Page 1

WA_DEV_Q26RD_PTS_001

002

April 20, 2010

AirPrime Q2687 Refreshed

Product Technical Specification

and Customer Design Guideline

Page 2

Product Technical Specification and

Customer Design Guideline

Important Notice

Due to the nature of wireless communications, transmission and reception of data can never be

guaranteed. Data may be delayed, corrupted (i.e., have errors) or be totally lost. Although significant

delays or losses of data are rare when wireless devices such as the Sierra Wireless modem are used

in a normal manner with a well-constructed network, the Sierra Wireless modem should not be used

in situations where failure to transmit or receive data could result in damage of any kind to the user or

any other party, including but not limited to personal injury, death, or loss of property. Sierra Wireless

accepts no responsibility for damages of any kind resulting from delays or errors in data transmitted or

received using the Sierra Wireless modem, or for failure of the Sierra Wireless modem to transmit or

receive such data.

Safety and Hazards

Do not operate the Sierra Wireless modem in areas where blasting is in progress, where explosive

atmospheres may be present, near medical equipment, near life support equipment, or any equipment

which may be susceptible to any form of radio interference. In such areas, the Sierra Wireless modem

MUST BE POWERED OFF. The Sierra Wireless modem can transmit signals that could interfere with

this equipment. Do not operate the Sierra Wireless modem in any aircraft, whether the aircraft is on

the ground or in flight. In aircraft, the Sierra Wireless modem MUST BE POWERED OFF. When

operating, the Sierra Wireless modem can transmit signals that could interfere with various onboard

systems.

Note: Some airlines may permit the use of cellular phones while the aircraft is on the ground and the door is

open. Sierra Wireless modems may be used at this time.

The driver or operator of any vehicle should not operate the Sierra Wireless modem while in control of

a vehicle. Doing so will detract from the driver or operator’s control and operation of that vehicle. In

some states and provinces, operating such communications devices while in control of a vehicle is an

offence.

Limitations of Liability

This manual is provided “as is”. Sierra Wireless makes no warranties of any kind, either expressed or

implied, including any implied warranties of merchantability, fitness for a particular purpose, or

noninfringement. The recipient of the manual shall endorse all risks arising from its use.

The information in this manual is subject to change without notice and does not represent a

commitment on the part of Sierra Wireless. SIERRA WIRELESS AND ITS AFFILIATES

SPECIFICALLY DISCLAIM LIABILITY FOR ANY AND ALL DIRECT, INDIRECT, SPECIAL,

GENERAL, INCIDENTAL, CONSEQUENTIAL, PUNITIVE OR EXEMPLARY DAMAGES INCLUDING,

BUT NOT LIMITED TO, LOSS OF PROFITS OR REVENUE OR ANTICIPATED PROFITS OR

REVENUE ARISING OUT OF THE USE OR INABILITY TO USE ANY SIERRA WIRELESS

PRODUCT, EVEN IF SIERRA WIRELESS AND/OR ITS AFFILIATES HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES OR THEY ARE FORESEEABLE OR FOR CLAIMS BY ANY

THIRD PARTY.

Notwithstanding the foregoing, in no event shall Sierra Wireless and/or its affiliates aggregate liability

arising under or in connection with the Sierra Wireless product, regardless of the number of events,

occurrences, or claims giving rise to liability, be in excess of the price paid by the purchaser for the

Sierra Wireless product.

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 2

Page 3

Product Technical Specification and

Customer Design Guideline

Patents

5,515,013

5,629,960

5,845,216

5,847,553

5,878,234

5,890,057

5,929,815

6,169,884

6,191,741

6,199,168

6,339,405

6,359,591

6,400,336

6,516,204

6,561,851

6,643,501

6,653,979

6,697,030

6,785,830

6,845,249

6,847,830

6,876,697

6,879,585

6,886,049

6,968,171

6,985,757

7,023,878

7,053,843

7,106,569

7,145,267

7,200,512

7,295,171

7,287,162

D442,170

D459,303

D599,256

D560,911

Sales Desk:

Phone:

1-604-232-1488

Hours:

8:00 AM to 5:00 PM Pacific Time

E-mail:

sales@sierrawireless.com

Post:

Sierra Wireless

13811 Wireless Way

Richmond, BC

Canada V6V 3A4

Fax:

1-604-231-1109

Web:

www.sierrawireless.com

Portions of this product may be covered by some or all of the following US patents:

and other patents pending.

This product includes technology licensed from QUALCOMM

®

3G

Manufactured or sold by Sierra Wireless or its licensees under one or more patents licensed from

InterDigital Group.

Copyright

© 2010 Sierra Wireless. All rights reserved.

Trademarks

AirCard® and Watcher® are registered trademarks of Sierra Wireless. Sierra Wireless™, AirPrime™,

AirLink™, AirVantage™ and the Sierra Wireless logo are trademarks of Sierra Wireless.

, , ®, inSIM®, WAVECOM®, WISMO®, Wireless Microprocessor®,

Wireless CPU®, Open AT® are filed or registered trademarks of Sierra Wireless S.A. in France and/or

in other countries.

Windows

®

and Windows Vista® are registered trademarks of Microsoft Corporation.

Macintosh and Mac OS are registered trademarks of Apple Inc., registered in the U.S. and other

countries.

QUALCOMM

®

is a registered trademark of QUALCOMM Incorporated. Used under license.

Other trademarks are the property of the respective owners.

Contact Information

Consult our website for up-to-date product descriptions, documentation, application notes, firmware

upgrades, troubleshooting tips, and press releases: www.sierrawireless.com

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 3

Page 4

Product Technical Specification and

Customer Design Guideline

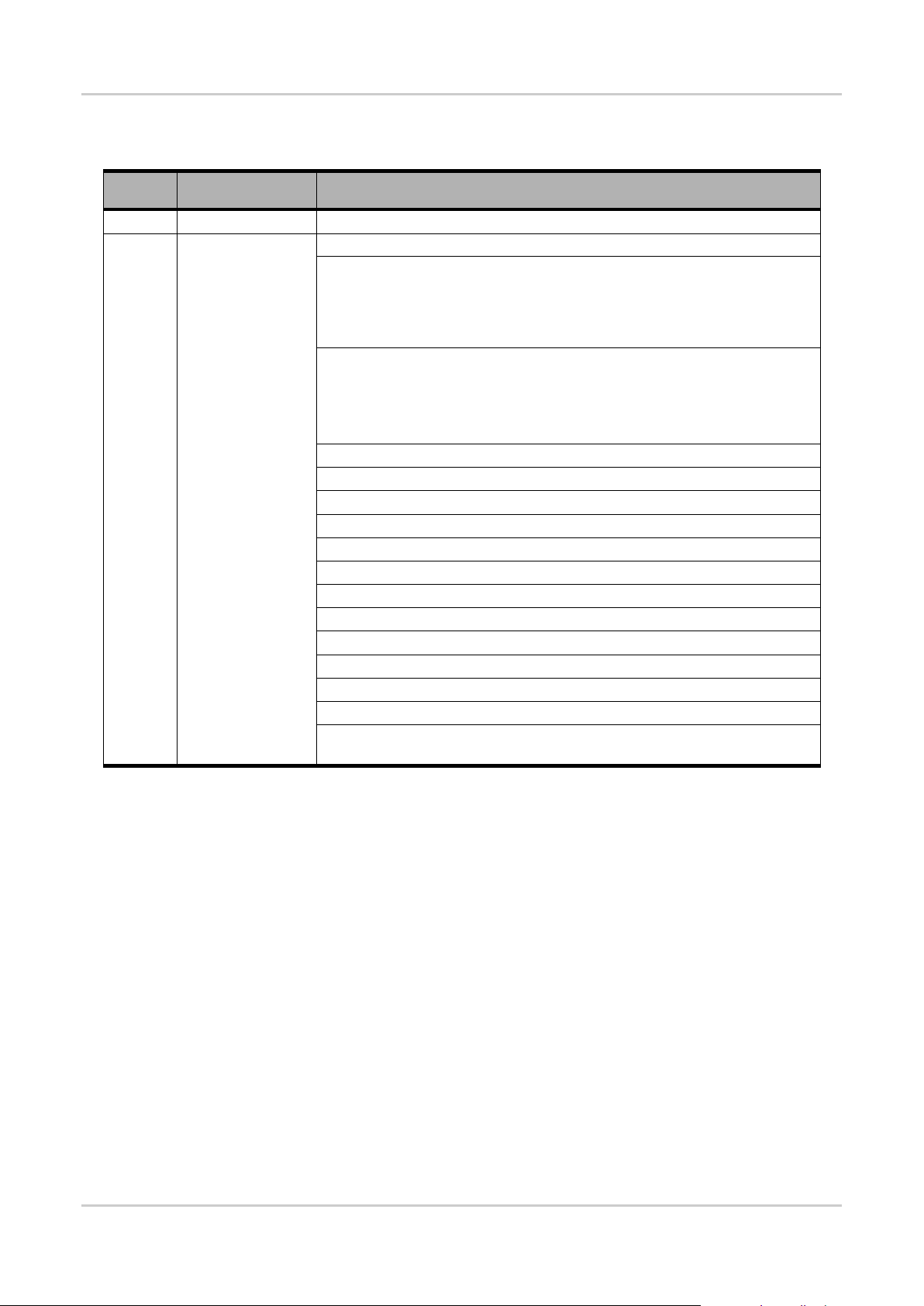

Document History

Version

Date

Updates

001

January 28, 2010

Creation

002

April 20, 2010

Reformatted in the rebranded SWI template.

