Page 1

Page 2

SAFETY 2

Model Indication Method 4

Name and Functions of Individual Parts 5

Installation 6

Example of Internal Circuit and Wiring 8

Setting 10

OUT1 Output Specifications 11

Function Setting 13

Other Functions 18

Specification 20

Full View with Dimensions 22

Thank you for purchasing the SMC PF2A7□H Series Digital Flow

Switch.

Please read this manual carefully before operating digital flow

switch and understand digital flow switch, its capabilities and limitations. Please keep this manual handy for future reference.

OPERATOR

●This operation manual has been written for those who have

knowledge of machinery and apparatus that use pneumatic

equipment and have full knowledge of assembly, operation and

maintenance of such equipment.

●Please read this operation manual carefully and understand it

before assembling, operating or providing maintenance service

to the flow switch

.

CONTENTS

Page 3

32

SAFETY

IMPORTANT MESSAGES

WARNING

NOTE

Indicates a potentially hazardous situation

which could result in death or serious

injury if you do not follow instructions.

Gives you helpful information.

Read this manual and follow its instructions. Signal words such

as WARNING and NOTE will be followed by important safety

information that must be carefully reviewed.

Do not disassemble, remodel (including change of printed

circuit board) or repair.

An injury or failure can result.

Do not operate beyond specification range.

Fire, malfunction or switch damage can result.

Do not use with a combustible fluid.

Otherwise, a fire or an explosion or damage may potentially result.

This flow switch is for air only.

Do not operate in a combustible gas or explosive gas

atmosphere.

Fire or an explosion can result.

This flow switch is not an explosion proof type.

WARNING

The Digital Flow Switch and this manual contain essential information

for the protection of users and others from possible injury and

property damage and to ensure correct handling.

Please check that you fully understand the definition of the following

messages (signs) before going on to read the text, and always follow

the instructions.

NOTE

Follow the instructions given below when handling your flow

switch.

Otherwise, the switch may be damaged or may fail, thereby

resulting in malfunction.

・Do not drop it, bring it into collision with other objects or apply

excessive shock (490m/s

2

or more).

・

Do not pull the lead wire with force nor lift the main unit by holding

the lead wire. (Pulling strength less than 49N)

・Wiring correctly.

・Do not wiring while power is on.

・

Do not wire with the same circuit of power line or high-voltage line.

・Do not use in a place in which water, oil, or a chemical is

splashes.

・Install a filter and/or mist seprator on the primary side ( inlet

side) if foreign matter is feared to mix in a fluid.

・

Flush the dust in the piping with air blow before piping the switch.

・Do not push the setting buttons by a sharply pointed object.

・Apply the power.supply when the flow rate is zero.

・

Start measurement by the flow switch three seconds after turning

on the power.

・

Maintain the switch status for measurement output before setting

when initializing or setting a flow rate of the flow switch.

Measure after checking impacts to the equipment.

・

Opening and closing of flow passage by restrictor should be

within max.

measured flow rate value.

