Page 1

Technical Reprint TR-002

Gas Risk Management – A Safer Approach to

Monitoring for Hazardous Gases

Monitoring for gas leaks has historically consisted of the use of dosimeters, or fixed detectors. Little has been done to

use these measurement methods within a system’s concept; and, collectively, these technologies do not encompass all

the ingredients required to comprehensively manage the risk of personnel or equipment exposure to gas leaks.

Essential to the goal of protecting people and facilities from the hazards of exposure to gas are the selection of the

appropriate gas measurement techniques, timely analysis of monitoring data and a plan to respond to a leak. This

article discusses issues and options to be considered in formulating a gas risk management program with a focus on

area monitoring and system capability.

Hazards of Gas

The hazards of gas exposure are generally categorized as combustible, toxic, or the special category of oxygen

deficiency. These hazards are typically found in-plant at the source, at landfills, and in incinerators.

Combustible Gas. In industrial facilities, methane, natural gas and Hydrogen are the combustible gases of primary

concern. Methane and natural gas are used in the facility for fuel and can be present due to pipeline leaks, or poor

maintenance. Solvents, propane, and other combustible gases may also be present and require monitoring.

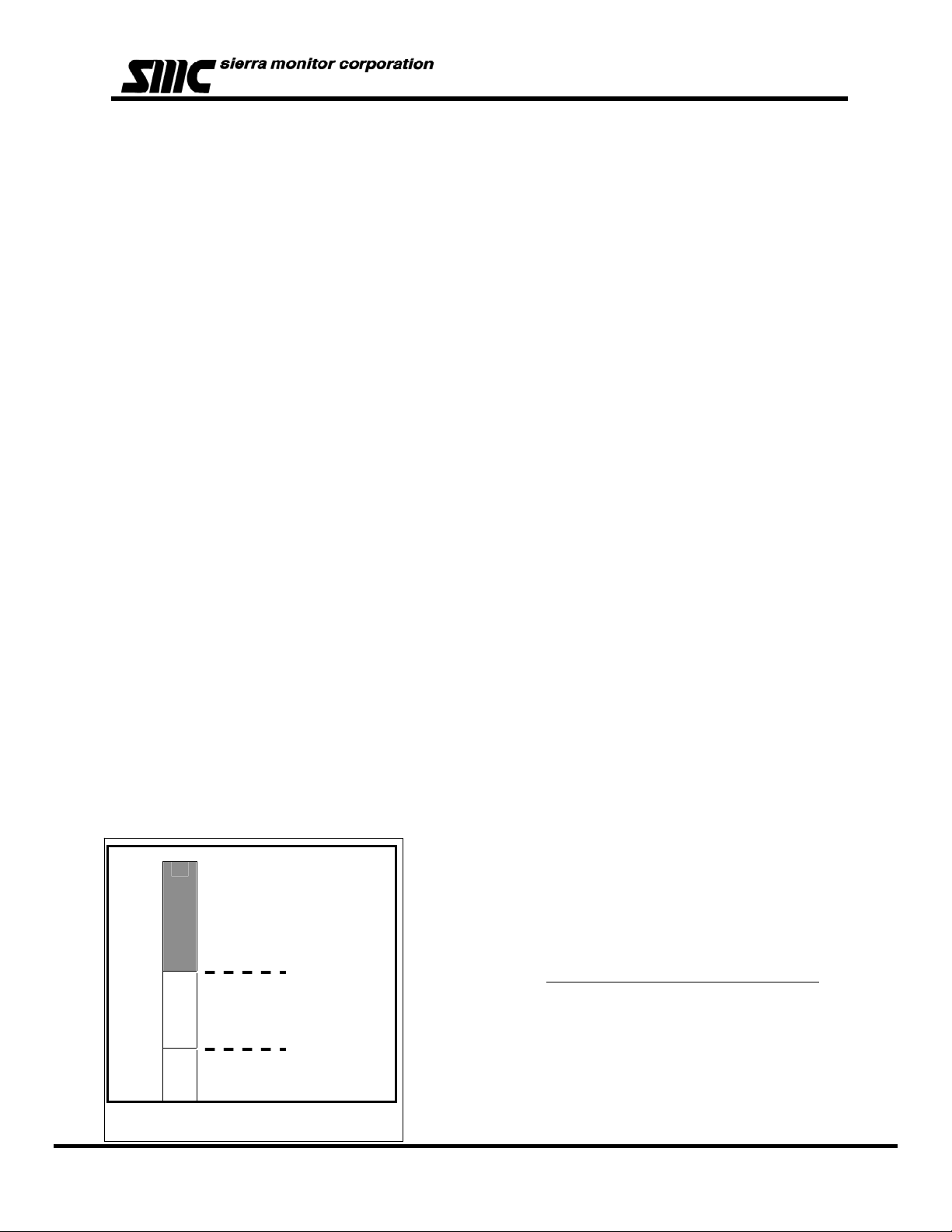

The lowest concentration at which a gas will support combustion is called the Lower Explosive Limit (LEL). Below this

