Siemens Building Technologies Two-way Valves Data Sheet

Siemens

Product Guard

Warranty

Two-way Valves

1/2 to 1-inch

Normally Open or Normally Closed

Powermite

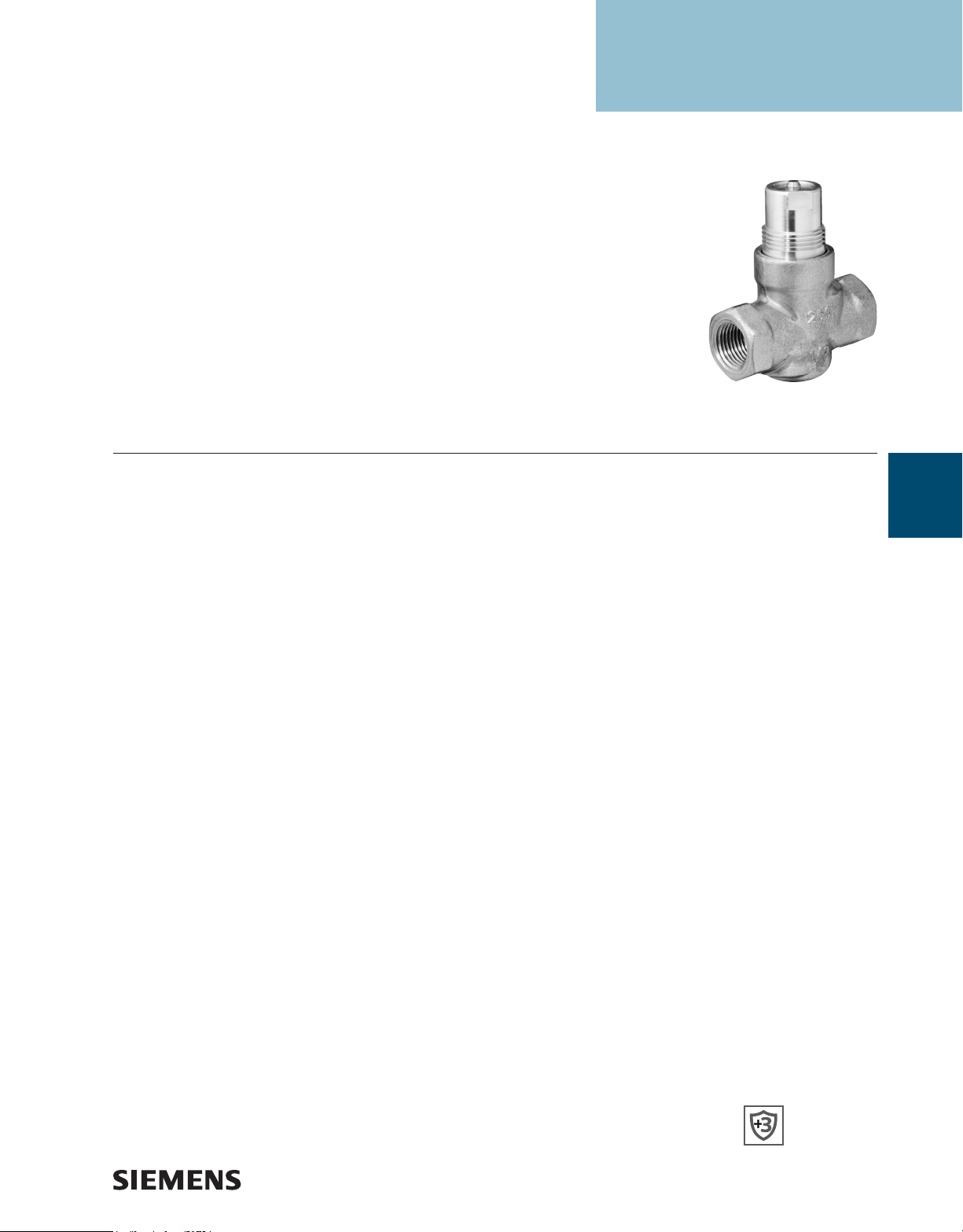

MT Series Globe

Powermite MT Series

Two-way Globe Valve.

Description

The Powermite MT Series Two-way Globe Valves are

designed to work with either a pneumatic or electronic

actuator with a 7/32-inch (5.5 mm) stroke. Compatible

actuators deliver a minimum of 67 lbf. (300 N) of force.

Features

• Direct-coupled universal bonnet/No tools required

for installation

• Choice of brass or stainless steel trim

• ANSI Leakage Class IV (0.01% of Cv)

• ANSI Class 250 body

• Available in 3 to 8 psig, 8 to 13 psig or 10 to 15 psig

spring ranges with pneumatic actuation

• Rated for 15 psig steam with stainless steel trim

• Interchangeable pneumatic or electronic actuators

• Orderable as a valve only or as a complete

valve/actuator assembly

Applications

The Powermite MT Series Globe Valves are used

for hot or chilled water or low pressure steam (<15 psig

with stainless steel trim only) control on convectors, fan

coil units, unit conditioners, radiation, reheat coils, and

similar terminal units.

Recommendation:

Only use the MT Series Valve Actuators. When using

this valve with a pneumatic actuator, note that MT valve

bodies have the spring in the body, rather than the

actuator. To order the correct valve body, select the

proper spring range.

Alternate spring ranges for pneumatic sequencing are

available as valve and actuator factory assemblies only.

A-135

Valves

Siemens

Product Guard

PLUS 3 Warranty

www.usa.siemens.com/hvac

Two-way MT Series Valve Specifications

A-136

Valve Size .............................................................1/2 to 1" (15 to 25 mm)

Body Style ....................................................................................... Globe

Seat Style ...........................................................................Metal to Metal

Action ........................................................................................... NO/NC

Valve Body Rating .......................................................... ANSI Class 250

Stem Travel (Stroke) .........................................................7/32" (5.5 mm)

Materials

Body ...................................... Forged Brass C37700 (1/2 and 3/4 inch)

or UNS CA 844 Bronze (1 inch)

Trim ................................................................ Stainless Steel or Brass

Stem ...........................................Stainless Steel ASTM A582 Type 303

Packing ........................................................................... EPDM O-rings

Controlled Medium .................Water, Steam, Glycol Solutions up to 50%

Spring Range

Standard

Normally Closed ....................................... 10 to 15 psig (69 to 103 kPa)

Normally Open ............................................... 3 to 8 psig (21 to 55 kPa)

Optional

Normally Closed ............................................. 3 to 8 psig (21 to 55 kPa)

8 to 13 psig (55 to 90 kPa)

Normally Open ............................................. 8 to 13 psig (55 to 90 kPa)

10 to 15 psig (69 to 103 kPa)

Accessories & Service Kits

Medium Temperature Range ........................... 35 to 250°F (2 to 120°C)

Max. Recommended Differential

Pressure for Liquid Modulating Service

Brass Trim ................................................................... 25 psi (173 kPa)

Stainless Steel Trim ..................................................... 50 psi (345 kPa)

Steam Stainless Steel Trim ......................................... 15 psi (103 kPa)

Rangeability

Cv<1 ............................................................................................... >50:1

Cv>1 ............................................................................................. >100:1

Close-off Ratings ......................................... According to ANSI/FCI 70-2

Leakage Rate ....................................................... Class IV (0.01% of Cv)

Flow Characteristics .................................... Modied Equal Percentage

Mounting Location .............................................. NEMA 1 (Interior Only)

Refer back to the Selection Charts at the beginning of this section

to make sure the conguration is valid.

A-257

Valves

www.usa.siemens.com/hvac

Loading...

Loading...