Page 1

y

Doc. No.IZ*-OMK0015

- B

OPERATION MANUAL

PRODUCT NAME

MODEL:

:

Ionizer

IZS31 Series

○Read this operation manual carefully to

understand before installation and operation.

○Pay extra attention on the clause concerning the

safety.

○Keep this operation manual available whenever

necessar

.

Page 2

INDEX

1.Sefety instructions・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・ 2

2.Installation・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

2-1.Installation of Ionizer body・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

2-2.Installation of sensor・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 8

2-3.Connection of cable・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 9

3.Function description・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 10

3-1.Operation mode・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 10

3-2.Detection of the dirt on the electrode needle・・・・・・・・・・・・・・・・・・・・・ 11

3-3.Indication/Setting part description・・・・・・・・・・・・・・・・・・・・・・・・・・ 11

4.Selection and setting of equipment・・・・・・・・・・・・・・・・・・・・・・・・・・・ 12

4-1.Sensing DC mode・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 12

4-2.Pulse DC mode・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 16

4-3.DC mode・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 20

4-4.Poser supply cable connection circuit・・・・・・・・・・・・・・・・・・・・・・・・ 22

5.Specifications・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 24

5-1.Ionizer・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 24

5-2.Sensor・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 25

1

Page 3

2

1. Safety instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage. These

instructions indicate the level of potential hazard by labeling "Caution", "Warning", and "Danger". To

ensure safety, be sure to observe ISO4414, JIS B8370and other safety precautions.

CAUTION Operator error could result in injury or equipment damage.

!

WARNING Operator error could result in serious injury or loss of life.

!

DANGER In extreme conditions, there is a possibility of serious injury or loss of life.

!

※1) ISO 4414 : Pneumatic fluid power –Recommendation for application of equipment to transmission and

control systems

※2) JIS B 8370 : Rule for Pneumatic System

!

WARNING

1.The compatibility of equipment is the responsibility of the person who designs the system or

decides its specifications.

Since the products specified here are used in various operating conditions, their compatibility with the specific

system must be based on specifications or after analysis and /or tests to me et y our spe cific require men ts.

Those who decide the compatibility of equipment shall take the responsibility to guarantee the initial system

performance and safety. Construct system as reviewing all specifications in the latest catalog or documents as

well as considering the possibility of equipment in every occasion.

2. Only trained personnel should operate machinery and equipment.

This product generates high voltage, so it can be dangerous if an operator is unfamiliar with it. Assembly,

handling or repair of systems shou ld be p erf orme d by trained and e xperien ced o pera tor s.

3. Do not service machinery/equipment or attempt to eliminate components until safety is

confirmed.

1) Inspection and maintenance of the machinery and equipment should be performed after

confirmation of the safety such as earthing, prevention of electric shock and each type of

injury.

2) When equipment is to be eliminated, confirm the safe ty proce ss a s ment ioned above . Cu t air

pressure supply and electric power su pply tha t are the energy sou rce for the equip ment, and

exhaust all residual compressed air in the system.

3) Before machinery/equipment is re-started, take measures to prevent short circuit etc. with

enough care.

4.Do not use product under the following conditions or environments. If it is not avoidable, take

appropriate measures and contact SMC.

1) Conditions and environments beyond specifications or if product is used outdoors.

2) Installation on equipment in conjunction with atomic energy, railway, air navigation, vehicles,

medical equipment, food and beverage, recreation equipment , emergency stop circuits,

pressing clutch, break circuit and safety equipment.

3) An application which has the possibility of having negative effects on people, property, or

animals requiring special safety analysis.

Page 4

3

WARNING

!

1. This product is intended to be used for the general FA devices.

If other applications (especially the ones indicated in 4 on page 2) are used, please contact SMC

before the use.

2. Use under specified voltage and temperature.

Voltage out of specification may cause malfunction, breakage, electric shock and fire.

3. Use clean compressed air for fluid.

Do not use inflammable or explosive gas for fluid. It may cause fire or explosion. When other fluid except

compressed air is used, please contact SMC service representative.

4. This product doesn’t incorporate explosion-proof construction.

Do not use this product in the place where dust explosion might be triggered or inflammable or explosive

gas is present. It may cause fire.

Selection

!

CAUTION

1. This product has not been washed.

When bringing into clean room. Use after confirming its purification level after flushing.

WARNING

!

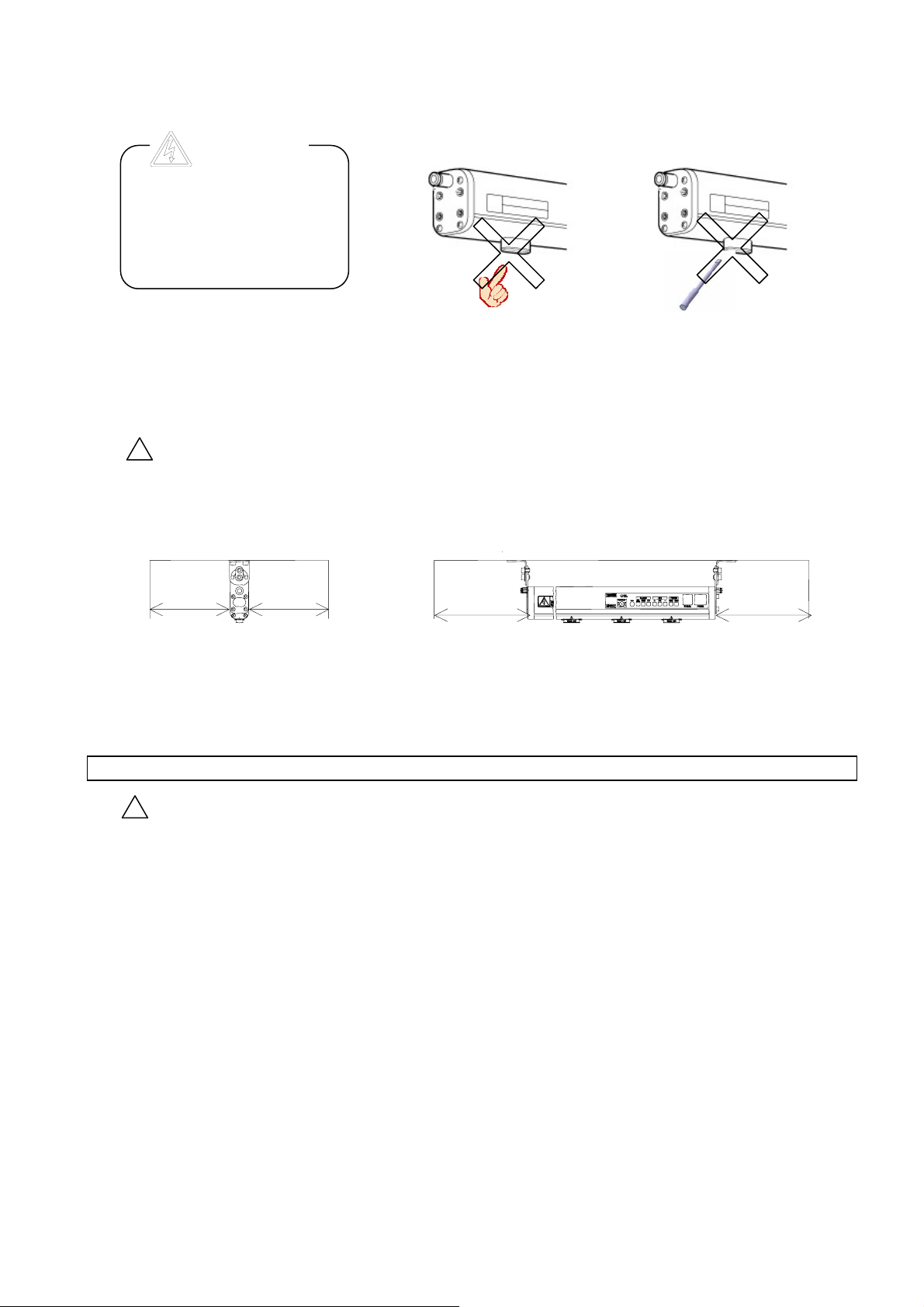

1. Get required space for maintenance, wiring and piping at installation.

Install connector and One-touch fitting for air supply to be able to eliminate and mount cable and tube.

