Page 1

722

4

Modulating refrigerant

M3FK..LX..

valves with magnetic

actuator, PN 32

hermetically sealed, for condenser control

• Mixing or straight-through valves with magnetic actuator for modulating

capacity control of condensers.

• Short positioning time (approx. 1 s)

• High resolution

• High rangeability

• Hermetically sealed

• Versatile electrical interface

• Friction-free

• Port 1 -> 3 closed when de-energized

• Robust and maintenance-free

Use

CE2N4722en

08.06.2010

The M3FK..LX.. mixing or straight-through valves with magnetic actuator can be used

for modulating capacity control of condensers. They may be used for liquid or gas

control.

Suitable for safety refrigerants such as R22, R134a, R404A, R407C, R507, etc.

Building Technologies

Page 2

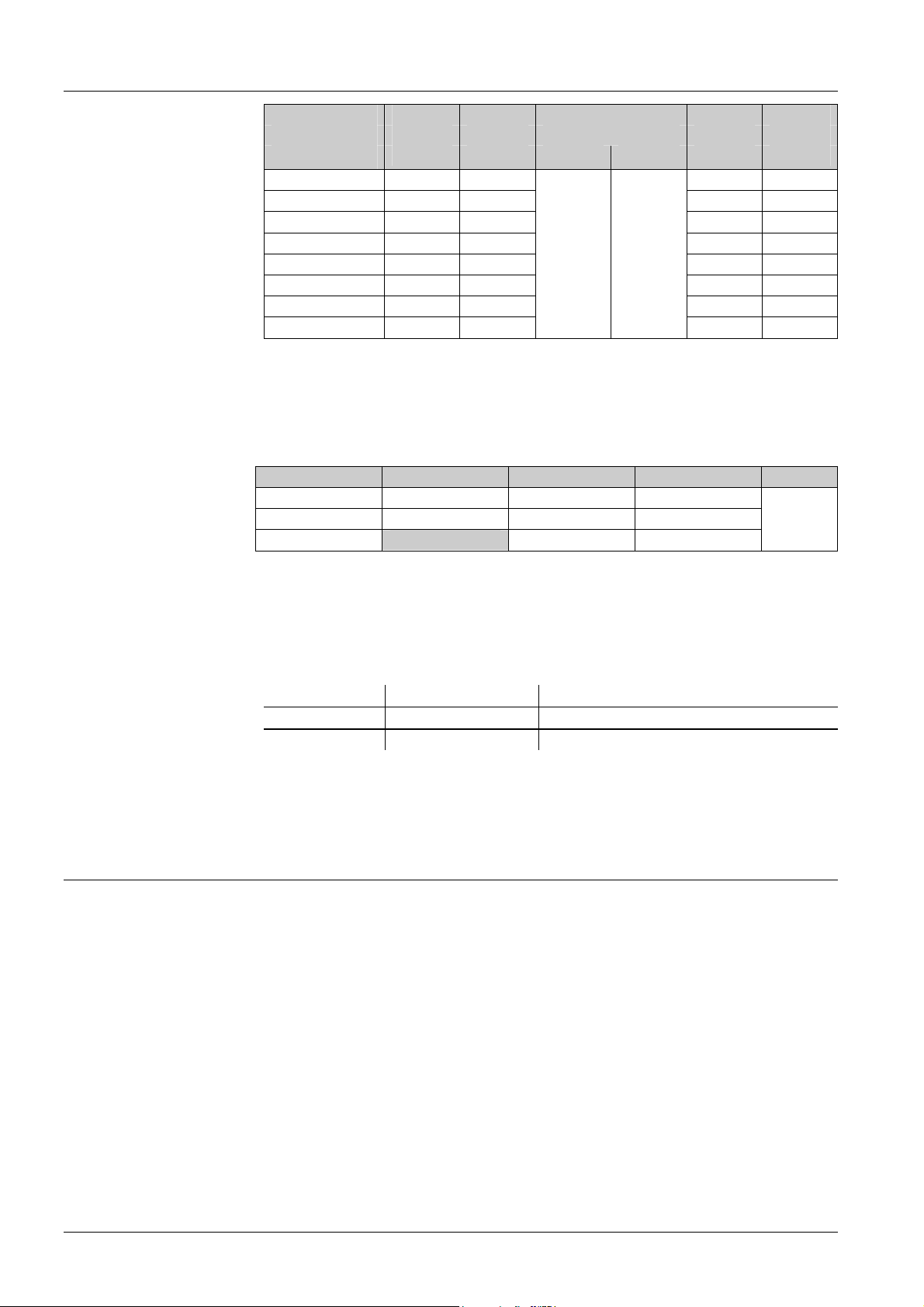

Type summary

Accessories /

ZM.. terminal housing

Order

Type reference DN kvs Δp

Liquid Gas

[m3/h] [MPa] [bar] [VA] [W]

