Page 1

1

Revision Date:

06/01/2015

Instruction Manual

Rack P

ower Distribution Unit

7M,

7N,

7S

, 7T

and

7WSeries

Firmware Version

3

.12.7

Page 2

2

Contents

Contents

................................

................................

................................

............................

2

Specifications

................................

................................

................................

....................

4

Overview

4

Environmental

4

Electric

al4Receptacle Ratings

4

Networking

4

Data Formats

5

EMC Verification

5

Installation

................................

................................

................................

.......................

6

Guidelines

6

Mounting

7

Network Overview

8

Default IP Address

8

Initial Setup

9

Web Interface

................................

................................

................................

.................

13

Overview

13

Sensors Page

13

Logging Page

16

Display Page

18

Alarms Page

19

Control Page (7S and 7W Only)

20

Configuration Page

22

Unit

Configuration

................................

................................

................................

...........

27

Network Configuration

27

Time and Date

28E-

Mai

l/ Business Hours

29

SNMP

30

Accounts and Passwords

30

Telnet

31

Camera Configuration

32

Admin Information

32

Kilowatt

-

Hours Res

et33XML File Backup

33

SSL Certificate Upload

34

Alarms

................................

................................

................................

.............................

35

Alarm Notifications

35

Alarm Types

35

Thresholds

35

Sensors

................................

................................

................................

...........................

37

Overview

37

Internal Sensors

37

Data Logging and Display

38

Remote Outlet Switching (7S and 7W Only)

................................

................................

....39Actions

39

Configuration

40

Power

-

On Actions

40

Accessories

................................

................................

................................

.....................

42

Serial Communication (Delta Configured Units Only)

42IP-

Addressable Network Cameras

42

Alter

nate Data Formats

43

Page 3

3

Technical Support

................................

................................

................................

...........

44

Firmware Version

44Firmware Updates

44

Resetting PDU

44

Service and Maintenance

44More Technical Support

44

Table of Figures

................................

................................

................................

...............

45

Revision History

4

5

Page 4

4

Specifications

Overview

The7M,

7N,7S,7Tand 7W

series

units

arerack

level

PDUs with

circuit

m

onitoring

via a built

-inweb server.

In the

7M

series, b

uilt-in se

nsors monitor Voltage, Current, instantaneous and

cumulative Power, as well as

calculated Power Factor

.

The7Sseries

un

its have all these

sensors plus

outlet level switching, while

7W

series units are the same as the

7S

with added

outlet level

current and power

monitoring

.

Web pages, including graphs,

are

generated

by

the

unittomonitor power and environmental conditions

within the cabinet. No software other than

a web browser is required

for operation

and several data formats are available. Optional

external sensors and network cameras are

also

available.

These units can be built for

installation in either Delta or Wye

building wiring configurations.

Environmental

Temperature

Operating

(

Vertical

):10°C (50°F) min

40°C (104°F) max

Operating (

Horizontal

):10°C (50°F) min

45°C (113°F) max

Storage:

-

25°C (

-

13°F) min

65°C (149°F) max

Humidity

Operating:

5% min

95% max

(non

-

condensing)

Storage:

5% min

95% max

(non

-

condensing)

Elevation

Operating:

0 m (0 ft) min

2000 m (6561 ft) max

Storage:

0 m (0 ft) min

15240 m (50000 ft) max

Electrical

See nameplate for

u

nit

ratings.

Receptacle Ratings

NEMA 5

-

15R or L5

-15R

125 Volts, 15 Amp

NEMA 5

-

20R or L5

-

20R

125 Volts, 20 Amp

NEMA 6

-

20R or L6

-

20R

250 Volts, 20 Amp

NEMA L5

-

30R

125 Volts, 30 Amp

NEMA L6

-

30R

250 Volts, 30 Amp

NEMA L15

-

30R

250 Volts (3 phase), 30 Amp

IEC-320 C13

125/250 Volt, 15 Amp (per Receptacle Ba

nk)

IEC-320 C19

125/250 Volt, 20 Amp

Networking

Protocols

HTTP, HTTPS (SSL/TLS), SMTP, POP3, ICMP, DHCP, TCP/IP, NTP,

Telnet

, Syslog

Page 5

5

Ethernet Link Speed

10 M

B

it; half

-

duplex

Data Formats

HTML, SNMP, CS

V/Plain Text

, XML

EMC Verification

This

Class A

device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undes

ired

operation.

This Class A digital apparatus complies with Canadian ICES

-

003.

Cet appareil numérique de la classe A est conforme à la norme NMB

-

003 du Canada.

Warning: Changes or modifications to this unit not expressly approved by the party responsi

ble

for compliance could void the user’s authority to operate this equipment.

Page 6

6

Installation

Guidelines

If the PDU is installed in a cabinet the ambient temperature of the rack should be no greater

than

the PDU’s maximum rated operating temperature

.Inst

all the PDU such that the amount of airflow required for safe operation of equipment is

not compromised.

Mount the PDU so that a hazardous condition is not achieved due to uneven mechanical

loading.

Follow nameplate ratings when connecting equipment to the

branch circuit. Take into

consideration the effect that overloading of the circuits might have on over

-

current

protection and supply wiring.

The PDU relies on the building installation for protection from over

-

current

conditions

. A

Listed circuit breake

r is required

with

in the building installation. The circuit breaker should

be sized according to the PDU’s nameplate ratings and local/national electrical code

s

.

Reliable earthing of rack

-

mount equipment should be maintained. Particular attention

should

be given to supply connections other than direct connections to the branch circuit.

The PDU must be connected to an earthed socket

-

outlet.

The

PDU is intended for Restricted Access Location

s only and o

nly service personnel should

install and access the PD

U.For pluggable equipment, install the PDU so

that

the input plug or appliance coupler may be

disconnected for service.

Sequential power

-

up via Power

-

On Actions of devices powered by

the

PDU is recommended

to avoid high inrush current. See

Power

-

On Actions

(page

38

) for details.

Caution:

Disconnect all power cords before servicing.