Do not bend cable and tube with steep angle but fix them straight considering minimum bending radius to

prevent forcible stress applied to installation base of connector and One-touch fitting.

Forcible installation and elimination may cause malfunction, broken wire, fire and air leakage.

Minimum bending radius: Power supply cable・・・・・・・・・・・・・35mm

Sensor cable・・・・・・・・・・・・・・・・・・・25 mm

(Note: Here is allowable bending radius when fixing wiring at 20

it may apply forcible force to connector even with minimum bending radius or more.)

See instruction or catalog for minimum bending radius fo tube.

2. Install on the plane face.

Forcible force may apply to frame or case due to concave and convex or deformed mounting face and

large level gap, and it may cause breakage or operation failure. Also, dropping or strong impact may

cause operation failure or accident.

3. Do not use in the place where subject to noise (electromagnetic wave, surge etc.)

It may cause a malfunction, or deteriorate or damage internal elements. Take measures to prevent noise

source and avoid lines from touching and mixing each other.

4. Tighten within the specified torque.

See the following table for the tightening torque. When exceeding the tightening torque, mounting screw

and mounting bracket etc. might be broken. The screw might loosen for less than range of the tightening

torque.

Installation

o

C. If bending cable at lower temperature,

Screw size Recommended

tightening torque

M3 0.61 to 0.63 Nm

M4 0.73 to 0.75 Nm

M5 1.3 to 1.5 Nm

Page 5

4

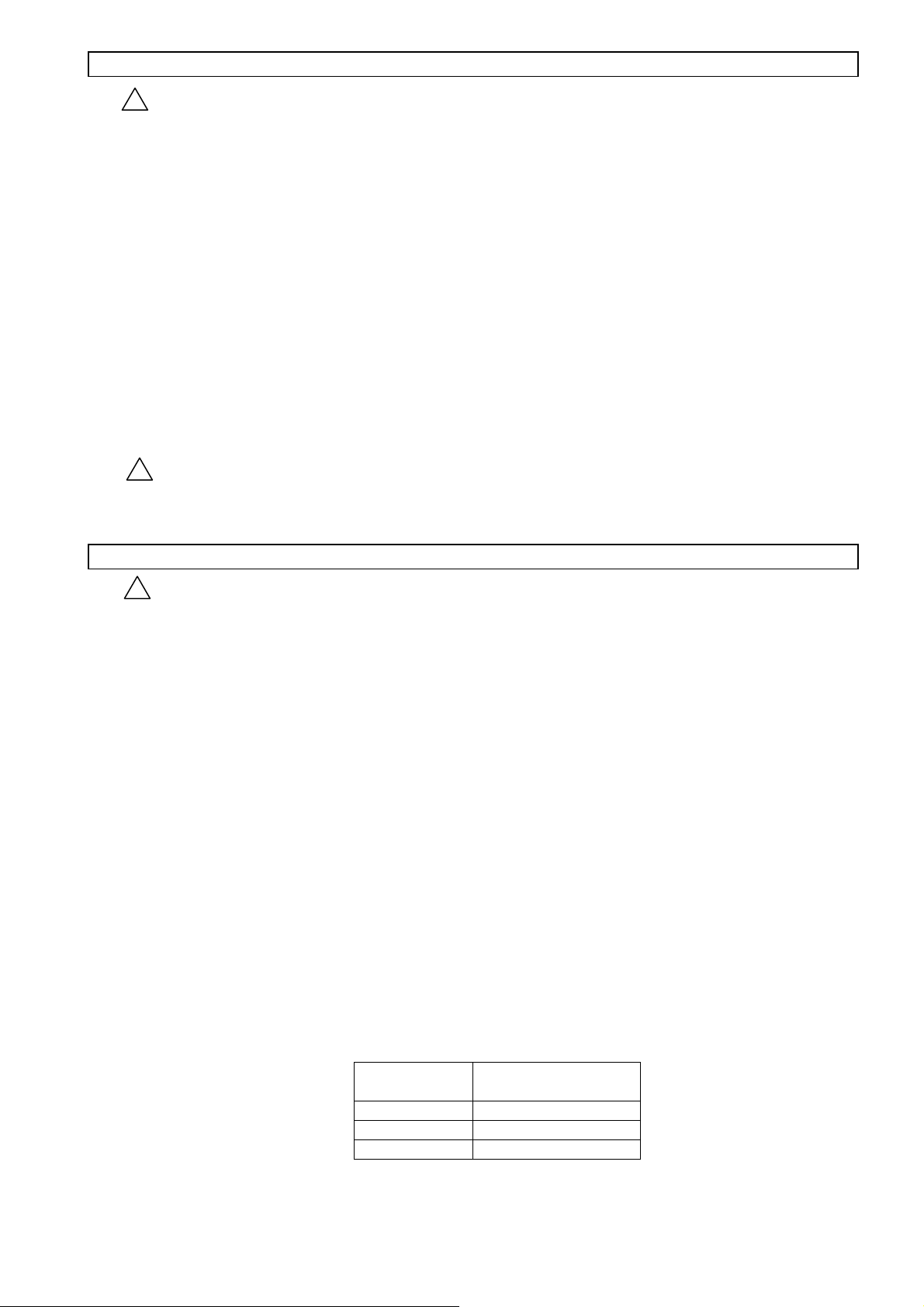

5. Do not touch electrode needle with finger or metal tool directly. It may cause injury.

If electrode needle or cartridge is it may stick to the fingers, damaged by tools, it will not only interfere the

specification function and performance but also may cause operation failure or accident.

Do not touch the electrode needle.

High voltage is supplied.

If foreign substances are inserted

or persons come in contact with it,

they might get injured when trying

to avoid the electric shock or

instantaneous lightning stroke.

Caution

High Voltage

for

6.Do not attach tape or seal on the product body.

If conductive adhesive and reflective paint is contained in the tape or seal, dielectric phenomenon will

occur due to the produced ion and it may lead to the electrostatic charge and electric leakage.

7.Be sure to install and adjust after power supply is stopped.

!

CAUTION

1. Install IZS31 series with keeping distance from the wall etc. as shown in the figure below.

The generated ion might not reach the target effectively and efficiency decrease, where there is wall etc.

inside the area shown in the figure below.

200mm

2.Be sure to check the effect of static charge elimination after installation.

The effect of static charge elimination largely varies depending on the ambient installation conditions and

operation conditions. After installation, be sure to check the effect of static charge elimination.

!

WARNING

1.Check that power supply capacity is enough and voltage is in specification before piping.

2.When selecting power supply,always use a UL-Listed power supply that either provides Class2 output as

defined in the National Electrical Code,or that has been evaluated as a Limited Power Source as defined in

UL60950.

3. To maintain the product performance, Apply Ground at a resistance not exceeding 100 Ωto prevent

electrical shock in accordance with instructions on this operation manual.

4. Be sure to cut off power supply at wiring (including connector plug-in/out) .

5. Use a dedicated cable with a sensor to connect the ionizer and a feed back sensor or an auto balance

sensor, and do not disassemble and/or modify the cable for the sensor.

6. Turn on the power after examining wiring and a surrounding situation enough, and confirming safety.

7. Do not connect and disconnect connectors while supplying the power. Ionizer might be broken and cause

malfunction.

