Page 1

MapIT G2

Hardware Installation Training Manual

January 2019

Copyright Information

MapIT G2 is a trademark of the Siemon Company, with all rights reserved by the Siemon Company.

Some of the product names mentioned herein have been used for identification purposes only and may

be trademarks and/or registered trademarks of their respective companies. Information is subject to

change without notice. For the latest information, visit our Web site at http://www.siemon.com.

© 2015 Siemon Company. All Rights Reserved.

Page 2

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

2

Table of Contents

Module 1: Hardware Components

Siemon MapIT G2 Intelligent Cabling Solution Overview 3

How the MapIT G2 System Works 6

MapIT G2 System Connectivity/Components 8

Master Control Panel (MCP) 12

Distribution Control Panel (DCP) 14

Smart Patch Panel (SPP) 16

Smart Fiber Enclosure (SFE) 18

Module 2: MapIT G2 System Design and Installation

System Design Guidelines 21

System Configuration Examples 26

MapIT G2 Site Survey 29

Site and Requirement Survey Forms 32

Summary of Design Rules 34

MapIT G2 Hardware Installation 35

Installing MapIT G2 Control Bus Cables 37

Module 3: Navigating the MapIT G2 Menus

Main Menu 40

Menu Navigation 41

Diagnostic Menu 42

Circuit Trace 50

Setup Menu 51

Mapping 56

Module 4: Troubleshooting the MapIT G2 Hardware Installation

Troubleshooting guide 59

Module 5: Documentation

Certifications 61

Technical Specifications 63

Warranty Information 65

Page 3

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

3

Module 1: Hardware Components

MapIT G2 - Intelligent Cabling Solution

Introduction:

MapIT G2 intelligent hardware is used in conjunction with Siemon’s EagleEye software

and provides a complete Automated Infrastructure Management (AIM) system.

The objective of this manual is to provide information on how to properly install,

configure and use the MapIT G2 hardware. It does not provide a comprehensive

overview of the EagleEye software. Separate manual and training class are available

for EagleEye software. This manual covers these 5 key topics:

Module One; Hardware Components,

Module Two; System Design and Installation,

Module Three; Navigating the MapIT G2 Menus

Module Four; Troubleshooting

Module Five; Documentation

MapIT G2 Overview

Siemon’s MapIT G2 solution helps you better manage and protect your IT

infrastructure. The system tracks physical layer connections and IP enabled network

devices in real-time. While other software solutions may detect IP devices on the

network, they cannot track them to their exact physical location. The MapIT solution

provides a detailed view of your infrastructure, whether it is in your headquarters or at a

remote office on the other side of the world. This powerful combination of Siemon

intelligent cabling products and advanced software takes management of complex

data/telecommunications networks and critical applications to a new level.

This manual provides instruction on the MapIT G2 hardware. A separate EEC

software training program is available. Please contact Siemon if you would like to

arrange software training.

MapIT System Features

MapIT G2 Hardware is designed to work with Siemon’s EagleEye Connect and

EagleEye Enterprise software. This combination provides a comprehensive set of

network management capabilities.

Key features include:

Page 4

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

4

Infrastructure Documentation

▪ Navigation Tree with hierarchical view of the infrastructure

▪ Graphical view of racks and cabinets

▪ Import floor images and overlay database items

▪ View complete circuit diagrams, including network devices

▪ Show network and power connections

▪ Real-time updates to the database

▪ Extensive search functionality

▪ Store virtually any asset in the infrastructure database

Physical Layer Monitoring

▪ Monitors and updates all MapIT patch panel/fiber enclosure connections in real-

time

▪ Provides a complete end-to-end circuit trace

▪ Quickly identifies the root cause of network troubles

▪ Maps active devices to their physical layer connection and location

▪ Automates the process of discovering, documenting, monitoring, and managing

the physical network’s connections and its devices

Asset Management

▪ Discovers and documents all IP enabled devices and ties them to a physical

location

▪ Reports switch port utilization and availability

▪ Reports physical Layer port utilization and availability

▪ Rack space reports, including available u space, available contiguous u space

▪ Tracks and reports on assets by type and/or location

Remote Site Management

▪ Automated database updates ensures accuracy of remote site infrastructure

documentation

▪ Views end-to-end circuit status remotely

▪ Work order status updated automatically

▪ Automated alerts on unauthorized activity

▪ View database from any compatible web browser

Improve Work Order Process

▪ Advanced work order capabilities allow you to create and manage tasks

▪ Technicians can view work orders on MapIT G2 equipment and get immediate

feedback on accuracy

Page 5

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

5

▪ Automatic updates when work orders are completed

▪ Track costs for work orders by department

▪ Email/text alerts on email status

▪ SNMP traps alert 3

rd

party software of work order status

▪ Auto routing feature helps design the best path for new circuits or location in a

rack

▪ Greater efficiency reduces the cost of moves, adds and changes

Enhanced Security

▪ Detects when unauthorized devices connect to the network

▪ Monitors network for unauthorized activity such as patching changes, device

movement or device disconnection

▪ Wide variety of responses to unauthorized activity include email and text alerts,

snmp commands to disable switch ports, IP camera pictures

▪ Maintains an audit log of all network events

▪ EagleEye database can be backed up remotely and used for disaster recovery

How the MapIT G2 System Works

Smart Patch Panels (SPP) and Smart Fiber Enclosures (SFE) have the built in ability to

track patch connections. This connection information is transmitted to the Master

Control Panel (MCP) supporting the patch zone. The MCP relays this patch

connection information via TCP/IP over the customer’s LAN/WAN to the EagleEye

database. It is also possible to expand the capability of a given patching zone by

installing Distribution Control Panels (DCP) to support large numbers of SPPs and/or

SFEs.

Panel to Panel Communication

• Each port on a SPP or SFE has unique port ID. When two ports are connected

with a MapIT G2 Patch Cable or Fiber Jumper, the panels will sense the ID of

the connected ports and transmit that information back to the MCP/DCP

• The initial setup of the system will detect all ports within 2 minutes or less

• Subsequent changes are detected within 3 seconds

• Each SPP/SFE is connected to the MCP or DCP via a Control Bus Cable

Master Control Panel (MCP) Functions

• The MCP tracks new items that are connected in the Patch Zone (DCPs, SPPs

and SFEs)

• The MCP collects connection data from the panels in the Patch Zone

Page 6

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

6

• It communicates via TCP/IP with the EagleEye database

• The MCP supplies power to SPPs and SFEs when connected directly to these

items. It does not supply power to DCPs.

Distribution Control Panel (DCP) Functions

• The DCP relays information on connected SPP/SFEs to the MCP

• Relays information on patch connections between SPPs/SFEs to the MCP

• Communicates with the MCP via a Control Bus Cable

• Supplies power to SPPs/SFEs

• The DCP has its own power supply. It is not powered from the MCP via the

Control Bus Cable

Patch Cord Connections Example:

When a MapIT G2 Patch Cable is inserted into a monitored port,

the probe located in the boot of the MapIT G2 Patch Cable

touches the sensor pad on the SPP.

When the other end of the MapIT G2 Patch Cable is inserted into

another monitored port, a connection is created between the two sensors via a 9th wire

that connects the two probes inside the MapIT G2 Patch Cable.

The MapIT G2 Smart Panel detects the connection and port ID information is passed

between the two panels. This information is passed to the Master Control Panel

(MCP).

Page 7

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

7

The MCP relays the connection information to the EagleEye database over a TCP/IP

network connection. The database is also updated when a connection or

disconnection is detected.

Note: Detection of sensor connectivity is only possible between sensors connected in

the same Patch Zone. A Patch Zone is a group of panels all connected to the same

MCP.

The EagleEye software, upon receiving the data from the MCP, immediately updates

its database and then may trigger predefined "events”.

MapIT G2 System Components

Master Control Panel (MCP)

The MCP is the interface between the EagleEye software and all the Smart

Panels/Enclosures in the Patch Zone. The MCP has two Ethernet ports on the rear of

the unit for connecting to the TCP/IP network. It has 24 ports to connect either directly

to Smart Patch Panels/Fiber Enclosures (SPP/SFE) or to Distribution Control Panels

(DCP).

MCP Dimensions

Component

Width

Height

Depth

MCP

483 mm

19 inches

45 mm

1.75 in

170 mm

7.0 in

Supplied Components

- MCP

- 24 S310 stuffer caps

- Sensor pen

- Rear cable manager & cable ties

- DC power supply

- Installation instructions

Page 8

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

8

The Front of the MapIT G2 Master Control Panel

1. 24 RJ45 I/O Control Bus Outlets – For connections to lower level components

(either directly to SPPs/SFPs or DCPs). Use either the RJ45s or the S310s (on

rear of panel). DO NOT connect both the RJ45 and S310 of a single port

simultaneously.

2. LCD - 4 Line LCD used to view the MCP Menu

3. Alphanumeric Keypad - Use to input information into the MCP

4. Scroll and Enter Buttons - Used to navigate the MCP menu. The Enter button is in

the center.

5. Sensor Pen RJ45 Port - The pen is used for system diagnostics, circuit trace,

mapping and more.

The Rear of the MapIT G2 MCP

Page 9

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

9

1. Twenty Four S310 I/O Bus Connections – For connections to lower level

components (either directly to SPPs/SFPs or to DCPs). Use either S310 connections

on the rear of MCP or the RJ45 ports on the front. DO NOT connect both the RJ45 and

the S310 of a single port simultaneously. If the RJ45 ports are used, Siemon

recommends putting the supplied S310 stuffer caps on the S310 ports on the rear of

the panel. If S310s are used, use the Siemon RJ45 port blockers (p/n LL-05, sold

separately) to prevent access to the RJ45 ports on the front of the MCP.