Page 7

7

Mounting

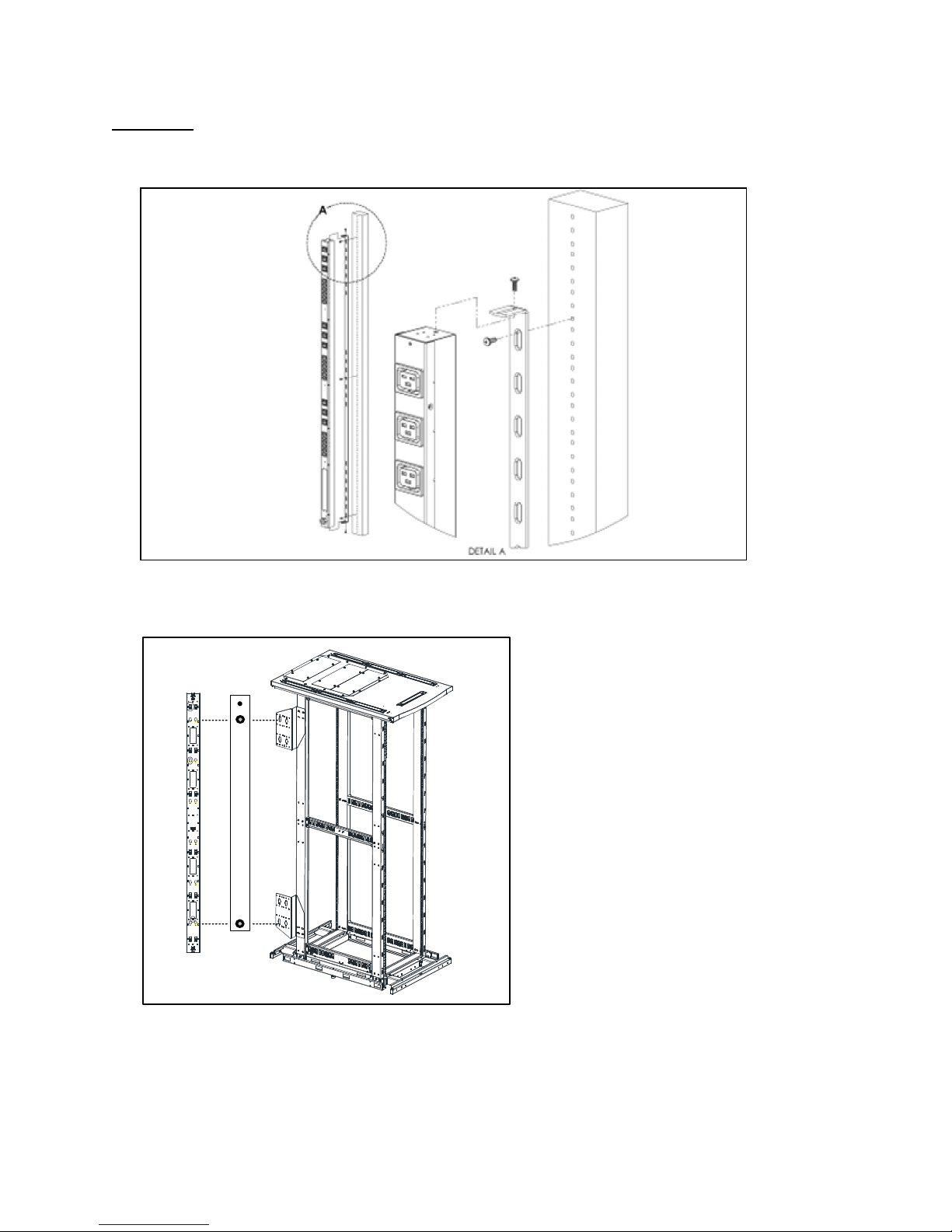

Figure

1

: Full Length Bracket

Using the full length bracket, mount PDU to rack as shown

Figure

2

: Toolless Mounting Hardware

Secure toolless mounting buttons to PDU as shown. Use toolless buttons with key

-

holed slots

built into cabinet or with optional

Siemon

PDU

brackets

(V-PDU & VP

-

PDU

-

002 shown)

.

Page 8

8

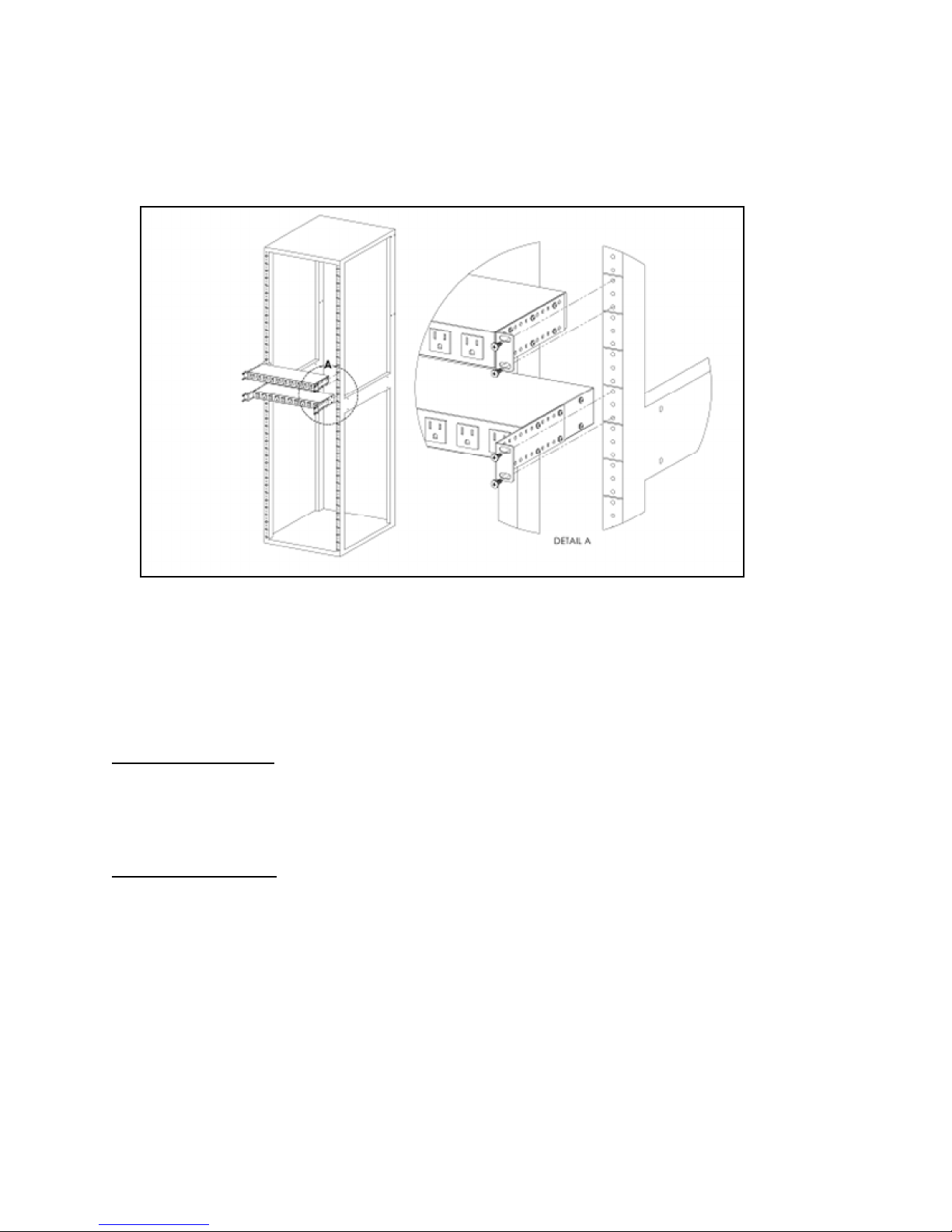

Figure

3

: Adjustable Mount Brackets

Using adjustable mount brackets, attach PDU to rack as shown

Network Overview

This product

comes preconfigured

with a default IP address set

. Simply connect to the PDU and

access th

e web

page with your browser.

Default

IP Address

7M,7N,7Sand7Wunits have a

default

IP address for initial setup and access to the unit if

the

assigned address is lost or forgotten

.

Once an IP address is assigned to a unit, the default IP

address i

s no longer active. To restore the default IP address, press

and hold

the reset button

located below the network connector

for 20 seconds

while the unit is powered up

.

The Idle and

A

ctivity lights

next to the

network connector will both light up when

the

IP address has been

reset

.

The reset button is accessed through the white, circular hole located below the Ethernet

jack.

Note:

Pressing the reset button under the network connector will restore the default IP address and will

also clear all password

settings.

Page 9

9

The Configuration page allows you to assign the network properties or use DHCP to connect to

your network. Access to the unit requires the IP address to be known, so use of a Static IP or

reserved DHCP is recommended. The

default

address is sh

own on the front of the uni

t:IP Address:

192.168.123.123

Subnet

Mask:

255.255.255.0

Gateway:

192.168.123.1

Initial Setup

Connect the

7M,7N,7Sor7Wseries

unit to your computer using a crossover cable or

hub/switch.