In Section 3 Technical Specifications:

Moved the Power Supply Design Requirements to section 9.1

Power Supply

Updated Figure 5

In section 4 Interfaces:

Updated section 4.7.4 5-wire Serial Interface

Updated section 4.8.1 Pin Description

Updated section 4.8.3 4-wire Serial Interface

Updated section 8.4 Reliability Prediction Model.

Updated links in section 13.1.1 Web Site Support.

Updated Intelligent Embedded Module weight to 8g.

Updated the RF Component list.

Removed references to IMP Connector throughout the document.

Updated Figure 10 Example of a 4-wire SPI Bus Application.

Updated section 4.15 Temperature Sensor Interface.

Updated Power ON information based on Tracker 01626.

Updated U1 Chip information based on CUS57225.

Updated antenna gain information.

Updated FCC ID.

Updated power consumption values in section 6 Power Consumption.

Updated Figure 5 Q2687 Refreshed Embedded Module Mechanical Drawing

and Figure 6 Maximum Bulk Occupied on the Host Board.

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 4

Page 5

Contents

1. INTRODUCTION ................................................................................................ 16

1.1. Physical Dimensions ................................................................................................... 16

1.2. General Features ........................................................................................................ 16

1.3. GSM/GPRS/EGPRS Features .................................................................................... 18

1.4. Interfaces ................................................................................................................... 18

1.5. Operating System ....................................................................................................... 18

1.6. Connection Interfaces ................................................................................................. 19

1.7. Environment and Mechanics ....................................................................................... 19

1.7.1. RoHS Directive Compliant ................................................................................... 19

1.7.2. Disposing of the Product ...................................................................................... 19

2. FUNCTIONAL SPECIFICATIONS ...................................................................... 20

2.1. Functional Architecture ............................................................................................... 20

2.1.1. RF Functionalities ................................................................................................ 20

2.1.2. Baseband Functionalities ..................................................................................... 21

2.2. Operating System ....................................................................................................... 21

3. TECHNICAL SPECIFICATIONS ........................................................................ 22

3.1. Power Supply ............................................................................................................. 22

3.1.1. Power Supply Pin-Out .......................................................................................... 23

3.1.2. Start-Up Current .................................................................................................. 24

3.1.3. Decoupling of Power Supply Signals .................................................................... 24

3.2. Mechanical Specifications ........................................................................................... 24

3.3. Firmware Upgrade ...................................................................................................... 27

4. INTERFACES ..................................................................................................... 28

4.1. General Purpose Connector (GPC) ............................................................................. 28

4.1.1. Pin Description .................................................................................................... 29

4.1.2. Pin Out Differences .............................................................................................. 34

4.2. Electrical Information for Digital I/O ............................................................................. 35

4.3. General Purpose Input/Output .................................................................................... 37

4.3.1. Pin Description .................................................................................................... 37

4.4. Serial Interface ........................................................................................................... 39

4.4.1. SPI Bus ............................................................................................................... 39

4.4.1.1. Characteristics ........................................................................................................ 39

4.4.1.2. SPI Configuration .................................................................................................... 39

4.4.1.3. SPI Waveforms ....................................................................................................... 40

4.4.1.4. SPI1 Pin Description ................................................................................................ 41

4.4.1.5. SPI2 Pin Description ................................................................................................ 41

4.4.1.6. Application .............................................................................................................. 42

4.4.2. I2C Bus ................................................................................................................ 43

4.4.2.1. I2C Waveforms ........................................................................................................ 43

4.4.2.2. I2C Pin Description .................................................................................................. 44

4.4.2.3. Application .............................................................................................................. 44

4.5. Parallel Interface ......................................................................................................... 45

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 5

Page 6

Product Technical Specification and

Customer Design Guideline

4.5.1. Pin Description .................................................................................................... 45

4.5.2. Electrical Characteristics ...................................................................................... 46

4.5.3. Asynchronous Access .......................................................................................... 46

4.5.4. Synchronous Access ........................................................................................... 48

4.5.5. Additional Information Regarding Address Size Bus ............................................. 51

4.5.6. Application ........................................................................................................... 51

4.6. Keyboard Interface ..................................................................................................... 52

4.6.1. Pin Description .................................................................................................... 52

4.6.2. Application ........................................................................................................... 53

4.7. Main Serial Link (UART1) ........................................................................................... 54

4.7.1. Pin Description .................................................................................................... 54

4.7.2. Level Shifter Implementation ................................................................................ 55

4.7.2.1. Recommended Components .................................................................................... 55

4.7.3. V24/CMOS Possible Designs ............................................................................... 56

4.7.4. 5-wire Serial Interface .......................................................................................... 57

4.7.5. 4-wire Serial Interface .......................................................................................... 57

4.7.6. 2-wire Serial Interface .......................................................................................... 57

4.8. Auxiliary Serial Link (UART2) ...................................................................................... 58

4.8.1. Pin Description .................................................................................................... 58

4.8.2. Level Shifter Implementation ................................................................................ 59

4.8.2.1. Recommended Components .................................................................................... 59

4.8.3. 4-wire Serial Interface .......................................................................................... 60

4.8.4. 2-wire Serial Interface .......................................................................................... 60

4.9. SIM Interface .............................................................................................................. 61

4.9.1. Pin Description .................................................................................................... 61

4.9.2. Electrical Characteristics ...................................................................................... 61

4.9.3. Application ........................................................................................................... 62

4.9.3.1. SIM Socket Pin Description ...................................................................................... 62

4.9.3.2. Recommended Components .................................................................................... 63

4.10. USB 2.0 Interface ....................................................................................................... 64

4.10.1. Pin Description .................................................................................................... 64

4.10.2. Electrical Characteristics ...................................................................................... 64

4.10.3. Application ........................................................................................................... 65

4.10.3.1. Recommended Components .................................................................................. 65

4.11. RF Interface ................................................................................................................ 66

4.11.1. RF Connections ................................................................................................... 66

4.11.1.1. UFL Connector ...................................................................................................... 66

4.11.1.2. Soldered Solution .................................................................................................. 66

4.11.1.3. Precidip Connector ................................................................................................ 66

4.11.2. RF Performance .................................................................................................. 66

4.11.3. Antenna Specifications ........................................................................................ 67

4.11.3.1. Application ............................................................................................................ 67

4.12. Analog Audio Interface................................................................................................ 68

4.12.1. Pin Description .................................................................................................... 68

4.12.2. Microphone Features ........................................................................................... 68

4.12.2.1. MIC1 Microphone Input .......................................................................................... 68

4.12.2.2. MIC2 Microphone Input .......................................................................................... 72

4.12.3. Speaker Features ................................................................................................ 75

4.12.3.1. Speakers Output Power ......................................................................................... 76

4.12.3.2. SPK1 Speaker Output............................................................................................ 76

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 6

Page 7

Product Technical Specification and

Customer Design Guideline

4.12.3.3. SPK2 Speaker Output............................................................................................ 77

4.12.3.4. Differential Connection Example ............................................................................ 78

4.12.3.5. Single-Ended Connection Example ........................................................................ 78

4.12.3.6. Recommended Characteristics .............................................................................. 79

4.13. Digital Audio Interface (PCM) ...................................................................................... 80

4.13.1. PCM Waveforms.................................................................................................. 81

4.13.2. Pin Description .................................................................................................... 82

4.14. Battery Charging Interface .......................................................................................... 83

4.14.1. Charging Algorithms ............................................................................................ 84

4.14.1.1. Ni-Cd/Ni-Mh Charging Algorithm ............................................................................ 84

4.14.1.2. Li-Ion Charging Algorithm ...................................................................................... 85

4.14.2. Pre-Charging ....................................................................................................... 88

4.14.3. Temperature Monitoring ....................................................................................... 88

4.14.4. Recharging .......................................................................................................... 88

4.14.5. Application ........................................................................................................... 89

4.14.5.1. Temperature Computation Method ......................................................................... 89

4.14.6. Charger Recommendations ................................................................................. 90

4.15. Temperature Sensor Interface .................................................................................... 91

5. SIGNALS AND INDICATORS ............................................................................ 92

5.1. ON/~OFF Signal ......................................................................................................... 92

5.1.1. Pin Description .................................................................................................... 92

5.1.2. Electrical Characteristics ...................................................................................... 92

5.1.3. Power-ON ............................................................................................................ 92

5.1.4. Power-OFF .......................................................................................................... 94

5.1.5. Application ........................................................................................................... 95

5.2. Reset Signal (~RESET) .............................................................................................. 96

5.2.1. Reset Sequence .................................................................................................. 96

5.2.2. Pin Description .................................................................................................... 97

5.2.3. Electrical Characteristics ...................................................................................... 97

5.2.4. Application ........................................................................................................... 97

5.3. BOOT Signal .............................................................................................................. 99

5.3.1. Pin Description .................................................................................................... 99

5.4. BAT-RTC (Backup Battery) ....................................................................................... 100

5.4.1. Pin Description .................................................................................................. 100

