Page 1

SB555

Development Kit

Hardware Integration

Guide

Proprietary and Confidential

2130075

Rev 1.0

Page 2

Page 3

Preface

Important

Notice

Safety and

Hazards

Because of the nature of wireless communications, transmission and reception of data can

never be guaranteed. Data may be delayed,

corrupted (i.e., have errors) or be totally lost.

Although significant delays or losses of data are

rare when wireless devices such as the Sierra

Wireless modem are used in a normal manner

with a well-constructed network, the Sierra

Wireless modem should not be used in situations

where failure to transmit or receive data could

result in damage of any kind to the user or any

other party, including but not limited to personal

injury, death, or loss of property. Sierra

Wireless, Inc., accepts no responsibility for

damages of any kind resulting from delays or

errors in data transmitted or received using the

Sierra Wireless modem, or for failure of the

Sierra Wireless modem to transmit or receive

such data.

Do not operate the Sierra Wireless modem in

areas where blasting is in progress, where

explosive atmospheres may be present, near

medical equipment, near life support equipment,

or any equipment which may be susceptible to

any form of radio interference. In such areas, the

Sierra Wireless modem MUST BE POWERED

OFF. The Sierra Wireless modem can transmit

signals that could interfere with this equipment.

Do not operate the Sierra Wireless modem in any

aircraft, whether the aircraft is on the ground or

in flight. In aircraft, the Sierra Wireless modem

MUST BE POWERED OFF. When operating,

the Sierra Wireless modem can transmit signals

that could interfere with various onboard

systems.

Rev 1.0 Apr.02 Proprietary and Confidential 1

Page 4

SB555 Hardware Integration Guide

The driver or operator of any vehicle should not

operate the Sierra Wireless modem while in

control of a vehicle. Doing so will detract from

the driver or operator's control and operation of

that vehicle. In some states and provinces,

operating such communications devices while in

control of a vehicle is an offence.

Note: Some airlines may permit the use of cellular

phones while the aircraft is on the ground and the

door is open. Sierra Wireless modems may be

used at this time.

Limitation of

Liability

The information in this manual is subject to

change without notice and does not represent a

commitment on the part of Sierra Wireless, Inc.

SIERRA WIRELESS, INC. SPECIFICALLY

DISCLAIMS LIABILITY FOR ANY AND ALL

DIRECT, INDIRECT, SPECIAL, GENERAL,

INCIDENTAL, CONSEQUENTIAL, PUNITIVE

OR EXEMPLARY DAMAGES INCLUDING,

BUT NOT LIMITED TO, LOSS OF PROFITS OR

REVENUE OR ANTICIPATED PROFITS OR

REVENUE ARISING OUT OF THE USE OR

INABILITY TO USE ANY SIERRA WIRELESS,

INC. PRODUCT, EVEN IF SIERRA WIRELESS,

INC. HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES OR THEY ARE

FORESEEABLE OR FOR CLAIMS BY ANY

THIRD PARTY.

2 Proprietary and Confidential 2130075

Page 5

Preface

Patents Portions of this product are covered by some or

all of the following US patents:

5,515,013 5,617,106 5,629,960 5,682,602

5,748,449 5,845,216 5,847,553 5,878,234

5,890,057 5,929,815 6,169,884 6,191,741

6,199,168 6,327,154 6,339,405 D367,062

D372,248 D372,701 D416,857 D442,170

D452,495 D452,496 and other patents pending.

This product includes

technology licensed from:

Copyright ©2002 Sierra Wireless, Inc. All rights reserved.

Printed in Canada.

Tr a d e m a r k s

Rev 1.0 Apr.02 Proprietary and Confidential 3

“Heart of the Wireless Machine” is a registered

trademark of Sierra Wireless, Inc.

Sierra Wireless, the Sierra Wireless logo, the red

wave design, and Watcher are trademarks of

Sierra Wireless, Inc.

®

Windows

Corporation.

Qualcomm

Qualcomm Incorporated.

Other trademarks are the property of the

respective owners.

is a registered trademark of Microsoft

®

is a registered trademark of

Page 6

SB555 Hardware Integration Guide

Contact Information

Sales Desk: Phone: 1-604-232-1488

Technical Support: Included with the purchase of the SB555

Post: Sierra Wireless, Inc.

Fax: 1-604-231-1109

Web: www.sierrawireless.com

Hours: 8:00 AM to 5:00 PM Pacific Time

e-mail: sales@sierrawireless.com

Development Kit you receive five hours of tier 3

engineering integration support. You will have

received instructions by e-mail on how to access the

OEM Customer Support web site. For more details,

please contact your account manager, or the Sierra

Wireless sales desk.

13811 Wireless Way,

Richmond, BC

Canada V6V 3A4

Your comments and suggestions on improving

this documentation are welcome and appreciated. Please e-mail your feedback to

documentation@sierrawireless.com. Thank you.

Consult our website for up-to-date product

descriptions, documentation, application notes,

firmware upgrades, troubleshooting tips, and

press releases:

www.sierrawireless.com

4 Proprietary and Confidential 2130075

Page 7

Table of Contents

About this Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Document structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Terminology and acronyms . . . . . . . . . . . . . . . . . . . . . . . . 13

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mechanical Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Physical dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mounting the module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Module weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Module shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Module connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Host interface connector . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Location of pin 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Antenna connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Assembly sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Environmental issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Thermal dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Shock and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Dust, dirt, and moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rev 1.0 Apr.02 Proprietary and Confidential 5

Page 8

Hardware Integration Guide

Electrical Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Modem specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Location of pin 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

General requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Unused pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Preventing back-power when the modem is off . . . . . . . . 27

Voltage regulation and buffering . . . . . . . . . . . . . . . . . . . . 28

Electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Sample power integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

MOSFET power switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Pins 1 and 2: Modem VCC . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Power regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Pins 3, 4, 25, 30: Ground connection . . . . . . . . . . . . . . . . . 33

Requirements of the power interface. . . . . . . . . . . . . . . . . . . . 34

Module shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Power ramp-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Power-up timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Trace widths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6 Proprietary and Confidential 2130075

Page 9

Contents

Serial Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Serial port specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 37

External pullup and pulldown resistors . . . . . . . . . . . . . . 38

ESD protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Primary port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pin 21: /DCD1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Pin 22: RxD1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Pin 23: TxD1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Pin 24: /DTR1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Pin 25: GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pin 26: /DSR1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pin 27: /RTS1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pin 28: /CTS1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Pin 29: /RI1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Pin 30: GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Port configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Primary port sample integrations . . . . . . . . . . . . . . . . . . . 45

Sample 1: Internal host integration . . . . . . . . . . . . . . . . . 46

Sample 2: External serial connector. . . . . . . . . . . . . . . . . 47

Sample 3: Minimum integration . . . . . . . . . . . . . . . . . . . . 49

Secondary port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pin 17: /CTS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Pin 18: /RTS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Pin 19: TxD2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Pin 20: RxD2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Pin 25: GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Rev 1.0 Apr.02 Proprietary and Confidential 7

Page 10

Hardware Integration Guide

Port configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Secondary port sample integration . . . . . . . . . . . . . . . . . . 54

Minimum integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Voice Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Introduction to voice features . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Audio block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

ESD protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Headset integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Headset interface specifications . . . . . . . . . . . . . . . . . . . . 60

Microphone input (headset) . . . . . . . . . . . . . . . . . . . . . . . . 62

Speaker output (headset) . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Sample headset integration . . . . . . . . . . . . . . . . . . . . . . . . 62

Line level voice integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Microphone input (line level) . . . . . . . . . . . . . . . . . . . . . . . 65

Speaker output (line level). . . . . . . . . . . . . . . . . . . . . . . . . . 65

Control Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Control interface specifications . . . . . . . . . . . . . . . . . . . . . 67

External pullup and pulldown resistors . . . . . . . . . . . . . . . 68

ESD protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Status indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Human interface (LEDs) . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Sample LED status interface . . . . . . . . . . . . . . . . . . . . . . . . 70

8 Proprietary and Confidential 2130075

Page 11

Contents

Machine interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Sample machine interface to status outputs . . . . . . . . . 72

Shutdown and reset control. . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Pin 37: /Shdn_Ack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Pin 38: /ShutDown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Pin 39: /Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Sample shutdown interface integration . . . . . . . . . . . . . 76

Shutdown sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Shutdown timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

RF Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

RF connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Connector considerations . . . . . . . . . . . . . . . . . . . . . . . . . 80

Ground plane isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

ESD protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Antenna and cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Matching antenna and cable. . . . . . . . . . . . . . . . . . . . . . . 83

Antenna options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Interference and sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Power supply noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Device generated RF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Modem generated RF switching noise . . . . . . . . . . . . . . 87

Rev 1.0 Apr.02 Proprietary and Confidential 9

Page 12

Hardware Integration Guide

Appendix A:

Host Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Appendix B:Sample Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Appendix C:

Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Charge creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Damage from ESD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Types of damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Exposed interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Protection from ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

TVS diodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

PCB design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

ESD integration considerations . . . . . . . . . . . . . . . . . . . . . . . 101

Return ground path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Selection guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10 Proprietary and Confidential 2130075

Page 13

1: About this Guide

• Introduction

• Document

structure

• References

• Conventions

Introduction

This guide is one component of the SB555 Development Kit. It covers the integration of the

product from the hardware point of view. Other

guides in the kit cover project planning, software

integration, and product verification and configuration.

For details on the features of the SB555

embedded modem, please consult the SB555

Embedded Modem Product Specification

(document #2130072).

To aid you in making decisions on what aspects

of the modem require integration in your project,

and to determine what hardware is required to

support particular features, please consult the

SB555 Development Kit Design Guide

(document #2130179). This hardware guide

covers the details of integrating each interface

but does not discuss the reasons to include or

exclude any particular element.

Where configurable features are mentioned, the

method of configuring or calibrating can be

found in the Verification and Configuration

Guide (document #2130078).