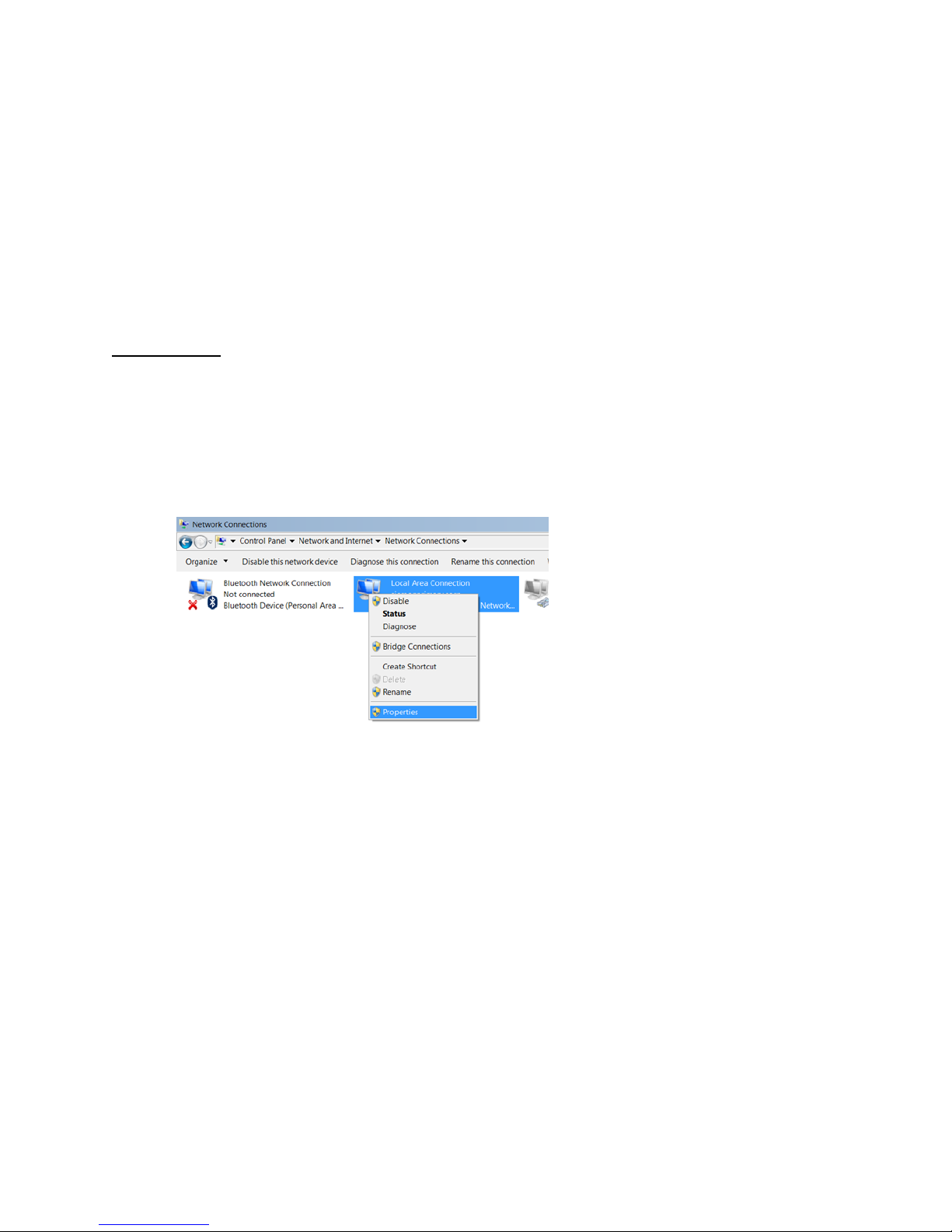

Windows 7

On your computer,

go to “Start > Settings > Control Panel > Network & Sharing Center”

Right click on “Local Area Connection” and select “Properties”

Change IP address and Subnet Mask as shown below:

Page 10

10

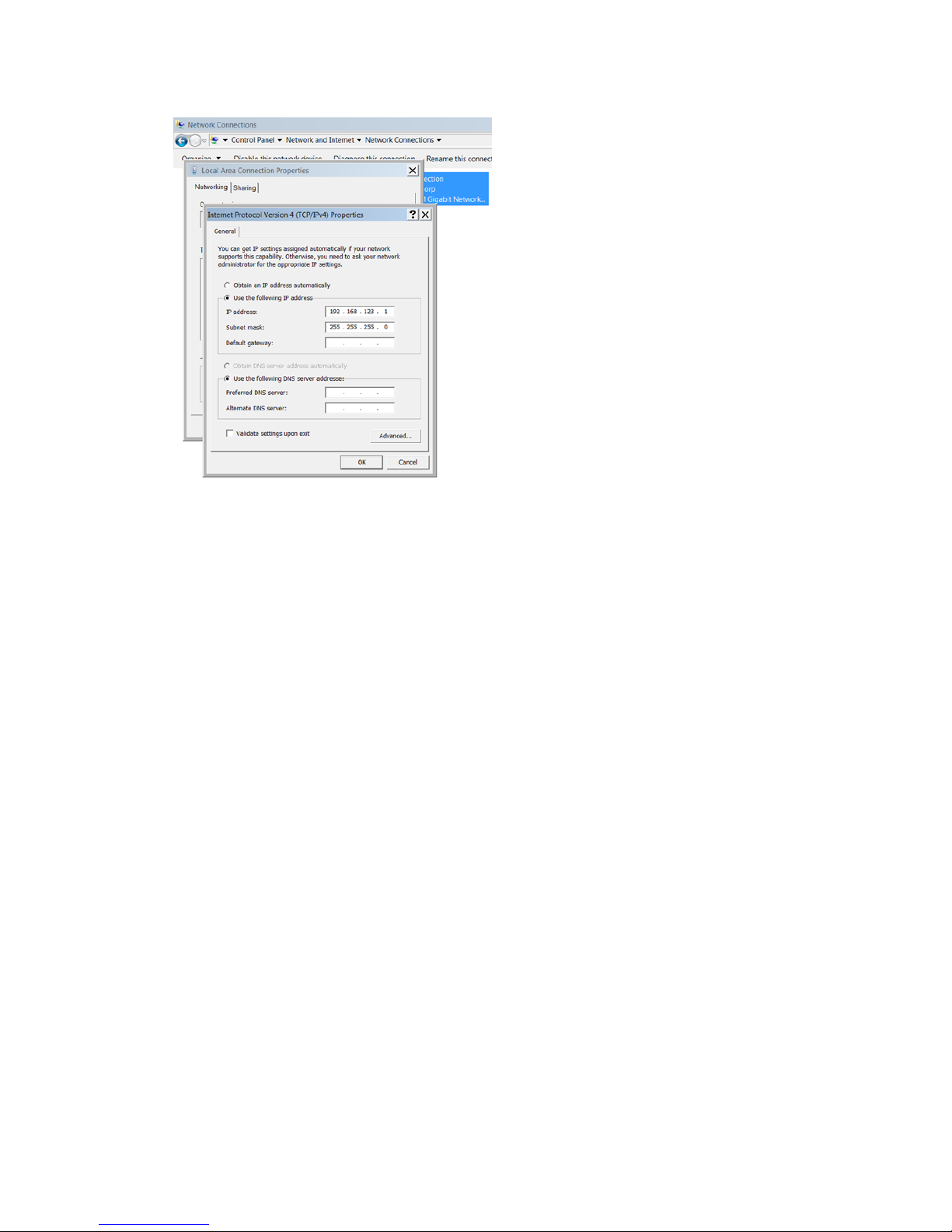

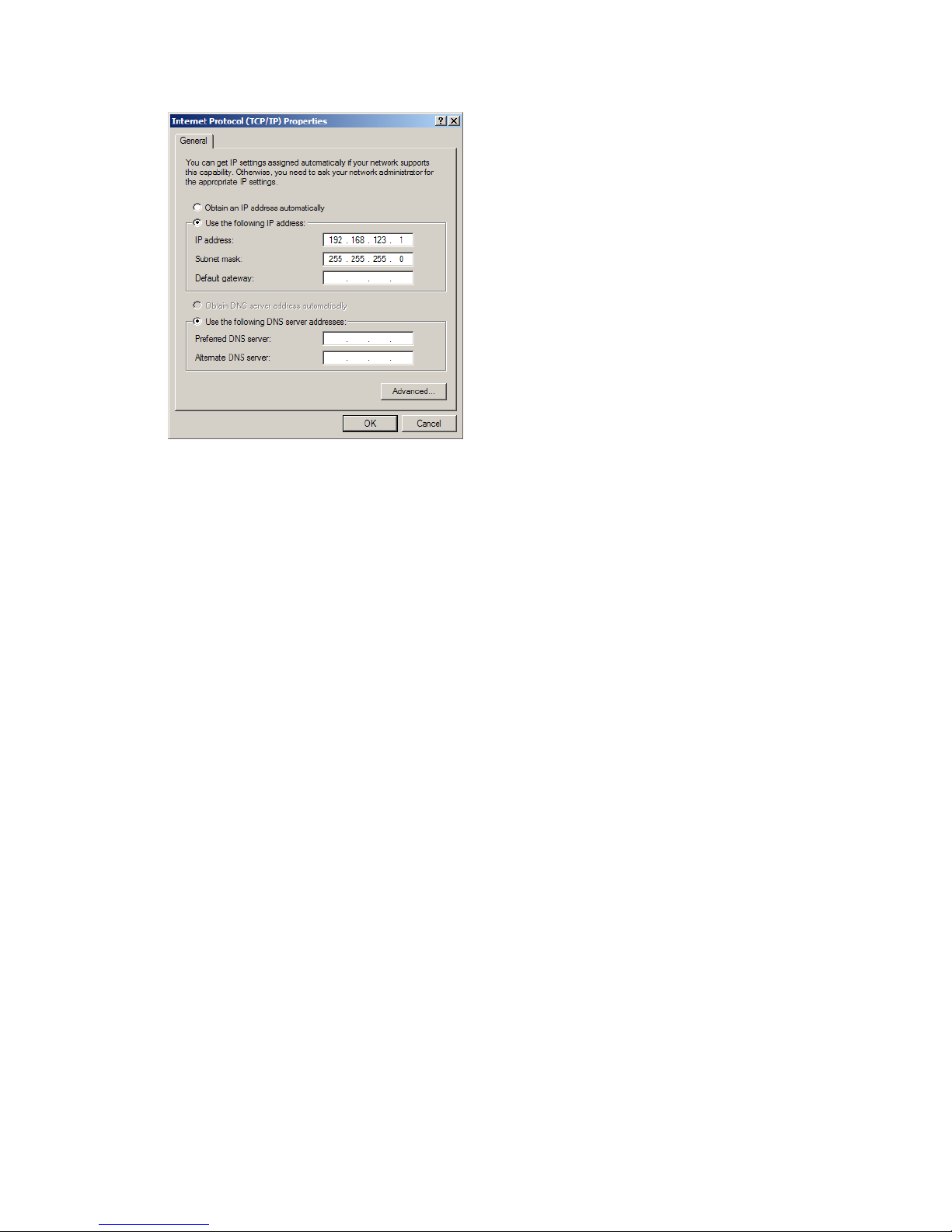

Windows XP

On your computer, go to “Start > Settings > Control Panel

> Network and Dial Up

Connections”