Page 4

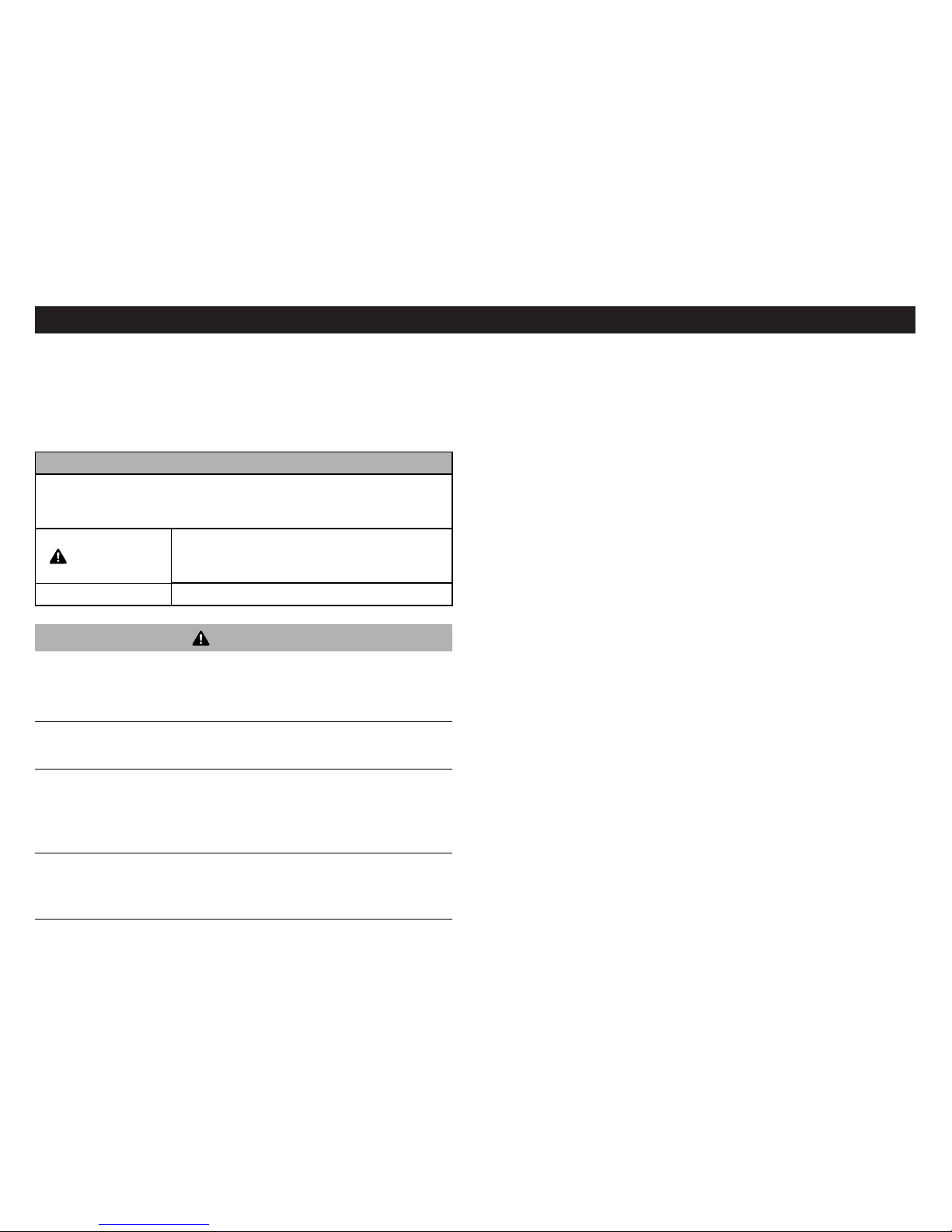

54

Unit Specification

No Symbol:Unit selection function provided

-

M: SI units fixed

Lead Wire Specification

No Symbol: Lead wire with connector 3m

N: None Lead wire with connector

PF2A7 H- -

Flow Rate Range

03: 150 to 3000 /min

06: 300 to 6000 /min

12: 600 to 12000 /min

NOTE1:

The revised Measurement Law of Japan

does not allow use of meters or measuring

instruments, which have a unit selection

function, in Japan.