1

Rev 1.0 Apr.02 Proprietary and Confidential 11

Page 14

SB555 Hardware Integration Guide

Document structure

This document covers hardware integration

issues in these main categories:

• Mechanical Integration

· Mounting

· Connectors

· Environmental Issues

• Electrical Integration

· General Specifications

· General Considerations

· Power Supply

· Electrostatic Discharge (ESD)

• Serial Interface

· Primary Port (Serial 1) - Data

· Secondary Port (Serial 2) - Control

• Voi ce Interf ace

· Analog Voice

• Control Signals

· Status Signals

· Shutdown Control

· Reset

• RF integration

· RF Connections

· Antenna and Cabling

· Interference and Sensitivity

• Appendix A—Pinouts

• Appendix B—Sample Integration, a typical

MCU integration block diagram

• Appendix C—Electrostatic Discharge (ESD)

12 Proprietary and Confidential 2130075

Page 15

About This Guide

References

This guide covers only the hardware integration

of the SB555 modem. It does not deal with

specifics of product modem operation or use of

the optional Embedded Modem Interface Kit.

Please consult the other documents provided

with the Development Kit or the Interface Kit

User Guide for additional information on operations.

You may also want to consult other documents

available on our Internet site at

www.sierrawireless.com.

Terminology and acronyms

This document makes wide use of acronyms that

are in common use in data communications and

cellular/PCS technology. Our Internet site

provides a Glossary (document 2110032) that

may be helpful in understanding some acronyms

and terminology used in this guide.

Conventions

Numerics Numeric values are generally

presented in decimal but may also be expressed

in hexadecimal or binary. Hexadecimal values

are shown with a prefix of 0x, i.e. in the form

0x3D. Binary values are shown with a prefix of

0b, i.e. in the form 0b00111101. Otherwise,

values are presumed decimal.

Rev 1.0 Apr.02 Proprietary and Confidential 13

Page 16

SB555 Hardware Integration Guide

Units Units of measure are given in metric.

Where measure is provided in imperial units,

they are shown in parenthesis after the metric

units.

Signal Names When signals are discussed by

their function, the functional name is used in

standard font (i.e. Reset, Shutdown

Acknowledge). When the pin, wire, or trace

carrying the signal is referenced, it will use the

proper name in an alternate font:

/Reset

/Shdn_Ack

Signals that are active low are named with a

prefix slash “/” as shown in the sample above.

Signal names without the slash are active high.

Fonts Command and register syntax is noted

using an alternate font:

AT~AUDMOD=1

Responses from the modem, or host system

software prompts, are shown in this font:

CONNECT 14400

Character codes which are described with words

or standard abbreviations are shown within

angle brackets: such as

<space> for a blank space character.

and

<CR> for Carriage Return

14 Proprietary and Confidential 2130075

Page 17

2:

Mechanical Integration

• Introduction

• Physical

dimensions

• Mounting

• Connectors

• Assembly

sequence

• Environmental

issues

Introduction

The SB555 CDMA2000 1X embedded modem

form factor is the proprietary Sierra Wireless

embedded module package. Physical dimensions, mounting holes, and connectors are

identical to other upcoming Sierra Wireless

embedded modem products.

This chapter covers the integration issues

surrounding:

• Mounting

• Connector fit

• Assembly sequence

• Environmental issues

2

Rev 1.0 Apr.02 Proprietary and Confidential 15

Page 18

SB555 Hardware Integration Guide

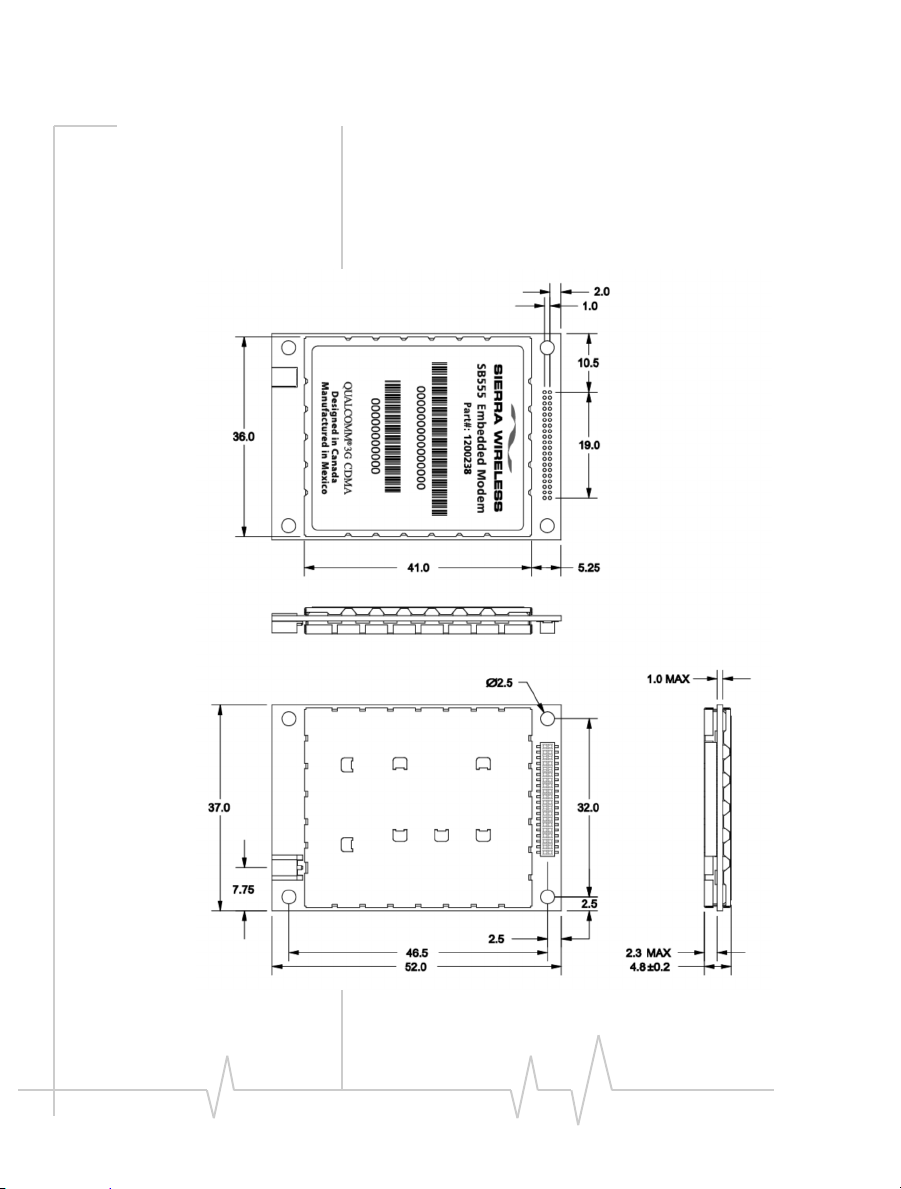

Physical dimensions

The SB555 comes in the Sierra Wireless proprietary standard module package. Dimensions in

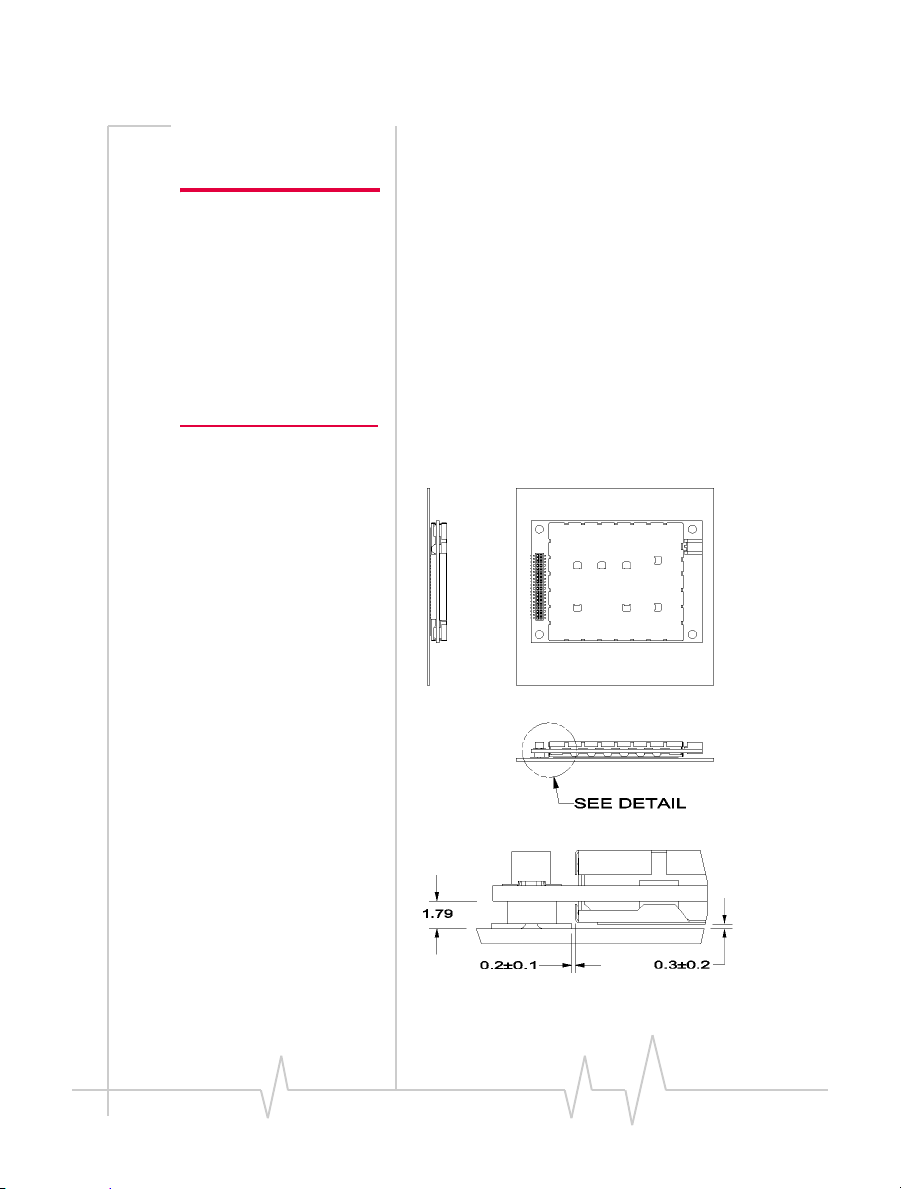

millimeters are shown in the figure below.

Figure 2-1: Module dimensions (in mm)

16 Proprietary and Confidential 2130075

Page 19

Mechanical Integration

Mounting the module

Note: The integration

should include standoffs

of some kind to protect

the modem shields from

being crushed during

assembly and from

coming into contact with

circuitry on the host

device.

