Page 1

Modulating Control Valves

with Magnetic Actuators, Positioning Control and

Position Feedback for Domestic Water

MXG461B Series

MXG461B Series Modulating Control Valve.

Description

The MXG461B Modulating Control Valve is a control valve

with magnetic actuator, for modulating control of domestic

water, cold water and hot water systems.

Features

• Fast positioning time (< 2 seconds)

• Selectable valve characteristic: Equal

percentage or linear

• Selectable control signal: 0/2 to 10 Vdc or

0/4 to 20 mA

• High resolution (>1000:1)

• High rangeability

• Wear-free inductive stroke measurement

• Spring return A

de-energized

• Positioning control and position

feedback signal

• Low-friction, heavy-duty and

maintenance-free

→

AB closed when

Applications

The MXG461B... Modulating Control Valves are throughport or mixing valves with magnetic actuators. The

actuator is equipped with an electronics module for

positioning control and position feedback. If the power is

off, the valve control path A

→

AB is closed.

The short positioning time, high resolution and high

rangeability make these valves ideal for modulating control

of domestic, hot and cold water systems.

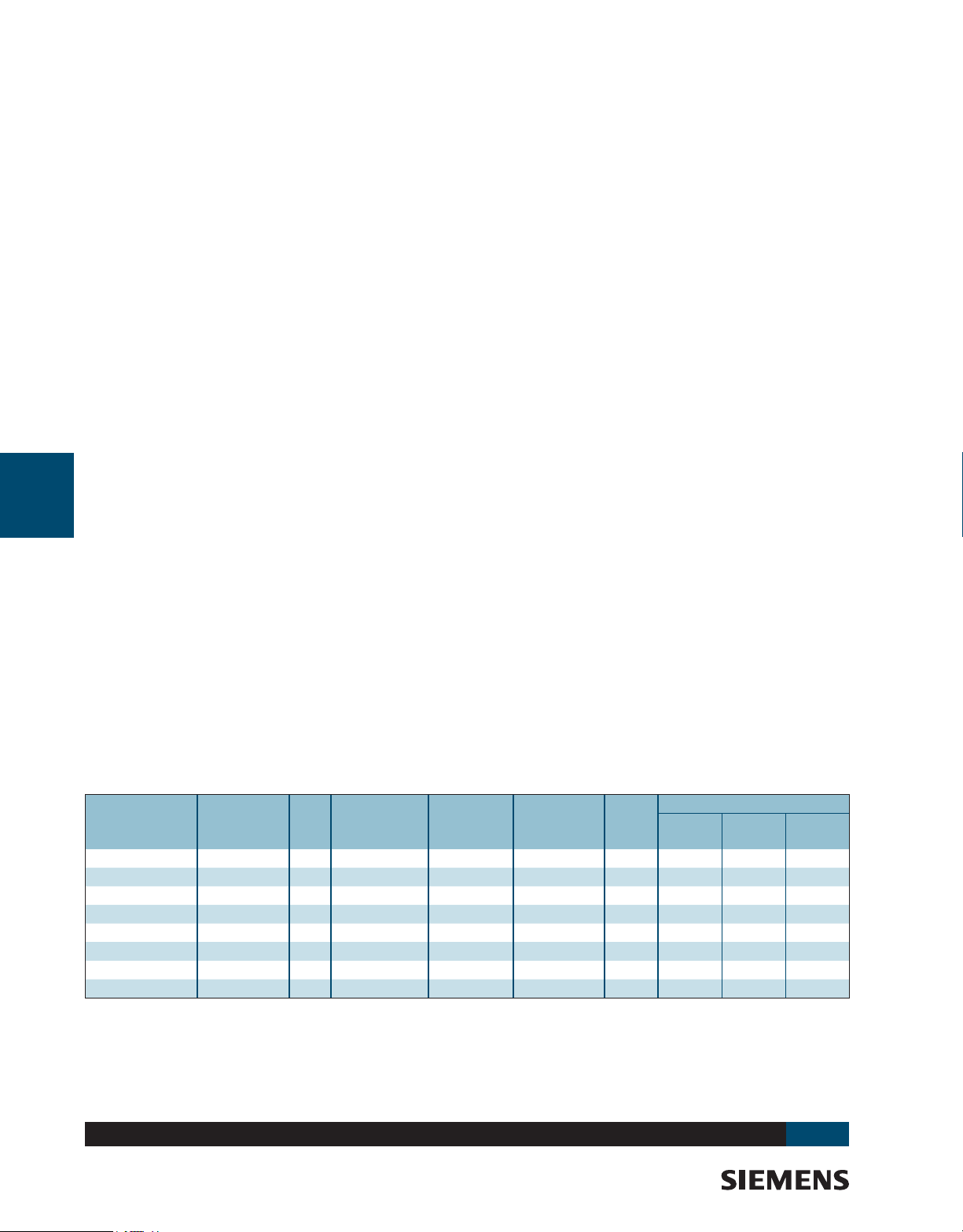

Wiring Diagram

Transformer

Controller

SSEN0346R1

F

G0

G

Y

M

U

G0

G

Y

M

U

Z

System neutral (SN)