2. Twelve Ground Termination Points – terminate the drain wire of the cat 5e Control

Bus Cables on these (two drain wires per ground termination point)

3. Two Ethernet RJ45s – The MCP has two 10BASE-T Ethernet ports. Both ports can

be connected to the network for a redundant connection, however only one connection

is operational at a time. If both Ethernet ports are connected, the MCP will attempt to

connect to the network on port #1. If successful it will establish the connection and will

not attempt to connect on port #2. If not successful on port #1, it will attempt to

connect on port #2. The same logic will apply in the event a connection is lost. The

MCP will continue to alternately attempt connections on both ports until a connection is

established. Connect the Ethernet port(s) to the TCP/IP network via RJ45 Patch

Cables (T568A or B wired, Cat 5e Shielded or higher).

4. Two Ethernet Status LEDs – There are LEDs on either side of the Ethernet RJ45s.

When the LED is not lit there is no connection. When an LED is green it indicates the

port has an active Ethernet connection

5. Two Power Connections – The MCP features two ports for redundant power. The

MCP is sold with one power supply. If redundant power is required, purchase a second

power supply (P/N M-PS). Use of a non-Siemon power supply will void the product

warranty and may damage the unit. Connect the power supply(s) to the power port(s).

Secure the power supply cable(s) to the rear manager of the MCP with a cable tie.

6. Rear Manager – A rear manager is provided to secure Control Bus cables (if the

S310 termination style is used). Secure cables with cable ties (supplied) or Velcro

(optional) to the rear manager.

8. Panel Grounding – A ground lug is provided on the rear of the MCP to ground it to

the rack or telecommunications ground. The MCP must be properly grounded for the

system to function properly.

Distribution Control Panel (DCP)

The DCP is used to create larger Patch Zones. MCP can support up to 2880 ports in a

single Patch Zone when used as a standalone device connected directly to

SPPs/SFEs. DCPs can be used to increase the size of the Patch Zone up to 65,000

ports (more details on Patch Zone design guidelines below). You will notice that the

Page 10

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

10

DCP is almost exactly the same as the MCP with two key exceptions – 1) it does not

have Ethernet ports and 2) it has an S110 and RJ45 for connection to the MCP.

Distribution Control Panel Dimensions

Component

Width

Height

Depth

DCP

483 mm

19 inches

45 mm

1.75 in

170 mm

7.0 in

Supplied Components

- DCP

- 24 S310 stuffer caps

- Sensor pen

- Rear cable manager & cable ties

- DC power supply

- Installation instructions

The Front of the Distribution Control Panel (DCP)

1. 24 RJ45 I/O Control Bus – For connections to SPP/SFEs. Use either these RJ45s

or the S310s (on rear of panel). DO NOT connect both the RJ45 and S310 of a

single port simultaneously. If the RJ45s are used, Siemon recommends putting the

supplied S310 stuffer caps on the S310 ports on the rear of the panel. If S310s are

used, use the Siemon RJ45 port blockers (p/n LL-05, sold separately). Always use

T568A wiring scheme for all cables connected to these ports.

2. LCD – 4 Line LCD used to view the DCP menu

3. Alphanumeric Keypad – Use to input information to the Distribution Panel

4. Scroll and Enter Buttons – Used to navigate the DCP menus and input data

5. Sensor Pen Port – Insert supplied probe pen here. Pen can be used for system

diagnostics, circuit trace, mapping and more

Page 11

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

11

The Rear of the MapIT G2 Distribution Control Panel

1. Twenty Four S310 I/O Bus Cable Connections – For connections to SPPs/SFEs,

Terminate the Control Bus Cable to the S3110s using T568A wiring scheme. Use

either these RJ45s or the S310s (on rear of panel) connections. DO NOT connect

both the RJ45 and S310 of a single port simultaneously. If the RJ45s are used,

Siemon recommends putting the supplied S310 stuffer caps on the S310 ports on

the rear of the panel. If S310s are used, use the Siemon RJ45 port blockers (p/n

LL-05, sold separately).

2. Twelve Ground Termination Points – terminate the drain wire of the cat 5e Control

Bus Cables on these (two drain wires per ground termination point)

3. RJ45 & S110 – Terminate the cable coming from the MCP to either of these ports.

Use cat 5e solid, shielded cable. Terminate using T568A wiring scheme

4. Two Power Connections – The DCP features two ports for redundant power. The

DCP is sold with one power supply. If redundant power is required, purchase a second

power supply (M-PS). Use of a non-Siemon power supply will void the product

warranty and may damage the unit. Connect the power supply(s) to the power port(s).

Secure the power supply cable(s) to the rear manager of the DCP with a cable tie.

5. Rear Manager – A rear manager is provided to secure Control Bus Cables (if the

S310 termination style is used). Secure cables with cable ties or Velcro to the

manager.

6. Panel Grounding – A ground lug is provided on the rear of the DCP to ground it to

the rack or telecommunications ground. The DCP must be grounded for the system to

function properly

MCP and DCP Power Requirements

• One supplied, additional may be purchased separately for redundant power (p/n

M-PS)

Page 12

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

12

• Input 100-240v

• 50-60Hz, 0.6A

• 6v DV, 3.3 Amp

• Use two per MCP or DCP if redundant power is desired

• Use of a non-Siemon power supply will void the system warranty

• Power supply comes with adapters for US, UK, Australia, Europe and China

• SPPs and SFEs do not have their own power supplies. Power is provided to

them via the Control Bus Cable

Smart Patch Panels (SPP/SPPA/TPPA)

MapIT G2 smart patch panels and fiber enclosures SFPs have capabilities beyond any

other product in our industry today. The ability to track connections is built into the

panel. This reduces rack space required for monitoring equipment by up to 89%. The

system also uses much less power than competing systems. Finally, it does not

require proprietary cables to devices in the system. The use of standard 5e solid

shielded cable reduces cost and speeds installation time. Also, fewer cables are used

to connect items in the system, so less space is required for pathways. The Smart

Panels/Enclosures also feature two LEDs and an LCD which provide a local user

interface, which can save significant time during diagnostics and work order

provisioning.

The SPP (flat smart patch panel) and SPPA (angled smart patch panel) are typically

sold empty and accept Siemon keystone ZMAX outlets. The TPPA (angled TERA

smart panel) accepts Siemon TERA outlets.

Smart Panel Dimensions

Component

Width

Height

Depth

SPP (Flat)

483 mm

19 in

45 mm

1.75 in

170 mm

7.0 in

SPPA (Angled)

483 mm

19 in

45 mm

1.75 in

225 mm

8.86 in

TPPA (TERA

Angled)

483 mm

19 in

45 mm

1.75 in

225 mm

8.86 in

The Front of the MapIT G2 Smart Patch Panels

Flat Panel

Page 13

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

13

Angled Panel

TERA Panel

1. Panel Design - 24 ports, 1U modular design accepts UTP or F/UTP connectors

2. LCD – Displays Patch Cable trace information, port and panel diagnostics and work

order instructions (future capability). Display is backlit for best viewing in a variety

of lighting conditions

3. LEDs – One green and one red LED for guidance on work orders instructions

4. Probe Pads – Gold pad above each port. This is the landing area for the pogo pin

built into MapIT G2 Patch Cables. This pad can also be used for circuit traces and

diagnostics via the Pen Probe

5. Port Labeling Space – Space provided for labeling of ports

6. Mounting – mounts on standard 19” racks and cabinets

7. Power – The Smart Panel gets its power from its connection to the MCP or DCP

Page 14

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

14

When a MapIT G2 Patch Cable is inserted or removed from a port, the Smart Panel

discovers the connection and communicates the port ID information to the MCP via the

Control Bus cable. The MCP relays the information to the EEC software over a TCP/IP

connection. Any changes in connectivity are immediately updated in the EEC

database. This provides network administrators with vital up-to-the minute information

about the status of their network, from the hardware layer and up… anytime,

anywhere.

The Rear of the MapIT G2 SPP

Flat Panel

Angled Panel/TERA Panel

Rear View of the MapIT G2 Smart Patch Panel

1. Flat Panels – have two S110 Control Bus Cable Connections. Terminate the

control bus cables routed from the MCP or DCP to the IN port. Daisy chain Control

Bus Cables from the OUT port of one panel to the IN port of the next panel

(adjacent or below). Up to five SPPs can be daisy chained on a single connection.

A redundant daisy chain path can be created by connecting the OUT ports of the

last panels of two separate daisy chains. Important Note: If the redundant daisy

Page 15

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

15

chain is used, the two Daisy chained links must be served from the same MCP or

DCP. Do not attempt to span the redundant link between different MCPs or DCPs.

2. Angled Panels – have two RJ45 Control Bus Cable Connections. The top RJ45

is the IN port. The bottom is the OUT port. Connect the IN port to a port on the

MCP, connect the OUT port to the IN port of the next SPP in the daisy chain (if

applicable). A maximum of five panels can be connected in each daisy chain. Important

Note: If the redundant daisy chain is used, the two Daisy chained links must be

served from the same MCP or DCP. Do not attempt to span the redundant link

between different MCPs or DCPs.

3. Flat Panel Ground Termination Points – terminate the drain wire of the cat 5e

bus/daisy chain cables on these (one drain wire per connector). Not required for

angled panels

4. Rear Manager – A rear manager is integrated into the panel. Secure cables with

Velcro or cable ties securely to the manager.

