Page 1

M3FB…LX… Series

Modulating Control Valve

for Hot Gas Control

Technical Instructions

Document No. CA2N4721E-P25

Rev. 1, February, 2000

Description

Features

Application

Product Numbers

Valves with magnetic actuator for modulating capacity control of refrigeration units and

for heat recovery.

•

Quick positioning time (approx. 1 second)

•

High resolution (> 1 : 200)

•

High rangeability

•

Hermetically sealed

•

Versatile electrical inter f ac e

•

Low friction

•

Port 1 → 3 closed when de-energized

•

Heavy-duty and maintenance-free

The M3FB...LX... three-way or straight-through valves with magnetic actuator are used

for modulating capacity control of refrigeration units and for heat recovery. They may be

used as hot gas diverting or straight-through valves.

Suitable for safety refrigerants suc h as R22, R13 4a, R40 4A, R40 7C and R507 .

See

Warning/Caution Notations

Table 1.

WARNING:

CAUTION:

Personal injury/loss of life may occur if a procedure is not

performed as specified.

Equipment damage may occur if the user does not follow a

procedure as specified.

Siemens Building Technologies, Inc.

Page 2

Technical Instructions M3FB…LX… Series Modulating Control Valve

Document Number CA2N4721E-P25 for Hot Gas Control

Rev. 1, February, 2000

Ordering

The M3FB...LX... valve and the ZM... or ZM.../A module must be ordered separately.

When placing an order, specify the quantity, product number and product description.

Example :

1 M3FB15LX/A control valve and 1 ZM101/A module.

Table 1. Product Numbers.

N

Valve Product Number

(Without ZM...)

Line Size

[in]

1

Cv

→→→→

3

∆∆∆∆

1

max

p

v

3

→→→→

P

[VA]

P

[VA]

[gpm]

[psi] [bar]

M3FB15LX06/A

M3FB15LX15/A

M3FB15LX/A

M3FB20LX/A

M3FB25LX/A

M3FB32LX

1/2 0.7 319 22 26 6

1/2 1.8 319 22 26 6

1/2 3.5 319 22 26 6

3/4 5.9 261 18 26 6

1 9.4 174 12 40 10

1-1/4 14.0 116 8 40 10

Key :

max

∆

p

= Max. admissible pressure differential

v

N

P

P

= Nominal power

med

= Mean operating power

Cv = Flow rate tolerance ±10 %

med

Technical Design

Mechanical Design

The armature or magnetic core is designed as a floating component within the pressure

system, so that no external shaft gland is required. Therefore, leakage losses common

with moving parts are avoided. The valve cross-section allows for easy flow whether

the valve is fully or only partially open. This reduces pressure losses and ensures quiet

operation.

The valves are fitted with extended female solder unions, making pipe connections

easy.

The control signal is converted in the ZM.../A module into a phase cut signal, which

generates a magnetic field in the coil. This causes the only moving part, the armature,

to change its position in accordance with the interacting forces (magnetic field, counterspring, hydraulics etc.). The armature responds rapidly to any change in signal,

transferring the corresponding movement directly to the control disc, enabling fast

changes in load to be corrected quickly and accurately.

The valve is normally closed. A spring closes the valve automatically if the power is

switched off or fails.

Page 2

Siemens Building Technologies, Inc.