M3FK15LX06

M3FK15LX15

M3FK15LX

M3FK20LX

M3FK25LX

M3FK32LX

M3FK40LX

M3FK50LX

= Maximum permissible differential pressure across the valve’s control path 1 → 3 valid for the

Δp

max

entire actuating range

= Rated apparent power for transformer selection

S

NA

P

= Typical power consumption

med

k

= Nominal flow rate of cold water through the fully open valve (H

vs

100 kPa (1 bar), to VDI 2173

15 0.6 13 3

15 1.5 13 3

15 3.0 13 3

20 5.0 16 4

25 8.0 16 4

0.2 0.8

32 12.0 20 5

40 20.0 40 10

50 30.0

SNA P

max

40 10

) by a differential pressure of

100

med

Type reference Operating voltage Positioning signal Working range Data sheet

ZM101/A AC 24 V DC 0…10 V DC 4…8 V

ZM121/A AC 24 V DC 4…20 mA DC 8…16 mA

ZM111 DC 0…20 V Phs DC 10…15 V Phs

For the ZM101/A and ZM121/A types also the DC 0…20 V Phs positioning signal is possible without

operating voltage.

N4591

The M3FK..LX.. valve and the ZM.. or ZM../A terminal housing must be ordered

separately.

When placing an order, please specify the quantity, product description and type code.

Type reference Stock number Description

M3FK15LX M3FK15LX Refrigerant valve

ZM101/A ZM101/A Terminal housing

Delivery

Rev. no.

Valves and terminal housings are packed separately.

Overview table, see page 9.

Technical and mechanical design

The armature or magnetic core is designed as a floating component within the pressure

system, so that no external shaft gland is required. The leakage losses common with

moving parts are thus avoided. The valve cross-section allows for easy flow whether

the valve is fully or only partially open. This reduces pressure losses and ensures quiet

operation.

The valves are fitted with extended female solder unions, making pipe connection easy.

The control signal is converted in the ZM../A terminal housing into a phase cut signal,

which generates a magnetic field in the coil. This causes the only moving part, the

armature, to change its position in accordance with the interacting forces (magnetic

field, counter-spring, hydraulics etc.). The armature responds rapidly to any change in

signal, transferring the corresponding movement directly to the control disc, enabling

fast changes in load to be corrected quickly and accurately.

The force of the counter-spring closes the valve automatically (control path ports 1 -> 3)

if the power is switched off or fails.