Sierra Wireless embedded modules have four (4)

mounting holes of 2.5 mm (0.984”) diameter, one

located at each corner of the module (as seen in

Figure 2-1). The mounting holes are sized to

accommodate a metric M2 (#2 screw).

The 40-pin host connector allows for either

bottom or top entry, to permit mounting in any

orientation. Sierra Wireless does not provide

mounting hardware.

The sample illustration does not show standoffs.

Figure 2-2: Sample bottom entry mounting (mm)

Rev 1.0 Apr.02 Proprietary and Confidential 17

Page 20

SB555 Hardware Integration Guide

Module weight

The module has a total weight under 14

grams (0.49 ounces). Typical weight is 13.5

grams (0.48 ounces).

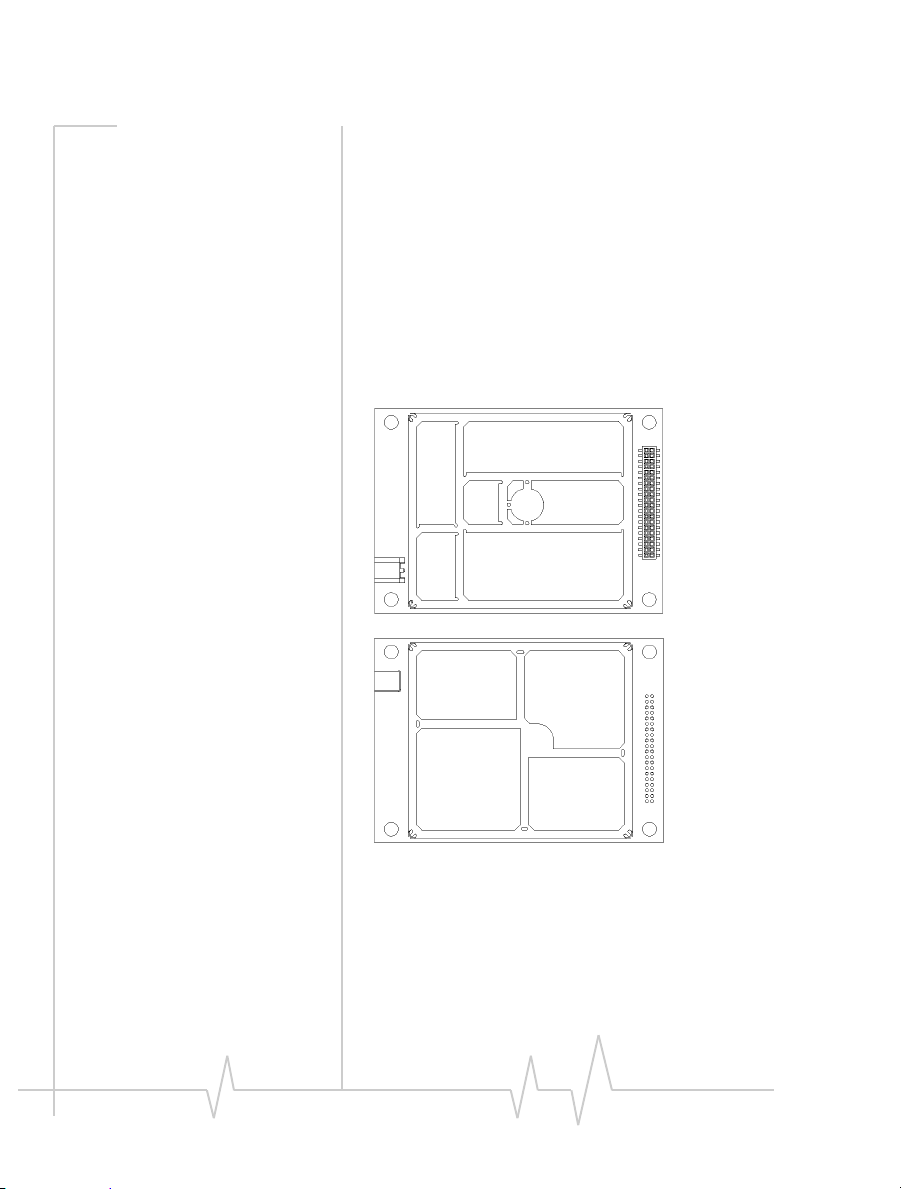

Module shields

The SB555 comes with shields on both top and

bottom. These shields are attached to a fence

surrounding the circuitry.

Figure 2-3: Shield fence frame

The internal webbing of the fence frame may be

removed in some units to permit factory rework.

This webbing is used for automated pick-and-

18 Proprietary and Confidential 2130075

Page 21

Mechanical Integration

place only. The product has been fully qualified

mechanically and electrically with and without

the webbing.

Module connectors

There are two connectors: a 40-pin header for the

host interface, and an MMCX connector for the

antenna. Both are mounted offset from the

module centerline to prevent assembly orientation errors.

Host interface connector

The host connector is a 40-pin, 1 mm pitch,

2-row, female header (Samtec part #CLM-120-02F-n-BE with bottom entry option). This host

connector is capable of accepting either a top or

bottom entry mating header connector.

Suitable mating connectors are:

• Samtec (

FTMH series

• Major League Electronics

(

www.majorleagueelectronics.com) BSTCM-7

series

The recommended exposed pin length is:

• 1.4 mm (0.055”) for top entry

• 3.2 mm (0.125”) for bottom entry

The connector is not keyed. The connector is

offset from the module centerline to prevent

assembly orientation errors.

www.samtec.com) MW, FTM or

Rev 1.0 Apr.02 Proprietary and Confidential 19

Page 22

SB555 Hardware Integration Guide

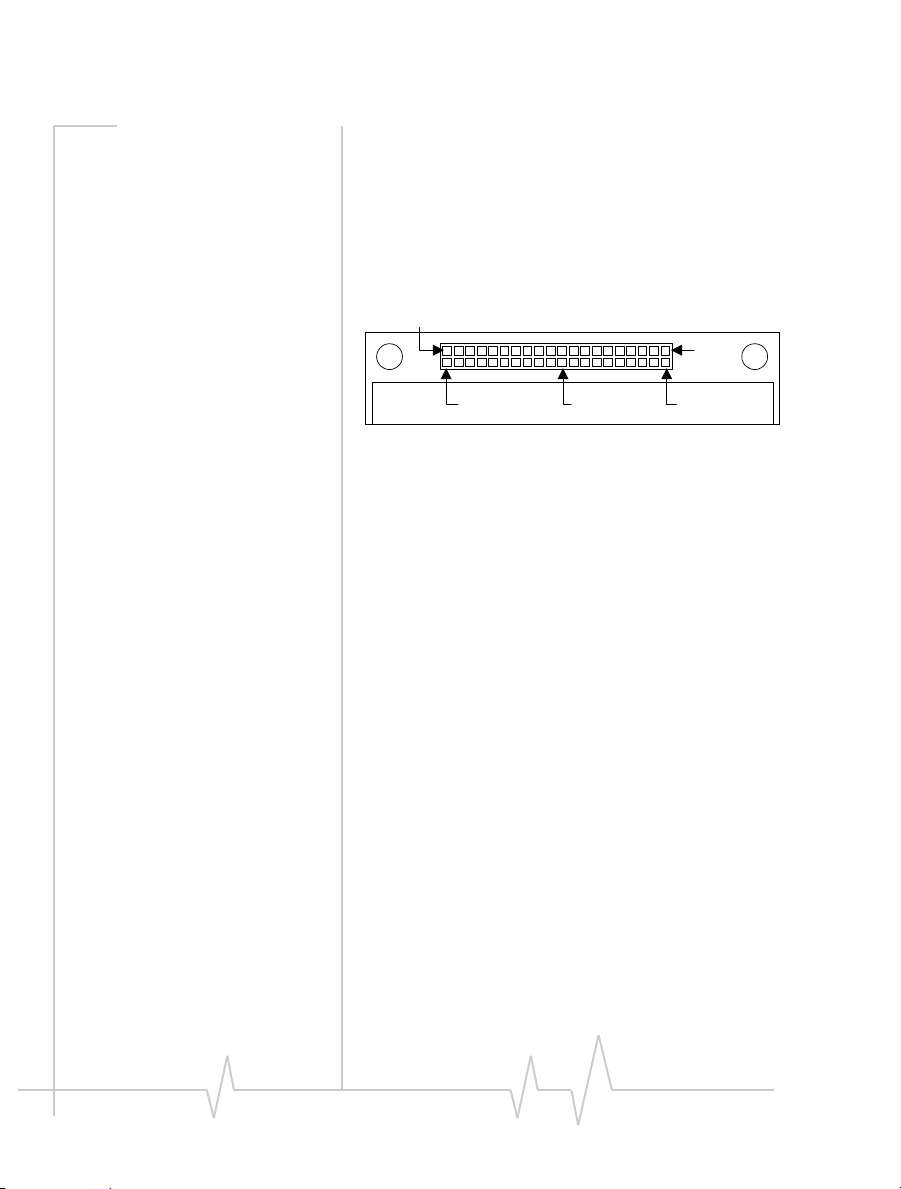

Location of pin 1

Pin 1 of the host connector is shown in

Figure 2-4. When viewing the module with the

connector facing up and the RF connector at the

bottom, pin 1 is on the extreme right of the inside

edge (lower row).

Pin 40

Pin 2

Pin 19Pin 39

Figure 2-4: Host connector pin locations

Pin 1

Antenna connector

The antenna connector is an MMCX female jack

oriented in line with the module longitudinal

axis. Mating plugs can be either straight or rightangle.

The detent on the connector is quite stiff to

ensure the connection remains intact through

vibration and shock. The connector is designed

for 500 connection cycles, which may not be

sufficient for some end-user applications. For

this reason, and to allow for ESD protection, the

modem’s MMCX connector should not be

presented directly to the user for antenna

attachment.

The integration can include a host system built-in

antenna—without presenting a connector to the

user—or any of a variety of RF connector types

(SMA, SMB, TNC, etc.) as suits the application.

See “Ground plane isolation” on page 81 for

additional information on insulating the RF

connector ground.

20 Proprietary and Confidential 2130075

Page 23

Mechanical Integration

For mechanical integration, use a flexible 50 Ω

coaxial cable to allow attachment of the MMCX

connector to the modem either before or after

mounting the module on the host device.

