Page 1

Technical Reprint TR-001

To minimize risks, a plant-wide gas monitoring system must meet the specific needs of

the facility in terms of system inputs and outputs and data acquisition.

Plant-Wide Gas Monitoring for Risk Control

as monitoring has become an integral part of many environmental protection and safety programs. Because of

G

increased attention to risks posed by gas, systems that simply annunciate an alarm condition are no longer

adequate. Gas monitoring programs now comprise employee training, data analysis, multiple alarm strategies,

self-diagnostic system verification, and documentation. Data communication has also become a fundamental

component of system design and operation as well. And finally, environmental factors help guide the program

selection process.

GAS MONITORING RATIONALE

Gas Monitoring is an integral part of environmental protection and safety programs. There are three major

categories of hazardous gases. Combustible gases pose a risk to personnel and facilities through fire or explosion..

Oxygen displacing gases deplete workers' oxygen supply in confined spaces. Toxic gases create both immediate

and long term risks to personnel. Toxic gases are those OSHA and other organizations have defined as hazardous to

human health. They are typically monitored both below and above the threshold limit value (TLV). TLV is an

8-hour time weighted average concentration that is the highest value acceptable as a safe working environment.

System design requirements such as the number of sensors required, sensor placement, and system alarm levels will

vary according to the type of gas.

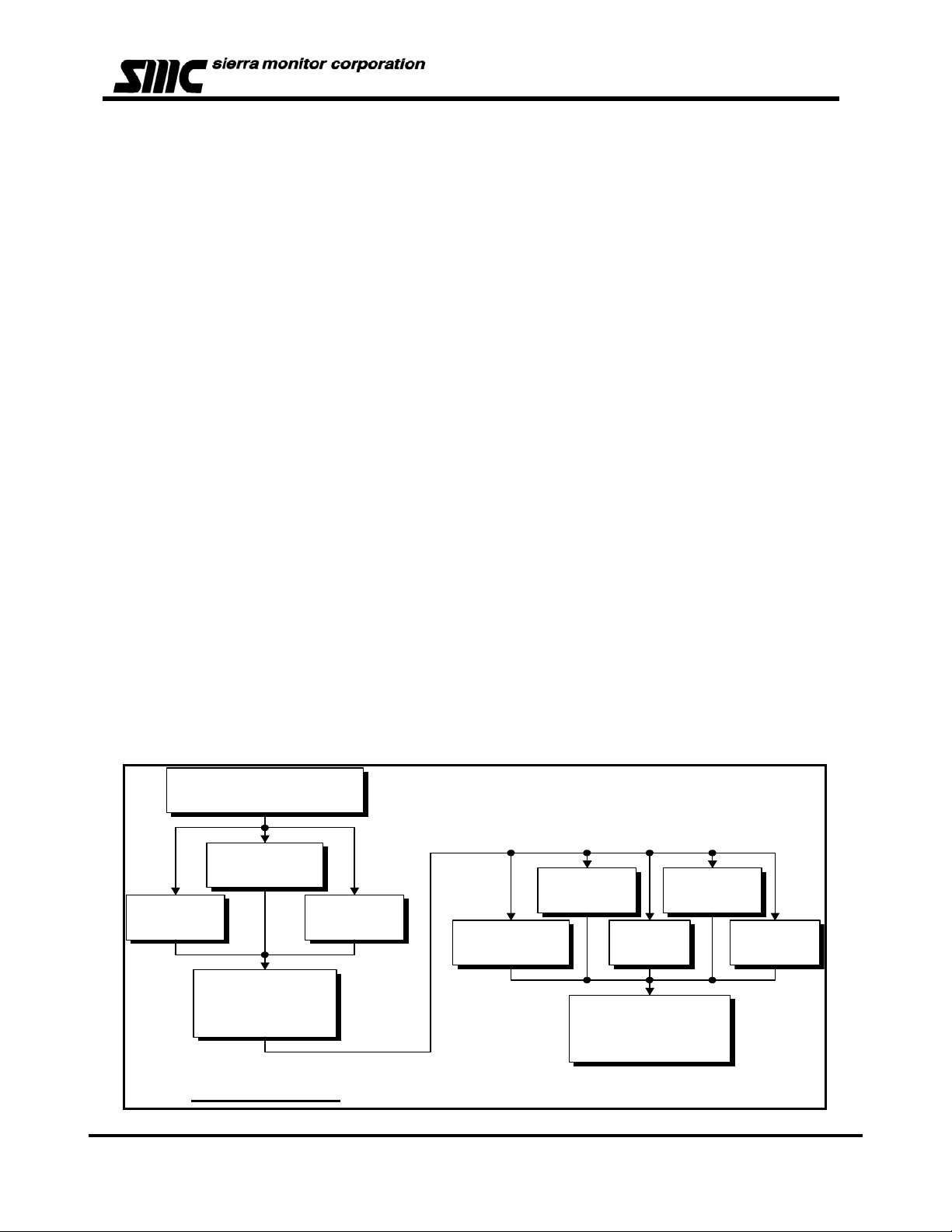

A properly designed gas risk management program can reduce risk. A successful program needs to first, identify the

hazards at the facility, then assess the risk of a hazardous event to the plant, personnel, the community and the

environment. Next, the program needs to comply with insurance, legal and regulatory req uirements. Also, liabilities

and financial risks need to be evaluated. Finally, the program must incorporate company safety philosophies.