4. Panel Grounding – A ground lug is provided on the rear of the SPP for grounding to

the rack or telecommunications ground (TGBB). The Smart Panel must be properly

grounded for the system to function properly

Smart Fiber Enclosures (SFE & SMTP)

The Front of the MapIT G2 Smart Fiber Enclosure (SFE & SMTP)

1. Panel Design – 48 LC fiber (24 managed duplex connections) 1U, compatible with

either multimode or single mode fiber

2. LCD – Displays Patch Cable trace information, port and panel diagnostics and work

order instructions (future capability). Display is backlit for best viewing in a variety

of lighting conditions

3. LEDs – Provide guidance for work order instructions

4. Probe Pads – Used for diagnostics and is the landing area for the pogo pin built into

MapIT G2 Fiber Jumpers

5. Port Labeling Space – Space provided for labeling of ports and panel

6. Mounting – mounts on standard 19” racks and cabinets

Page 16

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

16

7. Power – The Smart Enclosure gets its power from its connection to the MCP or DCP

via the Control Bus Cable

8. Integrated Front Cable Manager (SMTP version only) – Provide management of

LC fiber jumpers connected to the front of the SMPT enclosure

Front view of the MapIT G2 Smart Fiber Enclosures

SFE

SMTP

Rear of SFE

1. 2 RJ45 Control Bus Cable Connections –Connect the Control Bus

cable routed from the MCP or DCP to the IN port on the inside of the

SFE. Daisy chain control bus cables from the OUT port of the SFE to the

IN port of the SFE adjacent or below. Up to 5 SFEs can be daisy chained

together. A redundant daisy chain path can be created by connecting the

OUT ports of the last panels of two separate daisy chains. Important

Page 17

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

17

Note: If the redundant daisy chain is used, the two daisy chained links

must be served from the same MCP or DCP. Do not attempt to span the

redundant link between different MCPs or DCPs.

2. Enclosure Grounding – A ground lug is provided on the rear of the SFE

to ground it to the rack or telecommunications ground. The SFE must be

properly grounded for the system to function properly

3. SFE vs. SMTP – The SFE is use for direct termination LC, fusion splicing

and LC trunks. The SMTP is prepopulated with LC to MTP cassettes.

Use the SMTP when using MTP fiber trunks

Expanded View of SMTP Enclosure

Page 18

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

18

Module 2: System Design and Installation

System Design Guidelines

The center of the design is the Master Control Panel (MCP). A Master Control Panel

can support a single patch zone. A patch zone is a collection of SPPs and SFEs that

can be connected by patching between them using MapIT G2 Patch Cables or Fiber

Jumpers. This is typically a single telecommunications room.

Patch zones with less than 2880 monitored ports (120 panels x 24 ports each) ports)

can be served by a single MCP. To create larger Patch Zones we add one or more

DCPs to the system.

Therefore, to design a system, patch zones must be clearly planned and installed with

an MCP and lower level components.

Note: Detection of SPP/SFP port connectivity is only possible between panels

connected to the same MapIT G2 MCP.

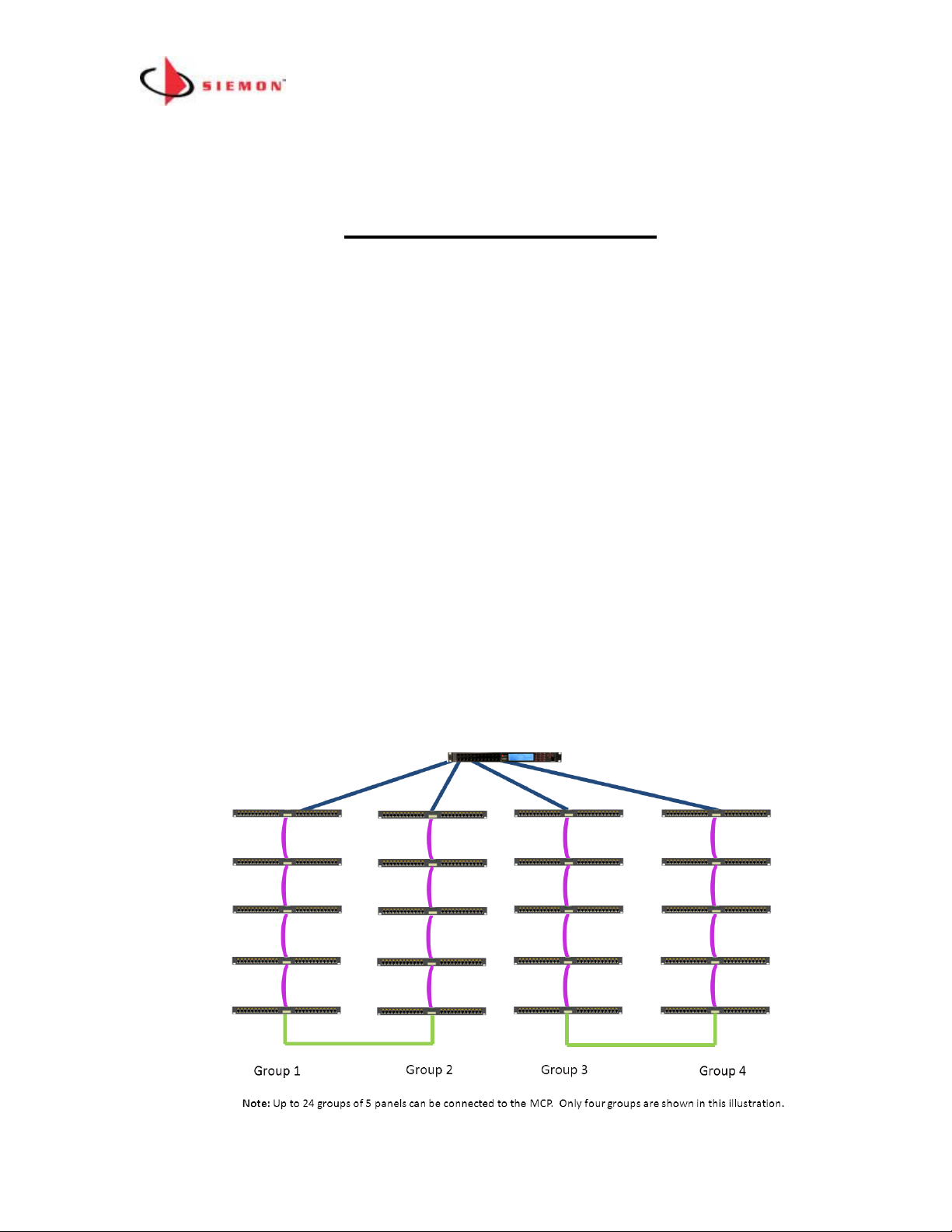

How to Configure a Patch Zone of less than 120 Patch Panels

Each MCP can support up to 120 patch panels/fiber enclosures. If you are installing a

patch zone with less than 120 patch panels and do not plan on any expansion beyond

this number, you can use the following topology:

Page 19

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

19

Small Patch Zone Topology Rules

1. Use one MCP (supports from 1 up to 120 panels/enclosures (5x24))

2. Each of the 24 Control Bus Cable ports on the MCP can have up to 5

panels/enclosures connected to it via a daisy chain

3. Maximum length a MapIT G2 Patch Cable/Fiber Jumper can be 75’ (24m)

4. Panels do not have to be in the same rack/cabinet as the MCP

5. A redundant daisy chain can be used as an option for greater system reliability.

In the example above the OUT port of the last panel in Group 1 is connected via

Control Bus Cable to the OUT port of the last panel in Group 2. In the event that

