ASSEMBLY MANUAL

KIT NO. SIGRC100ARF

SIG EDGE 540T ARF ASSEMBLY MANUAL

Table of Contents:

Introduction..........................................................................................................................................1

Specifications.......................................................................................................................................1

Items Required To Complete Kit ..........................................................................................................1

Radio Equipment System Choice........................................................................................................2

Receivers And Battery Packs..............................................................................................................2

Servos..................................................................................................................................................2

Servo Output Arms..............................................................................................................................2

Servo Extensions & Y-Harnesses........................................................................................................2

On/Off Switches...................................................................................................................................2

Engine Selection..................................................................................................................................3

Covering ..............................................................................................................................................3

Kit Contents.........................................................................................................................................4

Individual Part Inspection ....................................................................................................................5

Incidence & Thrust Angle Information .................................................................................................5

Pre-Assembly ......................................................................................................................................5

Graphics Application............................................................................................................................5

Assembly.............................................................................................................................................6

Mounting The Wing Panels..................................................................................................................6

Mounting The Stabilizer Halves...........................................................................................................6

Hinging Flight Surfaces ........................................................................................................ ...............7

Hinge Gap Sealing .............................................................................................................. ................8

Aileron Servo Installation .....................................................................................................................8

Elevator Servo Installation .................................................................................................................10

Landing Gear & Wheel Pant Assembly.............................................................................................11

Mounting The Tail Wheel ...................................................................................................................12

Mounting The Engine.........................................................................................................................13

Mounting The Ignition Module...........................................................................................................13

Mounting The Cowl............................................................................................................................14

Fitting The Cowl.................................................................................................................................15

Fuel Tank Assembly...........................................................................................................................15

Fuel Tank Installation.........................................................................................................................16

Throttle Servo Installation ..................................................................................................................16

Rudder Servo & Pull-Pull Installation ................................................................................................17

Receiver & Battery Pack Installation.................................................................................................18

Mounting The Propeller & Spinner....................................................................................................19

Center of Gravity (CG).......................................................................................................................19

Flight Surface Movements & Exponential Inputs ...............................................................................20

Pre-Flight...........................................................................................................................................20

Flying.................................................................................................................................................21

Aerobatics..........................................................................................................................................22

Referenced Manufacturer Information...............................................................................................23

Because this 33% model aircraft is exceptionally large, it is

absolutely paramount that your first consideration in anything and

everything to do with this model be safety-oriented. This model

airplane was NOT designed and NOT intended as a beginner's

model. It should only be assembled and flown by experienced R/C

pilots, fully familiar with high-performance model aircraft. A model

airplane of this size and mass is capable of causing considerable

damage to both property and people. It is therefore y

our

responsibility to take every step possible in minimizing and/or

totally eliminating any possible failures of the airframe, radio

equipment, and engine.

Finally, there is the very real issue of transporting this model

safely to and from the flying field. Most modelers that we know,

who fly giant scale models, use a dedicated trailer for this purpose.

Let's face it, the SIG Edge 540T ARF is simply not going to fit in

the back seat of your car! Therefore, serious consideration has to

be given to the safe transportation of this model, in order to avoid

damaging the airframe.

Specifications: Imperial Metric

Wing Span: 100 in. 254 cm

Wing Area: 1881 sq. in. 121.4 sq. dm

Length: 98.25 in. 249.6 cm

Flying Weight (typical): 27 lbs. 12.5 kg

Radio Required: 4 Channel, 8 Servos

Engine Required: 5.8 - 6.8 cu. in. 95 - 110 cc

Items Required To Complete This Kit

• Engine - 95 to 110 cc, gasoline model aircraft type (see Engine

Selection section)

• Radio System with Eight (8) Servos - (see below and Radio

Equipment section for reference)

• Servos - The Edge 540T ARF requires a total of eight (8)

servos. The rudder, elevator, and aileron servos m

ust all be

heavy-duty metal gear types with the minimum torque values

as described below. Never use plastic geared ser vos in this

model - they will fail. The throttle servo can be a standard

system servo, if desired.

Rudder: 1 each Rated @ 225 in/oz minimum

Elevator: 2 each Rated @ 160 oz/in minimum

Ailerons: 4 each Rated @ 160 oz/in minimum

Throttle: 1 each Standard System Servo @ 38 oz/in (typical)

• Heavy-Duty Aftermarket Servo Output Arms

• Large Capacity Battery Pack (airborne system) - We used

2400maH 7.4volt Li-Ion Packs*

(*Note - When using this pack, it is necessary to step down the

voltage to 6 volts using a voltage regulator, such as the Maxx

Products 6 volt regulator, P/N ACC134)

• Large Capacity Battery Pack (engine ignition) - We used a

2400maH 7.4volt Li-Ion pack*

(*Note - When using this pack, it is necessary to step down the

voltage to 5.4 volts using a voltage regulator, such as the Maxx

Products 5.4 volt regulator, P/N ACC139t)

• Servo Extensions -

See Servo Extensions & Y-Harnesses information

• Propeller - Sized to match engine of choice

• Spinner - 4" dia. -

Such as Maxx Products, P/N PS400 (spun aluminum)

Dave Brown, P/N S240-8240 (cast aluminum)

Pete Models, P/N 4-EX (carbon fiber)

• Engine Mounting Hardware - To mount our F.P.E. 6.8 Twin

engine, we used:

4 each #10-32 x 1-1/2" Hex Head Hardened Steel Bolts

4 each #10-32 Lock Nuts

4 each #10-32 Flat Washers

1

INTRODUCTION

Congratulations on the purchase of your SIG Edge 540T ARF kit.

This aircraft has been carefully designed, tested and refined to

offer you incredible performance, coupled with outstanding

airframe strength. In terms of control response, the Edge 540T

ARF kit is loaded with well-proven innovations. For example,

precise control of the elevators has been achieved by using two

elevator servos, one in each stabilizer half, keeping the linkage as

short as possible. Likewise, very precise and powerful aileron

control is achieved by placing two aileron servos into the bottom

of each wing panel. The rudder control pull-pull system has

also been optimized, by placing the control horn location at the

approximate aerodynamic center of the rudder. Every bit of this

forethought adds up to one very exciting and very precise airplane

in the air!

In terms of construction, the SIG Edge 540T ARF has been

expertly hand assembled by highly skilled individuals, each with

many years of experience, employing accurate fixtures with very

tight tolerances. In addition, all of the Edge 540T structural parts

have been laser-cut using extremely accurate CAD-generated

programs, ensuring that each airframe is as close to identical as

humanly possible. Great care has been taken in the building and

covering of this model to produce an exceptionally light, yet very

strong airframe. This will all show up soon enough when you begin

flying your own Edge 540T. Properly assembled, powered, and

flown, the SIG Edge 540T is a very capable aircraft! Our Edge

prototypes, powered with the F.P.E. 6.8 c.i. twin cylinder engine

shown in this manual, easily performs virtually any 3D maneuver

you can think of. The SIG Edge is both IMAC and IMAA legal and

potentially a great contender in such events. We would urge you

to give participation in these events serious consideration in terms

of honing and furthering your flying skills.

Your SIG Edge 540T has been skillfully and beautifully covered at

the factory, using SIG AeroKote

®

. This makes the airframe very

easy to work with in terms of repair. This also means that your

Edge 540T is both very light and very strong and, with reasonable

care, it will remain beautiful for a long time to come.

The SIG Edge 540T ARF is highly pre-fabricated, making its

completion very straightforward and relatively easy. However,

there are the all-important issues of engine and radio selection and their correct installations - to address. This manual will provide

you with information on how we at SIG dealt with and handled

these issues. This is valuable information that will make your own

custom installations that much easier. To fully take advantage of

this model, we urge you to carefully read this manual completely.

Doing so should provide you with insights and possible solutions in

the installation of your own equipment.

