

y important that you always remain aware of the position of

the throttle stick on your transmitter. Under no circumstances

should you hold this model by the nose when the radio system

is turned on. The motor/geardrive unit used in this model is

relatively powerful and can cause damage if it is running and

should come in contact with people, property, etc.

DECAL APPLICATION:

The decals supplied with the Lil’ Rascal ARF are high quality

Mylar

®

with an extremely aggressive adhesive. These are not

die-cut and must each be cut from sheet with a hobby knife and a

sharp #11 blade or with sharp scissors.

The small decals can easily applied to the model using tweezers

and finger pressure to set them. For the larger decals, such as the

door outline and the ”Lil’ Rascal” wing decal, we suggest the

following method to accurately apply them. Carefully cut out the

decal with a hobby knife . Lift it carefully off its sheet with tweezers.

Use a product like SIG Pure Magic Model Airplane Cleaner,

Fantastic

®

, or Windex®to spray the area of the model that will

receive the decal. Then spray the adhesiv

e side of the decal as

well. Lightly position the decal in place on the model. The liquid

cleaner allows the decal to slide easily into the desired position do not press down on the decal. Once in position, hold the decal

lightly in place with your finger and use a paper towel to gently blot

the excess liquid awa y. Use a small squeegee to now set the decal

in place, removing all excess liquid and any air bubbles. The SIG

4” Epoxy Spreader - #SIGSH678 - is perfect for this job. Blot up

any excess cleaner with a dry cloth and allow the decals to set

overnight. They will be solidly adhered to the model without any air

bubbles.

BALANCE:

IMPORTANT: The flight pack battery must be installed in the

fuselage and the propeller and spinner mounted in place to the

gearbox when setting up the correct Center of Gravity (CG)

location.

The correct CG location for the Lil’ Rascal ARF is located

precisely at the main spar. This means that when you place you

fingers, one on each side of the bottom of the wing, at the main

spar location, the airplane must balance in a level position. If the

nose hangs low, the model is “nose heavy”. If the tail hangs low,

this means that the model is “tail heavy”. If either of these

conditions exists, you must make adjustments to correct the

problem. Never attempt to fly your model in an out of balance

condition. Since the flight battery pack is the single heaviest

component in the airplane, it can be used to adjust almost any tail

heavy or nose heavy condition. This is simply done by moving the

battery forwards or backwards.

PRE-FLIGHT NOTES:

Be sure your flight battery packs are fully charged or that you take

your 12-volt battery charger to the field with you. Also, be sure

your transmitter is fully charged. We highly recommend that you

perform a standard range check of your radio system - with and

without the motor running. Any problems you have will not

magically disappear at the field! Make sure your propeller is

balanced and has no nicks or cracks - never fly with a faulty

propeller! Finally, take a few minutes to make sure that you go

through your model to make sure ever ything is secure and tight.

FLYING:

If you are new to the hobby/sport of flying R/C model airplanes, DO

NOT attempt to fly this model by yourself! There are hundreds of

AMA (Academy of Model Aeronautics) chartered R/C clubs in the

U.S. The easiest way to find flying clubs in your area is to ask your

hobby retailer. AMA chartered clubs often have qualified

instructors who can teach you how to fly and perhaps even test fly

your model for you. If you are already an R/C pilot, then you will

likely have no problems at all with flying the Lil’ Rascal ARF.

Choose a calm day with little or no wind for the initial flights. This

is important in getting the model properly trimmed. We also

suggest that for the first few familiarization flights, you have a

buddy hand-launch the model. When hand launching, the airplane

must be launched straight and level directly into the wind, with the

nose aimed at a point on the ground about 75’ in front of you.

Never launch the model with the nose pointed up or the wings

tipped to one side or the other. The launch should be firm enough

to achieve flight speed but yet not overly hard. Later, when you’re

more familiar with the airplane and how it flies, you can perfor m

R.O.G.(Rise Off Ground) takeoffs from smooth surfaces.

With a fully charged 7-cell battery pack, your Lil’ Rascal ARF

should climb out well at full power and you should have no

problem getting to a comfortable trimming altitude quickly. At

altitude, throttle back to a comfortable “cruise” speed and get

7

familiar with the model at slower speeds. Take care of any trim

requirements that might be needed and settle back and have fun!

