Page 1

AirPrime XA1110/XM1110

AirPrime XA1110/XM1110

41111116

Rev 1

Page 2

AirPrime XA1110/XM1110 Hardware Design Guide

Important

Notice

Safety and

Hazards

Due to the nature of wireless communications, transmission and reception of data

can never be guaranteed. Data may be delayed, corrupted (i.e., have errors) or be

totally lost. Although significant delays or losses of data are rare when wireless

devices such as the Sierra Wireless modem are used in a normal manner with a

well-constructed network, the Sierra Wireless modem should not be used in

situations where failure to transmit or receive data could result in damage of any

kind to the user or any other party, including but not limited to personal injury,

death, or loss of property. Sierra Wireless accepts no responsibility for damages

of any kind resulting from delays or errors in data transmitted or received using

the Sierra Wireless modem, or for failure of the Sierra Wireless modem to

transmit or receive such data.

Do not operate the Sierra Wireless modem in areas where blasting is in progress,

where explosive atmospheres may be present, near medical equipment, near life

support equipment, or any equipment which may be susceptible to any form of

radio interference. In such areas, the Sierra Wireless modem MUST BE

POWERED OFF. The Sierra Wireless modem can transmit signals that could

interfere with this equipment.

Do not operate the Sierra Wireless modem in any aircraft, whether the aircraft is

on the ground or in flight. In aircraft, the Sierra Wireless modem MUST BE

POWERED OFF. When operating, the Sierra Wireless modem can transmit

signals that could interfere with various onboard systems.

Limitation of

Liability

Note: Some airlines may permit the use of cellular phones while the aircraft is on the

ground and the door is open. Sierra Wireless modems may be used at this time.

The driver or operator of any vehicle should not operate the Sierra Wireless

modem while in control of a vehicle. Doing so will detract from the driver or

operator's control and operation of that vehicle. In some states and provinces,

operating such communications devices while in control of a vehicle is an offence.

The information in this manual is subject to change without notice and does not

represent a commitment on the part of Sierra Wireless. SIERRA WIRELESS AND

ITS AFFILIATES SPECIFICALLY DISCLAIM LIABILITY FOR ANY AND ALL

DIRECT, INDIRECT, SPECIAL, GENERAL, INCIDENTAL, CONSEQUENTIAL,

PUNITIVE OR EXEMPLARY DAMAGES INCLUDING, BUT NOT LIMITED TO,

LOSS OF PROFITS OR REVENUE OR ANTICIPATED PROFITS OR REVENUE

ARISING OUT OF THE USE OR INABILITY TO USE ANY SIERRA WIRELESS

PRODUCT, EVEN IF SIERRA WIRELESS AND/OR ITS AFFILIATES HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES OR THEY ARE

FORESEEABLE OR FOR CLAIMS BY ANY THIRD PARTY.

Notwithstanding the foregoing, in no event shall Sierra Wireless and/or its

affiliates aggregate liability arising under or in connection with the Sierra Wireless

product, regardless of the number of events, occurrences, or claims giving rise to

liability, be in excess of the price paid by the purchaser for the Sierra Wireless

product.

Rev 1 Jun.17 2 41111116

Page 3

Preface

Patents This product may contain technology developed by or for Sierra Wireless Inc. This

product includes technology licensed from QUALCOMM

manufactured or sold by Sierra Wireless Inc. or its affiliates under one or more

patents licensed from InterDigital Group and MMP Portfolio Licensing.

®

. This product is

Copyright © 2017 Sierra Wireless. All rights reserved.

Trademarks Sierra Wireless

are registered trademarks of Sierra Wireless.

Windows

Corporation.

Macintosh

the U.S. and other countries.

QUALCOMM

under license.

Other trademarks are the property of their respective owners.

®

, AirPrime®, AirLink®, AirVantage® and the Sierra Wireless logo

®

and Windows Vista® are registered trademarks of Microsoft

®

and Mac OS X® are registered trademarks of Apple Inc., registered in

®

is a registered trademark of QUALCOMM Incorporated. Used

Contact

Information

Sales information and technical

support, including warranty and returns

Web: sierrawireless.com/company/contact-us/

Global toll-free number: 1-877-687-7795

6:00 am to 6:00 pm PST

Corporate and product information Web: sierrawireless.com

Revision

History

Revision

number

1 June 23, 2017 Initial draft in SWI template.

Release date Changes

Rev 1 Jun.17 3 41111116

Page 4

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Rules for Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Circuit Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Supply - Compatible Models: Gmm-g3, Gmm-g3(B), Gms-g6a, Gms-

g9, Gms-g6, Gms-b6,PA6E-CAM, XM1110, XA1110 . . . . . . . . . . . . . . . .9

VBACKUP backup battery - Compatible Models: Gmm-g3, Gmm-g3(B),

Gms-g6a, Gms-g9, Gms-g6, Gms-b6, PA6E-CAM, XM1110, XA1110 . .10

UART / I2C/ SPI Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

GND-Ground - Compatible Models: Compatible Models: Gmm-g3, Gmmg3(B), Gms-g6a, Gms-g9, Gms-g6, Gms-b6, PA6E-CAM, XM1110, XA1110 12

Antenna Compliance Design - Compatible Models: Gmm-g3, Gmm-g3(B),

XM1110, XA1110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1PPS - Compatible Models: Gmm-g3, Gmm-g3(B), Gms-g6a, Gms-g9, Gms-

g6, Gms-b6,PA6E-CAM, XM1110, XA1110 . . . . . . . . . . . . . . . . . . . . . . .17

3D_Fix - Compatible Models: Gmm-g3, Gmm-g3(B), Gms-g6a, Gms-g9,

Gms-g6, Gms-b6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1.8V Boost to 3.3V Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Layout Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Layout Underneath the GNSS Module - Compatible Models: Gmm-g3,

Gmm-g3(B), Gms-g6a, Gms-g9, Gms-g6, Gms-b6,PA6E-CAM, XM1110,

XA1110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Keep Far Away from High Profile or Metal-Canned Components - Compatible Models: Gms-g6a, Gms-g9, Gms-g6, Gms-b6,PA6E-CAM, XA1110 25

Placement - Compatible Models: Gmm-g3, Gmm-g3(B), Gms-g6a, Gms-g9,

Gms-g6, Gms-b6, PA6E-CAM, XM1110, XA1110 . . . . . . . . . . . . . . . . . .26

Trace - Compatible Models: Gmm-g3, Gmm-g3(B), Gms-g6a, Gms-g9, Gms-

g6, Gms-b6,PA6E-CAM, XM1110, XA1110 . . . . . . . . . . . . . . . . . . . . . . .26

Ground Segmentation - Compatible Models: Gmm-g3, Gmm-g3(B), Gms-g6a,

Gms-g9, Gms-g6, Gms-b6, PA6E-CAM, XM1110, XA1110 . . . . . . . . . .27

Ground Plane - Compatible Models: Gms-g9,PA6E-CAM, Gms-g6, Gms-b6,

XA1110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Metal Effect on the GNSS Module Compatible Model: Gms-g6a. . . . . . . . . 29

Rev 1 Jun.17 4 41111116

Page 5

Thermal Profile for SMD Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SMT Reflow Soldering Temperature Profile . . . . . . . . . . . . . . . . . . . . . . . . 30

SMT Solder Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Manual Soldering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

How to Check the Working Status of the GPS Module . . . . . . . . . . . . . . . . 31

Super Capacitor Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

About Super Capacitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

How to Calculate the Backup Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Contents

50 Ω Antenna Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

UART to RS232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

UART to USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

How to Efficiently Transfer 1PPS Through Extended Distances . . . . . . . . 37

1pps Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

The Delay Time Caused by the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Calculating the Delay Time in Respect to the Communication Cable Length 39

Waveform Rising Time Caused by OP-amp . . . . . . . . . . . . . . . . . . . . . . . . 40

Recommended OP-amp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Voltage degradation of Communication cable . . . . . . . . . . . . . . . . . . . . . . . 40

Reflow Soldering Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Other Cautionary Notes on the Reflow-Soldering Process . . . . . . . . . . . . . 43

Manual Soldering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Soldering Iron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rev 1 Jun.17 5 41111116

Page 6

1: Introduction

The purpose of this application note is to assist the system developer and integrator

with the MT3333 chip-based Sierra Wireless receiver modules during the process of