Right click on “Local Area Connection” and select “Properties”

Select “Use the following IP address”. Use these settings:

IP Address:

192.168.123.1

Subnet Mask:

255.255.255.0

Gateway:

Leave blank

Click “OK” twice.

The unit should now be accessible in a web browser via the unit’s permanent IP address:

http://192.168.123.123/

. See

Unit Configuration

(page

27

) for details.

Page 11

11

Figure

4:W

indows XP n

etwork settings for initial setup.

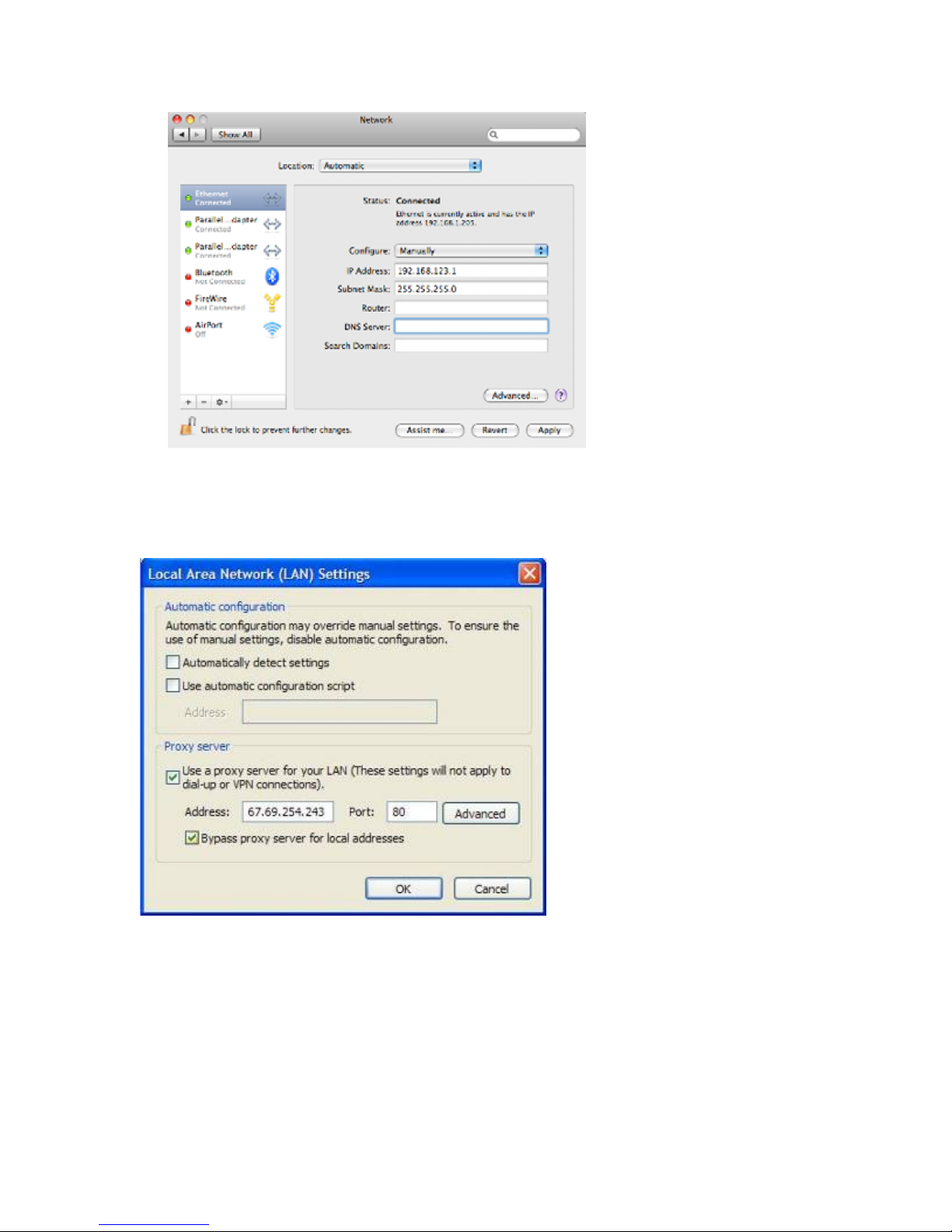

MacOS X

10.5 and 10.6

Open System Preferences via the Dock or the Apple menu.

Select “Network” under “Internet & Network.”

Select “Ethernet” from the list on the left side of the window and enter these setti

ngs on the

right side of the window:

Configure:

Manually

IP Address:

192.168.123.1

Subnet Mask:

255.255.255.0

Router

:

Leave blank

Hit “Apply” and confirm the changes.

The unit should now be accessible in a web browser via the unit’s permanent IP addre

ss:

http://192.168.123.123/

. See

Unit Configuration

(page

26

) for details.

Page 12

12

Figure

5

: MacOS X network settings for initial setup

Note

: Problems connecting to the local PDUs may be caused by the use of

proxy servers. Turn

off “Use a proxy server for your LAN” or select “Bypass proxy server for local addresses” under

your web browser’s LAN settings.

Figure

6

: Internet Explorer's LAN Settings for selecting proxy settings

Page 13

13

Web

Interface

Overview

The unit is accessible via a standard, unencrypted HTTP connection as well as an encrypted

HTTPS (SSL) connection. The following web pages are available:

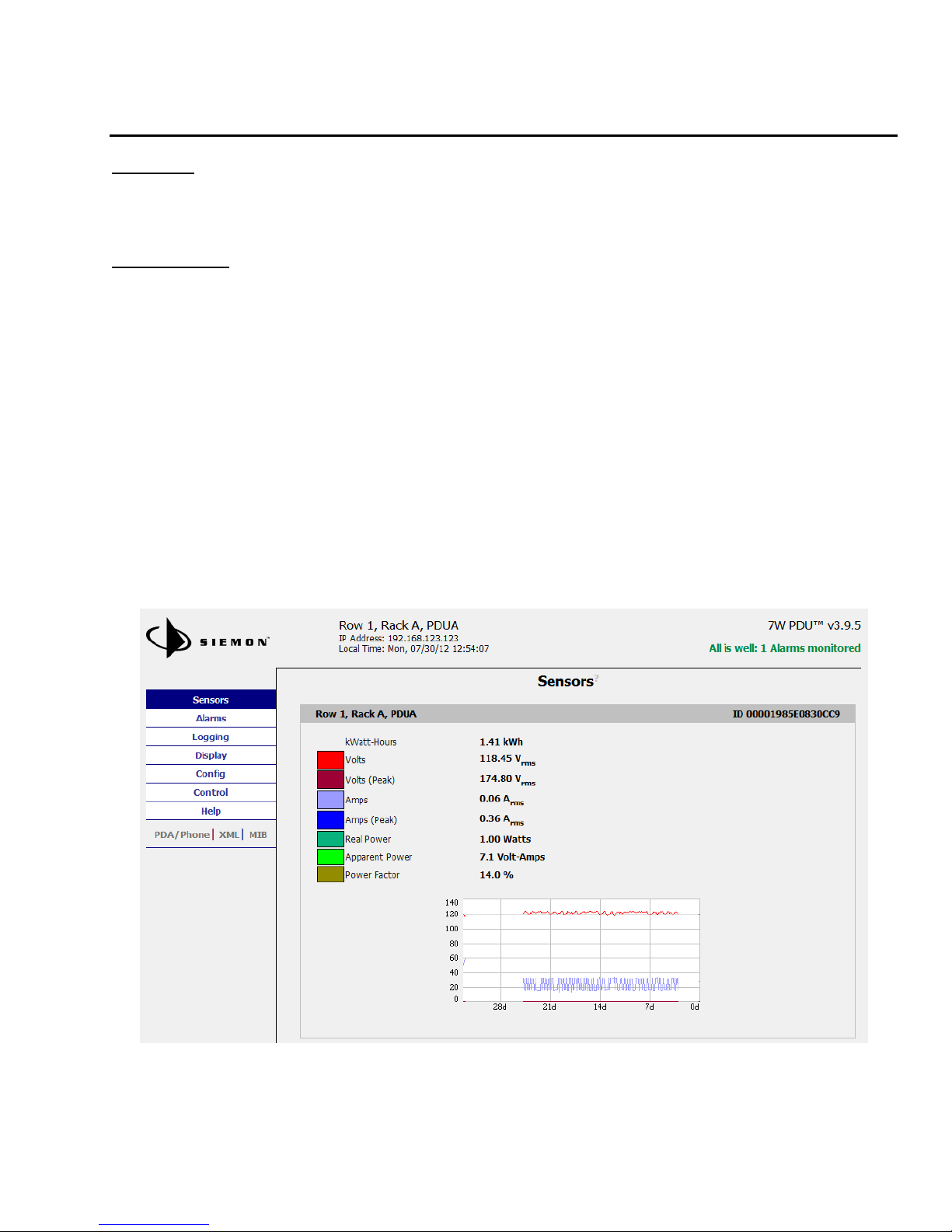

Sensors Page

The front page

,

Sensors

,

gives

both instantaneous and historical

views of the unit’s data

.

Real

time readings are provided for all

power strip data, outlet group data

(7Wonly)

, and sensor

data

next to

historical

graphs.

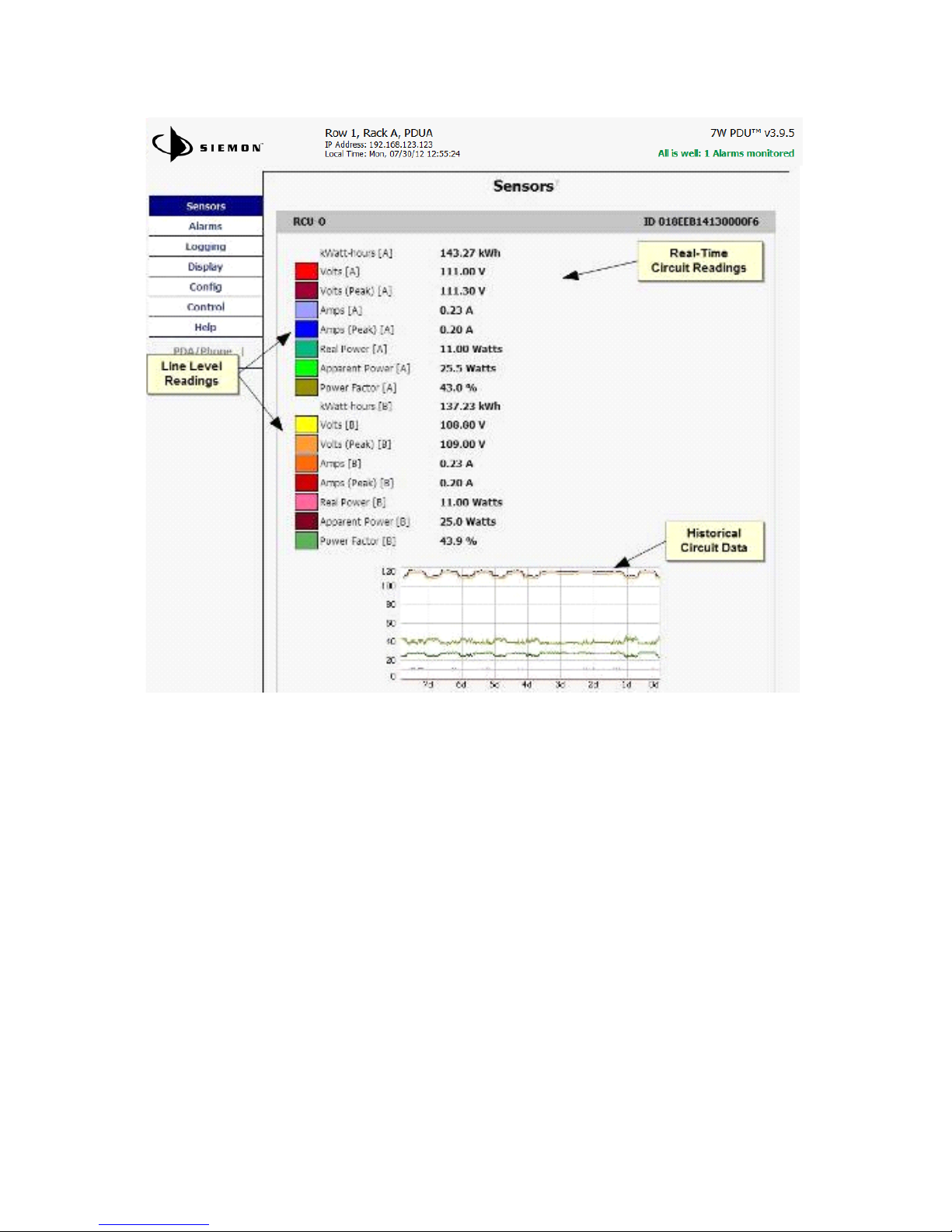

For units configured for Wye wiring

all readings are based on the line currents; A, B, C.

For uni

ts configured for Delta wiring c

urrent readings are based on input line current

(A, B, C)

.

All other readings (Voltage, Real/Apparent Power, Power Factor and kWatt

-

Hours) are based on

the Phase

-to-

Phase Load (AB, BC, CA).

Optional cameras may be added an

d

their live

snapshot

s

are shown on this page. P

lug-and-play sensors appear bel

ow the internal sensors when attached.

Themenubar

allows

access

to the rest

of the PDU

’s

functionality

.

Alternate formats for t

he

real-time data can be downloaded in PDA,

XML and SNMP formats, and historical data is

available in PDA

format

.

Figure

7:Sensors Page

–

Wye Configuration

Page 14

14

Figure

8

: Sensors Page

–

Delta Configuration

Page 15

15

Figure

9:Sensors Page

–

Group and Sensor Data

Page 16

16

Log

ging

Page

The

Log

ging

page

allows the user to access the historical data by selecting the desired sensor

s

and time range

to be

logged

.

The

Sensor Measurement Data Graph section

contains check

boxes which allow the user

to select which readings are to be

graphed on the Logging page

and

/or

displayed on the

internal LCD

.

The “Logging Control” allows users to select between different modes of logging data.

Normal:

Data logged once per minute in

to data log file

.High

-

water Mark:

High value logged each minute into the data log file.

Low

-

water Mark:

Low value logged each minute into the data log file.

Logging Off

The data will be logged

into the data file at a rate of one point per minute

and will

be available

for graphing and display

. Please note that although data is logged once per minute, all sensor

data

used in the real time display and alarm functions

is read at least once every 15 seconds

for internal sensors and once every 30 seconds for e

xternal sensors

.

Recorded data is available

for download in

acomma

-

separated values

(CSV)

file.To reset the logs click the “Reset Logs”

check box and save the changes.

Page 17

17

Figure

10

: Logging Page

Page 18

18

Dis

play Page

The

Display

page

allows the user to

assign

friendly

names

to

attached

sensors

,

change the

default unit

of measure

for

all temperature

sensors

,

and change what is scrolling on the LCD

display

(Measurements or Alarms)

.

The display page also allows

the user to select between the

default and classic web page layouts. The default interface displays a vertical menu bar to the

left of the main window

(shown in Figure 1

1), while the classic interface displays a horizontal

menu bar across the top of the

screen.

Figure

11:Display Page

Page 19

19

Alarms Page

The

Alarms

page

allows the user to establish alarm conditions for each sensor reading. Alarm

conditions can be established with either high or low trip th

resholds. The alarms are displayed

in different sections based on the device the alarm is associated with.

Alarm options include a

local Buzzer, Email and SNMP Trap.

See

Alarms

(page

35

) for

more

de

tails.

Figure

12:Alarms Page

Page 20

20

Control Page

(7Sand

7W

Only)

The

Control

page

has

two sub

-

tabs

;

Actions

and

Settings

.