• Engine Mounting Hardware - To mount our F.P.E. 6.8 Twin

• Fueling System - The J'Tec #F2G EZ Fueler or the Bisson

#29011 Fuel Dot recommended

• Nylon Pushrod Set - For throttle servo pushrod - see product

suggestions

• Yellow AeroKote

®

, #SIGSTL330 - Hinge Gap Sealing

• Gas-Compatible Fuel Tubing - Large ID Tygon tubing

suggested - Du-Bro #506, about 30"

• 1/2" 2-Sided Velcro Tape - To secure receiver, fuel tank and

radio battery packs

• 1/4" Thick Foam Rubber - Receiver and battery pack

cushioning

• Small 4" Tie-Wraps - Used to secure and organize wiring

• Thread Locking Compound - Such as Loctite

®

#242

• 30-Minute Epoxy - SIG 2-Part Epoxy Glue

• 5-Minute Epoxy - SIG Kwik-Set Epoxy Glue

• CA Glue - SIG Thin, Thick, and SIG Accelerator

• Scrap Lite-Ply - Used as needed for custom mounting

purposes - battery packs, etc.

• Heat Shrink Tubing – Used to secure connectors

• A selection of appropriate tools and materials, such as:

Electric Drill

Dremel

®

Tool with assorted bits

A selection of drill bits and/or a drill index set

Assorted sizes of Phillips screwdrivers

Assorted hex wrenches & ball drivers (a 3mm ball-driver is

required for the hex head wing mounting bolts)

Hobby knife with #11 blades

Fine CA Applicator Tips

Scissors

Masking Tape

Radio Equipment System Choice

The SIG Edge 540T ARF is a giant scale radio control aircraft

that benefits greatly from the use of a sophisticated computer

radio system that includes at least the following features and

capabilities:

• Servo Reversing

• Dual Rates, including rudder movement

• End Point Adjustment (EPA) for all flying surfaces

• Exponential

• Coupling and Mixing Capability

• Differential Mixing

There are a number of excellent computer radio systems on the

market that provide the above capabilities and in some cases, e v en

more. It is obviously not possible in this manual to cover every

radio system and its installation in the SIG Edge 540T ARF.

Instead, we will cover the installation of the radio system that we

used in our prototypes, the Hitec Eclipse 7 Q-PCM system. This

excellent and affordable 7-channel computer radio system has

provided us with virtually every feature required to control,

optimize, and enjoy our Edge 540T models.

Receivers & Battery Packs

In the interest of redundancy, we chose to use two separate

receivers in our Edge prototypes. These were the Hitec Supreme

IIS 8-channel receivers, P/N 23972. In addition we used two

separate 2-cell 2400 mAh Lithium Ion battery packs - one pack for

each receiver - to power the airborne system. These battery packs

have 7.4 volt capacity, which meant that we needed a voltage

regulator for each pack to drop the voltage down to 6 volts. This

was easily accomplished by using two 6-Volt Regulators, one for

each battery pack. The small, lightweight regulator we used was

the unit sold by Maxx Products, P/N ACC134.

Servos

As mentioned earlier, the servos you choose for your Edge 540T

are extremely important to the success of your model. This is

because the servos represent the last link to your flight surfaces. If

you are trying to save money, DO NOT try to save money on your

choice of servos! As also mentioned, we chose to run our airborne

system at 6 volts. A 6-volt system provides considerably faster and

more precise servo response. This is very desirable, especially

when flying this airplane in 3D maneuvers. Earlier, we provided

you with our recommended minim

um torque requirements for the

flight surface servos used in this airplane. The following is a list of

the specific Hitec servos we used in our own Edge prototypes:

Rudder:

#HS5745MG Digital Servo - 249.9 oz/in Torque @ 6 volts

Ailerons & Elevators:

#HS5985MG Digital Servo - 172.2 oz/in Torque @ 6 volts

Servo Output Arms

As mentioned above, the servos are the last link to the flight

surfaces, and this is true. However, the servo output arms

themselves are likewise of equal importance. On a giant scale

high performance R/C aircraft, such as the Edge 540T, plastic

servo output arms are to be strictly avoided, with the possible

exception of the throttle servo. The flight loads are just too high to

risk the use of plastic output arms.

We chose to make our own aluminum servo output arms. Doing

this allowed us to make our arms at the exact distances from the

servo to maximize mechanical advantage. As the basis for our

servo output arms, we used the Air Wild Uni-Hubs, fitted for our

Hitec servos. This is a nice system if you want to make your own

custom output arms. If you would rather work with commercial

aftermarket heavy-duty servo arms, you can purchase good

quality arms, such as the SWB products, for your specific servos.

See the Referenced Manufacturer Inf ormation section at the end of

this manual for contact information.

Servo Extensions & Y-Harnesses

Due to the remote elevator and aileron servo locations in the SIG

Edge 540T ARF airframe, servo extensions are a must. It is

therefore important to minimize electrical resistance by using servo

extensions that use heavier wire. We have used and like the new

Maxx Products 20g twisted wire servo extensions, without inline

chokes. These efficient extensions tend to stay neat within the

airframe and are available in eight different lengths, from 3" all the

up to 48". These can be ordered from Maxx Products with the

connectors of your choice, at reasonable prices. In our Edge 540T

prototypes, we used the following servo lead extensions:

Elevator Servos: 2 each 36" Extensions

Aileron Servos (outboard) 2 each 36" Extensions

Aileron Servos (inboard) 2 each 18" Extensions

In addition to the servo extensions, you will also require "Y"

harness connections, with heavy-duty wiring, for both the aileron

and elevator servo leads, in order to connect them to your

receiver. These are also available from Maxx Products, fitted with

the connectors of your choice. The extensions and other wiring

products that are required will depend upon your own particular

radio system.

On/Off Switches

One of the most failure-prone components in any radio system

tends to be the simple On/Off switch. This is because these light

duty assemblies are subjected to almost constant vibration and

contamination from the elements. This can be especially true with

large gas-powered models, such as the Edge 540T ARF. To

2

3

provide a bit more insurance in our own airborne radio installations,

we used heavy-duty aftermarket On/Off switch assemblies in our

prototypes. And once again, these are available from Maxx

Products. Maxx calls this switch their "Soft Mount One-Piece

Charge Switch" - P/N 3470. This well-built switch also allows the

airborne battery packs to be charged externally, directly from the

covered charge jack in the switch itself. This switch also includes

a silicon pad soft-mount - very desirable in large gas-powered

models. We used three (3) of these switch assemblies in our Edge

540T models - one for each of the two redundant receivers and

their battery packs, and a third switch for the engine ignition battery

pack.

(NOTE: The manufacturer's part numbers provided in this manual were correct and

current as of it's writing. Part numbers and/or products are subject to change.)

