Siemens Building Technologies BT300 HVAC Drive Owners Manual

Siemens BT300 HVAC Drive

Building Technologies

Operator's Manual

DPD01809

2017-09-28

Copyright Notice

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Copyright Notice

Notice

Document inform ation is subject to change without notice by Siemens Industry, Inc.

Companies, names, and various data used in examples are fictitious unless otherwise

noted. No part of this document may be reproduced or transmitted in any form or by

any means, elect ronic or mechanical, for any purpose, wit hout the express written

permission of Siemens Industry, Inc.

Warning

This equipment generates, uses, and can radiat e radio frequency energy. If equipm ent

is not installed and used in accordance with the instructions manual, it may cause

interference t o radio communications. Equipment has been tested and found to comply

within the limits for a Class B digital device pursuant to Part 15 of the FCC rules. These

limits are designed to provide reasonable protection against such interf erence when

operated in a commercial environment. Operation of this equipment in a residential

area is likely to cause interference. Residential area equipm ent users are required t o

take whatever measures necessary to correct the interference at their own expense.

Service Statement

Control devices are c ombined to make a system. Each control device is mechanical in

nature and all mechanical components must be regularly serviced to optimize their

operation. Siemens Industry, Inc. branch offices and authorized distributors offer

Technical Support Programs that will ensure continuous, trouble-free system

performance.

For further information, contact your nearest Siemens Industry representative.

Copyright Siemens Industry, Inc.

FCC Regulations

The manual for an intentional or unintentional radiator shall caution the user that

changes or modificat ions not expressly approved by the party responsible could void

the user’s authority to operate the equipment.

For a Class B digital device or peripheral, the instructions furnished the user shall

include the following or similar statement, placed in a prom inent location in the text of

the manual:

NOTE: This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to part 15 of the FCC Rules. These limit s are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generat es, uses and can radiate radio frequency ener gy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur

in a particular inst allation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged t o try to correct the interference by one or more of the following

measures:

●

Reorient or relocate the receiving antenna.

●

Increase the separ ation between the equipment and receiver.

●

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connect ed.

●

Consult the dealer or an experienced radio/TV technician for help.

2 | 180

Copyright Notice

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

To the Reader

Your feedback is important to us. If you have comments about this manual, please

submit them to: SBT_technical.editor.us.sbt@siemens.com

Credits

APOGEE is a registered trademark of Siemens Industry, Inc. Other product or

company names mentioned herein may be the trademarks of their respective owners.

Printed in the USA.

Siemens Industry, Inc.

3 |

Copyright Notice

4 | 180

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

180

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Table of contents

Ho w to U se this M a nu a l ....................................................................................... 9

Ch a p t e r 1 - U s er In t e r f aces o n S iemens BT 3 00 .....................................................11

Drive Keypad ............................................................................................................ 11

Keypad Butto ns .............................................................................................. 11

Keypad Displ ay ................................................................................ 12

Using the Keypad............................................................................. 13

NET (Software Too l) ................................................................................................. 15

Fieldb u s.................................................................................................................... 16

Ch a p t er 2 - Co ntro l Boar d Ter m inal Conn ecti ons ...................................................17

Analo g Input Termina l Connectio ns .......................................................................... 18

Analo g Inp u t 1 ................................................................................................ 18

Analo g Inp u t 2 ................................................................................................ 18

Digital Input Terminal Connections............................................................................ 19

Digita l Inputs 1 through 6 ................................................................................ 19

Analo g Output Termina l Connecti ons ........................................................................ 19

Analo g Output 1 .............................................................................................. 19

Digita l Output Termi na l Conne ctio ns ......................................................................... 20

Chapter 3 - Start-up Infor mation ..........................................................................21

Proced ure and Checkli st ........................................................................................... 21

Commissi oni ng Flowchart ......................................................................................... 21

Wizards .................................................................................................................... 22

Startup Wizard (P1.19 ) ................................................................................... 22

PID Mini-Wi za rd (P1.17) ................................................................................. 24

Multi-Pu mp Wiza rd (P1 .18 ) ............................................................................. 25

Fire Mode Wiza rd (P1.20 ) ............................................................................... 25

Bypass Wiza rd (P1.21) ................................................................................... 26

Ch a pter 4 - Parame ters and M enu S tructure .........................................................28

Quick Setup (M1) ...................................................................................................... 29

Monito r Men u (M2) ................................................................................................... 30

Multimo nitor (M2.1) ......................................................................................... 30

Basic (M2.2) ................................................................................................... 31

Timer functi on s monitori ng (M2.3 ) ................................................................... 32

PID Control le r 1 Monito ri ng (M2 .4 ) .................................................................. 33

PID Control le r 2 Monito ri ng (M2 .5 ) .................................................................. 33

Multi-pump monitoring (M2.6) ......................................................................... 33

Fieldb us data monito rin g (M2.8) ...................................................................... 34

Temperature inputs monitoring (M2.9) ............................................................ 35

Parame ters (M3)....................................................................................................... 35

Motor Set ti n g s (M3.1) ..................................................................................... 35

5 |

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Basic Settings (M3.1 .1) .....................................................................36

Motor Control Settings (M3.1.2) ........................................................36

Start/Sto p setup (M3.2) ....................................................................................38

Start Function (P3 .2.4) ......................................................................40

Stop Functi on (P3 .2.5 ) ......................................................................41

I/O start/stop logi c (P3.2.6) ................................................................41

Contro l reference setti ngs (M3 .3) .....................................................................47

Understanding Prese t Freq ue n ci es ...................................................50

Ramp and Brake s Setup (M3.4 ) .......................................................................51

I/O Confi guration (M3 .5) ..................................................................................53

Digita l Inputs (M3.5.1) .......................................................................53

Analo g Inputs (M3.5.2) ......................................................................57

Digita l Outp uts ( M3 .5.3 ) ....................................................................60

Analo g Outputs (M3.5 .4) ...................................................................63

Fieldb us Data Map pi ng (M3.6 ) .........................................................................66

Prohib ited Frequ enci es (M3.7) .........................................................................69

Limit supervi si on s (M3.8) .................................................................................70

