Page 1

MXG461…U,

MXF461…U Series

Modulating Control Valves with

Magnetic Actuators

Technical Instructions

Document No. CA1N4455E-P25

April 2, 2013

Description

Features

Product Numbers

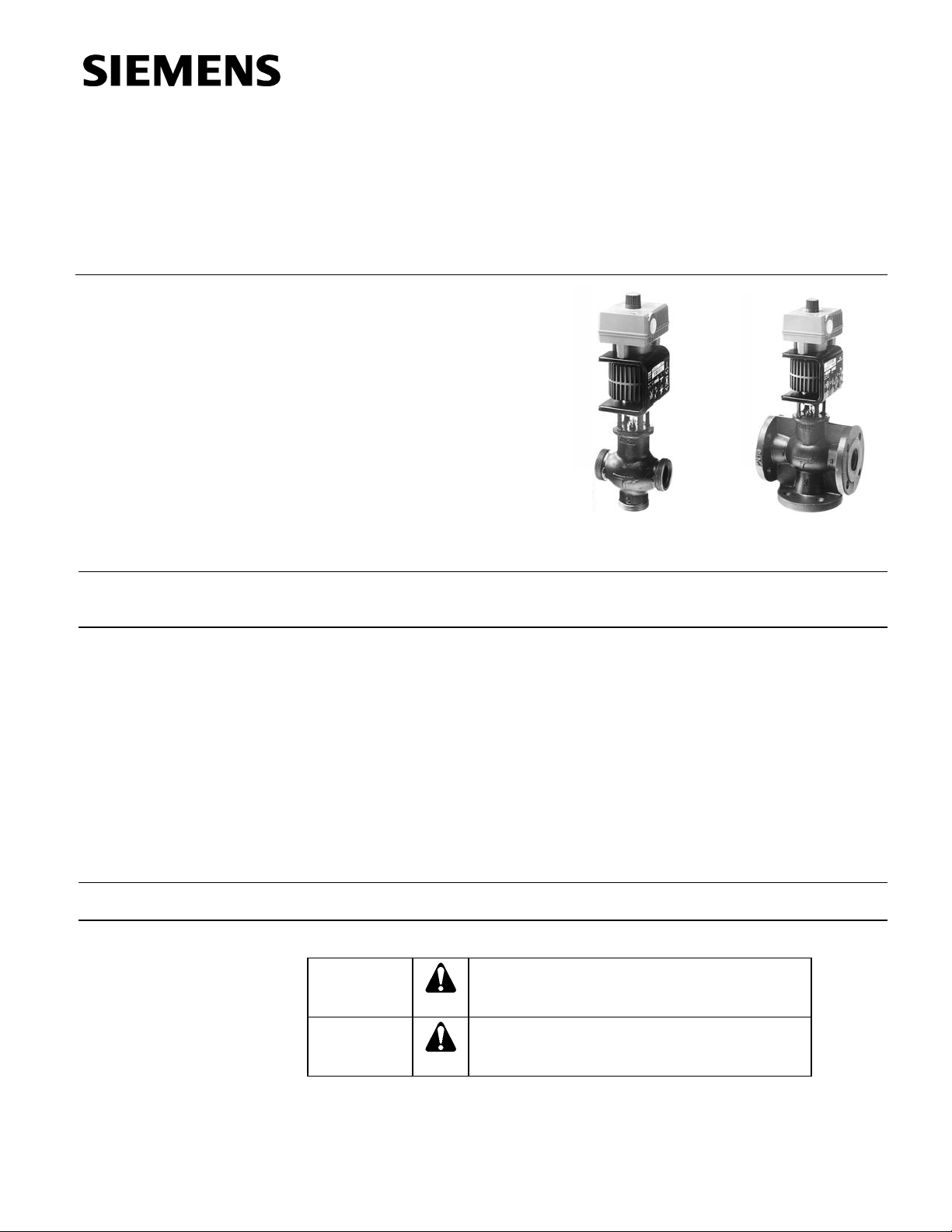

Mixing or straight-through valves with magnetic actuators for modulating control of hot

and chilled water systems in closed circuits.

•

Fast positioning time (< two seconds), high-resolution stroke (1:1000).

•

Linear or equal-percentage valve characteristic (user-selected).

•

Switch-selectable control signal: 0 to 10 Vdc, 2 to 10 Vdc, or 4 to 20 mA.

•

Wear-free inductive stroke measurement.

•

Low friction, robust, no maintenance required.

•

Fail-safe feature: A → AB closed when de-energized.

•

Positioning control.

•

Position feedback.

•

Manual control.

See Table 1.

Warning/Caution Notations

Sval0016R1

MXG461…U MXF461…U

Sval0015R1

WARNING:

CAUTION:

Personal injury or loss of life may occur if you do not

follow the procedures as specified.

Equipment damage or loss of data may occur if you

do not follow the procedures as specified.

Siemens Industry, Inc.

Page 2

Technical Instructions MXG461…U, MXF461…U Modulating Control Valves

Document Number CA1N4455E-P25 with Magnetic Actuators

April 2, 2013

Application

Principles/

Construction

Automatic Control

Valve Characteristic

The MXG461...U (screwed fitting) and MXF461...U (flange fitting) valves are mixing or

straight-through valves with a factory calibrated and mounted magnetic actuator. The

magnetic actuator incorporates an electronics module for position control and

positioning feedback. Control path A → AB is closed when the valve is de-energized.