Page 3

M3FB…LX… Series Modulating Control Valve Technical Instructions

for Hot Gas Control Document Number CA2N4721E-P25

Rev. 1, February, 2000

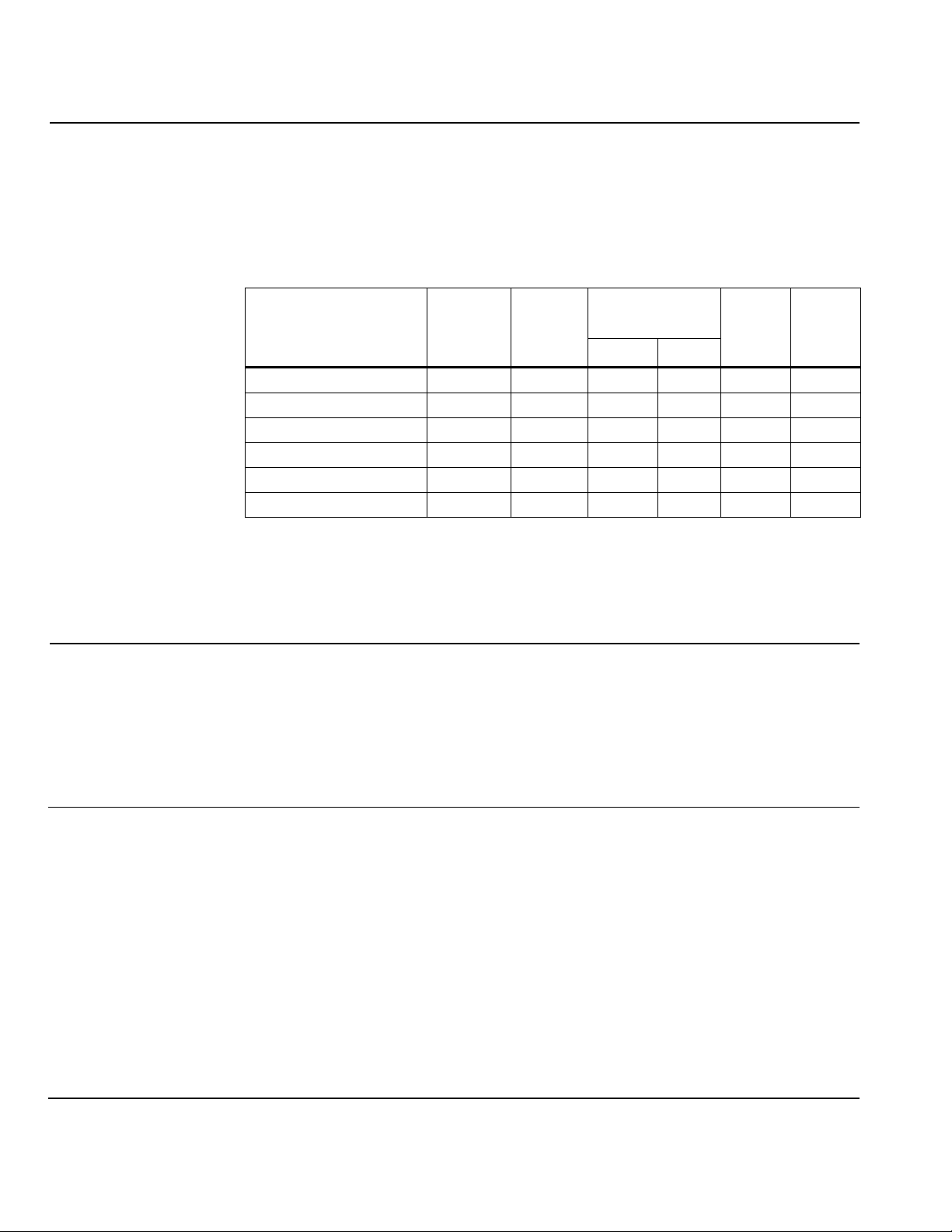

Sizing

Table 2

See

NOTE:

.

Correct valve sizing (to ensure a sufficiently large pressure drop ∆p

100

v

across

the fully open valve) is the key to the correct operation of a refrigeration unit.

All the components must be coordinated, and this can be ensured only by the

refrigeration specialist.

The application examples that follow show the recommended pressure drop

in each case.

Refrigeration capacity in tons

Nominal capacity in tons at evaporation temperature t

c

= 41°F (5 °C)

Table 2. Selection Table for Hot-Gas Applications.

(Approximate Guide to Valve Size)

Refrigerant

R407C (R22) R134a (R12) R404A / R507

Condensation temperature tc [°F]