8. Installation with high-voltage line and power line in the same wiring route may cause malfunction by noise.

Install separately with them.

200mm

150mm

Wiring and piping

150mm

Page 6

5

9. Be sure there is no incorrect wiring before operation. Incorrect wiring may cause product breakage or

malfunction.

10. Flush pneumatic piping before its installation. Make sure that all dust, water droplet, oil etc. are eliminated

before piping.

!

WARNING

Environment

1. Use within operating fluid and ambient temperature range.

Operating fluid and ambient temperature range for Ionizer, feed back sensor and auto balance sensor

are 0 to 50

o

C. Though ambient temperature is within specification, dew condensation might be generated

where temperature is suddenly changed. Therefore do not use under such environment.

2.Do not use this product in an enclosed space.

This product utilizes the corona discharge phenomenon. Since a small amount of ozone and NOx

is generated, do not use it in an enclosed space.

3. Environment to avoid

Do not use or store under the following environments, as these may cause operation failure. If it is

unavoidable, take the appropriate measures.

a. The place where ambient temperature exceeds 0 to 50

o

C.

b. The place where ambient humidity exceeds 35 to 85% RH.

c. The place where dew condensation is generated due to sudden temperature change.

d. The place where there is corrosive gas, inflammable gas, and volatile inflammable substance is stored.

e. The atmosphere where the product is exposed to conductive powder such as iron powder and dust, oil

mist, salt and organic solvent or machining chips, particles and cutting oil (water, liquid).

f. The place where product is directly exposed to the blow from air-conditioners.

g. The place where sealed and ventilation is not installed.

h. The place the product is exposed to the direct sunlight and radiant heat.

i. The place where strong electromagnetic noise is generated. (Strong electric field/ strong magnetic

field/ surge.)

j. The place where electricity is discharged. The situation which causes electric discharge on the product.

k. The place where strong high frequency is generated.

l. The place where lightning disaster is expected.

m. The place where the product is directly exposed to the vibration and impact.

n. The situation where the force and weight that causes deformation of the product is applied.

4. Do not use air containing mist or dust.

Air containing mist or dust may lower function and shorten maintenance cycle. Dryer (IDF series), air filter

(AF/AFF series), mist separator(AFM/AM series) to produce clean compressed air.

5. Ionizer, feed back sensor and auto balance sensor are not tolerable against surge of lightning.

Protection against lightning surge should be incorporated in the equipment..

Maintenance

!

CAUTION

1. Keep electrode needle clean by regular maintenance.

Make sure that the equipment is operating without any failure by regular

maintenance. Those who have enough knowledge and experience should

perform the maintenance of the equipment.

Dust attached on the electrode needle due to longer operating lowers the

function to eliminate static electricity. If electrode does not recover

its function to eliminate static electricity due to worn out after cleaning,

A high voltage generating circuit is

installed. Be sure to stop the supply

voltage at the maintenance. Do not

disassemble / renovate the product as

it may deteriorate the functions and

cause risks due to electric shock and

electric leakage.

Caution

for

High Voltage

replace it with the new one. In order to maintain the stable performance,

regular maintenance and cleaning of electrode are recommended.

2. Stop supplying power to the body without fail when cleaning the electrode needle or exchanging the

electrode cartridge. Do not touch the electrode needle while energizing, or it may cause electric shock or

Page 7

6

accident.

3. Do not open the case to disassemble and reconstruct the product.

It may cause electric shock, operation failure and disaster such as fire. In addition, note the product, which

is disassembled or reconstructed, may not satisfy the functions and performance in the specifications and

is out of guarantee.

4. Do not operate the product with the wet hands.

It may cause electric shock or accident.

!

WARNING

1. Do not drop, hit to the object and give excessive impact (10G or more) at handling.

Though Ionizer itself doesn’t break, inside construction might be broken and cause malfunction.

2. When cable is mounted or eliminated, pinch modular plug claw with finger and insert or take out the plug

itself vertically. If mounted or eliminated to inappropriate direction, mounting part of modular jack might be

damaged and finally it leads to operation failure.

2. Installation

2-1. Installation of Ionizer body

Investigate the places where static problem occurs, or process and parts which generate ESD

(Electro static discharge), and carefully consider the required conditions to ensure appropriate static

charge elimination before installation.

1. Installation height

When the ionizer is installed, keep the distance between charged objects and the ionizer within the

range below.

Ion-production

frequency

[Hz]

1 400 to 2000 400 to 500

3 300 to 2000 300 to 400

5 300 to 2000 300 to 400

10 200 to 2000 200 to 300

15 200 to 2000 200 to 300

20 150 to 2000 150 to 250

30 50 to 2000 50 to 200

60 50 to 2000 50 to 150

(Note)・As the installation height stated above is a standard, check the effect of the static charge elimination

before installation.

・The minimum installation height should be 200mm or more when the feed back sensor is use, and

that for the auto balance sensor should be 100mm or more. When the ionizer is used outside of these

conditions, be sure to check if these sensors will operate properly.