NOTE2: The fixed unit

For instantaneous flow rate is : /min

For integrated flow rate is : , m

3

,

m

3

×

10

3

Port Screw Type

No Symbol: Rc N: NPT F: G

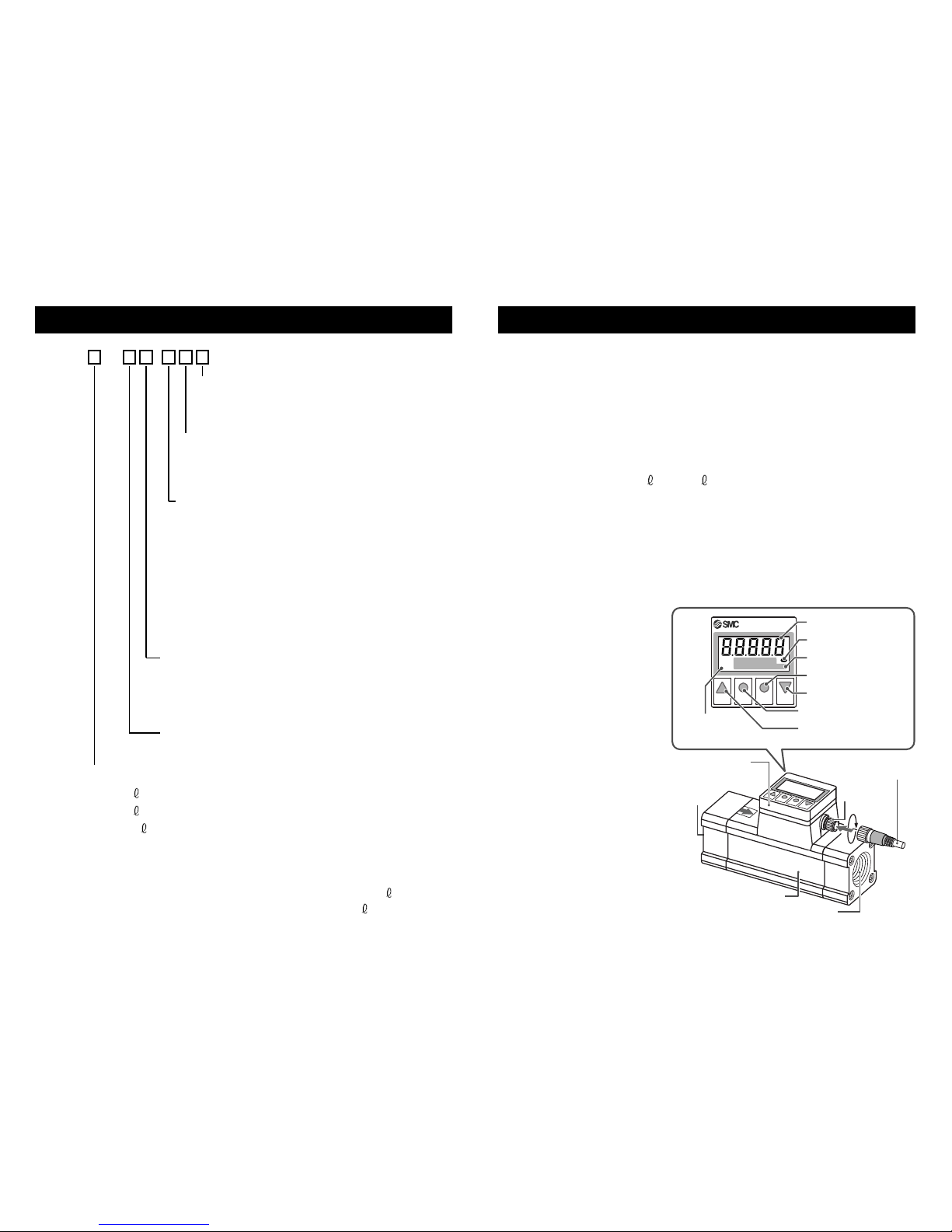

Body

Flow switch sensor body.

The arrow on the side of

the body indicates the

direction of flow.

Display Part

Output( OUT1)Lamp : Lit when OUT1 is ON.

Flickers when an overcurrent error occurs.

Flow display : Instantaneous flow, integrated flow and set value are

displayed.

Flow check display : Flickering interval varies depending on the flow.

Unit display : Selected unit is displayed. Single unit type is displayed

in SI unit ( /min or , m

3

, m

3

×

103).

▲

Button (UP) : Selects a mode and increases a set ON/OFF value.

▼Button (

DOWN

):

Selects a mode and decreases a set ON/

OFF

value.

Button (MODE) : Changes the mode.

Button (SET) : Changes the mode and sets a set value.

*RESET

Pressing the ▲and ▼buttonssimultaneously will activate the RESET

function. Use this

function to clear errors

when a trouble occurs.

●

SET

●

MODE

Body

Lead wire with connector

on one end (option)

Piping Port(

OUT

)

Display part

Connector

Piping port

(IN)

UP

DOWN

MODE

SET

Flow check display

Output(

OUT1

)

display

Button(MODE

)

▼

Button (DOWN

)

▲

Button (UP

)

Button (SET

)

FLOWSWITCH

ANR

OUT

Unit display

Flow display

●

MODE

●

SET

Accessories

(When no symbol is specified

for wiring in the type specification)

Lead wire with connector on one end

(3 m in length)

Names and Functions of Individual Parts

Output Specification

28: NPN open collector 1output

+ Analog output (1 to 5V)

29: NPN open collector 1output

+ Analog output (4 to 20mA)

68: PNP open collector 1output

+ Analog output (1 to 5V)

69: PNP open collector 1output

+ Analog output (4 to 20mA)

Model Indication Method

Piping Port

10: Port size 1 (Applicable for PF2A703H)

14: Port size 1・1/2 (Applicable for PF2A706H)

20: Port size 2 (Applicable for PF2A712H)

Piping port

This port connects with

pipeline. Use a pipe fitting to

connect with external pipeline.