See

Remote O

utlet Switching

(page

39)for details.

Control Actions Tab

The

Actions

tab

on the

Control

page

gives the user control of the outlets.

Outlets can be

rebooted or turned on/off with or

without

pre-programmed

delays.

The status of each

outlet is also shown for verificat

ion by the user.

For7Wseries units, outlet readings for

current, power and logged k

ilowatt

-hours

are also shown

.

Figure

13

: Control Actions Tab

Page 21

21

Control Settings Tab

TheSettings

tab

on the

Contr

ol

page

allows

the user to name and

define

a

URL for

outlets in

addition to set

ting

time delays

for each outlet action

. Boot up status and sequential boot up

options are also available

. A

ll delay settings are

referenced

from the trigger event. This tab

also allows the user to restore factory default settings

for the outlets

.

Figure

14:Control Settings Tab

Page 22

22

Configuration Page

The

Configuration

p

age has five sub

-

tabs

;

Network

,

Monitoring

,

Diagnostics

,

Event Log

,

and

Admin

.

See

Unit Configuration

(page

27

) for details.

Configuration Network Tab

The user can enter and update the network settings on the

N

etwork

tab

of the

Configuration

page

. See

Unit Configuration

section for details.

Figure

15

: Configuration Network Tab

Page 23

23

Configuration Monitoring Tab

The user

can enter and update the email alert, SNMP, and camera se

ttings on the

Monitoring

tab of the

Configuration

page. See

Unit Configuration

section for details.

Figure

16

: Configuration Monitoring Tab

Page 24

24

Configuration Di

agnostics Tab

The user can update the Syslog settings on the

D

iagnostics

tab

of the

Configuration

page

.

Figure

17

: Configuration Diagnostics Tab

Page 25

25

Configuration Event Log Tab

The user can view the E

vent Log and update the Memory Syslog settings on the

Event Log

tab of the

Configuration

page.

Figure

18

: Configuration Event Log Tab

Page 26

26

Configuration Admin Tab

The user can set the system clock and adm

inistrative information on this tab. Additionally

,

the user can set administrator and account passwords. See

Unit Configuration

section for

details.

Figure

19

: Configuratio

n Admin Tab

Page 27

27

Unit Configuration

Network Configuration

The unit’s network configuration is set on the

N

etwork

tab

of the

Configuration

page

.

Settings

pertaining to the unit’s network connection are:

Figure

20

: Network Configura

tion

DHCP:

Allows the unit to request a dynamic IP address from a server on the network.

Static IP Address/Net Mask/Gateway:

When not using a dynamic address, enter static

network configuration information here.

Telnet Service:

Enable or disable the built

-

in Telnet server. See

Telne

t

(page

31

) for

details.

HTTP Services:

Enables/disables access via HTTP and HTTPS. Available options are: HTTP

and HTTPS, HTTP only, and HTTPS only. It is not possibl

e to disable the web interface

completely.

HTTP/HTTPS Server Port:

Changes the TCP port that each server listens on.

DNS Servers:

Allows the unit to resolve host names for Email, NTP and SNMP servers as

well as cameras.

Page 28

28

Time and Date

The system clock is s

et on the

A

dmin

tab

of the

Configuration

page

.

The unit comes

preconfigured with the IP addresses of two

NIST time

servers and

is

set to the Central Time

Zone (

-0500 GMT). Should a local time server be preferred,

select “NTP Server” from the “Set

Clock m

ethod” drop

-

down menu,

enter its IP address into the

“NTP primary server”

box and

click

“Save Changes”.

C

learing the time server addresses and clicking “Save Changes” will set

the time servers back to the defaults. The unit

attempts to contact the time

s

ervers

during

boot up and periodically while running

.

Until a time server is contacted

or the system clock is

manually set

,

all log time stamps will present time as the number of seconds since the unit was

powered up

and graphs will not be shown.

The clo

ck can also be setup to automatically change for Daylight Savings Time when needed.

When enabled, the user can select the dates and times for the clocks to adjust.

Note:

Enabling automatic DST or s

etting the time z

one offset forward and backward

will cau

se a gap or

overwriting of logs

.

Figure

21:Manual

Time Settings

Figure

22

: NTP Time Settings

Page 29

29

The time, date, IP address and friendly name of the unit are displayed at the top of each web

page.

E-M

ail

/ Business Hours

The e

-

mail and business hours configuration are set on the

Monitoring

tab of the

Configuration

page.

The unit is capable of sending e

-

mail to

as many as

five addresses at once. Most SMTP

and ESMTP servers are compatible. Authenticati

on options are None, POP3 (POP

-

before

-

SMTP)

or ESMTP.

The unit can be configured to send alarm emails always, only during business hours

or only after hours by selecting the desired option next to each email address.

Figure

23

: E-Mail Configuration

An SMTP server as well as “From” and “To” addresses are required to send e

-

mails. Some mail

servers may require a username and password.

In most cases, the username does not have to

match the “From” address, but does need to be a

valid user on the

authenticating

server

.

Microsoft Exchange servers will have to be set to allow SMTP relay from the IP address of the

Page 30

30

unit. In addition, a test email can be sent from the bottom of the

Monitoring

tab of the

Configuration

page

.

Note:

The

unit cannot receive e

-

mails

.

The

POP3 server is used strictly for authentication and is not

required when

the protocol is set to

ESMTP

or

None

.

Status Reports

When enabled, the unit will periodically send a full status report to all “To” e

-

mail addresses

selected for the report

. The report includes current unit data from all attached sensors as

well as alarm states.

Reporting frequency options are:

weekly,

hourly, every 2,

3,4,6,8,12, 24

, or 48

hours.

E-mail addresses are selected when the report i

s created by checking

the

corresponding e

-

mail destination box. Allowing the cursor to hover over an e

-

mail

destination box will display the e

-

mail address that the box is associated with.

Figure

24

: Email Report Settings

SNMP

The unit supports retrieval of all data via Simple Network Management Protocol (SNMP) v1,

v2c, and v3. In addition, alarm traps can be sent to up to two IP addresses. The SNMP

configuration is entered on the

Monitoring

tab of the

Configuration

page.

Figure

25

: SNMP Configuration

Figure

26

: Initial SNMP V3 Data

The default community string is “public” and the MIB is downloadable via a link

on the web

pages menu bar.

Accounts

and

Passwords

The7M,

7N,7Sand7Woffer account security options that are entered on the

A

dmin

tab of the

Configuration

page. There are

three levels of account security:

Page 31

31Administrator:

Password protects the Display, Alarms and Configuration pages

along with

protecting the

Telnet and Serial access

.Control Access:

Password protects the Control Actions and Control Settings pages.

View

-

Only:

Password protects the Sensors, PDA, WAP and XML pages.

Figure

27

: Account Configuration

User account names m

ay include alphanumeric characters, spaces and underscores. Passwords

may include alphanumeric characters and underscores.

Note:

The Administrator account must be

active

to enable the Control Access and View

-

Only accounts.

Note:

The Control Access accoun

t must be

active

to enable the View

-

Only account.

Note:

The account names “root” and “admin” are disabled for security reasons and cannot be re

-

enabled.

Warning:

Record your passwor

ds. To reset lost passwords, follow the instructions for resetting the uni

t’s

IP address and passwords given in the

Default

IP Address

section. To generate a temporary recovery

password to access the unit, c

ontact customer service from a location where the unit can be accessed via

the internet.

Telne

t

Page 32

32

The unit provides a Telnet server for basic monitoring via the command line. The Administrator

account must be enabled to use the Telnet interface

. Type “help” after logging in

to the unit to

see a list of available commands. The Telnet service can be

disabled under “

Web Server

” on

the

Network

tab

of the

Configuration

page

.

Note:

All data sent via Telnet is unencrypted. Some settings can be changed and user names and

network settings are available via Telnet. In

un

secure environments, it is recommen

ded that Telnet be

disabled.

Camera Configuration

Enter the domain names/IP addresses and models of up to four IP

-

addressable network

cameras

in the “Cameras” section of the

M

onitoring

tab on the

Configuration

page

. The unit

will present a linked snapsho

t from each camera on the

Sensors

page.

Figure

28:Configuration and Supported Models

Note:

Each camera must be set to allow anonymous access to enable this feature.

Admin

Information

Page 33

33

Information entered

in the “Admin Inf

o” section of the

A

dmin

tab of the

Configuration

page

will

show up at the bottom of the unit’s web interface.