Now is the time to find out how the airplane reacts to the control

inputs. It does not take much so take it easy on the elev ator. Avoid

trying to use elevators to “force” the airplane to altitude. Instead,

use forward airspeed to allow the airplane to climb on its own.

Properly set-up, with the correct CG location, the airplane should

be very comfortable to fly at the suggested initial control

movements. Throttle all the way back, tur ning off the motor and

check out the glide. It should be fairly flat and relatively slow perfect for a little thermal hunting! While still at altitude, with motor

off, test the stall characteristics of your airplane. The Lil’ Rascal

ARF should demonstrate a fairly sedate stall with almost instant

recovery.

The Lil’ Rascal is capable of some interesting aerobatics.

Consecutive loops are easy. It can also perform some neat

looking rudder rolls, and even inverted flight is possible with

practice. It can be forced into a great looking spin by applying a

little throttle along with full up and hard left or right rudder. Don’t

worry, the pull out from a spin is virtually instantaneous. From

experience, we can assure you that you will find low flybys and

thermal soaring a source of endless pleasure. Even though the

color schemes offer great visibility, be careful of the altitude gain!

This airplane can get small fairly quickly.

Landing the Lil’ Rascal is easy. Throttle back to achieve a shallow

rate of sink, turn into the wind and allow the airplane to settle in

smoothly to a 3-point landing. With a little experience, you’ll be

landing the Lil’ Rascal right in front of you every time!

A final word of caution is in order. Never land your air plane in

tall grass or weeds with the motor running. Always throttle

completely back if you see that you may wind up landing in such

terrain or nose over. Tall grass and weeds may get tangled in the

propeller and stall the motor if it is running. A stalled motor can

overheat the ESC and batteries, causing them to fail. Fly smart

and you will fly for a long time.

IMORTANT NOTE:

Although the Lil’ Rascal ARF is considered a “park flyer” and can

be flown in fairly confined spaces by accomplished pilots, it should

never be flown within five miles of an organized R/C aircraft flying

site. This one simple precaution can prevent the loss of your model

from radio interference. Do yourself a favor and join your local R/C

club – you’ll almost always get assistance and good advice and

you might even make a friend or two!

8

9

LIMIT OF LIABILITY

The craftsmanship, attention to detail, and actions of the builder/flyer of this model airplane kit will

ultimately determine the airworthiness, flight performance, and safety of the finished model. SIG MFG.CO.’s

obligation shall be to replace those parts of the kit proven to be defective or missing. The user shall

determine the suitability of the product for his or her intended use and shall assume all risk and liability in

connection therewith.

CUSTOMER SERVICE

SIG MANUFACTURING COMPANY, INC.is totally committed to your success in both assembling and flying

the LIL’ RASCAL ARF kit. Should you encounter any problem building this kit or discover any

missing or damaged parts, please feel free to contact us by mail or telephone.

SIG MANUFACTURING COMPANY, INC.

P.O. Box 520

Montezuma, IA 50171-0520

SIG MODELER’S ORDERLINE: 1-800-247-5008

(to order parts)

SIG MODELER’S HOTLINE: 1-641-623-0215

(for technical support)

SIG WEB SITE: www.sigmfg.com

WARNING! THIS IS NOT A TOY!

Flying machines of any form, either model-size or full-size, are not toys! Because of the speeds that

airplanes must achieve in order to fly, they are capable of causing serious bodily harm and property

damage if they crash. IT IS YOUR RESPONSIBILITY AND YOURS ALONE to assemble this model

airplane correctly according to the plans and instructions, to ground test the finished model before each

flight to make sure it is completely airworthy, and to always fly your model in a safe location and in a safe

manner. The first test flights should only be made by an experienced R/C flyer, familiar with high

performance R/C aircraft.

The governing body for radio-control model airplanes in the United States is the ACADEMY OF MODEL

AERONAUTICS, commonly called the AMA. The AMA SAFETY CODE provides guidelines for the safe

operation of R/C model airplanes. While AMA membership is not necessarily mandatory, it is required by

most R/C flying clubs in the U.S.and provides you with important liability insurance in case your R/C model

should ever cause serious property damage or personal injury to someone else. For more information,

contact:

ACADEMY OF MODEL AERONAUTICS

5161 East Memorial Drive

Muncie, IN 47302

Telephone: (765) 287-1256

AMA WEB SITE: www.modelaircraft.org

10

R

Loading...

Loading...