Page 1

Siemens

Product Guard

Warranty

Two-way Flanged Iron Globe Valves

2-1/2 to 6-inch

Normally Open or Normally Closed

Flowrite Globe

Flowrite Two-Way Flanged Iron Valve.

Description

Designed to work with either pneumatic or electronic

actuators, the Flowrite Two-way Valves are available

in both ANSI Class 125 and 250 for normally closed or

normally open action.

Features

• Valve ange face-to-face dimensions meet

ANSI/ISA S75.03 standards

• Direct-coupled, universal bonnet

• Bronze or stainless steel trim

• Standard- or high-temperature packing

• Close-off up to 250 psi

• Fully serviceable

• Greater than 100:1 rangeability

• Equal percentage or linear ow characteristics

• 2-1/2 and 3-inch sizes available with 3/4-inch

stroke only

• 4-, 5-, 6-inch are available with a 1-1/2-inch stroke

• ANSI Leakage Class IV (0.01% of Cv)

• Cartridge-type packing for easy service

• Orderable as a valve only or as a complete

valve/actuator assembly

Applications

The Flowrite Two-way valves are recommended for water,

steam, and glycol solutions up to 50 percent. Additional

specications include the following:

• Water inlet pressures up to ANSI 125 and ANSI 250

cast iron body rating

• Water modulating differential pressure up to 25 psi

(172 kPa) for bronze trim and 50 psi (345 kPa) for

stainless steel trim

• Steam inlet to 100 psi with modulating differential

pressure up to 50 psi (345 kPa)

A-165

Valves

Siemens

Product Guard

PLUS 3 Warranty

www.usa.siemens.com/hvac

Page 2

Two-way Flanged Iron Globe Valve Specifications

A-166

Valve Size ........................................................2-1/2 to 6" (65 to 150 mm)

Body Style ....................................................................................Flanged

Seat Style ................................................................................Single seat

Action ...................................Normally Closed (NC); Normally Open (NO)

Valve Body Rating ...............................................ANSI Class 125 or 250

Stem Travel (Stroke)

2-1/2 and 3" ........................................................................3/4" (20 mm)

4, 5 and 6" .......................................................................1-1/2" (40 mm)

Materials

Body .......................................................Cast Iron ASTM A126 Class B

Trim .............................................................. Bronze or Stainless Steel

Stem ........................................... Stainless Steel ASTM A582 Type 303

Packing

Normal Duty Packing....................................................... EPDM O-rings

Steam Packing .....................................PTFE V-rings and EPDM O-ring

Operating

Controlled Medium .......................................... Saturated Steam, Water,

Glycol Solutions up to 50%

Medium Temperature Range

Normal Duty Packing...................................... 20 to 250°F (-7 to 120°C)

Steam Packing ........................................................337°F (170°C) max.

Max. Inlet Pressure

Water .............................................Refer to Flowrite Reference Section.

Steam ....................................................................... 100 psig (690 kPa)

Max. Recommended Differential

Pressure for Modulating Service

Bronze Trim

Liquid ....................................................................... 25 psi (173 kPa)

Steam ...................................................................... 15 psi (103 kPa)

Stainless Steel Trim

Liquid ....................................................................... 50 psi (345 kPa)

Steam ...................................................................... 50 psi (345 kPa)

Rangeability .................................................................................. >100:1

Close-off Ratings ......................................... According to ANSI/FCI 70-2

Close-off Pressure ....................Refer to the Flowrite Reference Section.