2/10

Siemens Modulating refrigerant valves with magnetic actuator, PN 32 CE2N4722en

Building Technologies 08.06.2010

Page 3

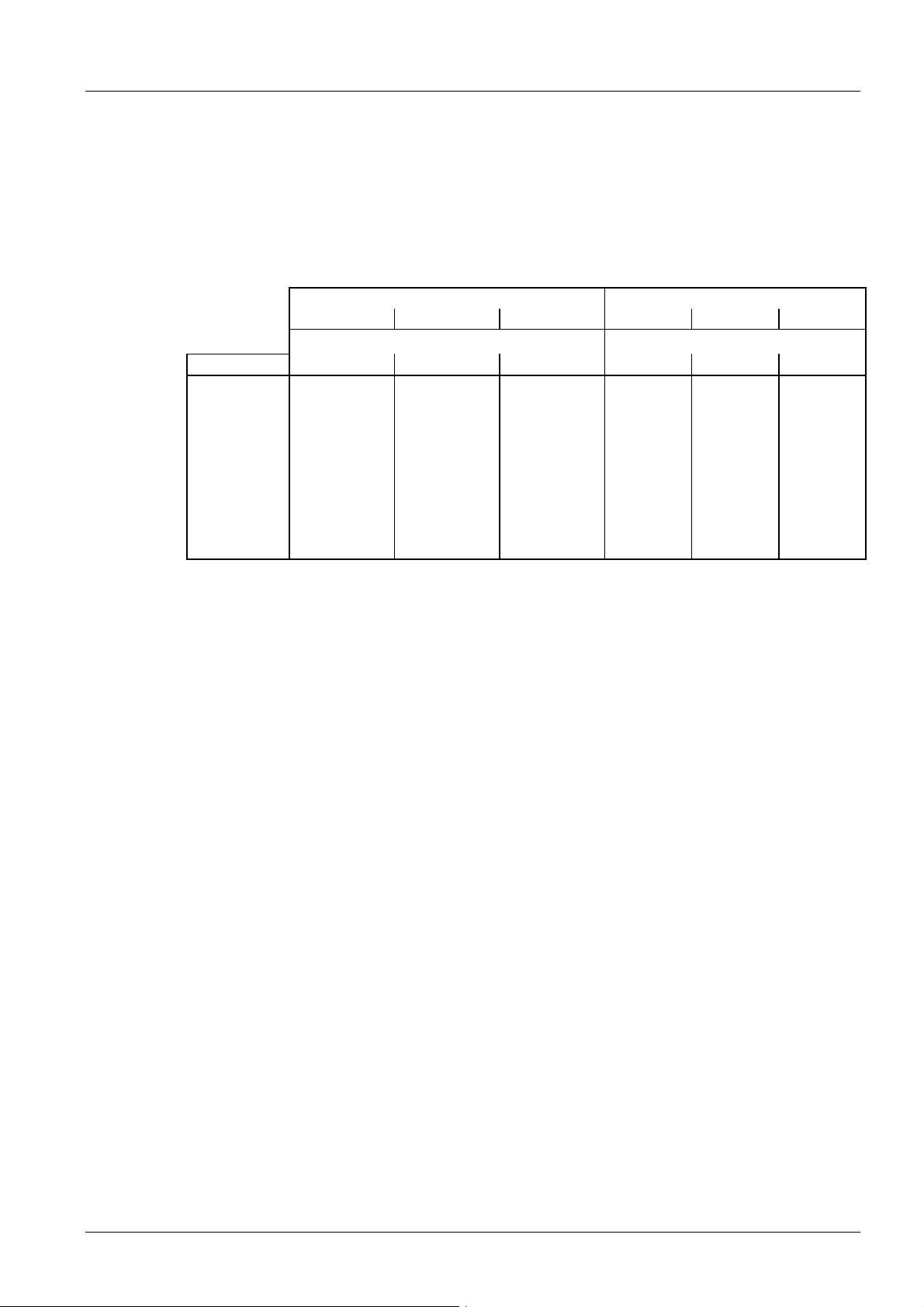

Sizing

Refrigeration capacity

Q

0

Selection table for

approximate guide to

valve size

Hot gas Liquid

R407C (R22) R134a (R12) R404A / R507 R407C (R22) R134a (R12) R404A R507

Condensation temperature tc [°C] Liquid temperature tfl [°C]

Valve type 30 40 50 30 40 50 30 40 50 30 40 30 40 30 40

M3FK15LX06 4.5 4.0 3.6 3.7 3.3 2.9 3.6 3.2 2.9 21 19 20 18 15 12

M3FK15LX15 11 10 8.9 9.2 8.2 7.2 8.9 8.0 7.2 54 49 51 45 37 31

M3FK15LX 22 20 18 18 16 14 18 16 14 107 97 102 91 74 62

M3FK20LX 37 33 30 31 27 24 30 27 24 179 162 170 151 124 103

M3FK25LX 59 53 48 49 44 38 47 43 38 286 259 272 242 199 165

M3FK32LX 89 80 72 74 66 57 71 64 58 429 389 408 364 298 248

M3FK40LX 149 134 119 123 109 96 119 107 96 715 648 681 606 497 413

M3FK50LX 223 201 179 184 164 143 178 160 144 1073 971 1021 909 745 619

Correct valve sizing (to ensure a sufficiently large pressure drop Δp

100 across the fully

v

open valve) is the key to the correct operation of a refrigeration unit. All the components

must be coordinated, and this can be ensured only by the refrigeration specialist.