concentration, the gas is too “lean” to support combustion. There is a corresponding Upper Explosive Limit above

which the concentration is too “rich” to support combustion, Figure 1. It is important that the concentration of gas in a

facility remains below the LEL and that appropriate action is executed to insure the LEL is not reached.

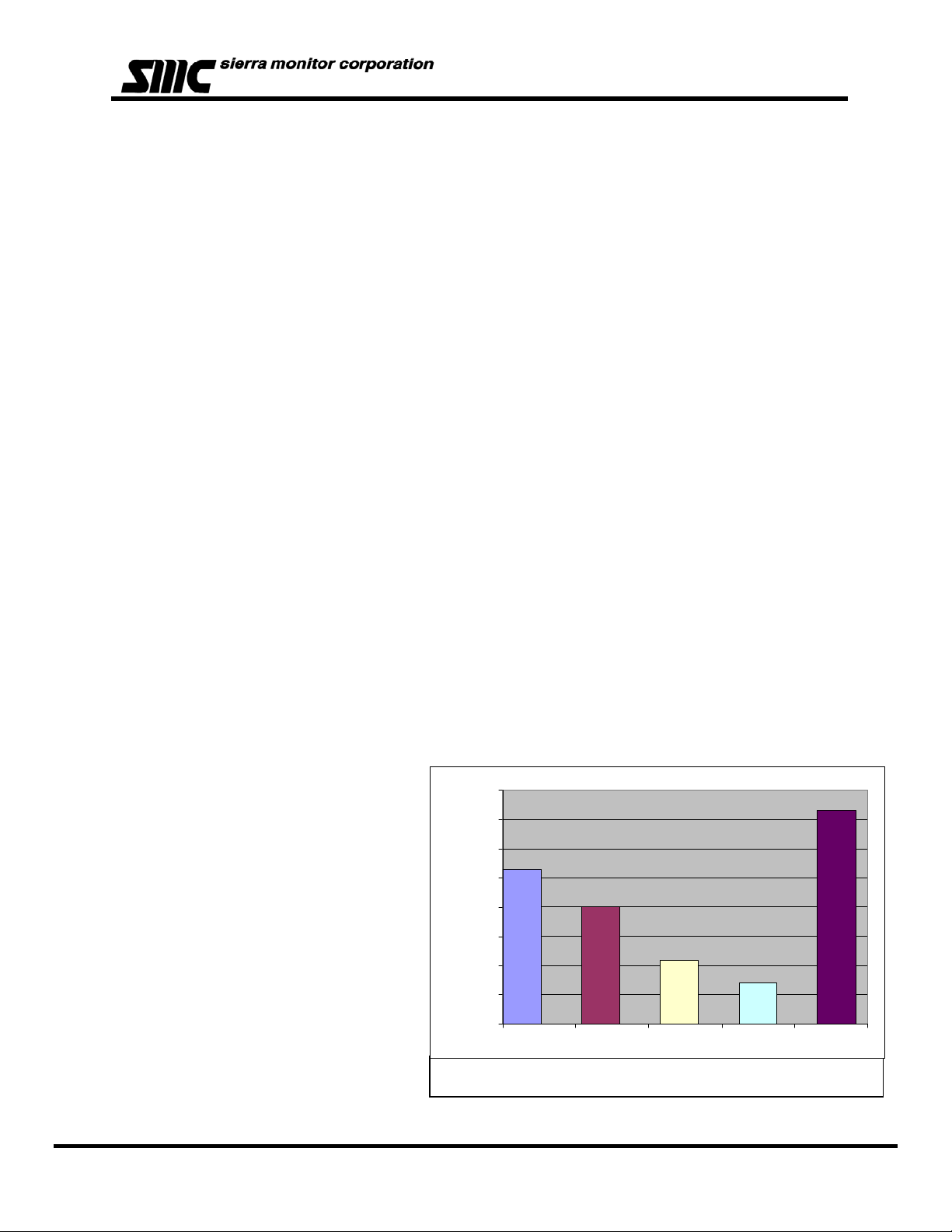

Although the concentration at which different gases will combust varies widely, the Lower Explosive Limit is used as a

common reference in setting alarm levels of gas monitoring systems. The approach employs alarm levels that are

determined by how close the gas concentration is to the LEL and not an arbitrary absolute concentration of the gas. In

this fashion, all gases can be compared to their specific explosive limit and relative comparisons of risk can be made.