Leakage Rate ....................................................... Class IV (0.01% of Cv)

Flow Characteristics ....................................Equal Percentage or Linear

Dimensions

Face-to-face ................................................................ ANSI/ISA S75.03

Valves

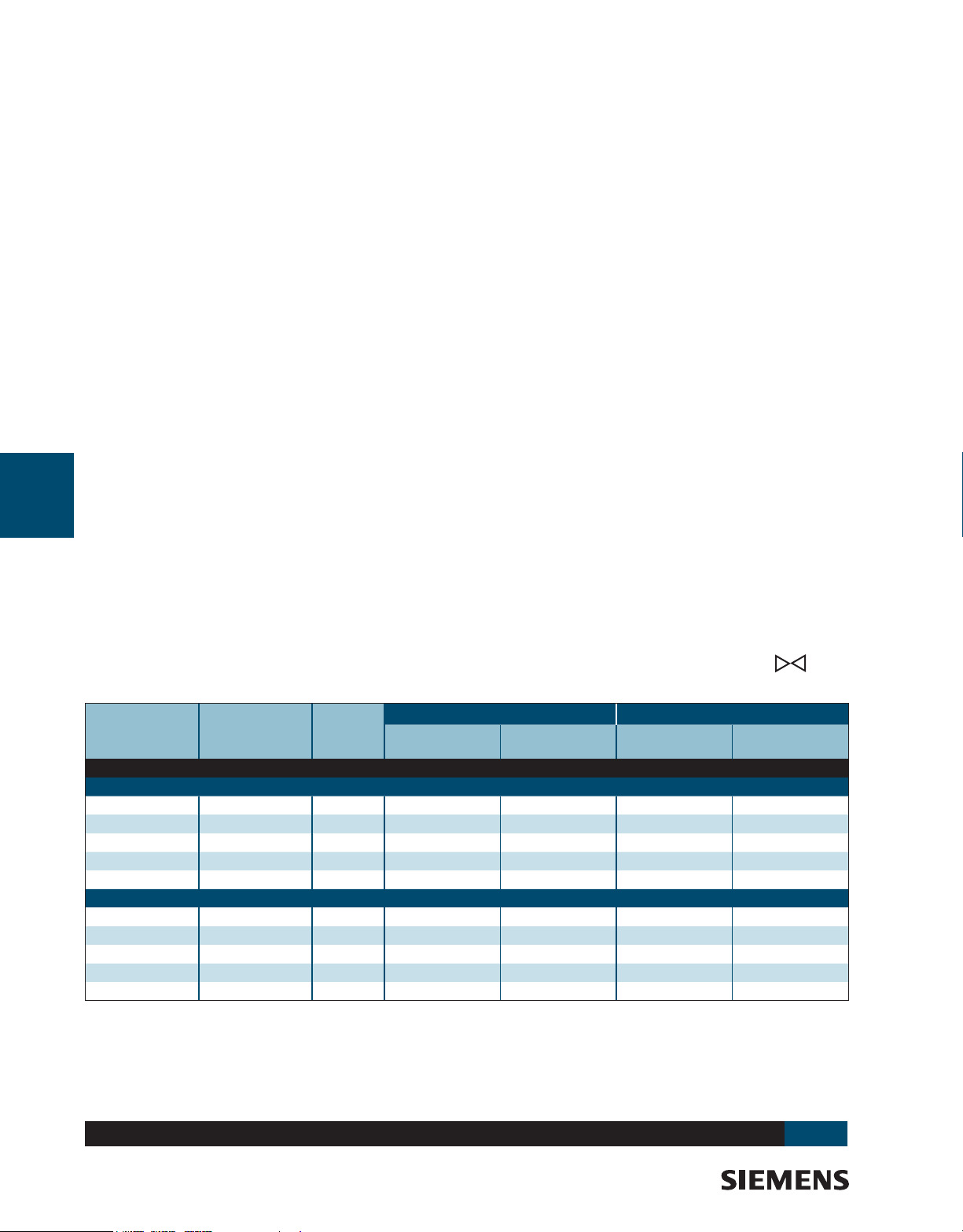

Two-way Flanged Iron Globe Valve Body Product Ordering

Normally Open/Normally Closed, Equal Percentage

Valve Size

in. (mm)

2-1/2 (65)