Assembly sequence

Due to the strong detent in the MMCX antenna

connector, Sierra Wireless recommends that you

connect the antenna cable to the modem before

connecting the modem’s 40-pin connector to the

host device. This will avoid stress on the host

connector. Your situation may vary; this is only

a recommendation. Where host mounting is

performed prior to antenna cable attachment, the

module should be secured, with screws and

standoffs, to the host device.

Use suitable standoffs with screws or other

mounts to hold the module securely in place,

while preventing the modem’s shield from

grounding to the host device.

Environmental issues

The SB555 embedded modem conforms to the

specifications listed in Table 2-1 on the following

page. Enhanced specifications may be achieved

through appropriate mounting.

Rev 1.0 Apr.02 Proprietary and Confidential 21

Page 24

SB555 Hardware Integration Guide

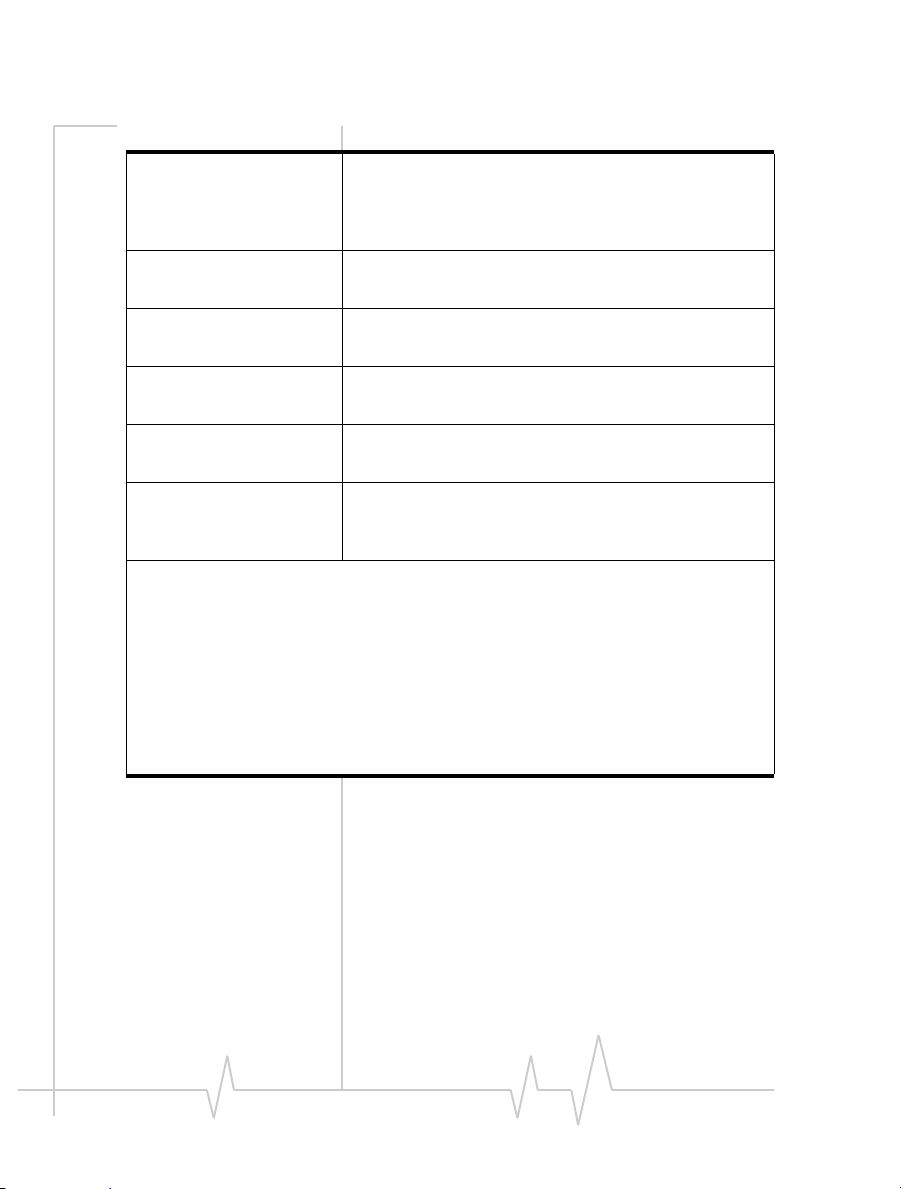

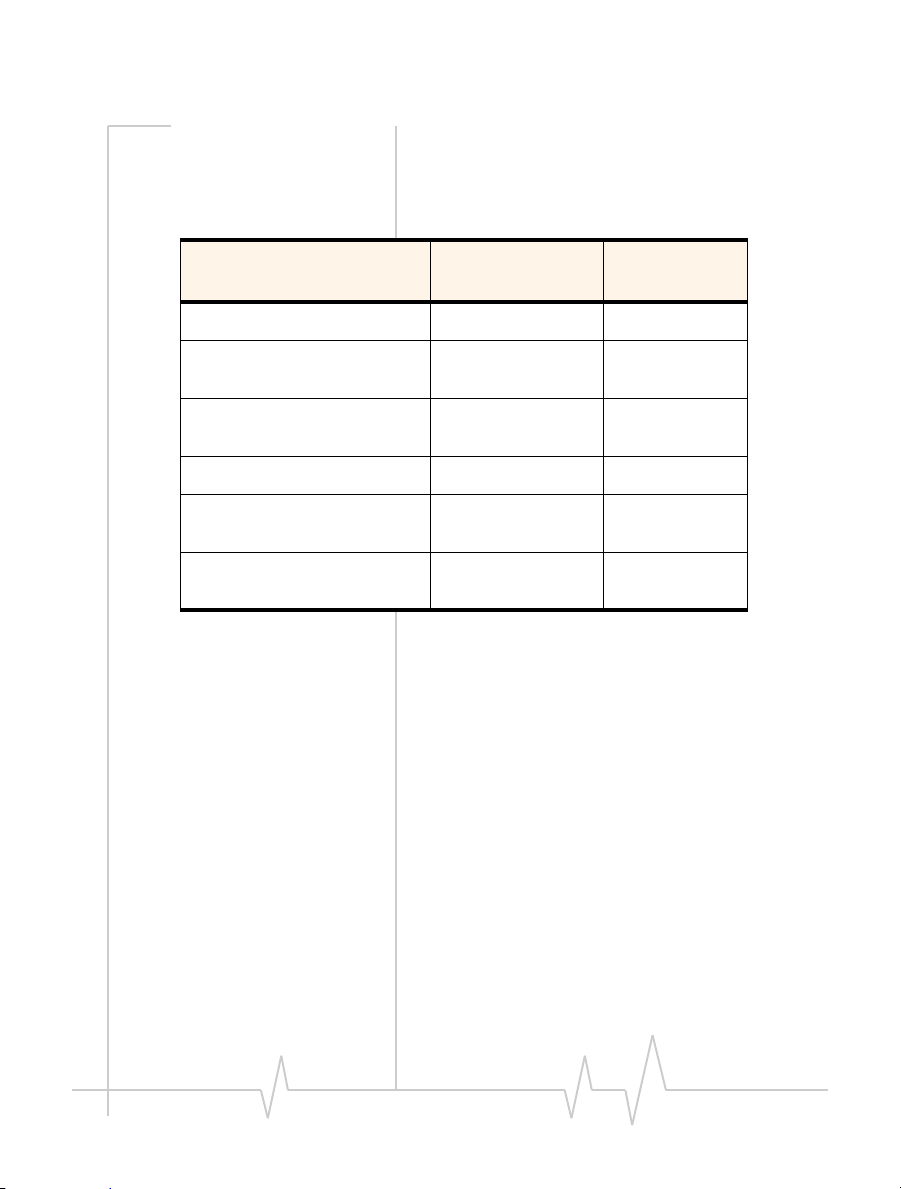

Table 2-1: Environmental specifications

Temperature range Operating: -30 to +60°C (-22 to +140°F)

(modem ambient*)

Storage: -40 to +85

°C (-40 to +185°F)

Humidity MIL-STD-202F

95% non-condensing @ 65

Vibration

(random)**

Vibration

(sine wave)**

MIL-STD-810E

0.04 g2/Hz, 10 – 2000 Hz

PC Card Standard

15 g (147 m/s

Shock** MIL-STD-202F

50 g (490 m/s

Drop**

(unpackaged)

PC Card Standard

0.75 meter drop onto non-cushioned vinyl

2

), 10 – 2000 Hz

2

), 11 ms, 6 pulses/axis

°C (149°F)

(2 drops on each axis, 6 drops total)

* Modem ambient means in the immediate area of the modem, not the ambient

temperature around the finished device. This is typically a temperature inside

your device.

A thermistor inside the modem (monitored by the modem CPU firmware)

causes flow control to be activated should the internal temperature reach

75ºC (167ºF) as measured at the radio. Flow control is released when the

temperature falls below 75ºC. Should the temperature of the radio reach

80ºC (176ºF), the modem terminates the connection in order to protect components and avoid drifting outside radio specifications.

** Vibration, shock, and drop tests are performed for survivability. The modem is

not in operation during the test. Cosmetic damage is ignored.

Thermal dissipation

Determination of thermal dissipation depends

heavily on the usage model of the modem. The

SB555 modem generates more heat when actively

transmitting. However the transmitter is not on

at all times, nor is the transmit power constant.

22 Proprietary and Confidential 2130075

Page 25

Table 2-2 provides a guideline of the energy to be

dissipated when the modem is in various states

of activity.

Table 2-2: Energy dissipation (typical)

Mechanical Integration

Mode Current

consumption

Shutdown 3.3 V @ 0.7 mA 2.3 mW

Slotted sleep (SCI = 2)

(DTR deasserted)

Slotted sleep (SCI = 2)

(DTR asserted)

Receive 3.3 V @ 160 mA 528 mW

Transmit

(typical at +3 dBm)

Transmit (worst case)

(full power +23.5 dBm)

3.3 V @ 5 mA 16.5 mW

3.3 V @ 40 mA 132 mW

3.3 V @ 370 mA 1219 mW

4.2 V @ 900 mA 3376 mW

Energy to

dissipate

Transmit cases are usually short duration bursts.

Electrostatic discharge

This is treated as an electrical integration issue.

The SB555 does not provide a specified level of

protection from electrostatic discharge (ESD).