the chain is broken at any point, the panels in the daisy chain will still track

connections and communicate with the MCP. The system can also provide an

alert in the event that the redundant daisy chain is broken. The fault should be

repaired at the earliest possible convenience to ensure greatest system

reliability

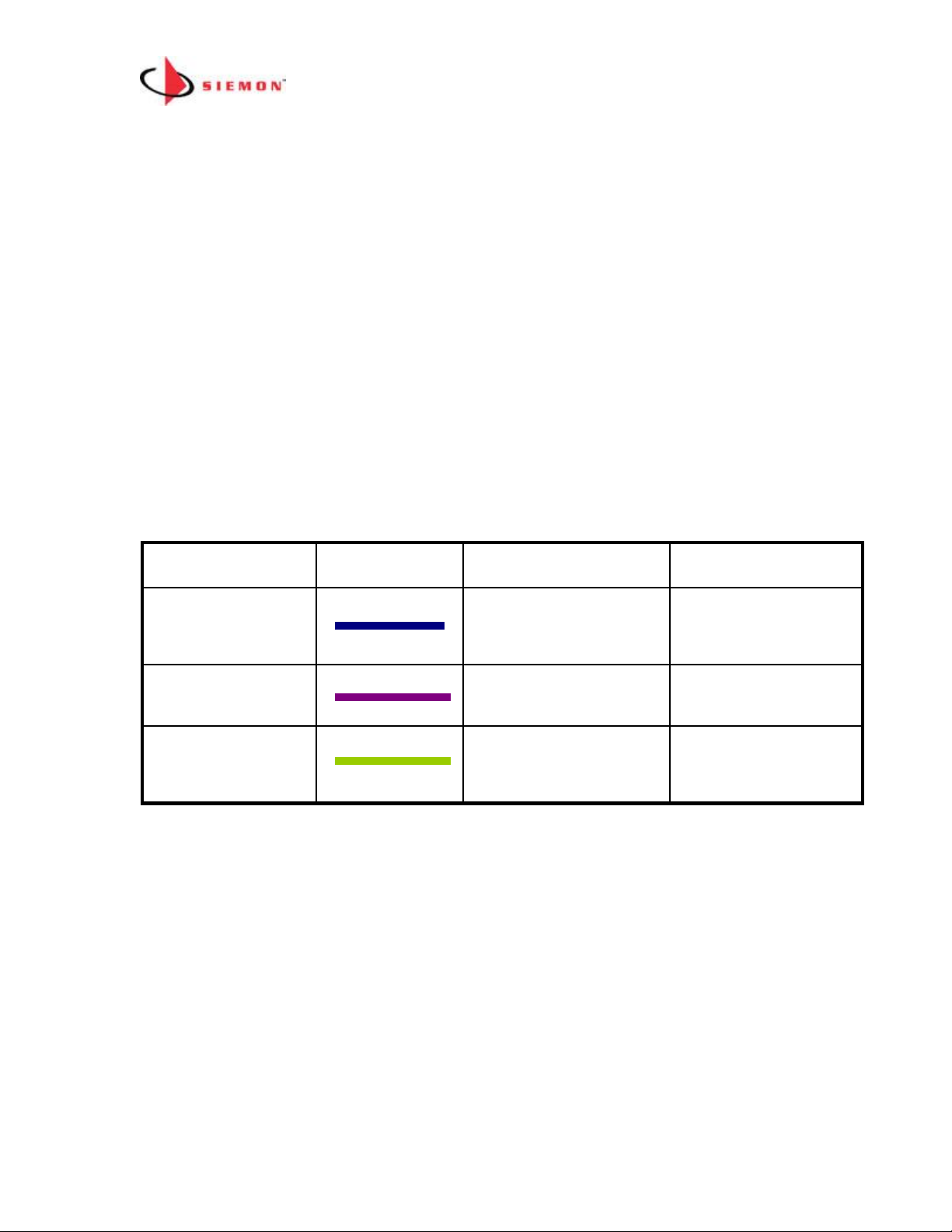

Control Bus Cable Length Limitations (per Small Patch Zone Diagram shown

above)

(See the Control Bus Installation section below)

25’ per cable

(7.6m)

Connects last Panels

in a Daisy Chain

Optional

Redundant Path

Connection

3’ per cable

(1m)

Panels in the Daisy

Chain

Smart Panel

Daisy Chain

50’ per cable

(15m)

MCP to First Smart

Panel in a Daisy

Chain

MCP Control Bus

Maximum Length

Connects

Color Code

Cable Type

Page 20

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

20

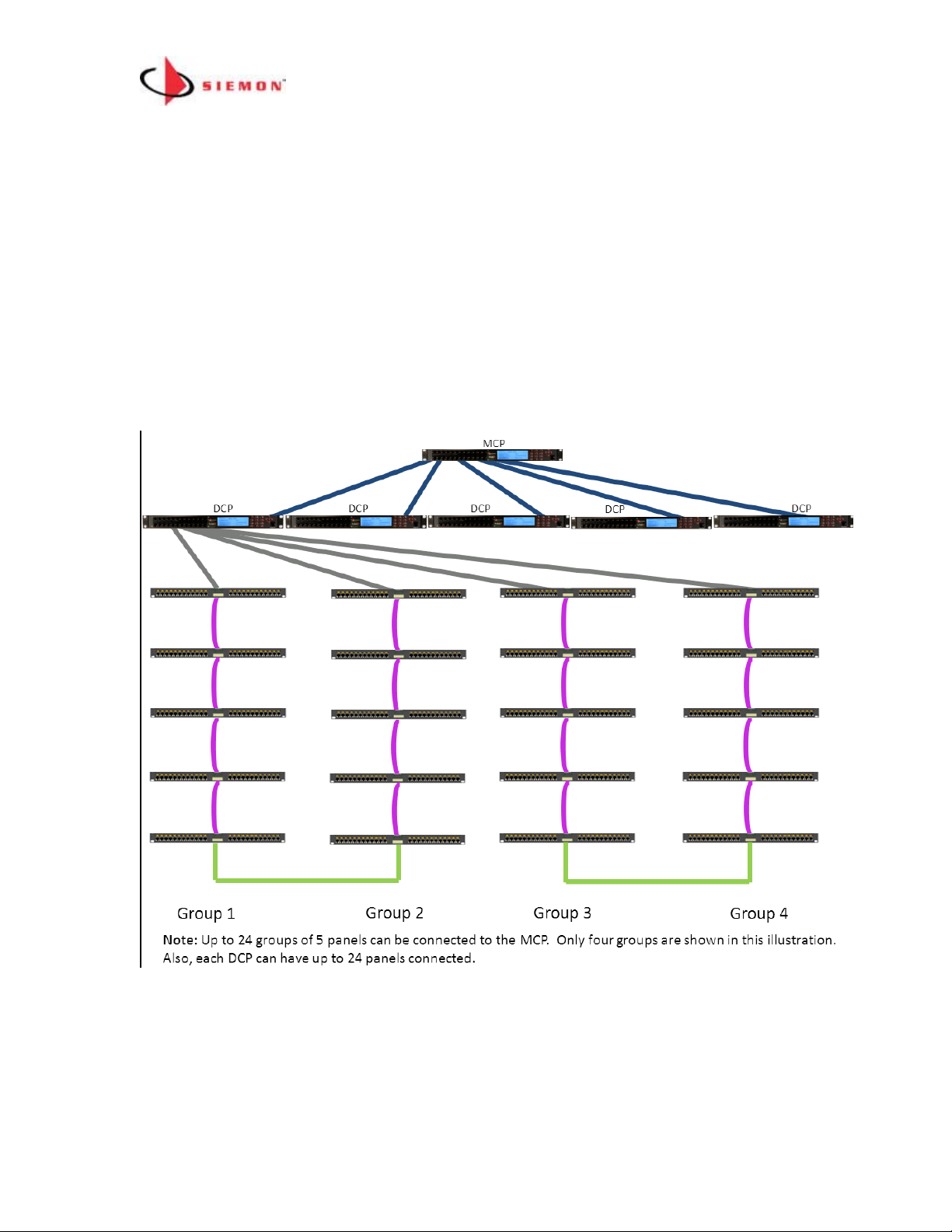

How to Configure Large Patch Zones (Greater than 120 Panels/Enclosures)

Use a combination of one MCP and up to 24 DCPs to create a Patch Zone with up to

65,000 ports. The topology for this type of Patch Zone is shown below (Only DCP #1

and connections for three of its ports are shown for clarity).

Large Patch Zone Topology Rules

Page 21

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

21

1. Use one MCP and up to 24 DCPs for patch zones with 121+

panels/enclosures

2. Each port on the MCP can have one DCP connected to it

3. SPPs and SFEs can be daisy chained to DCP ports (up to 5 per DCP port).

4. SPPs and SFEs can also be connected to unused MCP ports

5. A redundant daisy chain can be created by connecting the last panels in two

daisy chains for greater system reliability. In the above example the last

panel in Group 1 is connected to the last panel in Group 2. In the event that

the chain is broken at any point, the system will still work and it will provide

an alert of the fault. The fault should be fixed at the earliest possible

convenience.