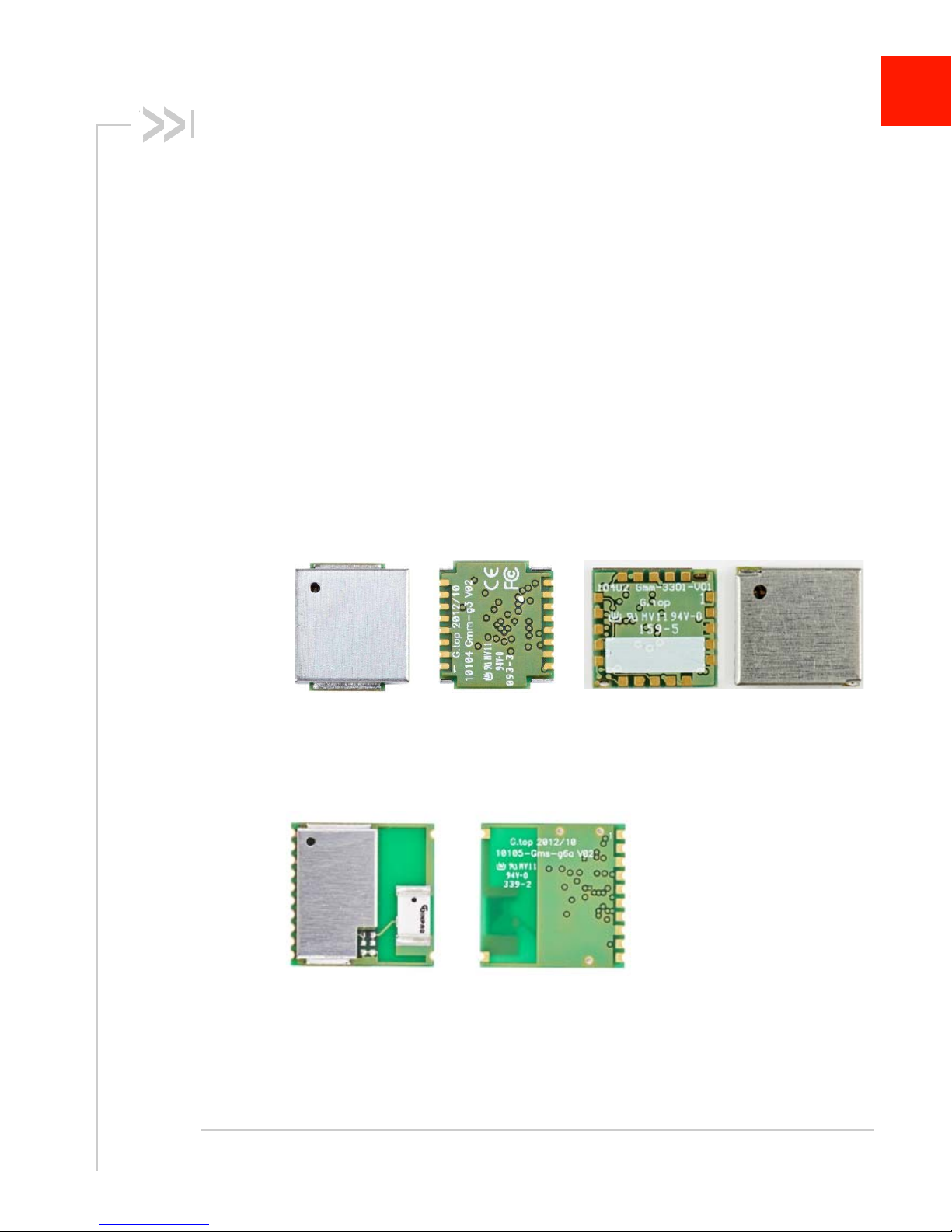

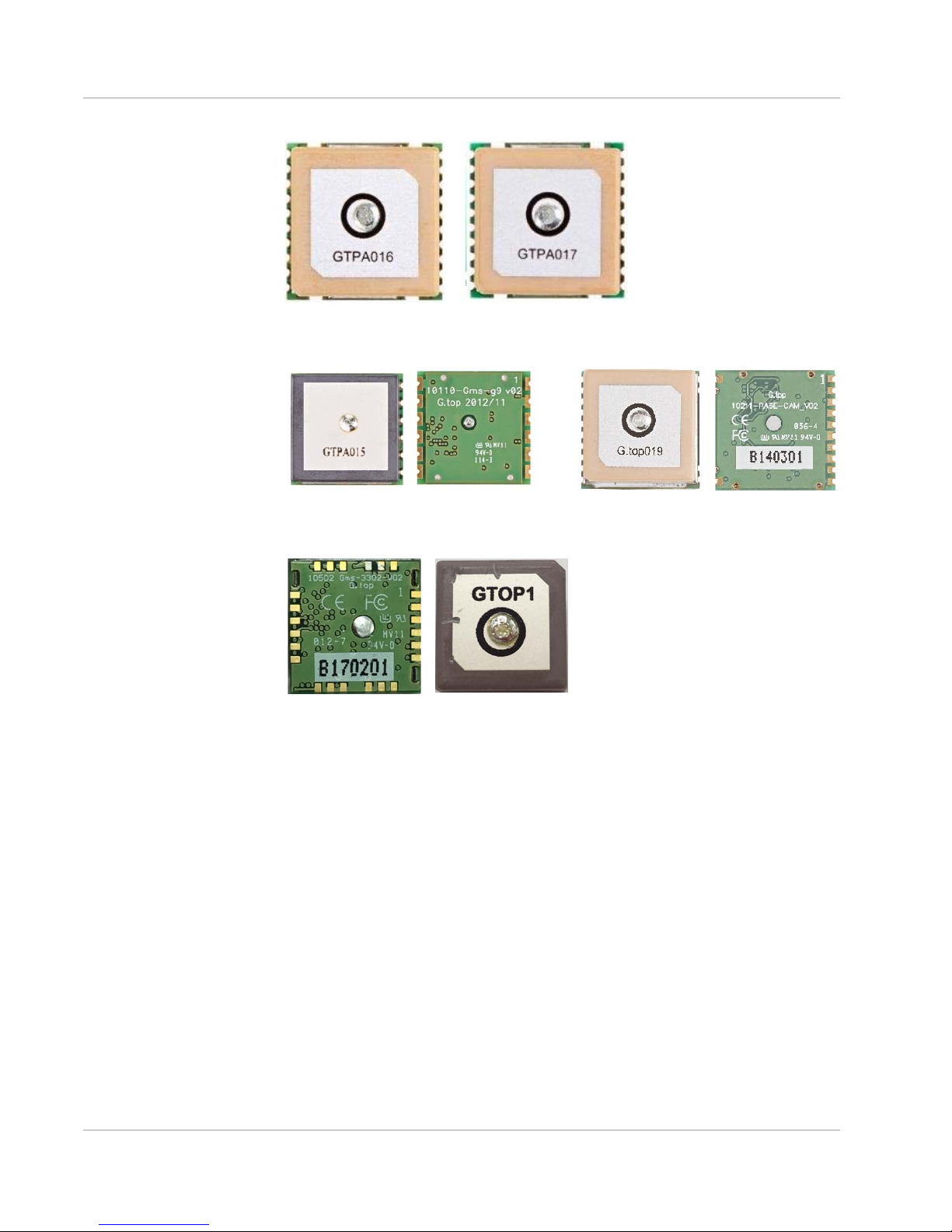

implementation. This document covers the following receiver modules:

Standard Modules

• XM1110

• Firefly 1 (Gmm-g3)

• Firefly 1b (Gmm-g3b)

Antenna Modules

• XA1110

• Titan 1 (PA6E-CAM)

• Titan 2 (Gms-g6)

• Titan 2B (Gms-b6)

• Titan 3 (Gms-g6)

• Stand Alone GPS module: FireFly 1 & FireFly 1b (Gmm-g3, Gmm-g3(B)) and

XM1110

1

Figure 1-1: Stand Alone GPS modules. Left: FireFly 1 & FireFly 1b (Gmm-g3, Gmm-g3(B)). Right: XM1110

• Built-in Chip Antenna Module: Carrion 2 (Gms-g6a)

Figure 1-2: Built-in Chip Antenna Module: Carrion 2 (Gms-g6a)

• Built-in Patch Antenna Modules: Titan 2 (Gms-g6) and Titan 2B (Gms-b6), Titan 3

(Gms-g9) and Titan1 (PA6E-CAM), and XA1110.

Rev 1 Jun.17 6

41111116

Page 7

Figure 1-3: Titan 2 (Gms-g6) and Titan 2B (Gms-b6)

Figure 1-4: Titan 3 (Gms-g9) and Titan1 (PA6E-CAM)

Introduction

Figure 1-5: XA1110

Precautions

Please read carefully before you start

If you use the GNSS receiver inside buildings, tunnels, or beside any huge

objects, the GNSS signals might be cut-off or weakened. Please do not assume

the receiver has malfunctioned.

This application note provides the necessary guidelines for a successful system

design using GNSS modules. For detailed module specifications, please refer to

the corresponding datasheet of the GNSS module.

The GNSS module is an electrostatic sensitive device, please DO NOT touch the

GPS module directly. Follow ESD safety rules when handling.

When using the device for the first time, it is strongly recommended to test the

device outdoors with open sky for at least 10 to 15 minutes to ensure that full

ephemeris data received.

Rev 1 Jun.17 7 41111116

Page 8

AirPrime XA1110/XM1110 Hardware Design Guide

Technical Support

If you have any technical problems or cannot find the required information in our

documents, please feel free to contact us for technical support. Below is a list of

information which you can provide to us to help us in determining the source of

the problem and the necessary solution:

1. Your company name and website.

2. Description about application and system.

3. GNSS module type.

4. GNSS firmware version.

5. Description of the question or problems encountered, together with figures,

pictures or videos files.

a. Test setup.

b. The problem or issue shown in figures.

Rev 1 Jun.17 8 41111116

Page 9

2: General Rules for Design

This section provides some rules when using the GNSS module to obtain good GNSS

performance.