CAUTION:

The valve is suitable for straight-through normally closed or three-way

applications and may be installed only in a mixing arrangement.

The direction of flow (A → AB) must be as indicated on the valve.

The fast positioning time, high resolution and high rangeability make these valves ideal

for modulating control of chilled and hot water systems in closed circuits. Sturdy

construction makes maintenance and regular servicing unnecessary and ensures a

long service life.

The control signal is converted by the microprocessor in the electronics module into an

output signal that generates a magnetic field in the core. This causes the only moving

part, the armature, to change its position in accordance with the interacting forces

(magnetic field, counter-spring, hydraulics, and so on). The armature responds rapidly

to any change in signal, transferring the corresponding movement directly to the control

disc, enabling fast changes in load to be corrected quickly and accurately. The valve

position is measured continuously. The positioning controller ensures an exactly

proportional relationship between the control signal and the valve stroke.

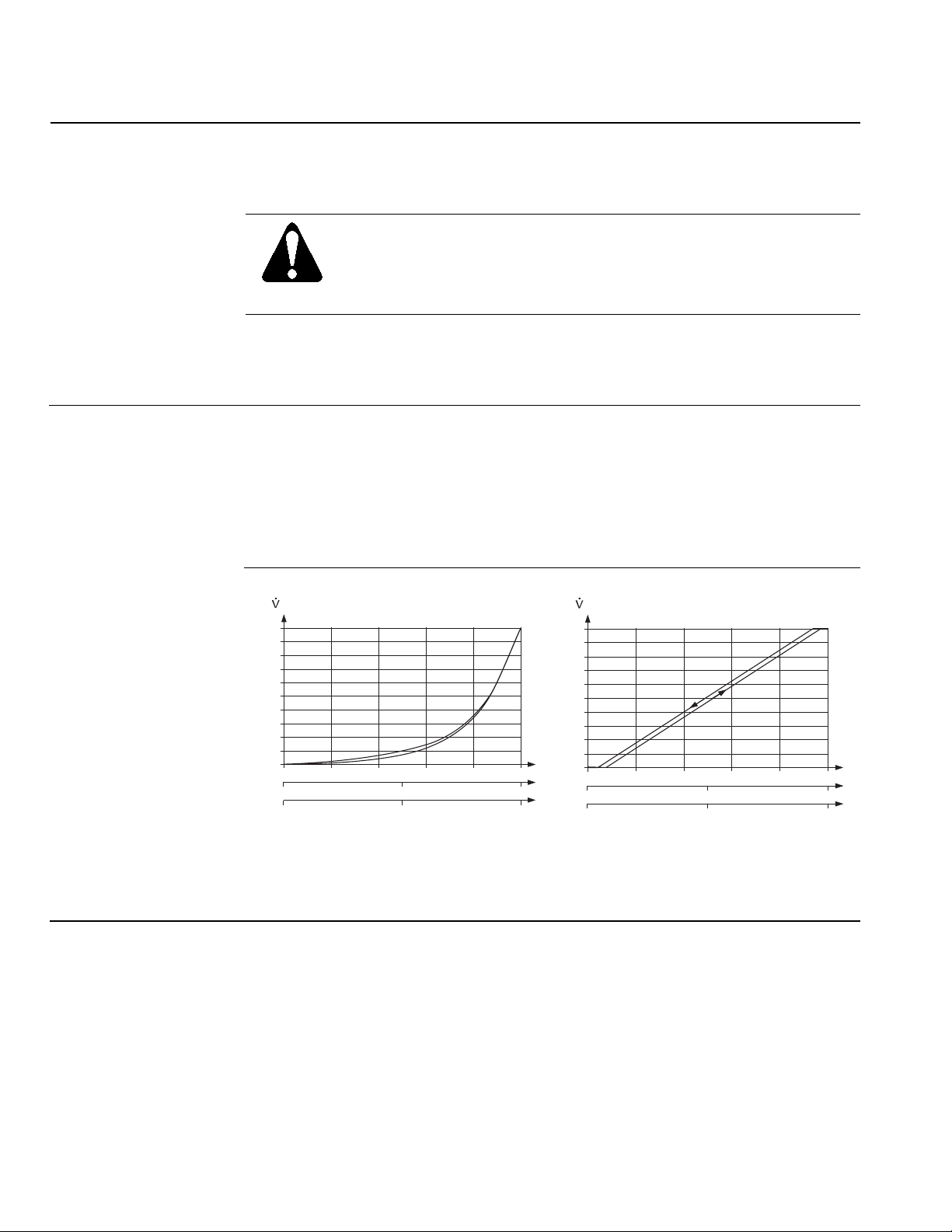

Volumetric flow

[%]

100

Volumetric flow

[%]

100

80

60

40

20

0

2

4

SVAL0227R1

6

12

10 [V]

86420

10 [V]

20 [mA]

Control signal

Figure 1. Equal-percentage. Figure 2. Linear.

In the event of a power failure, or if the power is switched off, the spring force closes the

80

60

40

20

y

0

y

2

y

Sval0012R2

4

6

12

86420

10 [V]

10 [V]

20 [mA]

y

y

y

Control signal

valve automatically (control path ports A → AB normally closed).