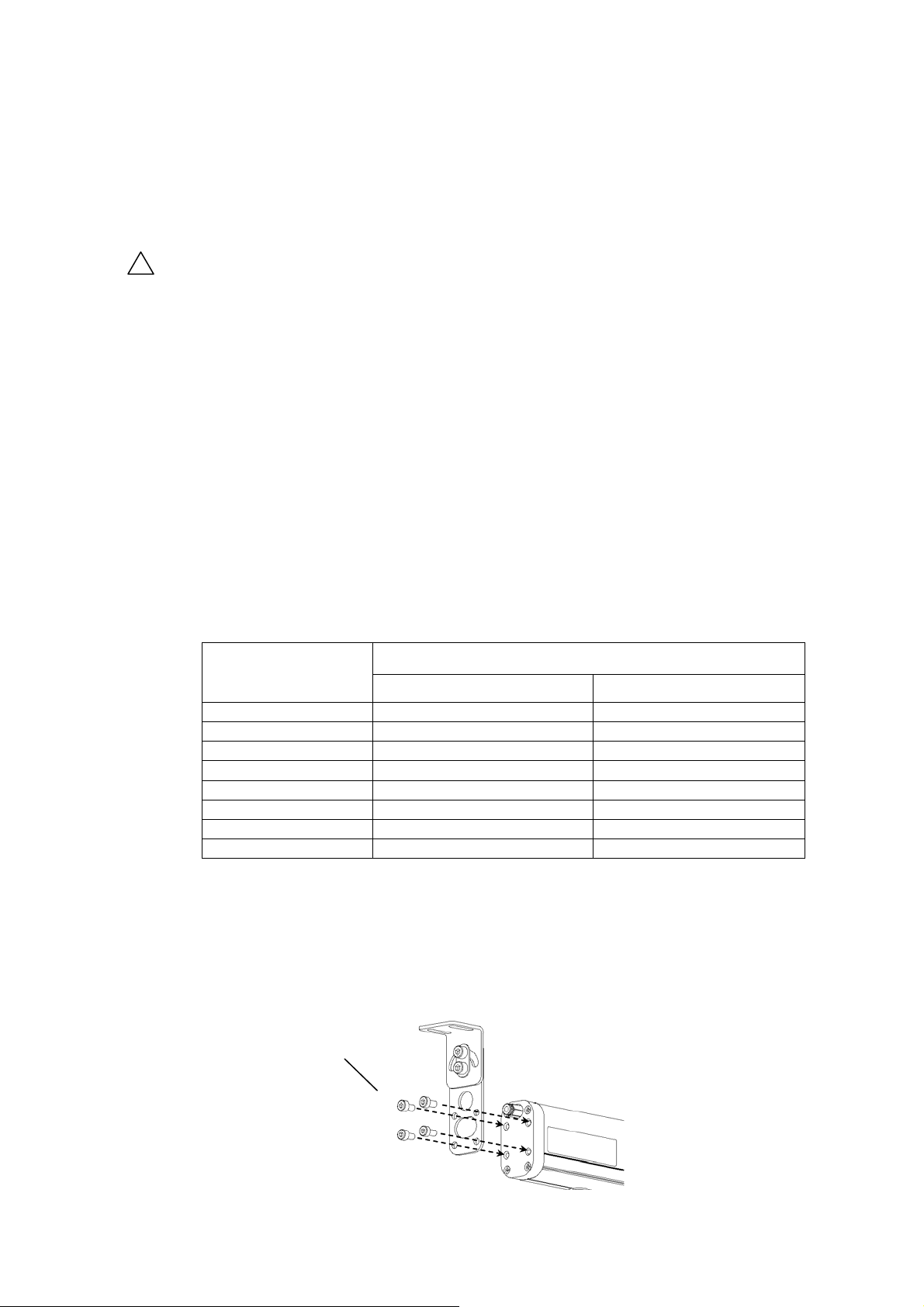

2. Mount end brackets on both sides of the ionizer body with the attached M4 threads.

Distance between the charged objects and ionizer (mm)

With air purge (note) W/o air purge

Attached M4 threads

Page 8

7

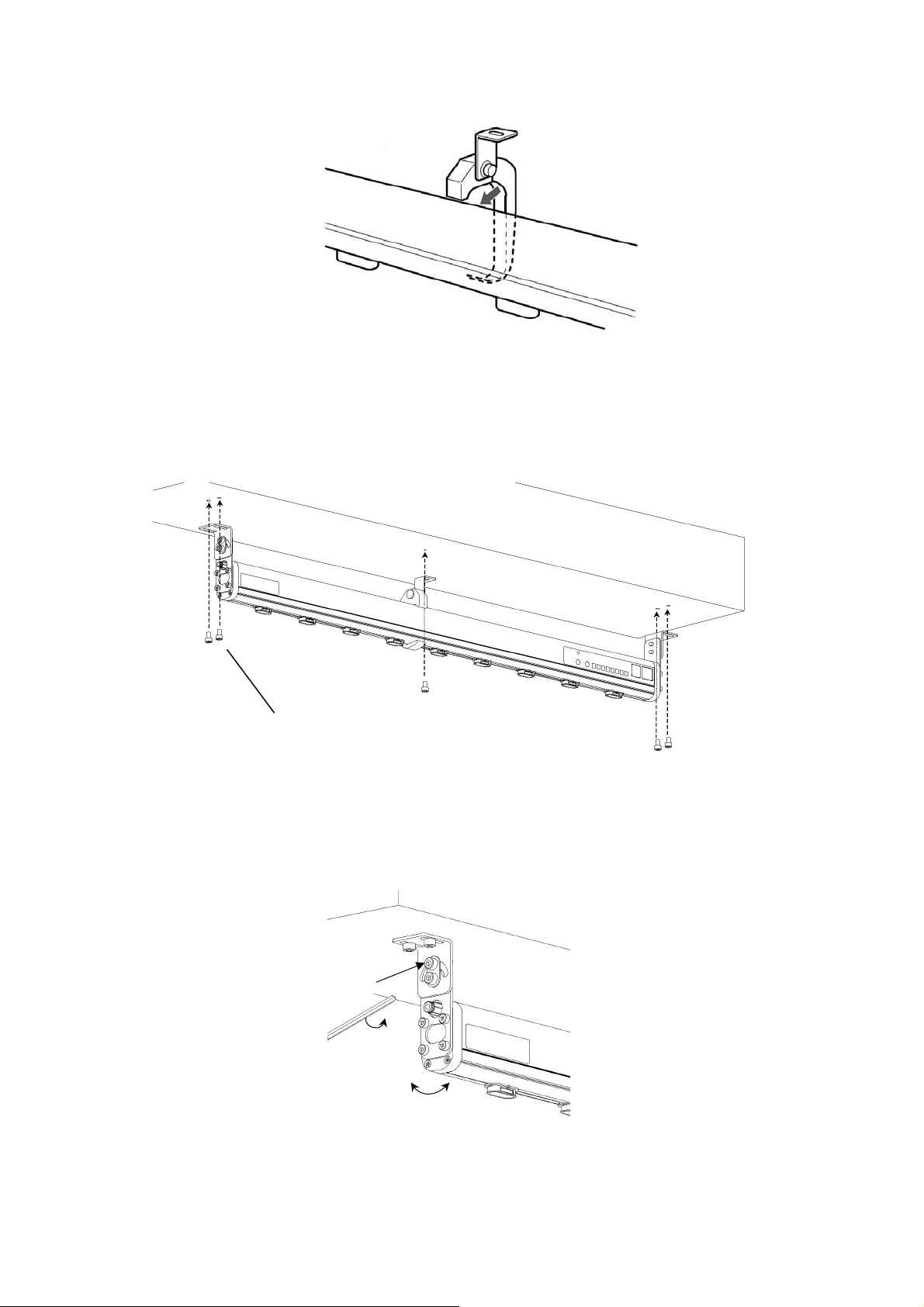

3. Mount intermediate brackets on the ionizer body at regular interval.

Intermediate bracket

4. Tap M5 thread on the brackets mounting positions at the installation side, and fix the ionizer body and

brackets with M5 threads.

M5 threads

5. Adjust angle of the ionizer body to ensure proper static charge elimination, and fix it with detent threads

(M5) of brackets.

M5 threads

Page 9

8

6. Be sure to ground the DC1 (-) lead wire [blue] of the power supply cable (Resistance between the lead

wire and the earth ground should be 100Ω or less.)

If the lead wire is not grounded, the ion balance will be unstable, and an electric shock may occur. At the

same time, the ionizer and power supply might be damaged.

DC Power supply

Ground the DC1 (-) lead wire [blue]

of the power supply cable

Brown

Blue

2-2. Installation of sensor

Ground

1. Installation of sensor head Feed back sensor

Keep the detecting hole of the sensor head towards the charged object to precisely detect the target’s

static charge. Keep the distance between the detecting hole and surface of the charged object within 10

to 50mm to prevent the sensor from coming in contact with the charged object. The detecting range and

sensor output will be changed depending on the installation distance.

Mount the sensor head with two pieces of M3 screws (sold separately).

M3 screws

As the sensor head case is connected to the GND, pay great

attention to the installation or power supply to prevent

short-circuit between the GND and 24V power supply.

Detecting hole

The detecting hole is open to detect static electricity. When

foreign substances are intruded into the hole or tools come in

contact with the inside of the detecting hole, it leads to a

malfunction or damage of the sensor, resulting in an improper

detection of the static electricity. Therefore, do not put any

foreign substances in the detecting hole or touch it with a tool.

Do not pull a cable out of the sensor head. If the cable is

pulled with a strong force, the sensor head might be damaged

or its wires might be broken.

Page 10

9

Auto balance sensor

Horizontally place the auto balance sensor under the ionizer and face its metal plate upward. Because

the ion balance will be changed depending on the installation height, install the sensor on the same level

with a workpiece as much as possible. The auto balance sensor can be removed once the ion balance

adjustment is completed.

Keep the height between the auto balance sensor and ionizer within the installation height stated in

2-1.

Mount the head sensor with 2 pieces of M3 screws (sold separately).

Metal plate

2. Installation of sensor amp

A sensor amp should be mounted with 2 pieces of M3 screws (sold separately).

Do not pull a cable out of the sensor amp. If the cable is pulled with a strong force, the sensor amp might

be damaged or its wires might be broken.

Be sure to ground the sensor amp case. (Resistance between the sensor amp case and the earth

ground should be 100Ω or less.) Because the sensor amp case surface is treated with conductive

plating, FG wiring is not necessary when the sensor amp case is connected to the mounting surface of the

grounded unit. If the mounting surface is insulated with painting or being anodized, be sure to connect the

FG wiring for grounding.