Page 5

76

Nominal size of screws

Rc 1 36 to 38

Rc 1・1/2

48 to 50

Rc 2 48 to 50

Before you mount a flow switch, read "SAFETY" and "Installation"

described in this chapter carefully to obtain safe and correct

measurement.

Mounting

●Use this flow switch under the specified operating pressure

range.

●Use this flow switch under the specified operating temperature

range.

●Withstand pressure is 2.25 MPa.

●Do not install a flow switch at a foothold position.

●Install a flow switch so that the flow direction agrees with the

arrow direction on the side of the body.

●Mount the body so that the bottom of the body does not face

upward.

●Provide a straight pipe length of more than eight times the pipe

diameter to upstream and downstream of the flow switch.

●

Set Display Part proper position taking the cable entry and display

position into account. Display Part rotates in 270 degree.

FLOWSWITCH

FLOWSWITCH

FLOWSWITCH

FLOWSWITCH

Installation

Piping connections

●Observe the specified tightening torque when connecting pipes.

Refer to the following table for the appropriate torque values.

Spanner

Spanner

●When connecting pipeline to the switch, apply a spanner to the

metal part of the piping section for the switch.

●Make sure that sealing tapes will not enter inside the pipe when

connecting pipes.

Appropriate tightening torque

(N・m)

Page 6

98

OUT1

Analog Output

Load

Load

24VDC

+

−

1

4

2

3

Brown

Black

White

Blue

Main Circuit

Analog Output

OUT1

+

−

Load

Load

Brown

Black

Blue

White

1

4

2

3

24VDC

Main Circuit

Connector pin number

Min. measured flow Max. measured flow

1

5

Analog Output [

V

]

4

20

Analog Output [

mA

]

Instantaneous flow [

/

min ]

Output Specification

When the Lead wire with connector provided by SMC corporation

is used the color of wire (Brown, white, Black, Blue) shown on

circuit diagram will be applied.

−28, −29

NPN open collector 1 output + Analog output

Max. 30V, 80mA Internal voltage drop : 1V or less

−68, −69

PNP open collector 1 output + Analog output

Max. 80mA Internal voltage drop : 1.5V or less

Example of Internal Circuit and Wiring

4 3

12

Key

●

Turn off power before connecting or disconnecting the connector.

●To insert the connector, push the connector socket of the lead

wire to the key part of the switch connector after aligning them

to each other and secure the connector with the lock nut.

●To disconnect the connector, unlock the connector lock nut and

pull out the connector straight.

●Install the lead wire separately from the route for power cable

or high-voltage cable. Otherwise, malfunction may potentially

result due to noise.

PF2A7□ H-□ -28/68

Output :1 to 5V

PF2A7□ H

-□-

29/69

Output :4 to 20mA

Pin No. Pin name

1 DC

(+)

2 Analog Output

3 DC

(-)

4 OUT1

Model No.

Max. measured flow

(/min)

PF2A703H

150

PF2A706H

300

PF2A712H

600

Min. measured flow

(/min)

3000

6000

12000

Page 7

1110

Note

1)

(Display unit selection mode) does

not exist for -M(SI unit fixed ) type.

Note2) (Flow rate setting mode) does not

exist when selecting

during

(Output spec. selecting mode).

●

MODE

●

SET

●

SET

●

MODE

●

SET

●

MODE

●

SET

●

MODE

●

SET

●

MODE

●

SET

●

MODE

●

SET

●

MODE

●

MODE

●

SET

●

MODE

▲

▼

*

*

note2)

ON

OFF

n_1

Instantaneous

flow

Instantaneous

flow

Instantaneous

flow

Instantaneous

flow

ON

OFF

H

n_2n_1

H

n_2

Hysteresis mode

Window comparator mode

Hysteresis mode

Window comparator mode

n_1≧ n_2

Yes

[n]

[P]

No

Yes

No

H H

ON

OFF

P_1

ON

OFF

P_2P_1

P_2

P_1≧ P_2

Output

mode

Normal

mode

1. Initial setting mode

2. Display selecting mode

3. Display unit selecting mode

4. Output spec. selecting mode

6. Key lock mode

7. Flow rate setting mode

5. Output method selecting mode

8. Flow conversion mode

H : Hysteresis

n : Reverse

P : Non-reverse

Setting Procedure: Check installation condition and wiring

and set as below

*

Pressing▼button at each

mode of F_0 to F_7, returns to

previous mode, pressing

▲

button moves a mode ahead.