Circuit Design

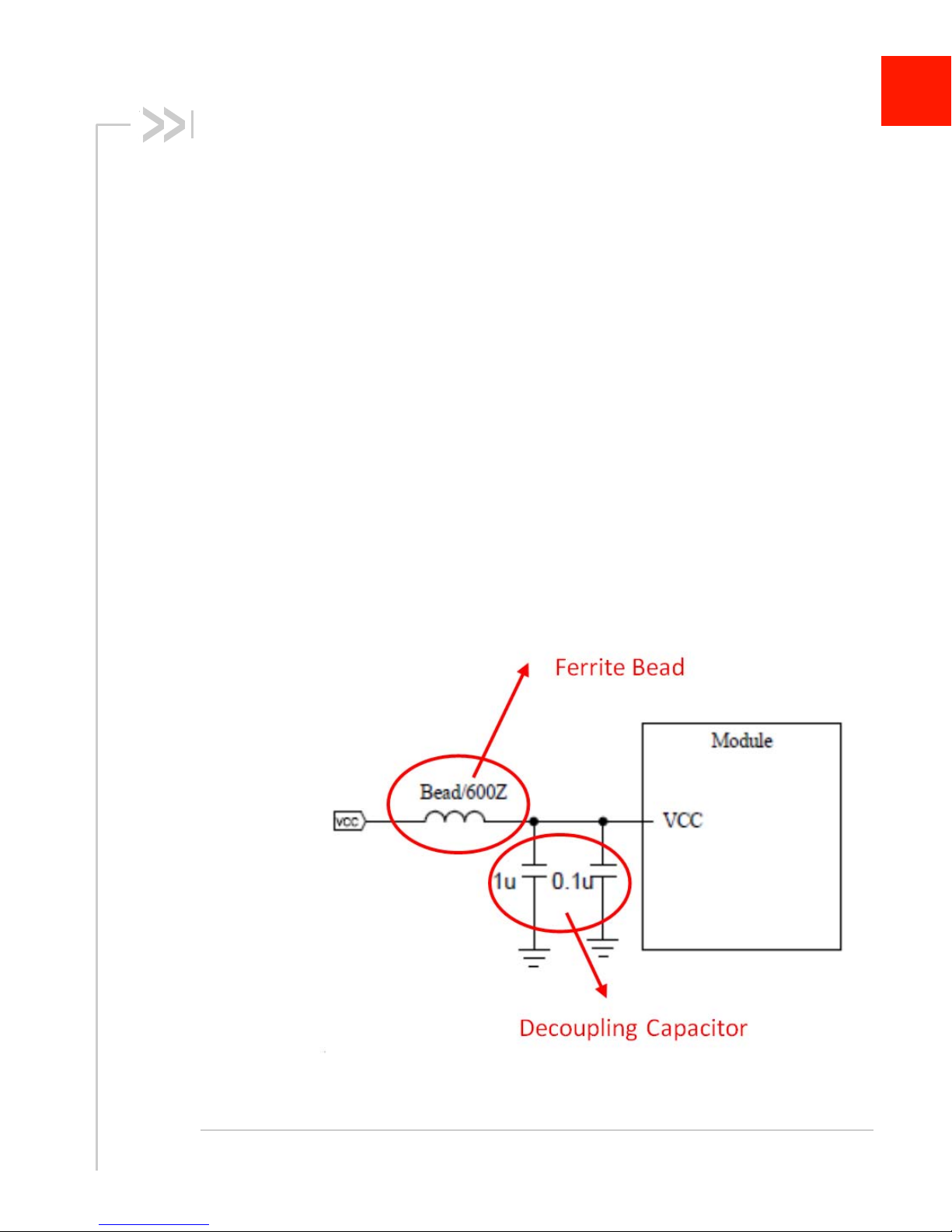

Power Supply - Compatible Models: Gmm-g3,

Gmm-g3(B), Gms-g6a, Gms-g9, Gms-g6, Gmsb6,PA6E-CAM, XM1110, XA1110

It is necessary to provide a clean and stable power supply for our GNSS module in

order to obtain good performance. An unstable power source will have a significant

negative impact on the performance. To achieve high-quality performance, the VCC

ripple must be controlled under 50mVpp. In addition, there are also some important

suggestions for main power circuit design:

1. Add a ferrite bead, power choke, or low pass filter for power noise reduction.

2. A linear regulator (LDO) is better than a switch DC/DC power supplier in the

ripple.

3. Use enough decoupling capacitors beside the VCC for stable voltage.

2

Figure 2-1: Power Design for the GNSS Module

Rev 1 Jun.17 9

41111116

Page 10

AirPrime XA1110/XM1110 Hardware Design Guide

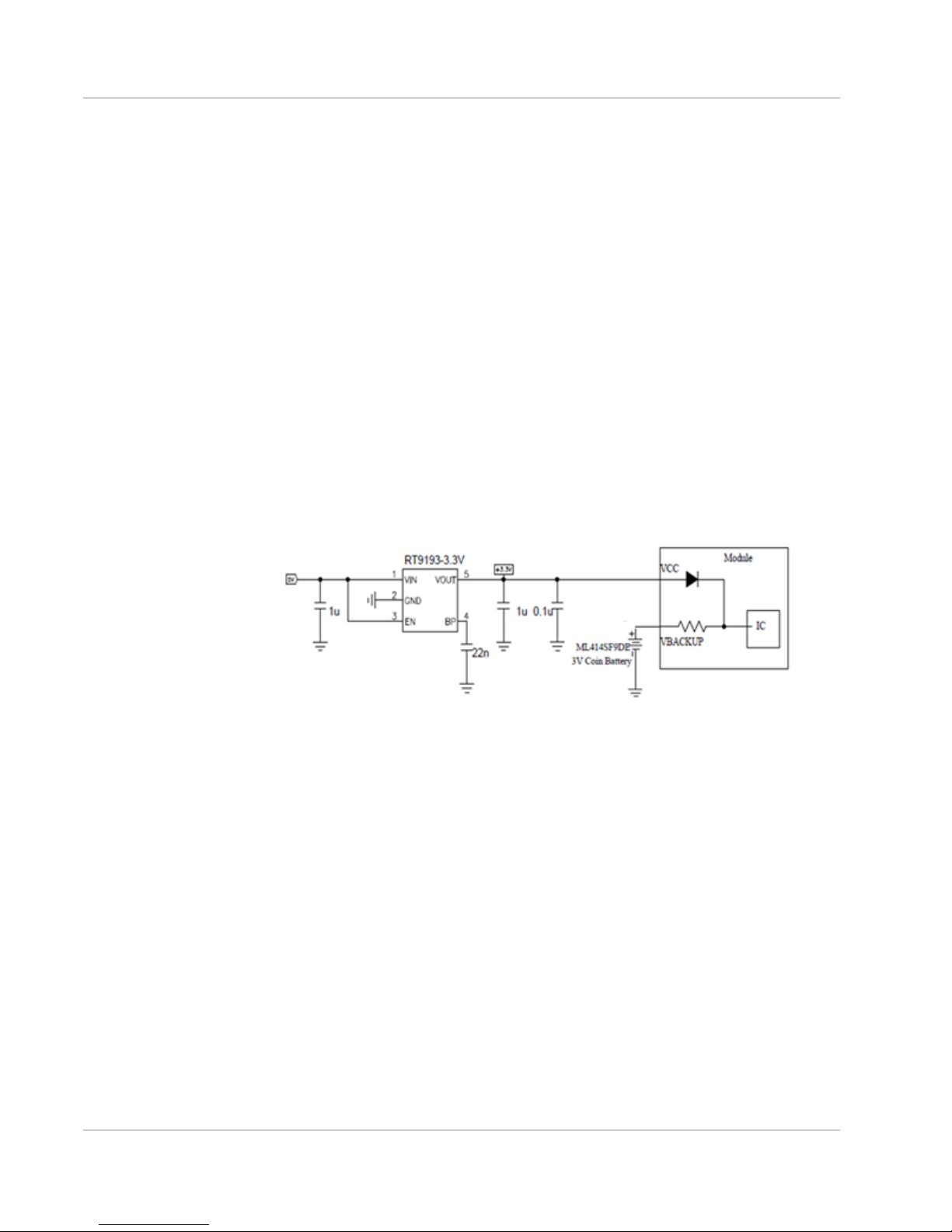

VBACKUP backup battery - Compatible

Models: Gmm-g3, Gmm-g3(B), Gms-g6a, Gmsg9, Gms-g6, Gms-b6, PA6E-CAM, XM1110,

XA1110

The GNSS module has a built-in charging circuit which charges the rechargeable

coin battery.

For most systems, it is recommended to provide the module with backup power

(e.g. Li-Ion rechargeable coin battery, super capacitor). See Figure 2-2 for a

reference design.

For information on the super capacitor reference design, please refer to Super

Capacitor Design.

Backup power is useful in order to maintain RTC operation and retain Ephemeris

data in flash memory which can get a faster TTFF and acquire PVT (Position,

Velocity, Time) information.

If VBACKUP isn’t connected to any coin battery, the GNSS module will execute a

cold start whenever the system is restarted.

Figure 2-2: Built-in a charging circuit for GNSS module

UART / I2C/ SPI Serial Interface

UART 0 (RX/TX) Compatible Models: Gmm-g3, Gmmg3(B), Gms-g6a, Gms-g9, Gms-g6, Gms-b6,PA6ECAM, XM1110, XA1110

1. UART is the TTL level interface that carries the baud rate ranging from 4800

bps to 115200 bps.

