Page 1

714

4

ACVATIX

TM

Modulating refrigerant

valves with magnetic

actuator, PS45

Hermetically sealed, for safety refrigerants

MVL661..-..

Use

CE2N4714en

30.05.2011

• One valve type for expansion, hot-gas and suction throttle applications

• Hermetically sealed towards outside

• Selectable standard interface DC 0/2...10 V or DC 0/4...20 mA

• High resolution and control accuracy

• Precise positioning control and position feedback signal

• Short positioning time (< 1 s)

• Closed when deenergized

• Robust and maintenance-free

• Five valve sizes with k

The MVL661..-.. refrigerant valve is designed for modulating control of refrigerant

circuits including chillers and heat pumps. It can be used in expansion, hot-gas and

suction throttle applications as well as with all commonly used safety refrigerants (R22,

R134a, R404A, R407C, R410A, R507, etc.) and R744 (CO

inflammable refrigerants.

values from 0.25 to 12 m³/h

vs

). Not suitable for

2

Building Technologies

Page 2

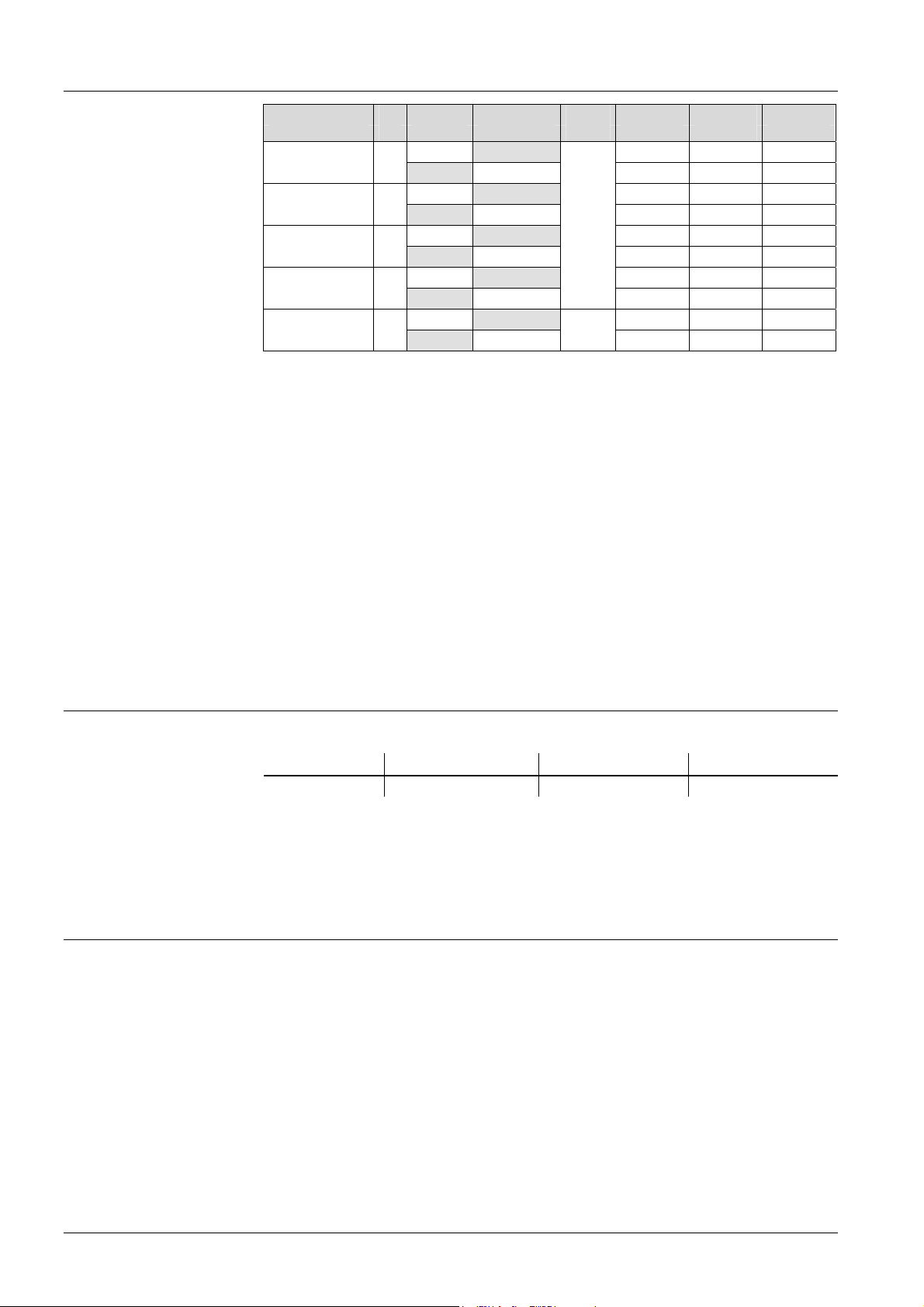

Type summary

Type reference DN kvs k

reduced

vs

1)

Δp

max

Q0 E Q0 H Q0 D

[m3/h] [m3/h] [MPa] [kW] [kW] [kW]

MVL661.15-0.4 15

MVL661.15-1.0 15

MVL661.20-2.5 20

MVL661.25-6.3 25

MVL661.32-12 32

1)

63% of kvs, refer to "kvs reduction" on page 4

2)

MVL661.32-12.0 is only approved for suction throttle applications

Nominal flow rate of refrigerant through the fully open valve (H

k

vs

0.40 47 9.2 1.7

0.25 29 5.7 1.0

1.0 117 23 4.2

0.63 74 14 2.6

2.5 293 57 10

2.5

1.6 187 37 6.6

6.3 737 144 26

4

12

8

0.2

468 92 17

2)

2)

) at a differential pressure of

100

2)

50

2)

33

100 kPa (1 bar) to VDI 2173

Q

E Refrigeration capacity in expansion applications

0

Q

H Refrigeration capacity in hot-gas bypass applications

0

D Refrigeration capacity in suction throttle applications and Δp = 0.5 bar

Q

0

With R407C at t0 = 0 °C, tc = 40 °C

Q

0

The pressure drop across evaporator and condenser is assumed to be 0.3 bar each, and 1.6 bar

upstream of the evaporator (e.g. spider).

The capacities specified are based on superheating by 6 K and subcooling by 2 K.

The refrigeration capacity for various refrigerants and operating conditions can be

calculated for the 3 types of application using the tables at the end of this data sheet.

For accurate valve sizing, we recommend the valve selection program "Refrigeration

VASP".

Ordering

Example:

Spare parts

Rev. no.

Functio

n / mechanical design

Features and benefits

Valve body and magnetic actuator form one integral unit and cannot be separated.

Product number Stock number Designation

MVL661.15-0.4 MVL661.15-0.4 Refrigerant valve 1

Quantity

If the valve’s electronics become faulty, the entire electronics housing must be replaced

by spare part ASR61, supplied complete with mounting instructions (74 319 0270 0).

See table on page 17.

• 4 selectable standard signals for setpoint and measured value

• DIP switch to reduce the k

value to 63% of the nominal value

vs

• Potentiometer for adjustment of minimum stroke for suction throttle applications

• Automatic stroke calibration

• Forced control input for “Valve closed” or “Valve fully open”

• LED for indicating the operating state

The MVL661..-.. can be driven by Siemens or third-party controllers that deliver

a DC 0/2...10 V or DC 0/4...20 mA output signal.