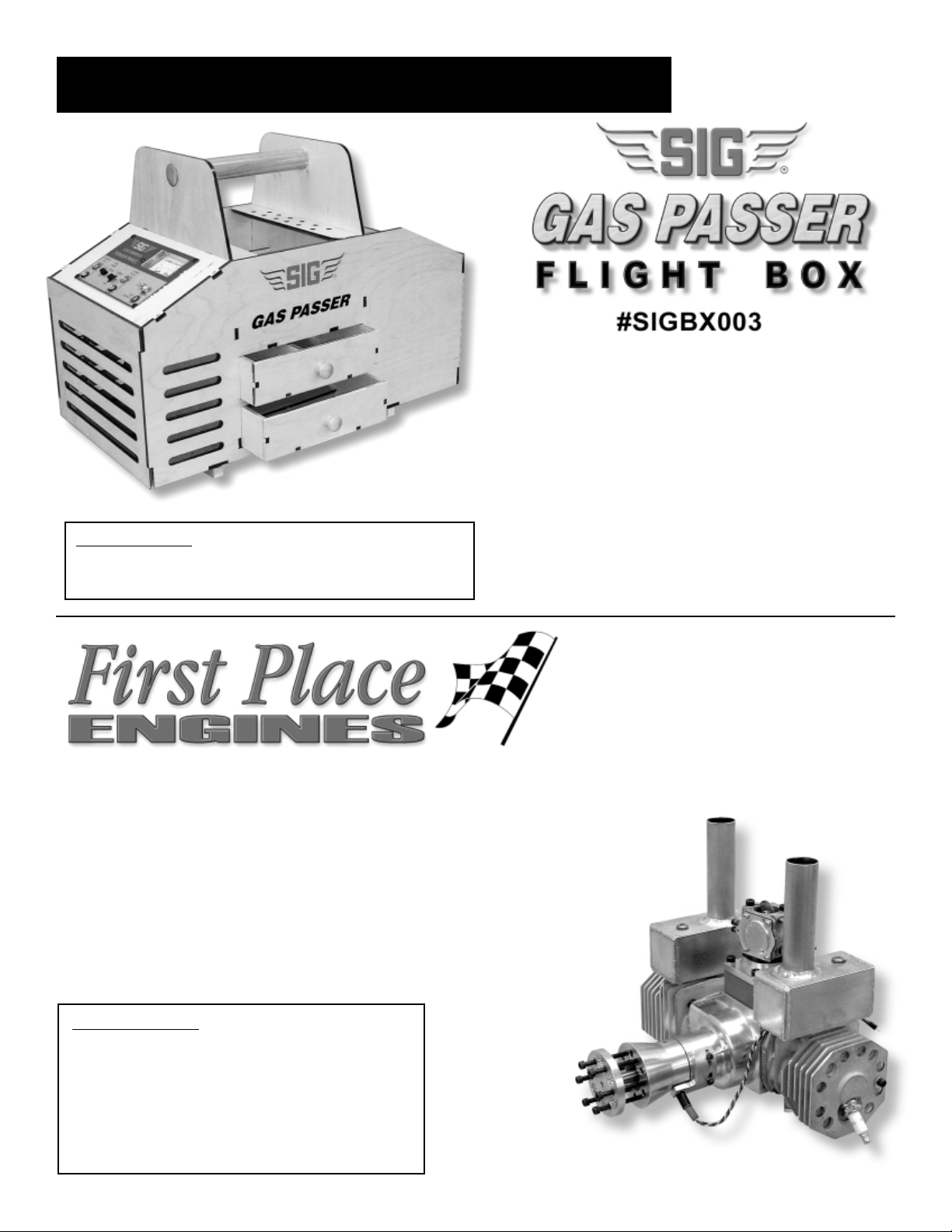

Engine Selection

At 33%, the SIG Edge 540T ARF model is obviously very large.

Typical flying weights can vary with different engines, airborne

equipment, and batteries but in general, fall within 26 to 27-1/2

pounds, ready to fly. We have flown and tested our prototypes

using the very powerful and compact F.P.E. 6.8 ci (111.4 cc) twin

cylinder gas engine. The F.P.E. 6.8 Twin weighs 116 ounces (3289

grams), including the electronic ignition module and mufflers that

come with the engine. This very smooth running engine, turning a

Biela 27 x 10 composite propeller, produces about 11.5 hp @ 6000

rpm. This translates to approximately 75 pounds of static thrust!

This is precisely the kind of power-to-weight ratio that makes the

SIG Edge 540T a very capable 3D aircraft.

The SIG Edge 540T design incorporates a large and spacious

fiberglass cowl. This cowl is large enough to fully enclose the

F.P.E. 6.8 twin cylinder engine, including the rubber sparkplug

boots. This means that with the exception of creating the required

clearance holes for the two stock mufflers and opening the bottom

rear half-round air dump, there are no other required cowl

openings.

If you choose to power your Edge 540T with a different brand of

gas engine, then we suggest using engines in the 95 to 110cc

range. Again, when choosing an engine for your Edge, other than

the F.P.E. 6.8 twin, you should carefully consider the weight of the

engine and the overall mounting dimensions. To assist you, the

following dimensions are provided:

1) Firewall to front spinner opening surface of cowl: 7-7/32" (this

can be adjusted fore or aft by about 1/8")

2) Maximum (non-contact) internal cowl width: 13-1/16"

We urge you to carefully consider the engine you choose for your

Edge 540T ARF model. Reliability, power, w eight, and dimensions

are all very important in obtaining maximum performance and a

long life for your model. Finally, under no circumstances do we

recommend any engine for this model in excess of 111.4cc

displacement.

Covering

The SIG Edge 540T ARF model has been professionally covered

with SIG AeroKote

®

covering film. This high quality polyester

covering film has been expertly applied, using a beautiful and

unique trim scheme, designed specifically to provide maximum

contrast between the top and bottom of the model. This feature

offers excellent attitude reference during 3D or IMAC maneuvers.

The SIG Edge 540T ARF model was manufactured and covered in

a part of the world that is typically humid. When the individual

covered parts are removed from their plastic bags, some wrinkling

of the covering may occur after a day or so. This is especially

possible if you live in a drier climate. This phenomenon is

perfectly normal and DOES NOT mean that your model has a

defect. These wrinkles are caused by wood losing moisture and

dimensionally shrinking in the process. This is the nature of wood,

especially softer types.

Some modelers may feel that the covering on their ARF model

should be perfect and that they should not be e xpected to re-shrink

wrinkles. This is not realistic, because any covering material regardless of brand - that has been hand applied over wood, is

indeed subject to the possibility of wrinkling.

The requirement is to therefore re-shrink the covering, as needed.

This is not difficult to do and can be done using normal hobby-type

covering tools, such as a heat iron, a trim seal tool, and a heat gun.

Carefully note that we do not recommend the use a heat gun

around any areas where two pieces of covering material have

been seamed together. The heat gun generates a great deal of

broadcast type heat that in turn, can loosen seamed covering

material, causing these seams to "creep". If you must use a heat

gun around or near such seams, we urge you to protect them first.

To do this, simply soak some paper towels in cool tap water and

arrange them directly onto the seams. You can then use your heat

gun to carefully shrink areas close to the seam.

When using a hobby-type heat iron, we always suggest that the

surface of the shoe be covered with a soft cloth. This will help to

prevent scratching or hazing the surface of the covering material.

For years we ha ve used old cotton T-shirt cloth for this purpose and

it works very well. There are also commercially available "covering

socks" that fit onto most covering iron shoes. These can vary in

quality, so choose one that feels the softest. Also note that the

temperatures required to shrink and seal AeroKote

®

(275O- 325

O

F) are definitely high enough to melt or distort plastic par ts. Use

common sense when working around the plastic parts on your

model!

Also be aware that the aft top turtledeck on the Edge 540T ARF

model is a composite of shaped white foam, sheeted with

balsawood. This makes for a very light structure, eliminating the

need for stringers. However, we do suggest that you only use a

heat iron on this area for re-shrinking purposes, and then, only

lightly.

For reference, the SIG Edge 540T ARF model was covered using

the following AeroKote

®

colors and SIG part numbers:

Blue Opaque................................................................#SIGSTL250

Bright Y ello w Opaque ..................................................#SIGSTL330

Black Opaque (Striping) ..............................................#SIGSTL201

Yellow/Black Checkerboard (1" sq.) Fin/Rudder ..........#SIGSTL432

4

Red/White Checkerboard (2" sq.) Stab/Elev Bottom ..#SIGSTL413

Red/White Checkerboard (4" sq.) Wing Bottom ..........#SIGSTL414

Kit Contents

The following is a full and complete list and description of each of

the parts contained in the two kit boxes that make-up the complete

Edge 540T ARF kit. We strongly suggest that you now take the time

to carefully and completely inventory each of the parts listed below,

using the boxes (

❑

) on the left hand side to check off each part. If

you are missing any of these parts, make a note of the missing part

or parts and contact the location where you originally purchased the

model for replacement.

Box 1 of 2:

❑ 1 each Fuselage - Covered, with vertical fin in place - Hinge

Holes Drilled

- Main Landing Gear Hatch in place with

2 each T3 x 16mm Hatch

Mount Screws (taped to inside

of hatch)

❑ 1 each Fiberglass Cowl - Painted, with cowl mounting

hardware bag:

❑ 6 each M3 Blind Mounting Nuts

❑ 6 each M3 x 10mm PWA Bolts

❑ 1 Bag Fiberglass Wheel Pants, 1 left, 1 right, pre-drilled for

mounting with M3 Blind Mounting Nuts Installed

❑ 1 Bag Main Landing Gear - Painted White, pre-drilled for axle

and wheel pant mounting

❑ 1 Bag Main Wing Mounting Tube - 40mm dia.x 973mm, Black

Anodized Aluminum

Fwd Stabilizer Mounting Tube - 12.5mm dia. x 198mm,

Black Anodized Aluminum

Rear Stabilizer Mounting Tube - 12.5mm dia. x 478mm,

Black Anodized Aluminum

❑ 1 Bag Large SIG Tail Wheel Assembly:

35mm dia.Tail Wheel - Mounted

Steel Tail Wheel Yoke, Axle, Nylon Bellcrank - Mounted

❑ 3 each Graduated Aluminum Leaf Springs

❑ 2 each Centering Spr ings

❑ 1 each Rudder Mounted Aluminum "T" Bracket

❑ 3 each T3 x 16mm PWA Screws - Tail Wheel

Mounting Screws

❑ 2 each T2 x 12mm PWA "T" Bracket Mounting

Screws

❑ 1 Bag Main Wheel Bag:

❑ 2 each 110mm (4.3") dia. Main Wheels* (see

note below)

❑ 2 each Main Wheel Axles - 4.75mm dia. x 50mm

❑ 2 each 5/16-24 Axle Lock Nuts

❑ 4 each 5mm I.D.Wheel Collars with Set Screws

❑ 4 each M3 x 15mm PWA Bolts - Wheel Pant

Mounting

❑ 4 each M3 Split Washers

❑ 4 each M4 x 20mm PWA Bolts - Main Landing

Gear/Fuselage

❑ 4 each M4 Split Washers

❑ 1 Bag ❑ 1 each Throttle Ser vo Mounting Tray - 2.75mm

Plywood

❑ 2 each M4 x 20mm Hex Head Bolts - Rear Wing

Attachment Bolts

❑ 1 Bag ❑ 1 each Throttle Ser vo Mounting Tray - 2.75mm

Plywood

❑ 2 each M4 x 20mm Hex Head Bolts - Rear

Wing

Attachment Bolts

❑ 2 each M4 x 25mm Hex Head Bolts - F

orward

Wing Attachment Bolts

❑ 4 each M4 Washers

❑ 4 each T2.6 x 16mm PWA Screws - Stabilizer

Mounting Screws

❑ 1 Bag ❑ 8 each Heavy Duty Control Horns w/Nylon Inserts

(4 Left, 4 Right)

❑ 32 each T2.6 x 16mm Phillip Head Screws -

Control Horn Mounting Screws

❑ 2 each .08mm x 1200mm (47") Nylon Coated

Steel Cables

❑ 4 each Steel Clevises with 2mm Threaded

Rigging Couplers and Lock

Nuts - Rudder Pull-Pull Connectors

❑ 4 each Copper Rigging Swages - 3.5mm x 4mm

❑ 1 Bag ❑ 6 each Aileron and Elevator Control Linkages:

4-40 Threaded Steel Rod with 4-40

Clevises at each end with 4-40 Lock Nuts

and Spring Clevis Retainers

❑ 1 each Throttle Pushrod - 1.8mm x 300mm with

Clevis at one end

❑ 1 Bag ❑ 1 each Fuel Tank Body - 800cc Capacity (27.05

ounces)

❑ 1 each Gasoline-Compatible Rubber Tank

Stopper

❑ 3 each Aluminum Fuel Tubes

❑ 1 each Gasoline-Compatible Fuel Tubing Piece

❑ 1 each Fuel Pick-up Clunk Weight

❑ 1 each Edge 540T Graphics Sheet - 11-1/4" x 59-1/4"

❑ 1 each Edge 540T Assembly Manual

Bo

x 2 of 2:

❑ 1 each Rudder Assembly - Covered, with Control Horn

Hardpoint and five (5) heavy-duty Super Hinge Point

hinges in place - NOT glued

❑ 1 each Left

Horizontal Stabilizer Half - Covered with Control

Horn Hardpoint and four (4) heavy-duty Super Hinge

Point hinges in place - NOT glued, with servo cut-out

made and ready

❑ 1 each Right

Horizontal Stabilizer Half, Covered with Control

Horn Hardpoint and four (4) heavy-duty Super Hinge

Point hinges in place - NOT glued, with servo cut-out

made and ready

❑ 1 each Left

Main Wing Panel - Covered, with Aileron in place

with five (5) Super Hinge Point hinges in place - NOT

glued, with:

• Two (2) aileron wiring strings in place for each

aileron servo bay

• 12.5mm O.D. aluminum tubing rear wing locator

tube in place

• 40mm I.D.fiberglass wing tube receiver in place

• Two (2) M4 blind mounting nuts installed for wing

mounting

❑ 1 each Right

Main Wing Panel - Covered, with Aileron in place

with five (5) Super Hinge Point hinges in place - NOT

glued, with (see Left Wing Panel above)

IMPORTANT NOTE: Each Edge 540T ARF kit has been carefully

and completely inspected and inventoried on three different

occasions. Therefore, you can be assured that your kit has been

checked and was shipped with all of the listed parts included. Missing

part claims made after

the assembly of the model begins cannot be

honored.

*WHEEL NOTE: The two 4.3" dia. main wheels provided with the

Edge 540T ARF kit are of high quality, designed to be as light as

possible, with a weight of only 44.5 grams per wheel! Our reason for

using these wheels has everything to do with weight. Saving every

5

Individual Part Inspection:

Although your Edge 540T ARF airframe was carefully and

expertly constructed, we still suggest that you conduct a full and

complete airframe inspection. Finding and correcting any

structural issues now will greatly enhance and prolong the life of

your model. Inspect each joint to make sure these are all secure.

If necessary, use a good quality 15 or 30-minute epoxy to re-glue

or reinforce any suspect joint.

Incidence & Thrust Angle Information:

Incidence and thrust have been built into the model at the factory.

However, some people may still wish to know these values:

Incidence:

Wing 0

O

Stabilizer 0

O

Engine Thrust: Right Thrust 2O(Built into engine mount)

Down Thrust 0

O

Pre-Assembly:

The Edge 540T ARF is a very large model airplane that obviously

requires a large enough space to assemble it and work on it, in

order to avoid damage. We strongly suggest that your workbench

area be protected with sheet rubber foam or some similar padding

material in order to minimize the possibility of scratching or

denting the covered airframe parts.

With the exception of the hinging procedure for the flight surfaces,

and the use of CA to harden various threaded holes in wood, there

will not be much further need to use epoxy or CA glues in or

around the outer surfaces of the various airframe parts. However,

if you should accidentally drip or spill these adhesives onto the

covering of your model, they can usually be totally remo v ed. In the

case of epoxy, use denatured alcohol and a soft cloth to remove it

as quickly as possible, before it cures. In the case of CA glues,

when this stuff dries, it can be difficult to remove. We suggest

using a soft cloth and CA debonder to first soften the glue and then

carefully wiping it away.

The canopy hatch on the top of the fuselage should be removed

and set aside until the model is fully assembled. The canopy hatch

is held in place with four M3 x 10mm PW A bolts - two on each side

of the fuselage. Remove these bolts and remove the canopy

hatch. Keep the bolts with the hatch so as not to lose them.

It is always best to have all of the equipment that you plan to use

in your model - engine, radio system, various accessories, etc. available to you before you start assembly.

Graphics Application:

We have found that it is much more convenient to apply the

graphics to the wing panels, fuselage, and rudder of the Edge

540T model before the assembly process. However, you can use

the following instructions to apply your graphics either now or after

you have completed the assembly steps.

Your Edge 540T ARF kit includes a beautiful and very large

graphics sheet. These graphics are of high quality and include a

unique light-tack clear carrier sheet that allows you to precisely

position each separate graphic onto the surface of the model.

There are six (6) basic graphics contained on this sheet - 2 each

large "EDGE 540" graphics, tapered to fit onto the wings, 2 each

smaller "EDGE 540" graphics, tapered to fit onto the fuselage

sides, behind the canopy, and 2 each "N540SG" graphics for the

rudder. Use the box label for locations of each graphic.

Begin by using a pair of scissors to cut each of the six graphics

from the overall sheet. The following technique is the easiest way

to locate and then adhere these very large graphics. Use a good

quality cleaning solution, such as SIG Pure Magic Model Airplane

Cleaner, Winde x

®

, or Fantastic®to first liberally spray the area that

will receive the graphic. Next, carefully and slowly remove the

white paper backing from the graphic, leaving it in place on the

clear carrier film. Now spray the adhesive side of the graphic

liberally.

Lightly place the graphic and clear film carrier sheet - adhesive

side down - in place onto the model, in the area where it will be

permanently mounted. The cleaning liquid will keep the adhesive

from actually sticking. Do not press down on the graphic; just

position it approximately in place. You can now shift the graphic

into its final location on the model. Once the graphic is exactly

where you want it, hold it in place at one end with your fingers and

use a paper towel to lightly begin smoothing it in place with light

pressure. This will begin to remove some of the liquid beneath the

graphic, allowing it to begin to adhere.

last gram of weight wherever possible is very important. We

understand fully that this type of wheel has a tendency to develop a

flat spot when the model is stored on its wheels over time. We

therefore suggest that the weight of the fuselage be taken off of the

wheels when airplane is being stored or is sitting on the flight line for

prolonged periods of time. For us, this bit of effort is worth it in the

long run. If you wish, you can replace the kit wheels with aftermarket

wheels of approximately the same diameter and hub width.