Page 2 Siemens Industry, Inc.

Page 3

MXG461…U, MXF461…U Modulating Control Valves Technical Instructions

With Magnetic Actuators Document Number CA1N4455E-P25

April 2, 2013

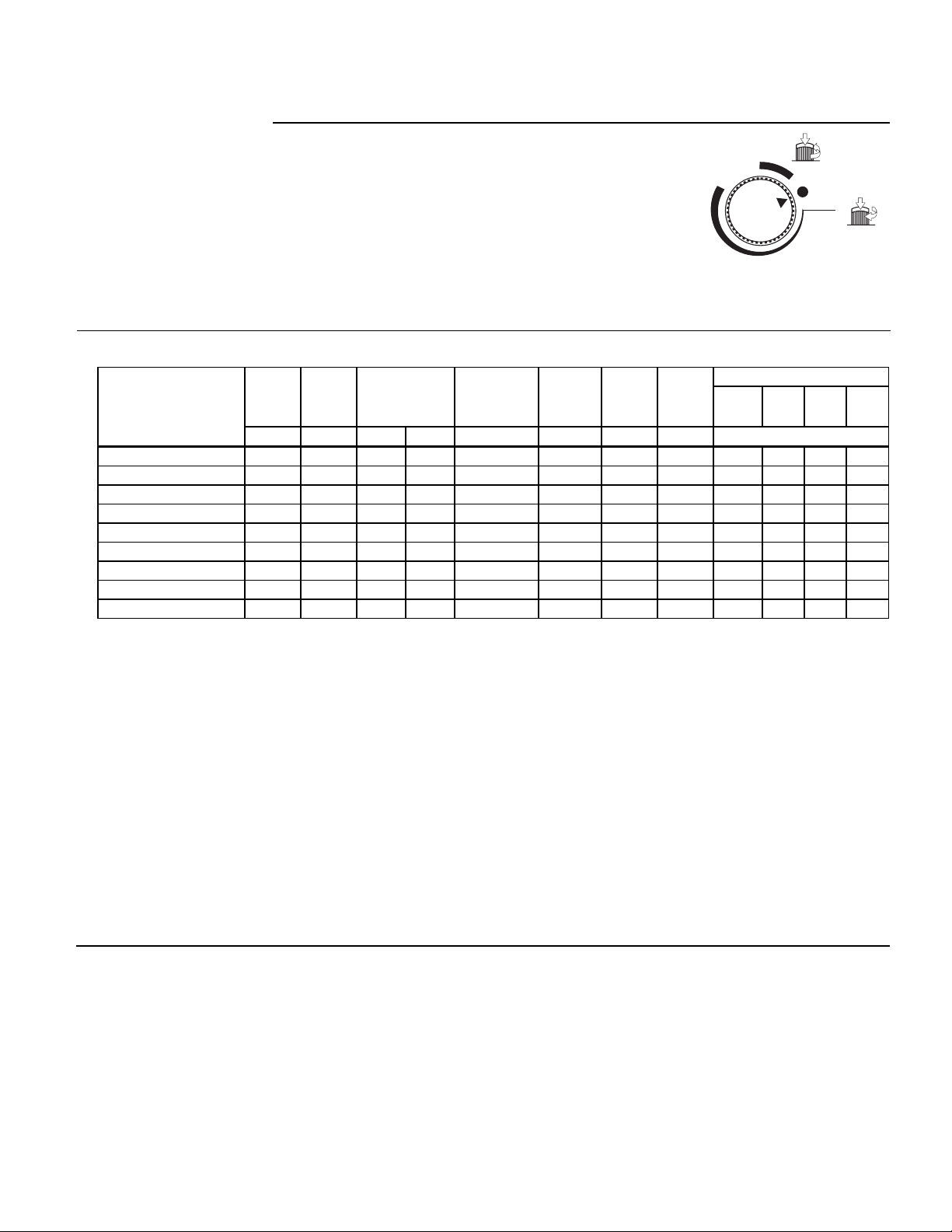

Manual Control

The valve control path (ports A → AB) can be opened

mechanically up to 95% of the full stroke by pressing the

handwheel inward and turning it clockwise (to the

MANUAL position). This disables the control signal from

the controller.

To disable automatic control of the valve, press the

handwheel inward and turn it counterclockwise (to the

OFF position). The valve will close.

For automatic control, the handwheel must be set to the

OFF

AUTO

MANUAL

Sval0006R1

Figure 3. Selecting

Automatic Control.

AUTO position (the handwheel will spring out).

Sizing

Product Numbers

Line

Size

C

V

Δ P

Table 1. MX.461…U - Valves Sizing.

max

Maximum

Close-off

1

S

NA

P

Pressure

med

1

1

I

N

Wire Gauge

18 16 14 12

(in) (gpm) (psi) (bar) (psi) (VA) (W) (A) Cable Length L (ft)

MXG461.15-0.6U 1/2 0.7 44 3 44 29 5 3.15 108 213 361 525

MXG461.15-1.5U 1/2 1.7 44 3 44 29 5 3.15 108 213 361 525

MXG461.15-3.0U 1/2 3.5 44 3 44 29 5 3.15 108 213 361 525

MXG461.20-5.0U 3/4 5.8 44 3 44 29 5 3.15 108 213 361 525

MXG461.25-8.0U 1 9.3 44 3 44 29 5 3.15 108 213 361 525

MXG461.32-12U 1-1/4 14.0 44 3 44 29 5 3.15 108 213 361 525

MXG461.40-20U 1-1/2 23.0 44 3 44 44 6 4.00 66 118 197 328

MXG461.50-30U 2 35.0 44 3 44 44 6 4.00 66 118 197 328

MXF461.65-50U 2-1/2 58.0 44 3 44 46 6 5.00 49 98 164 262

Key:

ΔPmax = Maximum permissible differential pressure across the valve’s control path,

valid for the entire actuating range of the motorized valve.