2-3. Connection of cable

Head side

M3 threads

Class D ground

Sensor

1. Insert the modular plu g of power supply cable IZS31-CP

into the modular jack for indicating [power] on the ionizer

body. A lever will snap when the modular plug is correctly

locked. Fix cables with a tie wrap or other measures in the

vicinity of connection not to apply compulsive force to the

modular jack and plug.

Page 11

0

2. Connect the lead wires in accordance with the lead wire list. (See

Chapter 4) Arrange lead wires in accordance with the wiring table. The

unused wires should be cut short or covered with vinyl tape without

pealing the coat to prevent them from coming contact with other wires.

3. When the feed back sensor or auto balance sensor is used, remove

the dust cover from the modular jack with [signal] indication, and insert

the modular plug of the sensor cable (IZS31-CS). A lever will snap

Sensor cable

when the modular plug is correctly locked. Fix cables with a tie wrap or

other measures in the vicinity of their connection not to apply

compulsive force to the modular jack and plug.

Dust cover

3. Function description

3-1. Operation mode

3 types of operation modes are available with IZS31 (sensing DC mode, pulse DC mode and DC mode.)

These modes are selectable depending on the applications and operating conditions.

1. Sensing DC mode

This mode detects the charged condition of the workpiece with the feed back sensor, and feed back the

condition to the ionizer. With this mode, ions with optimal polarity are discharged to shorten the static

charge elimination time. When the static charged of the workpiece becomes +/-30V or less

completion signal of the static charge elimination will turn off.

This mode is suitable for the object that is largely charged.

Once the static charge elimination is completed, [energy-saving operation] or [continuous static charge

elimination mode] can be selected.

note)

, the

Energy-saving

operation

The ion-discharge output will automatically stop once the static charge

elimination is completed. If the charged potential of the work becomes +/- 30 V

or more, the ion will be discharged again.

The [energy-saving operation] is recommended for conductive workpieces.

Continuous

static charge

eliminating

operation

The static charge will be continuously eliminated with pulse DC as maintaining

the ion balance to make the charged potential +/-30V or less

note)

even after the

static charge is completed.

The [continuous static charge eliminating operation] is recommended for

nonconductive workpieces.

Note) when the installation height of the feed back sensor is 25mm.

2. Pulse DC mode

The ionizer discharges plus ions and minus ions by turns.

When the auto balance sensor is used, the ion balance is automatically adjusted within +/-30V. If the ion

balance exceeds +/-30V due to the dirt on the electrode needle, the maintenance output signal will be

output.

This mode is suitable for eliminating the static charge in the air and/or on the workpieces.

When the auto balance sensor is used.

[Manual operation] or [auto operation] can be selected for the ion balance adjustment.

Manual

operation

When maintenance start-up signal is input, or the power supply of the ionizer

Is applied, the ion balance adjustment will begin.

When workpieces are moving, [manual operation] is recommended. Start the

equipment after ion balance is adjusted.

Auto operation The ion balance is continuously adjusted.

When the static charge of the still workpieces or in the atmosphere is

eliminated, the [auto operation] is recommended.

When the auto balance sensor is not used.

The ion balance is adjusted with a balance adjusting trimmer. An instrument is separately needed to

check the ion balance.

1

Page 12

3. DC mode

Plasma ions or minus ions are continuously discharged. The parts other than the charged object need to

be grounded to prevent them from being charged. The plasma and minus ions cannot be discharged

simultaneously.

3-2. Detection of the dirt on the electrode needle

When the maintenance start-up signal is input, the ionizer detects if the static charge elimination

capability is degraded due to the dirt on the electrode needle. If the electrode needle needs to be cleaned

because of the degraded capability of the static charge, the maintenance LED lights up, and then the

maintenance output signal is output. Because just installing the feed back sensor or auto balance sensor is

not enough to detect if the static charge eliminating capability is degraded, regularly input the maintenance

start-up signal to check the static charge elimination capability.

3-3. Indication/ Setting part description

No. Name Type Description

Power supply

①

indication

Sensor connecting

②

indication

Minus indication

③

Completion indication

④

Plus indication LED

⑤

Indication for abnormal

⑥

high voltage

Sensor failure

⑦

indication

Maintenance indication

⑧

Maintenance level

⑨

selecting switch

Frequency selecting

⑩

switch

Balance adjusting

⑪

trimmer

⑪ ⑩ ⑨ ⑧ ⑦ ⑥ ⑤ ④ ③ ② ①

LED(Green)

LED(Green)

LED(Blue)

LED(Green)

(Orange)

LED(Red)

LED(Red)

LED(Red)

Rotary

switch

Rotary

switch

Trimmer This trimmer is used to adjust the ion balance when the

Lights up green when the power supply is turned ON.

Flashes when the power supply voltage is not proper.

Lights up when the feed back sensor and/or auto

balance sensor is connected.

LED will change depending on the operating modes.

4. See the selection of models and setting.

Lights on red when overcurrent is applied to the

electrode needle.

Lights on red when the feed back sensor and/or auto

balance sensor is not operating properly.

Flashes red when dirt on the electrode needle is

detected.

LED will change depending on the operating modes.

4. See the selection of models and setting.

auto balance sensor is not used.

11

Page 13

2

4.Selection and setting of equipment

w

4-1.Sensing DC mode

1. Selection of bar length

・Select the length applicable to work size base on static charge elimination area and static charge

elimination characteristics.

2. Installation of body

・Keep the distance between the ionizer and charged objects within 200 to 2000mm. Although the ionizer

can be mounted outside of this range, it may not operate properly depending on the operating conditions.

Therefore, be sure to check if the ionizer will operate properly.

3. Installation of the sensor

・Install the feed back sensor. Keep the detecting hole towards the charged face.

・It should be mounted within a 10 to 50mm of installation height. Although the ionizer can be mounted

outside of this range, it may not operate properly depending on the operating conditions. Therefore, be

sure to check if the sensor will operate properly.

・When the ionizer and feed back sensor are connected, the mode is automatically shifted to the sensing

DC mode.

4. Setting of the maintenance level selecting switch

・Set the level for detecting the dirt on the electrode needle.

・Select the level from H(High), M(Middle) or L(Low). The dirt on the electrode needle cannot be

detected with other levels.

・The dirt detection is done when the maintenance start-up signal is input.

5. Setting of frequency selection switch

・This switch is used to switch the [energy-saving operation] and [continuous static charge eliminating

operation].

・With [continuous static charge eliminating operation], the ion-production frequency needs to be

selected after the static charge elimination is completed.

H(High) ・・・ The level that doesn’t affect the static charge eliminating time (Even a small amount of

dirt can be detected).

M(Middle) ・・The level that can notify the maintenance just before the static charge elimination time becomes

slow.

) ・・・ The level that the static charge elimination time becomes slower than the one in the initial state.

L(Lo

Operation details Switch setting

Energy-saving

operation

Continuous

static charge

eliminating

operation

When the static

charge elimination is

completed, the

ion-discharge-output

will automatically

stop.

The static charge

elimination continues

as controlling the ion

balance with pulse

DC even after the

static charge

elimination is

completed so that the

charged potential of

works maintains

+/-30V or less.

Ions are discharged

with the set

frequency.

8

+ion

-ion

+ion

-ion

(e.g.)Charged work: negative charge

- - - - Static charge

stops

Pulse operation

Elimination completed

0 ・・・ 1Hz

1 ・・・ 3Hz

2 ・・・ 5Hz

3 ・・・ 10Hz

4 ・・・ 15Hz

5 ・・・ 20Hz

6 ・・・ 30Hz

7 ・・・ 60Hz

1

Page 14

3

6. Wiring of the power supply cable

・Connect dedicated power supply cables.