With everything now pre-fitted, disassemble the wing panels from

the fuselage and remove the main wing tube. Set the tube aside

for now. The best way to keep the wing mounting bolts in a place

where they can always be found is to thread them into the two bolt

holes in each wing panel.

Mounting The Horizontal Stabilizer Halves:

The two horizontal stabilizer/elevator halves on the Edge 540T

ARF kit are made to be removable. This feature can be useful in

transportation and/or storage situations. Both stabilizer halves

mount onto anodized aluminum tubes that fit through the rear of

the fuselage. From the kit contents, locate the front

12.5mm dia. x

198mm stab tube, the rear

12.5mm dia. x 478mm stab tube and

four T2.6 x 16mm PWA screws. (Note that the stabilizer mounting

tubes have hardwood inserts in place at each end.) For fitting

purposes, it's convenient to first remove the rudder from the fin and

the elevators from their stabilizer halves.

1) Use high-pressure air to blow out each female tube receptacle

holes in both stab halves. Slide the shorter forward tube into the

forward receptacle in one of the stab halves. Note that there

are plywood tubing "stops" built-in to the inner ends of these

receptacle tubes. Be sure the inserted tube bottoms out against

this stop. The fit may be stiff, so while the tube is in place, firmly

grasp it and rotate it a few times until it's a bit freer. Remove the

tube and slide the opposite end into the other stab half. If the fit

feels tight, rotate the tube a few times until it too feels a bit freer.

Repeat this with the longer rear stab tube in the rear stab

receptacle holes.

2) The stab halves are now trial-fitted to the fuselage. Insert the

front and rear tubes into one of the stab halves until both tubes

bottom out at their stops. Inser t the exposed ends of the tubes all

the way through the front and rear stab mounting holes at the rear

of the fuselage, until the root rib of the stab contacts the fuselage.

Slide the opposite stab half in place onto the exposed tube ends

and press it firmly all the way in place until it too contacts the side

of the fuselage. This is the fit you're trying to achieve.

In the unlikely event that one of these two tubes may be a little too

long, preventing the stab halves to fit against the fuselage sides, it

will have to be slightly trimmed in length. If this is the case, you

have to determine which tube needs to be shortened. Remove

both stab halves and either the front or rear tube from one of the

halves. Reinser t the one tube into its correct receptacle and slide

it in place through the appropriate fuselage stab hole. Slide the

other stab half in place onto the tube end and press it up against

the fuselage. If the two stab halves now fit against the fuselage

sides, you now know it is the remaining tube that needs to be

trimmed. Likewise, if the tube currently in place does not allow the

stab halves to fit against the fuselage sides, then it is this tube

causing the problem. Visually deter mine how much of the end of

the tube needs to be trimmed. Use a bench grinder or vertical

sander, to lightly trim the offending tube. Lightly chamfer the

trimmed end of the tube at a 30

O

angle or so. Finally, remount the

two stab halves in place to the fuselage and check the fit. It should

now be fine. Remove the stab halves and tubes from the fuselage.

3) The mounting tubes must now be secured in place in the stab

halves, using four T2.6 x 16mm PWA screws. On the bottom

surface of each stab half you will see two small pre-drilled holes.

These are hole locations for the stab tube retaining screws. In

order to use these screws, the stab mounting tubes need to be

accurately marked and then drilled with guide holes. To easily

mark the ends of the tubes, we used a short length of 3/32" dia.

music wire with a sharpened point at one end.

The graphic is now adhered permanently in place. To do this, we

suggest using a plastic squeegee. The SIG 4" plastic Epoxy

Spreader squeegee - P/N SH678 - is perfect for this purpose.

Smoothly and firmly use the squeegee to completely remove all of

the liquid and air bubbles from beneath the graphic. Use paper

towels to clean up the excess liquid. Once you're satisfied that all

of the liquid has been removed, allow the graphic to dry overnight.

When the graphic has dried, pick up one of the edges of the clear

plastic carrier film and remove it by pulling the film back against

itself. The graphic that is left in place on the model is now all but

permanently in place.

Assembly:

Mounting The Wing Panels:

The two main wing panels are attached to the fuselage using the

40mm dia. x 973mm black anodized wing tube. It is important that

you pre-fit the wings and wing tube, making sure that everything

fits. The first thing to do is to make sure that the fiberglass

receptacle tubes in both the fuselage and the wing panels are

clear of obstructions, allowing the tube to fit fully in place. We used

high-pressure air to first blow out any dust or debris from these

tubes.

Insert the wing tube fully into one of the wing panels, until it

bottoms out against the plywood stop inside the female receptacle

tube. The fit should be firm, not sloppy. Remove the tube and

repeat this process on the other wing panel. Remove the tube.

Slide the main wing tube in place through the fuselage, roughly

centering it. Hold the tube and slide one of the wing panels in

place onto the tube, sliding it inwards towards the fuselage side.

As the wing root gets close to the fuselage side, the permanently

mounted aluminum tube stub at the rear of the wing root must now

engage into the hole in the fuselage side. With the rear tube now

engaged into the hole, the wing panel can be firmly pressed

against the fuselage side. Repeat this mounting procedure with

the remaining wing panel.

There are four M4 Hex Head Bolts pro vided in the kit. Two of these

are 20mm long and are the rear

attachment bolts. The other two

are 25mm long and are the forward wing attachment bolts. Using

these four M4 bolts and four 4mm flat washers, the two wing

panels are now secured to the fuselage. Slide a washer onto one

of the 25mm bolts and from the inside of the fuselage insert the

bolt into the f

orward bolthole through the aluminum L-bracket. With

the wing against the fuselage, use a 4mm ball-driver to tighten the

bolt into the blind mounting nut already in place in the wing root.

Move back to the rear

bolthole and insert a 20mm bolt and

washer in place and use the ball-driver to secure the bolt. Repeat

this process with the opposite wing panel.

6

Hinging Flight Surfaces:

The proper hinging of the flight surfaces for any model is very

important. This is even more so with giant-scale models.

Improperly installed hinges can and will have a detrimental effect

on how the model flies in terms of precise control response.

Further, it is imperative that each hinge be securely glued in place.

The Edge 540T ARF kit includes excellent Super Hinge Point

hinges. These are high quality, very strong, and easy to install.

Also note that all of the required hinge mounting holes have been

pre-drilled for your convenience. The correct mounting of these

hinges requires the use of 30-minute epoxy - never use 5 or

15-minute epoxy types for gluing these hinges in place. It's most

efficient to mix 1/2-ounce batches of glue at a time for hinge

installation. If during the hinging process the glue begins to feel

"thick", mix a fresh batch and continue on.

Note that this section is generic to hinging all of the flight surfaces.

The same techniques and materials should be used. All five of the

flight surfaces - 2 ailerons, 2 elevators, and the rudder - can be

hinged at this time. To illustrate this instr uction, we are using the

left stabilizer and elevator half. We always suggest installing the

hinges into the flight surface (elevator, in this case) first, followed

by then mounting the flight surface to its corresponding part.

1) We suggest wiping down each hinge with alcohol before it is

installed. This removes all oils, etc. from the hinge, allowing the

best bonding surface for the epoxy.

2) Mix a fresh batch of 30-minute epoxy in a cup. Use a thin stick

(we like using bamboo skewers for this purpose) to apply glue into

one of the hinge holes in the elevator . Also apply glue to the ribbed

surface of one half of one of the hinges. Insert the hinge into the

hole in the elevator until it is fully in place. The center hinge pin

should be aligned in parallel with the hinge line of the elevator.

Quickly wipe off any oozing glue with a paper towel and alcohol.

Orient the hinge at 90

O

to the hinge line, allowing full movement up

and down. Repeat this process, installing the remaining hinges.