2. Placing a damping resistor on the RX and TX of the GNSS module could limit

the interference from the host MCU or high speed digital logics. Fine tuning

the damping resistor is required to efficiently suppress interference. The

damping resistor is a wire wound component and may function as a choke

coil.

Rev 1 Jun.17 10 41111116

Page 11

General Rules for Design

3. Please don’t connect diode(s) to RX/TX as it will decrease the signal driving

capability which might adversely affect the RX/TX signal level. In some cases

no data output will occur.

4. If RS232 logic-level is needed for any particular application, the level shifter

will be necessary. For more information please refer to UART to RS232

Interface.

5. If USB logic-level is needed for any particular application please refer to

UART to USB Interface.

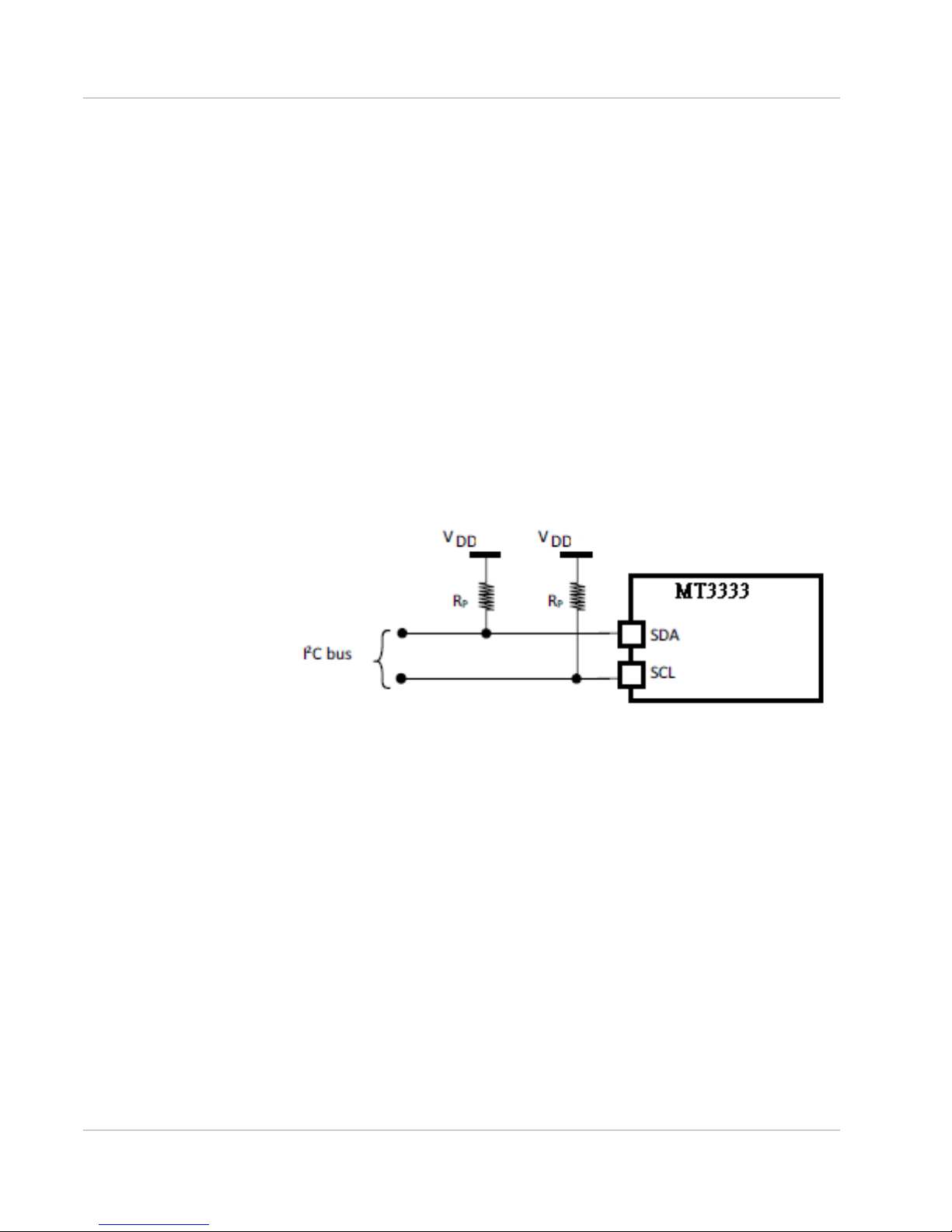

I2C (SCL/SDA) - Compatible Models: XM1110, XA1110

1. The I2C interface is mainly connected to external devices. MT3333 supports

only slave mode (default slave address is 0x10). MT3333 has 256 bytes

URAM mode and 8-byte FIFO mode for transmitting and receiving data. The

bit rate is up to 400 kb/s for fast mode. In addition, MT3333 supports manual

or automatic indicator for data transfer in the slave mode. Device addresses

in the slave mode are programmable.

2. Pull-up resistor must be added for I

2

C bus:

Figure 2-3: Addition of Pull-up Resistor

SPI (CS/CLK/MISO/MOSI) - Compatible Model: Gmm3301, XA1110

1. The serial peripheral interface port manages the communication between the

digital BB and external devices. The MT3333 supports only slave mode. The

slave has a 4 byte-register mode or URAM mode. In URAM mode, the transmitted and received data size is 256 bytes. The clock phase and clock polarity

are selectable. The MT3333 supports a manual or automatic indicator for

data transfer in slave mode. The bit rate is up to 700kb/s.

Rev 1 Jun.17 11 41111116

Page 12

AirPrime XA1110/XM1110 Hardware Design Guide

GND-Ground - Compatible Models: Compatible

Models: Gmm-g3, Gmm-g3(B), Gms-g6a, Gmsg9, Gms-g6, Gms-b6, PA6E-CAM, XM1110,

XA1110

Make sure all GND pins of the module are connected to a completed ground

plane.

The separation of ground between the GNSS module and the rest of the system

are recommended to avoid interference. If this setup is not possible, it is best to

follow these rules: divide the segmentation of the ground between the digital and

analogue system, high current and low current system, and different radiation

systems in general (such as GNSS and GPRS).

One method to segment the ground is to place digital and noise components at

one corner of the board, while placing analog and quiet components at the

opposite corner of the board. Make sure there is no crossing of microstrip or

current between the two component sets with the ground of each set to be

connected to one point only.

Another method is to place the two different sets at different layers of the board

while the ground of each layer is connected to one point only which is preferably

located at the border of the board practically.

Antenna Compliance Design - Compatible

Models: Gmm-g3, Gmm-g3(B), XM1110, XA1110

The GNSS antenna is a receiving part of the device to acquire weak GNSS

signals from the sky. A common solution would be to use a ceramic patch

antenna because of its small form factor and low cost. There are two types of

antennas: passive and active.

A passive antenna, like a patch antenna and chip antenna, is solely by itself

without signal amplifier such as LNA. It must be fine tuned for the specific module

model to obtain the best signal receiving performance.

An external antenna is a standalone device, which integrates an LNA and patch

antenna with an RF cable for higher gain. This performs better than a passive

antenna.

The antenna can be chosen according to the radiation efficiency, radiation

pattern, gain, bandwidth, form factor, and cost. Make sure the ground plane is

sufficient for the antenna to ensure better performance.