v100

p

∆∆∆∆

Valve Product

122 104 86 122 104 86 122 104 86

Number

0.5 bar M3FB15LX06/A 1.3 1.1 1.0 1.1 0.9 0.8 1.1 0.9 0.8

(7.2 psi) M3FB15LX15/A 3.1 2.8 2.5 2.7 2.4 2.1 2.6 2.3 2.1

M3FB15LX/A 6.3 5.7 5.1 5.4 4.8 4.0 5.1 4.6 4.0

M3FB20LX/A 10.5 9.4 8.5 9.1 8.0 6.8 8.8 7.7 6.8

M3FB25LX/A 16.8 15.1 13.7 14.5 12.5 10.8 13.9 12.2 10.8

M3FB32LX 25.3 22.8 20.5 21.6 19.1 16.2 21.1 18.5 16.5

1.0 bar M3FB15LX06/A 1.8 1.6 1.4 1.5 1.3 1.1 1.5 1.3 1.1

(14.5 psi) M3FB15LX15/A 4.6 4.0 3.4 3.7 3.1 2.8 6.5 3.1 2.8

M3FB15LX/A 8.8 8.0 7.1 7.4 6.5 5.7 7.4 6.5 5.7

M3FB20LX/A 14.8 13.1 11.7 12.5 10.8 9.4 12.2 10.8 9.4

M3FB25LX/A 23.6 21.1 18.8 19.9 17.4 14.8 19.6 17.4 15.1

M3FB32LX 35.6 31.6 28.2 30.2 26.2 22.2 29.3 25.9 22.8

4.0 bar M3FB15LX06/A 3.2 2.8 2.4 2.6 2.1 1.7 2.7 2.4 2.0

(58 psi) M3FB15LX15/A 8.0 7.1 6.0 6.5 5.4 4.3 6.8 6.0 5.1

M3FB15LX/A 16.2 14.2 12.0 13.1 10.8 8.3 13.7 11.7 10.0

M3FB20LX/A 27.0 23.6 19.9 21.6 17.9 13.7 22.8 19.6 16.5

6.0 bar M3FB15LX06/A 3.7 3.1 2.5 2.8 2.2 1.7 3.1 2.7 2.2

(87 psi) M3FB15LX15/A 9.4 8.0 6.3 7.1 5.4 4.3 8.0 6.5 5.4

M3FB15LX/A 18.5 15.7 12.8 14.2 10.8 8.3 15.7 13.4 11.1

M3FB20LX/A 30.7 26.2 21.1 23.6 17.9 13.7 26.2 22.2 18.2

8.0 bar M3FB15LX06/A 4.0 3.1 2.5 2.8 2.2 N/A 3.4 2.8 2.2

(116 psi) M3FB15LX15/A 10.0 8.0 6.3 6.8 5.4 NA 8.5 7.1 5.4

M3FB15LX/A 19.6 15.9 12.8 13.9 10.8 N/A 17.1 13.9 11.1

M3FB20LX/A 32.7 26.8 21.1 23.1 17.9 N/A 28.5 23.3 18.2

100

∆

p

= Pressure drop across the fully open valve

v

Siemens Building Technologies, Inc.

Page 3

Page 4

Technical Instructions M3FB…LX… Series Modulating Control Valve

Document Number CA2N4721E-P25 for Hot Gas Control

Rev. 1, February, 2000

Key :

o

Evaporation temperature [°F]

t

c

t

Condensation temperature [°F]

fl

t

Liquid temp. ( tc – degree of sub-cooling) [°F]

o

Q

Refrigeration capacity [tons]

m Mass flow of refrigerant [lbs/h]

s

Flow rate [ft3/h]

C

v

v

∆

p

Admissible pressure differential [psi]

Figure 1. Selection Chart for Hot-Gas Applications.

Page 4

Siemens Building Technologies, Inc.

Page 5

M3FB…LX… Series Modulating Control Valve Technical Instructions

for Hot Gas Control Document Number CA2N4721E-P25

Rev. 1, February, 2000

Mounting Notes

Maintenance Notes

Specifications

Electrical

Product Specific Data

Materials (Valve Body)

General Ambient

Conditions

Mounting instructions are enclosed with the valve: Ref. 35541 (connecti on ter minal)

and Ref. 35548 (valve).

The refrigerant valves can be mounted in any orientation, but upright mounting is

preferable. The pipes should be fitted so that the alignment does not distort the valve

connections. Before soldering the pipes, ensure that the direction of flow through the

valve is correct.

The pipes must be soldered with care. The flame should be large enough to ensure that

the junction heats up quickly and the valve does not get too hot. The flame should be

directed away from the valve. Cool the valve body with a wet cloth while soldering.

Port 2 must be sealed off when the valve is used in a straight-through application.

CAUTION:

Always switch off the power supply before connecting or disconnecting the

ZM... module.

The modulating control valves for hot gas control from the M3FB...LX... series require

no maintenance.