3) With the hinges in place and properly oriented, allow the epoxy

to cure for at least 4 hours to ensure the best bond. After the glue

has cured, work each hinge repeatedly through the full range of

movement. This will break up any glue that may have gotten into

the hinge area. Continue doing this until each hinges moves

absolutely freely with no binding at all.

4) Mix a fresh batch of 30-minute epoxy. Use a thin stick or

bamboo skewer to apply glue into each hinge hole in the

stabilizer. Apply glue to the exposed ribbed ends of each hinge

half. Carefully installed each hinge half into their corresponding

holes in the stabilizer. Press the elevator half uniformly into place

against the stabilizer hinge line. You want to leave the minimum

possible gap. Use alcohol and paper towels to carefully remove

any visible signs of glue at each hinge location.

7

Insert the front and rear mounting tubes in place into the stab,

making sure they both bottom out against their stops. Inser t the

pointed end of the music wire into one of the pre-drilled holes on

the bottom of the stab. Press the music wire against the aluminum

tube and rotate the tube inside the stab. This will scribe a mark on

the tube. Repeat this process with the remaining stab tube.

Remove the tubes from the stab half.

4) Use an electric drill and a .081 dia. dr ill bit (#46 index size), to

drill a hole through the aluminum tube and into the hardwood

insert at the scribed location on the tube, at 90

O

to the length of the

tube. Do not dr ill all the way through the tube. In the interest of

accuracy, we used a drill press for this step. Repeat this process

with the other tube end. Clean up any debris on the tubes where

the holes were drilled, using sandpaper to smooth it.

Using one of the T2.6 x 16mm PWA screws and a Phillips Head

screwdriver, tap the hole just drilled in the tube, running the screw

about 3/4 of the way into the tube. To do this correctly, make just

a 1/2 turn or so with the screw, back it out a bit and then screw it

in another 1/2 turn or so. Repeat this tapping process - a little in,

a little out - until the hole is tapped. Now do the same thing with

the remaining tube. Remove any debris on the surface of the

mounting tubes with sandpaper. Install the two now drilled and

tapped tubes back into the stab half. Install the two retaining

screws into the stab and tube ends, bringing the heads of both

screws down to the surface of the stab - there is no need to overtighten these screws.

5) With the front and rear mounting tubes and the retaining screws

now accurately in place in one of the stab halves, the same thing

has to be done with remaining stab half. Slide the opposite stab

half onto the mounting tubes, all the way to the internal stops.

Chuck the .081 dia. drill bit into an electric hand-held drill. Using

the two hole locations on the bottom surface of the stab, insert the

bit into each hole and use a little pressure to mark the hole

locations onto the ends of both tubes. Remove the stab half from

the tubes and remove the retaining screws from the opposite stab

half and then remove both tubes. Drill the now marked tube ends

at 90

O

with the .081 dia.drill bit, again about 3/4 of the way through

the tubes. Tap the two holes with a T2.6 x 16mm screw, using the

technique described earlier. Remove any debris from the surface

of the two tubes with sandpaper.

Insert the mounting tubes into one of the stab halves and install

the retaining screws. Install the exposed tube ends through the

fuselage holes. Slide the remaining stab half in place onto the

tubes, all the way up to the fuselage side. Install the two retaining

screws. This completes the stab mounting and retaining screw

installation. Remove the stab halves and tubes from the fuselage.

3) The strip is now cut to the correct length for the aileron hinge

line. This should be 35-3/4". The completed strip will now be

placed into the aileron/wing panel hinge line and ironed in place.

4) Remove the clear backing from the AeroKote

®

strip and place it

into the hinge line bevels, with the crease directly over the

aileron/wing panel gap. With the wing panel on a flat surface,

place a straight edge into the hinge gap with its edge directly over

the crease. This serves to hold the AeroKote

®

strip firmly in place

against either the wing or aileron bevel.

5) Use a smaller trim seal tool, set to "High", to now iron one side

of the strip to its bevel. Work from one end to the other, moving

slowly to make sure the strip is completely ironed in place.

Remove the straight edge when you're finished.

6) Flex the aileron to its maximum full down position and use a

piece of masking tape to hold it in place. The opposite side of the

AeroKote

®

strip is now ironed in place to its beveled side. Again,

we prefer using our trim seal tool for this step, making sure the

material is completely ironed in place. Remove the tape holding

the aileron.

The hinge gaps in both the stabilizer/elevator assemblies can

now be sealed in the same manner described above. For these

assemblies, you need to cut two 7/8" x 13" AeroKote

®

strips,

creased at the lengthwise center.

Aileron Servo Installation:

For the aileron servo installation, you will need four aileron servos

and the appropriate servo extensions for both wing panels. You will

also need the servo mounting screws and eyelets that came

with your radio system. From the kit contents, locate the bag

containing the heavy-duty control horns and the small bag

containing the T2.6 x 16mm Phillips head screws. You will need

four control horns - 2 left and 2 right horns. You will need a total of

16 control horn mounting screws.

Again, check the hinge gap for the closest possible fit, while

maintaining full movement ability. Allow the glue to cure for at least

6 hours. Before the glue fully cures, we suggest checking the fit

and movement of the surface, adjusting it as needed.

5) When the glue has fully cured, carefully check the movement of

the control surface, moving it bac k and forth completely through its

full range of movement.

Hinge Gap Sealing:

It is mandatory to seal the aileron and elevator hinge gaps,

making them airtight to prevent flutter. Sealing these gaps also

serves to make these flight controls much more precise as well as

making them much more efficient and easier to trim. Failure to

seal the aileron and elevator hinge gaps may well lead to control

surface flutter, potentially causing the model to crash. Hinge gap

sealing is really not all that difficult and could save your model. In

the interest of maintaining the color scheme, we used AeroKote

®

Bright Yellow #SIGSTL330 (not included) for sealing our aileron

and elevator hinge gaps.

Sealing the hinge gaps need only be done on one side or the other

of the surface. Our suggestion is this; if you are proficient in

working with iron-on films, seal the hinge gaps from the top. If

you're not very good at working with such films, then seal the

bottoms of the hinge gaps, where they are less conspicuous. This

instruction sequence assumes you are sealing the hinge gaps on

the tops.

1) For the ailerons, cut a piece of AeroKote

®

about 4" x 36". On a

flat surface, fold and crease this strip lengthwise, color to color, at

the 2" center. Make the crease sharp at this fold.

2) At each end of the strip, use a ruler and a marker pen to

measure and mark a point that is 1/2" from the crease fold. Lay

the strip on a flat cutting surface and use a straight edge and a

hobby knife with a sharp #11 blade to cut the strip lengthwise at

the two marks just made.

8

Note: For clarification purposes in this manual, we define a left

and a right control horn by simply looking straight down on the

horn, as shown. If the mounting pad (4 screw holes in each pad)

is facing left, it is a left control horn. If the pad is facing to the right,

it is of course a r

ight control horn. Use this identification method

when following any instruction where control horns are being

mounted to the flight surfaces.

1) Each wing panel has two servo extension strings - one for each

servo - in place for your convenience. These strings are

temporarily attached in each aileron servo bay and to the inside of

the root rib.

2) Working with the outboard aileron servo first, break away the

piece of balsa holding the servo extension string and pull out

enough string to attach the connector of your longest servo

extension (as previously mentioned, we used a 36" non-choked

heavy-duty servo extension in our models). Install the four rubber

grommets and eyelets that came with your radio system into the

servo mounting tabs. From the wing root rib, pull the extension

lead through the wing and out of the wing root rib. Note that we

suggest using a 1" or so piece of heat shrink tubing over the

extension and servo connectors to secure them. Plug the servo

connector into the servo extension and shrink the heat tubing.

The servo is now positioned into the servo bay, with its output

spline forward, toward the leading edge of the wing panel. Using

the mounting screws supplied with your radio system and secure

the servo to the mounting rails in the servo bay.

3) The inboard aileron servo is now mounted in place into the

inboard servo bay opening in exactly the same way as described

above. As mentioned earlier, we used 18" servo extensions.

4) Using the same instructions above, mount the remaining two

aileron servos in the opposite wing panel.

5) If you are using a single receiver, you now need plug the two

servo extensions from each wing panel into a Y-harness - one

harness for each wing panel. The Y-har ness connectors are now

plugged into the appropriate aileron servo receptacles in your

receiver (with our Hitec receiver, these are Channel 1 for right

aileron and Channel 6 for left aileron - consult your radio system

manual for this information). Connect a switch and a charged

battery pack to your receiver. Turn on the transmitter and then the

receiver. Using the instructions that came with your radio system,

make sure the servos are moving in the correct directions and that

the aileron trim is in neutral. When the servos are properly set-up,

turn off the receiver and the transmitter and disconnect the aileron

servos from the receiver.