5.4.2. Electrical Characteristics .................................................................................... 101

5.4.3. Application ......................................................................................................... 101

5.4.3.1. Super Capacitor .....................................................................................................101

5.4.3.2. Non-Rechargeable Battery ......................................................................................101

5.4.3.3. Rechargeable Battery .............................................................................................102

5.5. Buzzer Output........................................................................................................... 103

5.5.1. Pin Description .................................................................................................. 103

5.5.2. Electrical Characteristics .................................................................................... 103

5.5.3. Application ......................................................................................................... 104

5.5.4. Recommended Characteristics .......................................................................... 104

5.6. External Interrupt ...................................................................................................... 105

5.6.1. Pin Description .................................................................................................. 105

5.6.2. Electrical Characteristics .................................................................................... 105

5.6.3. Application ......................................................................................................... 105

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 7

Page 8

Product Technical Specification and

Customer Design Guideline

5.7. VCC_2V8 and VCC_1V8 Output ............................................................................... 107

5.7.1. Pin Description .................................................................................................. 107

5.7.2. Electrical Characteristics .................................................................................... 107

5.8. FLASH-LED (LED0) .................................................................................................. 108

5.8.1. Pin Description .................................................................................................. 108

5.8.2. Electrical Characteristics .................................................................................... 109

5.8.3. Application ......................................................................................................... 109

5.9. Analog to Digital Converter ....................................................................................... 110

5.9.1. Pin Description .................................................................................................. 110

5.9.2. Electrical Characteristics .................................................................................... 110

5.10. Digital to Analog Converter ....................................................................................... 111

5.10.1. Pin Description .................................................................................................. 111

5.10.2. Electrical Characteristics .................................................................................... 111

6. POWER CONSUMPTION ................................................................................ 112

6.1. Power Consumption without the Sierra Wireless Software Suite ................................ 112

6.2. Power Consumption with the Sierra Wireless Software Suite .................................... 113

7. CONSUMPTION MEASUREMENT PROCEDURE .......................................... 116

7.1. Hardware Configuration ............................................................................................ 116

7.1.1. Equipments Used .............................................................................................. 116

7.1.2. Q Series Development Kit Board v3 ................................................................... 117

7.1.3. SIM Cards ......................................................................................................... 117

7.2. Software Configuration ............................................................................................. 118

7.2.1. Embedded Module Configuration ....................................................................... 118

7.2.2. Equipment Configuration.................................................................................... 118

8. RELIABILITY COMPLIANCE AND RECOMMENDED STANDARDS ............. 120

8.1. Reliability Compliance............................................................................................... 120

8.2. Applicable Standards Listing ..................................................................................... 120

8.3. Environmental Specifications .................................................................................... 121

8.3.1. Function Status Classification ............................................................................ 121

8.4. Reliability Prediction Model ....................................................................................... 122

8.4.1. Life Stress Tests ................................................................................................ 122

8.4.2. Environmental Resistance Stress Tests ............................................................. 123

8.4.3. Corrosive Resistance Stress Tests..................................................................... 124

8.4.4. Thermal Resistance Cycle Stress Tests ............................................................. 125

8.4.5. Mechanical Resistance Stress Tests .................................................................. 126

8.4.6. Handling Resistance Stress Tests ...................................................................... 128

9. DESIGN GUIDELINES ..................................................................................... 129

General Rules and Constraints ................................................................................................ 129

9.1. Power Supply ........................................................................................................... 129

9.2. Antenna .................................................................................................................... 129

9.1. Layout/Pads Design .................................................................................................. 130

9.2. Routing Constraints .................................................................................................. 131

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 8

Page 9

Product Technical Specification and

Customer Design Guideline

9.2.1. System Connector ............................................................................................. 131

9.2.2. Power Supply .................................................................................................... 131

9.2.2.1. Ground Plane and Shielding Connection .................................................................133

9.2.3. SIM Interface ..................................................................................................... 133

9.2.4. Audio Circuit ...................................................................................................... 133

9.2.5. RF Circuit .......................................................................................................... 133

9.2.5.1. UFL/SMA Connector...............................................................................................135

9.2.5.2. Coaxial Cable .........................................................................................................135

9.2.5.3. Precidip Connector .................................................................................................136

9.3. EMC and ESD Recommendations ............................................................................ 137

9.4. Mechanical Integration .............................................................................................. 137

9.5. Operating System Upgrade ....................................................................................... 138

10. EMBEDDED TESTABILITY ............................................................................. 139

10.1. Serial Link Access .................................................................................................... 139

10.2. RF Output Accessibility ............................................................................................. 140

11. CONNECTOR AND PERIPHERAL DEVICE REFERENCES .......................... 141

11.1. General Purpose Connector ..................................................................................... 141

11.2. SIM Card Reader ...................................................................................................... 141

11.3. Microphone............................................................................................................... 141

11.4. Speaker .................................................................................................................... 142

11.5. Antenna Cable .......................................................................................................... 142

11.6. RF board-to-board connector .................................................................................... 142

11.7. GSM antenna ........................................................................................................... 142

11.8. Buzzer ...................................................................................................................... 143

12. CERTIFICATION COMPLIANCE AND RECOMMENDED STANDARDS ....... 144

12.1. Certification Compliance ........................................................................................... 144

12.2. Applicable Standards Listing ..................................................................................... 144

13. REFERENCES ................................................................................................. 146

13.1. Web Site Support ..................................................................................................... 146

13.2. Reference Documents .............................................................................................. 146

13.2.1. Sierra Wireless Software Documentation ........................................................... 146

13.2.2. Firmware Documentation ................................................................................... 147

13.2.3. Hardware Documentation .................................................................................. 147

13.2.4. Other Sierra Wireless Documentation ................................................................ 147

13.2.5. Other Related Documentation ............................................................................ 148

13.2.6. Application Notes ............................................................................................... 148

13.3. List of Abbreviations ................................................................................................. 148

14. SAFETY RECOMMENDATIONS (FOR INFORMATION ONLY) ..................... 151

14.1. RF Safety ................................................................................................................. 151

14.1.1. General ............................................................................................................. 151

14.1.2. Exposure to RF Energy ...................................................................................... 151

14.1.3. Efficient Terminal Operation ............................................................................... 151

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 9

Page 10

Product Technical Specification and

Customer Design Guideline

14.1.4. Antenna Care and Replacement ........................................................................ 151

14.2. General Safety.......................................................................................................... 152

14.2.1. Driving ............................................................................................................... 152

14.2.2. Electronic Devices ............................................................................................. 152

14.2.3. Vehicle Electronic Equipment ............................................................................. 152

14.2.4. Medical Electronic Equipment ............................................................................ 152

14.2.5. Aircraft ............................................................................................................... 152

14.2.6. Children ............................................................................................................. 153

14.2.7. Blasting Areas ................................................................................................... 153

14.2.8. Potentially Explosive Atmospheres..................................................................... 153

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 10

Page 11

List of Figures

Figure 1. Functional Architecture ............................................................................................... 20

Figure 2. Power Supply During Burst Emission .......................................................................... 22

Figure 3. Power Supply Ripple Graph (TBC) .............................................................................. 23

Figure 4. Start-up Current Waveform ......................................................................................... 24