S

NA = Nominal apparent power for selecting transformer

Pmed = Typical power consumption

IN = Required slow fuse

= Flow rate to IEC534-2-4

C

V

Control path A → AB (normally closed): Tolerance ±5%

Control path B → AB (normally open): Tolerance ±10%

L = Maximum cable length. With four-wire connections, the maximum

permissible length of the separate 16 AWG Cu (copper) signal cable is

656 feet. With three-wire connections, the maximum permissible cable

length is reduced to 1/3 of the values shown in the table.

1 = All data relates to a 24 Vac supply.

Siemens Industry, Inc. Page 3

Page 4

Technical Instructions MXG461…U, MXF461…U Modulating Control Valves

Document Number CA1N4455E-P25 with Magnetic Actuators

April 2, 2013

Table 2. Water Flow Chart.

Number

MXG461.15-0.6U 1/2 0.7 0.7 1 1.2 1.4 1.6 1.7 1.9 2.0 2.1 2.2 2.7 3.1 3.8 4.4 4.9

MXG461.15-1.5U 1/2 1.7 1.7 2.4 2.9 3.4 3.8 4.2 4.5 4.8 5.1 5.4 6.6 7.6 9.3 10.8 12

MXG461.15-30U 1/2 3.5 3.5 4.9 6.1 7 7.8 8.6 9.3 9.9 10.5 11 14 16 19 22 25

MXG461.20-50U 3/4 5.8 5.8 8.2 10 12 13 14 15 16 17 18 22 26 32 37 —

MXG461.25-8.0U 1 9.3 9.3 13 16 19 21 23 25 26 28 29 36 42 51 59 —

MXG461.32-12U 1-1/4 14 14 20 24 28 31 34 37 40 42 44 54 63 77 89 —

MXG461.40-20U 1-1/2 23 23 33 40 46 51 56 61 65 69 73 89 103 126 145 —

MXG461.50-30U 2 35 35 49 61 70 78 86 93 99 105 111 136 157 192 221 —

MXF461.65-50U 2-1/2 58 58 82 100 116 130 142 153 164 174 183 225 259 318 367 —

Line

Size

(in)

ΔP

C

V100

1 2 3 4 5 6 7 8 9 10 15 20 30 40 50

VS

PSI Product

LED Indicators

The two-color LED display indicating operating status can be viewed by opening the

cover of the electronics module.

Table 3. LED Display.

LED Display Status Description

LED green

On continuously Automatic mode: Auto (normal, no faults)

Flashing – Mechanically set to MANUAL

– Mechanically set to OFF

– Currently in auto-calibration mode

LED red

On continuously – General fault

– General calibration fault

– Microcontroller fault

Flashing – Faulty 24 Vac supply (that is, too low)

LED Off – No 24 Vac supply

– Fault with electronics module

As a general rule, the LED can only assume the conditions in Table 3 (continuously red

or green, flashing red or green, or off).

Mounting

Mounting and operating instructions are printed on the actuator and on the electronics

module.

The valve is suitable only for straight-through or three-way applications and may be

installed only in a mixing arrangement. In the case of the straight-through valve, strict

observance of the direction of flow is essential.

Do not mount with actuator below horizontal position.

Access for Mounting

It is essential to maintain the specified minimum clearance above and to the side of the

actuator and/or electronics module for servicing, installing and heat dissipation:

• 1/2-inch to 1-1/4 inches = 4 inches

• 1-1/2 inches to 2-1/2 inches = 6 inches

Also see Dimensions.

Page 4 Siemens Industry, Inc.

Page 5

MXG461…U, MXF461…U Modulating Control Valves Technical Instructions

With Magnetic Actuators Document Number CA1N4455E-P25

April 2, 2013

Mounting,

Continued

Only three-way MXG461...U valves are supplied. They may be used as straight-through

normally closed valves by closing off port "B":

Straight-through Valves

Port "B" can be sealed with the

accessories supplied (blanking disk,

gasket, and the nut).

No blanking flange is available for

MXF461.65-50U.

Installation

MXG461...U screwed valves are flat-faced to facilitate sealing with the gaskets

supplied.

Do not use hemp, tape or thread-sealing compound.

Do not insulate the actuator.

For notes on electrical installation, see Terminal Layout.

Maintenance

The valves and actuators require no maintenance or service. The valve stem is sealed

with a maintenance-free O-ring gland.

Should the valve electronics prove faulty, the electronics module should be exchanged

for a replacement part, part number ASE1 (1/2-inch to 1-1/4 inches) or ASE2

(1-1/2 inches to 2-1/2 inches). Mounting instructions are enclosed (Ref. 35678).