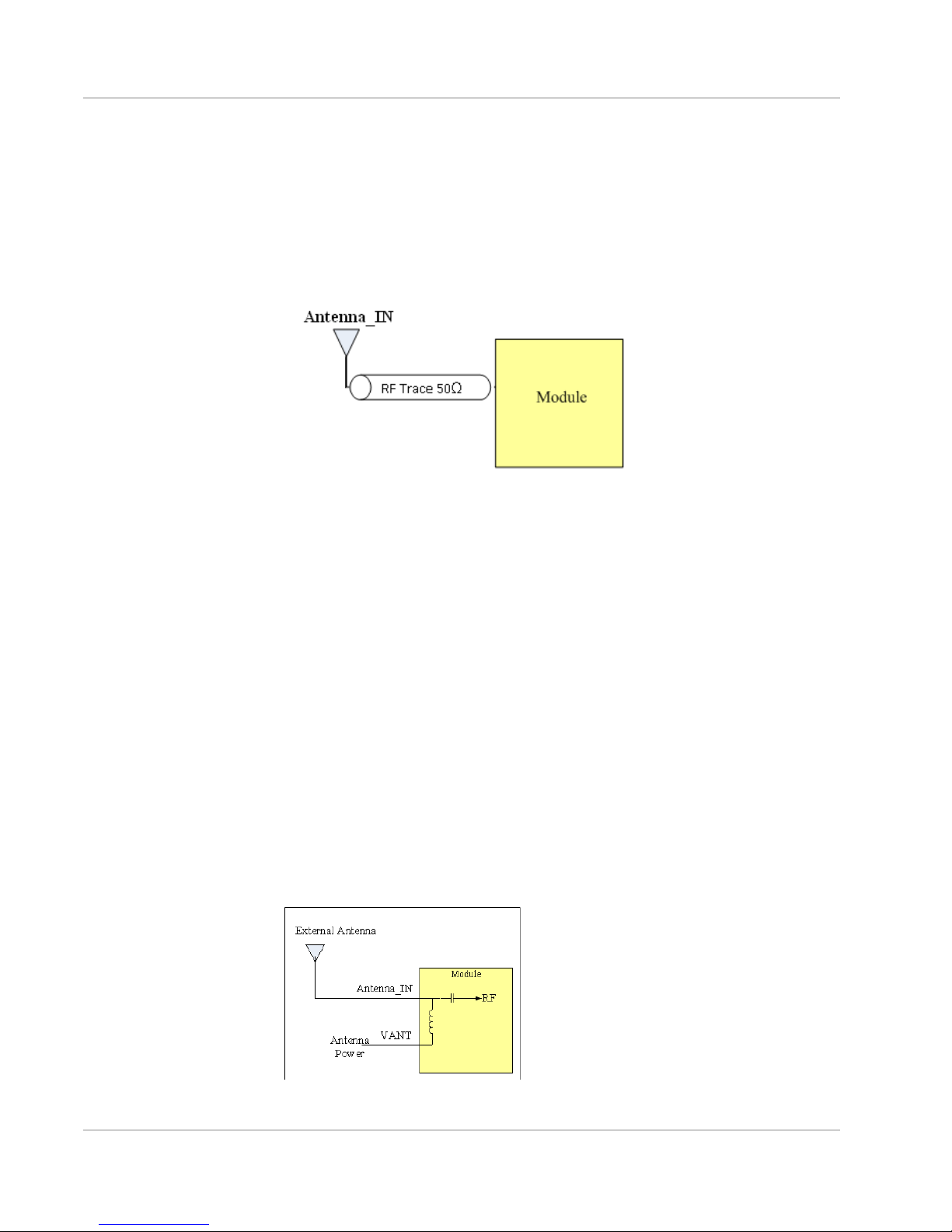

Design Patch Antenna with GNSS module.

1. In general, a 50Ω patch antenna will work well with the GNSS module. The

antenna can be connected to the Antenna IN pin with a 50Ω impedance

trace.

2. Please keep the patch antenna far away from noise sources such as the

switching power supply and high speed digital logic and radar wave guide.

Rev 1 Jun.17 12 41111116

Page 13

General Rules for Design

3. The 50Ω trace should be kept as short as possible to reduce the chance of

picking up noise from the air and PCB. A simple direct-line trace is recommended.

4. If needed, a matching circuit could be placed between the patch antenna and

the GNSS module. The matching circuit design should be discussed with the

module and patch antenna manufacturer.

5. For 50Ω matching, please refer to 50 Ω Antenna Matching.

Figure 2-4: PCB trace design for antenna impedance matching

Selecting an External Antennal Architecture for the

GNSS Module

An external antenna requires DC power in order to work properly. A typical

method is to feed DC into the RF trace. The external antenna then extracts the

DC from the RF trace. Thus the RF trace transports both the RF signal and DC

power. An RF chock coil couples the DC power to the RF trace to perform this

method.

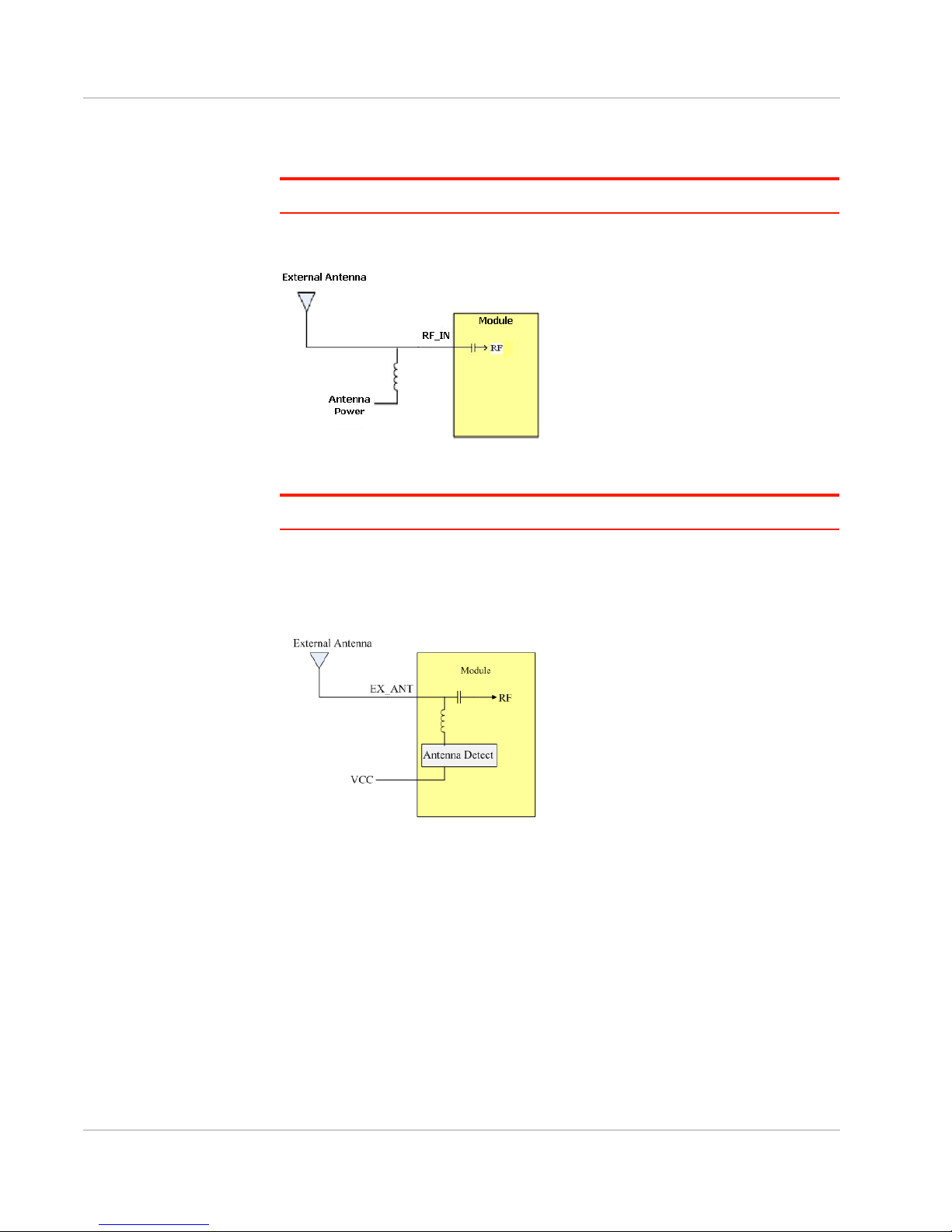

The Sierra Wireless modules provide a circuit for connecting an external antenna

and power feeding method as depicted in Figure 2-5, Figure 2-6, and Figure 2-7

below. Please select the module prudently while applying the design with an

external antenna.

• Mode1 (i.e. Gmm-g3, Gmm-g3(B)): the power supply for the external

antenna needs to be externally fed into the module via the VANT pin and the

antenna connected to the Antenna IN pin:

Figure 2-5: Mode 1: (Internal chock coil)

Rev 1 Jun.17 13 41111116

Page 14

AirPrime XA1110/XM1110 Hardware Design Guide

• Mode2 (i.e. XM1110): The power supply needs to be externally provided and

is connected directly to the external antenna via a chock coil.

Note: Chock Coil for reference: LQG15HS33NJ02D (Murata)

Figure 2-6: Mode 2: (External chock coil)

Note: Chock Coil for reference: LQG15HS33NJ02D (Murata)

• Mode3 (i.e. PA6E-CAM, XA1110): The power supply for the external antenna

needs to be externally fed into the module from the VCC pin directly and

connect antenna to EX_ANT pin.

Figure 2-7: Mode 3: (Internal chock coil)

Rev 1 Jun.17 14 41111116

Page 15

General Rules for Design

Figure 2-8: Modes

Design chip antenna with GNSS module

Different vendors have different reference designs, so we list two chip antenna

sources: Pulse and Unictron.

1. Antenna source: Pulse

Figure 2-9: Pulse Schematic Design

Figure 2-10: Pulse PCB Layout

When selecting the Antenna source, check its datasheet first before tuning an RF

match component’s footprint (such as: C27, C28). You can base this on its PCB

size and housing to tune for an optimal value and meet the GNSS’s frequency in

order to get a good reception effect.

Rev 1 Jun.17 15 41111116

Page 16

AirPrime XA1110/XM1110 Hardware Design Guide

Pulse web site:

www.pulseeng.com/antennas

Note: C27, C28’s value are still based on your actual trace to tune it.

2. Antenna source: Unictron

Figure 2-11: Unictron Schematic

Figure 2-12: Unictron PCB

When you select this source, check its datasheet first before tuning the RF match

component’s footprint (such as: C26, C27, C28, C29, C30). You can tune based

on the PCB size and housing to tune for an optimal value in order to meet the

GNSS’s frequency and obtain good reception.

Unictron web site:

http://www.unictron.com/index/

Note: C26,C27,C28,C29,C30’s value are still based on your actual trace to tune it.