System potential (SP)

0 to 10Vdc / 2 to 10Vdc

0 to 20 mA / 4 to 20 mA

Measuring neutral (= G0)

0 to 10Vdc / 2 to 10Vdc

0 to 20 mA / 4 to 20 mA

Override input

AC/DC 24 V Operating voltage

Control signal

Positioning feedback signal

A-229

Valves

www.usa.siemens.com/hvac

Page 2

Specications/Sizing

MXG461B Modulating Control Valve Specifications

A-230

Valves

Electrical

Low-voltage Use Only ..............................................Class 2 (SELV, PELV)

24 Vac

Operating Voltage........................................................24 Vac +20/-15%

Frequency ............................................................................ 45 to 65 Hz

Typical Power Consumption .................................................See Table 1

Standby ......................................................... <1 W (Valve Fully Closed)

Nominal Apparent Power..............................................See Sizing Table

Suitable Fuse .............................................................Slow, See Table 1

24 Vdc

Operating Voltage............................................................... 20 to 30 Vdc

Functional Data of Actuator

Input

Positioning Signal Y 0/2 to 10 Vdc or 0/4 to 20mA

Impedance

0/2 to 10Vdc ...............................................................100 kΩ//5nF

0/4 to 20 mA ................................................................240 Ω//5nF

Forced Control

Impedance ................................................................................ 22 kΩ

Closing the Valve (Z Connected to G0) .................. <1 Vac; <0.8 Vdc

Opening the Valve (Z Connected to G0) ..................> 6 Vac; >5 Vdc

No Function (Z Not Wired)....................... Positioning Signal Y Active

Output

Position Feedback Signal Voltage .................................... 0/2 to 10 Vdc;

Load Resistance > 500Ω

Current ..................................................................... 0/4 to 20 mA;

Load Resistance < 500Ω

Stroke Measurement ................................................................ Inductive

Nonlinearity ................................................................±3% of End Value

Functional Data of Valve

Nominal Pressure .......................................................ANSI 125 (PN 16)

Operating Pressure pemax1 .......................................... 232 psi (16 bar)

Pressure Differential Dpvmax ......................................See Sizing Table.

Leakage..................................................... A → AB Maximum 0.05% Cv

B → AB Depends on Application Data

(0.2% Cv)

Water Temperature2 ....................................... -4 to 248°F (-20 to 120°C)

Valve Characteristic3 .................Equal Percentage or Linear, Optimized

...................................................................Near the Closing Point

Resolution .......................................................................................1:1000

Type of Operation ..................................................................Modulating

Position De-energized ...................................................... A → AB Closed

Orientation ................................................................Upright to Horizontal

Positioning Time ................................................................... < 2 Seconds

Materials

Body ....................................................................................Red Bronze

Cover Flange ........................................................................Red Bronze

Seat/Inner Valve ..............................................................Stainless Steel

Packing

Normal Duty ....................................................................EPDM (O-ring)

Pipe Connections ................................... Screwed Fittings, Bronze/Brass

Electrical Connections

Cable Entries ............................................3 x M20 x1.5 or PG13.5/G1/2

Connection Terminals ......................Screw Terminals for 12 AWG Wires

Min. Cross-sectional Area4 .................................................. 18 ga. AWG

Max. Cable Length ................................................... Refer to Sizing Table.

Ambient Conditions

Temperature

Operation and Storage .................................23 to 113°F (-5 to 45°C)

Transport ..................................................-13 to 158°F (-25 to 70°C)

Humidity .............................................................................. 5 to 95% rh

Agency Approvals .......................................................... IP31 to IEC 529

Conforms to CE Requirements, UL 873,

Certied to Canadian Standard C22.2 No. 24, C-Tick N-474,

Par. 1, Section. 2.1.4 / Par. 3, Section 3, Fluid Group 2

Flow Characteristics ................................... Equal Percentage or Linear

Notes:

1

Tested at 1.5 x PN (24 bar), similar to DIN 3230-3

2

For medium temperatures <32°F (0°C), the Z366 stem heating

element is required.