B

Sval0007R1

Figure 4. MXG461...U Screwed Valves in

Straight-through Applications.

WARNING:

Under operating conditions within the limits defined by the application

data, the actuator will become hot, but this does not represent a fire risk.

Always maintain the minimum clearance specified (see Dimensions).

Siemens Industry, Inc. Page 5

Page 6

Technical Instructions MXG461…U, MXF461…U Modulating Control Valves

Document Number CA1N4455E-P25 with Magnetic Actuators

April 2, 2013

Specifications

Electrical Interface

Power supply Class 2

Supply voltage 24 Vac, 50/60 Hz

– Maximum voltage tolerance +20/–15%

Control signal (user-selected) 0 to 10 Vdc, 2 to 10 Vdc, or 4 to 20 mA

Software class Class A

Nominal power See Sizing

Position Signal Y 0 to 10 Vdc, 2 to 10 Vdc, or 4 to 20 mA

Impedance 0 to 10 Vdc or 2 to 10 Vdc 100k Ω //5nF

4 to 20 mA 100 Ω //5nF

Position feedback signal 0 to 10 Vdc; load resistance > 500 Ω

Product Specific Data Applications To EN60730

Nominal pressure 232 psi (16 bar)

Permissible Operating pressure p

Differential pressure ΔP

max See Table 1

max 150 psi

e

Leakage at ΔPv = 14.5 psi (0.1 Mpa) (1bar) A → AB Max. 0.02 % Cv (to IEC534-4)

B → AB Depends on operating

conditions (<0.2% C

v)

Admissible media Water, or water/glycol mixtures with

maximum 50% glycol

Temperature of medium 34°F to 266°F (1°C to 130°C)

Valve characteristic (stroke, k

vs) Linear or equal percentage (user-

selected), optimized near the closing

point (to IEC534-2-4)

Stroke resolution ΔH/H

100 1:1000 (H = stroke)

Hysteresis Typically 3%

Type of operation Modulating

Manual adjustment Yes, with handwheel

Position with actuator de-energized A → AB closed

Orientation Upright to horizontal

Note that orientation affects protection

standard

Positioning time <2 seconds

Materials (valve body) Housing parts Cast iron

Plug CrNi Steel

Seat Brass

Valve stem seal EPDM (O-ring)

Bellows Tombac, bronze, CrNi steel

Electrical connection Connection terminal Screw terminals

Per terminal, with wire (no lug) 2 × 16 AWG or 1 × 14 AWG

Per terminal with wire 2 × 16 AWG or 1 × 12 AWG

Miscellaneous Weight (including packaging) See Dimensions

Dimensions See Dimensions

Ambient conditions Maximum ambient temperature 113°F (45°C)

Agency Approvals UL listing Per UL 873

C-UL Certified to Canadian Standard

C22.2 No. 24

Suitable for use in air handling spaces

NEMA Type 1

Page 6 Siemens Industry, Inc.

Page 7

MXG461…U, MXF461…U Modulating Control Valves Technical Instructions

With Magnetic Actuators Document Number CA1N4455E-P25

April 2, 2013

Wiring Terminals

WARNING:

Earth ground must be connected to the pipe work.

1

2

3

4

5

6

Sval0011R1

G0

G

Y

YM

X

YF

24 Vac

~

24 Vac

Control signal input

Control signal reference voltage

0 to 10 Vdc stroke signal output (position feedback)

Override control

Figure 5. Terminal Layout for Four-wire Connections.

Wiring Diagram

Forced Control Feature

(Input Terminal YF/6)

24

VAC

1

2

3

4

5

6

MX...461...

G0

G

Y

YM

X

YF

0-10 VDC

2-10 VDC

4-20 mA

Sval00228R1

24 VAC

24

VAC

+

±

U

1

2

3

4

5

6

MX...461...

G0

G

Y

YM

X

YF

Figure 6. Connection to Controller with Four-wire Output.

U = Indication of valve position (only where required). 0 to 10 Vdc → 0 to 100%

volumetric flow.

SSEN0093R1

TWISTED PAIRS

If the cables for the 24 Vac supply and the control signal 0 to 10 Vdc

(2 to 10 Vdc, 4 to 20 mA are routed separately, twisted pairs are not required for the

24 Vac cable).

0 Vac (Bridge G0 – YF)

24 Vac (Bridge G – YF)

1 to 9 Vdc at F

Control path A → AB closed

Control path A → AB open

Continuously variable low limit control 10% to 90% volume

flow (the higher value YF of Y takes priority).

This function is available with valves with a manufacturing

date of 990701 or later.

Siemens Industry, Inc. Page 7

Page 8

Technical Instructions MXG461…U, MXF461…U Modulating Control Valves

Document Number CA1N4455E-P25 with Magnetic Actuators

April 2, 2013

Configuration

Switches

Switch

1 Characteristic

2 Control signal

3 Volts or mA

Off

Linear

0 to 10 Vdc*

0(2) to 10 Vdc*

On

Equal percentage*

2 to 10 Vdc or 4 to 20 mA

4 to 20 mA

* Factory setting: equal percentage valve characteristic, 0 to 10 Vdc control signal.

70038c

A

Calibration

Application Example

B

Figure 7. DIP Switches.