Rev 1 Jun.17 16 41111116

Page 17

General Rules for Design

External Antenna of Specification

When select your external antenna, refer to the specification shown in Table 2-1

and Table 2-2 below.

The Gmm-g3 module uses the GPS/GLONASS External Antenna:

Table 2-1: GPS/GLONASS External Antenna

Characteristic Specification

Polarization Right-hand circular polarized

Frequency Received 1.575GHz~1.615GHz

Power Supply 3.3V

DC Current 5mA<IDC<11mA at 3.3V

Total Gain 27±3dB

Output VSWR 2.0

Impendence 50Ω

Noise Figure 2dB

The Gmm-g3(B) module uses the Beidou/GPS External Antenna:

Table 2-2: Beidou/GPS External Antenna

Characteristic Specification

Polarization Right-hand circular polarized

Frequency Received 1.561GHz~1.575GHz

Power Supply 3.3V

DC Current 3mA<IDC<30mA at 3.3V

Total Gain 27±1dB

Output VSWR 2.0

Impendence 50Ω

Noise Figure 1.5dB

1PPS - Compatible Models: Gmm-g3, Gmmg3(B), Gms-g6a, Gms-g9, Gms-g6, Gmsb6,PA6E-CAM, XM1110, XA1110

1PPS signal is an output pulse signal used for timing applications. Its electrical

characteristics are:

• Low Voltage level: 0~0.4V

• High Voltage level: 2.8~3.1V

Rev 1 Jun.17 17 41111116

Page 18

AirPrime XA1110/XM1110 Hardware Design Guide

• Period: 1s

• Accuracy (jitter):±20ns

• 100ms pulse width duration (firmware customization for pulse width duration

is available)

Figure 2-13: 1PPS signal and its pulse width with 100ms duration

Free run 1PPS Output Before 3D_FIX

The Sierra Wireless standard GNSS module outputs 1PPS signal after the

module obtains a 3D_FIX. This is a factory default setting.

Cable Delay Compensation

In some cases a long distance connection (~300m) may be needed. For a timing

application, the cable length is critical. For more information on 1PPS signal

transmission delay please refer to How to Efficiently Transfer 1PPS Through

Extended Distances.

LED Indicator for 1PPS Signal

For 1PPS LED indication, you may connect an LED indicator with a 330ohm

resistor in series.

Rev 1 Jun.17 18 41111116

Page 19

General Rules for Design

Figure 2-14: 1PPS Signal Design for IO

3D_Fix - Compatible Models: Gmm-g3, Gmmg3(B), Gms-g6a, Gms-g9, Gms-g6, Gms-b6

3D_Fix signal is an output pulse signal used for GPS fix applications. Its electrical

characteristics are:

• Low Voltage level: 0~0.4V

• High Voltage level: 2.8~3.1V

• Source current (Max.): 14mA, sink current 14mA

Signal Output Before 2D Fix:

Duration: 1 second high and 1 second low.

Period: 2s

(Firmware customizable)

Figure 2-15: Signal Output Before 2D Fix

Rev 1 Jun.17 19 41111116

Page 20

AirPrime XA1110/XM1110 Hardware Design Guide

Signal Output After 2D or 3D Fix

Duration: Constant low level output

(Firmware customizable)

Figure 2-16: Signal output after 2D or 3D Fix

For 3D_Fix indication, you may connect an LED with a 330ohm resister in series

in two ways as shown in Figure 2-17 and Figure 2-18.

Figure 2-17: 3D_F ix signal design for IO (LED ON when high, LED OFF when low)

Figure 2-18: 3D_F ix signal design for IO (LED ON when low, LED OFF when high)

Rev 1 Jun.17 20 41111116

Page 21

General Rules for Design

1.8V Boost to 3.3V Application

If you want to use the 3.3V’s GNSS module in the 1.8V system there are two

considerations: power supply translation and signal level shift. For power supply

translation, you can use a boost circuit which can boost 1.8V to 3.3V (refer to

Figure 2-19 below).

TPS61097A-33 is the Ti’s boost IC which can support boost functionality. In its

application C1 and C2 need to use 10uF and L1 is 10uH. It can support

approximately 100mA of output. For information about the capacitor and

inductor’s placement, refer to the application note on the Ti web site:

http://www.ti.com/lit/ds/symlink/tps61097a-33.pdf

Figure 2-19: Application Schematic

Figure 2-20: Output Voltage vs Output Current

Rev 1 Jun.17 21 41111116

Page 22

AirPrime XA1110/XM1110 Hardware Design Guide

For signal level shift, when your host system is 1.8V and the Sierra Wireless

module is 3.3V, the host system can control the Sierra Wireless module by using

a signal level shift circuit (refer to theFigure 2-21 below). R1 to R4’s values are

default values. In actual design, you can adjust their values to achieve control.

The 2N7002L can select low RDS(On) to reduce power consumption through a

voltage drop.

Figure 2-21: Signal Level Shift Circuit

Layout Guidelines

Please follow the layout guideline for the right GPS module during the design

process.

Layout Underneath the GNSS Module Compatible Models: Gmm-g3, Gmm-g3(B),

Gms-g6a, Gms-g9, Gms-g6, Gms-b6,PA6ECAM, XM1110, XA1110

In general, GNSS modules have high receiving sensitivity at around -165dBm.

During hardware integration, try to avoid noise or harmonics in the following

bands to prevent unnecessary reception degradation:

• Beidou 1561.098MHz ±2.046MHz and GPS 1572.42MHz±2MHz

• GLONASS 1598.0625~1605.375MHz

Modern GNSS positioning products include many components such as an LCD

screen, MCU, high speed digital signal (access memory card), and an RF system

(i.e. Cellular module, BT, Wi-Fi, DVB-T). Keep these components away from the

GNSS module in order to avoid the noise interference, otherwise poor GNSS RF

reception may result.

For modules Gmm-g3, Gmm-g3(B) and XM1110

Don’t leave any trace or mark underneath the GNSS module as indicated by the

circled area in figure Figure 2-22 below. In other words, provide the GNSS

module with a clean GND plane.

Rev 1 Jun.17 22 41111116

Page 23

Figure 2-22: GPS Module on a clean GND Plane

General Rules for Design

Don’t place any trace such as I2C (SCL/SDA), SPI (CLK/MISO/MOSI), UART (TX/

RX) underneath the GNSS module, otherwise it will cause a sensitivity decrease.

For Modules Gms-g9, Gms-g6, Gms-b6 and PA6ECAM

Place a hole according to the location of the RF feeding pin of the module. The

hole will provide an area to fit the RF feeding pin on your system PCB and provide

the appropriate hole size.

Don’t place any high speed trace such as I

UART (TX/RX) underneath the GNSS module, otherwise it will cause a sensitivity

decrease.

2

C (SCL/SDA), SPI (CLK/MISO/MOSI),

Figure 2-23: Hole Placement

Rev 1 Jun.17 23 41111116

Page 24

AirPrime XA1110/XM1110 Hardware Design Guide

Figure 2-24: GPS on a clean GND plane and antenna hole

For Module XA1110

In order to avoid the interference, place many vias on the two sides of the RF

trace which is from the module to the SMA/RF connector on your system PCB as

illustrated in xxx below.

Don’t place any high speed trace such as I

UART (TX/RX) underneath the GNSS module, otherwise it will cause a sensitivity

decrease.

2

C (SCL/SDA), SPI (CLK/MISO/MOSI),

Figure 2-25: Avoiding Interference

Rev 1 Jun.17 24 41111116

Page 25

General Rules for Design

Keep Far Away from High Profile or MetalCanned Components - Compatible Models:

Gms-g6a, Gms-g9, Gms-g6, Gms-b6,PA6ECAM, XA1110

It is good practice to place the GNSS module far away from any high-profile

components especially with metal case enclosed components such as the E-CAP,

coin battery, and Pin Header. The antenna field pattern can be affected and

pattern distortion can occur. At worst, this will decrease the GNSS signal up to

~10dB.

Figure 2-26: First Example of bad and good GNSS module placements

Figure 2-27: Second Example of bad and good GNSS module placements

Figure 2-28: Third Example of bad and good GNSS module placements

Rev 1 Jun.17 25 41111116

Page 26

AirPrime XA1110/XM1110 Hardware Design Guide

Placement - Compatible Models: Gmm-g3,

Gmm-g3(B), Gms-g6a, Gms-g9, Gms-g6, Gmsb6, PA6E-CAM, XM1110, XA1110

• Place the decoupling capacitors for the VCC close to the GNSS module.

• Place the damping resistors for TX/RX close to GNSS module.

Do not place:

• the GNSS module in proximity to high-speed digital processing circuitry

• the GNSS module in proximity to high-current switching power circuitry

• the GNSS module in proximity to clock sources circuitry

Trace - Compatible Models: Gmm-g3, Gmmg3(B), Gms-g6a, Gms-g9, Gms-g6, Gmsb6,PA6E-CAM, XM1110, XA1110

1. The USB differential signals should be traced closely and of equal length for

better noise immunity and minimum radiation.

2. Apply a 50 ohm impedance RF trace for correct impedance matching.

3. Any right angle turn in trace routing should be done with two 135 degree

turns or an arc turn.