The application examples on pages 5 and show the recommended pressure drop in

each case.

Pressure differential ∆p

in kW at an evaporation temperature t

= 0.5 bar across the fully-open valve. Nominal capacity Q0

V100

of 5 °C and a liquid temperature tfl of 30 °C.

o

Δp

= Differential pressure across the fully open valve (control path 1 → 3) by a volume flow

v100

V

100

3/10

Siemens Modulating refrigerant valves with magnetic actuator, PN 32 CE2N4722en

Building Technologies 08.06.2010

Page 4

Selection chart

+10

+5

0

-5

-10

-15

-20

]

-25

C

°

[

-30

0

t

-35

-40

5

2

+

+10

+5

-10

-15

-20

-25

-30

-35

-40

+10

-10

-15

-20

-25

-30

-35

-40

]

0

C

°

[

l

f

-5

t

+5

0

-5

+5°C

]

C

°

[

0

t

]

C

°

[

0

t

50320A

0

6

0

7

5

4

3

p

[bar]

Δ

0

0

5

5

4

3

3

2

+

+

+

]

C

°

[

l

f

t

5

0

5

0

4

4

3

3

+

+

+

+

0

0

5

5

5

6

5

6

+

+

+

+

5

0

5

0

5

6

6

5

5

4

+

+

+

+

+

+

R134a

(R12)

V

p

Δ

V

[bar]

,

,

,

1

0

,

1

,

0

0

0

7

5

,

,

,

0

0

0

2

,

,

0

0

t

4

3

2

,

,

0

0

R407C

(R22)

2

3

4

5

7

0

[bar]

p

Δ

V

5

2

+

4

4

3

3

+

+

+

+

]

C

°

[

l

f

t

6

6

5

5

+

+

+

+

R404A

R507

5

0

5

0

5

0

5

0

1

,

,

,

0

0

0

,

,

,

0

0

+

0

4

+

0

2

+

]

C

°

[

l

f

V

p

Δ

0

6

+

0

4

+

0

2

+

]

C

°

[

l

t

f

0

6

+

0

4

+

0

2

+

]

C

°

[

l

t

f

(R502)

1500

1000

800

600

500

400

300

200

150

100

80

60

50

40

30

20

15

10

8

6

5

]

W

k

[

0

.

Q

t0 = Evaporation temperature [°C]

= Condensation temperature [°C]

t

c

= tc - degree of sub-cooling [°C]

t

fl

Q

= Refrigeration capacity [kW]

0

m = Mass flow of refrigerant [kg/h]

= Admissible differential pressure

Δp

v100

[bar], installation-specific

0

0

0

0

5

M

3

F

K

5

0

L

0

0

0

0

2

0

0

0

0

1

0

0

0

5

0

0

0

3

0

0

0

2

0

0

0

1

0

0

6

0

0

4

0

0

3

0

0

2

0

0

1

]

h

/

g

k

[

.

m

X

M

3

F

K

4

0

L

X

M

3

F

K

3

2

L

X

M

3

F

K

2

5

L

X

M

3

F

K

2

0

L

X

M

3

F

K

1

5

L

X

M

3

F

K

1

5

L

X

1

5

M

3

F

K

1

5

L

X

0

6

= Nominal flow rate [m3/h] of cold water through

k

vs

the fully open valve (H

) by a differential

100

k

v

s

3

0

k

v

s

2

0

k

v

s

1

2

k

v

s

8

k

v

s

5

k

v

s

3

k

v

s

1

,

5

k

v

s

0

,

6

pressure of 100 kPa (1 bar)