Setting

Normal

mode

Instantaneous switch output (oU1_0)

See "Flow rate setting mode" to input setting value.

OUT1 Output Specifications

Page 8

1312

[P]

Output

mode

50ms

50ms

Time

Time

ON

OFF

ON

OFF

note2)

[n]

Display Intrgrated flow

100

/pulse

note2)

Integrated

flow

Integrated

flow

ON

OFF

n_3

ON

OFF

P_3

[n]

[P]

Output

mode

10.0 f t

3

/pulse

U_1

U_2

Flow rate per pulse

note1)

OUT1 Output Specifications (continue)

Integration switch output (oU1_1)

See "Flow rate setting mode" to input setting value.

Integration Pulse output(oU1_2)

Note1) Unit selection function type

(Unit is fixed to SI unit for the type without this function)

Note2) Reversed output is assigned at shipment.

Initial setting

Display mode(Instantaneous flow/Integrated flow),

display unit and output specification are set.

Flow rate setting

Input the flow set value to start switch output.

Output mode selecting

Select output mode(Reverse/non-reverse output).

Key lock setting

Set the key lock.

Finish

Note 1)

Note 2)

Function Setting

Note1)

Display unit setting is not started when the model indication

specifies the unit as "-M".

Note 2) It does not go into Flow rate setting mode when the

integration pulse output「oU1_2」is selected as output

specification.

1. Initial setting mode

Page 9

Display unit selecting mode

(When Unit spec. in Model Indication is w/o "M")

Unit can be selected from that of Instantaneous flow and integrated

flow. The unit is changed by pressing ▲button.

It will be set up if the button is pressed.

If the button is

pressed instead of

the button, it will

change to「F_3」

.

●

SET

●

MODE

●

SET

14 15

Display

Instantaneousd flow

/min

CFM

U_1

U_2

Intrgrated flow

,m3,m

3

×

10

3

ft

3

,

ft

3

×

10

3

,

ft

3

×

10

6

2. Display selecting mode

Select the display from instantaneous flow or

integrated flow. Press

▲

button to select desired flow, then

press button.

「d_1」means instantaneous flow,「d_2」integrated flow.

●

SET

3. Display unit selecting mode

Display unit can be selected when the unit spec. of model

Indication is No Symbol. -M means the unit is fixed to SI unit. It

does not go into Display unit selecting mode. See "Display unit

selecting mode" below for details.

Function Setting (continue)

6. Key lock mode

Prevents wrong operation such as unintentional change of set

value.

LOCK

・Press button, and the display changes from

「F_5」to「unL」.

・Set the display as「Loc」by

▲

button

・Mode changed to「F_6」by pressing button.

(「F_7」when selecting「oU1_2」during「F_3」)

・Setting completed by pressing button.

RELEASE

・Press button longer than 3 sec. at the normal

mode to display「F_5」, then press button.

・Press

▲

button to display 「unL」.

・Setting completed by pressing button.

●

SET

●

SET

●

MODE

●

SET

●

MODE

●

SET

4. Output specification selecting mode

Set OUT1 output specifications.

Press

▲

button to select OUT1 output spec., then press

button.「oU1_0」indicates instantaneous switch output,

「oU1_1」integrated switch output and「oU1_2」integrated

pulse output.

See "OUT1 output specifications".

Input the set value after selecting OUT1 output specifications.

See "7. Flow rate setting mode" for details.

Flow setting not required when selecting integrated pulse

output「oU1_2」.

●

SET

5. Output method selecting mode

Set OUT1 output mode. Reverse output and

non-reverse output mode are available for output.

*Press

▲

button to select the mode from reverse output or

non-reverse output. And press button is to set.

「oU1_n」indicates reverse output mode,「oU1_P」is

non-reverse output mode.

Pressing

button instead of

button switches to「F_5」.

●

SET

●

MODE

●

SET

Page 10

1716

Function Setting (continue)

7. Flow rate setting mode

Input set value. Input method depends on OUT1 output specification.

It does not go into Flow rate setting mode when the integration pulse

output is selected as OUT1.