Protecti on s (M3 .9) ...........................................................................................72

Automati c Rese t (M3 .1 0) .................................................................................79

Timer Function s (M3.11 ) ..................................................................................81

Time Channels..................................................................................81

Intervals ............................................................................................81

Timers ..............................................................................................84

Exampl e ...........................................................................................84

PID Control le r 1 (M3.1 2) ..................................................................................85

Basic Setting s (M3.12.1 ) ...................................................................85

Setpoints (M3.12.2)...........................................................................86

Feedba cks (M3.12.3) ........................................................................88

Feedforward (M3.12.4)......................................................................90

Process Supervision (M3.12.5) .........................................................91

Pressure Loss Compensation (M3.12.6)............................................92

PID Control Seque nce Detai ls ...........................................................92

PID Control le r 2 (M3.1 3) ..................................................................................97

Basic Setting s (M3.13.1 ) ...................................................................98

Setpoints (M3.13.2)...........................................................................98

Feedba ck (M3.13.3) ..........................................................................99

Process Supervision (M3.13.4) .......................................................100

Multi-pump (M3.14)........................................................................................100

Multi-Pu mp .....................................................................................10 1

Fire Mode (M3.1 6) .........................................................................................105

Appli ca tio n Setti n gs (M3 .17 ) ..........................................................................108

Bypass (M3.1 8) .............................................................................................108

Diagnostics (M4) .....................................................................................................110

6 | 180

180

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Active faults (M4 .1 ) ....................................................................................... 110

Reset faults (P4.2 ) ........................................................................................ 110

Fault Histo ry (M4 .4 ) ...................................................................................... 110

Total Counte rs (M4.6 ) ................................................................................... 111

Trip Counters (M4.7 ) ..................................................................................... 111

Software Info (M4.8) ..................................................................................... 112

I/O and Hardware (M5) ........................................................................................... 112

Basic I/O (M5.1) ............................................................................................ 112

Slot C (M5.2 ) ................................................................................................ 113

Slot D (M5.3 ) ................................................................................................ 113

Slot E (M5.4) ................................................................................................ 114

Real time cl o ck (M5.5) .................................................................................. 114

Power un it settings (M5.6 ) ............................................................................ 114

Fan (M5.6.1 ) .................................................................................. 114

Sine Filter (M5.6.4) ........................................................................ 115

Keypad (M5.7) .............................................................................................. 115

RS-485 (M5.8) .............................................................................................. 116

Common Settings (M5.8.1) ............................................................ 117

N2 (M5.8.3) .................................................................................... 118

BACnet MS/TP (M5.8.3)................................................................. 123

P1 FLN (M5.8 .3 ) ............................................................................ 131

Modbu s RTU (M5.8.3) .................................................................... 136

Etherne t (M.5.9) ............................................................................................ 152

Common Settings (M5.9.1) ............................................................ 152

Modbu s TCP (M5.9 .2) .................................................................... 153

BACnet IP (M5.9.3 ) ........................................................................ 158

User Settings (M6) .................................................................................................. 162

Parame ter Backup (M6.5 ) ............................................................................. 162

Parame te r Co mp a re (M6.6) .......................................................................... 163

Favorite s (M7 ) ........................................................................................................ 163

User Leve ls (M8 ) .................................................................................................... 163

Ch apt er 5 - Faul t Tra c in g .................................................................................. 165

Fault Displays ......................................................................................................... 165

Fault history ............................................................................................................ 165

Fault Codes ............................................................................................................ 166

Ch ap te r 6 - Tech ni c al In fo r ma ti o n ...................................................................... 171

Product Numbers .................................................................................................... 171

Power Ratin gs ........................................................................................................ 172

Interpre ting Serial Nu mbers and Date Cod es .......................................................... 172

Techni cal Data ....................................................................................................... 173

Contro l Board Tech ni ca l Speci fi cati o ns ................................................................... 175

Fieldbus Technical Data ......................................................................................... 176

Accesso ries and Repla ceme nt Parts ....................................................................... 177

7 |

How to Use this Manual

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

How to Use this Manual

About This Manual

This manual is written for the owner and user of the BT300 HVAC Variable Speed Drive. It is designed to help you

become familiar with the BT300 HVAC Variable Speed Drive and its applic ations.

This section covers manual organization, docum ent conventions and symbols used in the manual, how to access

help, related publications, and any other inform ation that will help you use this manual.