3 (80) 100 (86) 3/4 599-05981 599-05991 599-05941 599-05951

4 (100) 160 (140) 1-1/2 599-05982 599-05992 599-05942 599-05952

5 (125) 250 (215) 1-1/2 599-05983 599-05993 599-05943 599-05953

6 (150) 400 (340) 1-1/2 599-05984 599-05994 599-05944 599-05954

2-1/2 (65)

3 (80) 100 (86) 3/4 599-05961 599-05971 599-05921 599-05931

4 (100) 160 (140) 1-1/2 599-05962 599-05972 599-05922 599-05932

5 (125) 250 (215) 1-1/2 599-05963 599-05973 599-05923 599-05933

6 (150) 400 (340) 1-1/2 599-05964 599-05974 599-05924 599-05934

Flow Rate

Cv (Kvs)

63 (54) 3/4 599-05980 599-05990 599-05940 599-05950

63 (54) 3/4 599-05960 599-05970 599-05920 599-05930

Stroke

(in.)

Standard-Temperature Packing — 20 to 250ºF (-7 to 120ºC)

Normally Open

ANSI Class 125 ANSI Class 250

Part No.

Bronze

Stainless Steel

Normally Closed

Part No.

Normally Open

Part No.

Normally Closed

Part No.

Accessories & Service Kits

www.usa.siemens.com/hvac

A-257

Page 3

Two-way Flanged Iron Globe Valve Body Product Ordering

Normally Open/Normally Closed, Linear, Stainless Steel

Valve Size

in. (mm)

2-1/2 (65)

3 (80) 100 (86) 3/4 599-06061 599-06071 599-06141 599-06151

4 (100) 160 (140) 1-1/2 599-06062 599-06072 599-06142 599-06152

5 (125) 250 (215) 1-1/2 599-06063 599-06073 599-06143 599-06153

6 (150) 400 (340) 1-1/2 599-06064 599-06074 599-06144 599-06154

2-1/2 (65)

3 (80) 100 (86) 3/4 599-06041 599-06051 599-06121 599-06131

4 (100) 160 (140) 1-1/2 599-06042 599-06052 599-06122 599-06132

5 (125) 250 (215) 1-1/2 599-06043 599-06053 599-06123 599-06133

6 (150) 400 (340) 1-1/2 599-06044 599-06054 599-06124 599-06134

Flow Rate

Cv (Kvs)

63 (54) 3/4 599-06060 599-06070 599-06140 599-06150

63 (54) 3/4 599-06040 599-06050 599-06120 599-06130

Stroke

(in.)

Standard-Temperature Packing — 20 to 250ºF (-7 to 120ºC)

High-Temperature Packing — 337ºF (170ºC)

Normally Open

ANSI Class 125 ANSI Class 250

Part No.

Normally Closed

Part No.

Normally Open

Part No.

Normally Closed

Part No.

Flowrite Valve Actuator Product Ordering

Description Part No. Actuator Prex Code

20 mm Stroke/Normal Temp. 599-01050 277

Pneumatic

20 mm Stroke/Hi-Temp. 599-01051 278

A-167

Valves

8"

12"

8"

12"