Through such a program you can reduce the risks associated with hazardous gas leaks at your facility. Sierra

Monitor offers products that provide critical data to prompt corrective action before a minor leak becomes a major

event. Information can be retrieved from the equipment display, printed locally or recorded by a computer. This

information aids in evaluating potential hazards in relation to operating practices.

Hazard Identification &

Assessment

Risk to

Risk to

Personnel

Control System

Capability/C ost

Environment

Tradeoffs

Risk to

Fa c ility

Regulations

Ins u r a n c e

Requirements

Laws &

Lia b ility

Decision ,

Control Strategy,

System Selection

Company

Philosophy

Financial

Risks

Risk Reduction

Sierra Monitor Corp. 1991 Tarob Ct., Milpitas, California 95035 USA 408-262-6611, 800-727-4377 FAX: 408-262-9042

Visit our Web Site at: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

Page 2

Technical Reprint TR-001

GAS MONITORING OPTIONS

Gases are monitored with permanently installed (fixed) systems or portable instruments, or by taking samples for

evaluation in a laboratory. Portables and sampling are by their very nature only spot checks and are appropriate

only when the risk is extremely low or fixed instruments are not practical. As a general principle, areas where the

risk is sufficient to justify periodic monitoring with a portable instrument, warrant a fixed system.

Conventional Technology. Fixed gas monitoring systems historically have been reactive systems consisting of a

sensor and a controller. The sensor, which can be mounted remote to the controller, usually transmits an analog

signal proportional to the gas concentration. Principles of detection include catalytic bead, solidstate/semiconductor, electrochemical and infrared.

Performance variables that should be considered for sensor performance include:

• Response speed

• Measurement range

• Resolution

• Interfering gases

• Operating range

• Temperature and humidity effects

• Sensor life span

• Ease and frequency of calibration

• Replacement cost

The gas monitoring system required depends upon the scope of the hazardous gas risk. For applications where the

risk is minor, a simple gas monitor that sounds an alarm when the concentration reaches the setpoint may meet the

need. Applications involving a higher risk generally require continuous output of gas concentration to a display,

printer or other indicating or control device. Sierra Monitor's analog gas sensor modules offer a continuous 4-20 mA

DC output and are available for a wide range of hazardous gases.

In applications with the highest level of risk or where the hazard is present throughout the facility, a smart gas

sensor module such as the IT Series and/or the Sentry Gas Risk Management System will meet the need. With

extensive diagnostic capability, flexible configuration, expandability, microprocessor controls, and the ability to

interface with plant-wide control systems, Sierra Monitor IT Series and Sentry Systems are the choice for plantwide monitoring systems.

System self-diagnostics on both the IT Series sensors and the Sentry controller and sensors help the user know that

the data they are receiving in reliable and accurate.

Gas exposure data analysis needs to be available to prove due diligence in hazardous gas risk management. This

data can be available either via preformatted reports available with the optional printer for Sentry or via a third party

HMI package resident on a computer. Serial communication and the MODBUS interface enable Sentry and IT

Series sensors to interface with the Human-Machine-Interface (HMI) package that can provide complete data

analysis and information on the operator's computer. Such information would include alarm status, gas

concentrations, alarm setpoints, fault alarms, and more. Hundreds of data points are available from Sentry via the

serial communications port.

Sentry’s ability to accept input from a wide variety of devices such as flame detectors, or other unique gas detectors

provides a complete hazard monitoring system to improve the safety management of the facility.

Sierra Monitor Corp. 1991 Tarob Ct., Milpitas, California 95035 USA 408-262-6611, 800-727-4377 FAX: 408-262-9042

Visit our Web Site at: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

Page 3

Technical Reprint TR-001

PLANT-WIDE MONITORING

Plant-wide gas monitoring offers many benefits, among them:

• Centralized monitoring of all gas measurements

• Monitoring the status of control elements

• Establishing a “command center” to respond to alarm events

• Remote access to all system data

• Centralized reporting

In a plant that has been instrumented over a period of years, the gas detection system is likely to be an autonomous

installation. The controller might be in the field close to the sensors or in a control room. Both approaches have

limitations. Controllers in the field do not transfer gas concentration information to the co ntrol room. Alarm data

are limited to local annunciation of an alarm event, or long wiring runs are required in order to report sensor-bysensor alarm status to a central control room. Alarms are therefore usually limited to relays activated by groups of

sensors and/or field controllers in a given area.