Figure 2-29: Examples of turns in trace routing

It is better to have an independent trace of the power source for any device:

Figure 2-30: Examples of Independent Trace

Rev 1 Jun.17 26 41111116

Page 27

General Rules for Design

Ground Segmentation - Compatible Models:

Gmm-g3, Gmm-g3(B), Gms-g6a, Gms-g9, Gmsg6, Gms-b6, PA6E-CAM, XM1110, XA1110

In general, the separation of ground between the GNSS module and the rest of

the system is recommended to avoid interference. If this is not possible, it is best

to follow these typical rules: segmentation of ground between digital and

analogue system, high current and low current system, and different radiation

systems such as GNSS and GPRS. One way to segment the ground is to place

digital and noise components at one corner of the board, while placing analog

and quiet components at the opposite corner of the board. Make sure there is no

crossing of microstrip or current between the two component sets with ground of

each sets to be contacted to one point only.

Another method is to place the two different sets at different layers of the board,

while the ground of each layer is contacted at one point only which is practically

located at the border of the board.

Ground Plane - Compatible Models: Gmsg9,PA6E-CAM, Gms-g6, Gms-b6, XA1110

For Gms-g9, PA6E-CAM, Gms-g6, Gms-b6, XA1110

A large GND plane directly underneath the module could enhance the magneticfield line of the antenna for better GNSS signal reception. Typically it will improve

~2dB maximum. It is strongly recommended to have a ground plane designed

underneath the GNSS module as big as possible.

The recommended thickness for the ground layer is 0.5 to 1 OZ (0.0175 to 0.035

mm). It is best to place the ground plane on the top layer of the PCB, directly

underneath the GNSS module as shown in Figure 2-31:

Figure 2-31: Ground Plane for FR4 Design

Rev 1 Jun.17 27 41111116

Page 28

AirPrime XA1110/XM1110 Hardware Design Guide

C o m p a t i b l e M o d e l : G m s - g 6 a

For the Gms-g6a with a built-in chip antenna module, a special ground plane is

required to improve chip antenna reception performance.

As shown in the circled area of figure Figure 2-32 where the chip antenna area is

when placed on the PCB, no ground plane should be placed on this chip antenna

area or all other layers underneath:

Figure 2-32: Area where no ground plane should be placed

Note: The clearance area size at least 15x6.3mm.

To enhance the antenna efficiency for better GNSS signal reception, it is

recommended to cover the rest of the PCB top layer with ground plane except

where the chip antenna seats as shown in Figure 2-33:

Figure 2-33: Variation in reception sensitivity according to the different size of the GND plane

Rev 1 Jun.17 28 41111116

Page 29

General Rules for Design

Metal Effect on the GNSS Module

Compatible Model: Gms-g6a

The Gms-g6a chip antenna is a sensitive component with the environment.

Care consideration should be taken regarding the housing and the environment

where it is placed:

1. The housing (case) of the host device should not be made of or include any

conductive material for the basic antenna reception.

2. The host device should not be placed underneath conductive material such

as a metal case, metal film, or plastic housing coated in conductive material,

which blocks the GNSS signal from reaching the antenna. If there is metal

material placed underneath the chip antenna, this will also decrease the

antenna reception performance.

As shown in the figure, the distance (d) between metal and module should be

kept as far as possible.

Figure 2-34: Distance between metal and module should be as large as possible

Table 2-3 shows how reception performance can be negatively affected in regard

to the distance between metal and the mounted module.

Table 2-3: Decrease in Sensitivity due to Distance

Distance (MM) Sensitivity Decrease in dB

0mm -14 dB ~ -18dB

1mm -7dB~ -9dB

3mm -6dB ~ -7dB

5mm -3dB~ -5dB

7mm -2dB~ -4dB

10mm 0dB

Rev 1 Jun.17 29 41111116

Page 30

3: Thermal Profile for SMD Modules

The following information is Pb-Free compliant. The details are for reference only.

SMT Reflow Soldering Temperature Profile

• Average ramp-up rate (25 ~ 150°C): 3°C/sec. max.

• Average ramp-up rate (270°C to peak): 3°C/sec. max.

• Preheat: 175 ± 25°C, 60 ~ 120 seconds

• Temperature maintained above 217°C: 60~150 seconds

• Peak temperature: 250 +0/-5°C, 20~40 seconds

• Ramp-down rate: 6°C/sec. max.

• Time 25°C to peak temperature: 8 minutes max.

3

Figure 3-1: SMT Reflow Soldering Temperature Profile

SMT Solder Mask

Please use the dimension of PCB pad as reference and shrink the size by 0.1 to 0.2

mm and use that as layout for paste mask (for PCB pad layout, please see

“Recommended PCB pad layout” on the individual GPS module data sheet).

Manual Soldering

• Soldering iron: Bit Temperature: under 380°C | Time: under 3 second.

Rev 1 Jun.17 30

41111116

Page 31

4: Troubleshooting

How to Check the Working Status of the

GPS Module

The first thing to check for is the NMEA sentence output through TX using various

application tools. For example: you may use the Windows tool: Hyperterminal or you

may use another GPS application program.

If there is no NMEA output at the TX pin, this indicates that the module is currently not

working. Please double check your schematic design. The following is a list of

possible items to check:

Item 1: VCC

The voltage should be kept between 3V to 4.3V (typical: 3.3V).

Item 2: VBACKUP

The voltage should be kept between 2.0V~4.3V (typical: 3.0V). If a backup battery is

not installed for the VBACKUP pin, the pin could still be measured as the voltage

comes from the built-in battery recharging circuit. It is recommended to provide power

to the VBACUP pin as it is used to keep RTC time running and preserve stored

navigation data.

4

Item 3: 3D-FIX

If all the measurements are within the specifications, please also measure the 3D-FIX

signal. Before 2D Fix, the pin should output one second high followed by a one

second low signal.

Note: this is not applicable to those with a customized 1PPS which always has a 1PPS signal

configuration as described in 1PPS - Compatible Models: Gmm-g3, Gmm-g3(B), Gms-g6a,

Gms-g9, Gms-g6, Gms-b6,PA6E-CAM, XM1110, XA1110.

Figure 4-1: 3D-Fix

Rev 1 Jun.17 31

41111116

Page 32

AirPrime XA1110/XM1110 Hardware Design Guide

Item 4: TX0

The UART transmitter of the module outputs the GPS NMEA information for the

application.

Figure 4-2: TX0

Rev 1 Jun.17 32 41111116

Page 33

Appendix A:Super Capacitor Design

About Super Capacitors

Super capacitors have a lifetime similar to that of aluminum electrolytic capacitors.

The service life of a super capacitor is greatly dependent on the operating

temperature, humidity, applied voltage, current, and backup time. Therefore, the

service life is determined based on the backup time set by the customer.

How to Calculate the Backup Time

The example below shows how to calculate the backup time:

A

Figure A-1: Calculating backup time

Rev 1 Jun.17 33

41111116

Page 34

Appendix B:50 Ω Antenna Matching

We used the AppCAD tool to simulate 50Ω impedance for the RF PCB layout.

Table B-1: Antenna Matching

B

RF Line Width (W) PCB FR4

Thickness

1.8mm 1mm 4.6 0.035mm

Dielectric

Parameters

Copper Thickness

per ounce

Figure B-1: Dimensions

Notice:

For multi-layer layouts, you could place a ground layer in the second layer to minimize

the trace width in a specific PCB (such as FR4) and impedance.

For impedance calculation, there is free software available to calculate the trace width

or impedance. Once such software package is:

http://www.awrcorp.com/products/additional-products/tx-line-transmission-linecalculator

Rev 1 Jun.17 34

41111116

Page 35

Appendix C:UART to RS232 Interface

Typically an RS232 or USB interface is required to connect the PC to the Sierra

Wireless GNSS module for communication. The majority of Sierra Wireless modules

use a set of communication ports in TTL-logic. Some newer ones support direct USB

connection. A bridge IC is needed for RS232 signal conversion.

The supported baud-rates are 4800, 9600, 14400, 19200, 38400, 57600, and 115200

bps.

Please refer to the reference circuit in Figure C-1 below for RS232 signal conversion.

An SP3320 IC is used here as an example.

C

Figure C-1: RS232 Signal Conversion Example

Rev 1 Jun.17 35

41111116

Page 36

Appendix D:UART to USB Interface

If the Sierra Wireless module you have purchased does not come with a USB

interface, it is possible to connect the module to an external USB IC. To further

enhance the transferring speed, use one that is capable of USB version 2.0. Once the

driver for the chosen USB Bridge IC is successfully installed onto Windows or another

operating system, the USB Bridge IC will automatically be recognized as a COM port.

Note: a proper driver must be installed or else the operating system will not be able to

recognize the device!

Please refer to the reference circuits in Figure D-1 below for the conversion. A

CP2102 IC is used here as an example.

D

Figure D-1: UART to USB

Pin29 and Pin30 are the bottom ground pads which are not documented in the IC

datasheet. You may ignore these two pins in the drawing.

Rev 1 Jun.17 36

41111116

Page 37

Appendix E:How to Efficiently Transfer

1PPS Through Extended Distances

There are several aspects to note when transferring a 1PPS signal through a long

cable which will result in a 1PPS signal degradation, an increase in noise, and an

increase in signal delay. As the 1PPS signal is traveling through the communication

cable, impedance matching must be implemented to prevent waveform distortion.