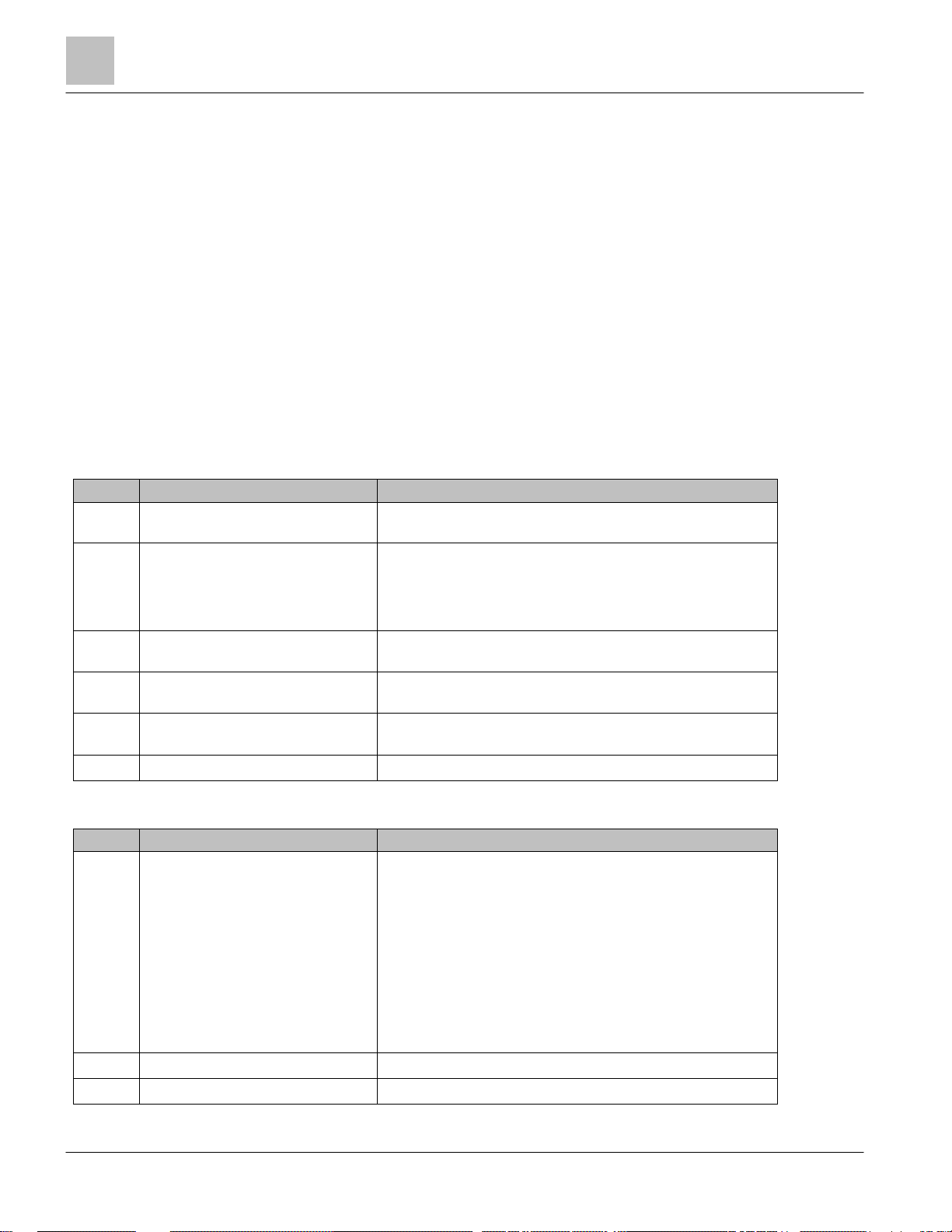

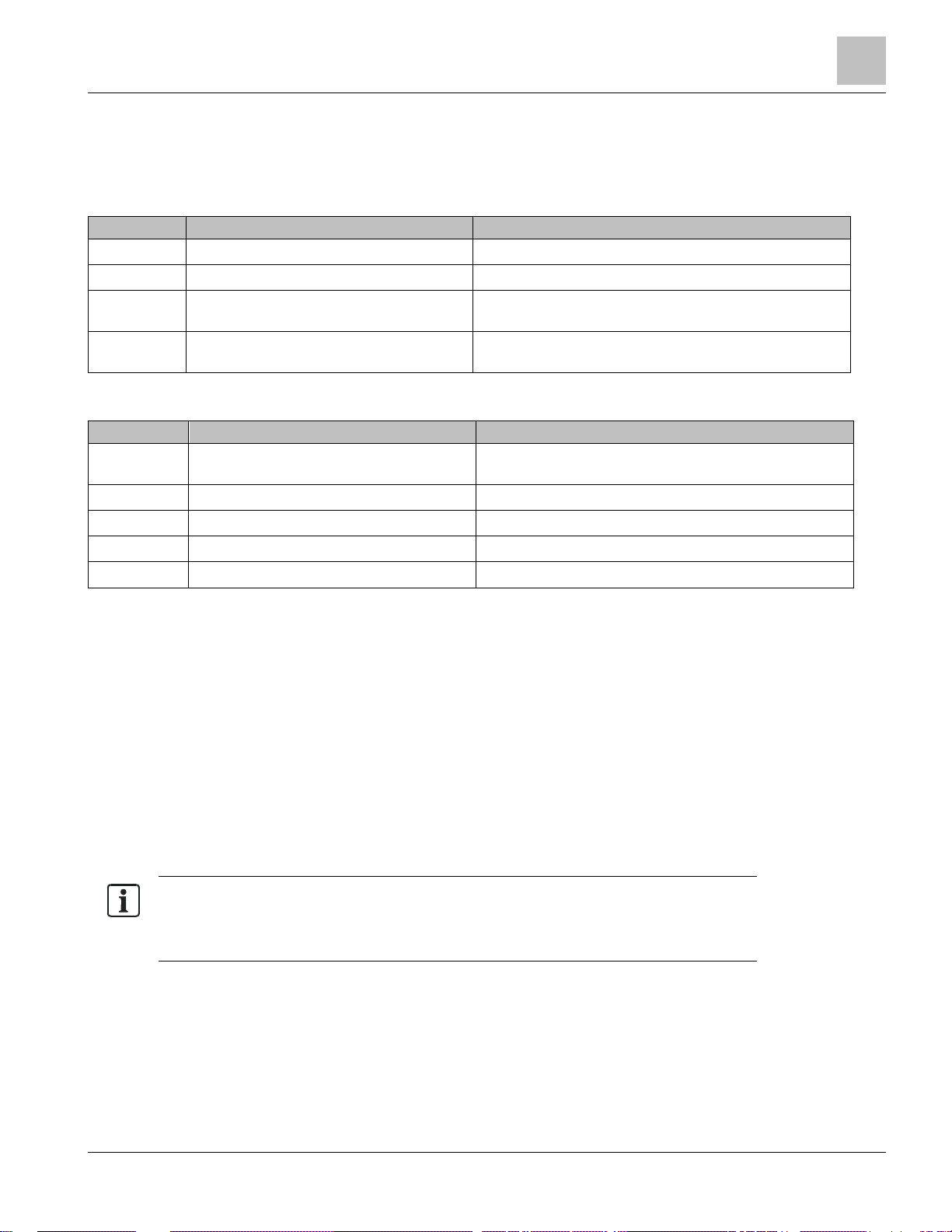

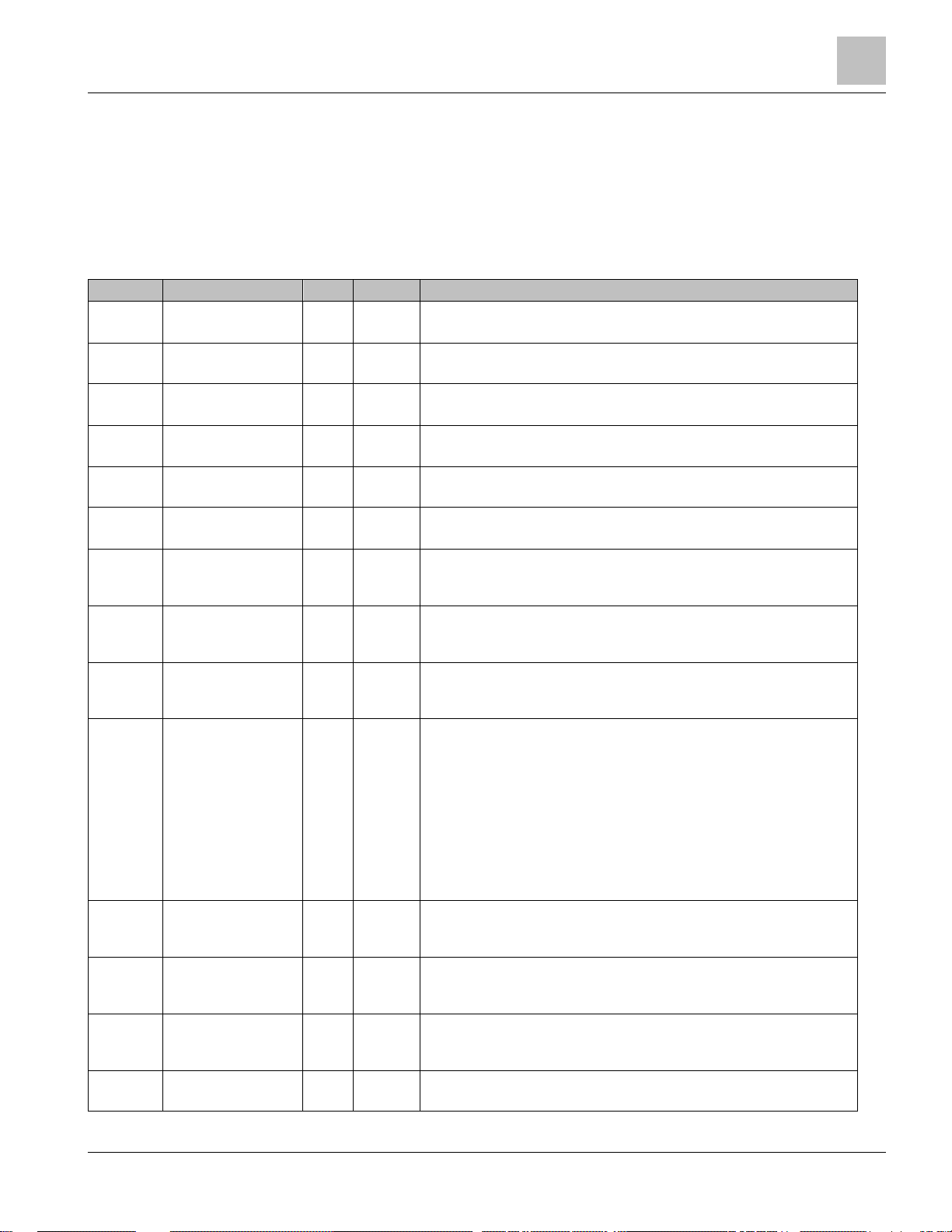

Document Conventions

The following table list s conventions to help you use this manual in a quick and efficient manner.

Convention Exam ples

Numbered Lists (1, 2, 3…) indicate a

procedure with sequential steps.

Conditions that must be c ompleted or met

before b eginning a task are design ated with a

⊳.

Intermediate results (what wi ll happen

following the execution of a step), are

designated with a ⇨.

Results, which inform the user that a task was

completed successfully, are designated with a

⇨.

Actions that should be performed are specified

in boldfac e fo nt.

Error and s ystem messages are dis played in

Courier New font.

New terms appearing for the first time are

italicized.

1. Turn OFF power to the field panel.

2. Turn ON power to the field panel.

3. Contact the local Siemens Industry representative.

⊳Composer software is properly installed.

⊳A Valid license is available.

1. Select Start > Programs > Siemens > GMS >

Composer.

⇨The Project M anagement window displays.

2. Open an existing project or create a new one .

⇨The project wi ndow displays.

Type F for Field panels.

Click OK to save changes and close the dialog box.

The message Report Definition successfully

renamed displays in the status bar.

The field panel continu ously executes a user-defined set

of instructions called the

This symbol signifies Notes. Notes provide additional

informat io n or helpful hi nts .

control program

.

Siemens Industry, Inc.

Cross references to other informa tion are

indicat ed with an arrow and the page number,

enclosed in brac kets: [→ 92]

Placeholders indicate text that can vary based

on your selectio n. Placeholders are specified

by italicized letters, and enclosed with brackets

[ ].

For more information on creating flowcharts, see

Flowcharts [→ 92].

Type A C D H [

username

] [

field panel #]

.