Exposed interfaces should be protected by your

circuitry design. Details are covered in Chapter

3:Electrical Integration.

Consult “Electrostatic Discharge” on page 95 for

a general discussion of ESD.

Rev 1.0 Apr.02 Proprietary and Confidential 23

Page 26

SB555 Hardware Integration Guide

Shock and vibration

The specifications provided on shock and

vibration are for the module free of integration

hardware.

A person rolling off a bed onto the floor is likely

to emerge without injury; whereas one with a fire

hydrant strapped to his back may not. Once

integrated into your device, the surrounding

hardware can have a significant impact on the

modem’s survivability.

Through the mounting and integration decisions

you make, your design will need to meet your

own product’s survivability specifications.

Dust, dirt, and moisture

The shields are not intended to provide the

modem with protection from dust, dirt, or

moisture. Your integration should provide

reasonable insulation from these environmental

factors as needed to meet your product’s specificatons.

24 Proprietary and Confidential 2130075

Page 27

3: Electrical Integration

• Introduction

• Specifications

• General

requirements

• Power supply

• Electrostatic

discharge

Introduction

This chapter covers the integration requirements

and issues related to the general electrical

connection of the SB555 modem, and the power

supply in particular. RF issues are covered in

Chapter 7:RF Integration on page 79.

The SB555 embedded modem presents all

electrical interfaces on the single 40-pin host

connector. This chapter covers:

• The connector and the general electrical

characteristics of the modem

• Power supply considerations

• Electrostatic Discharge (ESD) protection

The elements of integrating each of the modem

interfaces (serial, voice, and control signals) are

covered in subsequent chapters.

3

Modem specifications

The SB555 embedded modem provides a single

40-pin (2x20) header. The connector pinouts are

specified in Appendix A:Host Connector Pinouts

on page 89.

All signals are 3.0 V, HCMOS logic compatible.

Rev 1.0 Apr.02 Proprietary and Confidential 25

Page 28

SB555 Hardware Integration Guide

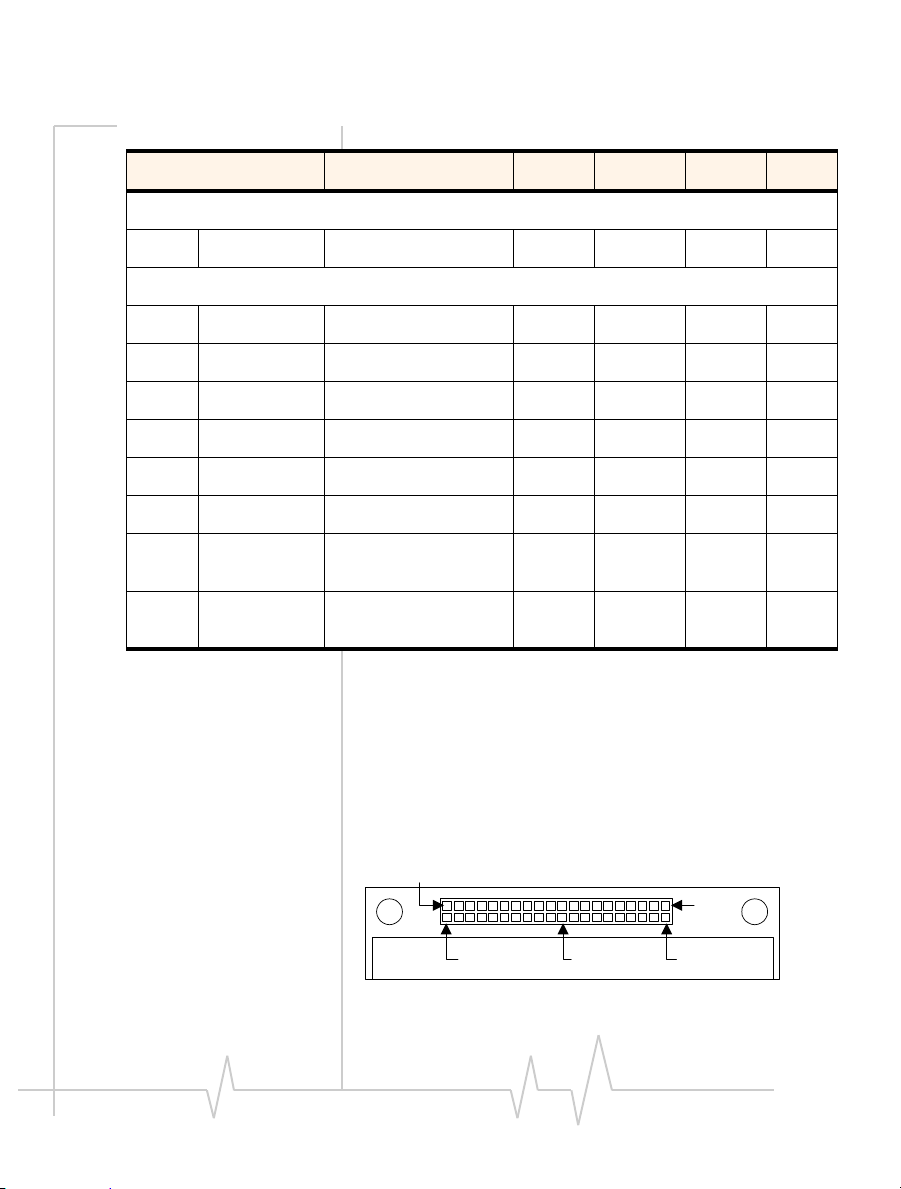

Table 3-1: Host interface electrical characteristics

Parameter Test Conditions Min Typical Max Units

Power

V

DC supply Max ripple 100 mV

cc

Digital Interface

V

V

I

I

V

V

I

I

IH

IL

OH

OL

IH

IL

OH

OL

HI threshold 2.1 3.0 3.3 V

LO threshold 0 0 0.8 V

Input current 3 V applied to input 0 120 µA

Input current 0 V applied to input 0 -120 µA

HI output IOH = 2.0 mA 2.4 3.0 V

LO output IOL = -2.0 mA 0 0.4 V

Output

current

Output

current

p-p

3.2 3.3 4.2 V

VOH > 2.0 V 3.0 mA

VOL < 1.0 V -3.0 mA

Location of pin 1

Pin 1 of the connector is shown in Figure 3-1.

When viewing the module with the connector

facing up and the RF connector at the bottom,

pin 1 is on the extreme right of the inside edge

(lower row).

Pin 40

Pin 2

Pin 19Pin 39

Figure 3-1: Host connector pin locations

26 Proprietary and Confidential 2130075

Pin 1

Page 29

Electrical Integration

General requirements

Unused pins

Unused signals must be terminated properly.

The pinout tables, both in the Appendix and in

the interface sections, include a column for termination of unused pins.

Preventing back-power when the modem is off

Note: Without proper

input protection, the

modem may draw

sufficient current to

remain powered, even

when the normal supply

power is removed.

Active low signals may be deasserted (driven

high) by the host device when the modem is not

needed. This applies 3.0 V to the modem on

these pins and presents the risk of backpowering.

All connector inputs must be either high

impedance (>20 kΩ), or driven low, when the

modem is powered off. This is required to

prevent back-powering the modem. This is

particularly important if the DTR signal is

deasserted (high) when the modem is not in use.

The sample integration shown in the appendix

uses buffers. These provide both voltage

conversion between 3.0 V of the modem and

3.3 V of the host MCU, and the required

protection from back powering both the MCU

and the modem.

Rev 1.0 Apr.02 Proprietary and Confidential 27

Page 30

SB555 Hardware Integration Guide

Voltage regulation and buffering

All logic signals at the SB555 host connector are

referenced to 3.0 V. Logic signals at the host

device may be referenced to 3.3 V, thus requiring

the use of buffers between the devices. These

buffers are discussed in the sections on the

specific interfaces. See the Typical MCU

Integration block diagram in the appendix.

Note: The actual VCC of

the logic internal to the

SB555 is 3.0 V, not the

3.2 V–4.2 V applied to

the V

SB555 module. The

74AHC series parts can

tolerate 3.3 V applied to

inputs while VCC=0V.

pins of the

CC

This buffer is mainly to protect the SB555 when it

is powered down while the host device remains

powered up.

Additionally, the modem’s input pins should not

have a voltage applied to them that is more than

0.3 V above the internal V

, which could

CC

happen when the modem is powered down.

Although some of the SB555 output lines are

configured as inputs by a reset, they all have

weak internal pullup or pulldown devices

(approx. 50 k to 375 k

Ω), so no external resistors

need to be added. If you decide to add external

resistors:

• Use pulldown resistors for:

· /RI1

· /DCD1

• Use pullup resistors (to 3.0 V) for:

· /DSR1

· /CTS2

· RxD2

· /Shdn_Ack

This is consistent with the internal devices. A

suggested value is 100 k

Ω.

28 Proprietary and Confidential 2130075

Page 31

Electrical Integration

Note: Floating signal

lines can be noisy, and

increase power

consumption.

Table 3-2: Power pinouts

If a host reset configures any of its I/O pins

(controlling outputs to the modem: DTR1,

/RTS1, TxD1, /RTS2, TxD2, /ShutDown,

MdmReset) as an input, and the pin does not

have any internal pullup or pulldown device, use

a pulldown resistor to prevent the line from

floating. A suggested value is 100 kΩ.

Electrostatic discharge

You are responsible for any ESD protection on

digital circuits. Specific recommendations are

provided as needed for each of the interfaces

described in this guide. An appendix (page 95)

also provides background on ESD.

Power

The SB555 CDMA2000 1X embedded modem

requires 3.2—4.2 VDC (+3.3 V nominal); suitable

for direct connection to a lithium-ion battery.

The modem uses the following pins for the

power interface:

Pin Name Description Typ e Termination

if not used

1, 2 V

cc

3, 4 GND Ground Power Required

25 GND Ground Power Required

30 GND Ground Power Required

Rev 1.0 Apr.02 Proprietary and Confidential 29

3.3 VDC power supply Power Required

Page 32

SB555 Hardware Integration Guide

Pins 25 and 30 are included to provide a

connection to ground near the pins for the two

serial ports.

The electrical characteristics of the power supply

are:

• Max ripple: 100 mV

• Minimum: 3.20 V

• Typical: 3.30 V

• Maximum: 4.20 V

(1 Hz – 100 kHz)

p-p

Current consumption

The current consumption of the modem varies

considerably on the usage model of your device.