The MX…461…P magnetic valves are factory-calibrated at 0% and 100% stroke. When

commissioning the valves (especially under extreme usage conditions) there may still

be some leakage via control path A → AB with a 0% stroke control signal (0 Vdc, 4 mA

or 2 Vdc). In this case, the valve can be recalibrated as follows (see Figure 8):

• Use a pin or paper clip to push the button in opening (A) in the terminal housing.

• During calibration, the LED light (B) in the electronics module will flash green for

approximately 10 seconds. The valve will be briefly closed and fully opened.

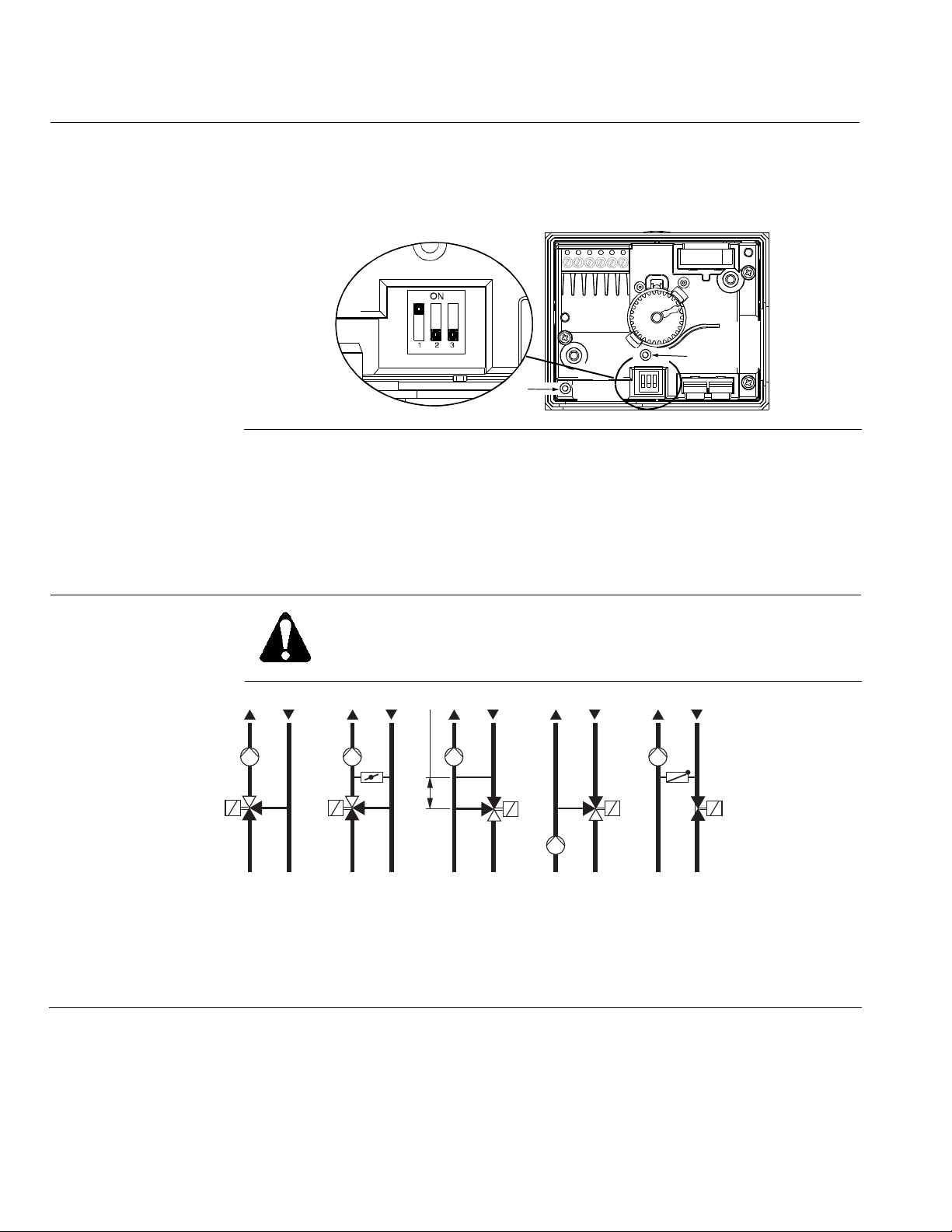

CAUTION:

This valve is suitable for straight-through normally closed or three-way

applications only, and should only be installed in a mixing arrangement.

(min. 20 in)

AB

B

A

A

AB

x D N

B

10

B

AB

A

B

AB

A

A

AB

Sval0014R1

A

B

C

D E

A Mixing circuit

B Mixing circuit with bypass (underfloor heating)

C Injection circuit

D Diverting circuit

E Injection circuit with straight-through valve

Page 8 Siemens Industry, Inc.

Figure 8. Hydraulic Circuits.

Page 9

MXG461…U, MXF461…U Modulating Control Valves Technical Instructions

With Magnetic Actuators Document Number CA1N4455E-P25

April 2, 2013

Service

CAUTION:

Do not disassemble the valve and actuator combination. This assembly is factorycalibrated, and should only be replaced by qualified personnel.