9 |

How to Use this Manual

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

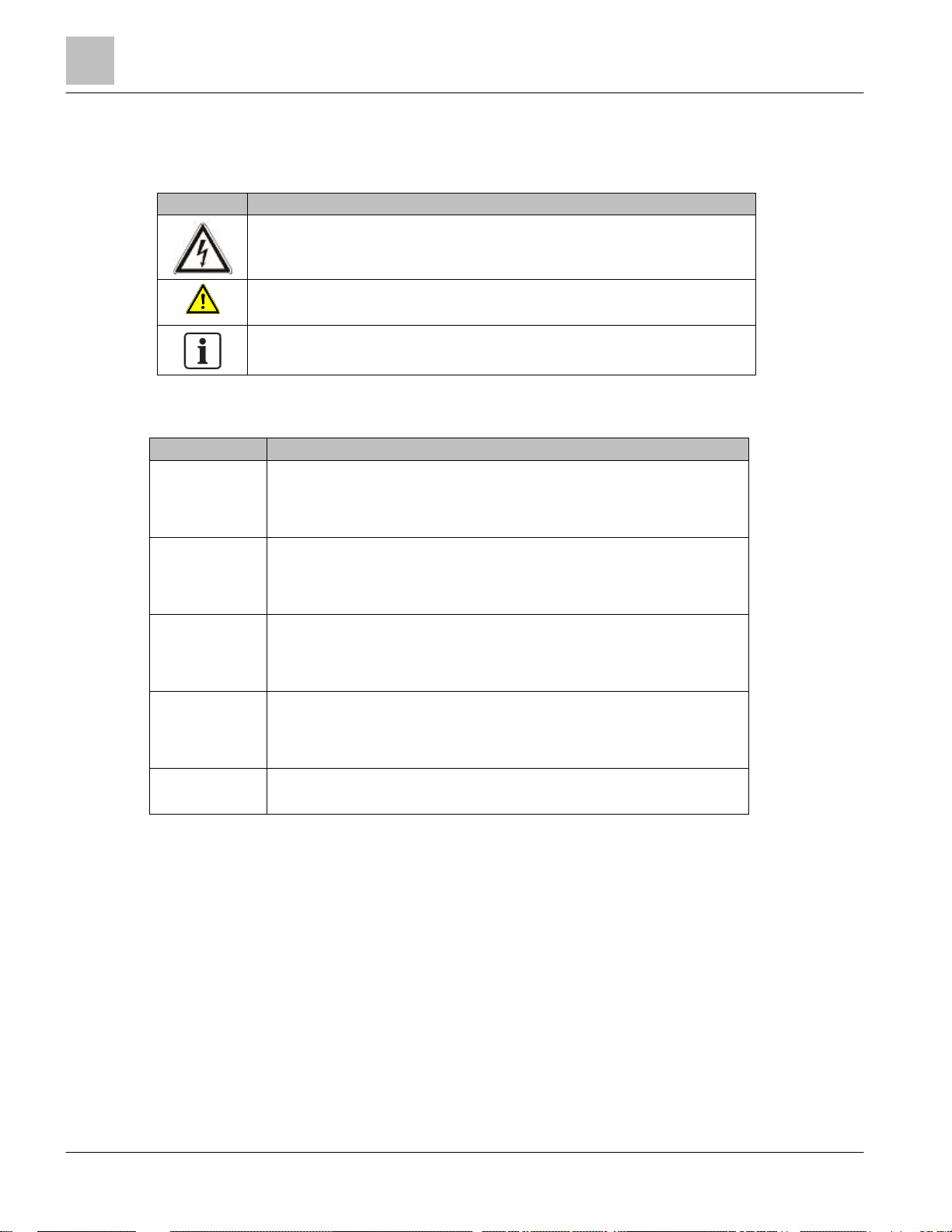

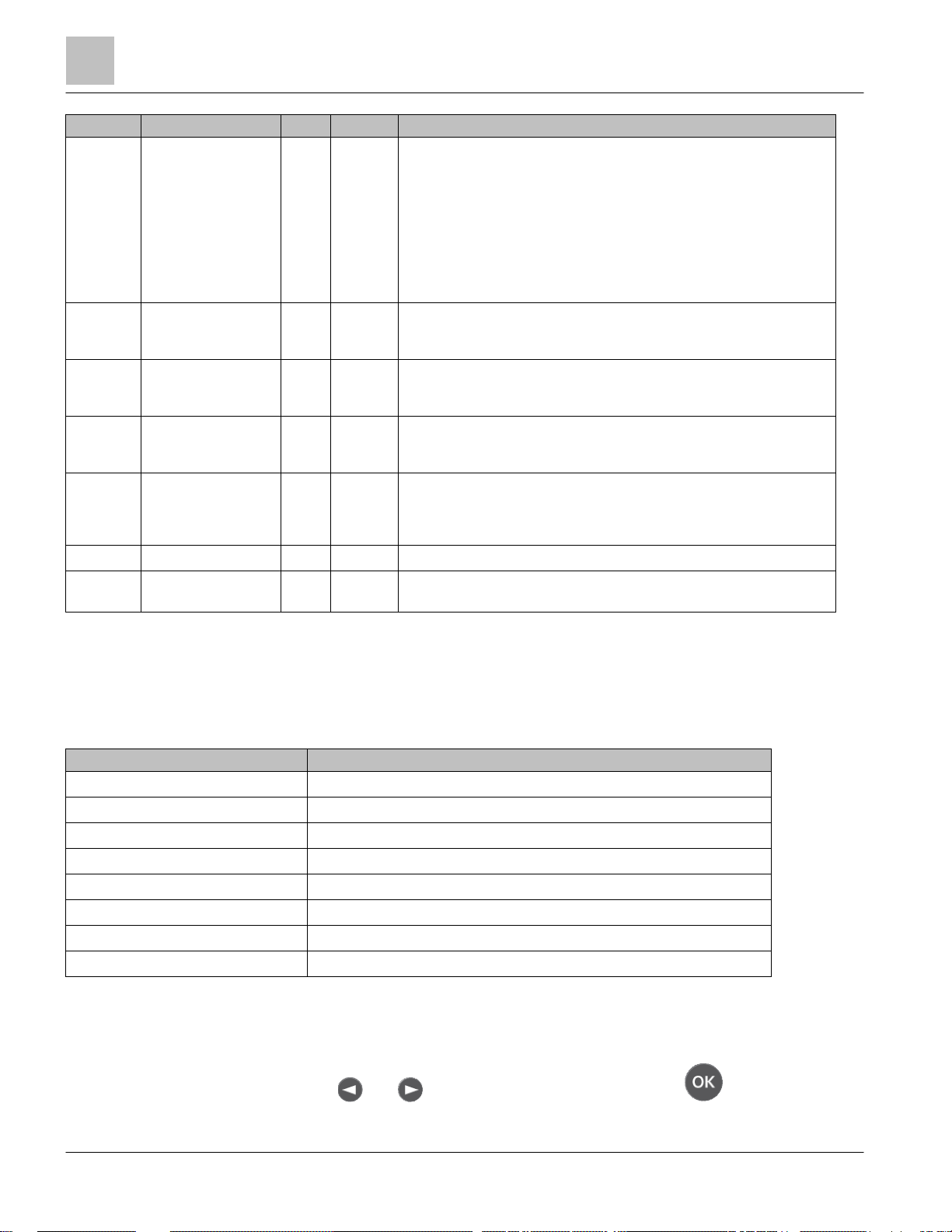

Safety Symbols

The following table lists the safety symbols used in this manual to draw attention to important infor mation.