For optimum control performance, we recommend a 4-wire connection between

controller and valve. When operating on DC voltage, a 4-wire connection is mandatory!

The valve stroke is proportional to the control signal.

2/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 3

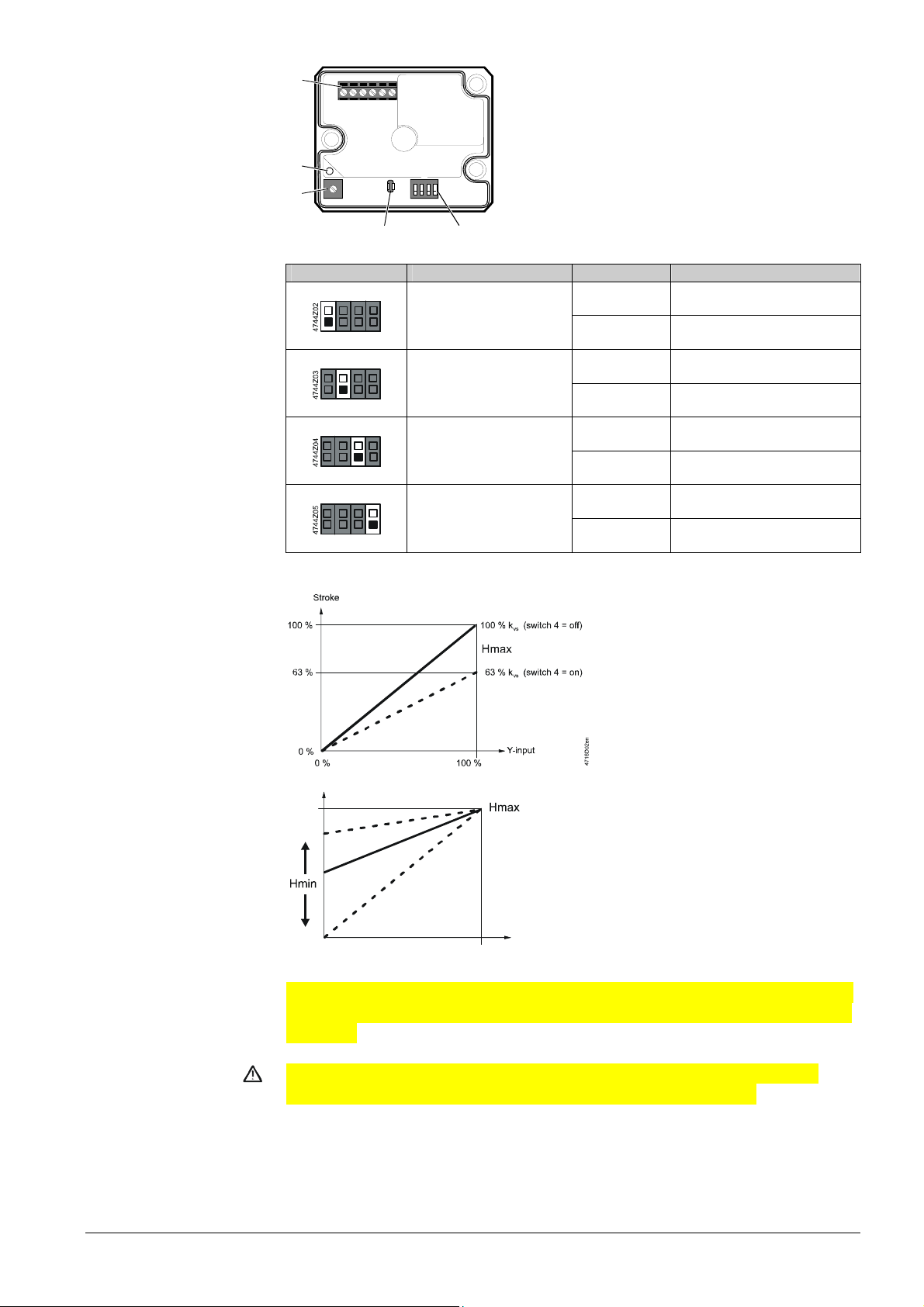

Operator controls and

indicators in the

electronics housing

1

G0 G Y UMZC

1 Connection terminals

2 LED for indication of operating state

3 Minimal stroke setting potentiometer Rv

4 Autocalibration

2

3

on

1234

5 DIL switches for mode control

Configuration of

DIL switches

-reduction

k

vs

Minimum stroke

setting

Caution

45

4716Z15

Switch Function ON / OFF Description

ON

1

ON

2

ON

3

ON

1)

Factory setting

Positioning signal Y

Positioning range Y and U

Position feedback U

Nominal flow rate k

4

vs

ON Current [mA]

1)

OFF Voltage [V]

ON DC 2…10 V, 4…20 mA

OFF DC 0…10 V, 0…20 mA

ON Current [mA]

OFF Voltage [V]

ON

OFF

For k

63%

100%

reduction (DIL switch 4 in

vs

1)

1)

position ON), the stroke is limited to

63% mechanical stroke. 63% of full

stroke then corresponds to an

input/output signal of 10 V.

If, in addition, the stroke is limited

to 80%, for example, the minimum

stroke is 0.63 x 0.8 = 0.50 of full

stroke.

100 %

80 %

Stroke

In the case of a suction throttle valve, it is

4716D01en

essential that a minimum stroke limit be

maintained to ensure compressor cooling

and efficient oil return. This can be

achieved with a reinjection valve, a bypass

line across the valve, or a guaranteed

minimum opening of the valve. The

0 %

0 % 100 %

Y-i np ut

minimum stroke can be defined via the

controller and control signal Y, or it can be

set directly with potentiometer Rv.

The factory setting is zero (mechanical stop in counterclockwise direction, CCW). The

minimum stroke can be set by turning the potentiometer clockwise (CW) to a maximum

of 80% kvs.

Do not under any circumstances use potentiometer Rv to limit the stroke on

expansion applications. It must be possible to close the valve fully.