Connection with the power supply for ionizer operation

Symbol Cable

color

DC1(+)

DC1(-)

OUT4 Dark

※ Be sure to ground DC1(-)[Blue]. (Resistance between the lead wire and the earth ground should be 100Ω or less.)

If not, it may break the ionizer.

Brown Power supply DC24V

Blue Power supply GND[FG]

Green

Cable name Connectio n Description

○

○

Sensor monitor output

△

Power supply cable for

ionizer operation

Charged potential of the

work is output with

analog signal (1 to 5V)

Brown

Blue

Connection with the power supply for I/O signal

Symbol Cable

color

DC2(+)

DC2(-)

IN1 Light

IN2 Gray Maintenance start-up signal

-

-

OUT1 Pink Completion signal for

OUT2 Yellow Maintenance output signal

OUT3 Purple Signal for failure

Red Power supply DC24V

Black Power supply GND

Discharge-stop signal

Green

White

Orange

- - -

- - -

static charge elimination △

Cable name Conne

ction

○

○

○

△

△

△

Description

Power supply cable for I/O signal

Signal for starting/ stopping the discharge

(NPN spec)Operation will begin when it is connected with

DC2(-)[Black].

(PNP spec)Operation will begin when it is connected with

DC2(+)[Red].

A signal that is input when the maintenance of the

electrode needle is necessary.

Outputs when the charged potential of the work is +/-30V

or more, and when the dirt on the electrode needle is

detected.

Outputs when the maintenance of the electrode needle is

necessary.

Outputs in case of abnormal high voltage and sensor

and/or CPU failure.

(B contact output)

○ : Wires that are minimum required to operate the ionizer.

△ : Wires that are required to use the functions.

- : Wires that are not necessary with the sensing DC mode. T hese wires should not be short-circuited with other

cables.

7. Air piping

・When the piping is only connected to one port, the other unused port should be plugged with the M-5P

that is packaged together with the ionizer.

DC Power supply

Ground

1

Page 15

4

8. LED display

■

POWER LED ・・・ The power supply input and the connection of the sensors are displayed.

LED name Functions

POWER

MAIN Lights up when the power supply is applied. (Green)

(Flashes when wrong power supply is applied.)

SNSR Lights up when the feed back sensor is connected.(Green)

ION LED ・・・ The charged condition of the work is displayed.

LED name Functions

ION

+ The charged potential of the work is positive.(Orange)

OK

- The charge potential of the work is negative.(Blue)

The charged potential of the work is low.(Green)

・The charged condition of the work can be identified with the LED display.

Charged polarity of work

Plus

static charge elimination

Minus

LED

+ OK -

■□□

■□□

■■□

□■□

□■■

□□■

□□■

Charged potential of the work

More than +400V

+100V to +400V

+30V to +100V

+30V to -30V

-30 to -100V

-100 to -400V

More than -400V

■light on

flash with 4 Hz

□light out

ALARM LED ・・・ Failure of the ionizer is displayed.

LED name Functions

ALARM

HV Lights up when overcurrent is applied to the electrode

needle.(Red)

SNSR Lights up when the feed back sensor doesn’t work properly.

(Red)

NDL

CHECK

Lights up when dirt on the electrode needle is detected.

(Red)

(Flashes when the dirt is being detected. )

1

Page 16

5

9. Alarm

Type of alarm Description How to reset

Abnormal high voltage Notifies when overcurrent such as high voltage

leakage occurs. The ion-discharge-output is

stopped, HV ALRM sets off and outp ut the

Turn off the power supply to solve the problem.

Once it’s solved, apply the power supply again.

Or turn on and off the discharge-stop signal.

signal for failure.

Sensor failure Notifies that the feed back sensor doesn’t work

properly. SN SR ALARM lights up, and the

signal for sensor failure is output.

CPU failure Notifies that CPU fails due to noise. All LEDs

Flashes, and the signal for CPU failure is

output.

Electrode needle

maintenance

Notifies when the maintenance of the electrode

needle is necessary. NDL CHECK ALARM

lights up, and the maintenance output signal is

Turn off the power supply to solve the problem.

Once it’s solved, apply the power supply again.

Or turn on and off the discharge-stop signal.

Turn off the power supply to solve the problem.

Once it’s solved, apply the power supply again.

Or turn on and off the discharge-stop signal.

Turn off the power supply and clean the

electrode needle. Then apply the power

supply.

output.

10. Timing chart

Timing chart with a norma l operation

Input

OFF

30V

0V

ON

Charged condition of the work

Power supply DC24V

Discharge-stop signal

Completion signal for

static charge elimination

Sensor monitor output

Charged condition

(with ION LED)

Input

Output

Output

LED

ON

OFF

ON

OFF

ON

OFF

ON

OFF

(Opration)

(discharge)

(Output)

(LED)

Timing chart when the dirt on the electrode needle is detected

Power supply

DC24V

Discharge stop

signal

Completion signal for

i

h

r

Maintenance

start-up signal

Maintenance

output signal

Maintenance indication

(With NDL CHECK ALARM)

Input

Input

Output

Input

Output

LED

ON

OFF

ON

OFF

ON

OFF

ON (SW ON)

OFF

ON (SW ON)

OFF

ON

OFF

(Operation)

(discharge)

(LED)

Contamination detecting of electrode

2s

100ms or more

Blink

・The completion signal for static charge elimination is output while the dirt on the electrode needle is being detected

・Because ions are discharged from the ionizer when the electrode needle is being detected, the workpiece might be charged.

Therefore, the workpieces should not be mounted when the detection is executed.

ON and OFF status will be changed depending on the situation

1

Page 17

6

4-2. Pulse DC mode

w

1. Selection of the bar length

・Select an appropriate length that is suitable for the work size, static charge elimination characteristics

and static charge elimination range.

2. Installation of the ionizer

・Keep the distance between the ionizer and charged object within 50 to 2000mm. When the auto

balance sensor is used, the distance should be ranged from 100 to 2000mm. When the ionizer is used

outside of the operating conditions, it might not operate properly. In that case, be sure to check if the

ionizer will operate properly.

3. Installation of the sensor

・Install the auto balance sensor to adjust the ion balance.

・Horizontally place the auto balance sensor under the ionizer, and install the sensor on the same level

with a workpiece as much as possible.

・When he auto balance sensor is connected, the balance adjustment trimmer will be invalid.

4. Setting of the maintenance level selecting switch

・[manual operation] or [auto operation] can be selected when the ion balance needs to be adjusted with

the auto balance sensor.

Description Switch setting

Manual

operation

MANUALAUTO

Auto operation Ion-balance is continuously adjusted.

* Set the switch in line with the detection level of the dirt on the electrode needle.

Ion balance is adjusted when the maintenance

start-up signal is input or when the power

supply of the Ionizer is applied.

The ion-balance adjustment values are

retained per ion-production frequency. When

the ion-production frequency is changed, adjust

the ion balance.

Once the ion-balance adjustment is completed,

the ion balance adjustment will not be executed

unless the next maintenance start-up signal is

input. Therefore, the auto balance sensor can

be removed.

Once the auto balance sensor is removed,

manually adjust the ion-balance with a balance

adjustment trimmer.

MANUAL

AUTO

・When the auto balance sensor is not used, change the switch setting to AUTO, and manually adjust the

ion-balance with a balance adjustment trimmer.

Balance aadjustment trimmer

・Set the level for detecting the dirt on the electrode needle.

Model

NuFile

00

・Select the level from H(High), M(Middle) or L(Low). The dirt on the electrode needle cannot be

detected with other levels.

H(High) ・・・ The level that doesn’t affect the static charge eliminating time (Even a small amount of

dirt can be detected).