Table 1: Warning Symbols.

Symbol Description

DANGER or WARNING: Dangerous voltage is present.

DANGER ou AVERTISSEMENT: Présence de tension dangereuse.

WARNING or CAUTION

AVERTISSEMENT ou ATTENTION

NOTE

REMARQUE

The following table describes the safety notices used in this manual to draw attention to important informat ion.

Table 2: Warning Descriptions.

Warni ng Ty pe Desc ription

DANGER

WARNING

CAUTION

NOTICE

NOTE Notes provide additional information o r helpful hints.

Serious injury, death, or severe equipme nt damag e is imminent if a p rocedur e or

instruction is not followed as specified.

Le non respect d'une procédure o u instruction peut provoquer ins tantanément des

blessur es graves, voir mortelles , ou endom mager l'é quipement

Serious injury, death, or severe equipme nt damag e could occur if a p rocedure or

instruction is not followed as specified.

Le non respect d'une procédure ou instruction peut prov oquer des blessures graves

voir mortelles ou e nd ommager l'équipe ment.

Minor or moderate injury m ay occur if a procedure or instruction is not followed as

specified.

Le non respect d'une procédure o u instruction peut provoquer des bless ures

mineures ou modérés.

Equipm ent damag e or unwan ted operation may occur if a procedur e or instruction is

not foll owed as s pecified.

Le non res pect d'u ne procédure ou instructi on peut end ommager l 'équipement ou

entraîner un fonc tionnement intempestif.

Les remarques fournissent des informations supplémentaires ou des conseils utiles.

Getting Help

For more information about BT300 products, contact your local Siemens Industry representative.

10 | 180

Chapter 1

-

User Interfaces on Siemens BT300

Drive Keypad

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Chapter 1 - User Interfaces on Siemens BT300

This chapter presents the different user interf aces on Siemens BT300:

● Keypad

● Siemens NET

● Fieldbus

Drive Keypad

The control keypad with graphical interface is the interface between the Siemens BT300 HV AC Drive and the user.

With the control keypad it is possible to control the speed of a motor, to supervise the state of the equipment and

to set the variable frequency driver's parameters .

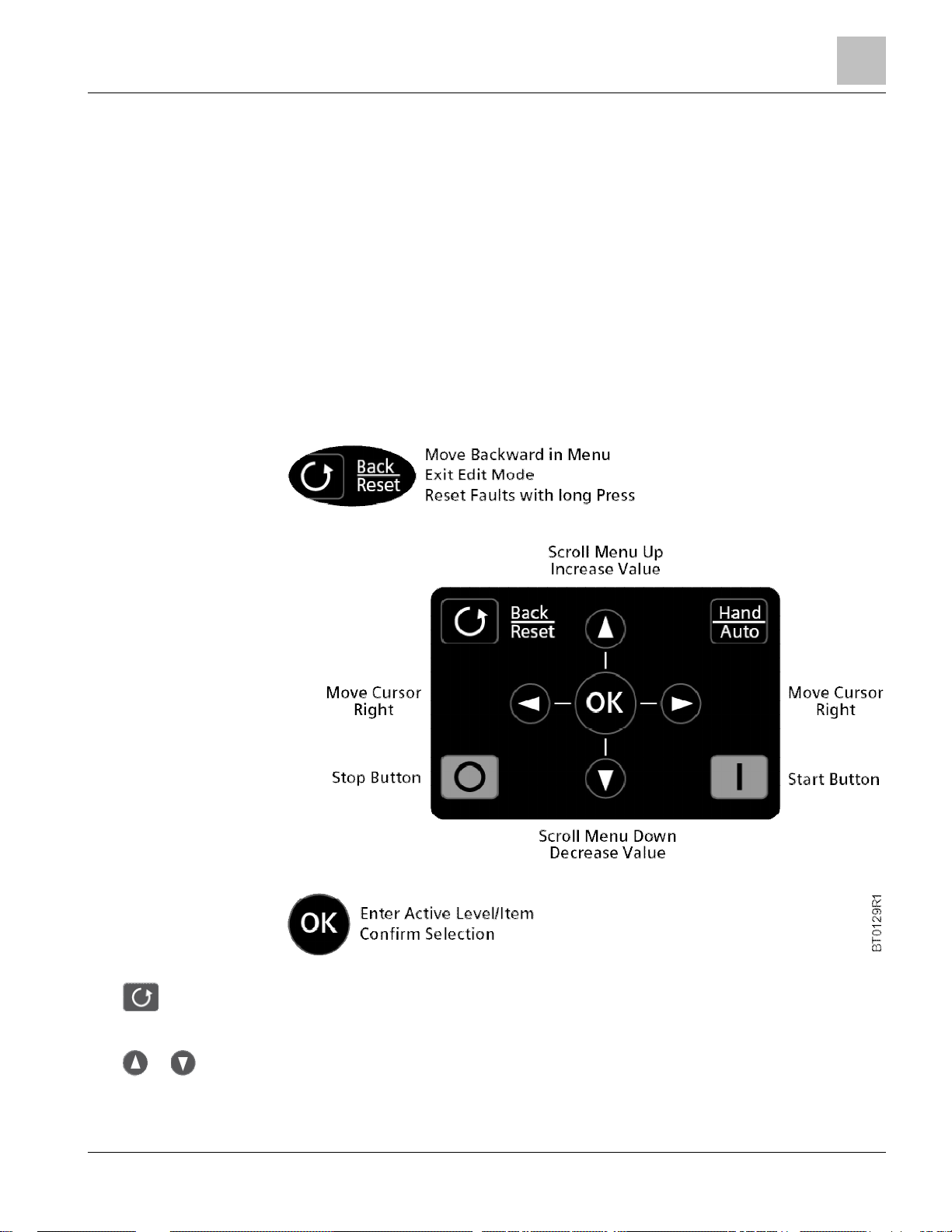

Keypad Buttons

The keypad features nine buttons used to configure and control the drive.