Depending on your application, an OP-amp can be added to effectively control the

accuracy of the voltage level for the 1PPS signal.

When using a 1PPS signal for time synchronization, the OP-amp chosen should have

a high slew rate property to prevent a large delay in the 1PPS. The accuracy level of

1PPS for Sierra Wireless GNSS modules is within 100ns. This applies to most of

Sierra Wireless’ MTK GNSS modules. The reference design in Figure E-1 below can

be used to improve accuracy to within 80ns.

E

Figure E-1: Design to improve accuracy to within 80ns

Rev 1 Jun.17 37

41111116

Page 38

AirPrime XA1110/XM1110 Hardware Design Guide

1pps Delay Time

When using coaxial cable for long distance communication using an OP-amp for

amplification, pay close attention to the coaxial cable time delay and the rising

time of the wave form due to the OP-amp’s Slew Rate. A brief explanation for this

is given below.

Figure 5-2 shows the specification of the coaxial cable with the model number

RG6U.

Figure E-2: RG60 Specifications

Figure E-3: RG6U Design and Characteristics

Rev 1 Jun.17 38 41111116

Page 39

The Delay Time Caused by the Cable

Figure E-4: The delay time caused by the cable

Calculating the Delay Time in Respect to

the Communication Cable Length

The simplest method to calculate this is to have a good grasp of the relationship

of the three parameters:

1. The speed of the traveling waveform.

2. The distance of the wave form traveled.

3. The delay time.

= Distance of the wave form traveled (m)

= Speed of the waveform (m/s)

= Delay Time (ns)

If the speed of the waveform (in the coaxial cable) is unknown, it is possible to use

a known coaxial cable length to test. For example, the signal travel in one meter

of coaxial cable may have a delay time measured by an oscilloscope as 5ns and

consequently the will be 2 * 10

If the value of capacitance and inductance for the coaxial cable is known, then

(m/s) can also be calculated.

Rev 1 Jun.17 39 41111116

8

(m/s).

Page 40

AirPrime XA1110/XM1110 Hardware Design Guide

Other coaxial cable electromagnetic fundamental parameters along with the inner

and outer diameter of the physical cable can be used in combination to perform

theoretical calculations.

Waveform Rising Time Caused by OPamp

Figure E-5 shows Slew Rate which is the time needed for a rising waveform.

When the SR (V/

sec) of OPA is higher, the rising time will be shortened as well.

Figure E-5: Slew Rate

Recommended OP-amp

If an inadequate OP-amp is chosen (i.e. with a low slew rate), the delay at the

rising time introduced to the waveform can be significantly larger than that of the

coaxial wire.

We recommend using OP-amp 301 to decrease the waveform rising time.

Specification of OP-amp 301:

• Low Power: 9.5mA (Typ) on 5.5V

• Single Power: 2.7V ~ 5.5V

• High Slew Rate: 80 V/?sec

• Tiny Packages: MSOP and SOT23

Voltage degradation of Communication

cable

We tested a 10m long coaxial cable and observed that only insignificant amount

of voltage degradation occurred. Users should not be concerned with this issue.

Rev 1 Jun.17 40 41111116

Page 41

Appendix F:Reflow Soldering Precautions

Table F-1: Precautions

Details Suggestions Notes

F

1 Before proceeding with

the reflow-soldering

process, the GPS

module must be prebaked.

2 Because PCBA (along

with the patch antenna)

is highly endothermic

during the reflowsoldering process, extra

care must be paid to the

GPS module's solder

joint for any signs of cold

welding or false welding.

3 Special attention is

needed for the PCBA

board during reflowsoldering to see if there

are any symptoms of

bending or deformation

to the PCBA board,

possibly due to the

weight of the module. If

so, this will cause

concerns at the latter half

of the production

process.

Pre-bake Time:

6 Hours @ 60°±5°C or

4 Hours @ 70°±5°C

The parameters of the

reflow temperature must be

set accordingly to module’s

reflow-soldering

temperature profile.

A loading carrier fixture must

be used with PCBA if the

reflow soldering process is

using rail conveyors for the

production.

The maximum tolerated temperature for

the tray is 100°C.

After the pre-baking process, please make

sure the temperature is sufficiently cooled

down to 35°C or below in order to prevent

any tape and reel deformation.

Double check to see if the surrounding

components around the GPS module are

displaying symptoms of cold welding or

false welding.

If there is any bending or deformation to

the PCBA board, this might cause the

PCBA to collide into one another during the

unloading process.

4 Before the PCBA

undergoes a reflowsoldering process, the

production operators

must check with their

own eyes to see if there

are positional offsets to

the module, because it

will be difficult to readjust

after the module has

gone through the reflowsoldering process.

Rev 1 Jun.17 41

41111116

The operators must check

with their own eyes and

readjust the position before

the reflow-soldering

process.

If the operator is planning to readjust the

module position, please do not touch the

patch antenna while the module is hot in

order to prevent a rotational offset between

the patch antenna and module.

Page 42

AirPrime XA1110/XM1110 Hardware Design Guide

Table F-1: Precautions

Details Suggestions Notes

5 Before handling the

PCBA, they must be

cooled to 35°C or below

after they have

undergone a reflowsoldering process, in

order to prevent a

positional shift which

may occur when the

module is still hot.

6 1. When separating the

PCBA panel into

individual pieces using

the V-Cut process,

special attention is

needed to ensure that

there are sufficient gaps

between patch antennas.

2. If the V-Cut process is

not available and the

pieces must be

separated manually,

please make sure the

operators are not using

excess force which may

cause a rotational offset

to the patch antennas.

1. One may use an electric

fan behind the reflow

machine to cool them down.

2. Cooling the PCBA can

prevent the module from

shifting due to fluid effect.

1. The blade and the patch

antenna must have a gap

greater than 0.6mm.

2. Do not use the patch

antenna as the leverage

point when separating the

panels by hand.

It is very easy to cause a positional offset

to the module and its patch antenna when

handling the PCBA under high

temperatures.

1. Tests must first be performed to

determine if the V-Cut process is going to

be used. Ensure that there is enough

space between the blade and patch

antenna so that they do not touch one

another.

2. An uneven amount of manual force

applied to the separation will likely to cause

a positional shift in the patch antenna and

module.

7 When separating the

panel into individual

pieces during latter half

of the production

process, special

attention is needed to

ensure the patch

antennas do not come in

contact with one another

in order to prevent

chipped corners or

positional shifts.

Use a tray to separate the

individual pieces.

Note: for patch antenna users: patch antenna refers to the patch-on-top antenna which is

built on the GPS module (i.e. PA/Gmm Module Series) and may not be applicable to all

GPS modules.

It is possible to chip a corner and/or cause

a shift in position if the patch antennas

come into contact with each other.

Rev 1 Jun.17 42 41111116

Page 43

Other Cautionary Notes on the ReflowSoldering Process

1. Module must be pre-baked before going through the SMT solder reflow

process.

2. The usage of solder paste should follow the “First-in-First-out” principle.

Opened solder paste needs to be monitored and recorded in a timely manner

(refer to IPQC standards for related documentation and examples).

3. Temperature and humidity must be controlled within an SMT production line

and storage area. A temperature of 23°C, 60±5% RH humidity is recommended (please refer to IPQC standards for related documentation and

examples).

4. When performing solder paste printing, check if the amount of solder paste is

in excess or insufficient, as both conditions may lead to defects such as

electrical shortage, empty solder, and etc.

5. Make sure the vacuum mouthpiece is able to bear the weight of the GPS

module in order to prevent a positional shift during the loading process.

6. Before the PCBA goes through the reflow-soldering process, the operators

should check by his/her own eyes to see if there is a positional offset to the

module.

7. The reflow temperature and its profile data must be measured before the

SMT process and match the levels and guidelines set by IPQC.

8. If an SMT protection line is running a double-sided process for PCBA, please

process the GPS module during the second pass only to avoid repeated

reflow exposures of the GPS module. Please contact Sierra Wireless

beforehand if you must process the GPS module during the first pass of

double-side process.

Figure F-1: Placing the GPS module right-side up when running the reflow-solder process; do not

invert.

Rev 1 Jun.17 43 41111116

Page 44

AirPrime XA1110/XM1110 Hardware Design Guide

Manual Soldering

Soldering Iron

Heat Temperature: Under 380°C | Time: Under 3 sec.

Notes:

1. To prevent further oxidation, do not directly touch the soldering pads on the

surface of the PCB board.

2. The solder paste must be defrosted to room temperature before use so that it

can return to its optimal working temperature. The time required for this

procedure is unique and dependent on the properties of the solder paste

used.

3. The steel plate must be properly assessed before and after use, so its

measurement stays strictly within the specification set by SOP.

4. Watch out for the spacing between the soldering joints, as excess solder may

cause electrical shortages.

5. Exercise caution and do not use an extensive amount of flux due to possible

siphon effects on neighboring components, which may lead to electrical

shortages.

6. Please do not use a heat gun for long periods of time when removing the

shielding or inner components of the GPS module, as it is very likely to cause

a shift to the inner components which will lead to electrical shortages.

Rev 1 Jun.17 44 41111116

Loading...

Loading...