M(Middle) ・・The level that can notify the maintenance just before the static charge elimination time becomes

slow.

) ・・・ The level that the static charge elimination time becomes slower than the one in the initial state.

L(Lo

・The dirt detection will begin once the maintenance start-up signal is input.

・If H, M and L levels are set, ion balance adjustment is executed after the dirt on the electrode needle is

detected.

1

Page 18

7

5. Setting of the frequency selecting switch

・Select the ion-production frequency.

Ion-production

frequency

1Hz 0

3Hz 1

5Hz 2

10Hz

15Hz 4

20Hz 5

30Hz 6

60Hz 7

Switch setting

3

6. Wiring of the power supply cables

・Connect a dedicated power supply cable.

Connection power supply for ionizer drive

No Lead wire color

DC1(+)

DC1(-)

OUT4 Dark Green Sensor monitor

※ Be sure to ground DC1(-)[Blue]. (Resistance between the lead wire and the earth ground should be 100Ω or less.)

If not, it may break the ionizer.

Brown Power supply

Blue Power supply

Description

DC24V

GND[FG]

output

Direction

of signal

○

power supply cable for

ionizer drive

○

- -

Function

Brown

Blue

Connection power supply for I/O signal

No Lead wire

color

DC2(+)

DC2(-)

IN1 Light

IN2 Gray Maintenance start-up

-

-

OUT1 Pink Completion signal for

OUT2 Yellow Maintenance output

OUT3 Purple Signal for failure

Red Power supply DC24V

Black Power supply GND

Green

White

Orange

Description

Discharge-stop signal

signal

- - -

- - -

static charge elimination

signal

Direction

of signal

○

○

○

△

△

△

△

Function

Power supply cable for I/O signal

Signal for starting/ stopping the discharge

(NPN spec)Operation will begin when it is

connected with DC2(-)[Black].

(PNP spec)Operation will begin when it is

connected with DC2(+)[Red].

A signal that is input when the maintenance of the

electrode needle is necessary.

Outputs when the dirt on the electrode needle is

detected.

Outputs when the maintenance of the electrode

needle is necessary.

Outputs in case of abnormal high voltage and

sensor and/or CPU failure.

(B contact output)

○ : Wires that are minimum required to operate the ionizer.

△ : Wires that are required to use the functions.

- : Wires that are not necessary with the pulse DC mode. These wires should not be short-circuited with other cables.

7. Air piping

・When the piping is only connected to one port, the other unused port should be plugged with the M-5P

that is packaged together with the ionizer.

DC Power supply

Ground

1

Page 19

8

8. LED display

POWER LED ・・・ The power supply input and the connection of the sensors are displayed.

LED name Functions

POWER

MAIN Lights up when the power supply is applied. (Green)

(Flashes when wrong power supply is applied. )

SNSR Lights up when the auto balance sensor is connected.(Green)

ION LED ・・・ The discharged ion polarity and ion balance are displaye d.

LED name Function

ION

+

OK

-

Lights on when plus ions are generated.(Orange)

[With auto balance sensor]Condition of the ion balance (Green)

[W/o auto balance sensor] Goes out

Lights on when minus ions are generated.(Blue)

・The ion balance state can be identified with the LED display.

Ion balance OK LED

Below +/-30V

+/-30V or more Goes out

※ LED [OK] flashes when the ion balance nears the limit of the adjustment of the ion balance and indicates that

it is time for maintenance of the electrode needle.

Lighet up.(or flashes)

ALARM LED ・・・ Failure of the ionizer will be indicated.

LED name Functions

ALARM

HV Lights up when overcurrent is applied to the electrode

needle.(Red)

SNSR

NDL

CHECK

Lights up when the auto balance sensor doesn’t work properly.(Red)

Lights up when dirt on the electrode needle is detected. (Red)

(Flashes when the dirt is being detected. )

1

Page 20

9

9. Alarm

p

Type of alarm Description How to reset

Abnormal high voltage Notifies when overcurrent such as high voltage

leakage occurs.The ion-discharge-output is

stopped, HV ALRM sets off and outp ut the sign al

Turn off the power supply to solve the problem.

Once it’s solved, apply the power supply again.

Or turn on and off the discharge-stop signal.

for failure.

Sensor failure Notifies that the auto balance sensor doesn’t

work properly. SNSR ALARM lights up, and the

signal for sensor failure is output.

CPU failure Notifies that CPU fails due to noise. All LEDs

Flashes, and the signal for CPU failure is output.

Turn off the power supply to solve the problem.

Once it’s solved, apply the power supply again.

Or turn on and off the discharge-stop signal.

Turn off the power supply to solve the problem.

Once it’s solved, apply the power supply again.

Or turn on and off the discharge-stop signal.

Electrode needle

maintenance

Notifies when the maintenance of the electrode

needle is necessary. NDL CHECK ALARM lights

Turn off the power supply and clean the

electrode needle. Then apply the power supply.

up, and the maintenance output signal is output.

10. Timing chart

Timing chart with a norma l operation

Power supply DC24V

Discharge-stop signal

State of ion discharge

Input

Input

ON

OFF

ON (Operati on)

OFF

ON (Discharge)

OFF

Timing chart when the dirt on the electrode needle is detected/adjust ion balance

(a)With auto balance sensor

① Manual operation

ON

OFF

Power supply DC24V

Discharge-stop signal

Completion signal for

Static charge elimination

Maintenance

Start-up signal

Maintenance

Output signal

Maintenance indication

(NDL CHECK ALARM)

Contamination detecting

Ionizer

of electrode needle

operation

Input

Input

Output

Input

Output

LED

Adjust ion balance

ON

(Operation)

OFF

(Contamination detecting of electrode nee dle / Ion balance is being adjusted.)

ON

OFF

ON

(SW ON)

OFF

ON

(SW ON)

OFF

ON

(Lighting)

OFF

100ms or more

Blink

Detection is executed when the

maintenance level selecting switch,

H, M or L is selected.

② Auto o

Power supply DC24V

Discharge-stop signal

2s

Completion signal for

Static charge elimination

Maintenance

Start-up signal

Maintenance

Output signal

Maintenance indication

(NDL CHECK ALARM)

Ionizer

operation

eration

Input

Input

Output

Input

Output

LED

Contamination detecting

of electrode needle

Adjust ion balance

ON

OFF

ON

(Operation)

OFF

(Contamination detecting of electrode nee dle)

ON

OFF

ON

OFF

ON

OFF

ON

OFF

(SW ON)

(SW ON)

(Lighting)

100ms or more

Blink

2s

Detection is executed when the

maintenance level selecting switch,

H, M or L is selected

.

(b)W/o auto balance sensor

Ionizer

operation

Power supply DC24V

Discharge-stop signal

Completion signal for

Static charge elimination

Maintenance

Start-up signal

Maintenance

Output signal

Maintenance indication

(NDL CHECK ALARM)

Contamination detecting

of electrode needle

Adjust ion balance

ON

OFF

Input

ON

(Operation)

OFF

Input

(Contamination detecting of electrode nee dle)

ON

OFF

Output

ON

(SW ON)

OFF

Input

ON

(SW ON)

OFF

Output

ON

(Lighting)

OFF

LED

2s

100ms or more

Blink

Detection is executed when the

maintenance level selecting switch,

行)

H, M or L is selected

.

・The completion signal for static charge elimination is output while the dirt on the electrode needle is being detected

・Because ions are discharged from the ionizer when the electrode needle is being detected, the workpiece might be charged.

Therefore, the workpieces should not be mounted when the detection is executed.

ON and OFF status will be changed depending on the situation.

1

Page 21

0

4-3.DC mode

1. Selection of bar length

・Select the length applicable to work size base on static charge elimination area and static charge

elimination characteristics.