Instantaneous switch output (oU1_0)

1. Press button to input n_1(P_1) set value.

「n_1」and the set value appears in turn if previous

setting select reverse output mode.(「P_1」and the set value

appears in turn when non-reverse output mode is selected)

2. Select set value by

▲

button or ▼button. ▲button to increase

the value,

▼button to reduce.

3. Press button to input n_2 (P_2) set value.

「n_2

」and the set value appears in turn if previous

setting select reverse output mode. (「P_2」and the set value

appears in turn when non-reverse output mode is selected)

4. Select the set value by

▲

and ▼button as in 2. above.

5. Press button to set the value.

6. *n_1< n_2(P_1 < P_2): Window comparator mode

「HIS」and hysteresis value appears in turn.

Press button after selecting hysteresis

with

▲

or ▼button.

▲

button to increase the value, ▼button to reduce.

0 to 3% of rated flow value is adjustable as hysteresis value.

If the difference between n_1(P_1) and n_2(P_2) is smaller

than 6% of rated flow, max. set value of hysteresis is the half

of the difference between n_1(P_1) and n_2(P_2).

*n_1≧ n_2(P_1≧P_2) : hysteresis mode

Hysteresis value is not set.

●

SET

●

SET

●

SET●SET

L/min

OUT

L/min

OUT

L/min

OUT

Integration switch output (oU1_1)

The value can be set up to 9999[m

3

×10

3

], 999[m3], 999[ ].

1. Press button to input the set value in the digit of [ ].

The set value and P_3(or n_3) appears in turn,

an "OUT" and " L" flicker.

*Press button longer than 2 sec. to complete setting.

2. Select set value with

▲

and ▼button. ▲button to increase the

value,

▼button to reduce.

3. Press button to input the set value in the digit of [m

3

].

The set value and P_3(or n_3) appears in turn,

an "OUT" and "m

3

" flicker.

*Press button longer than 2 sec. to complete setting.

4. Select the set value by

▲

and ▼button as in 2. above.

5. Press button to input the set value in the digit

of [m

3

×10

3

]. The set value and P_3(or n_3)

appears in turn, an "OUT" and "m

3

×10

3

" flicker.

*Press button longer than 2 sec. to complete setting.

6. Select the set value by

▲

and ▼button as in 2. above.

7. Press button to return to the status of 1. above.

Press button longer than 2 sec. to complete setting.

●

SET●SET

●

SET

●

SET

●

SET●SET

●

SET●SET

8. Flow conversion mode

Displays air flow converted during standard condition (Anr: 20℃,

101.3kPa, 65%RH[ANR]), and datum condition (nor:0

℃

,

101.3kPa).

1. Press button, and switch with

▲

button. "Anr"

indicates standard condition, "nor" datum condition.

2. Press button or button to complete the setting.

●

MODE

●

SET

●

SET

L

OUT

m

3

OUT

m

3

×

10

3

OUT

ANR

Page 11

1918

Error Display and Troubleshooting

This function displays error location and nature. When a problem

or an error occurs, take the following actions.

Flow display check

Check integrated flow when instantaneous flow is selected

Integrated flow is displayed only during ▼button is pressed.

(Returns to instantaneous flow when releasing

▼button.)

*The unit of integrated flow is changed as[L]→[ m

3

]→

[m

3

×10

3

]→[L]if press ▲button while pressing ▼button.

Check instantaneous flow when integrated flow is selected

Instantaneous flow is displayed only during ▼button is pressed.

(Returns to integrated flow when releasing ▼button.)

Switching the unit of integrated flow display

Set the integrated flow display unit while integrated flow is

selected.

1. Unit flickers by pressing ▲button.

2. The unit is changed as[L]→[ m

3

]→[ m

3

×10

3

]→[L]by

▲

button.

3. Unit stops flickering when deciding the unit by button.

*The unit stops flickering unless pressing button for 5 sec.,

and complete switching the flow display unit. Integrated flow

display unit is not switched.

Clear of Integrated Value

Integrated value is cleared by pressing ▲button pressing

▼

button for 5sec.

●

SET

Other Functions

Initialize the Set Value

All the setting can be initialized to values at shipment.

Press

▲

button and ▼button for longer than 2 sec. during initial

setting mode「F_0」. Press button after「F_00」appears.

*Setting is not initialized but switched to「F_0」if pressing

button. See below for setting at shipment.