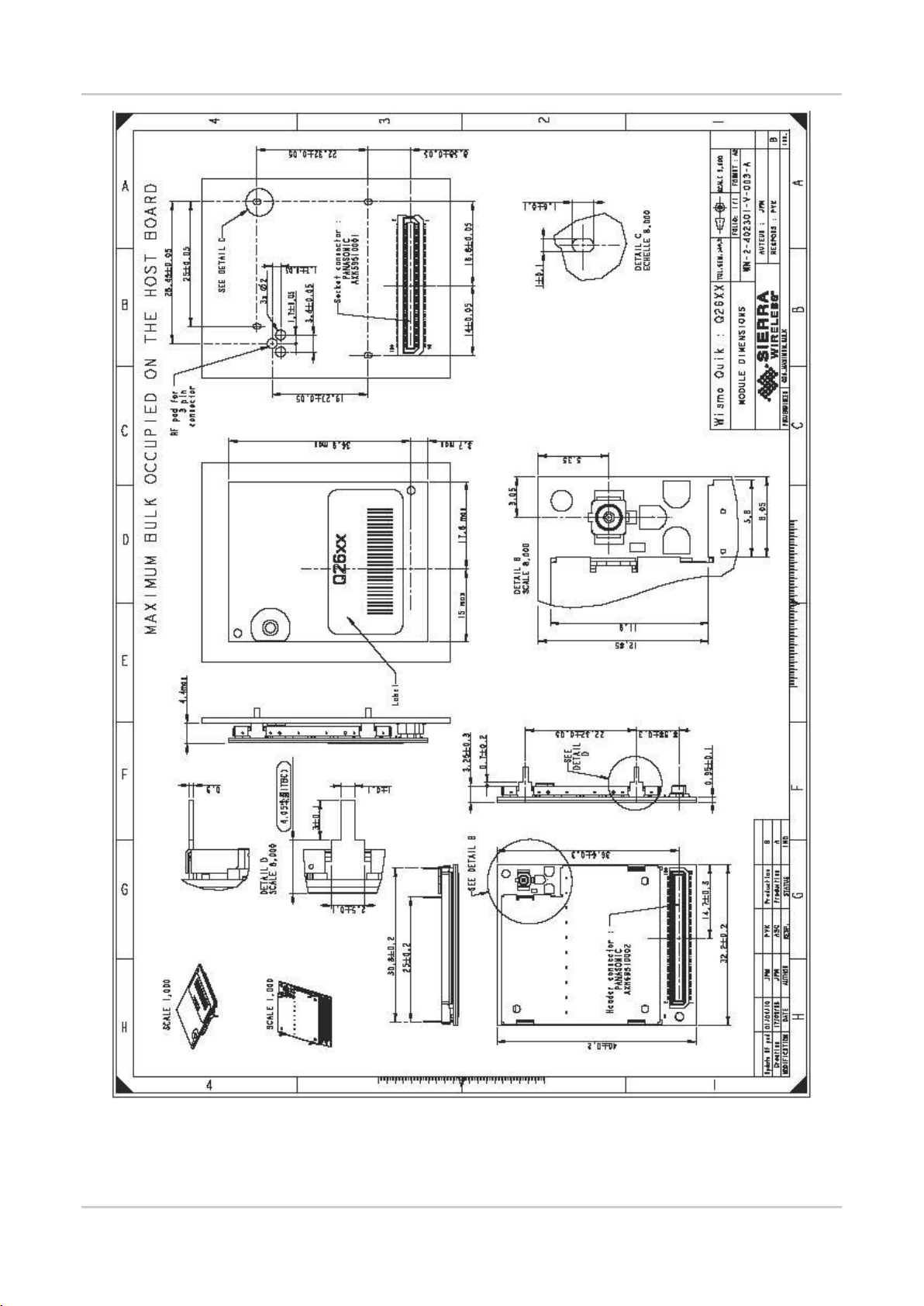

Figure 5. Q2687 Refreshed Embedded Module Mechanical Drawing ......................................... 25

Figure 6. Maximum Bulk Occupied on the Host Board ............................................................... 26

Figure 7. SPI Timing Diagram (Mode 0, Master, 4 wires) ........................................................... 40

Figure 8. SPI Timing Diagram with LOAD Signal (Mode 0, Master, 4 wires) ............................... 41

Figure 9. Example of a 3-wire SPI Bus Application..................................................................... 42

Figure 10. Example of a 4-wire SPI Bus Application..................................................................... 42

Figure 11. I2C Timing Diagram (master) ....................................................................................... 43

Figure 12. Example1 of an I2C Bus Application ............................................................................ 44

Figure 13. Example2 of an I2C Bus Application ............................................................................ 44

Figure 14. Asynchronous Access................................................................................................. 47

Figure 15. Synchronous Access .................................................................................................. 49

Figure 16. Read Synchronous Timing .......................................................................................... 49

Figure 17. Write Synchronous Timing .......................................................................................... 50

Figure 18. Example of a Parallel Bus Application (NAND Memory) .............................................. 51

Figure 19. Example of a Keyboard Implementation ...................................................................... 53

Figure 20. Example of an RS-232 Level Shifter Implementation for UART1 ................................. 55

Figure 21. Example of V24/CMOS Serial Link Implementation for UART1.................................... 56

Figure 22. Example of a Full Modem V24/CMOS Serial Link Implementation for UART1 .............. 56

Figure 23. Example of RS-232 Level Shifter Implementation for UART2 ...................................... 59

Figure 24. Example of a Typical SIM Socket Implementation ....................................................... 62

Figure 25. Example of a USB Implementation .............................................................................. 65

Figure 26. MIC1 Equivalent Circuits ............................................................................................. 69

Figure 27. Example of a MIC1 Differential Connection with LC Filter ............................................ 69

Figure 28. Example of a MIC1 Differential Connection without an LC Filter .................................. 70

Figure 29. Example of a MIC1 Single-Ended Connection with LC Filter ........................................ 71

Figure 30. Example of a MIC1 Single-Ended Connection without an LC Filter .............................. 71

Figure 31. MIC2 Equivalent Circuits ............................................................................................. 72

Figure 32. Example of a MIC2 Differential Connection with LC Filter ............................................ 73

Figure 33. Example of a MIC2 Differential Connection without an LC Filter .................................. 74

Figure 34. Example of a MIC2 Single-Ended Connection with LC Filter ........................................ 74

Figure 35. Example of a MIC2 Single-Ended Connection without an LC Filter .............................. 75

Figure 36. SPK1 Equivalent Circuits ............................................................................................ 76

Figure 37. SPK2 Equivalent Circuits ............................................................................................ 77

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 11

Page 12

Product Technical Specification and

Customer Design Guideline

Figure 38. Example of an SPK Differential Connection................................................................. 78

Figure 39. Example of an SPK Single-Ended Connection ............................................................ 78

Figure 40. PCM Frame Waveform ............................................................................................... 81

Figure 41. PCM Sampling Waveform ........................................................................................... 81

Figure 42. Battery Charging Diagram........................................................................................... 83

Figure 43. Ni-Cd/Ni-Mh Charging Waveform ................................................................................ 84

Figure 44. Li-Ion Full Charging Waveform .................................................................................... 85

Figure 45. Phase 2 Pulse ............................................................................................................ 86

Figure 46. Phase 2 Rest .............................................................................................................. 87

Figure 47. Phase 3 Switch ........................................................................................................... 87

Figure 48. Example of an ADC Application .................................................................................. 89

Figure 49. Temperature Sensor Characteristics ........................................................................... 91

Figure 50. Power-ON Sequence (no PIN code activated) ............................................................. 93

Figure 51. Power-OFF Sequence ................................................................................................ 95

Figure 52. Example of ON/~OFF Pin Connection ......................................................................... 95

Figure 53. Reset Sequence Waveform ........................................................................................ 96

Figure 54. Example of ~Reset Pin Connection with Switch Configuration ..................................... 98

Figure 55. Example of ~Reset Pin Connection with Transistor Configuration ................................ 98

Figure 56. Example of BOOT Pin Implementation ........................................................................ 99

Figure 57. Real Time Clock Power Supply ................................................................................. 100

Figure 58. RTC Supplied by a Gold Capacitor ........................................................................... 101

Figure 59. RTC Supplied by a Non-Rechargeable Battery.......................................................... 101

Figure 60. RTC Supplied by a Rechargeable Battery ................................................................. 102

Figure 61. Example of a Buzzer Implementation ........................................................................ 104

Figure 62. Example of an LED Driven by the Buzzer Output ...................................................... 104

Figure 63. Example of INT0 Driven by an Open Collector .......................................................... 106

Figure 64. Example of INT1 Driven by an Open Collector .......................................................... 106

Figure 65. LED0 State During RESET and Initialization Time ..................................................... 109

Figure 66. Example of FLASH-LED Implementation................................................................... 109

Figure 67. Typical Hardware Configuration ................................................................................ 116

Figure 68. Layout Requirement ................................................................................................. 130

Figure 69. Precidip Connector Pad Design (Sierra Wireless Side).............................................. 131

Figure 70. Power Supply Routing Example ................................................................................ 132

Figure 71. Burst Simulation Circuit ............................................................................................. 132

Figure 72. AppCad Screenshot for MicroStrip Design ................................................................ 134

Figure 73. Routing Examples..................................................................................................... 134

Figure 74. UFL/SMA Connector ................................................................................................. 135

Figure 75. Antenna Connection to both RF pad and Ground pad ............................................... 136

Figure 76. Precidip Connector ................................................................................................... 136

Figure 77. Main Serial Link (UART1) Debug Access .................................................................. 139

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 12

Page 13

List of Tables

Table 1: Q2687 Refreshed Embedded Module Features........................................................... 17

Table 2: List of RF Frequency Ranges...................................................................................... 20

Table 3: Input Power Supply Voltage ........................................................................................ 23

Table 4: Power Supply Pin-Out................................................................................................. 23

Table 5: Current Start-Up (TBC) ............................................................................................... 24

Table 6: Available Interfaces and Signals ................................................................................. 28

Table 7: General Purpose Connector Pin Description ............................................................... 29

Table 8: Signal Comparison between the Q Series Intelligent Embedded Modules ................... 34

Table 9: Electrical Characteristic of a 2.8 Volt Type (2V8) Digital I/O ......................................... 35

Table 10: Electrical Characteristic of a 1.8 Volt Type (1V8) Digital I/O ......................................... 35

Table 11: Open Drain Output Type ............................................................................................. 35

Table 12: Reset State Definition ................................................................................................. 36

Table 13: GPIO Pin Description .................................................................................................. 37

Table 14: SPI Bus Configuration................................................................................................. 39

Table 15: SPI Bus AC Characteristics ........................................................................................ 40

Table 16: SPI1 Pin Description ................................................................................................... 41

Table 17: SPI2 Pin Description ................................................................................................... 41

Table 18: I2C AC Characteristics ................................................................................................ 43

Table 19: I2C Pin Description ...................................................................................................... 44

Table 20: Parallel Interface Pin Description ................................................................................ 45

Table 21: AC Characteristics of Asynchronous Accesses ........................................................... 47

Table 22: AC Characteristics of Synchronous Accesses ............................................................. 50

Table 23: Address Bus Size Details ............................................................................................ 51

Table 24: Keyboard Interface Pin Description ............................................................................. 52