Controllers located in the control room usually require extensive wirin g to the sensors and alarm activity is often

minimized to reduce wiring cost. Furthermore, when the controller is in the central control room, there are no

concentration data available in the field for plant personnel to make on-the-spot decisions; only an alarm light or

horn is activated.

Systems designed for plant-wide monitoring avoid these deficiencies. They:

• Accept sensors for multiple gases

• Accept sensors from various manufactures

• Accept other environmental and process sensor measurements

• Provide local display of gas concentration

• Permit auto-adjusting calibration

• Accept feedback signals from final control elements

• Provide independent battery backup

• Allow low-cost communications link to the control room

• Provide relays for local alarm action

• Implement user-defined alarm strategy

• Provide centralized monitoring of sensor status as shown on the plant log plan and at each operation /

facility with bar graphics, configuration screens, and real-time trends

• Provide centralized data logging

• Provide alarm acknowledgment from the control room

• Allow access to control room computer from other sites in facility

• Operate independently even if communications with the control room are severed

• Provide for easy system reconfiguration via computer at the control room

Distributed intelligence is central to system design philosophy. Because the field controllers can implement alarm

logic and operate independently of the host computer, they do not interrupt or hamper field operation. A plant-wide

monitoring system provides the user with clear, understandable data that make it possible quickly to analyze the

situation and take appropriate action. A correctly designed plant-wide monitoring system offers the best features of

local control, and centralized monitoring systemizes the entire monitoring process.

CRITICAL SYSTEM COMPONENTS

The components of the system are the sensors, the field controller, and the monitoring software. Sentry, from

Sierra Monitor, is an example of a system that can implement plant-wide gas monitoring. The gas sensor modules

can be multiplexed on a single cable back to the controller.

To offer complete solutions at each site, field systems need full I/O capability. Sentry fulfills this requirement by

accepting a variety of sensors or 4-20 mA transmitters. The Sentry controller is an intelligent device that can access

the sensor modules for diagnostic data, non-intrusive calibration and gas concentration information.

MODBUS communications interface enables Sentry and the IT Series sensors to easily interface with a PC-based

Distributed Control System (DCS) providing a graphical display of hazardous gas conditions in the plant. PC-based

Sierra Monitor Corp. 1991 Tarob Ct., Milpitas, California 95035 USA 408-262-6611, 800-727-4377 FAX: 408-262-9042

Visit our Web Site at: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

Page 4

Technical Reprint TR-001

DCS software in conjunction with Sentry provides the operator enhanced data acquisition, alarming and alarm

management, historical trending, distributed architecture, and integration into the plant's distributed control system.

Sentry's MODBUS communication interface provides over 620 different parameters accessible by the PC-based

DCS software, including:

• Gas concentration

• Alarm setpoints

• Sensor diagnostic messages

• Historical reset time/date

• Power up/down time/dale trouble alarm time/date

• Minimum/maximum values plus time/date

• High/low alarm latch/non-latched

• Auto calibration enabled

• Calibration status/coefficients

• Calibration concentrations

• Calibration due date

• Zone option enabled

• Operate mode

With the MODBUS communications option for Sentry and the graphic based man-machine software program a

variety of graphic screens can be developed. These screens make it easy for the operator to efficiently monitor hazardous gas risks in any plant. Typically the system will include a main screen providing an overall view of the plant.

This screen is linked to individual zone displays, historical and real-time trend charts, bar charts indicating gas

concentration and alarm levels, and more.

SUMMARY

The key to any plant-wide monitoring system is the flexibility to configure system inputs/outputs and data

acquisition to meet the specific needs of the plant. By monitoring sensors throughout the plant, better visibility of

the ambient environment can be realized and more informed decisions can be managed in the event of gas exposure.

A plant-wide monitoring system using distributed intelligence coupled with advanced PC based software offers an

improved approach to limit in plant risks. The benefits to employee safety and environmental responsibility are

self-evident, as are the economic rewards of reducing the chance of loss from interruptions in operation and from

litigation. Risk minimization, including plant-wide gas monitoring, makes good business and social sense.

Sierra Monitor Corp. 1991 Tarob Ct., Milpitas, California 95035 USA 408-262-6611, 800-727-4377 FAX: 408-262-9042

Visit our Web Site at: http://www.sierramonitor.com E-Mail: sales@sierramonitor.com

Loading...

Loading...