1)

3/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 4

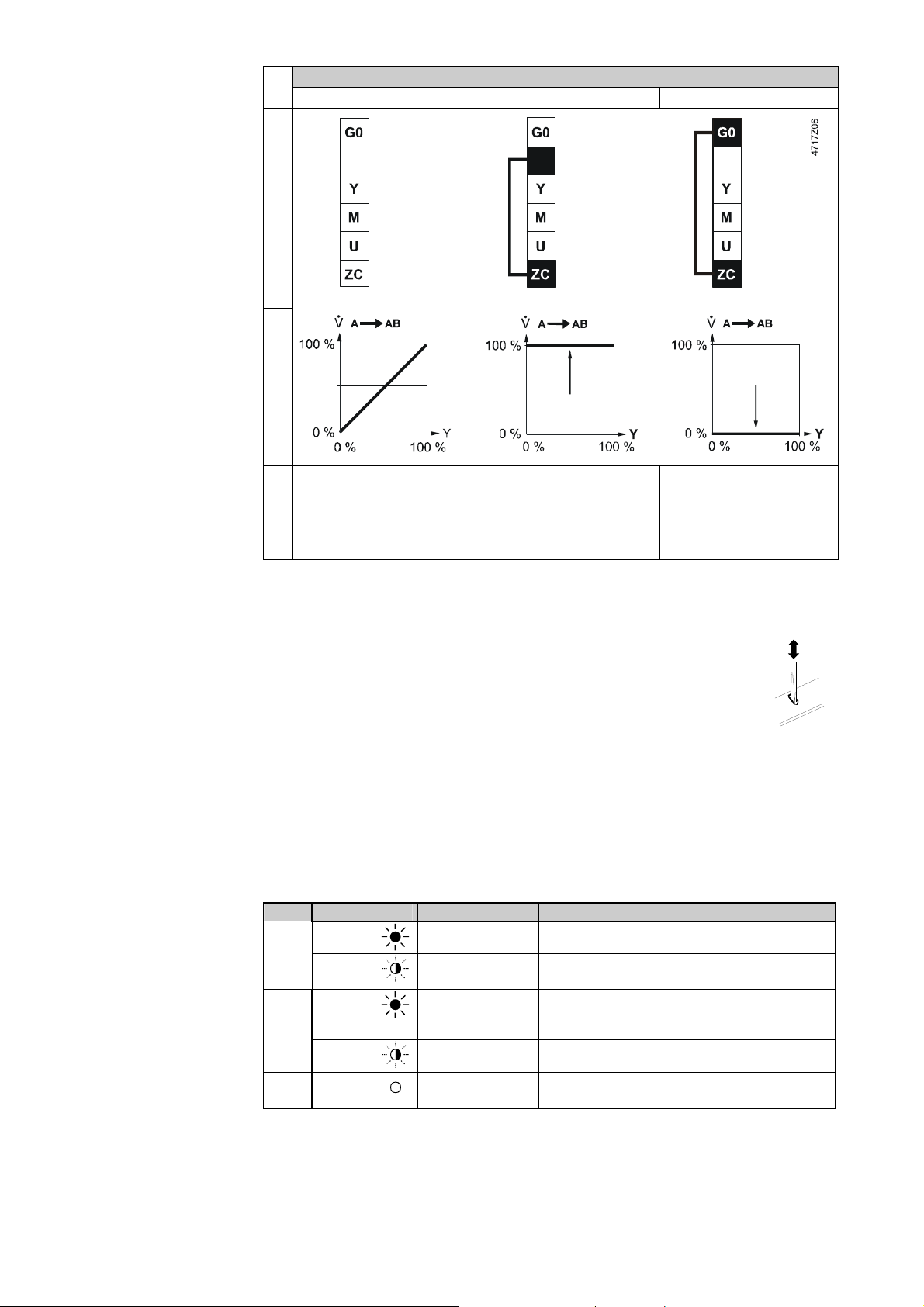

Forced control input ZC

No function Fully open Closed

ZC – Function

Signal priority

Calibration

When is a calibration

required?

Indication of operating

state

Connections Transfer

• ZC not connected

• Valve will follow the Y-signal

• Minimum stroke set-ting

function

with potentiometer Rv

possible

G

• ZC connected to G

• Valve will fully open control

path A AB

• ZC connected to G0

• Valve will close control path

GG

A AB

1. Forced control signal ZC

2. Signal input Y and/or minimum stroke setting with potentiometer Rv possible.

The printed circuit board of the MVL661..-.. has a slot to facilitate calibration.

01124

To calibrate, insert a screwdriver in the slot so that the contacts inside are

connected. As a result, the valve will first be fully closed and then fully

opened.

Calibration matches the electronics to the valve mechanism.

During calibration, the green LED flashes for about 10 seconds; refer to

"Indication of operating state" (page 4).

MVL661..-.. refrigerant valves are supplied fully calibrated.

Execute a calibration after replacing the electronics, when the red LED is lit or flashing

or when the valve is leaking (at seat).

LED Indication Function Remarks, troubleshooting

Green Lit

Flashing

Red Lit

Flashing

Both Dark

Control mode Automatic operation; everything o.k.

Calibration in

progress

Calibration error

Internal error

Mains fault Check mains network (outside the frequency or

No power supply

Electronics faulty

Wait until calibration is finished

(green or red LED will be lit)

Recalibrate (operate button in opening 1x)

Replace electronics module

voltage range)

Check mains network, check wiring

Replace electronics module

4/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 5

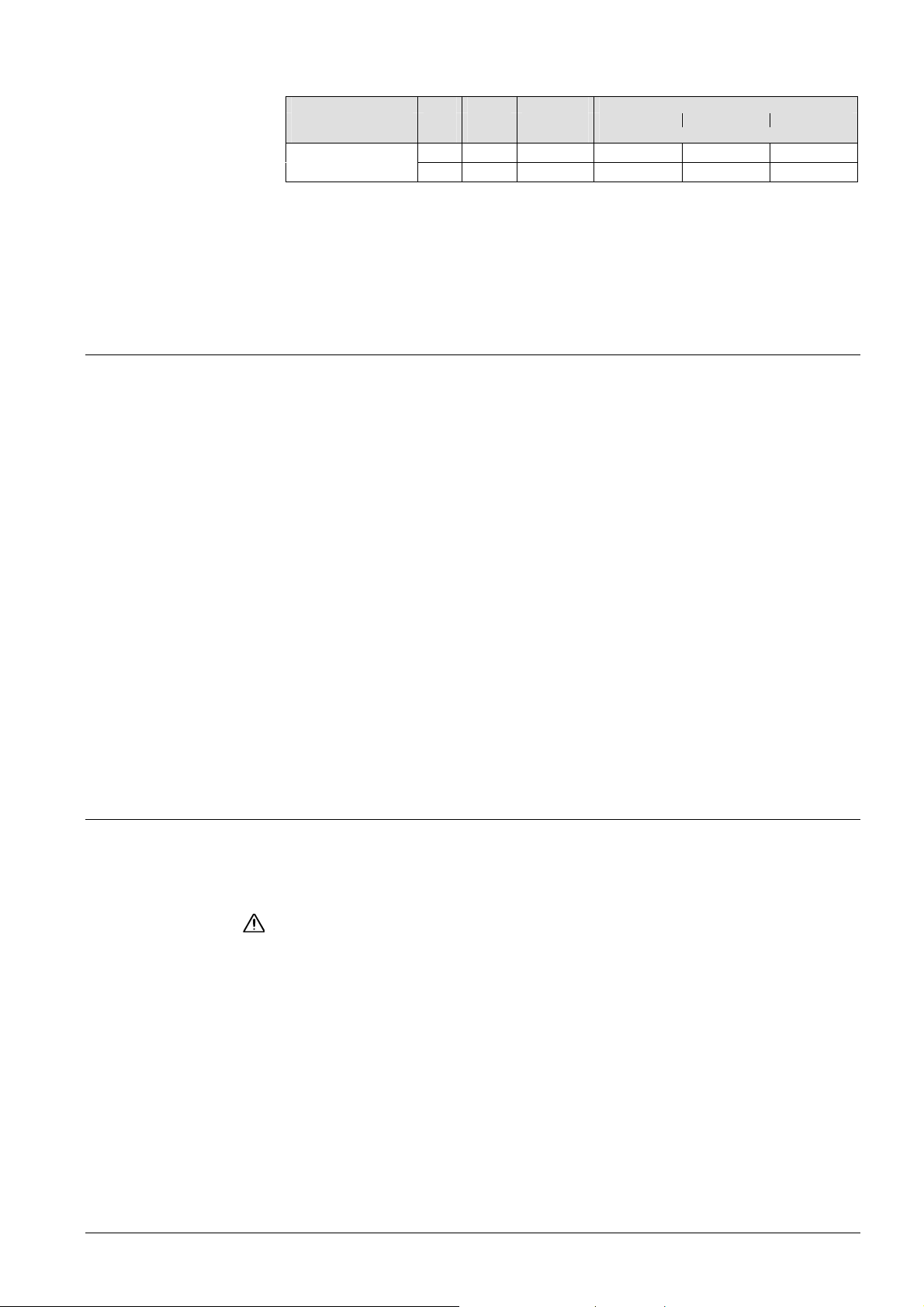

Connection type

1)