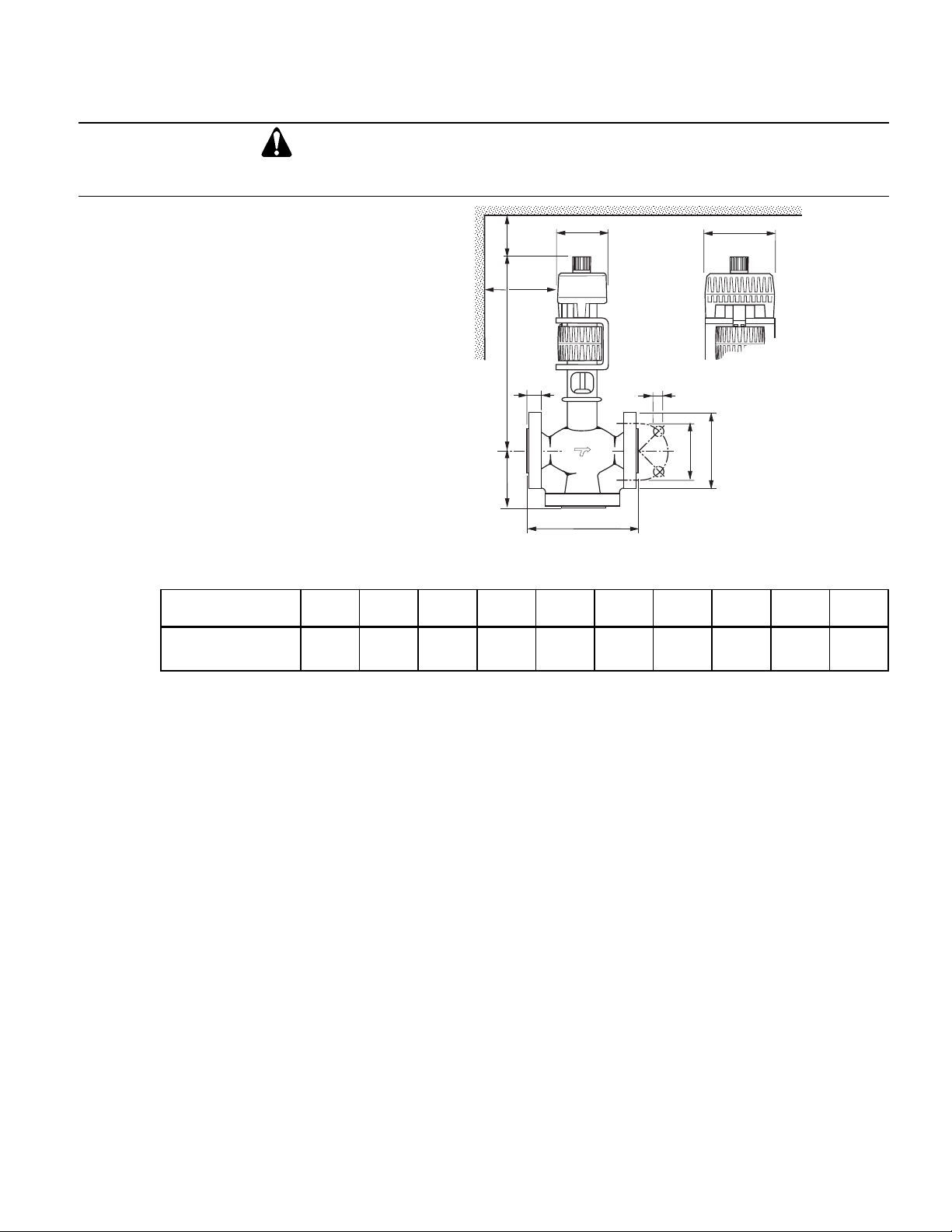

Dimensions

All dimensions in inches (millimeters)

Sval0009.eps

min.

H

1

L

100

min.

100

b

E

ø d

A B

A

B

L

ø k

F

ø D

Table 4. MXF461…U – Flanged Valve with Electronics Module.

Product Number L L1 D b k d H E F

4X

MXF461.65-50U

11.42

(290)

4.92

(125)

7.00

(177.8)

0.88

(22.4)

5.50

(139.7)

0.75

(19.05)

15.43

(392)

3.15

(80)

3.94

(100)

lbs

(kg)

63.1

(28.6)

NOTE: Installer must supply counterflanges. lbs. (kg) = Weight (including packaging)