Table 25: UART1 Pin Description ............................................................................................... 54

Table 26: UART2 Pin Description ............................................................................................... 58

Table 27: SIM Pin Description .................................................................................................... 61

Table 28: Electrical Characteristics of the SIM Interface ............................................................. 61

Table 29: SIM Socket Pin Description ......................................................................................... 62

Table 30: USB Pin Description ................................................................................................... 64

Table 31: Electrical Characteristics of the USB Interface ............................................................ 64

Table 32: Antenna Specifications ............................................................................................... 67

Table 33: Analog Audio Pin Description ...................................................................................... 68

Table 34: Electrical Characteristics of MIC1 ................................................................................ 69

Table 35: Recommended Components for a MIC1 Differential Connection ................................. 70

Table 36: Recommended Components for a MIC1 Single-Ended Connection ............................. 72

Table 37: Electrical Characteristics of MIC2 ................................................................................ 72

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 13

Page 14

Product Technical Specification and

Customer Design Guideline

Table 38: Recommended Components for a MIC2 Differential Connection ................................. 74

Table 39: Recommended Components for a MIC2 Single-Ended Connection ............................. 75

Table 40: Speaker Information ................................................................................................... 76

Table 41: Electrical Characteristics of SPK1 ............................................................................... 76

Table 42: Electrical Characteristics of SPK2 ............................................................................... 77

Table 43: AC Characteristics of the Digital Audio Interface ......................................................... 82

Table 44: PCM Interface Pin Description .................................................................................... 82

Table 45: Electrical Characteristics of Ni-Cd/Ni-Mh Battery Timing Charge ................................. 85

Table 46: Electrical Characteristics of Li-Ion Battery Timing Charge............................................ 86

Table 47: Battery Charging Interface Pin Description .................................................................. 88

Table 48: Electrical Characteristics of the Temperature Monitoring Feature ................................ 88

Table 49: Charger Recommendations ........................................................................................ 90

Table 50: ON/~OFF Signal Pin Description ................................................................................. 92

Table 51: Electrical Characteristics of the ON/~OFF Signal ........................................................ 92

Table 52: T

on/off-hold

Minimum Values ........................................................................................... 94

Table 53: Reset Signal Pin Description ....................................................................................... 97

Table 54: Electrical Characteristics of the Reset Signal .............................................................. 97

Table 55: Reset Settings ............................................................................................................ 98

Table 56: BOOT Settings ........................................................................................................... 99

Table 57: Boot Signal Pin Description ......................................................................................... 99

Table 58: BAT-RTC Pin Description ......................................................................................... 100

Table 59: Electrical Characteristics of the BAT-RTC Interface................................................... 101

Table 60: PWM/Buzzer Output Pin Description ......................................................................... 103

Table 61: Electrical Characteristics of the Buzzer Output .......................................................... 103

Table 62: External Interrupt Pin Description .............................................................................. 105

Table 63: Electrical Characteristics of the External Input/Interrupt ............................................. 105

Table 64: VCC_2V8 and VCC_1V8 Pin Description .................................................................. 107

Table 65: Electrical Characteristics of the VCC_2V8 and VCC_1V8 Signals ............................. 107

Table 66: FLASH-LED Status ................................................................................................... 108

Table 67: FLASH-LED Pin Description ..................................................................................... 108

Table 68: Electrical Characteristics of the FLASH-LED Signal .................................................. 109

Table 69: ADC Pin Description ................................................................................................. 110

Table 70: Electrical Characteristics of the ADC ......................................................................... 110

Table 71: DAC Pin Description ................................................................................................. 111

Table 72: Electrical Characteristics of the DAC ......................................................................... 111

Table 73: Power Consumption Without the Sierra Wireless Software Suite; Typical Values ...... 112

Table 74: Power Consumption With the Application CPU @ 26MHz, Typical Values................. 113

Table 75: Power Consumption With the Application CPU @ 104MHz, Typical Values ............... 114

Table 76: Recommended Equipments ...................................................................................... 117

Table 77: Operating Mode Configuration .................................................................................. 118

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 14

Page 15

Product Technical Specification and

Customer Design Guideline

Table 78: Standards Conformity for the Q2687 Refreshed Embedded Module .......................... 120

Table 79: Applicable Standards and Requirements................................................................... 120

Table 80: Operating Class Temperature Range ........................................................................ 121

Table 81: ISO Failure Mode Severity Classification................................................................... 122

Table 82: Life Stress Tests ....................................................................................................... 122

Table 83: Environmental Resistance Stress Tests .................................................................... 123

Table 84: Corrosive Resistance Stress Tests ........................................................................... 124

Table 85: Thermal Resistance Cycle Stress Tests .................................................................... 125

Table 86: Mechanical Resistance Stress Tests ......................................................................... 126

Table 87: Handling Resistance Stress Tests ............................................................................. 128

Table 88: Contact Information of GSM Antenna Providers ........................................................ 143

Table 89: Standards Conformity for the Q2687 Refreshed Embedded Module .......................... 144

Table 90: Applicable Standards and Requirements for the Q2687 Refreshed Embedded Module ...

................................................................................................................................. 144

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 15

Page 16

1. Introduction

The Q2687 Refreshed Intelligent Embedded Module is a self-contained E-GSM/DCS/GSM850/PCS

GPRS/EGPRS 900/1800/850/1900 quad-band embedded module. It supports the Sierra Wireless

Software Suite, the world’s most comprehensive cellular development environment which allows

embedded standard ANSI C applications to be natively executed directly on the embedded module.

For more information about Sierra Wireless Software Suite, refer to the documents listed in section

13.2 Reference Documents.

Note that this document only covers the Q2687 Refreshed Intelligent Embedded Module and does not

cover the programmable capabilities available through the Sierra Wireless Software Suite.

1.1. Physical Dimensions

Length: 40 mm

Width: 32.2 mm

Thickness: 4 mm

Weight: 8g

Note: The physical dimensions mentioned above do not include the shielding pins.

1.2. General Features

The following table lists the Q2687 Refreshed embedded module features.

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 16

Page 17

Product Technical Specification and

Customer Design Guideline

Introduction

Table 1: Q2687 Refreshed Embedded Module Features

Featur e

Descri ption

Shieldin g

The Q2687 Refreshed embedded module has complete body shielding.

Intelligent

Embedded Modul e

Control

Full set of AT commands for GSM/GPRS/EGPRS including GSM 07.07 and

07.05 AT command sets

Status indication for GSM

GSM/DCS Output

Power

Class 4 (2 W) for GSM 850 and E-GSM

Class 1 (1 W) for DCS and PCS

GPRS

GPRS multislot class 10

Multislot class 2 supported

PBCCH support

Coding schemes: CS1 to CS4

EGPRS

EGPRS multislot class 10

Multislot class 2 supported

PBCCH support

Coding schemes MCS5 to MCS9

Voice

GSM Voice Features with Emergency calls 118 XXX

Full Rate (FR)/ Enhanced Full Rate (EFR) / Half Rate (HR) / Adaptive Multi

Rate (AMR)

Echo cancellation and noise reduction

Full duplex Hands free

SMS

SMS MT, MO

SMS CB

SMS storage into SIM card

GSM

Supplementar y

Services

Call Forwarding, Call Barring

Multiparty

Call Waiting, Call Hold

USSD

Data/Fax

Data circuit asynchronous, transparent, and non-transparent up to 14400

bits/s

Fax Group 3 compatible

SIM Interface

1.8V/3V SIM interface

5V SIM interfaces are available with external adaptation

SIM Tool Kit Release 99

Real Tim e Cl ock

Real Time Clock (RTC) with calendar and alarm

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 17

Page 18

Product Technical Specification and

Customer Design Guideline

Introduction

1.3. GSM/GPRS/EGPRS Features

2-Watt EGSM – GPRS 900/850 radio section running under 3.6 volts

1-Watt GSM-GPRS1800/1900 radio section running under 3.6 volts

0.5-Watt EGPRS 900/850 radio section running under 3.6 volts

0.4-Watt EGPRS 1800/1900 radio section running under 3.6 volts

Hardware GSM/GPRS class 10 and EGPRS class 10 capable

1.4. Interfaces

Digital section running under 2.8V and 1.8V

3V/1V8 SIM interface

Complete Interfacing:

Power supply

Serial link

Analog audio

PCM digital audio

SIM card

Keyboard

USB 2.0 slave

Serial LCD (not available with AT commands)

Parallel port for specific applications (under Open AT® control only)

1.5. Operating System

Real Time Clock (RTC) with calendar

Battery charger

Echo cancellation + noise reduction (quadri codec)

Full GSM or GSM/GPRS/EGPRS Operating System stack

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 18

Page 19

Product Technical Specification and

Customer Design Guideline

Introduction

1.6. Connection Interfaces

The Q2687 Refreshed embedded module is compliant with RoHS Directive

2002/95/EC which sets limits for the use of certain restricted hazardous substances.

This directive states that “from 1st July 2006, new electrical and electronic equipment

put on the market does not contain lead, mercury, cadmium, hexavalent chromium,

polybrominated biphenyls (PBB) or polybrominated diphenyl ethers (PBDE)”.