4-wire connection

3-wire connection

Sizing

Notes

Engineering notes

Always give preference to a 4-wire connection!

SNA P

Product number [VA] [W] [A] max. cable length L [m]

MVL661..-.. 22 12 1.6…4 A 65 110 160

MVL661..-.. 22 12 1.6…4 A 20 35 50

SNA = Nominal apparent power for selecting the transformer

P

med

IF = Required slow fuse

L = Max. cable length; with 4-wire connections, the max. permissible length of the separate 1.5 mm2

1)

All information at AC 24 V

2)

With 4 mm2 electrical wiring reduce wiring cross-section for connection inside valve to 2.5 mm2.

= Typical power consumption

copper positioning signal wire is 200 m

IF Wire cross-section [mm2]

MED

1.5 2.5 4.0 2)

For straightforward valve sizing, refer to the tables for the relevant application (from

page 13).

For accurate valve sizing, we recommend to make use of the valve sizing software

"Refrigeration VASP", available from your local Siemens office.

The refrigeration capacity Q

is calculated by multiplying the mass flow by the specific

0

enthalpy differential found in the h, log p-chart for the relevant refrigerant. To help

determine the refrigeration capacity more easily, a selection chart is provided for each

application (page 9 and following). With direct or indirect hot-gas bypass applications,

the enthalpy differential of Q

(the condenser capacity) must also be taken into account

c

when calculating the refrigeration capacity.

If the evaporating and / or condensing temperatures are between the values shown in

the tables, the refrigeration capacity can be determined with reasonable accuracy by

linear interpolation (refer to the application examples on page 9 and following).

At the operating conditions given in the tables, the permissible differential pressure

(25 bar) across the valve is within the admissible range for these valves.

Δp

max

If the evaporating temperature is raised by 1 K, the refrigeration capacity increases by

about 3%. If, by contrast, subcooling is increased by 1 K, the refrigeration capacity

increases by about 1 to 2% (this applies only to subcooling down to approximately

8 K).

Depending on the application, additional installation instructions may need to be

observed and appropriate safety devices (e.g. pressostats, full motor protection, etc.)

fitted.

Warning

To prevent damage to the seal inside the valve insert, the plant must be vented on the

low-pressure side following a pressure test (valve port AB), or the valve must be fully

open during the pressure test and during venting (power supply connected and

positioning signal at maximum or forced opening by G → ZC).

Expansion application

To prevent formation of flash gas on expansion applications, the velocity of the

refrigerant in the fluid pipe may not exceed 1 m/s. To assure this, the diameter of the

fluid pipe must be greater than the nominal size of the valve, using reducing pieces for

making the connections to the valve.

5/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 6

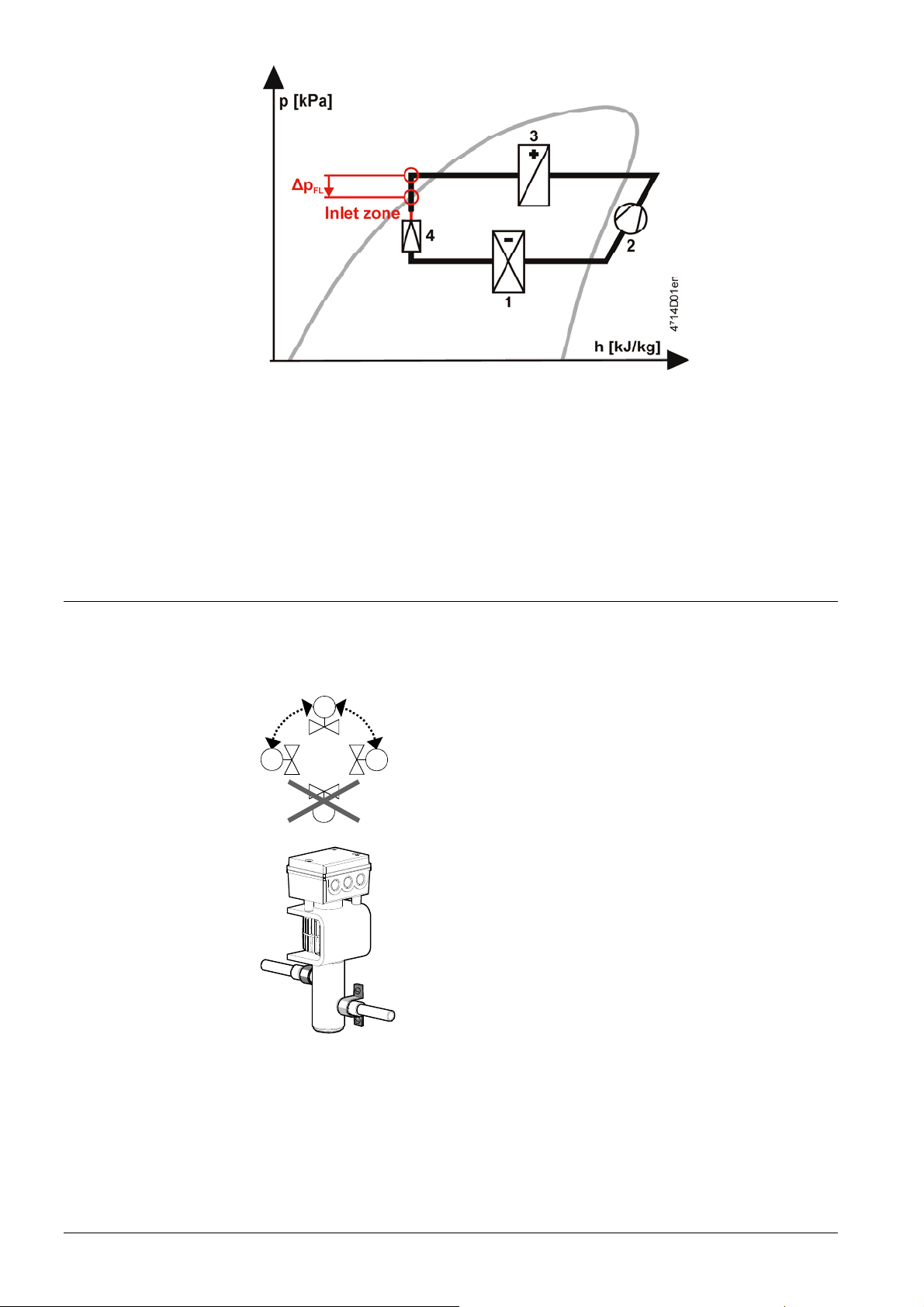

Engineering notes

1 = Evaporator

2 = Compressor

3 = Condenser

4 = Expansion valves

a) The differential pressure over reduction must be less than half the differential

pressure Δp

.