Siemens Industry, Inc. Page 9

Page 10

Technical Instructions MXG461…U, MXF461…U Modulating Control Valves

Document Number CA1N4455E-P25 with Magnetic Actuators

April 2, 2013

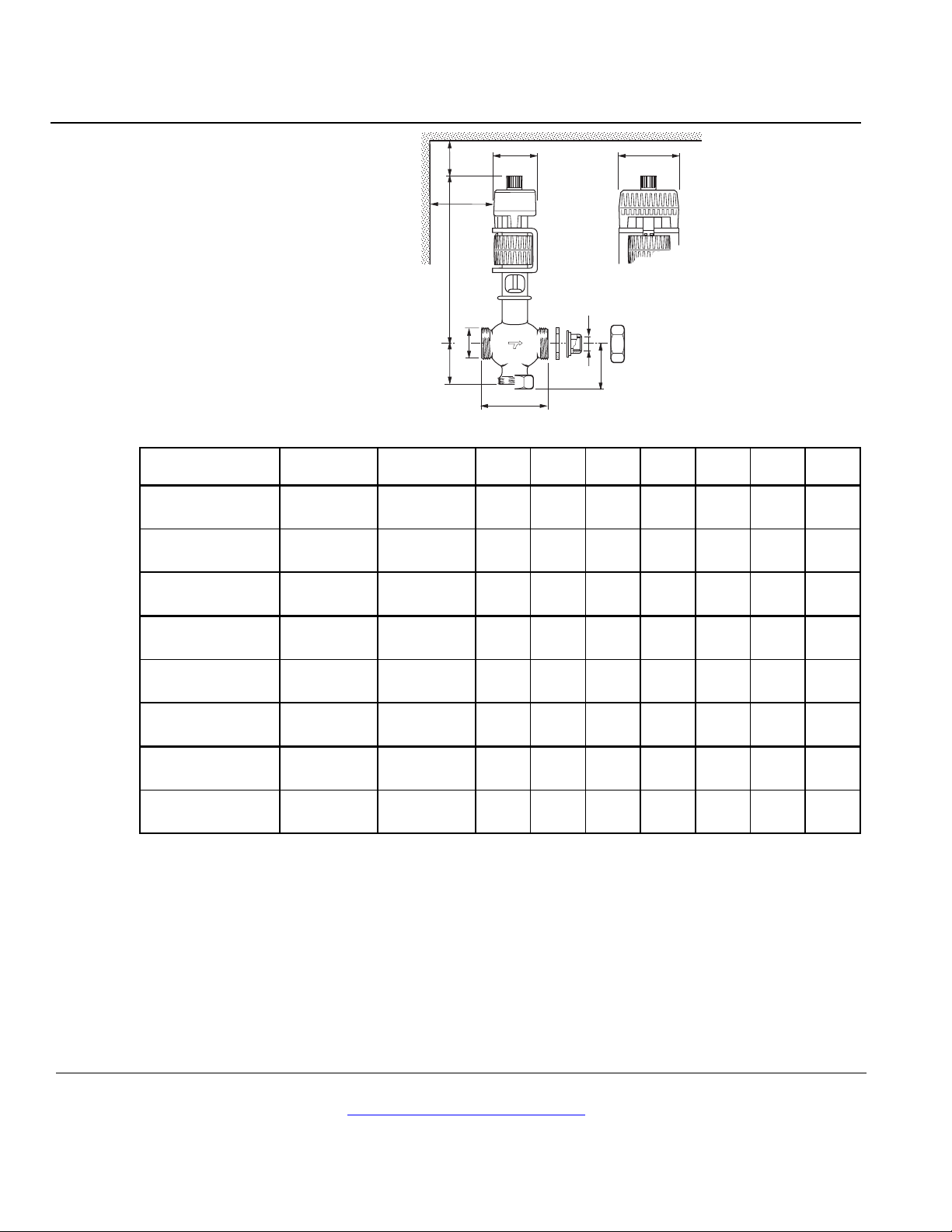

Dimensions,

Continued

All dimensions in inches

(millimeters)

Sval0010R1

1

L

min.

H

100

min.

100

DA

E

DI

AB

A

B

L

2

L

60433

F

Table 5. MXG461…U –Valves with Electronics Module.

Product Number DI DA L L1 L2 * H E F

MXG461.15-0.6U 1/2 1

MXG461.15-1.5U 1/2 1

MXG461.15-3.0U 1/2 1

MXG461.20-5.0U 3/4 1-1/4

MXG461.25-8.0U 1 1-1/2

(110)

MXG461.32-12U 1-1/4 2

(125)

MXG461.40-20U 1-1/2 2-1/4

(140)

MXG461.50-30U 2 2-3/4

(170)

3.15

(80)

3.15

(80)

3.15

(80)

3.74

(95)

4.33

4.92

5.51

6.69

1.67

(42.5)

1.67

(42.5)

1.67

(42.5)

2.07

(52.5)

2.22

(56.5)

2.66

(67.5)

3.17

(80.5)

3.68

(93.5)

2.01

(51)

2.01

(51)

2.01

(51)

2.40

(61)

2.56

(65)

2.99

(76)

3.70

(94)

4.29

(109)

9.45

(240)

9.45

(240)

9.45

(240)

10.24

(260)

10.63

(270)

11.22

(285)

12.60

(320)

13.39

(340)

3.15

(80)

3.15

(80)

3.15

(80)

3.15

(80)

3.15

(80)

3.15

(80)

3.94

(100)

3.94

(100)

3.94

(100)

3.94

(100)

3.94

(100)

3.94

(100)

3.94

(100)

3.94

(100)

4.72

(120)

4.72

(120)

lbs

(kg)

8.4

(3.8)

8.4

(3.8)

8.4

(3.8)

9.3

(4.2)

10.4

(4.7)

12.3

(5.6)

20.5

(9.3)

26.2

(11.9)

* When used as a straight-through valve lbs. (kg) = Weight (including packaging)

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. Product or company names mentioned herein may be the trademarks of their respective owners.

© 2013 Siemens Industry, Inc.

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

USA

+1-847-215-1000

Your feedback is important to us. If you have

comments about this document, please send them

to SBT_technical.editor.us.sbt@siemens.com

Document No. CA1N4455E-P25

Printed in the USA

Page 10

Loading...

Loading...