6) The two required aileron control horns are now mounted at the

bottom bevel leading edge locations of the aileron. Note that there

are two thick hardwood pads built into the bottom of each aileron

for control horn mounting. The outline of these pads can usually

be seen, by holding the aileron at an oblique angle to the light.

These hardwood pads measure about 7/8" x 2", offering plenty of

hardened area for mounting the control horns. In the photo below,

we have outlined one of these aileron mounting pads.

a) Starting with one of the wing panels, use a piece of masking

tape to lock its aileron in the neutral position. Install an aileron

servo output arm onto each aileron servo, with the arms both

pointed outboard toward the wing tip. The servo arms should both

9

LEFT

RIGHT

onto the hardwood mounting rails. Remove the servo from the

stab.

2) Pre-drill small guide holes for the servo. Re-install the servo

and mount it in place into stab servo bay. Use a piece of masking

tape to hold the elevator in the neutral position to the stab.

3) Attach a clevis to the servo output arm and on the other end,

attach one of the control horns. Press the servo output arm in

place onto the splined servo output shaft, with its arm pointed

outwards towards the stab tip and at 90

O

to the servo body.

4) Like the ailerons, the two elevator halves have been built with

thick hardwood control horn mounting pad. Holding the bottom of

the elevator at an ob lique angle to a light source usually allows y ou

to see its location.

a) Turn the threaded metal control rod to adjust the distance of the

control horn from the leading edge of the elevator bevel. The

correct position for the elevator control horn is with its forward

mounting pad edge up to the bevel edge of the elevator. The

upright arm of the control horn should be directly facing the output

arm and the control rod should be parallel with the servo body.

Hold the control horn in this position and mark the mounting hole

locations onto the elevator with a marker pen or sharpened pencil.

b) Move the pushrod and control horn out of the way. Use an

electric drill and a .043" (#57 index drill) to drill four guide holes at

the marks just made. Use four T2.6 x 16mm Phillips head screws

to mount the control horn, just enough to establish threads in the

mounting pad. Remove the screws and apply a drop of thin CA

glue with a fine-tipped applicator, into each screw hole to harden

the threads. Remount the control horn with the screws and

tighten them firmly . Repeat the above steps with the opposite stab

and elevator assembly. Remove the pieces of tape holding the

elevator in neutral.

be aligned to the servo at 90

O

and should both be in line and

parallel with each other. Select two of the pre-assembled aileron

linkages. On both pushrods, thread the two lock nuts all the way

in toward each other, leaving the maximum amount of threads

exposed. Connect one of the R/C links to the servo arm on both

servos. In the photos we show the left wing panel, so we selected

two left

control horns. Connect the two control horns to the R/C

links on each pushrod.

b) Place the control horn mounting pad onto the surface of the

aileron. Turn the threaded metal control rod to adjust the distance

of the control horn from the leading edge bevel of the aileron. The

correct position for the control horn on the aileron is with its

forward mounting pad edge up to the bevel edge of the aileron.

The upright arm of the control horn should be directly facing the

output arm and the control rod should be parallel with the servo

body. Hold the control horn in this position and mark the hole

locations onto the aileron with a marker pen or sharpened pencil.

c) Swing the pushrod and horn out of the way. Use an electric drill

and a .043" (#57 index drill) to drill four holes at the marks just

made. Use four T2.6 x 16mm Phillips head screws to mount the

control horn, just enough to establish threads in the mounting pad.

Remove the screws and apply a drop of thin CA glue with a

fine-tipped applicator, into each screw hole to harden the threads.

Remount the control horn with the screws and tighten them firmly.

Repeat this process with the remaining control horn and the

opposite wing panel. Remove the pieces of tape holding the

ailerons in neutral.

7) Use your transmitter and receiver to now test the ailerons.

Make any linkage and/or servo arm adjustments necessary to

achieve smooth, non-binding aileron movement. The pushrod

locking nuts and clevis safety springs do not need to be tightened

or in place until after you have set the final surface movements,

later in this manual.

Elevator Servo Installation:

The elevator servos are mounted into each stabilizer half in much

the same way as the aileron servos were mounted in the wing

panels. Because the left

stabilizer half is shown in the following

instructions, we will mount a left

control horn to the elevator. For

the following steps you will need four T2.6 x 16mm Phillips head

screws and one left and one right heavy-duty control horns. You

will also need two of the #4-40 pushrod and clevis assemblies. You

will need your two elevator servos, with the rubber grommets and

eyelets installed, and the mounting screws that came with the

radio system.

1) Feed the servo lead through the servo bay opening and out of

the root rib. Position the servo into the servo bay with its output

arm spline forward toward the leading edge of the stab. Hold the

servo in this position and mark the four mounting screw locations

10

this process with the remaining wheel and wheel pant. Once you

are satisfied, remove the M3 x 15mm pant mounting bolts and the

wheel pants. Then remove the axle assemblies - with the wheels

and collars still in place - from the landing gear.

d) With the wheels and collars now in the correct positions on their

axles, you now want to file or grind small "flats" onto each axle

for the wheel collar setscrews. Loosen and remove one of the

outer wheel collars. Use a marker pen to mark the axle at the

approximate location of the setscrew. Use a file or a Dremel

®

Tool

with a carbide cut-off wheel to now create a small "flat" in the

surface of the axle. Remember, you want the setscrew pointing

straight down. Repeat this process on the remaining wheel axle.

Slide the wheel back in place on the axle and slide the wheel

collar back in place. Use a screwdriver to lightly tighten the

setscrew over the "flat". You will be able to feel this "flat" by

rotating the collar a bit. If the flat is insufficient, remove the collar

and adjust it a bit with a file. Repeat this on the remaining wheel

axle.

With the two outer wheel collars now located and lightly tightened

in place against the outer wheel hubs, loosen the setscrew on one

of the inner wheel collars and slide it back to the hex fitting. Use a

small file to create a "flat" on the axle, at the setscrew position.

Check the "flat" positioning by sliding the collar back in place and

lightly tightening the setscrew. Adjust the "flat" until the collar can

be positioned correctly. Repeat this process on the remaining

wheel axle and inner wheel collar.

Working with one wheel collar at time, remove the setscrew, coat

the threads with thread locking compound and reinstall it into the

collar. Use a screwdriver to now firmly tighten it to the axle, over

its axle "flat". Repeat this process with the remaining wheel collars

and setscrews.

e) Remount both wheel/axle assemblies to the main landing gear.

As before, use a couple of wrenches to firmly and permanently

install the 5/16-24 axle lock nuts in place. Coat the threads on the

four M3 x 15mm PWA pant mounting bolts with thread locking

compound. Position a wheel pant of the over its wheel, and

against the landing gear, and bolt it firmly in place. Mount and

secure the remaining wheel pant.

f) The completed landing gear and wheel pant assembly can now

be mounted to the bottom of the fuselage, using four M4 x 20mm

PWA bolts and four 4mm split ring washers. Again, we suggest

using thread-locking compound on the bolt threads before

installation. Tighten each bolt securely.

5) Use your transmitter and receiver to now check and adjust the

proper movement of the elevator halves. The pushrod clevis

locking nuts and clevis safety springs do not need to be tightened

or slipped into place until after the final control movements are

established later in this manual.

Landing Gear & Wheel Pant Assembly:

From the kit contents locate the Fiberglass Wheel Pants bag, the

Main Wheel bag (also contains wheel and pant hardware bag) and

the Main Landing Gear bag. In addition you will need to remove

the two pieces of tape holding the Main Landing Gear Hatch in

place to the bottom front of the fuselage. Taped to the Inside of this

hatch you will find a small bag containing two (2) T3 x 16mm Hatch

Mounting Screws. Also note that in side view there is a front

and

rear edge to the main landing gear. In side view the leading edge

(or front) is straight and the trailing edge (or rear) is slightly angled.