6. If you are using a redundant daisy chain both groups of panels must be

connected to the same MCP or DCP. You cannot span the redundant link

between DCPs or MCP to DCP

7. Maximum length of a MapIT G2 Patch can be 75’ (25m)

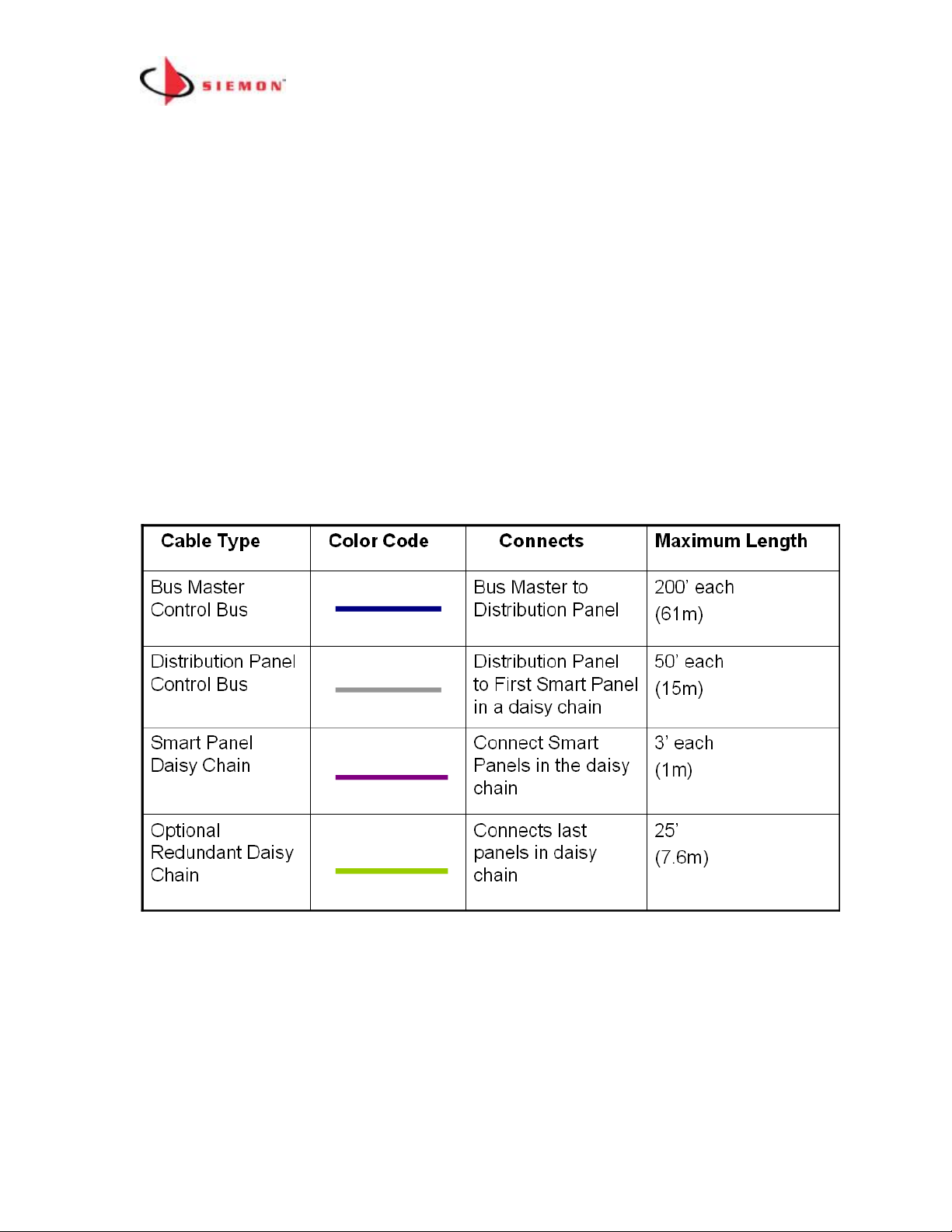

Control Bus Cable Length Limitations (for Large Patch Zone Diagram shown

above)

(See the Control Bus Installation section below)

Page 22

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

22

MapIT G2 System Configuration Examples

Example 1:

In this small Patch Zone we have 50 panels connected to the MCP. Each group of 5

panels is connected to a single port on the MCP. In this case the 50 panels would

occupy 10 of the 24 available ports in the MCP. Note that a single MCP can connect to

panels in adjacent racks as well as the same rack as the MCP.

Page 23

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

23

Example 2:

The number of panels and port count is exactly the same as in example #1 above.

However, in this example DCPs are used in four racks and an MCP is used in one

rack. This configuration can be used if better visibility of LCD screens is desired. The

MCP is connected to each of the DCPs. The SPPs/SFEs on the same rack as the

MCP can be connected directly to the MCP if desired. Panels can be daisy chained as

describe above, however since there are very few panels in this example, each of the

10 panels in each rack can be connected directly to individual ports on the MCP and

DCPs.

Page 24

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

24

Example 3:

In the example below each rack has 40 24-port Patch panels. In this scenario each

DCP (in light blue) can support 3 racks (a total of 120 panels). There are a total of 18

racks (total of 66 panels). You would need 6 DCPs to accommodate all the panels in

this patch zone. The MCP can be located anywhere in this patch zone as long as any

individual cable connecting it to a DCP is no longer than 200’. The MCP could support

up to 18 more DCPs, so there is plenty of room for expansion in this example.

MapIT G2 Patch Zone Sizing and Capacity Planning

When creating a design from your site survey, there are many decisions to be made

based on customer specifications and needs. The type and number of units used can

vary depending upon the following criteria:

• Real-estate space available in the rack or cabinet

• The number of panels to be monitored initially in each patch zone

• The expected port growth in each patch zone

• The maximum length of MapIT G2 Control Bus cables and MapIT G2 Patch

Cables

Page 25

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

25

MapIT G2 Site Survey

This section provides the recommended procedure and forms to complete a Site

Survey for a new MapIT G2 installation.

The MapIT G2 Site Survey is an information-gathering activity used to survey the

client’s existing network infrastructure, to determine the necessary MapIT G2

components for completing a successful installation.

The survey forms will help outline the proper placement of MapIT G2 components

based on the number, distribution and location of MapIT G2 Panels to be monitored.

The survey forms include a general summary of the project, a MapIT G2 Patch

Panel/Equipment Profile form, a Rack Configuration form and a general Bill of

Materials (Cables) form.

Survey Information

The information found at the site survey is the foundation upon which all future design

plans and the final design solution will be based. If additional information is needed,

the site administrator should be contacted to gather this information before proceeding.

At a minimum, the following should be obtained:

Physical layout of the site (Floor Plans, Map, etc.)

Type of MapIT G2 equipment to be used

Placement of MapIT G2 MCP and (if required) DCPs within each Patch Zone

MapIT G2 Control Bus cables and maximum MapIT G2 Patch Cable lengths

Defining the Client Needs

The demands to tailor different systems and configurations will vary dramatically from

client to client. For this reason, it is essential to determine the specific needs and

requirements of each client to create a specific design to meet their

needs/expectations. Defining client needs encompasses all aspects of the design and

project management processes. Below is a suggested list of items that should be

defined at the site survey:

1. Is there enough room on the rack(s) for MapIT G2 MCP and (if required) DCPs?

2. Does the client provide rack space for the MCP and DCPs near the SPPs/SFEs

or will they need to be placed away from the rack? If so, how far away will they be

installed?

Page 26

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

26

3. What is to be tracked? Voice, Data, or both?

4. It is important to know the client’s operating system and how the network

operates to determine whether the system meets specifications and to determine

what part of the network the client is going to want MapIT G2 enabled and

monitored by EEC software. Many clients focus on enabling essential equipment

that is necessary to be up and running 99.9% of the time.

5. Determining the client’s network layout will also allow us to accurately gauge the

Patch Zone configuration.

6. System documentation is important in any system. Knowing where all the cables

begin and where they terminate is essential in creating an effective end-to-end

system. With the client, determine whether the existing documentation is

satisfactory or whether the cables will need to be toned out (for an existing

installation).

NOTE: A digital camera is useful to document existing conditions for future

reference.

Rack/Cabinet Configuration

Rack/Cabinet Configuration identifies the location of the existing equipment as well as

placement of the MapIT G2 MCP/DCPs in the racks. This allows the installer to

visualize the configuration of the installation and provides equipment information

including; floors, TRs, racks, Patch Zones, etc. Within the depicted racks, the

Equipment IDs are displayed. Distances between racks and associated floors should

be indicated. Control Bus Cable requirements are identified and a Notes section for

additional information is provided.

Page 27

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

27

Example #1

Page 28

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

28

Site and Requirement Survey Forms

Siemon will provide the following documents to collect data required to configure

the MCPs and build the database. These must be completed and returned to Siemon

in order to build the EEC database.

- MCP Network Settings and Locations

- Database Build

- Discovery Questionnaire

- Email Server and Events

- Floor Graphics

- Rack/Cabinet/Faceplate Locations

- Rack Elevations

MapIT G2 Hardware Installation

The following steps for the hardware installation of the MapIT G2 Components can be

used as a basic checklist to insure that all of the steps have been accounted for during

installation.

Step 1.

Mount the MapIT G2 MCP, DCPs (if applicable) and SPPs/SFEs in the equipment

rack(s) as specified on the drawings. These components may be stacked above or

below other components. Since all MapIT G2components generate virtually no heat,

there is no need for additional spacing for cooling. Use all of the installation hardware

supplied with each unit.

Step 2.

Make sure that all components are powered down before beginning terminations.

Disconnect all power supplies from the panels and the electric power outlets.

Step 3.

Connect the Control Bus Cables from the MCP to the DCPs (if applicable) or

SPPs/SFEs using the proper cable and termination practices. Connect the daisy chain

Control Bus cables between the Patch panels. If desired, connect the last panel in

each daisy chain to another panel to create a redundant daisy chain. The redundant

cable connection must connect 2 daisy chains on the same MCP or DCP. Do not span

across MCPs and/or DCPs. Siemon recommends that the daisy chained ports be

connected between panels on adjacent ports on a MCP or DCP (for example, create a

Page 29

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

29

redundant connection between the panels connected from port 1 and port 2 on an

MCP or DCP).

Step 4.

Connect a ground wire from the back of all components (MCP, DCPs, SPPs, SFEs) to

the telecommunications ground. Proper grounding is critical to proper functioning of

the MapIT G2 system

Step 5.

Install the provided power supply cords in each MCP and DCP (if used), then plug

each of them into the electrical power outlets.

Step 6.

Check the power connections: There are two methods of doing this:

1. When power is connected to the MCP and DCPs, power will be supplied to

the SPPs/SFEs in the Patch Zone. If firmware has not be loaded on the

MCP, the LCDs on the SPP/SFEs will display UNLICENSED. This is an

indicator that the panels have power and are communicating with the MCP.

If firmware is loaded in the MCP, then the starting assigned port number will

be displayed on the SPP. If the LCD on a panel is blank, check the power

connections to that panel.

2. You can also look in the MCP or DCP menu to view connections. See the

Diagnostics section below for more information.

Step 7.

Run Diagnostics for all components in the system to ensure all components are

functioning properly (see Diagnostics instructions below).

Step 8.

Terminate all of the horizontal cables that are to be monitored.

Install the terminated connectors in the SPPs and/or SFEs

Step 9.

Install the MapIT G2 Patch Cables and/or Fiber Jumpers as required.

V01.09

Unlicensed

Page 30

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

30

Installing MapIT G2 Control Bus Cables

The Control Bus Cables provide connectivity to the MCP, DCPs, SPPs and SFEs

installed in the system. The installation of the cabling should follow the installation

practices found in the Siemon Cabling System Training Manual.