Consult the Design Guide (document #2130179)

for assistance in planning your requirements.

Sample power integration

The integration is discussed with reference to the

sample block diagram in Figure 3-2: Power

interface block diagram on page 31. All samples

assume an MCU running at 3.3 V. If your host

device uses internal logic at 3.0 V then the buffers

discussed in this document may not be needed.

Power source

In the sample, the power source is a lithium-ion

battery. Your power source may differ provided

you stay within the 3.20–4.2 VDC requirement.

The power is shown independent of the host

device (MCU) power source, which may differ in

your integration.

30 Proprietary and Confidential 2130075

Page 33

Electrical Integration

For the SB555 modem to maintain a clean RF

signal, it is essential that the power supply also

be clean. Ensure the supply power is as free of

noise as possible.

Figure 3-2: Power interface block diagram

Rev 1.0 Apr.02 Proprietary and Confidential 31

Page 34

SB555 Hardware Integration Guide

MOSFET power switch

Note: This mechanism

is needed to follow the

recommended shutdown

sequence prior to

removing power from

the modem.

The MOSFET power switch is recommended to

provide the host device with software control of

the power to the SB555 modem. A suggested

part is SI2305DS from Siliconix (

brands/siliconix/).

If an MCU reset configures the I/O pin that

controls the MOSFET switch as an input, use a

pullup or pulldown resistor to default the

MOSFET control signal to the off state.

Pins 1 and 2: Modem V

To support a short burst power surge (current

draw) when the module’s transmitter is turned

on, the power supply is filtered by a 100 µF lowESR (Equivalent Series Resistance) capacitor

between the supply (V

this as close as possible to the module connector.

If a tantalum capacitor is used, it must have a

sufficient surge current rating to handle a lowimpedance current source like a battery,

otherwise it could fail.

BATT

www.vishay.com/

CC

) and ground. Locate

Power regulator

This regulator is used to provide the appropriate

voltage (3.0 V) for the LEDs and the digital signal

input buffer. However, if the source power

supply (V

regulator can be omitted, the LED resistors can

be connected directly to V

can also be powered directly by V

32 Proprietary and Confidential 2130075

) never exceeds 3.30 V, this voltage

BATT

, and the buffer

BATT

BATT

.

Page 35

Electrical Integration

If the LEDs were connected directly to a V

4.2 V, the voltage at the

the limit of V

+ 0.3 V, possibly damaging the

CC

/Status pins could exceed

BATT

of

modem. There could also be constant leakage

current, draining the battery. This will depend

on the voltage drop across the selected LEDs.

Similarly, if the buffer were powered by a V

BATT

greater than 3.30 V, the voltage at the input pins

of the SB555 would also exceed the V

+ 0.3 V

CC

limit.

Use a 3.0 V low-dropout (LDO) voltage regulator

of sufficient output current to provide power to

the I/O buffers (and LEDs if needed). A

suggested part is the LP3985-3.0 from National

Semiconductor.

Pins 3, 4, 25, 30: Ground connection

The ONLY ground connection to the modem

must be through the 40-pin host connector. No

ground connection to the modem shields must be

made. This is to avoid degrading the RF performance of the modem through ground loops.

Also consult the section: Ground plane isolation

on page 81.

Rev 1.0 Apr.02 Proprietary and Confidential 33

Page 36

SB555 Hardware Integration Guide

Requirements of the power interface

Module shielding

The module is fully shielded to protect against

EMI and to ensure FCC regulatory compliance.

To maintain the shield effectiveness the modem

shields must not be removed and must not be

connected to the host ground.

Ground loops must be avoided. See “Ground

plane isolation” on page 81.

Power ramp-up

The SB555 modem will hold the circuitry in reset

until stable power is established. When the

voltage reaches 2.7 V nominal (2.55–2.925 V) and

is held at or above that level for at least 10

timer is started. The modem continues to hold in

reset for 140–560 ms to ensure power is stable. If

power slips below 2.7 V for a few micro-seconds,

the timer must restart.

µs, a

Figure 3-3: Power ramp-up timing

34 Proprietary and Confidential 2130075

Page 37

Electrical Integration

Power-up timing

After release from reset, the modem performs a

self test and initialization. It begins normal

operation within 7–15 seconds.

All serial port signals should be considered

undefined or invalid until both

are asserted. Only at that time is the modem

ready for use.

Figure 3-4: Control signal timing

• t0—Reset is released.

—After self test, initialization begins.

• t

1

/DCD1 may change state based on its

condition at the time of the reset. It

should be ignored.

—/DSR1 asserts. Other signals should still

• t

2

be considered invalid.

• t

—/CTS1 asserts, typically 156 µs after /DSR1.

3

At this time, the modem is ready.

/DSR1 and /CTS1

Note: /DCD1 is shown

in its factory default

configuration.

Signals other than /DSR1 and /CTS1 should be

considered invalid or undefined until the process

is complete. The final state of

/DCD1 will depend

on its configuration.

Rev 1.0 Apr.02 Proprietary and Confidential 35

Page 38

SB555 Hardware Integration Guide

Trace widths

Ensure that the PCB trace widths to the SB555

and GND pins are sufficient for a maximum

V

CC

current of 900 mA. Consult the Design Guide

(document #2130179) for details on current

consumption in all modes.

Do not connect the modem package shield to

GND or AGND.

36 Proprietary and Confidential 2130075

Page 39

4: Serial Interfaces

• Introduction

• Primary port

• Secondary port

Introduction

The SB555 CDMA2000 1X embedded modem

presents two serial port interfaces.

• Primary port—the basic modem interface

offering AT command and user data I/O

• Secondary port—for modem management

using a Sierra Wireless proprietary

CnS (Control and Status) protocol

This chapter deals with the electrical integration

of each of these two serial ports. A full

integration of both ports is recommended but a

reduced integration is possible if you are

prepared to sacrifice some features. Consult the

Design Guide (document #2130179) for a

discussion of the issues related to excluding

connection of specific signals.

Serial port specifications

4

The serial ports operate at the same 3.0 V,

HCMOS level as the rest of the modem’s digital

interfaces, not +/-12 V RS-232C levels.

If a modem serial port is to be presented to the

user, appropriate level conversion and ESD

circuitry is required.

Rev 1.0 Apr.02 Proprietary and Confidential 37

Page 40

SB555 Hardware Integration Guide

Table 4-1: Serial interface electrical characteristics

Parameter Conditions Min Ty p . Max Units

Digital Interface

V

V

I

I

V

V

I

I

IH

IL

OH

OL

IH

IL

OH

OL

HI threshold 2.1 3.0 3.3 V

LO threshold 0 0.8 V

Input current 3 V applied input 10 120 µA

Input current 0 V applied input 0 -120 µA

HI output IOH = 1.0 mA 2.0 3.0 V

LO output IOL = -1.0 mA 0 0.4 V

Output

current

Output

current

VOH > 2.0 V 3.0 mA

VOL < 1.0 V 0 -3.0 mA

External pullup and pulldown resistors

Although some of the SB555 output lines are

configured as inputs by a reset, they all have

weak internal pullup or pulldown devices

(approx. 50 K to 375 k

need to be added. If you decide to add external

resistors (suggested value is 100 k

consistent with the internal devices:

• Use pulldown resistors for:

·

/RI1

· /DCD1

• Use pullup resistors (to 3.0 V V

·

/DSR1

· /CTS2

· RxD2

Ω), so no external resistors

Ω), to be

) for:

BUF

38 Proprietary and Confidential 2130075

Page 41

Serial Interfaces

If integrating to an MCU, and its reset configures

any of its I/O pins (controlling outputs to

/RTS1, or TxD1) as an input, and the pin does not

/DTR1,

have any internal pullup or pulldown device, use

a pulldown resistor to prevent the line from

floating. Floating signal lines can be noisy, and

increase power consumption. A suggested value

is 100 kΩ.

ESD protection

You are responsible for any ESD protection on

digital circuits.

If you plan to extend one or both serial ports to

the outside, choose a transceiver capable of 3.3 V

logic and with built-in ESD protection.

Suggested parts include:

• SIPEX (

• Maxim (

MAX3222E

• Texas Instruments (

www.sipex.com) SP3238E

www.maxim-ic.com) MAX3238E or

www.ti.com) MAX3238

Rev 1.0 Apr.02 Proprietary and Confidential 39

Page 42

SB555 Hardware Integration Guide

Primary port

The primary serial port pins (Serial 1) comprise a

standard set of serial data and handshaking

(control) lines. Signals must be terminated

properly if they are not used.

Table 4-2: Primary Port (1) Connector Pinouts

Pin Name Description Typ e Termination

21 /DCD1 Serial 1 – DCD Output Not connected

22 RxD1 Serial 1 – RX Output Required

23 TxD1 Serial 1 – TX Input Required

24 /DTR1 Serial 1 – DTR Input Ground

25 GND Ground Power Required

26 /DSR1 Serial 1 – DSR Output Not connected

27 /RTS1 Serial 1 – RTS Input Ground

if not used

28 /CTS1 Serial 1 – CTS Output Not connected

29 /RI1 Serial 1 – RI Output Not connected

30 GND Ground Power Required

At a minimum, the integration requires RxD,

TxD, and GND. The modem is not capable of

ignoring RTS/CTS flow control. If these signals

are not used in your integration, then

must be forced active (low, grounded) when the

modem is powered.

40 Proprietary and Confidential 2130075

/RTS1

Page 43

Serial Interfaces

Note: If your application

intends to use Windows

ACPI, then both DTR

and RI are required

signals.

The remaining primary port control lines (DCD,

DTR, DSR, and RI) are, strictly speaking, not

needed; however they are desirable in most

applications.

The SB555 modem is designed to use all control

signals of the serial interface. The recommended

integration is to use the full family of controls to

provide the greatest functionality.

Pin 21: /DCD1

Data Carrier Detect normally asserts when the

modem is on a traffic channel. It can be

configured to:

• Behave in a Unix-style “wink” mode—on at

all times and wink off (~1 s) when the traffic

channel is lost

• Reflect the state of the connection—on when

connected and off when disconnected

• Always assert

The configuration method is discussed in the

Verification and Configuration Guide (document

#2130078).

Although not required, it is recommended to use

DCD. If not used, the pin is left unconnected.