4/10

Siemens Modulating refrigerant valves with magnetic actuator, PN 32 CE2N4722en

Building Technologies 08.06.2010

Page 5

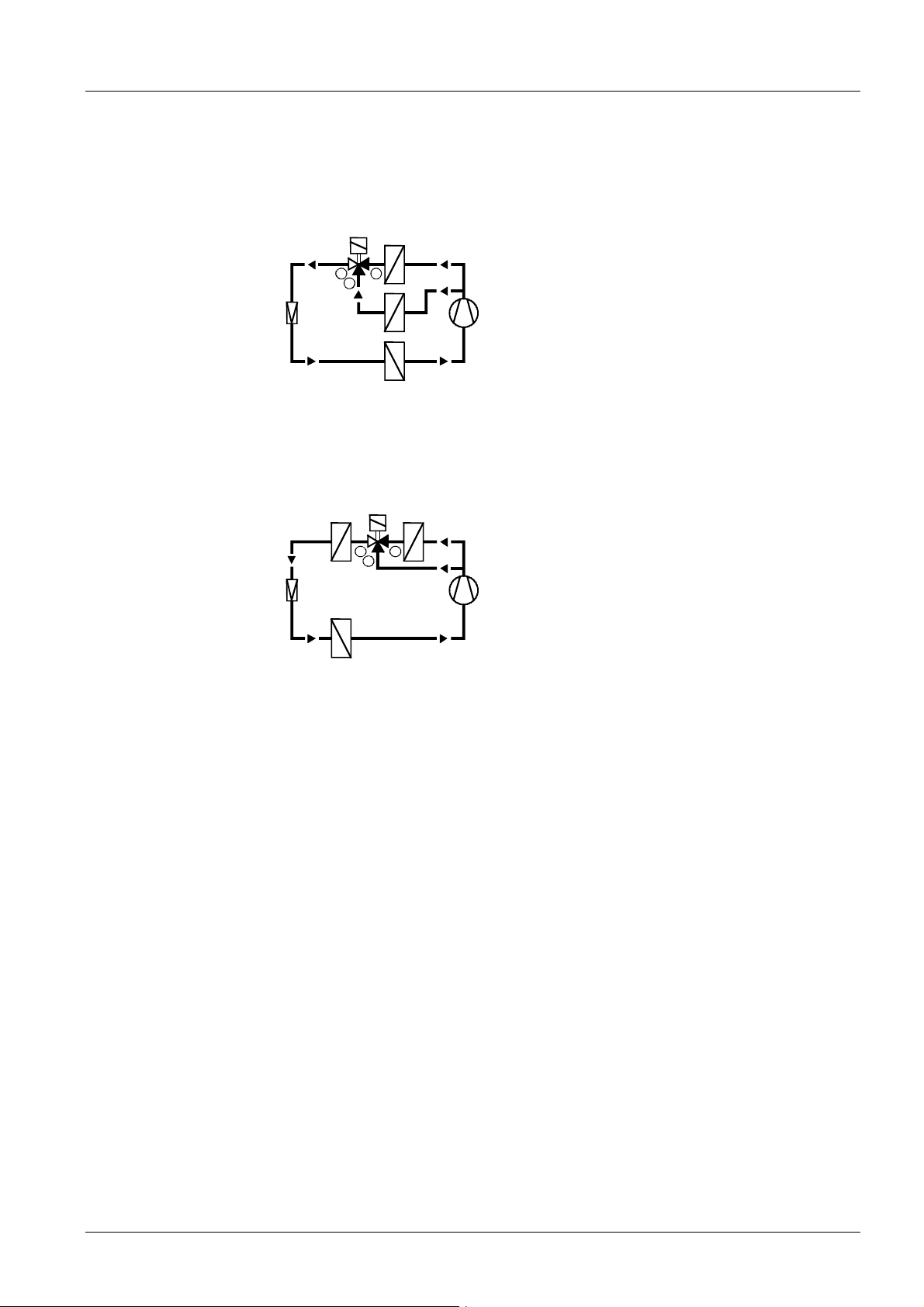

Application examples

3-way hot-gas bypass

control

Hot-gas control

The diagrams shown here are principles only, without installation-specific details.

The heat recovery condenser is connected in parallel with the main condenser and is

controlled on the liquid side by a mixing valve.

Recommended pressure drop Δp

(control path 1 → 3) 0.5 < Δp

+

321

+

940239

–

V100

across the fully-open valve

V100

< 1 bar (see selection chart)

Example:

Refrigeration capacity Q

Refrigerant

Condensation temperature t

Evaporation temperature t

Liquid temperature t

Selected valve

Actual differential pressure Δp

0

c

0

fl

across valve

v100

73 kW

50 °C

+ 5 °C

45 °C

M3FK15LX

0,32 bar

The heat-recovery condenser is connected in series upstream of the main condenser

(the most common application). The selected control valve is sized for hot gas (see

data sheet 4721).