FL

b) The inlet path between diameter reduction and expansion valve inlet

Must straight for at least 600 mm

May not contain any valves

A filter / dryer must be mounted upstream of the expansion valve.

The valve is not explosion-proof.

It is not approved for use with ammonia (NH3, R717).

Mounting notes

The valve should be mounted and commissioned by qualified staff. The same applies

to the replacement electronics and the configuration of the controller (e.g. SAPHIR or

PolyCool).

• The refrigerant valves can be mounted in any orientation, but

90°

90°

upright mounting is preferable.

• Arrange the pipework in such a way that the valve is not

located at a low point in the plant where oil can collect.

• The pipes should be fitted in such a way that the alignment

does not distort the valve connections. Fix the valve body so

4716Z16

00441

that that it cannot vibrate. Vibration can lead to burst

connection pipes.

• Before soldering the pipes, ensure that the direction of flow

through the valve is correct.

• The pipes must be soldered with care. To avoid dirt and the

formation of scale (oxide), inert gas is recommended for

soldering.

• The flame should be large enough to ensure that the junction

heats up quickly and the valve does not get too hot.

• The flame should be directed away from the valve.

• During soldering, cool the valve with a wet cloth, for example,

to ensure that it does not become too hot.

• Port B must be sealed off when a 2-port valve (AB A) is

used.

• The valve body and the connected pipework should be

lagged.

• The actuator must not be lagged.

6/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 7

The valve is supplied complete with mounting instructions 74 319 0232 0.

Maintenance

The refrigerant valve is maintenance-free.

Repair

The valve can not be repaired. It has to be replaced as a complete unit.

Disposal

Do not dispose of the actuator and its electrical and electronic components with

domestic waste.

The law may require special handling of certain components or it may make sense

from an ecological point of view.

Observe all applicable local laws.

Warranty

Observe all application-specific technical data.

If you ignore specified limits, Siemens Building Technologies / CPS Products will

nor assume any responsibility.

Technical data

Functional actuator data

Power supply Extra low-voltage only (SELV, PELV)

• AC 24 V

Operating voltage AC 24 V ± 20%

Frequency 45...65 Hz

Typical power consumption P

12 W

med

Standby < 1 W (valve closed)

Rated apparent power S

22 VA (for selecting the transformer)

NA

Required fuse 1.6...4 A (slow)

• DC 24 V

Operating voltage DC 20...30 V

Current draw 0.5 A / 2 A (max.)

Signal inputs Control signal Y DC 0/2...10 V or DC 0/4...20 mA

Impedance DC 0/2...10 V 100 kΩ / 5nF

Impedance DC 0 / 4...20 mA 240 Ω / 5nF

Forced control ZC

Input impedance 22 kΩ

Close valve (ZC connected to G0) < AC 1 V; < DC 0.8 V

Open valve (ZC connected to G) > AC 6 V; > DC 5 V

No function (ZC not wired) Positioning signal Y active

Signal outputs Position feedback signal U Voltage DC 0/2…10 V; load resistance ≥ 500 Ω

Current

Stroke detection

Nonlinearity

DC 0/4…20 mA; load resistance ≤ 500 Ω

Inductive

Accuracy ± 3 % full scale

Positioning time Positioning time < 1 s

Electrical connections Cable entry glands 3 x Ø 17 mm (for M16)

Min. wire cross-section 0.75 mm2

Max. cable length See «Connection type», page 5

Product data valve Permissible operating pressure max. 4.,5 MPa (45 bar) 1)

Max. differential pressure Δp

2.5 MPa (25 bar)

max

DN32: 200 kPa (2 bar)

Valve characteristic (stroke, kv) Linear (to VDI / VDE 2173)

Leakage rate (internally across seat) Max. 0.002% kvs or

Max. 1 Nl/h gas at Δp = 4 bar

Shut/off function, like solenoid normally closed

(NC) function

7/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 8

External seal Hermetically sealed (fully welded,

no static or dynamic seals)

Permissible media Commonly used safety refrigerants (R22,

R134a, R404A, R407C, R410A, R507 etc.)

and R744 (CO

Not suitable for flammable refrigerants

);

2

2)

Medium temperature -40...120 °C; max. 140 °C for 10 min

Stroke resolution

ΔH

/

1 : 1000 (H = stroke)

H100

Hysteresis Typically 3 %

Mode of operation Modulating

Position when deenergized Control path A AB closed

Orientation Upright to horizontal

3)

Materials Valve body and parts Steel / CrNi steel

Seat / piston CrNi steel / brass

Sealing disk PTFE

Pipe connections Sleeves Internally soldered, CrNi steel

Dimensions and weight Dimensions See "Dimensions" page 11

Weight See "Dimensions" page 11

Standards CE conformity

To EMC requirements

Immunity EN 61000-6-2:[2005] Industrial

2004/108/EC

4)

Emission EN 61000-6-3:[2007] Residential

Electrical safety EN 60730-1

Protection class Class III as per EN 60730

Degree of pollution Degree 2 as per EN 60730

Housing protection

Upright to horizontal

Vibration

5)

EN 60068-2-6

IP65 as per EN 60529

3)

5 g acceleration, 10...150 Hz, 2.5 h

(5 g horizontal, max. 2 g upright)

Conformant to UL standards

CSA, Canada

C-tick

UL 873

C22.2 No. 24

N 474

Environmental compatibility ISO 14001 (environment)

ISO 9001 (quality)

SN 36350 (environmentally-compatible products)

RL 2002/95/EG (RoHS)

Permissible operating pressure PED 97/23/EC

Pressure accessories As per article 1, section 2.1.4

Fluid group 2 Without CE-marking as per article 3, section 3

(sound engineering practice)

1)

To EN 12284 tested with 1,43 x operating pressure at 65 bar

2)

For flammable refrigerants use ATEX certified refrigerant valves (CDV..MVL..)

3)

At 45 °C < T

shortening the service life of the valve electronics

4)

Transformer 160 VA (e.g. Siemens 4AM 3842-4TN00-0EA0)

5)

In case of strong vibrations, use high-flex stranded wires for safety reasons.

< 55 °C and 80 °C < T

amb

< 120 °C the valve must be installed on its side to avoid

med

General

environmental conditions

Operation

EN 60721-3-3

Transport

EN 60721-3-2

Storage

EN 60721-3-1

Climatic conditions Class 3K6 Class 2K3 Class 1K3

Temperature –25...55 °C –25...70 °C –5...45 °C

Humidity 10...100% r. h. < 95% r. h. 5...95% r. h.

8/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 9

Connection terminals

Connection diagrams

Terminal assi

gnment

for controller with

4-wire connection

(to be preferred!)