Control Bus Cable Construction:

• Category 5e, 24 AWG, shielded, solid. Use Siemon Premium 5e F/UTP. Use of

UTP or stranded shielded cable is not permitted. All terminations (S110, S310

and RJ45) should be done using the T568A wiring scheme

• If double-ended shielded Patch Cable cables are used they must be constructed

with Siemon Premium 5e F/UTP 24 AWG, shielded, solid cable and PS-8-8

plugs. Cables must be wired using T586A wiring scheme. Stranded cable is

not acceptable.

• If single-ended Patch Cable cables are used, they must be wired T568A and

use Siemon Premium Category 5e, 24 AWG, shielded, solid cable

Rule for Termination of Control Bus Cable in a Small Patch Zone with a Single

MCP:

If using the S310 and S110 blocks to terminate control bus cables…

• Only use the S310 on the rear of the MCP. Do not use the RJ45s on the front of

the MCP. Use optional RJ45 port blockers (LL-05) to prevent use of RJ45s.

• Terminate cable to S310 blocks on the MCP using T568A wiring scheme.

Connect the drain wires to the ground termination points. Maximum length of

each cable is 50’ when connected to the first SPP/SFE as a daisy chain

• Terminate the Control Bus Cable coming from the MCP to the “IN” S110 block

on the first SPP in the daisy chain. Use T568A wiring scheme. Connect the

drain wire to the ground termination point on the rear of the SPP

• Terminate the SPP Daisy Chain cable to the OUT S110 block of the first SPP to

the IN S110 port on the next SPP/SFE in the daisy chain. Repeat for up to 5

Page 31

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

31

panels in a single daisy chain. The maximum length of each SPP/SFE daisy

chain segment between panels is 3’ (1m). Terminate the drain wire on the

ground termination points on the rear of the SPP/SFE

• If the redundant daisy chain is desired, connect the “OUT” of each of the last

panels in the daisy chain. Max length of this cable is 25’ (11m). Redundant

daisy chain connections can only be made between panels served by the same

DCP or MCP.

• Another termination option is to terminate the Control Bus Cable using S110 P4

plugs (for connections to SPPs or between SPPs). Leave enough drain wire out

the back of the P4 plug to connect it to the ground termination point.

If using the MCP RJ45s and SPP S110 Blocks to Terminate Control Bus Cables…

• Only use the RJ45s on the front of the MCP. Do not use the S310s on the rear

of the panel. You can use the supplied S310 stuffer caps to cover the unused

S310 to prevent connections to these ports.

• Plug in RJ45 plug end of the Control Bus Cable into RJ45 outlet on the front of

the MCP

• Terminate other end of the Control Bus cable to the “IN” S110 port on the first

Patch panel in the daisy chain. Use T568A wiring scheme. Terminate drain wire

to ground termination point. Maximum cable length is 50’ (14m)

• Terminate cable to “OUT” S110 block of the first panel in the daisy chain.

Terminate the other end of this cable to “IN” S110 block on the second Patch

panel in the daisy chain. The max length of this cable is 3’ (1m). Terminate the

drain wire on the ground termination point

• Continue this daisy chain termination method for remaining panels (max 5

panels per single daisy chain, up to 10 for the redundant daisy chain)

• If the redundant daisy chain is desired, connect the “OUT” S110 blocks of each

of the last panels in the daisy chain. Max length of this cable is 25’ (7.6m)

If using the MCP RJ45s an Angled Panel or Fiber Enclosure RJ45 Bus

Connections

• Use a shielded patch cord to connect the MCP RJ45 port to the IN port of the

panel

• Do not reuse the S310 ports on the back of the MCP

• Daisy chain an additional 4 panels (Connect OUT port from one panel to IN port

on the next panel)

• If the redundant daisy chain is desired, connect the OUT port of the last panel in

a group to the OUT port of the last panel in the next group

Rule for Termination of Control Bus Cable in a Large Patch Zone:

Page 32

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

32

If using the S310 and S110 blocks to terminate control bus cables…

• If using this configuration, only use the S310 on the rear of the MCP and

DCP(s). Do not use the RJ45s on the front. Option RJ45 port blockers (LL-05)

can be purchased to block these ports.

• Terminate cable to S310 blocks on MCP using T568A wiring scheme. Connect

drain wire to ground termination point. Max length of each MCP to DCP Control

Bus Cable is 200’

• Terminate the Control Bus Cables coming from the MCP to the vertical S110

block on the rear of each DCP. Use T568A wiring scheme. Connect drain wires

to ground termination point

• Terminate the DCP Control Bus Cables to the S310 blocks on the rear of the

DCP. Use T568A wiring scheme. Terminate the drain wire to ground

termination point. The maximum length of each DCP Control Bus Cable is 50’.

• Terminate the other end of the DCP Control Bus Cable to the “IN” S110 block on

the first SPP in a daisy chain. Terminate the drain wire to the ground

termination point.

• Terminate the SPP Daisy Chain cable to the “OUT” S110 block of the first panel

in the daisy chain. Terminate the other end of this cable to “IN” S110 block on

the second Patch panel in the daisy chain. Terminate drain wires to ground

termination points. The max length of each SPP Daisy Chain Cable is 3’ (1m).

• Continue this daisy chain termination method for remaining panels (max 5

panels per single daisy chain, up to 10 for the redundant daisy chain).

• If the redundant daisy chain is used, connect the “OUT” S110 blocks of each of

the last panels in the daisy chain. Max length of this cable is 25’

• Redundant daisy chain can only be used for panels served by the same DCP or

connected directly to the same MCP. Do not create redundant daisy chains

between panels served by different DCPs or MCPs.

If using Solid, Shielded Cat 5e Patch Cables to connect MCP to DCP and Singleended Solid, Shielded Cat 5e IC Cables to connect the DCP to SPP…

• Only use the RJ45s on the front of the MCP and DCPs. Do not use the S310s

on the rear of the panels. Use option supplied S310 stuffer caps to prevent

access to S310s on the rear of the panel

• Patch Cables used in the Control Bus may be terminated in the field, however

you must always 1) use approved Siemon components, 2) terminate cables

using T568A wiring and 3) test Cables for continuity prior to installation in the

system

• Plug Patch Cable into RJ45 ports on front of the MCP

• Plug the other end of the Cable into the RJ45 control bus cable port on the rear

of the DCP. The maximum length of this cable is 200’

• Use a single-ended Cable to connect the DCP to the first SPP in a daisy chain.

Plug one end into the RJ45 port on the front of the Distribution panel. The

maximum length of this cable is 50’

Page 33

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

33

• Terminate the open end of the cable to the “IN” port of the first SPP in a daisy

chain. Use T568A wiring scheme. Terminate the drain wire on the ground

termination point

• Terminate cable to “OUT” S110 block of the first SPP in the daisy chain.

Terminate the other end of this cable to “IN” S110 block on the second SPP in

the daisy chain. The max length of this cable is 3’ (1m)

• Continue this daisy chain termination method for remaining panels (max 5

panels per single daisy chain, up to 10 for the redundant daisy chain)

• If the redundant daisy chain is desired, connect the “OUT” S110 blocks of each

of the last panels in the daisy chain. Max length of this cable is 25’

• Redundant daisy chain can only be used for panels served by the same DCP or

connected directly to the same MCP. Do not create redundant daisy chains

between panels served by different DCPs or MCPs

If using the RJ45 Patch Cable cables for Control Bus connections throughout the

system (for Angled, TERA and Fiber Enclosures)…

• If using this configuration, only use the RJ45s on the front of the MCP and

Distribution Panel. Do not use the S310s on the rear of the panels. Siemon

recommends using the supplied S310 stuffer caps to prevent access to the

S310s.

• All RJ45 outlets used in the system are grounded.

• Patch Cables used in the Control Bus may be terminated in the field, however

you must always 1) use approved Siemon components, 2) terminate cables

using T568A wiring and 3) test Cables for continuity prior to installation in the

system

• Plug Patch Cable into RJ45 ports on front of the MCP

• Plug the other end of the Cable into the RJ45 bus cable port on the rear of the

DCP. The maximum length of this cable is 200’

• Use the next cable to connect the DCP to the first SFE in a daisy chain. Plug

one end into an RJ45 port on the front of the DCP. Plug the other end into the

“IN” RJ45 on the first SFE in a daisy chain. The maximum length of this Patch is

50’

• Plug another Patch Cable for the Daisy Chain into the “OUT” port on the first

SFP. Plug the other end into the “IN” port on the next SFE. The maximum

length for this type of Cable is 3’

• Continue this daisy chain termination method for remaining panels (max 5

panels per single daisy chain, up to 10 for the redundant daisy chain)

• If the redundant daisy chain is desired, connect the “OUT” RJ45s of each of the

last enclosures in the daisy chain. Max length of this Patch Cable is 25’

• Redundant daisy chain can only be used for panels served by the same DCP or

connected directly to the same MCP. Do not create redundant daisy chains

between panels served by different DCPs or MCPs

This completes the hardware installation.

Page 34

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

34

Module 4: Navigating the MapIT G2 Menus

Main Menu

Insure that the MCP is properly connected to a power source. The LCD backlight will

illuminate as soon as power is supplied. The LCD screen will timeout (i.e., go blank)

after a preset period of time. The default timeout period is 5 minutes. The time out

period can be changed (details below). If the screen has timed out, press any key to

reactive the screen.