● This button (back/ reset) allows you to move backwards in the menu, backup a step when using a wizard,

exit the edit mode, or reset a fault (when held for approximately one sec ond).

● or These buttons allow you to scroll up (or down) in the menu or increase (or decrease) a param eter

value when editing.

Siemens Industry, Inc.

Figure 1: Keypad Buttons.

11 |

Chapter 1

-

User Interfaces on Siemens BT300

Drive Keypad

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

● or These buttons allow you to move the cursor left (or right) when editing a paramet er value.

● This button allows you to move to the next step when using a wizard, select an item in the menu, or

select a setting for a parameter when editing.

● This button allows you t o quickly access the Control Page and to easily c hange between the Hand

(Keypad) or Auto mode of operation. If an Electronic Bypass is present, this button provides access to the

drive-off bypass functions.

● This button allows you to start the drive in Keypad (Hand) mode of operation.

● This button allows you to stop the drive in Keypad (Hand) mode of operation. This button can also be

used as an emergency stop (unless limited by the Keypad St op Button [P3.2.3]).

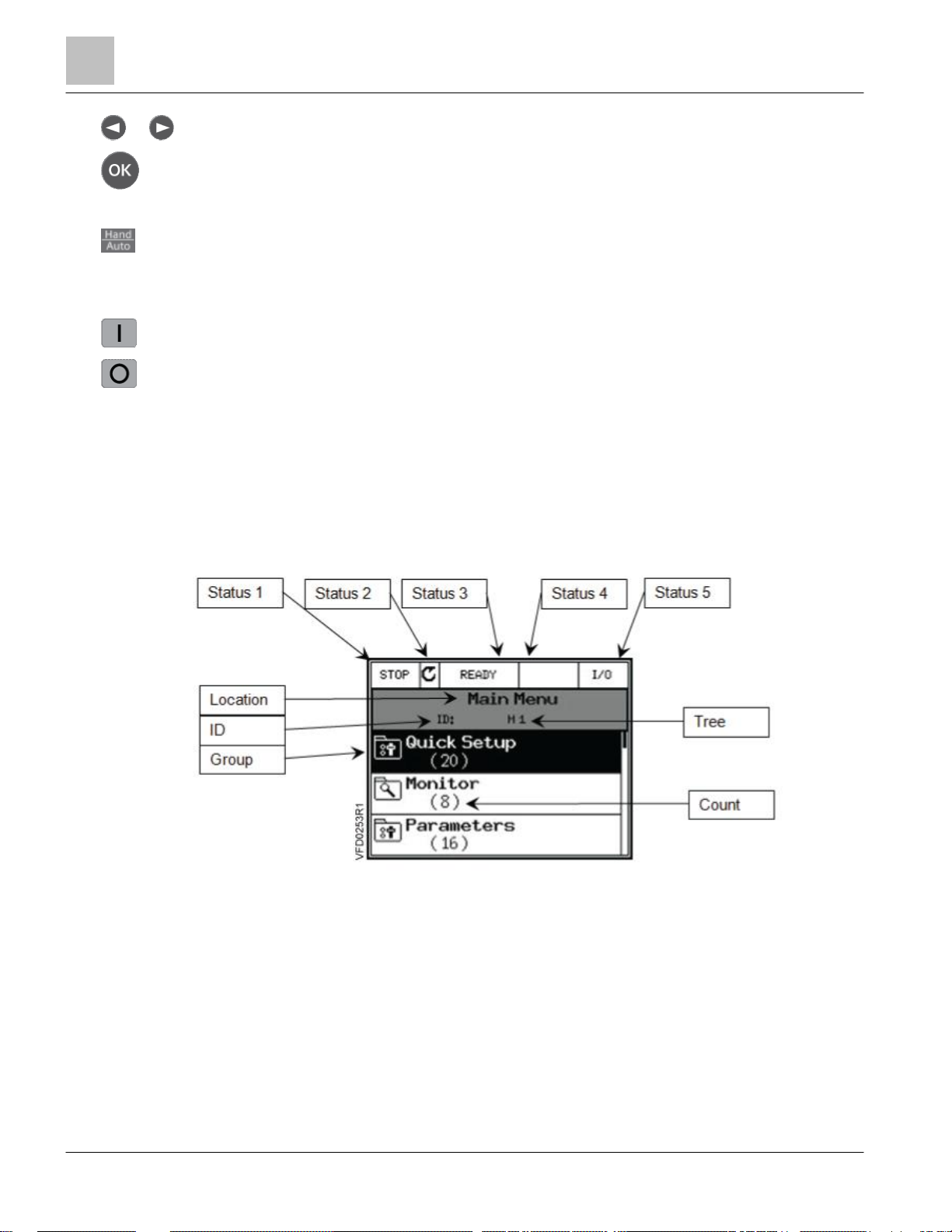

Keypad Display

The keypad display indicates the status of the motor and the drive and any irregularities in m otor or drive functions.

On the display, you can view information about the present locat ion in the menu structure and the item displayed.

See

Chapter 4

for a comprehensive view of the menu structure.

Several pieces of inf ormation are available on the display at any given moment. Five status fields are provided

across the top of the display, as well as the location/parameter selected. Group information is also available.

These fields are:

● Status 1: Indicates the drive’s run status.

● Status 2: Indicates the drive’s run direction.

● Status 3: Indicates if the drive is READY to run,NOT READY to run, in FAULT, or in BYPASS (if Electronic

Bypass is enabled).

● Status 4: Indicates if the drive is in ALARM.

● Status 5: Indicates the current control place, such as I/O, FB, KEYPAD, PC, or OFF (if Electronic Bypass is

enabled).

● Location: Indicates the Menu name, Sub-menu name, or parameter name that is currently selected.

12 | 180

Figure 2: Keypad Display.

Chapter 1

-

User Interfaces on Siemens BT300

Drive Keypad

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

● ID: Indicates the parameter ID (if applicable) for the parameter select ed.