Pneumatic

Pneumatic

w/ Positioner

Pneumatic

w/ Positioner

Electro-Hydraulic

20 mm Stroke 599-01010 279

40 mm Stroke 599-01000 281

20 mm Stroke/Normal Temp. 599-01050 + 599-00426 283

20 mm Stroke/Hi-Temp. 599-01051 + 599-00426 284

20 mm Stroke 599-01010 + 599-00423 285

40 mm Stroke 599-01000 + 599-00423 287

20 mm Stroke

24 V, Floating 3P, Spring Return SKD82.51U 276

24 V, Floating 3P, Spring Return SKB82.51U 289

24 V, Floating 3P, Non-Spring Return SKD82.50U 275

24 V, Floating 3P, Non-Spring Return SKB82.50U 290

24 V, 0-10 V, 4-20 mA, Non-Spring Return SKD60U 267

24 V, 0-10 V, 4-20 mA, Spring Return SKD62U 274

24 V, 0-10 V, 4-20 mA, Spring Return SKB62U 291

40 mm Stroke

24 V, Floating 3P, Spring Return SKC82.61U 292

24 V, Floating 3P, Non-Spring Return SKC82.60U 293

24 V, 0-10 V, 4-20 mA, Spring Return SKC62U 294

www.usa.siemens.com/hvac

Page 4

A-168

Valves

Two-way Flanged Iron Globe Valve Body Dimensions and Weights

ANSI Class 125 ANSI Class 250

Valve Size

2-1/2"

(65 mm)

3"

(80 mm)

4"

(100 mm)

5"

(125 mm)

6"

(150 mm)

2-1/2"

(65 mm)

3"

(80 mm)

4"

(100 mm)

5"

(125 mm)

6"

(150 mm)

A B C A B C

10-7/8"

(276 mm)

11-3/4"

(299 mm)

13-7/8"

(352 mm)

15-3/4"

(400 mm)

17-3/4"

(451 mm)

10-7/8"

(276 mm)

11-3/4"

(299 mm)

13-7/8"

(352 mm)

15-3/4"

(400 mm)

17-3/4"

(451 mm)

Dimensions

11"

(281 mm)

12-1/4"

(312 mm)

13-9/16"

(345 mm)

15-3/16"

(385 mm)

16-3/4"

(426 mm)

10-5/8"

(269 mm)

11-15/16"

(303 mm)

13-15/16"

(354 mm)

15-1/4"

(338 mm)

17-1/16"

(433 mm)

4-7/8"

(123 mm)

5-5/16"

(135 mm)

6-5/16"

(160 mm)

7"

(177 mm)

7-7/8"

(200 mm)

4-7/8"

(125 mm)

5-5/8"

(142 mm)

6-5/8"

(168 mm)

7-1/2"

(185 mm)

8-3/16"

(207 mm)

Weight

Normally Open

60 lb.

(27 kg)

76 lb.

(34 kg)

124 lb.

(56 kg)

155 lb.

(70 kg)

212 lb.

(96 kg)

Normally Closed

58 lb.

(26 kg)

75 lb.

(34 kg)

123 lb.

(56 kg)

153 lb.

(69 kg)

209 lb.

(95 kg)

11-1/2"

(292 mm)

12-1/2"

(318 mm)

14-1/2"

(368 mm)

16-5/8"

(422 mm)

18-5/8"

(473 mm)

11-1/2"

(292 mm)

12-1/2"

(318 mm)

14-1/2"

(368 mm)

16-5/8"

(422 mm)

18-5/8"

(473 mm)

Dimensions

11"

(281 mm)

12-1/4"

(312 mm)

13-5/8"

(344.7 mm)

15-3/16"

(385 mm)

16-3/4"

(426 mm)

11"

(279 mm)

12-7/16"

(315 mm)

14-3/8"

(364 mm)

15-3/4"

(399 mm)

17-1/2"

(444 mm)

4-7/8"

(123 mm)

5-5/16"

(135 mm)

6-5/16"

(160 mm)

7"

(177 mm)

7-7/8"

(200 mm)

5-3/8"

(135 mm)

6"

(154 mm)

7"

(178 mm)

7-3/4"

(196 mm)

8-5/8"

(218 mm)

Weight

76 lb.

(34 kg)

99 lb.

(45 kg)

160 lb.

(73 kg)

208 lb.

(94 kg)

302 lb.

(137 kg)

74 lb.

(34 kg)

98 lb.

(44 kg)

159 lb.

(72 kg)

207 lb.

(94 kg)

299 lb.

(136 kg)

www.usa.siemens.com/hvac

Loading...

Loading...