Terminal assignment

for controller with

3-wire connection

Common transformer Separate transformer

Common transformer Separate transformer

Indication of valve position (only if required). DC 0...10 V → 0...100% volumetric flow V100

U

Twisted pairs. If the lines for AC 24 V power supply and the DC 0...10 V (DC 2...10 V,

DC 0... 20 mA, DC 4... 20 mA) positioning signal are routed separately, the AC 24 V line need

not be twisted.

Warning

DIL switch

Piping must be connected to potential earth!

Factory setting: Valve characteristics equal-percentage, positioning signal DC 0...10 V.

Details see "Configuration DIL switches", page 3.

Calibration

See "Calibration", page 4.

9/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 10

Dimensions

Dimensions in mm

H4

D

H3

H1 H2

Type reference DN D L H1 H2 H3 H4 T M

[inch] [mm] [mm] [mm] [mm] [mm] [mm] [kg]

MVL661.15-0.4 15 5/8" 140 44 36 113 160 103 4.4

MVL661.15-1.0 15 5/8" 140 44 36 113 160 103 4.4

MVL661.20-2.5 20 7/8" 150 41 41 119 160 103 4.5

MVL661.25-6.3 25 1 1/8" 160 40 47 126 160 103 4.6

MVL661.32-12 32 1 3/8" 190 43 54 142 160 103 6.1

DN Nominal size

D Pipe connections [inch], internal dimension

T Depth

M Weight including packaging [kg]

Valve sizing with correction factor

The applications and tables on the following pages are designed for help with selecting

the valves. To select the correct valve, the following data is required:

• Application

− Expansion (starting on page 14)

− Hot-gas (starting on page 16)

− Suction throttle (starting on page 18)

• Refrigerant type

• Evaporating temperature t

• Condensing temperature t

• Refrigeration capacity Q

L

[°C]

0

[°C]

c

[kW]

0

To calculate the nominal capacity, use the following formula:

*

• k

[m³/h] = Q0 [kW] / K...*

vs

K... for expansion = KE

for hot-gas = KH

for suction throttle = KS

• The theoretical kv value for the nominal refrigeration capacity of the plant should not

be less than 50% of the kvs value of the selected valve.

10/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 11

• For accurate valve sizing, we recommend the valve selection program "Refrigeration

VASP".

The application examples on the following pages deal with the principles only. They do

not include installation-specific details such as safety elements, refrigerant collectors,

etc.

Use of the MVL661..-.. as an expansion valve

Note

Capacity optimization

Application example

Note on interpolation

Observe engineering notes page 6

• Typical control range 20...100%.

• Increased capacity through better use of the evaporator

• The use of two or more compressors or compressor stages significantly increases

efficiency with low loads

• Especially suitable for fluctuating condensing and evaporating pressures

4

1

2

40153A

3

1 = MVL661..-..

2 = evaporator

3 = compressor

4 = condenser

Electronic superheat control is achieved by using additional control equipment

(e.g. PolyCool).

Refrigerant R407C; Q

The correct k

value for the MVL661..-.. valve needs to be determined.

vs

= 205 kW; to = –5 °C; tc = 35 °C

0

The important section of table KE for R407C (see page 12) is the area around the

working point. The correction factor KE relevant to the working point should be

determined by linear interpolation from the four guide values.

In practice, the KE, KH or KS value can be estimated because the theoretical k

ascertained will be rounded off by up to 30% to one of the ten available k

vs

-value

vs

-values,

allowing you to proceed directly at Step 4.

Step 1: For t

= 35, calculate the value for to = –10 between values 20 and 40 in the

c

table; result: 112

Step 2: For t

= 35, calculate the value for to = 0 between values 20 and 40 in the

c

table; result: 109

Step 3: For t

= –5, calculate the value for tc = 35 between correction factors 112

0

and 109; calculated in steps 1 and 2; result: 111

Step 4: Calculate the theoretical k

Step 5: Select the valve; the valve closest to the theoretical k

value; result: 1.85 m3/h

vs

value is the

vs

MVL661.20-2.5

Step 6: Check that the theoretical k

k

value

vs

value is not less than 50 % of the nominal

vs

11/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 12

Capacity control

KE-R407C t0 = –10 °C t0 = 0 °C Interpolation at tc = 35 °C

tc = 20 °C 108 85 108 + [(113 – 108) x (35- 20) / (40 - 20)] 112

tc = 35 °C 112 109

tc = 40 °C 113 117 85 + [(117 - 85) x (35 - 20) / (40 - 20)] 109

Interpolation at t0 = -5 °C

112 +[(109 - 112) x (-5 - 0) / (-10 - 0)] 111

kv theoretical = 205 kW / 111 = 1.85 m3/h

Valve MVL661.20-2.5 is suitable, since: 1.85 m

3

/h / 2.5 m3/h x 100% = 74% (> 50%)

a) Refrigerant valve MVL661..-.. for capacity control of a dry expansion evaporator.

Suction pressure and temperature are monitored with a mechanical capacity

controller and reinjection valve.

• Typical control range 0...100%

• Energy-efficient operation with low loads

• Ideal control of temperature and dehumidification

40155A

MVL661

*

b) Refrigerant valve MVL661..-.. for capacity control of a chiller.

• Typical control range 10...100%

• Energy-efficient operation with low loads

• Allows wide adjustment of condensing and evaporating temperatures

• Ideal for use with plate heat exchangers

• Very high degree of frost protection

40156A

MVL661

Note

A larger valve may be required for low load operation than is needed for full load

conditions. To ensure that the selected valve will not be too small for low loads, sizing

should take account of both possibilities.

12/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 13

Correction table KE

Expansion valve

R22 R134a

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 82 68 37 00 27

20 101 104 107 105 81 18 20 71 74 77 66 43

40 108 111 114 118 120 123 40 74 78 81 85 89 92

60 104 108 112 116 119 122 60 67 72 76 81 85 89

R744

tc \ to -40 -30 -20 -10 0 10

-20 226 149

00 262 264 241 166

20 245 247 247 246 213

R401A R402A

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 31 00 73 69 50

20 80 83 85 72 46 20 77 81 85 88 74 35

40 87 90 94 97 101 102 40 71 75 80 84 88 91

60 85 89 94 98 102 106 60 50 55 60 65 69 74

R404A R407A

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 69 63 44 00 79 67 40

20 70 74 78 81 68 30 20 91 95 98 102 82 30

40 61 65 70 74 78 81 40 89 94 98 102 106 110

60 36 41 46 51 55 59 60 72 77 82 87 92 96

R407B R407C

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 72 66 45 00 79 65 31

20 77 80 84 88 75 34 20 98 101 105 108 85 21

40 69 74 78 83 87 91 40 100 104 109 113 117 121

60 46 51 56 61 66 70 60 87 93 98 103 108 113

R410A R410B

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 116 117 91 12 00 112 112 87 11

20 125 130 133 137 120 69 20 122 126 129 132 115 66

40 119 124 129 133 137 140 40 119 124 128 131 134 137

60 90 96 101 106 110 114 60 98 103 108 112 115 118

R507

tc \ to -40 -30 -20 -10 0 10

00 72 66 47

20 78 81 83 86 71 33

40 74 78 81 84 87 90

60 53 57 61 64 68 71

• With superheat = 6 K With subcooling = 2 K Δp upstream of evaporator = 1.6 bar

• Δp condenser = 0.3 bar Δp evaporator = 0.3 bar

13/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 14

Use of the MVL661..-.. as a hot-gas valve

The control valve throttles the capacity of a compressor stage. The hot gas passes

directly to the evaporator, thus permitting capacity control in the range from 100% down

to approximately 0%.