When power is applied to the MCP, the unit will go through a power on self test. In the

unlikely even you see error codes listed on the screen, contact Siemon Technical

Support. Otherwise, the MCP will show the Main Menu screen. See example below:

After the MCP is properly setup and working, the Main Menu will show Mapping to

indicate the system is communicating with the EEC software and tracking connections.

If it is not connected it will display Waiting. Note that the EEC software must be

running and the MCP service started in order to successfully connect.

Page 35

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

35

Each MCP has a 12 character serial number. This serial number is displayed on the

Main Menu. In the example above the serial number is A01001001827.

Menu Navigation

Scrolling within a menu: Use the scroll arrows on the keypad to the right-

hand side of the LCD to scroll to items within a menu screen. You can scroll left/right

and up/down. The LCD screen will display four lines at a time. You can use the down

arrow to scroll to additional lines that may be hidden below the initial 4 lines of display.

Alphanumeric Data Entry: Use the number keypad at the right of the LCD to enter

numbers and letters. To scroll to additional letters, continue to press the key until the

desired letter appears.

Entering Data: Once you have scrolled to an item or have entered data press the

Enter key to input your selection/data.

Previous Page/Next: Use the prev and next buttons to move to the previous menu or

forward to the next menu.

Multiple Users: Multiple users can access the system in a single Patch Zone at the

same time. Access is available from any MCP or DCP in the Patch Zone.

Diagnostics Menu

The Diagnostics Menu can be used to check the status of ports and components in the

MapIT G2 system as well as connections between components.

To enter the Diagnostics menu scroll to Diagnostics from the Main Menu and press

Enter. The following screen will appear:

Page 36

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

36

Port Diagnostics

Port Diagnostics allows you to test individual ports or trace Patch Cable connections

between panels/enclosures by using the pen probe to touch a sensor pad or the metal

contact on the back of a Patch cable/Fiber Jumper.

Note that Port Diagnostics works differently for interconnect mode. The instructions

here pertain to cross-connect mode. Instructions for interconnect mode are provide in

the Interconnect Mode section later in this manual.

To enter the Port Diagnostics mode, scroll to Port Diagnostics and press Enter. The

following screen will appear:

Use the pen probe to touch a smart panel/enclosure port pad for diagnostics. Touch

the probe pen to a sensor pad/point and press the button on the pen. The LED on the

back of the probe pen will flash green after a few seconds and the port information will

display. If a Patch Cable is connected between panels/enclosures, the screen will look

like this:

The second line has the port icon, port number, panel icon and the panel name pulled

from the MapIT software database. If the panel is not connected to the MapIT EEC

software or there is no panel name available, the panel serial number will be displayed.

The fourth line has information for the second port/panel.

Page 37

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

37

If no patch cable is connected to the port, only one line of information is displayed

showing the panel/port information.

If a port is probed and no information appears, begin troubleshooting sequence

described later in this document.

Port Diagnostics information is also displayed on the Smart Patch Panels and Fiber

Enclosures. Once the port is probed, the port number and panel ID will display on the

panel LCD. The green LED will also illuminate to help identify the panel(s).

The screens will show the port icon and port number on the first line and a panel icon

and panel ID on the second line. The LCD screens will then alternate between

showing this information for the connected panels. An example is shown below:

If no Patch Cable is present, only the LCD and LED on the probed panel will illuminate

and display the port and panel information.

If a port is probed and the LCD/LED does not illuminate and doesn’t display any

information, begin the troubleshooting procedure described later in this document.

This information will continue to display until one of the following events occurs:

1. You press the prev button

2. The components times out (see component time out in the Settings section)

To conduct port diagnostics on another port, hit the prev button and probe the next

port.

Page 38

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

38

Component Diagnostics

The Component Check menu allows you to check components for errors. To access

this menu, scroll to Component Diagnostics and press Enter. The following screen

will appear:

Please note that there is another option called Check SPP which is below the Check

DCP line. You can use the scroll down button to navigate to this option.

You can run diagnostics for all components in the system by selecting Check All and

pressing Enter. Please note that the system will suspend port tracking during the test.

If no errors are found the system will report All Components Passed Test. If errors

are found, the system will list the problem components. You can scroll to Reboot

below the component and press enter. The system will try a reboot of the component

to attempt to clear the error. An example is shown below:

If the reboot of the component reboots, the following will display:

Page 39

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

39

Depending on the type of error, the reboot may or may not clear the error code. You

can recheck the component to see if the error was cleared with the reboot. If not,

please see the troubleshooting section of this document for further guidance.

If the component reboots and the error does not clear, the field will show Failed. See

the troubleshooting section for procedures to resolve these issues.

Please note that a component may not be connected correctly or may not be

recognized by the MCP or DCP. In this case the component will not appear in the

menu. If this occurs, check the Control Bus cable connections. For the MCP and DCP,

check the power cable to make sure it is plugged in properly. The LCD should have

the Main Menu displayed. If the unit still doesn’t power up, try a different power supply.

If these steps fail to repair the problem, see the Troubleshooting section or contact

Siemon Technical Support.

You can also run diagnostics on individual components. Scroll to the desired option

(Check MCP, DCP or SPP) from the Component Diagnostics screen and press

Enter.

The Check MCP screen will look like this:

If errors appeared on this screen you could attempt to clear them by rebooting the

MCP. To Reboot; simply scroll down to the Reboot icon and press Enter. If rebooting

does not resolve the issue, see the troubleshooting section later in this document.

To check DCPs, scroll to the Check DCP option and press Enter. The following

screen will appear:

Page 40

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

40

The number to the left indicates the port the DCP is connected to on the MCP. If no

DCP is connected to a port, then DCP None is displayed. If a DCP is connected, you

will see DCP and the serial number of the unit. You can scroll down to see additional

DCPs (up to 24)

To run DCP diagnostics, scroll to the desired DCP and press Enter. You can try to

clear errors on DCPs by selecting REBOOT and pressing Enter. If rebooting does not

resolve the issue, see the troubleshooting section later in this document.

Check SPP

To check an individual SPP, scroll down to the Check SPP option (below Check DCP

option) and press Enter. The following screen will appear:

Use the probe pen to touch any port on the SPP you want to run diagnostics on. If a

patch cord is plugged into the port being probed, diagnostics will run on for both

panels. Press the button on the probe pen and wait for the LED to flash once. The

following screen will appear:

Page 41

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

41

If the MCP is connected to the server and the panel is mapped, the second line will

show the type icon (e.g., Patch Panel) and its name. If the MCP is not connected to

the database and/or the item is not mapped, it will show the SPP serial number.

The third line will display error codes (if any). If no errors or detected it will display No

Error. For a list of error codes and troubleshooting, see the Troubleshooting section of

this document.

The fourth line will display the Reboot option. Scroll to this line and press enter if you

wish to attempt to reboot the SPP. In some cases reboot of an SPP via this method

may not be possible (for example, if the SPP is not properly connected to the DCP or

MCP). If rebooting does not resolve the issue, see the Troubleshooting section later in

this document.

If the probed port has a patch cord connection, diagnostics will run on both panels.

Scroll down below the first panel information to see the second panel info.

Connections

This menu shows what is connected to the MCP or DCPs. To go to the Connections

menu, select Connections from the Diagnostics menu and press Enter. An example

of what this screen looks like is pasted below:

The numbers 01 through 24 on the left of the screen are the ports of the MCP. Only

the first 3 ports are shown. You can scroll down to see additional ports.

Moving from left to right, the next item over will be the device type (SPP24 or DCP).

Next over is the item name or serial number. If the item is a smart panel and the MCP

is connected to the MapIT software, the panel name will display. If the MCP is not

connected to the MapIT software, the panel serial number will display. If the item is a

DCP, the DPC serial number will display.

Finally on the far right is the number of additional items connected to the device. In the

example shown above SPP24 HQSPP-A102 has +02 next to it. This indicates that

there are two additional panels connected to it.

Page 42

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

42

You can scroll to this line and press Enter to see those panels. An example of this

screen is shown below:

The first line shows the type of device (MCP in this example), the device’s serial

number and the port number that the SPP or DCP is connected to. Below the top line

are the items that are connected to that port.

If there is a redundant daisy chain link connecting the last two panels, you will see Link

to chain on DCP or MCP port XX below the last panel.

If you are not seeing devices connected that should be connected, check control bus

cable connections.

Unlicensed Panels

Previous versions of the MapIT software required a license for each patch panel. EEC

no longer requires this. There is no panel specific license required by the EEC

software. This screen is only kept for older legacy systems.

This screen provides a quick view of licensed and unlicensed panels/ports in the patch

zone. An example of the screen is shown below:

Page 43

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

43

The MCP will allocate available port licenses on a first come, first serve basis. If

additional panels are added to the system and the MCP does not have additional port

licenses available for them, the panels will not be licensed.

There are two methods to determine unlicensed panels/enclosures in a Patch Zone.

1. Any unlicensed Smart Panel/Enclosure connected to the MCP will display

Unlicensed on its LCD (no backlight). Once the MCP has enough licensed

ports, this message will go away and the smart panel will begin to monitor

port connections.

2. You can also go to the Unlicensed Panels menu to view details on

unlicensed panels. To access this information scroll down below the

Unlicensed Panels line and any unlicensed panels will be listed here

(device type and serial number)

Reflash All

Firmware for all items in the MapIT G2 system can be upgraded via the firmware

upgrade process described in the EEC software manual. Once new firmware is

downloaded to the MCP items connected to the MCP will receive their new firmware (if

available) and upgrade themselves. We do provide the option to manually reflash

SPPs and DCPs in the system with the Reflash All option. Reflash All will only work if

there is a pending new SPP and/or DCP firmware loaded on the MCP.