This electronic product is subject to the EU Directive 2002/96/EC for Waste Electrical

and Electronic Equipment (WEEE). As such, this product must not be disposed off at

a municipal waste collection point. Please refer to local regulations for directions on

how to dispose of this product in an environmental friendly manner.

The Q2687 Refreshed Intelligent Embedded Module has four external connections:

Three for RF circuit:

UFL connector

Soldered connection

Precidip connection

One for baseband signals:

100-pin I/O connector (compatible with Q2686 and Q2687 embedded modules)

1.7. Environment and Mechanics

1.7.1. RoHS Directive Compliant

1.7.2. Disposing of the Product

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 19

Page 20

2. Functional Specifications

RF Bandwidth

Transmit Band ( Tx)

Receive Band (Rx)

GSM 850

824 to 849 MHz

869 to 894 MHz

E-GSM 900

880 to 915 MHz

925 to 960 MHz

DCS 1800

1710 to 1785 MHz

1805 to 1880 MHz

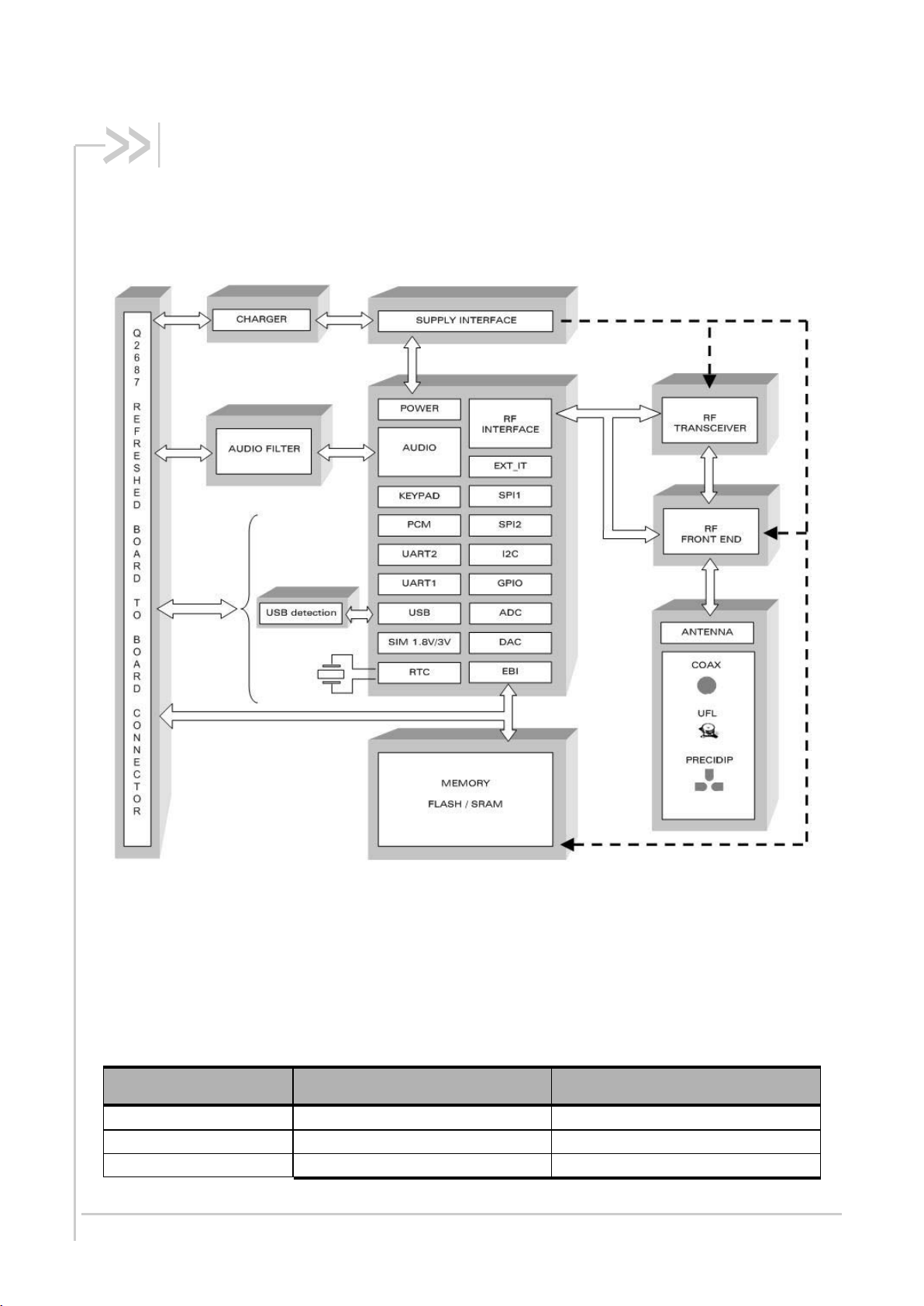

2.1. Functional Architecture

The global architecture of the Q2687 Refreshed Embedded Module is described in the figure below.

Figure 1. Functional Architecture

2.1.1. RF Functionalities

The Radio Frequency (RF) functionalities of the Q2687 Refreshed embedded module complies with

the Phase II EGSM 900/DCS 1800 and GSM 850/PCS 1900 recommendations. The frequency range

for the transmit band and receive band are given in the table below.

Table 2: List of RF Frequency Ranges

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 20

Page 21

Product Technical Specification and

Customer Design Guideline

Functional Specifications

RF Bandwidth

Transmit Band ( Tx)

Receive Band (Rx)

PCS 1900

1850 to 1910 MHz

1930 to 1990 MHz

The Radio Frequency (RF) component is based on a specific quad-band chip that includes the

following:

Quad-band LNAs (Low Noise Amplifier)

Digital Low-IF Receiver

Offset PLL/PL (Phase Locked Loop and Polar Loop) transmitter

Frequency synthesizer

Digitally controlled crystal oscillator (DCXO)

Tx/Rx FEM (Front-End module) for quad-band GSM/GPRS/EGPRS

2.1.2. Baseband Functionalities

The digital part of the Q2687 Refreshed embedded module is composed of a PCF5213 PHILIPS

chip. This chipset uses a 0.18µm mixed technology CMOS, which allows massive integration as well

as low current consumption.

2.2. Operating System

The Q2687 Refreshed Embedded Module is Sierra Wireless Software Suite compliant. With the Sierra

Wireless Software Suite, customers can embed their own applications with the Q2687 Refreshed

embedded module and turn the Q2687 Refreshed embedded module into a solution for their specific

market need.

The operating system allows for the Q2687 Refreshed Embedded Module to be controlled by AT

commands. However, some interfaces in the Q2687 Refreshed embedded module may still not be

available even with AT command control as these interfaces are dependent on the peripheral devices

connected to the Q2687 Refreshed embedded module.

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 21

Page 22

3. Technical Specifications

3.1. Power Supply

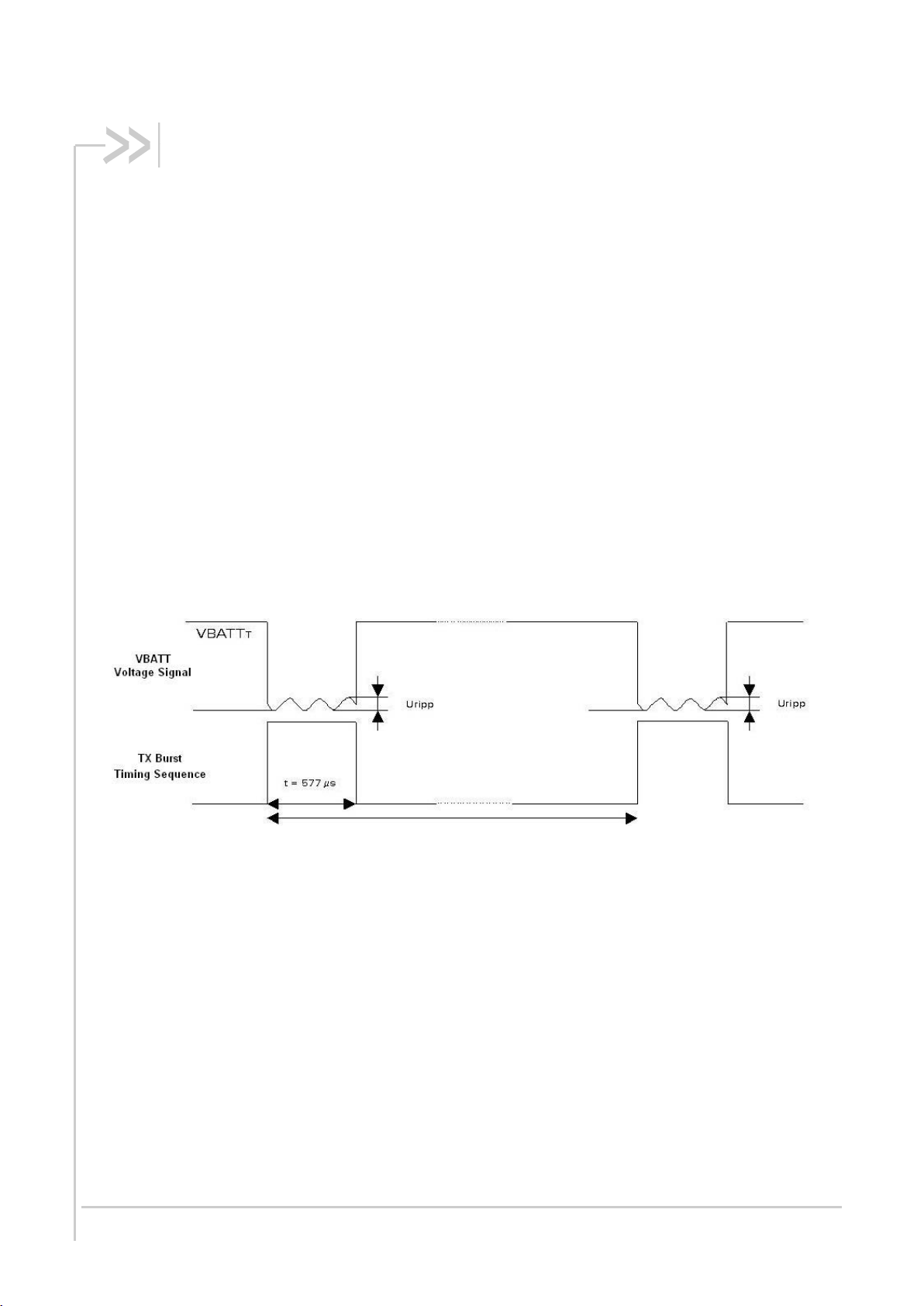

The power supply is one of the key issues in the design of a GSM terminal. Due to the burst emission