2. Installation of body

・Keep the distance between the ionizer and charged objects within 50 to 2000mm. Although the ionizer

can be mounted outside of this range, it may not operate properly depending on the operating conditions.

Therefore, be sure to check if the ionizer will operate properly.

3. Installation of the sensor

・[Plus ion discharge] or [minus ion discharge] can be selected.

Ion polarity Switch setting

Plus ion discharge 8

Minus ion discharge 9

4. Wiring of the power supply cable

・Connect dedicated power supply cables.

Connection with the power supply for ionizer operation

Symbol Cable

color

DC1(+)

DC1(-)

OUT4 Dark

※ Be sure to ground DC1(-)[Blue].(Resistance between the lead wire and the earth ground should be 100Ωor less.)

If not, it may break the ionizer.

Brown Power supply DC24V

Blue Power supply GND[FG]

Green

Cable name Connection Description

Sensor monitor output

○

○

- -

Power supply cable for

ionizer operation

Brown

Blue

Connection with the power supply for I/O signal

Symbol Cable

color

DC2(+)

DC2(-)

IN1 Light

IN2 Gray Maintenance start-up

-

-

OUT1 Pink Completion signal for

OUT2 Yellow Maintenance output

OUT3 Purple Signal for failure

Red Power supply DC24V

Black Power supply GND

Green

White

Orange

Cable name Connection Description

○

○

Discharge-stop signal

○

signal

- - -

- - -

static charge elimination

signal

- -

- -

- -

△

Power supply cable for I/O signal

Signal for starting/ stopping the discharge

(NPN spec)Operation will begin when it is connected

with DC2(-)[Black].

(PNP spec)Operation will begin when it is connected

with DC2(+)[Red].

Outputs in case of abnormal high voltage and sensor

and/or CPU failure.

(B contact output)

○ : Wires that are minimum required to operate the ionizer.

△ : Wires that are required to use the functions.

- : Wires that are not necessary with the sens ing DC mode. These wires should not be short-circuited with other

cables.

5. Air piping

・When the piping is only connected to one port, the other unused port should be plugged with the M-5P

that is packaged together with the ionizer.

DC Power supply

Ground

2

Page 22

6. LED display

POWER LED ・・・ The power supply input and the connection of the sensors are displayed.

LED name Functions

POWER

MAIN Lights up when the power supply is applied. (Green)

(Flashes when wrong power supply is applied. )

SNSR Goes out.

ION LED ・・・ The discharged ion polarity is displayed.

LED name Functions

ION

+

OK Goes out.

- Lights on when minus ions are generated.(Blue)

Lights on when plus ions are generated.(Orange)

ALARM LED ・・・ Failure of the ionizer is displayed.

LED name Functions

ALARM

HV

SNSR Goes out.

NDL

CHECK

Lights up when overcurrent is applied to the electrode needle. (Red)

Goes out.

7. Alarm

Type of alarm Description How to reset

Abnormal high voltage Notifies when overcurrent such as high voltage

leakage occurs. The ion-discharge-output is

stopped, HV ALRM sets off and outp ut the

signal for failure.

CPU failure Notifies that CPU fails due to noise. All LEDs

Flashes, and the signal for CPU failure is

output.

Turn off the power supply to solve the problem.

Once it’s solved, apply the power supply again.

Or turn on and off the discharge-stop signal.

Turn off the power supply to solve the problem.

Once it’s solved, apply the power supply again.

Or turn on and off the discharge-stop signal.

8. Timing chart

Timing chart with a norma l operation

Power supply DC24V

Input

ON

OFF

Discharge-stop signal

State of ion discharge

Input

ON

(Operation)

OFF

ON

(Discharge)

OFF

21

Page 23

2

4-4. Power supply cable connection circuit

■ NPN

Note) Because the sensor monitor output (OUT4:Dark Green) is not insulated from the internal circuit

of the ionizer, It is grounded. (It is connected to FG).

2

Page 24

3

■ PNP

Note) Because the sensor monitor output (OUT4:Dark Green) is not insulated from the internal circuit

of the ionizer, It is grounded. (It is connected to FG).

2

Page 25

4

5.Specifications

5-1. Ionizer

Ionizer model IZS31(NPN) IZS31P(PNP)

Type Corona discharge

Voltage supply method Sensing DC, pulse DC, Plus DC, Minus DC

Discharge output +/- 7000 V

Ion balance *1 +/-30V (For Stainless electrode needle, from -100 to +100V)

Fluid Air (Clean dry air)

Op. pressure

Purge air

Po we r su ppl y vo lt age DC24 V + / - 10 %

Current consumption

Input signal

static charge elimination

Output signal

Effective elimination distance 50 to 2000 mm (with sensing DC mode:200 to 2000 mm)

Ambient temperature 0 to 50 ℃

Ambient humidity 35 to 80 %Rh(No dew condensation)

Vibration resistance

Impact resistance 10G

Applicable standard/ directive

Maintenance output signal

Sensor monitor output

Material

※1:The distance between the charged object and ionizer is 300mm or more. With air purge.

※2:When the potential of the charged object is measured with the feed back sensor, the relation

between the charged potential and the sensor-monitor-output-voltage and the sensor detecting

range will vary depending on the installation distance between the ionizer and sensor.

[Electrode cartridge quantity and weight]

Bar length mm

Q’ty of electrode

cartridge

Weight g

300 380 620 780 1100 1260 1500 1900 2300

3 4 7 9 13 15 18 23 28

330 400 600 720 1000 1100 1500 2000 2500

(MPa)

Connection

tube size

Sensing DC mode operated 200 mA or less (When sensor is standby:120 mA or less)

Sensing DC mode stand-by 200 mA or less (When sensor is not used:170 mA or less)

Pulse DC mode 170mA or less

Discharge stop signal

Maintenance start-up

signal

Completion signal for

Signal for failure

*2

0.7 MPa or less

Φ4

No-voltage contact signal

Maximum load current : 100mA

Residual voltage : 1V or less

(when the load current is 100mA)

Max. applied voltage:DC28V

Output voltage: 1 to 5 V (Please connect the load of 10kΩ or more.)

Ionizer cover:ABS

Electrode needle:Tungsten, single crystal silicon, stainless

Endurance 50Hz Amplitude 1mm

2 hours to X,Y,Z each direction of vibration

CE (EMC directive:89/336/EEC,92/31/EEC,93/68/EEC,2004/108/EC、

Low Voltage Directive:73/23/EEC,93/68/EEC)

Maximum

load current : 100 mA

Residual voltage : 1V or less

(With load current of 100 mA)

2

Page 26

5

5-2. Sensor

Sensor model

Operating ambient temp 0 to 50 ℃

Operating ambient humidity 35 to 80%Rh(No dew condensation)

Case material ABS ABS, Stainless

Vibration resistance Endurance 50Hz, Amplitude 1mm, 2hours each for XYZ

Impact resistance 10G

Weight 200g(including cable weight) 220g(including cable weight)

Installation distance 10 to 50mm (Recommended) -

Applicable standard/ directive

Sensor monitor output (When feed back sensor is used)

6

5

4

3

2

1

Sensor output voltage V

0

Relation of sensor output and charge potential based pm

Installation distance

25mm

-2000 -1500 -1000 -500 0 500 1000 1500 2000

CE (EMC directive:89/336/EEC,92/31/EEC,93/68/EEC,2004/108/EC、

IZS31-DF

(Feed back sensor)

Low voltage directive:73/23/EEC,93/68/EEC)

installation distance

Installation distance

25mm

Installation distance

10mm

Charge potential V

Detection range of Feedback sensor

Sensor head

Detection hole

Installation

n distance

Installatio

Detection range

distance mm

IZS31-DG

(Auto-balance sensor)

Detection range

mm

10 45

25 100

50 180

2

Loading...

Loading...