Be sure to mount the wheel pants to the landing gear in this

alignment.

a) Temporarily mount the wheel/axle assemblies to the landing

gear legs. Insert the threaded end of the axle through the hole in

the landing gear leg and thread the 5/16-24 lock nut in place. Use

an open-end 7/16" wrench at the outer axle hex nut fitting and an

adjustable wrench or a 1/2" socket wrench to snug the lock nut in

place - do not permanently mount it yet. Note that the outer axle

hex flange has to be aligned vertically to the landing gear legs to

provide mounting clearance for the wheel pant slot, including the

alignment of the two pant mounting bolts. Use the wrenches to

make this alignment and check it by placing the correct wheel pant

in place against the landing gear.

b) Slide one of the 5mm wheel collars in place onto each axle.

Rotate the collar to position the setscrew pointing straight down

and about 1/4" away from the axle hex fitting. Use a Phillips head

screwdriver to lightly tighten the setscrews in this position. Slide a

main wheel onto each axle, against the wheel collar. Slide the

outer wheel collars in place, just loosely against the wheel hub with

the setscrew point straight down. Use a screwdriver to lightly

tighten the setscrews to hold the collar in place. Now position the

appropriate wheel pant in place over the wheel and up against the

landing gear. Insert one of the M3 x 15mm mounting bolts through

the inside face of the landing gear, into the wheel pant bolt hole to

engage the blind mounting nut threads. Use as screwdriver to run

the bolt all the way into the pant but do not tighten the bolt yet.

Install the remaining bolt in the same way. Repeat this process

with the remaining wheel pant.

c) View the relationship of the wheel to the wheel opening in each

wheel pant. What you want is the wheel approximately centered

within this opening. Use a screwdriver to adjust the two wheel

collars as needed to provide the correct centering of the wheel.

Re-tighten the collar setscrews to hold them in place and repeat

11

Measure forward 7/8" from the tip of the fin hinge line, mark this

location on the centerline. This point is the location for the

rearmost T3 x 16mm PWA tail wheel assembly mounting screw.

Use an electric drill and a 1/16" dia. bit to drill a perpendicular

guide hole through the fuselage bottom at this point.

b) Using the shortest leaf spring, place it onto the fuselage with its

rearmost screw hole over the drilled guide hole. Use one of the

T3 x 16mm screws and a Phillips screwdriver to install the screw

into the hole - just "snug" it in place. Line-up the forward screw

hole in the spring with the centerline drawn on the tape. Again

use an electric drill and a 1/16" dia. bit to make a guide hole

through the fuselage bottom, centered in the hole. Install another

T3 x 16mm screw in place. Repeat this process with the

remaining center hole in the spring. Remove all three screws, the

spring and the tape. As always, we suggest using a drop or two of

thin CA glue into each of the screw holes to harden the threads.

c) The complete tail wheel leaf spring assembly can now be

mounted to the fuselage using the three T3 x 16mm screws. The

shortest spring on top, the medium length spring in the middle and

the longest spring on the bottom. Tighten the three mounting

screws securely.

d) The flat metal "T" bracket is now mounted to the bottom forward

surface of the rudder. This bracket is used to connect the two

centering springs with the tail wheel tiller arm and the rudder. As

12

g) The Landing Gear Hatch Cover is now installed over the

mounted landing gear using two T3 x 16mm PWA screws. Note

that both the access and clearance holes are already provided in

this hatch for the mounting screws. Likewise, the landing gear also

has corresponding clearance holes for the two mounting screws.

With a 1/16" dia. bit and a hand drill, drill two holes through the

plywood landing gear base, at the centers of the clearance holes

in the landing gear. The landing gear hatch can now be mounted

in place.

Mounting The T ail Wheel:

From the kit contents, locate the Tail Wheel Assembly bag. Note

that the both the fuselage and the bottom forward surface of the

rudder have built-in plywood hard points for mounting this

assembly.

a) Use a 5" length of masking tape, centered over the bottom rear

of the fuselage, in place from the pointed tip of the fin hinge line

forward. Use a fine tip marker to now measure the width of the

fuselage at the forward most end of the tape. Divide this number

in two to find the center of the fuselage at this point and mark it on

the tape. With a small straight edge, draw a line on the tape from

the center mark just made, back to the tip of the fin hinge line.

13

The firewall on the Edge 540T ARF has been factory-built with 2

O

of right thrust. The firewall has also been accurately marked with

vertical and horizontal centerlines. These two lines, at their

intersection, represent the centered position of the engine when it

is mounted to the firewall, taking into account the built-in 2

O

of right

thrust and the 7-7/32" distance to the cowl's spinner ring opening.

Using the vertical and horizontal centerlines, you can now

accurately measure the motor mount plate location against the

firewall and its bolt hole mounting locations. If required, you must

also now make the firewall mounting spacers for your particular

engine, to move it f orward enough to clear the co wl b y 1/8" to 3/16"

when the spinner backplate is in place on the engine.

When the mounting bolt hole locations have been accurately

marked on the face of the firewall, use an electric drill and the

appropriate bit to make the required clearance holes for the bolts.

As also mentioned earlier, you will need to provide your own

mounting hardware. We used four #10-32 x 1-1/2" hardened steel

hex head bolts with #10-32 lock nuts and flat washers to mount our

F.P.E.6.8 engine. The engine and spacers can now be mounted in

place to the firewall. Check the cowl fit by sliding it in place over

the engine (with the mufflers removed) and onto the front of the

fuselage. Make any adjustments necessary.

Mounting The Ignition Module:

We mounted the electronic ignition module for our F.P.E. 6.8

engine to a simple lite-ply tray that was made from scrap 1/8" liteply, sized for our specific module. We glued a couple of pieces of

1/4" sq. balsa on each end of the tray to keep the module from

shifting and then glued two more pieces of 1/4" sq. balsa to the

opposite side of the tray to stand it off from the back face of the

firewall. We cut a piece of 1/4" foam rubber to fit between the tray

and the module. The module was then secured to the tray with a

pair of cable ties.

We used epoxy glue to then glue the module tray to the back face

of the firewall, directly behind the engine. In our F.P.E. 6.8

installation, this module mount location was perfect for routing the

shown, center the bracket onto the bottom of the rudder, with the

left and right arms spaced equally on each side. Mark the

locations of the two mounting holes onto the rudder with a

marking pen. Use a .042" dia. bit (#58 index drill) to drill two screw

guide holes at the marks just made. Mount the bracket in place

with the two T2 x 12mm PWA screws.

Mounting The Engine:

As mentioned earlier in this manual, the distance between the

firewall and the outside surface of the cowl, at the spinner location

is 7-7/32". As also mentioned, this distance is adjustable aft about

1/8" or can be moved forward as much as a 1/2" or so. Therefore,

you need to now measure the length of the engine that you plan to

install in your Edge. The measurement you need is the overall

length of the engine, from the back surface of the mounting plate

forward to the back surface of the spinner backplate when it's in

place. This measurement will tell you how far forward your

particular engine needs to be spaced from the firewall to fit within

the cowl, leaving about 1/8" - 3/16" clearance between the back

surface of the spinner backplate and the cowl itself.

For example, to mount our F.P.E. 6.8 twin cylinder engine in place

with the correct relationship to the firewall and the spinner

backplate, we needed to space it's mount 1/4" forward from the

firewall. We did this by using 1/4" plywood to make four 1"

diameter disks. These four disks were then center-drilled with a

.193" dia.bit (#10 index drill) to provide clearance holes for the f our

#10-32 mounting bolts. The photo shows the firewall, spacers, and

the bolts already in place.

MODELER’S TIP: The connection between the two centering springs

and the "T" bracket on the bottom of the rudder can be made using

two small cable ties. Doing this allows easy and accurate centering

of the tail wheel to the rudder and also avoids metal-to-metal contact

between the spring ends and the "T" bracket. The only requirement

needed to do this is to drill oversize holes in the "T" bracket arms to

allow clearance for the cable ties. We used a 7/64" drill bit to drill out

these two holes in the bracket. The centering springs are each

attached to the tail wheel tiller arms as usual. The opposite ends of

each spring were bent with round-nose pliers to create a couple of

small loops in the wire. The connection between the springs and "T"

bracket arms were then made with 4" cable ties at each spring.

front edge of the fuselage side, at each of these marks. At the

bottom line, measure back 1/2" from the front edge of the tape and

make a mark. On the top line, again measure back 1/2" and make

a mark. Use a straightedge to connect these two marks with short