Display setting : Instantaneous flow( d_1)

Unit setting : /min ( U_1)

Switch spec. : Instantaneous switch output( oU1_0 )

Output mode : Reverse output( oU1_n )

Flow setting value : Instantaneous flow Intermediate value of

full-range/ Integrated flow 0

Key lock mode : Unlocked( unL)

Flow conversion condition : 20

℃

, 101.3kPa,

65%RH[ANR](Anr)

●

MODE

●

SET

To reset display of Error 1 and 3, press ▲and ▼button simultaneously.

LED display

Error Nature Troubleshooting

A current exceeding

80mA

is flowing to OUT1.

Turn the power off. Check

the load and wiring of

OUT1.

Set data has been changed

due to some reason.

Reset all the data.

A fluid flow is higher than

rated rate.

Reduce the flow down to

the rated rate.

Page 12

2120

Specification

*1) With a unit selection function ( Without a unit selection function, fixed to

SI unit [

/min

or ,

m

3

, m

3

×

10

3

])

*2) Flow rate indication is possible to be switched to normal condition of

0

℃

/101.3kPa and standard condition of 20℃/101.3kPa/65%RH(ANR)

PF2A703H

Flow Rate Indication/Ra

nge

Flow rate indication range

( /min)

Indication Unit (*1,2)

Dry air

Operating fluid temp.

Linearliy

Repeatability

Model PF2A706H PF2A712H

125 to 3025 250 to 6050 550 to 12050

Measured min unit

( /min)

5 10

Flow rate converted

score of integrated pulse

100 /

pulse

Instantaneous flow rate : /min, CFM

Integrated flow rate : ,

m

3

, m

3

×

103, ft3, ft

3

×

103, ft

3

×

10

6

0 to 50℃(No condensation or freezing)

Current consumption

Mass (Weight) (*4)

±

1.5%F.S. or less

Temp. characteristics

Port size

±

1.5%F.S. or less(0.7MPa, 20℃)

±

2.0%F.S. or less (0 to 50℃, 25℃standard)

150mA or less (No load)

1.1kg 1.3kg 2.0kg

Attachment : A6063, Packin : H-NBR, Spacer : PPS,

Mesh : SUS, Inner body : A6063, Sensor case : PPS,

Sensor : Leaded glass/ptlr/FeNi/OFC

1

1・1/2

2

Material

Detecting method

Indication digit 5digits 7segment LCD

Operation indication range

Withstanding pressure

0.1 to 1.5MPa

2.25MPa

Integrated flow rate range

Ambient temperature

range

0 to 9,999,999,999

Operation : 0 to 50℃,Storage : -25 to 85

℃

(No condensation or freezing)

Output specification (*3)

[NPN open collector] Max. load current : 80mA,

Internal voltage drop : 1V or less (At load current

80mA), Max. input voltage : 30VA

NPN/PNP open collector (Same as

switchoutputs)

[PNP open collector] Max. load current : 80mA,

Internal voltage drop : 1.5V or less

(At load current 80mA)

Switch output

Integration pulse output

Voltage output : 1 to 5V (within rated flow range)

Linearliy :

±3%F

.S. or less

Permissible load impedance : 100k

Ω

or more

Current output : 4 to 20mA (within rated flow range)

Linearliy :

±

3%F.S. or less

Permissible load impedance : 250

Ω

or more

Analog output

Response time

1s or less

Power supply voltage

Hysteresis mode : Variable (Settable starting 0)

Window comparator mode : Set for 0 to 3%F.S.

24VDC, ripple±10% or less

Withstand voltage

1000VAC

, 1minute ( between lead block and case)

Insulation resistance

Noise resistance

50MΩor less (at 500VDC M)

(between lead block and case)

1000Vp-p pulse width 1μs first transition 1ns

Vibration proof

10 to 500Hz smaller one 1.5mm or 98m/s2, double

amplitude, each in directions of X,Y and Z 2hours

Impact proof

490m/s2, 3 tomes each in directions of X,Y and Z

Enclosure

IP65

Set flow rate range

( /min)

125 to 3025 250 to 6050 550 to 12050

Measured flow rate range

( /min)

150 to 3000 300 to 6000 600 to 12000

Analog output

±

3

%F.S. or less

Indicated value

PF2A703HModel PF2A706H PF2A712H

Hysteresis

Thermal sensing

*3) Switch output and integrated pulse are selected at initial setting.

*4) Except lead wire.

Page 13

Loading...

Loading...