in GSM/GPRS, the power supply must be able to deliver high current peaks in a short time. During

these peaks, the ripple (U

Input Power Supply Voltage).

Listed below are the corresponding radio burst rates in connected mode:

GSM/GPRS class 2 terminals emit 577µs radio bursts every 4.615ms (see Figure 2 Power

Supply During Burst Emission)

GPRS class 10 terminals emit 1154µs radio bursts every 4.615ms

In connected mode, the RF Power Amplifier current (2.0A peak in GSM /GPRS mode) flows with a

ratio of:

1/8 of the time (around 577µs every 4.615ms for GSM /GPRS cl 2 – 2RX/1TX)

) on the supply voltage must not exceed a certain limit (refer to Table 3:

ripp

and

2/8 of the time (around 1154µs every 4.615ms for GSM /GPRS cl 10 – 3RX/2TX)

with the rising time at around 10µs.

Figure 2. Power Supply During Burst Emission

Only VBATT (external power supply source) input is necessary to supply the Q2687 Refreshed

embedded module. VBATT also provides for the following functions:

Directly supplies the RF components with 3.6V. (Note that it is essential to keep a minimum

voltage ripple at this connection in order to avoid any phase error or spectrum modulation

degradation. On the other hand, insufficient power supply could dramatically affect some RF

performances such as TX power, modulation spectrum, EMC performance, spurious emission

and frequency error.)

Internally used to provide through several regulators, the power supplies VCC_2V8 and

VCC_1V8, which are needed for the baseband signals.

The Q2687 Refreshed embedded module shielding case is the grounding. The ground must be

connected on the motherboard through a complete layer on the PCB.

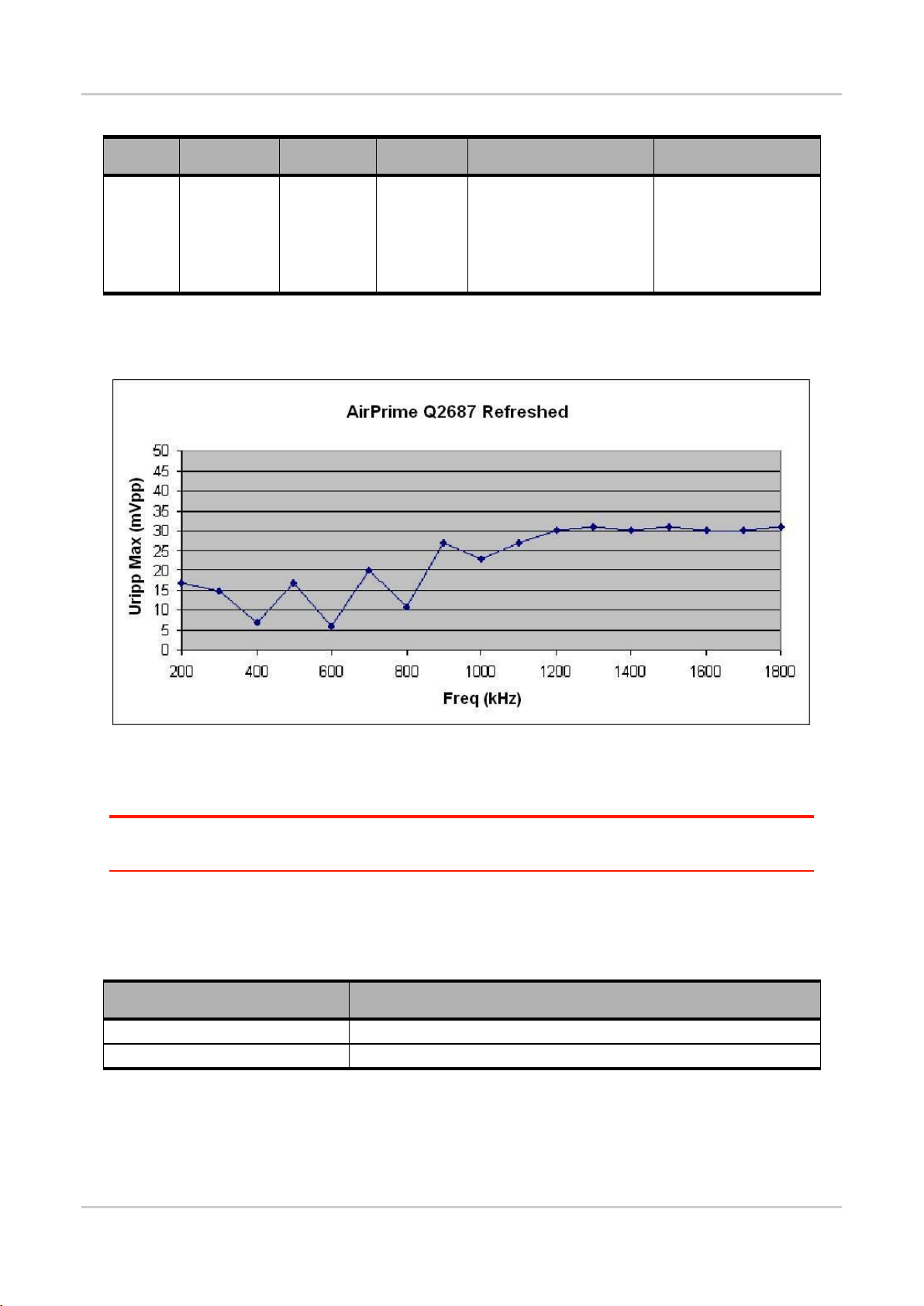

The following table describes the electrical characteristics of the input power supply voltage that will

guarantee nominal functioning of the Q2687 Refreshed embedded module.

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 22

Page 23

Product Technical Specification and

Customer Design Guideline

Technical Specifications

Table 3: Input Power Supply Voltage

V

MI N

V

NO M

V

MA X

Ripple M ax (U

ri pp

)

I

pe ak

M ax

VBATT

3.2V

1,2

3.6V

4.8V

250mVpp (freq < 10kHz)

40mVpp (10kHz < freq <

100kHz)

5mVpp (freq > 100kHz)

(TBC)

2.0A

Signal

Pin Number

VBATT

1, 2, 3, 4

GND

Shielding

1: This value must be guaranteed during the burst (with 2.0A Peak in GSM, GPRS or EGPRS mode)

2: Maximum operating Voltage Standing Wave Ratio (VSW R) 2:1.

Figure 3. Power Supply Ripple Graph (TBC)

When the Q2687 Refreshed embedded module is supplied with a battery, the total impedance

(battery + protections + PCB) should be less than 150 m.

Caution: When the Q2687 Refreshed embedded module is in Alarm mode or Off mode, no voltage has to be

applied on any pin of the 100-pin connector except on VBATT (pins 1 to 4), BAT-RTC (pin 7) for RTC

operation or ON/~OFF (pin 19) to power-ON the Q2687 Refreshed embedded module.

3.1.1. Power Supply Pin-Out

Table 4: Power Supply Pin-Out

The grounding connection is made through the shielding; therefore the four leads must be soldered to

the ground plane.

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 23

Page 24

Product Technical Specification and

Customer Design Guideline

Technical Specifications

3.1.2. Start-Up Current

Current Pe ak at

Am bien t Temper ature

(25°C)

VBATTmin (3. 2V)

VBATTtyp (3. 6V)

VBATTmax ( 4. 8V)

I

Startup

86 mA

77 mA

64 mA

During the initial second following Power ON, a peak of current appears. This peak of current is called

“I

current” and has a duration of about 161ms (typical) (TBC).

Startup

Figure 4: Start-up Current Waveform shows the current waveform and identifies the peak considered

as the start-up current.

<TBC>

Figure 4. Start-up Current Waveform

In this condition, we can consider the following results:

Table 5: Current Start-Up (TBC)

3.1.3. Decoupling of Power Supply Signals

Decoupling capacitors on VBATT lines are embedded in the Q2687 Refreshed embedded module, so

it should not be necessary to add decoupling capacitors close to the embedded module.