Pin 22: RxD1

This is the data channel from the modem

(network) to the host. This is a required pin in all

integrations.

Rev 1.0 Apr.02 Proprietary and Confidential 41

Page 44

SB555 Hardware Integration Guide

Pin 23: TxD1

This is the data channel from the host to the

modem (network). This is a required pin in all

integrations.

Pin 24: /DTR1

Data Terminal Ready is used extensively to

control modem operations as discussed in the

Design Guide. This pin is not strictly required,

although it is required for Windows ACPI.

If DTR is not used in your integration,

must be tied active (low) by connecting to

ground.

The sample integration in the appendix (page 93)

shows the

drain device (for example, a TMOS FET such as

the 2N7000 or 2N7002), with a pulldown resistor

on the input gate of the FET.

The MCU I/O pin driving the

should be high-impedance (or input), or an

output driven to 0 V during and immediately

after MCU reset. This allows the modem to

remain in shutdown mode if the host’s DTR pin

was deasserted to request the shutdown, and the

MCU is subsequently powered down, then

powered up again.

This FET also protects the MCU when it is

powered down while the modem remains

powered up. The modem’s

pullup resistor which could cause the voltage on

the MCU pin to exceed V

the MCU, and increase the drain on the modem’s

battery. This device prevents these problems.

/DTR1 line being driven by an open

/DTR1 signal

/DTR1 pin has a

+ 0.3 V, back-power

CC

/DTR1

42 Proprietary and Confidential 2130075

Page 45

Serial Interfaces

The SB555 is also protected by this FET when the

modem is powered down while the MCU

remains powered up. The modem’s input pins

should not have a voltage applied to them that is

more than 0.3 V above V

otherwise happen when the modem is powered

down.

, which could

CC

Pin 25: GND

This is a signal ground made available in

proximity to the other serial port pins for convenience.

Pin 26: /DSR1

Data Set Ready is normally asserted following

successful completion of a modem’s self-test and

initialization. DSR is deasserted when the

modem is in shutdown state, to advise the host

that it is not available for use.

DSR is optional but recommended. If not used, it

can be left unconnected.

Pin 27: /RTS1

Request To Send is asserted by the host when it is

capable of receiving data from the modem, and

deasserted to prevent overflow.

The modem cannot ignore RTS, so if it is not

used, it must be tied active (low) by connecting to

ground; however doing this will risk data

overflow at the host device.

Rev 1.0 Apr.02 Proprietary and Confidential 43

Page 46

SB555 Hardware Integration Guide

Pin 28: /CTS1

Clear To Send is asserted by the modem when it

is capable of receiving data from the host, and

deasserted when the modem’s buffers are full (or

the modem is not ready to receive commands

from the host).

This pin is also the final signal to the host

indicating that the modem has completed its

initialization and is ready for use.

Only if the application can tolerate data loss due

to transmission overruns, should this pin can be

left unconnected.

Pin 29: /RI1

Ring Indicator is used to advise the host of one of

the following conditions:

• An incoming call (telephone is ringing)

• An incoming SMS message

• A return to network coverage

Windows ACPI requires use of this signal.

Otherwise, the signal is optional. If not used, it

can be left unconnected.

RI is strongly recommended for any integration

using the voice feature of the modem. The RI

signal can be used to wake a sleeping host when

an incoming call arrives, allowing the device to

perform much like a standard cellular telephone.

If RI is used for wakeup, you must connect it to

an appropriate circuit to detect it and manage the

host wakeup operation.

/RI1 is an active low signal that asserts with a

duty cycle of 200 ms on and 200 ms off.

Incoming calls will trigger the RI to cycle until

44 Proprietary and Confidential 2130075

Page 47

Serial Interfaces

the connection attempt is either answered or

dropped. The other event triggers (SMS

messages and return to coverage) will assert

three times for each triggering event.

Your implementation must handle the detection

of events and ignore any additional cycles that

are not needed.

/RI1

Pin 30: GND

This is a signal ground made available in

proximity to the other serial port pins for convenience.

Port configuration

The primary serial port is configured for 8-data

bits, no parity bits, and 1-stop bit. The DTE host

data-rate on the primary serial port can be from

9600 bps to 230.4 kbps, configured by software

command. The factory default setting is

115.2 kbps.

The modem does not support autobaud

detection.

Primary port sample integrations

Three integration options are discussed below:

• Internal host integration connects to a serial

port of an MCU

• External serial connector exposing a standard

RS-232 connection

• Minimum integration, the minimal

connection (to an MCU in this sample).

Rev 1.0 Apr.02 Proprietary and Confidential 45

Page 48

SB555 Hardware Integration Guide

Sample 1: Internal host integration

This sample integrates all signals of the serial

port to an MCU.

Buffers are used to manage the level conversions

between 3.0 V at the modem and 3.3 V at the

MCU. SN74AHC541 (or equivalent) octal buffers

powered by a 3.0 V (V

inputs to the modem. Connect the /OE1 and

/OE2 buffer pins to GND.

Connect the inputs of any unused buffers to

GND and leave the outputs unconnected.

Another SN74AHC541 (or equivalent) octal

buffer, this time powered by the host's 3.3 V

(V

) rail, is used to protect the output lines

CC

from the modem.

The source of the 3.0 V V

input buffer is discussed in the section: Power

regulator on page 32. The output buffer is

powered by the host’s supply.

) rail will serve on the

BUF

power used by the

BUF

Figure 4-1: Primary serial port integration—MCU Sample

46 Proprietary and Confidential 2130075

Page 49

Serial Interfaces

This sample uses an open drain on /DTR1, which

is discussed in the description of Pin 24: /DTR1

on page 42.

If the host will be using partial system shutdown

to conserve power—relying on the modem to

wake up the host via the ring indicator—then the

/RI pin at the MCU will have to be an interrupt-

capable input to trigger the host wakeup.

Sample 2: External serial connector

If you are going to present the primary serial

port as an external RS-232 interface, you must

include appropriate level conversion and ESD

protection. Typically a MAX3238 is used, as

shown in Figure 4-2.

The supply power to the chip must be the same

3.0 V (V

of the SB555. This ensures the output signals

from the RS-232 conversion do not over drive the

SB555.

If the host system logic is used to enable the

conversion chip (as shown in the sample), the

same logic should control the power to the SB555

(although not shown in the sample). This

prevents a situation where the conversion chip

might back-power the SB555 through

/RTS1. Conversely, if the SB555 is powered

while the MAX3238 is not, there can be a current

drain through the SB555 serial outputs.

Values for the capacitors are not shown. Consult

the data sheet for the chip you use for values.

) level supported by the digital logic

BUF

/DTR1 and

Rev 1.0 Apr.02 Proprietary and Confidential 47

Page 50

SB555 Hardware Integration Guide

Figure 4-2: Primary serial port integration—external

RS-232 connector

Depending on the capabilities of the selected

chip, the ring indicator may still be used to

control host power. Provided the 3.0 V supply is

active and the software switch is off, the chip

may still pass the

/RI1 signal to another pin (not

shown) that can be used to wake the local host.

48 Proprietary and Confidential 2130075

Page 51

Serial Interfaces

Sample 3: Minimum integration

At a minimum, data receive (RxD1) and

transmit (

This sample integration does not enforce flow

control so data overruns and lost data are

possible; your application must be tolerant of

this.

The minimum required integration is described in

Table 4-3 and the block diagram in Figure 4-3:

Table 4-3: Primary port minimum

integration

Signal Pin Requirement

/DCD1 21 Optional (unconnected)

RxD1 22 Required

TxD1 23 Required

/DTR1 24 GND

TxD1), and ground (GND) are required.

GND 25 GND

/DSR1 26 Optional (unconnected)

/RTS1 27 GND

/CTS1 28 Optional (unconnected)

/RI1 29 Optional (unconnected)

GND 30 GND

Rev 1.0 Apr.02 Proprietary and Confidential 49

Page 52

SB555 Hardware Integration Guide

Figure 4-3: Primary serial port integration—minimum

sample

Note: The modem is not

capable of ignoring RTS/

CTS flow control. If

these signals are not

used in your integration,

then RTS must be

forced active (low) when

the modem is powered.

The modem firmware always respects hardware

handshaking. This means that if RTS/CTS are

not used, the

/RTS1 signal input to the modem

must be forced active (low) by connecting it to

ground.

The CTS signal is optional and can be left unconnected if not used. The modem will assert and

deassert it regardless of the hardware

integration.

DTR can be configured for a variety of control

applications in the modem. To prevent

accidental recognition of transitions and avoid

any flow control problems, the required

integration of an unused

/DTR1 signal is to tie it

active (low) by connecting to ground.

All other control lines are outputs from the

modem and can be safely left unconnected if not

needed.

50 Proprietary and Confidential 2130075

Page 53

Secondary port

Serial Interfaces

Note: This port is

required for operation

with Watcher, the Sierra

Wireless enabling

software.

Table 4-4: Secondary port connector pinouts

Pin Name Description Typ e Termination

17 /CTS2 Serial 2 – CTS Output Not connected

18 /RTS2 Serial 2 – RTS Input Ground

19 TxD2 Serial 2 – TX Input Ground

20 RxD2 Serial 2 – RX Output Not connected

The secondary port of the SB555 embedded

modem is used to exchange control and status

information while a data connection is in

progress on the primary port. The secondary

port can also support CAIT—a diagnostics tool—

used during CDG3 testing.

The port is, strictly speaking, optional, but

without it, the host device is very limited in its

ability to control or monitor the modem while

connected. See the Design Guide (document

#2130179) for a full discussion.

This port provides only the basic TX and RX lines

along with flow control—RTS and CTS. Other

control signals are not provided.

if not used

25 GND Ground Power Required

Rev 1.0 Apr.02 Proprietary and Confidential 51

Page 54

SB555 Hardware Integration Guide

Pin 17: /CTS2

The Clear To Send signal is optional and can be

left unconnected if not used. The modem will

assert and deassert it regardless of the hardware

integration.

Clear To Send is asserted by the modem when it

is capable of receiving CnS commands from the

host, and deasserted when the modem’s buffer is

full (or the modem is not ready to receive CnS

commands from the host).

Only if the application can tolerate loss of CnS

commands due to transmission overruns, should

this pin be left unconnected.

Pin 18: /RTS2

Request To Send is asserted by the host when it is

capable of receiving CnS responses and notifications from the modem, and deasserted to prevent

overflow.