3

Can be selected via DIP switch.

4

In case of strong vibrations, use high-ex stranded wires.

PED 97/23/EC: Pressure-carrying Parts,

Sizing

Max. Close-off

Valve

Part No.

MXG461B15-0.6 1/2 0.7 145 33 15 3.15 130 215 360

MXG461B15-1.5 1/2 1.8 145 33 15 3.15 130 215 360

MXG461B15-3 1/2 3.5 145 33 15 3.15 130 215 360

MXG461B20-5 3/4 5.8 11 6 33 15 3.15 130 215 360

MXG461B25-8 1 9.3 102 33 15 3.15 130 215 360

MXG461B32-12 1-1/4 14 87 43 20 4 100 165 260

MXG461B40-20 1-1/2 23 87 43 20 4 100 165 260

MXG461B50-30 2 35 87 65 22 6.3 65 100 185

Size (in.)

Cv

Pressure

(psi)

Power for

Transformer

Sizing (VA)

Power

Consumption

(W)

Slow

Fuse

Accessories & Service Kits

www.usa.siemens.com/hvac

Wire Gauge (AWG)

16 14 12

A-257

Page 3

MXG461B Modulating Control Valve

Product Ordering

Valve Size (in)

1/2 0.7 MXG461B15-0.6

1/2 1.8 MXG461B15-1.5

1/2 3.5 MXG461B15-3

3/4 5.8 MXG461B20-5

1 9.3 MXG461B25-8

1-1/4 14 MXG461B32-12

1-1/2 23 MXG461B40-20

2 35 MXG461B50-30

Ordering Notes:

• When placing an order, specify the quantity, product number

and description.

Example: 1 MXG461B15-0.6 valve and 1 Z366 stem heater

• The valve body and magnetic actuator assemblies cannot be

separated.

• The screwed ttings and gaskets are supplied with

these valves.

Cv Part No.

A-231

Valves

www.usa.siemens.com/hvac

Page 4

Dimensions and Weights

SVAL0233R1

min.

3.94

(100)

1.97

(50)

F

min.

3.94

(100)

A-232

Valves

H

L2

G

Dimensions shown in inches (mm).

Line Size

Part No.

MXG461B15-0.6 1/2 (15) 1/2 G1B 3.15 (80) 1.67 (42.5) 1.97 (50) 13.4 (340) 3.15 (80) 4.53 (115) 15.65 (7.1)

MXG461B15-1.5 1/2 (15) 1/2 G1B 3.15 (80) 1.67 (42.5) 1.97 (50) 13.4 (340) 3.15 (80) 4.53 (115) 16.09 (7.3)

MXG461B15-3 1/2 (15) 1/2 G1B 3.15 (80) 1.67 (42.5) 1.97 (50) 13.4 (340) 3.15 (80) 4.53 (115) 16.09 (7.3)

MXG461B20-5 3/4 (20) 3/4 G1-1/4B 3.74 (95) 2.07 (52.5) 2.36 (60) 13.3 (339) 3.15 (80) 4.53 (115) 16.97 (7.7)

MXG461B25-8 1 (25) 1 G1-1/2B 4.33 (110) 2.22 (56.5) 2.52 (64) 13.6 (346) 3.15 (80) 4.53 (115) 18.73 (8.5)

MXG461B32-12 1-1/4 (32) 1-1/4 G2B 4.92 (125) 2.66 (67.5) 2.95 (75) 15.12 (384) 3.94 (100) 4.92 (125) 28.22 (12.8)

MXG461B40-20 1-1/2 (40) 1-1/2 G2-1/4B 5.51 (140) 3.17 (80.5) 3.66 (93) 15.79 (401) 3.94 (100) 4.92 (125) 32.19 (14.6)

MXG461B50-30 2 (50) 2 G2-3/4B 6.69 (170) 3.68 (93.5) 4.2 (108) 17.58 (449) 3.94 (100) 4.92 (125) 41.00 (18.6)

Table expressed in inches (mm).

In. (mm) RP

G

(in) L1 L2 L3 H E F

E

AAB

B

L1

Rp

L3 *

Weight

lb. (kg)

Table Notes:

• A: External thread G...B to ISO228/1

• DN: Internal thread Rp to ISO7/1

• Fittings to ISO 49/DIN 2950 (supplied complete with ange gaskets)

www.usa.siemens.com/hvac

Loading...

Loading...