Indirect hot-gas

bypass application

Application example

With low loads, the evaporating and condensing pressures can fluctuate depending on

the type of pressure control. In such cases, evaporating pressure increases and

condensing pressure decreases. Due to the reduction in differential pressure across the

fully open valve, the volumetric flow rate will drop – the valve is undersized. This is why

the effective pressures must be taken into account when sizing the valve for low loads.

Refrigerant R507; 3 compressor stages; Q

Part load Q

0

KH-R507 t0 = 0 °C t0 = 10 °C Interpolation at tc = 23 °C

tc = 2 °C 14.4 9.0 14.4 + [(22.4 – 14.4) x (23 - 20) / (40 - 20)] 15.6

tc = 23 °C 15.6 11.0

tc = 40 °C 22.4 22.0 9.0 + [(22.0 – 9.0) x (23 - 20) / (40 - 20)] 11.0

Interpolation at t0 = 4 °C

15.6 + [(11.0 – 15.6) x (4 - 0) / (10 - 0)] 13.8

kvs theoretical = 28 kW / 13.8 = 2.03 m3/h

Valve MVL661.20-2.5 is suitable, since: 2.03 m

+

70179

Suitable for use in large refrigeration

MVL661

systems in air conditioning plant, to prevent

unacceptable temperature fluctuations

–

between the compressor stages.

= 75 kW; t0 = 4 °C; tc = 40 °C

0

per stage = 28 kW; t0= 4 °C; tc = 23 °C

3

/h / 2.5 m3/h x 100% = 81% (> 50%)

Direct hot-gas bypass

application

The control valve throttles the capacity of one compressor stage. The gas is fed to the

suction side of the compressor and then cooled using a reinjection valve. Capacity

control ranges from 100% down to approximately 10%.

+

MVL661

70180

Suitable for large refrigeration systems in air

conditioning applications with several

compressors or compressor stages, and

where the evaporator and compressor are

some distance apart (attention must be paid

–

to the oil return).

14/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 15

Correction table KH

Hot-gas valve

R22 R134a

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 8.9 8.4 6.3 00 4.5

20 15.3 15.1 14.8 14.6 13.2 6.5 20 9.8 9.6 9.5 9.2 7.4

40 24.2 23.7 23.2 22.8 22.4 22.1 40 15.9 15.6 15.3 15.1 14.9 14.7

60 35.7 34.7 33.8 33.0 32.3 31.7 60 23.8 23.2 22.7 22.3 21.9 21.6

R744 R290

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

-20 38.1 30.5 00 10.9 10.0 6.5

00 60.9 59.8 58.1 47.1 20 18.0 17.7 17.4 17.1 15.0

20 87.3 84.9 82.5 80.2 76.1 40 27.3 26.7 26.2 25.8 25.4 25.1

60 38.2 37.2 36.4 35.7 35.1 34.5

R401A R402A

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 4.7 00 9.7 9.5 8.3

20 10.2 10.0 9.9 9.5 7.6 20 15.9 15.7 15.4 15.2 14.5 9.3

40 16.9 16.6 16.2 16.0 15.8 15.6 40 23.7 23.2 22.7 22.4 22.0 21.7

60 25.9 25.2 24.6 24.1 23.7 23.3 60 31.5 30.7 29.9 29.2 28.7 28.1

R404A R407A

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 9.4 9.2 7.8 00 8.9 8.6 6.7

20 15.2 15.0 14.8 14.6 13.9 8.6 20 15.7 15.4 15.2 15.0 14.1 8.0

40 22.3 21.8 21.5 21.1 20.9 20.6 40 24.9 24.4 23.9 23.5 23.1 22.8

60 28.8 28.0 27.4 26.8 26.4 25.9 60 35.9 34.9 34.0 33.2 32.6 32.0

R407B R407C

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 9.0 8.8 7.4 00 8.6 8.1 5.9

20 15.3 15.1 14.8 14.7 14.0 8.8 20 15.3 15.0 14.8 14.6 13.6 7.0

40 23.3 22.8 22.4 22.0 21.7 21.5 40 24.7 24.2 23.7 23.3 22.9 22.6

60 31.6 30.7 30.0 29.3 28.8 28.3 60 36.3 35.3 34.4 33.6 33.0 32.4

R410A R410B

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 14.5 14.3 13.2 6.2 00 14.3 14.1 12.9 6.1

20 24.2 23.7 23.3 23.0 22.1 15.9 20 23.8 23.3 22.9 22.5 21.6 15.5

40 36.8 35.9 35.1 34.4 33.7 33.1 40 36.5 35.6 34.7 33.9 33.2 32.5

60 50.0 48.5 47.2 46.0 44.9 43.8 60 50.7 49.1 47.7 46.4 45.2 44.0

R507 R1270

tc \ to -40 -30 -20 -10 0 10 tc \ to -40 -30 -20 -10 0 10

00 9.8 9.5 8.1 00 13.5 13.0 10.3

20 16.1 15.8 15.5 15.3 14.4 9.0 20 22.0 21.6 21.2 20.9 19.0 9.9

40 24.5 23.8 23.3 22.8 22.4 22.0 40 33.0 32.2 31.6 31.1 30.6 30.1

60 33.1 31.8 30.7 29.8 29.0 28.3 60 46.1 44.8 43.8 42.8 41.9 41.2

• With superheat = 6 K With subcooling = 2 K Δp upstream of evaporator = 1.6 bar

• Δp condenser = 0.3 bar Δp evaporator = 0.3 bar

15/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 16

Use of the MVL661..-.. as a suction throttle valve

Application example

+

70177

Typical control range 50...100%.

Minimum stroke limit control:

MVL661

–

To ensure optimum cooling of the compressor,

either a capacity controller must be provided for

the compressor, or a minimum stroke must be set

via the valve electronics.

The minimum stroke can be limited to a maximum of 80%. At zero load, the minimum

stroke must be sufficient to ensure that the minimum gas velocity in the suction line is >

0.7 m/s and that the compressor is adequately cooled.

As the control valve closes, the evaporating temperature rises and the air cooling effect

decreases continuously. The electronic control system provides demand-based cooling

without unwanted dehumidification and costly retreatment of the air.

The pressure at the compressor inlet falls and the power consumption of the

compressor is reduced. The energy savings to be anticipated with low loads can be

determined from the compressor selection chart (power consumption at minimum

permissible suction pressure). Compressor energy savings of up to 40% can be

achieved.