Figure

29:Admin

Information Fields

Kilowatt

-

Hours Reset

The7M,

7N,7Sand7W

’s kilowatt

-

hours measurements are zer

oed at the factory and can be

reset at any time

, should it become necessary

.

On the

Admin

tab of the

Configuration

page,

s

imply

hit the button that corresponds to the desired circuit to be reset.

Figure

30

: Kilowatt Hours Reset

XML File Backup

The7S,7M, 7N

or7Wunit’s configuration is stored in the XML file. The XML file can be

downloaded and stored in order to backup the unit’s current configuration settings. On the

Admin

tab of the

Configurat

ion

page, simply hit the Download Current XML File button to

download the XML file.

A previously downloaded XML file can be uploaded to the unit in order to restore the unit’s

configuration to match the configuration contained in the XML file. On the

A

dmin

tab of the

Configuration

page, click the Upload Local XML file button to upload a local XML file.

Note:

XML files are unit specific, and

should only be uploaded to the unit that it was downloaded from.

Page 34

34

Figure

31

: XML Fil

e Upload

SSL Certificate Upload

The unit will automatically generate a unique SSL Certificate and Private Key. Alternatively, a

custom SSL Certificate and Private Key can be uploaded to the

unit

by pressing the

“

Upload SSL

Files

”

button on the

Admin

tab

of the

Configuration

page.

The SSL certificate and key file must

be in

Distinguished Encoding Rules (DER)

format.

The SSL Certificate and Private Key can be

cleared by clicking the

“

Erase SSL Data

”

button on the

Admin

tab of the

Configuration

page.

F

igure

32

: SSL Certificate and Private Key Upload

Page 35

35

Alarms

Alarm Notifications

The7S,7M, 7N

and7Wsupport

three types of alarm notification:

E-Mail

:

The unit can be configured to send alarm e

-

mails to up to five recipients.

SNMP

:

The unit can be configured to send SNMP traps to up to

two

trap servers

.

The unit is capable of any combination of the above alarms at once. Alarm type combinations

are selected per alarm via the check boxes which are displayed for each alarm on the Al

arms

page.

Figure

33

: Alarm State Menu

Alarm Types

The7M,7N,7S

and7Wprovide

three

types of alarm messages via E

-

Mail and SNMP:

Trip:

Occurs when a sensor value goes above a high trip threshold

or below a low trip

threshold.

Unplugged:

Occurs when a sensor with an alarm set loses contact with the main unit due

to the sensor being physically unplugged or another communications error.

Unplugged

alerts can be enabled or disabled on the

Alarm

s

page

.Clear:

Occurs when a sensor already in the Tripped or Unplugged state goes back into its

normal range.

Alarms can be added for each

internal device

or

external sensor displayed on the

Alarms

page.

An alarm is added by pressing the “Add New Alarm Button

” and selecting the sensor value to be

monitored from

the

drop down menu.

Thresholds

The user

must

set

a trip threshold and type for each alarm that is added to the

Alarms

page.

The threshold type is chosen as either “

Below

” or “

Above

” from a drop down

menu when the

alarm is created. The threshold value is typed into a data window when the alarm is created.

Alarms are triggered based on the

selected sensor’s data and the trip threshold type and value.

Alarm settings can be edited or deleted at any tim

e.

A

nalysis of each unit is recommended before setting alarm

threshold

s

as some of the values

monitored by the unit are relative values, whose scale will differ slightly between units. Allow

each unit to operate under normal, steady state conditions

for several hours before setting

Page 36

36

alarm thresholds.

By allowing the sensors to operate for several hours, the user can better

understand what the normal variations are; thereby allowing the user to choose alarm

thresholds that will not trigger numerous fal

se alarms.

Alarms can be set to only send notification

if the a

larm is in a tripped state for a certain amount

of time. The user sets the

amount of time required

by entering a value from 0

-

240 minutes in

the text box

on the

Alarms

page.

Additionally,

alarm notifications can be set to send multiple

notifications for an alarm that remains in a tripped state. The alarm notifications are set to

repeat at intervals of no repeat, 10, 30, or 60 minutes by selecting the desired option in the

drop down menu o

n the

Alarms

page.

Note:

Changes in settings take a few moments to become active. Rapidly resetting alarm values may not

provide the desired results. Allow up to 2 minutes after changing a setting before modifying it again.

Page 37

37

Sensors

Overview

All inter

nal sensors are measured every 15 seconds. External sensors are measured every 15

to 30 seconds

,

depending on the

number

of devices connected. Sensor data collected by the

7M,7N,7Sor7Wunit

gives useful trend analysis data. While all values are not

absolute in

relation to a known unit, trend analysis of the data allows users to view changes and draw

useful conclusions about what is happening

over time

in the monitored environment.

Note:

DM series units are connected as sensors and collect a large am

ount of data

.These will take

longer

than the usual 15 to 30 second for the

7M,

7N,

7S or 7W

units to measure.

Internal Sensors

The

7M,

7N,

7S and 7W

units

contain

internal sensors that are configured in two different ways

:

Wye Configuration

Total Unit

o

Kilowatt

-

Hours:

Cumulative sum of Real Power

for all lines

.oReal Power:

Total average of instantaneous voltage and current on all lines over

last 1.5 seconds.

Line Level (A, B, C

):

o

Kilowatt

-

Hours:

Cumulative sum of Real Power.

o

Volts

:

Measures instantaneo

us RMS voltage.

o

Volts (Peak):

Reports the highest reported voltage since the last time the data

was updated, typically every 15 seconds.

o

Real Power:

Average of instantaneous voltage and current over last 1.5 seconds.

o

Apparent Power:

The product of instanta

neou

s RMS Voltage and RMS Current.

o

Power Factor:

The ratio of Real Power to Apparent Power.

o

Amps:

Measures instantaneous RMS current.

o

Amps (Peak):

Reports the highest reported current since the last time the data

on the screen

Delta Configuration

Total Un

itoKilowatt

-

Hours:

Cumulative sum of Real Power

for all lines

.oReal Power:

Total average of instantaneous voltage and current on all lines over

last 1.5 seconds.

Phase Level (AB, BC, CA):

o

Kilowatt

-

Hours:

Cumulative sum of Real Power.

o

Volts

:

Measures insta

ntaneous RMS voltage.

o

Volts (Peak):

Reports the highest reported voltage since the last time the data

was updated, typically every 15 seconds.

o

Real Power:

Average of instantaneous voltage and current over last 1.5 seconds.

o

Apparent Power:

The product of in

stantaneous RMS Voltage and RMS Current.

o

Power Factor:

The ratio of Real Power to Apparent Power.

Line Level (A, B, C):

o

Amps:

Measures instantaneous RMS current.

The7Wcontains the following additional onboard sensors:

Page 38

38Group

Volts

:

Measures instantane

ous RMS voltage

for a group of outlets

.Group

Amps:

Measures instantaneous RMS current

for a group of outlets

.Outlet Amps:

Measures instantaneous RMS current for each outlet.

Outlet Real Power:

Average of instantaneous voltage and current over last 1.5 se

conds for

each outlet.

Outlet Kilowatt

-

Hours

:

Cumulative sum of Real Power for each outlet.

Data Logging and Display

All

sensor

data collected by the unit can be graphed

, except

kilow

att-hours

and outlet level data

(7Wonly)

. The

Log

ging

page allows

the user to select

data to be logged. The user can also

choose to view a graph of any logged data

.

Selected sensor values are logged into the data

file at a rate of one point per minute

.

The number of selected sensors determines the

maximum data loggin

g time span.

This period is calculated and displayed on the

Logging

page.

The oldest data will be deleted w

hen the onbo

ard memory fills up in order to make

room for

new data.

Sensor

values

can also be

selected for

display

on the

local LCD

.

Page 39

39

Remote O

utlet Switching

(7Sand

7W

Only)

Actions

The7Sand7WSeries are

equipped with individually switchable outlets

.

There are

seven

possible actions for any given outlet, available from the “Action” drop down box on the

Actions

tab

of the

Control

page

:

F

igure

34

: Outlet Actions

On–Immediate:

Turns on all

selected

outlets

with no delay.

On–Delayed:

Turns on all

selected

outlets with applicable delays.

Off–Immediate:

Turns off all

selected

outlets

with no delay.

Off–Dela

yed:

Turns off all

selected

outlets with applicable delays.

Reboot:

Cycles power to the selected outlets

with one applicable delay. Each out

let is

powered

-

down immediately, then

“Reboot Duration”

sets the delay

after power

-

down and

before power

-up.Rebo

ot-Delayed:

Cycles power to the selected outlets with two applicable delays.