To reflash components, go to Reflash All in the Diagnostics screen and press Enter.

You will see the following screen:

Page 44

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

44

Scroll down to UPDATE ALL and press Enter. This will download firmware to SPPs

and DCP in the patch zone.

Circuit Trace

Note that Circuit Trace works differently for interconnect mode. The instructions here

pertain to cross-connect mode. Instructions for interconnect mode are provide in the

Interconnect Mode section later in this manual.

Circuit Trace lets you see an end-to-end circuit on the MCP or DCP screen. To enter

the Circuit Trace menu, scroll to Circuit Trace on the Main Menu and press Enter.

The following screen will appear:

Use the probe pen to probe a port. Touch a sensor pad or contact point on a Patch

Cable/Fiber Jumper. Hold the button down on the probe pen and wait for the LED to

flash green. An example of the type of screen that will appear is shown below:

A graphical representation of the circuit is displayed on the top line. The icons

associated with the Class of the device are show in the circuit. In the example above

there are: (from left to right) a Switch, Patch Panel, Patch Panel, Faceplate and Work

Station.

You can use the left/right scroll buttons to highlight items in the circuit. A highlighted

item will have blinking > < symbols pointing to the device. In the example above the

first patch panel is highlighted. The three lines below will show additional details about

the highlighted item.

Page 45

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

45

The first line of information is usually a port or NIC. In the example above it shows the

position where the patch cord is connected in the panel.

The second line provides information on the device, in this case the patch panel name.

Finally, the last line provides location information. In this case the name of the

enclosure where the panel is located.

Even if a Patch Cable is not connected between smart panels/enclosures you can still

get a circuit trace for any connections to the Patch panel port.

Up to 8 items in a circuit will display at a time. If there are more than 8 items in a circuit

you can use the left/right scroll buttons to navigate and display the additional items.

Setup

The Setup Menu allows you to set network, product and language settings. You can

also clear unused panels that have been removed from the Patch Zone.

Scroll to Setup from the Main Menu (this is off screen below the Work Order option)

and press Enter. The following screen will appear:

Enter the password. The default password is SIEMON. Type in SIEMON and press

enter. If the incorrect password is entered Invalid Password, Please Try Again will

appear on the screen. You can change the password if desired once you are in the

Setup menu. If you forget your password, contact Siemon Technical Support for the

procedure on how to reset the MCP password.

Once the correct Password is entered, the following screen appears. Scroll to the

desired option and press Enter.

Page 46

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

46

Network Settings

Scroll to Network Settings and press Enter. The following screen will appear:

Scroll to the input fields and use the alphanumeric keypad to enter information. When

a line is complete, press Enter. If an invalid number is entered (higher than 255) the

MCP will default to 255. Check with you network administrator if you are having

trouble with correct values for input.

Product Settings

You can set the inactivity timeout period for all devices (up to 999 minutes for MCP and

DCP, 30 seconds for SPP). Scroll to the entry field and enter the desired timeout

period for each type of device. Once the data is entered, press Enter to store the new

settings. An example of this screen is show below:

Page 47

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

47

The default setting for the MCP and DPC timeout is 5 minutes. For the SPP it is 30

seconds. Minimum time for the MCP and DCP is 2 minutes and 3 seconds for the

SPP.

Below the timeout section there is an option for Connection Type. This is where you

will select cross-connect or interconnect mode. Details on the interconnect mode are

in the Interconnect Mode section of this manual.

Language Selection

This menu allows the user to select what language is displayed on the MCP, DCPs and

SPPs. Input is always in English characters via the keypad. The default language is

English. To select a language, scroll to the desired language and press Enter. An

example of the Language screen is shown on the next page:

Product Information

From the Setup Menu scroll to Product Information (below language settings), press

Enter. The following screen will display:

Scroll down to see additional information (MAC, Date Code, Licensed Ports, Ports

Used and Ports Free). An example of the next four items is shown below:

Page 48

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

48

Change Password

To change the MCP password from the Setup Menu scroll to Change Password and

press Enter. The following screen will appear:

1. Enter the new password, press enter.

2. Confirm the new password, press enter.

If there is a mismatch between the New Password and the second entry of the New

Password, the following error code will appear – Password Mismatch, Please Try

again. Reenter the New Password on both lines and press enter.

The password must be a minimum of 4 characters with no spaces.

Clear Unused Panels

Page 49

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

49

The MapIT G2 system assigns port numbers to each panel connected in the MCP

Patch Zone. The port assignments are retained by the MCP even if a panel is

disconnected. The clear unused panels feature allows you to clear any panels which

are no longer used in the Patch Zone. This will free unused port licenses for new

panels. This is primarily a legacy software feature since EEC has no license

requirement for panels.

Some examples of when you would use this feature are:

• Remove a panel from the Patch Zone

• Replace a defective panel board

To clear unused panels, scroll to the Clear Unused Panels option in the Setup Menu

and press Enter. The following screen will appear:

Make sure that the panels are disconnected from the MCP and/or DCP.

Scroll down to CLEAR MEMORY and press Enter to clear unused panels.

Update Panel IDs

This feature can be used to force an update of the panel IDs displayed on the SPP

LCD screens. The MCP will request the latest panel name information from the MapIT

EEC software and will update the panel displays. Scroll down to Update Panel IDs and

press Enter. The following screen will appear:

Page 50

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

50

Once the update process is complete the MCP will show the Setup Menu screen.

It is important to note that the panel update process is not a required step. The MCP

will automatically request the panel ID information every time it is connected to the

EEC software. You can also force a manual update from the EEC software by

pressing the Sync button in the Monitor tab.

Important Note: Panel names will not be displayed until the MCP is connected to the

EEC software and the panels have been mapped to the panels in the EEC database.

See mapping section below for details on how to map panels.

Mapping

The mapping feature allows the user to associate physical panels/enclosures with their

virtual counterparts in the EEC software.

Prior to mapping panels, you will have to create your database, setup you MCP, etc….

Complete instructions for this process can be found in the EEC software training

manual.

To perform port mapping go to the Tree Builder page in the EEC software. Then go to

the Mapping sub tab. The screen will look like this:

Page 51

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

51

Please note that the MCP assigns pin positions to all monitored SPP ports. The ports

start at 0 and go up to 64,999. So, the first panel in a Patch Zone would be assigned

ports 0 through 23, the next would get 24 through 47, etc…. The respective starting

pin assignment for each SPP is shown on the bottom left of the SPP LCD. An example

of a panel with a starting port assignment of 24 is shown below:

To map items following the following steps:

1. Select you MCP from the MCP pull down box. If your MCP is not shown go to

the MCP page and setup the MCP

2. Select a panel you want to map from the Navigation Tree to the left of the

screen

3. Enter the port number of the patch panel. The port number can be found on 2nd

line of the patch panel LCD

4. Click on the Save button. The panel and its port mapping will now be shown in

the box below

5. If you make a mistake you can click on a panel and change the port mapping.

You can also remove a panel from port mapping by clicking on the panel and

the Remove button

P 00024 V01.09

HQSPP-A102

Page 52

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

52

MapIT G2 Interconnect Training

Description of how the MapIT G2 Interconnect System Works

The MapIT G2 interconnect system allows for direct patching from the switch to a smart patch panel. It

eliminates the need for a cross-connect typology (i.e., using an extra patch panel to represent the switch

ports. The interconnect typology requires less rack space, less time to install and test and ultimately

less cost.

The interconnect system requires a new component, called the Ethernet Module, which discovers the

switch and port a MapIT patch cord is connected to. To make a connection, first connect the MapIT

patch cord into the switch. Then connect the other end to the Ethernet Module. The Ethernet Module

(EM) queries the switch to determine which switch and port it is connected to. Then the EM sends this

information to the MCP while connected to the switch. The technician then disconnects the EM and

connects that end of the patch cord into an SPP. The SPP port detects it has a connection since the 9th

wire pogo pin is now grounded out to the switch. This information is also sent to the MCP. The MCP

now has both ends of the patch cord connection and sends this information to the EEC database.

There is no need to use the EM for disconnects. Simply remove the patch cord from the SPP or switch

side and the system will detect the disconnection.

Install the Battery, Power On, Power Off

The EM is shipped with a 9v battery (not installed). To install the battery, remove the black battery cover

and connect the battery to the terminals. Reinstall cover. Press the black button to power on the EM.

The EM will power off after 30 seconds of non-use. To turn the unit off, press and hold the black power

button for 5 seconds.

When the battery is low, Low Batt will display on the display. Install a new 9v battery,

Install the latest Ethernet Module (EM) Firmware

Page 53

MapIT G2 Hardware Installation Training Manual Confidential – June 2014

53

The EM’s default IP address is 169.254.1.1. Prior to use you should install the latest EM firmware and

set the IP address you will use (or DHCP enabled).

1. Get the latest firmware file (HEX file) for the EM at siemon.com

2. Save the new Hex file to a known location on your hard drive

3. Connect the EM directly to your PC

4. You need to set your computer IP to 169.254.1.2

1. Start > Control Panel > Network Connections > Local Area Connection

2. In the status window click the "Properties" button

3. Highlight "Internet Protocol (TCP/IP)" and click the "Properties" button

4. If the radio button for “Use the following IP address” is not selected, select it (if it is already

selected, remember the IP address and Subnet Mask as you will need to change them back)

5. Set the IP address to 169.254.1.2 and the Subnet Mask to 255.255.0.0