Recommended pressure drop Δp

(control path 1 → 3) 0.5 < Δp

+

321

–

+

V100

940240

across the fully-open valve

V100

< 1 bar (see selection chart)

Example:

Refrigeration capacity Q

Refrigerant

Condensation temperature t

Evaporation temperature

Liquid temperature t

Selected valve

Actual differential pressure Δp

0

0

fl

c

across valve

v100

M3FK32LX

0,45 bar

R22

73 kW

R22

50 °C

5 °C

45 °C

5/10

Siemens Modulating refrigerant valves with magnetic actuator, PN 32 CE2N4722en

Building Technologies 08.06.2010

Page 6

Mounting notes

Caution

Mounting instructions are enclosed with the valve:

• Nr. 35551 (valve)

• Nr. 35541 (ZM.. terminal housing)

90°

90°

• The refrigerant valves can be mounted in any

orientation, but upright mounting is preferable.

• The pipes should be fitted such that the alignment does

not distort the valve connections. The valve body

should be fixed such that it cannot vibrate. Vibration can

lead to burst connection pipes.

• Before soldering the pipes, ensure that the direction of

4722Z01

flow through the valve is correct.

• The pipes must be soldered with care. To avoid dirt and

the formation of scale (oxide), inert gas is

recommended for soldering.

• The flame should be large enough to ensure that the

junction heats up quickly and the valve does not get too

hot.

4721Z02

• The flame should be directed away from the valve.

• During soldering, cool the valve with a wet cloth, for

example, to ensure that it does not become too hot

• Port 2 must be sealed off when the valve is used in a

straight-through application (1 → 3).

• The valve body and the connected pipework should be

lagged.

• The actuator must not be lagged.

Always switch off the power supply before connecting or disconnecting the ZM..

terminal housing.

Maintenance

Repair

Disposal

Warranty

The M3FK..LX.. modulating control valves are maintenance-free.

The valve cannot be repaired. It has to be replaced as a complete unit.

The device must not be disposed of together with domestic waste. This applies in

particular to the PCB.

Legislation may demand special handling of certain components, or it may be sensible

from an ecological point of view

Current local legislation must be observed

.

Application-specific technical data must be observed.

If specified limits are not observed, Siemens Switzerland Ltd / HVAC Products

will nor assume any responsibility.

6/10

Siemens Modulating refrigerant valves with magnetic actuator, PN 32 CE2N4722en

Building Technologies 08.06.2010

Page 7

Technical data

Functional actuator data

Power supply

Extra low-voltage only (SELV, PELV)

Operating voltage

1)

AC 24 V + 15 % / -10 %

Frequency 50…60 Hz

Typical power consumption P

refer to «Type summary» table

med

Rated apparent power SNA refer to «Type summary» table

Required fuse IF 1.6…4 A, slow

Input

Positioning signal ZM101/A DC 0…10 V or DC 0…20 V Phs (phase cut)

ZM121/A DC 4…20 mA or DC 0…20 V Phs

ZM111 DC 0…20 V Phs

Input resistance DC 0…10 V > 100 kΩ

Input resistance DC 4…20 mA < 150 Ω

Positioning time Positioning time < 1 s

Electrical connections Cable entry 2 x Pg11 (ZM101/A, ZM121/A)

Connection terminals max. 1 x 4 mm2 wire cross-section

Min. wire cross-section 0.75 mm2

Functional valve data PN class PN 32 to EN 1333

Permissible operating pressure 3.2 MPa (40 bar)

Max. differential pressure Δp

2 → 3

Leakage at ∆p = 100 kPa (1 bar) 1 → 3

2 → 3

1 → 3

max

refer to «Type summary» table

0.8 MPa (8 bar)

max. 0.05 % kvs

max. 0.5 % k

vs

Valve characteristic (stroke, kv) linear (to VDI / VDE 2173), optimized in low

opening range

Permissible media for safety refrigerants (R22, R134a, R404A,

R407C, R507 etc.).