“Reboot” delays before power down, and “Reboot Duration” sets the delay after power

-

down

and before power

-up.Reset kWh:

Resets the kWh total on all selected outlets to 0. (

7Wonly)Cancel Actions:

Cancels any actions currently in progress on the selected outlets.

Figure

35

: Outlet Action Confirmation

To perform an action, select the check box next to the outlets needing attention, select an

action

from the drop down box and click the “Execute” button. A dialog box will appear asking

for confirmation of the selected actions. Click OK to

execute the action. Click cancel to make

changes or ignore the action

.

Note:

“Reboot”

, Reboot

-

Delayed”

and “

On/

Off-Delayed” actions are subject to the delays set on the

Settings

Tab

of the

Control

page

.

Page 40

40

Configuration

The

7S and 7W

series

unitslist

all available outlets under “Configuration” on the

Settings

tabofthe

Control

page

. Each outlet has five fields ass

ociated with it:

Figure

36

: Outlet Configuration

Name:

A friendly name to easily identify what is plugged into the outlet. For example:

“Mail Server”

URL:

A URL associated with the equipment plugged

into the outlet. This will appear as a

clickable link on the Control Actions Tab next to the outlet status information.

Power

-

On Delay:

Delay from the time the “On

–

Delayed” action is executed until the

outlet will turn on.

Power

-

Off Delay:

Delay from t

he time the “Off

–

Delayed” action is executed until the

outlet will turn off.

Reboot:

Delay from the time the

“Reboot

-

Delayed” action is executed to the time the

selected outlets will be turned off.

Reboot D

uration

:

Delay from the time the

“Reboot” or

“Re

boot

-

Delayed

” action is

executed and

each selected outlet has

turned off until the outlet will turn back on.

Note:

A

ll delays are in seconds.

Power

-

On Actions

The

state of each of the

unit’s

switched outlets

on

unit power

-

up is user

configurable by sett

ing

a power

-

on action.

Available settings are:

Delay

:

Used in conjunction with On and Last actions to allow

sequencing of outlet power

-upto prevent overloading circuit breakers with inrush current.

Off:Leaves the outlet off until turned on manually via

the Control Actions page.

On:Turns the outlet on.

Last

:

Returns the outlet to its state prior to the unit losing power.

Figure

37

: Outlet Power

-

On Action Configuration

Tip:

To emulate legacy

7S or 7W

behavior for a particular

outlet, set

the

delay to 0 and action to On.

Note:

Outlets with their delay values set to 0 will perform the selected action

immediately upon receiving

power

.

Page 41

41

Note

for units with built

-

in circuit breakers

:

Should one of the unit’s circuit breakers trip,

upon being

reset any outlets powered by that breaker will perform their power

-

on actions.

Page 42

42

Accessories

Serial Communication

(Delta Configured Units Only)

The Delta configured units provide an out

-of-

band, serial line, monitoring interface.

The unit

pro

vides an RJ

-

45 port for RS

-

232 serial communication, giving monitoring via the command

line

similar to the Telnet service.

If the administrator name and password are setup then they

must be used to access the serial command line.

Type “help” after loggin

g-in to the unit to see

a list of available commands.

Note:

All data sent via the serial port is unencrypted. Some settings can be changed and user names and

network settings are available.

Figure

38

: Serial Command

IP-Add

ressable

Network

Camera

s

The unit is able to interface with up to four IP

-

addressable network cameras. A live snapshot

from each camera will be displayed on the unit’s

Sensors

page underneath the main unit’s

graph.

Clicking on

a snapshot opens the camera

’s website in a new browser window.

Page 43

43

Figure

39

: Camera Images

Camera model and IP address are entered on the

Monitoring

tab of the

Configuration

page

.

Note:

Some cameras require additional software downloads

to display live vid

eo in a web browser.

Alternate

Data

Formats

In addition to the full access, control and configuration available via a desktop web browser,

7M,7N,7Sand7WSeries products present

data in multiple formats

for easy integration with

other monitoring syste

ms.Data formats

available via links

on

the unit’s

web

page

are:

Figure

40

: Alternate Format Links

PDA

/Phone

: Presents data in a format best

-

suited for

PDA

or cellular phone

web browsers.

XML: Extensible Markup Language. Pres

ents data in a structured tree for use with

automated scripts and monitoring systems.

MIB: Management Information Base. Downloads the MIB for use with SNMP monitoring

tools.

Page 44

44

Technical Support

Firmware Version

The

firmware v

ersion is located in the up

per right section of the web

interface

header

,

represented by v3

.y.xx.

Before contacting support,

it is recommended that the PDU first be

updated

to the latest firmware version.

If this is not possible, please have the existing

firmware version number fo

r the unit

available when contacting

technical support

.

Figure

41

: Web Page Header

Firmware Updates

Keep your unit updated with the latest firmware releases or sign up for notifications.

www.siemon.c

om

Resetting PDU

Should the PDU loose communication

,

the processor may be manually rebooted without

affecting power to the outlets.

Pressing the ‘Reset’ button on the face of the unit wil

l cause the

processor to reboot. T

he

web interface

will remain off

-

line during boot up

.

Service and

Maintenance

No service or maintenance is required. Do not attempt to open the PDU or you may void the

warranty. No serviceable parts inside. It is recommended that power be removed from the

unit before installing or re

moving any equipment.

More Technical Support

http://www.siemon.com

(866)

474-1197

Email:

tech

support@siemon.com

Or c

ontact your distributor.

Page 45

45

Table of Figures

Figure 1: Full Length Bracket

................................

................................

................................

.7Figure 2: Toolless Mounting Hardware

................................

................................

...................

7

Figure 3:

Adjustable Mount Brackets

................................

................................

.......................

8

Figure 4: Windows XP network settings for initial setup.

................................

..........................

11

Figure 5: MacOS X network settings for i

nitial setup

................................

...............................

12

Figure 6: Internet Explorer's LAN Settings for selecting proxy settings

................................

......

12

Figure 7: Sensors Page

–

Wye Configur

ation

................................

................................

..........

13

Figure 8: Sensors Page

–

Delta Configuration

................................

................................

........

14

Figure 9: Sensors Page

–

Group and Sensor Data

................................

................................

...15Figure 10: Logging Page

................................

................................

................................

.....17Figure 11: Display Page

................................

................................

................................

......

18

Figure 12: Alarms Page

................................

................................

................................

.......

19

Figure 13: Control Actions Tab

................................

................................

.............................

20

Figure 14: Control Settings Tab

................................

................................

...........................

21

Figure 15: Configuration Network Tab

................................

................................

...................

22

Figure 16: Configuration Monitoring Tab

................................

................................

................

23

Figure 17: Configuration Diagnostics Tab

................................

................................

..............

24

Figure 18: Configuration Event Log Tab

................................

................................

................

25

Figure 19: Configuration Admin Tab

................................

................................

.....................

26

Figure 20: Network Configuration

................................

................................

.........................

27

Figure 21: Manual Time Settings

................................

................................

..........................

28

Figure 22: NTP Time Settings

................................

................................

..............................

28

Figure 23: E

-

Mail Configuration

................................

................................

............................

29

Figure 24: Email Report Settings

................................

................................

..........................

30

Fig

ure 25: SNMP Configuration

................................

................................

............................

30

Figure 26: Initial SNMP V3 Data

................................

................................

...........................

30

Figure 27: Account Configuration

................................

................................

.........................

31

Figure 28: Configuration and Supported Models

................................

................................

.....32Figure 29: Admin Information Fields

................................

................................

.....................

33

Fig

ure 30: Kilowatt Hours Reset

................................

................................

...........................

33

Figure 31: XML File Upload

................................

................................

................................

..34Figure 32: SSL Certificate and Private Key Upload

................................

................................

..34Figure 33: Alarm State Menu

................................

................................

...............................

35

Figure 34: Outlet Actions

................................

................................

................................

....39Figure 35: Outlet

Action Confirmation

................................

................................

...................

39

Figure 36: Outlet Configuration

................................

................................

............................

40

Figure 37: Outlet Power

-

On Action Configuration

................................

................................

....40Figure 38: Serial Command

................................

................................

................................

.42Figure 39: Camera Images

................................

................................

................................

..43Figure 40: Alternate Form

at Links

................................

................................

........................

43

Figure 41: Web Page Header

................................

................................

...............................

44

Revision History

Revision

Date

Notes

Approved By

0.0

8/14/12

Initial

Version

LM

Page 46

46

Loading...

Loading...