For example, the LEL of methane and Hydrogen are approximately 5.0 and 4.0 percent, respectively, of the gas in air.

A safe reference such as 20 percent of the LEL can be used as an alert to the danger of the gas leak (which

corresponds to 1.0 and 0.8 percent of methane and Hydrogen, respectively, in air). Figures 2 and 3 demonstrate this

approach.

Toxic Gases. Toxic gases create both an immediate and long-term risk to personnel and include such gases as

Carbon Monoxide, Chlorine, Nitric Oxide, Sulfur Dioxide, Hydrogen Chloride, Hydrogen Cyanide, Ammonia, Hydrogen

Fluoride and many others.

Toxic gases are often hazardous at low concentrations and are

usually characterized in terms of the Threshold Limit Value (TLV).

TLVs are the maximum 8-hour time-weighted average

concentration permitted of an airborne contaminant. The time

weighted average (TWA) is calculated as follows:

TWA= C

+ C2T2 + C1T1+ ………………CnT

1T1

n

8

where Ci= Concentration in period I where concentration

remains constant

T

= Period of duration in hours at concentration Ci

i

100%

(% gas in the air)

CONCENTRATION

0%

Too rich

for combustion

Upper Explosive

Limit (U.E.L.)

Will support

combustion

Too lean

for combustion

Fig. 1 – Explosive Limits

Lower Explosive

Limit (L.E.L.)

Sierra Monitor Corp. 1991 Tarob Ct., Milpitas, California 95035 USA 408-262-6611, 800-727-4377 FAX: 408-262-9042

Visit our Web Site at: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

Rev. A1

Page 2

Technical Reprint TR-002

For some gases, excursions are permitted where the gas concentration may increase above the TLV for a limited period

of time, i.e. the allowable excursion duration. The ceiling limit is the maximum concentration of a contaminant allowed

without regard to duration. For example, in California, Hydrogen Sulfide has a TLV of 10 ppm with an excursion limit of

20 ppm for minutes in an 8-hour period. Its ceiling limit is 50 ppm.

Oxygen Deficiency. Where purging or processing with an inert gas as helium, argon, or nitrogen is employed, a leak

may result in a depletion of the oxygen concentration in an area occupied by plant personnel. As the concentration

oxygen drops, asphyxiation will result. OSHA has established 19.5 percent oxygen in air as a lower limit of a safe

environment.

Contamination of Process Gas. If process gas is leaking out of a pipe, then some room air will be leaking into the

pipe even through the process gas is under pressure. This leak-in air of course affects purity and can possibly have

some detrimental effect on yield.

Components of a Gas Risk Management System

A gas monitoring system must provide information to insure that effective and comprehensive decisions are made in a

timely fashion. It is not sufficient to sound an alarm after a low alarm limit has been reached. To be most effective in

managing the risk of gas exposure, sufficient information is required to obtain an accurate assessment of the situation in

order to make good decisions. Data management is a key ingredient of a gas risk management system.

Within this perspective, each situation imposes objectives and constraints on the gas monitoring system design,

operation, response to alarms, maintenance, and record-keeping requirements. These considerations must address

the risks identified in a hazard assessment and must be formulated into a risk management plan.

Hazard Assessment. Hazard assessment is the first step in system design. Field studies can help determine the

what, where, when of hazardous situation and possible exposure. The characteristics of the hazard in terms of its

ignitability, reactivity, corrosivity, and toxicity can be determined. In turn, the risk to human health as reflected in

standards set by RCRA, OSHA, and EPA can be estimated. Correspondingly, NFPA and insurance company

guidelines can help estimate risk to facilities. The impact of environmental factors can also be assessed. This is not to

say that gas risks can be accurately quantified; however, the information obtained in a hazard assessment provides a

basis to better address the identified gas risk.