Not suited for ammonia (R717)

Medium temperature -40...120 °C

Position when de-energized 1 → 3 closed

Orientation upright to horizontal

Type of operation modulating

Materials Valve body steel

Pipe connections CU-pipe

Seat / inner valve brass / CrNi steel

Dimensions and weight Dimensions refer to «Dimensions»

Weight refer to table in «Dimensions»

Pipe connections Sleeves Extended female solder unions

Norms and Standards CE conformity

to EMV-requirements

Immunity EN 61000-6-2:[2005] Industrial

2004/108/EC

2)

Emission EN 61000-6-3:[2007] Residential

Electrical safety EN 60730-1

Housing protection

Upright to horizontal IP54 to EN 60529

Environmental compatibility ISO 14001 (Environment)

ISO 9001 (Quality)

SN 36350 (Environmentally compatible

products)

RL 2002/95/EC (RoHS)

7/10

Siemens Modulating refrigerant valves with magnetic actuator, PN 32 CE2N4722en

Building Technologies 08.06.2010

Page 8

Pressure Equipment directive PED 97/23/EC

Pressure accessories as per article 1, section 2.1.4

Fluid group 2 DN15…DN32

Fluid group 1 DN15…DN25

• without CE-marking as per article 3,

section 3 (sound engineering practice)

Fluid group 2 DN40…DN50 • category I, module A, with CE-marking

1)

No operating voltage is required for the DC 0…20 V Phs power positioning signal.

2)

Transformer 160 VA (e.g. Siemens 4AM 3842-4TN00-0EA0)

General

environmental conditions

Climatic conditions

Temperature

Humidity

Operation

EN 60721-3-3

Transport

EN 60721-3-2

Storage

EN 60721-3-1

Class 3K6 Class 2K3 Class 1K3

-25...55 °C -25...70 °C -5...45 °C

10...100 % r.h. < 95 % r.h. 5...95 % r.h.

Connection terminals

Warning

Connection diagrams

If a ZM../A terminal housing is used with DC 0...20 V Phs (phase cut), AC 24 V must

not be connected!

Always switch off the power supply before connecting or disconnecting the ZM..

terminal housing.

ZM101/A

1

2

3

4

5

6

ZM121/A

1

2

3

4

5

6

(DC 0...10 V or DC 0...20 V Phs)

~

Supply

~

AC 24 V

–

Positioning signal

+

DC 0...10 V

1

2

3

4

–

5

+

6

DC 0...20 V Phs (phase cut)

(DC 4...20 mA oder DC 0...20 V Phs)

~

Supply

~

AC 24 V

–

Positioning signal

+

DC 4...20 mA

1

2

3

4

–

5

+

6

DC 0...20 V Phs (phase cut)

(DC 0...20 V Phs)

ZM111

1

2

3

4

5

6

DC 0...20 V Phs

twisted

pairs

Refer to data sheet N4591 for the ZM.. terminal housings

4721Z03en

8/10

Siemens Modulating refrigerant valves with magnetic actuator, PN 32 CE2N4722en

Building Technologies 08.06.2010

Page 9

Dimensions

Dimensions in mm

D

A

B

1

3

2

L

9H702

3

H

C

2

H

2

H

1

H

DN ø D L H1 H2 H3 A B C W

Valve type [mm] [inches] [kg]

M3FK15LX06 15 5/8 150 57 25 164 60 73 67 2.6

M3FK15LX15 15 5/8 150 57 25 164 60 73 67 2.6

M3FK15LX 15 5/8 150 57 25 164 60 73 67 2.6

Revision numbers

M3FK20LX 20 7/8 170 62 30 173 70 78 67 3.5

M3FK25LX 25 1 1/8 200 66 36 177 70 78 71 4.2

M3FK32LX 32 1 3/8 250 91 43 197 80 84 80 6.0

M3FK40LX 40 1 5/8 300 92 50 202 100 94 98 10.7

M3FK50LX 50 2 1/8 350 102 60 202 100 94 85 12.0

D : Pipe connections

W : Weight (incl. packaging)

Type reference Valid up to rev. No.

M3FK15LX06

M3FK15LX15

M3FK15LX

M3FK20LX

M3FK25LX

M3FK32LX

M3FK40LX

M3FK50LX

..F

..F

..F

..F

..F

..G

..H

..H

9/10

Siemens Modulating refrigerant valves with magnetic actuator, PN 32 CE2N4722en

Building Technologies 08.06.2010

Page 10

ge

10/10

Siemens Modulating refrigerant valves with magnetic actuator, PN 32 CE2N4722en

Building Technologies 08.06.2010

2010 Siemens Switzerland Ltd Subject to chan

Loading...

Loading...