Electrical interf ac e: Only admissible with lo w voltag e

(Class 2)

Control signals: ZM101/A 0 — 10 Vdc or 0 — 20 V

phase cut

ZM121/A 4DC — 20 mA or

0 — 20 V phase cut

ZM111 0 — 20 V phase cut

Supply voltage 24 Vac for 0 — 10 Vdc and

4 — 20 mA

Max. voltage tolerance +15/–10 %

Nominal power See

Table 1

Connection terminals Screw terminals for 12 AWG wire

Operating pressure p

e

Pressure differential ∆p

max

max

v

464 psi (32 bar)

1 → 3 See

Table 1

1 → 2 116 psi (8 bar)

Leakage: 1 → 3 Max 0.03% Cv

1 → 2 Max 0.3% k

Cv

Temperature of medium -40—248°F (– 40 — 120 °C)

Valve characteristic (stroke, k

Resolution ∆H / H

100

v

) Linear, optimized in low opening range

>1 : 200 (H = stroke)

Type of operation Modulating

Position when de-energized 1 → 3 closed

Orientation Any

Positioning time Approx. 1 second

Pipe connections Extended female solder unions

Housing components Steel and copper

Seat / inner valve Bronze/CrNi steel

Ambient temperature -40—122°F (– 40 — 50 °C)

Siemens Building Technologies, Inc.

Page 5

Page 6

Technical Instructions M3FB…LX… Series Modulating Control Valve

Document Number CA2N4721E-P25 for Hot Gas Control

Rev. 1, February, 2000

Specifications,

Continued

Dimensions

Weight and Dimensions

See

Safety

Connection

Terminals

Conformity Meets the requirements for CE

marking

WARNING

: ZM.../A module used with 0 — 20 V phase cut signals :

•

Do not connect 24 Vac to Terminals 1 and 2.

•

Connect Terminal 5, (marked " – ") to Terminal 2 on type

NKOA terminal modules.

ZM101/A

1

2

3

4

5

6

SSEN0085R1

SSEN0086R1

Sval0029R1

(0 — 10 Vdc or 0 — 20 V phase cut)

~

SUPPLY

24 VAC

~

–

CONTROL SIGNAL

+

0-10 VDC

SSEN0087R1

ZM121/A

~

1

2

3

4

5

6

SUPPLY

24 VAC

~

–

CONTROL SIGNAL

+

4-20 mA

TWISTED PAIRS

(4 — 20 mA or 0 — 20 V phase cut)

1

2

3

4

–

5

+

6

SSEN0088R1

ZM111

0-20 VDC

PHASE CUT

1

2

3

4

–

5

+

6

0-20 VDC PHASE CUT

(0 — 20 V phase cut)

1

2

3

4

5

6

SSEN0094R1

0-20 VDC

PHASE CUT

Application

Examples

Three-way Hot-gas

Bypass Control

Figure 2. Connection Terminals.

The diagrams shown here are examples only, without installation-specific details.

For accurate control of evaporators, from 0—100% refrigeration capacity.

•

Suitable for test rooms, laboratory systems, small chilled water units and DX

evaporators with a refrigeration capacity of up to approx. 11.4 tons (40 kW).

v100

p

∆

Recommended pressure drop

between 7.2 and 14.5 psi (see

across the fully-open valve (control path 1 → 3):

Figure 1. Selection Chart

).

Page 6

Siemens Building Technologies, Inc.

Page 7

M3FB…LX… Series Modulating Control Valve Technical Instructions

for Hot Gas Control Document Number CA2N4721E-P25

Rev. 1, February, 2000

Application

Examples,

Continued

Indirect Hot-gas Bypass

+

3

–

SSEN0090R1

EEEExa

xammmmpppplllleeee::::

xaxa

2

Refrigeration capacity Q

1

Refrigerant

Condensation temperature t

Evaporation temperature t

Liquid temperature t

Selected valve

Pressure differential ∆p

o

6.8 tons

R22

c

o

fl

104°F (40°C)

41°F (+ 5 °C)

95°F (35 °C)

M3FB15LX/A

v

10.2 psi (0.7 bar)

across valve

Figure 3. Three-way Hot-Gas Bypass Control Application.

The control valve throttles the capacity of a compressor stage. The hot gas is injected

directly into the evaporator allowing capacity control from 100% to approximately 0%.