The recommended differential pressure Δp

between 0.15 <

Δp

< 0.5 bar.

v100

across the fully open control valve is

v100

Refrigerant R134A; Q

Differential pressure across MVL661: Δp

= 9.5 kW; t0 = 4 °C; tc = 40 °C;

0

= 0.25 bar

v100

In this application example, t

, tc and Δp

0

are to be interpolated.

v100

KS-R134a t0 = 0 °C t0 = 10 °C Interpolation at t0 = 4 °C

0.15 / 20 2.2 2.7 2.2 + [(2.7 – 2.2) x (4 - 0) / (10 - 0)] 2.4

0.15 / 50 1.7 2.1 1.7 + [(2.1 – 1.7) x (4 - 0) / (10 - 0)] 1.9

0.45 / 20 3.6 4.5 3.6 + [(4.5 – 3.6) x (4 - 0) / (10 - 0)] 4.0

0.45 / 50 2.7 3.4 2.7 + [(3.4 – 2.7) x (4 - 0) / (10 - 0)] 3.0

t0 = 4 °C tc = 20 °C tc = 50 °C

Δp

0.15

v100

Δp

0.45

v100

tc = 40 °C

2.1 3.3

kvs theoretical = 9.5 kW / 2.5 = 3.8 m3/h

Valve MVL661.25-6.3 is suitable, since 3.8 m

It is recommended that the k

2.4 1.9 2.4 + [(1.9 – 2.4) x (40 - 20) / (50 - 20)] 2.1

4.0 3.0 4.0 + [(3.0 – 4.0) x (40 - 20) / (50 - 20)] 3.3

Δp

v100

+

0.15 Δp

0.45

v100

value be set to 63% = 4 m3/h

vs

50941A

Interpolation at tc = 40 °C

Interpolation at

2.1 + [(3.3 – 2.1) x (0.25 – 0.15) / (0.45 –

0.15)]

3

/h / 6.3 m3/h x 10 % = 60% (> 50%)

Δp

v100

2.5

0.25

Typical control range 10...100%.

The capacity controller ensures that the

compressor is adequately cooled, making it

–

MVL661

unnecessary to set a minimum stroke in the

refrigerant valve.

16/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

Page 17

Correction table KS

Suction throttle valve

tc R22 tc R134a

Δp

\ to -40 -30 -20 -10 0 10 Δp

v100

\ to-40 -30 -20 -10 0 10

v100

0.15 / 20 1.2 1.5 1.9 2.4 2.9 3.4 0.15 / 20 0.7 1.0 1.4 1.8 2.2 2.7

0.15 / 50 0.9 1.2 1.5 1.9 2.3 2.7 0.15 / 50 0.5 0.7 1.0 1.3 1.7 2.1

0.45 / 20 1.5 2.3 3.0 3.9 4.8 5.7 0.45 / 20 0.7 1.2 1.9 2.7 3.6 4.5

0.45 / 50 1.2 1.8 2.4 3.0 3.8 4.6 0.45 / 50 0.5 0.9 1.4 2.0 2.7 3.4

tc R152A tc R290

Δp

\ to -40 -30 -20 -10 0 10 Δp

v100

\ to-40 -30 -20 -10 0 10

v100

0.15 / 20 0.9 1.3 1.7 2.2 2.7 3.3 0.15 / 20 1.5 1.9 2.4 3.0 3.6 4.3

0.15 / 50 0.7 1.0 1.4 1.7 2.2 2.7 0.15 / 50 1.0 1.4 1.8 2.2 2.7 3.3

0.45 / 20 1.0 1.5 2.4 3.3 4.3 5.3 0.45 / 20 2.0 2.8 3.8 4.8 6.0 7.2

0.45 / 50 0.7 1.2 1.9 2.6 3.5 4.4 0.45 / 50 1.4 2.1 2.8 3.6 4.5 5.5

tc R401A tc R402A

Δp

\ to -40 -30 -20 -10 0 10 Δp

v100

\ to-40 -30 -20 -10 0 10

v100

0.15 / 20 0.8 1.1 1.5 1.9 2.3 2.9 0.15 / 20 1.1 1.4 1.8 2.2 2.7 3.3

0.15 / 50 0.6 0.8 1.1 1.5 1.8 2.3 0.15 / 50 0.7 0.9 1.2 1.5 1.8 2.3

0.45 / 20 0.8 1.3 2.1 2.9 3.7 4.7 0.45 / 20 1.5 2.2 2.9 3.7 4.6 5.6

0.45 / 50 0.6 1.0 1.6 2.3 3.0 3.7 0.45 / 50 0.9 1.4 1.9 2.4 3.1 3.8

tc R404A tc R407A

Δp

\ to -40 -30 -20 -10 0 10 Δp

v100

\ to-40 -30 -20 -10 0 10

v100

0.15 / 20 1.0 1.3 1.7 2.2 2.7 3.3 0.15 / 20 1.0 1.4 1.8 2.3 2.9 3.5

0.15 / 50 0.6 0.8 1.1 1.4 1.7 2.1 0.15 / 50 0.7 1.0 1.3 1.6 2.1 2.6

0.45 / 20 1.4 2.1 2.8 3.6 4.5 5.5 0.45 / 20 1.3 2.0 2.9 3.8 4.7 5.9

0.45 / 50 0.8 1.2 1.7 2.3 2.9 3.6 0.45 / 50 0.9 1.4 2.0 2.7 3.4 4.3

tc R407B tc R407C

Δp

\ to -40 -30 -20 -10 0 10 Δp

v100

\ to-40 -30 -20 -10 0 10

v100

0.15 / 20 1.0 1.3 1.7 2.2 2.7 3.3 0.15 / 20 1.0 1.4 1.8 2.3 2.9 3.5

0.15 / 50 0.6 0.8 1.1 1.4 1.8 2.2 0.15 / 50 0.7 1.0 1.3 1.7 2.1 2.6

0.45 / 20 1.3 2.0 2.7 3.5 4.5 5.5 0.45 / 20 1.3 2.0 2.8 3.8 4.8 5.9

0.45 / 50 0.8 1.2 1.7 2.3 3.0 3.8 0.45 / 50 0.9 1.4 2.1 2.8 3.5 4.4

tc R410A tc R410B

Δp

\ to -40 -30 -20 -10 0 10 Δp

v100

\ to-40 -30 -20 -10 0 10

v100

0.15 / 20 1.5 2.0 2.5 3.0 3.6 4.4 0.15 / 20 1.5 1.9 2.4 2.9 3.6 4.2

0.15 / 50 1.0 1.3 1.7 2.1 2.6 3.1 0.15 / 50 1.0 1.3 1.7 2.1 2.6 3.1

0.45 / 20 2.3 3.1 4.0 5.0 6.1 7.4 0.45 / 20 2.3 3.1 3.9 4.9 6.0 7.2

0.45 / 50 1.6 2.1 2.8 3.5 4.4 5.3 0.45 / 50 1.6 2.1 2.8 3.5 4.3 5.2

• With superheat = 6 K With subcooling = 2 K Δp upstream of evaporator = 1.6 bar

• Δp condenser = 0.3 bar Δp evaporator = 0.3 bar

Revision numbers

Product number Valid from rev. no.

MVL661.15-0.4

MVL661.15-1.0

MVL661.20-2.5

MVL661.25-6.3

MVL661.32-12

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

C

C

D

C

C

17/18

Page 18

s

18/18

Siemens Modulating refrigerant valves with magnetic actuator, PS45 CE2N4714en

Building Technologies 30.05.2011

2011 Siemens Switzerland Ltd Subject to change

Loading...

Loading...