System Specification and Design. System specification and design is a key output of the risk management planning

process. Design begins with sensor type selection and location. Sensor performance should be evaluated in terms of

speed of response, concentration range, resolution drift, ease of calibration, and interfering gases. In general, the

controller, wiring, backup power and alarm response must meet the duty performance criteria established in the plan.

Day-To-Day Operation. Day-to-day operation of

a gas monitoring system focuses on data review

procedures. It is important to use fixed systems

not only as an indicator of an alarm event, but

also to provide an early notification of a leak. A

system clock is becoming a more important

function to document events accurately. Day-today operation also focuses on system reliability.

Automatic self-monitoring of unit functions

enhances reliability by providing an ongoing

indication of operability. Regular maintenance

should confirm the internal diagnostics.

One person calibration is an important feature in

simplifying calibration and reducing labor

requirements. This process can be further

simplified if all adjustments are made

automatically after application of calibration gas,

which can be accomplished with microprocessorbases controllers. Where there are a large

8

7

6

5.0 - 5.3

5

4

(% G a s in Air)

3

CONCENTRATION

2

1

0

Methane Hydrogen Propane Toluene Methanol

Fig. 2. The lower explosive limit varies substantially for different gases.

4.0

2.0 - 2.2

1.2 - 1.4

5.6 - 7.3

Sierra Monitor Corp. 1991 Tarob Ct., Milpitas, California 95035 USA 408-262-6611, 800-727-4377 FAX: 408-262-9042

Visit our Web Site at: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

Rev. A1

Page 3

Gas Risk Management – A Safer Approach to Monitoring for Hazardous Gases

numbers of sensors, it may be economical to apply the calibration gas automatically. A method to check sensor span

voltage versus acceptable tolerance should be available either through calculation or as a system report. Ad vanced

systems can prompt “calibration due” according to a user configured calibration frequency.

Response To Alarms. Response to alarms begins with preplanning – in plant and outside the plant perimeter. Next,

training is essential to insure all plant

METHANE HYDROGEN

100%

60%

Lower Explosive Limit (%LEL)

20%

PPM in

50,000 5.0

30,000 3.0

10,000 1.0

air

% Gas

in air

PPM in

Typical HIGH

Alarm Setpoint

EMERGENCY

Typical LOW

Alarm Setpoint

WARNING

air

40,000 4.0

24,000 2.4

8,000 0.8

% Gas

in air

Fig. 3 Alarm Setpoints for Methane and Hydrogen

The final element of responding to alarms concerns evacuation procedures, both in plan in the local vicinity, and

requesting outside assistance such as the fire department. Events that trigger these actions are based on the hazard

assessment. Recent catastrophes and near catastrophes more than demonstrate the need for this requirement.

Record-Keeping. Record-keeping becomes an important element of response to alarms. Sensor status reports

provide a valuable reference to assess the severity and breadth of the gas hazard. Real-time and post-event analysis

can be generated. Calibration reports give data for monitoring sensor performance over time. Sensor history reports

are useful for satisfying regulatory requirements and providing data on gas exposure. It is the transfer of information

provided from the system to plant personnel that enables gas risk management to be effective.

personnel understand their function and

have internalized their responsibilities. Part

of this training includes identifying false

alarms.

Relay action usually involves a low alarm

(warning light and siren and ventilation to

reduce the gas concentration) and high alarm

(emergency light and siren and a process

action). Process action involves turning off,

or isolation of, the source of the gas and

shutdown of process equipment. A high-high

alarm can be used as an indication that the

concentration is very dangerous. “Zone

voting,” where two or more sensors must be

in alarm before activating a zone relay, can

be used as a way to neutralize a faulty

sensor and to take action specific to the area

that the gas hazard exists.

New Wafer Processing Laboratory

A new wafer processing laboratory located in California had extensive Hydrogen and toxic gas piping and equipment

utilizing those gases. The facility was designed to minimize the possibility of a gas leak and further measures were

taken to contain rather than expel any gas that might accidentally leak. For example, all gas piping was run through a

NEMA duct to prevent gas from being uncontrollably dispersed into the room.

The facility installed both a Hydrogen and toxic gas monitoring system. It was necessary for the Hydrogen and toxic

gas monitoring system to be independent due to the capabilities of the sensors. The remainder of this discussion will

focus on the Hydrogen monitoring system; however, much of the discussion also applies to the toxic gas monitoring

system.