•

Suitable for use in large refrigeration systems in air conditioning applications to

prevent unacceptable fluctuations in temperature between compressor stages.

The pressure differential ∆p

v100

across the fully-open valve is determined by the

condensation pressure at low load minus the pressure upstream of the evaporator.

If no details are provided, the pressure differential ∆pv100 can be assumed to be

58 psi (4 bar).

+

1

3

–

SSEN0091R1

EEEExa

xammmmpppplllle

e ::::

xaxa

e e

Refrigeration capacity Q

o

of one

compressor stage

Refrigerant

Condensation temperatur e

full/low load

Evaporation temperature full

8.5 tons

R22

113/95°F (45/35°C)

41/59°F (5/15°C)

104/86°F (40/30°C)

load/low load

Liquid temperature t

fl

Pressure differential ∆pv (from

R22 vapor table)

Selected valve

Actual capacity

81 psi (5.6 bar)

M3FB15LX/A

Approx. 40 kW

M3FB15LX/A

Approx. 40 kW

Figure 4. Indirect Hot-gas Bypass Application.

Direct Hot-gas Bypass

The control valve throttles the capacity of a compressor stage. The gas is fed to the

suction side of the compressor and cooled by a re-injection valve. Capacity control

ranges from 100% to approximately 10%.

•

Suitable for large refrigeration systems for air conditioning with several

The pressure differential ∆p

condensation pressure at low load minus the suction pressure.

If no details are provided, the pressure differential ∆p

(6 bar).

Siemens Building Technologies, Inc.

compressors or compressor stages, and where the evaporator and compressor

are some distance apart (attention must be paid to oil return).

v100

across the fully-open valve is determined by the

v100

can be assumed to be 87 psi

Page 7

Page 8

Technical Instructions M3FB…LX… Series Modulating Control Valve

Document Number CA2N4721E-P25 for Hot Gas Control

Rev. 1, February, 2000

Application Examples,

Continued

Heat recovery

+

EEEExa

xammmmpppplllleeee::::

xaxa

1

3

–

SSEN0089R1

Refrigerant capacity of one

compressor stage

Refrigerant

Condensation temperatur e

full/low load

Evaporation temperature full

11.4 tons

R22

113/95°F (45/35°C)

36-50°F (2/10°C)

load/low load

Liquid temperature t

fl

104/86°F (40/30°C)

Pressure differential ∆pv (from

R22 vapor table)

Selected valve

94 psi (6.5 bar)

M3FB15LX/A

Figure 5. Direct Hot-gas Bypass Application.

The hot-gas diverting valve may be used for modulating recovery of the heat from the

condenser, even in the event of high pressur e dif f erentials.

v100

Recommended pressure drop ∆p

across the fully-open valve

(control path 1 –> 3): between 0.5 and 1 bar.

EEEExa

xammmmpppplllleeee::::

xaxa

Refrigeration capacity Q

3

Refrigerant

Condensation temperature t

1

Evaporation temperature t

Liquid temperature t

Selected valve

Actual pressure drop

19.1 tons

R134a

c

122°F (50°C)

o

fl

36°F (2°C)

113 (45°C)

M3FB32LX

10 psi (0.7 bar)

SSEN0092R1

+

+

2

–

Figure 6. Heat Recovery Application.

Page 8

Siemens Building Technologies, Inc.