The modem cannot ignore RTS, so if it is not

used, it must be tied active (low) by connecting to

ground.

Pin 19: TxD2

Note: See the Design

Guide for details of the

consequences of not

including the secondary

port in your integration.

52 Proprietary and Confidential 2130075

This is the data channel from the host to the

modem for CnS messages. This is a required pin

in all integrations using Watcher; otherwise the

pin is optional.

Page 55

Serial Interfaces

Pin 20: RxD2

This is the data channel from the modem to the

host for CnS messages and notifications. This is

a required pin in all integrations using Watcher;

otherwise it is optional.

Pin 25: GND

This is a signal ground made available in

proximity to the other serial port pins for convenience.

Port configuration

The secondary serial port is configured for 8-data

bits, no parity bits, and 1-stop bit. The DTE host

data-rate on the secondary serial port can be

from 9600 bps to 115.2 kbps, configured by

software command. The factory default setting

is 115.2 kbps.

The modem does not support autobaud

detection.

Rev 1.0 Apr.02 Proprietary and Confidential 53

Page 56

SB555 Hardware Integration Guide

Secondary port sample integration

Note: The secondary

port is typically not

extended to an outside

RS-232 connector,

although this can be

done in a completely

standalone modem

product—one not using

built-in host application

software.

This sample integrates all signals of the serial

port to an MCU.

Buffers are used to manage the level conversions

between 3.0 V at the modem and 3.3 V at the

MCU. This element of the integration is the same

as that described on page 46 for the primary port.

The source of the 3.0 V (V

) power used by the

BUF

input buffer is discussed in the section: Power

regulator on page 32. The output buffer is

powered by the host’s supply.

Figure 4-4: Secondary serial port sample integration

54 Proprietary and Confidential 2130075

Page 57

Serial Interfaces

Minimum integration

To use the port, the minimum integration is

described in the following table:

Table 4-5: Secondary port minimum

integration

Signal Pin Requirement

/CTS2 17 Optional

/RTS2 18 GND

TxD2 19 Required

RxD2 20 Required

GND 25 Required

Figure 4-5: Secondary serial port minimum integration

At a minimum, receive (RxD2) and

transmit (

TxD2) data, along with ground (GND)

are required. This integration does not enforce

flow control so data overruns and lost data are

possible; your application must be tolerant of

this.

Rev 1.0 Apr.02 Proprietary and Confidential 55

Page 58

SB555 Hardware Integration Guide

56 Proprietary and Confidential 2130075

Page 59

5: Voice Interface

• Introduction

• Headset

• Line level

Introduction to voice features

The SB555 CDMA2000 1X embedded modem

supports voice operation similar to a cellular

telephone. Integration of the modem to use the

voice features requires a microphone input and

speaker output. These can be either directly to a

standard cellular headset or to your custom

audio circuit (at line level).

The modem’s analog voice capability is

configured at the factory to use a direct

connection to a standard cellular headset.

Software commands are used to make configuration and calibration changes.

This chapter has sections describing each of the

two configurations of the voice interface.

Audio block diagram

5

The simplified block diagram on the following

page is intended to provide you with some

understanding of how the various configuration,

calibration, and user controls affect the circuit.

The AT commands used to control the audio

circuit are all prefixed with the tilde (~) character.

There are two areas where a loopback can be

configured for testing (not shown), that are

described in the Verification and Configuration

Guide.

Rev 1.0 Apr.02 Proprietary and Confidential 57

Page 60

SB555 Hardware Integration Guide

Figure 5-1: Simplified audio block diagram

Setting line level (~AUDMOD) primarily affects

the amount of microphone gain. There is also

some associated filtering, used to compensate for

the headset microphone, that will be switched

out (flat response) when using the line level

configuration.

Calibration of the microphone and speaker levels

is handled on the digital side of the Codec. Use

~MICLVL and ~SPKLVL is described in the

of

Configuration and Verification Guide.

The user’s volume control (

~SPKVOL) is prior to

the echo cancellation circuitry. It is also included

in the sidetone return, along with a separate

control of sidetone gain (

~STGLVL).

58 Proprietary and Confidential 2130075

Page 61

Voice Interface

Pinouts

Table 5-1: Analog voice interface pinouts

Pin Name Description Typ e Termination

if not used

13 MIC+ Voice Mi c + Input (Diff.) AGND

14 SPKR+ Voi c e Sp eaker Output Not connected

15 MIC- Voice M ic- Input (Diff.) AGND

16 AGND Audio Common Ground

(AGND)

Note: The Audio Common Ground is independent

of the system’s signal ground.

If the audio circuitry is not used, the inputs (pins

13 and 15) should be connected to

Under normal operation, the modem only turns

on the audio circuit when needed for a voice

connection. Note that if the audio circuit is

enabled, there is a bias current of just under

1 mA on the MIC pins that will cause some

current drain.

ESD protection

You are responsible for any ESD protection

required. An appendix (page 95) provides

background on ESD.

Not connected

AGND (pin 16).

Rev 1.0 Apr.02 Proprietary and Confidential 59

Page 62

SB555 Hardware Integration Guide

Headset integration

This is the default configuration from the factory.

Level calibration is described in the Verification

and Configuration Guide (document #2130078).

Headset interface specifications

The modem’s analog voice interface configured

for direct use with a standard cellular headset

has the following electrical specifications:

Table 5-2: Headset interface electrical characteristics

Parameter Conditions Min Ty p . Max Units

Microphone Input

Z

IN

V

I

0dBm0 Reference

∆A

SINAD S:(THD+N) -45 dBm0 to

60 Proprietary and Confidential 2130075

Input

impedance

Input level mic sens. =

level

Gain error -30 dBm0 to

V

Transmit

noise

Differential 4 4.2 4.5 kΩ

-58 dBV / µBar

1 kHz sine wave

Amp Gain =

26 dB

-1.5 0 +1.5 dB

+3 dBm0 input

C-message

weighted

25 45 dB

+3 dBm0 input

-44 -21.8 dBV

88 110.2 dB SPL

45.5 mV

10 µV

RMS

RMS

Page 63

Voice Interface

Table 5-2: Headset interface electrical characteristics (cont.)

Parameter Conditions Min Ty p . Max Units

I

MIC

Mic DC

current

Speaker Output

Z

L

P

O

Load

impedance

Speaker

output

power

THD To ta l

harmonic

distortion

MUTE Digital input =

∆A

Gain error -30 dBm0 to

V

Receive

noise

Electret

220 500 µA

condenser

Source =

1.8 VDC

@2200Ω

Single-ended 32 Ω

32Ω load digital

8.8 mW

input = +3 dBm0

@1020Hz

Maximum output

5 %

level into 32 Ω

@498Hz

-80 dB

+3 dBm0

@1020Hz

-1.5 0 +1.5 dB

+3 dBm0 input

Digital input =

200 µV

0x0000

A-weighted

RMS

SINAD S:(THD+N) -45 dBm0 to

25 42 dB

+3 dBm0 input

IMD Intermod.

distortion

498 Hz &

2020 Hz equal

50 dB

level

V

O

Rev 1.0 Apr.02 Proprietary and Confidential 61

DC on

speaker out

AC-coupled 0 VDC

Page 64

SB555 Hardware Integration Guide

Microphone input (headset)

The microphone input is a capacitively

connected differential input, with input

impedance greater than 4 k

signals should be -44 dBV (18 mV

Ω. Microphone

) nominal.

p-p

Note: Single-ended

drive will reduce input

impedance by 50% to

2.1 kΩ typical.

Note: The Audio

Common Ground is

independent of the

system ground used for

other operations.

If a single-ended drive is desired, the MIC- input

must be connected to the Audio Common

ground (pin 16) as close to the microphone, or its

connector, as possible. Do not use a general

system ground, but rather the Audio

Common (

The modem provides a microphone DC bias of

just under 1 mA of current for a standard microphone.

AGND) provided by the module.

Speaker output (headset)

The speaker output is a single-ended signal used

to interface to a headset. The output signal is

AC-coupled -21 dBV (250 mV

32

Ω load.

If additional amplification is needed, it is the

responsibility of the integrator.

) nominal into a

p-p

Sample headset integration

The simplest integration of the modem’s voice

service uses the conventional analog microphone and speaker pins (13–16). These can be

connected directly to a standard 3-wire cellular

headset.

62 Proprietary and Confidential 2130075

Page 65

Voice Interface

1

2

3

4

SJ - 2504N

Figure 5-2: Sample headset integration

A preferred integration would use both MIC+

and

MIC- as a differential pair (with ground on

either side) to reduce noise.

Note: This sample does not include ESD

protection. You are responsible for all ESD

protection circuitry.

13 MIC+

14 SPKR+

15 MIC -

16 AGND

Line level voice integration

The modem’s analog voice interface is

configured at the factory for direct use with a

standard cellular headset. The interface can be

configured for line level by using:

• AT c o mmand:

• CnS command KST_AUDMOD (5006)

When this is done, the microphone gain is

reduced by 28 dB and the frequency response is

flat (a filter is switched out). The speaker

circuitry is unchanged.

AT~AUDMOD=1

Rev 1.0 Apr.02 Proprietary and Confidential 63

Page 66

SB555 Hardware Integration Guide

The interface has the following electrical specifications:

Table 5-3: Line level interface electrical characteristics

Parameter Conditions Min Ty p . Max Units

Line Input

Z

IN

V

I

0dBm0 Reference

∆A

Input

impedance

Maximum

input level

level

Gain error -30 dBm0 to

V

Differential 4 4.2 4.5 kΩ

MIC+ or MICsingle-ended

Amp Gain =

-2 dB

+3 dBm0 input

SINAD S:(THD+N) -45 dBm0 to

+3 dBm0 input

Line Output

Z

L

V

O

Load

impedance

Reference

signal level

Single-ended 600 Ω

Digital input

0dBm0

@1020Hz

VOmax Maximum

output level

Digital input

+3 dBm0

@1020Hz

THD To ta l

harmonic

distortion

Maximum output

level into 600 Ω

@498Hz

2.28 V

1.14 V

-1.5 0 +1.5 dB

25 45 dB

375 mV

1.5 V

5 %

P-P

RMS

RMS

P-P

MUTE Digital input =

-80 dB

+3 dBm0

@1020Hz

64 Proprietary and Confidential 2130075

Page 67

Voice Interface