However, in case of EMI/RFI problems, the VBATT signal may require some EMI/RFI decoupling –

parallel 33pF capacitors close to the embedded module or a serial ferrite bead (or both to get better

results). Low frequency decoupling capacitors (22µF to 100µF) can be used to reduce TDMA noise

(217Hz).

Caution: When ferrite beads are used, the recommendation given for the power supply connection must be

carefully followed (high current capacity and low impedance).

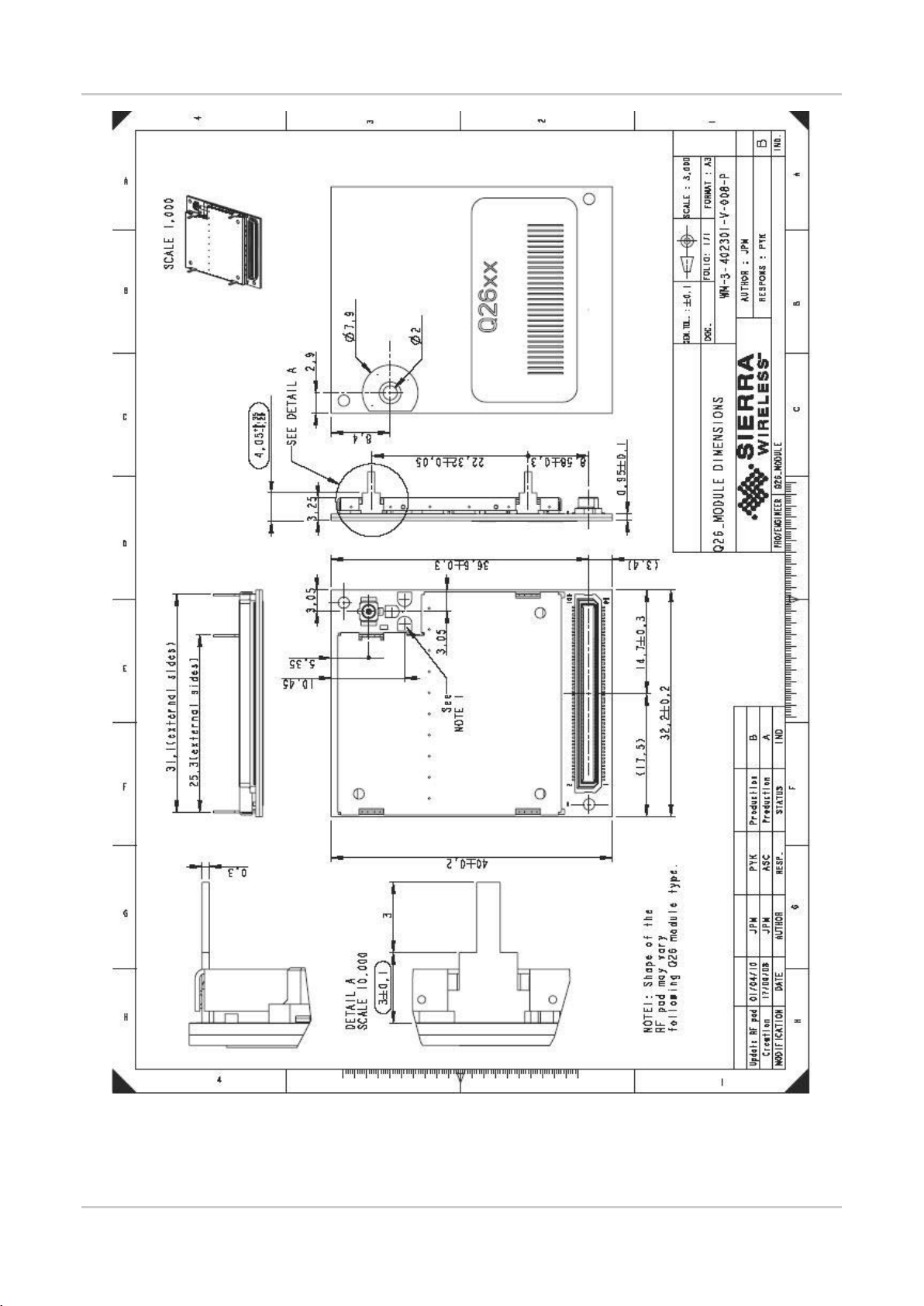

3.2. Mechanical Specifications

The Q2687 Refreshed Embedded Module has a complete self-contained shield and the mechanical

specifications are shown in the figure below, which also specifies the following:

The area needed for the Q2687 Refreshed embedded module to fit in an application

The drill template for the four pads to be soldered on the application board

The dimensions and tolerance for correctly placing the 100-pin female connector on the

application board

It is strongly recommended to plan a free area (no components) around the Q2687 Refreshed

embedded module in order to facilitate the removal/re-assembly of the embedded module on the

application board.

Also take note that when transmitting, the Q2687 Refreshed Embedded Module produces heat (due

to the internal Power Amplifier). This heat will generate a temperature increase and may warm the

application board on which the Q2687 Refreshed embedded module is soldered. This is especially

true for GPRS Class 10 use in low band. The Q2687 Refreshed Embedded Module’s built-in

temperature sensor can be used to monitor the temperature inside the module. For more information,

refer to document [14] AirPrime Q2687 Product Technical Specification.

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 24

Page 25

Product Technical Specification and

Customer Design Guideline

Technical Specifications

Figure 5. Q2687 Refreshed Embedded Module Mechanical Drawing

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 25

Page 26

Product Technical Specification and

Customer Design Guideline

Technical Specifications

Figure 6. Maximum Bulk Occupied on the Host Board

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 26

Page 27

Product Technical Specification and

Customer Design Guideline

Technical Specifications

3.3. Firmware Upgrade

The firmware upgrade process consists of downloading GSM/GPRS/EGPRS software into the

corresponding internal flash memories of the Q2687 Refreshed Intelligent Embedded Module.

Downloading is done through the GSM Main Serial link port (UART1) connected to a PC using the

XMODEM protocol.

A specific AT command, AT+WDWL, is used to start the download. For more information, refer to

document [8] Firmware 7.43 AT Commands Manual (Sierra Wireless Software Suite 2.33).

Access to the following UART1 main serial link signals are required to carry out downloading:

CT103-TXD1

CT104-RXD1

~CT106-CTS1

~CT105-RTS1

GND

Consequently, it is very important to plan and define easy access to these signals during the

hardware design of the application board. For more information about these signals, refer to section

4.7 Main Serial Link (UART1).

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 27

Page 28

4. Interfaces

Name

Driven by AT commands

Driven by Open AT®

Serial Interface

Parallel Interface

Keyboard Interface

Main Serial Link

Auxiliary Serial Link

SIM Interface

General Purpose IO

Analog to Digital Converter

Analog Audio Interface

PWM / Buzzer Output

Battery Charging Interface

External Interruption

BAT-RTC (Backup Battery)

LED0 signal

Digital Audio Interface (PCM)

USB 2.0 Interface

Caution: Some of the Embedded Module interface signals are multiplexed in order to limit the number of pins

but this architecture includes some restrictions.

4.1. General Purpose Connector (GPC)

A 100-pin connector is provided to interface the Q2687 Refreshed Intelligent Embedded Module with

a board containing either a serial or parallel LCD module; a keyboard, a SIM connector or a battery

connection.

The following table lists the interfaces and signals available on the GPC and specifies whether these

interfaces and signals are driven by AT Command, Open AT® or both.

Table 6: Available Interfaces and Signals

WA_DEV_Q26RD_PTS_001 Rev 002 April 20, 2010 28

Page 29

Product Technical Specification and

Customer Design Guideline

Interfaces

4.1.1. Pin Description

Pin

#

Signal Nam e

I/O

Type

Volt age

I/O*

Reset Stat e

Descri ption

Dealing wi th Unused Pins

Nominal

Mux

1

ADC0/VBATT

VBATT

I Power Supply

2 ADC0/VBATT

VBATT

I Power Supply

3 ADC0/VBATT

VBATT

I Power Supply

4 ADC0/VBATT

VBATT

I Power Supply

5 VCC_1V8

VCC_1V8

O 1.8V Supply Output

NC 6 CHG-IN

CHG-IN

I Charger input

NC

7

BAT-RTC

BAT-RTC

I/O RTC Battery connection

NC

8

CHG-IN

CHG-IN

I Charger input

NC

9

SIM-VCC

1V8 or 3V

O SIM Power Supply

10

VCC_2V8

VCC_2V8

O 2.8V Supply Output

NC

11

SIM-IO

1V8 or 3V

I/O

Pull-up (about

10kΩ)

SIM Data

12

SIMPRES

GPIO18

VCC_1V8

I Z SIM Detection

NC

13

~SIM-RST

1V8 or 3V

O 0 SIM reset Output

14

SIM-CLK

1V8 or 3V

O 0 SIM Clock

15

BUZZER0

Open Drain

O Z Buzzer Output

NC

16

BOOT

VCC_1V8

I Not Used

Add a test point / a jumper/ a switch to

VCC_1V8 (Pin 5) in case Download

Specific mode is used (See product

specification for details)

Refer to the following table for the pin description of the general purpose connector.