Page 9

M3FB…LX… Series Modulating Control Valve Technical Instructions

for Hot Gas Control Document Number CA2N4721E-P25

Rev. 1, February, 2000

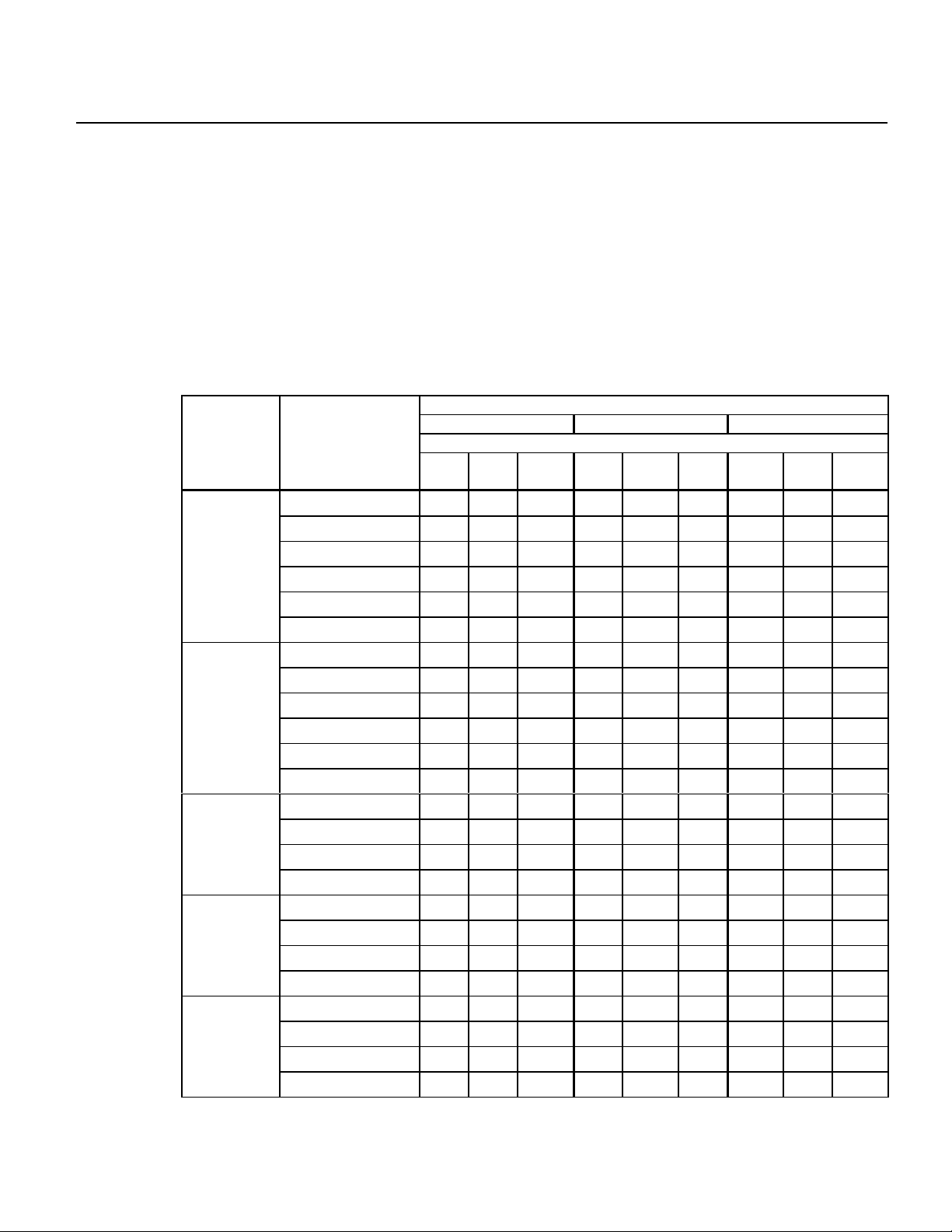

Dimensions

A

B

H3H1 H2

C

2

1

3

L

1

2

H

H2

3

H

ABCWValve Product

Number

D

SSEN0095R1

Line Size ø D L H

[mm] [in] [in] [lbs.]

M3FB15LX06/A 15 1/2 5/8 5.91 2.56 0.98 7.24 3.15 3.31 2.64 2

M3FB15LX15/A 15 1/2 5/8 5.91 2.56 0.98 7.24 3.15 3.31 2.64 9

M3FB15LX/A 15 1/2 5/8 5.91 2.56 0.98 7.24 3.15 3.31 2.64 9

M3FB20LX/A 20 3/4 7/8 6.69 2.72 1.18 9.37 3.94 3.70 3.31 20

M3FB25LX/A 25 1 1-1/8 787 2.83 1.42 9.76 3.94 3.70 3.70 21

M3FB32LX 32 1-1/4 1-3/8 9.84 3.58 1.69 9.65 3.94 3.70 3.86 25

D Pipe connections

W Weight (including packaging)

Figure 7. Dimensions.

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. © 2000 Siemens Building Technologies, Inc.

Siemens Building Technologies, Inc.

Landis & Staefa Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

U.S.A.

Document No. CA2N4721E-P25

Printed in the U.S.A.

Page 9

Loading...

Loading...