The hazardous gas monitoring system used was the Sierra Monitor SENTRY Gas Monitoring System. The system

uses a sophisticated microprocessor-based controller. System configuration is user programmable to allow the system

to be customized to the specific application requirements. SENTRY has extensive data management and internal

diagnostics that provide information required to help manage gas leak problems.

Sensor Locations. One of the first questions to be addressed as part of the system specification is how many sensors

are required and where should they be located? There are no rules or formulas to answer these questions. In general,

it is important to locate sensors close to the likely sources of leaks and in areas where a leaked gas might lighter than

air, thus dictating whether sensors be located below or above the leak. With Hydrogen being lighter than air, sensors

are always located in the ceiling as a backup to sensors located near the source of the leak.

Sierra Monitor Corp. 1991 Tarob Ct., Milpitas, California 95035 USA 408-262-6611, 800-727-4377 FAX: 408-262-9042

Visit our Web Site at: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

Rev. A1

Page 4

Technical Reprint TR-002

Typical Hydrogen gas sensor locations in a semiconductor manufacturing facility include:

• Hydrogen storage areas

• Valves in Hydrogen pipelines

• Furnace area – inlet, outlet, internal tubing

• Off gas ducts

• Return room air ducts

• Cavity between dropped ceiling and the roof (or floor above)

In this plant there are sixteen sensors located within four rooms. Sensors are a catalytic bead type. There are two

beads in each sensor element, one of which is activated by a catalyst in the presence of a combustible gas and the

other is not. These beads are inserted in a wheatstone bridge circuit and the relative resistance of the beads affects the

bridge output in the presence of gas. Changes in temperature and relative humidity have no effect on the output of the

circuit since the catalyzed bead and the reference bead are similarly affected and the relative difference in output does

not change.

Sensor output is digitalized at the sensor module and transmitted to the controller. Transmitting a digital signal give

great tolerance to RFI and EMI effects. In addition it enables diagnostics to be performed at the sensor and be

transmitted to the controller along with the concentration measurements. Also, sensor modules are given an address

which permits multiplexing multiple sensors on a single wire.

Benefits of Controller Capability. The controller is designed to provide high reliability, ease of operation and data

management capability. It is the data management capability that separates the SENTRY controller from other gas

monitoring systems. Conventional controllers simply react to events (as a thermostat reacts to temperature reaching a

setpoint). To manage a risk it is necessary to use information to formulate a response to leak rather than reacting to an

event after an alarm has occurred.

It has already been mentioned that the system configuration is user programmable. This includes alarm levels,

calibration procedures, report scheduling and display mode. The low alarm level is set at 10 percent of the LEL and the

high alarm level is set at 60 percent of the LEL. A single controller can handle up to eight sensors and four controllers

can be mounted in a standard 19 inch instrumentation rack. The controller displays the sensor concentration, the gas

type, concentration units, and alphanumeric messages.

Reports to Help Decision-Making and Document Due Diligence. The Sentry can provide data to a distributed

control system (DCS) via MODBUS or provide reports via a printer. The reports are also available at the display and

include status reports, history reports, calibration reports and system configuration reports. This particular customer

only needed the printer reports. When the concentration exceeds a user definable limit. The controller prints each key

event when it occurs.

This history reports are also very useful in determining if there is any regularity to gas leaks. For example, history

reports show the date and time the highest concentration occurred in the period. The frequency for the period can be

programmed on an hourly, shift, or daily basis. As one semiconductor facility one sensor recorded its highest

concentration at the time every day. After investigation it was found that a purging of a Hydrogen furnace was releasing

Hydrogen into the room. The purging procedure was changed and release of Hydrogen into the room stopped. Daily

history reports also provide good documentation to confirm the facility’s safe operating procedure if legal action was

brought against the company. In today’s legal environment, such documentation is essential to minimize liability. In

addition to the alarm indication at the controller, the facility has an annunciator panel located near a security area. The

panel displays each combustible and toxic gas sensor in alarm.

Summary

Gas risk management requires a comprehensive look at the hazards of gas leaks. Properly designed gas monitoring

systems provide suitable hardware in combination with data management and diagnostics capability to custom-fit a

solution for managing, rather than reacting to, gas leaks.

Sierra Monitor Corp. 1991 Tarob Ct., Milpitas, California 95035 USA 408-262-6611, 800-727-4377 FAX: 408-262-9042

Visit our Web Site at: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

Rev. A1

Loading...

Loading...