NOTE:

NOTES:

● Tree: Indicates the menu, sub-menu, or parameter tree structure number.

This field always shows standard English digits regardless of the language selected

by Language Selections (P6.1).

● Group: Indicates the group, sub-group, or parameter name that is in the list. The highlight represent s the

selected item.

● Count: Indicates the count of items listed in the group or sub-group.

The data on the control keypad are arranged in menus and sub-menus. Use the UP and DOWN arrows to

move between the menus. Enter the group/item by pressing the button and return to the previous level by

pressing the Back/Reset button.

Using the Keypad

This section covers the editing of parameter v alues, resetting of faults, accessing the control page, obtaining help

related to paramet ers, and configuring the items for the Favor ites menu.

Editing Values

1. Some parameters c annot be changed when the drive is in the Run stat e.

2. Some paramet ers require a power cycle to implement changes.

Change the value of a param eter by using the following procedure:

1. Locate the paramet er. See

2. Highlight the parameter and complete one of the following:

Press the button to enter the parameter choice menu, which contains Edit, Help, and Add To (or

Remove From ) Favorites. Highlight Edit and press the button a second time.

Press the button to enter directly into the parameter editing mode.

3. Set the new value using the or buttons.

Chapter 4

for parameter details.

NOTE:

You can move from digit-to-digit using the or buttons if the value is

Siemens Industry, Inc.

numerical.

13 |

Chapter 1

-

User Interfaces on Siemens BT300

Drive Keypad

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

4. Confirm the change with the button or ignor e the change by returning to the previous level with the

NOTE:

NOTE:

button.

5. To exit a parameter, press the button.

Resetting a Fault

When a fault has occurred, there are four ways to reset the fault:

Remove the external control signal before resetting the fault to prev ent unintentional

restart of the drive.

● If fieldbus communication is in use, command t he Reset Fault object.

● If a digital input is program med for Fault Reset Close (P3. 5.1.9) or Fault Reset Open (P3.5.1.10), toggle the

digital input.

The default setting for Fault Reset Close (P3.5.1.9) is Digital Input 6 (DigIN SlotA.6).

● Press and hold the butt on on the keypad for one second.

● Enter the Diagnostics (M4) menu, enter Reset Faults (P4.2) parameter, and select Reset F aults.

See

Chapter 6

for further informat ion on fault diagnostics.

Control Places

A

control place

is the source of control where the drive can be started and stopped. Every control plac e has its

own parameter for selecting the frequency reference source. In Hand, the control place is the keypad (by default).

The auto control place is determined by the setting in Auto Control Place (P1.15 or P3.2.1). The selected control

place is displayed on the keypad in the area marked Status 5 (see

Figure 2

).

Auto Control Place

I/O A, I/O B, and fieldbus can be used as auto control places.

● I/O A and fieldbus have the lowest priority and can be chosen with Auto Control Place (P3.2.1).

● I/O B can bypass the auto cont rol place selected using a digital input. The digital input is selected with I/O B

Control Force (P3.5.1.5).

● The keypad is always used as a control place while in Hand Control.

Selection of Hand from Auto

1. From any screen in the menu structure, press the button.

2. Use the or buttons to highlight Hand and press the button.

3. When Activate displays, press the button to confirm.

14 | 180

Chapter 1

-

User Interfaces on Siemens BT300

NET (Software Tool)

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Selecting Auto from Hand

1. From any screen in the menu structure, press the button.

2. Use the or buttons to highlight Auto and press the button.

3. When Activate displays, press the button to confirm.

Accessing the Co ntrol Page

The Control Page enables easy operation and monitoring of the most essential values . It contains the setpoint (in

hertz) and four additional pieces of information (output frequency, energy counter, motor current, and motor power)

that you can charge.

1. From any screen in the menu structure, press the button.

2. Use the or buttons to highlight Control Page and press the button.

3. When Activate displays, press the button to confirm.

Help

The graphical keypad features instant help, and information displays for various items.

All parameters offer an instant help display. Select Help and press the button.

Text information is also available for faults, alarms and the Start-up Wizar d.

Addin g an Item to Favorites

At times, you may need to r efer to certain parameter values or other items. Inst ead of locating them one-by-one in

the menu structure, you can add them to a folder called Favorites, where they can easily be reached.

To remove an item from Favorites, see Favorites (M7) [➙ 163] in

Chapter 4

.

NET (Software Tool)

NET is a personal computer tool used for commissioning and maint aining the BT300 HVAC Drive. Contact your

local Siemens Representative to obtain a copy of the Siemens NET Tool.

The tool includes the following features:

● Parameterizat ion, monitoring, drive information, data logging, and so on.

● Integrated soft ware download tool--Siemens LoadT ool.

● RS-422 and Ethernet support.

● Windows 7 support.

● Multiple languages: English, Chinese, Czech, Danish, Dutch, Finnish, French, German, Italian, Polish,

Portuguese, Romanian, Russian, Slovak, Spanis h, Swedish, and Turkish.

● Connection can be made using the USB/RS-422 cable (Part Number BT300-CABLE) or any standard

Category 5 Ethernet cable.

● USB/RS-422 drivers are automatically inst alled during the Siemens NET installat ion.

● When the connect ion is made, Siemens NET automatically finds the connected drive.

Siemens Industry, Inc.

15 |

Chapt

er 1-User Interfaces on Siemens BT300

Fieldbus

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

NOTE:

See the software’s Help menu for more information on using Siemens NET.

Fieldbus

The BT300 HVAC Drive has both RS-485 communication and Ethernet protocols built into the core product; there

are no special order requirem ents for obtaining t he desired protocols. The RS-485 protocols are: APOGEE-P1,

BACnet MS/TP, Johnson N2, and Modbus RTU. The Ethernet protocols are: BACnet IP and Modbus TCP.

The built-in RS-485 protocols are documented in section

documented in the

Ethernet

section in Chapter 4.

RS-485

in Chapter 4. The built-in Ethernet prot ocols are

16 | 180

Chapter 2

-

Control Board Terminal Connections

Fieldbus

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

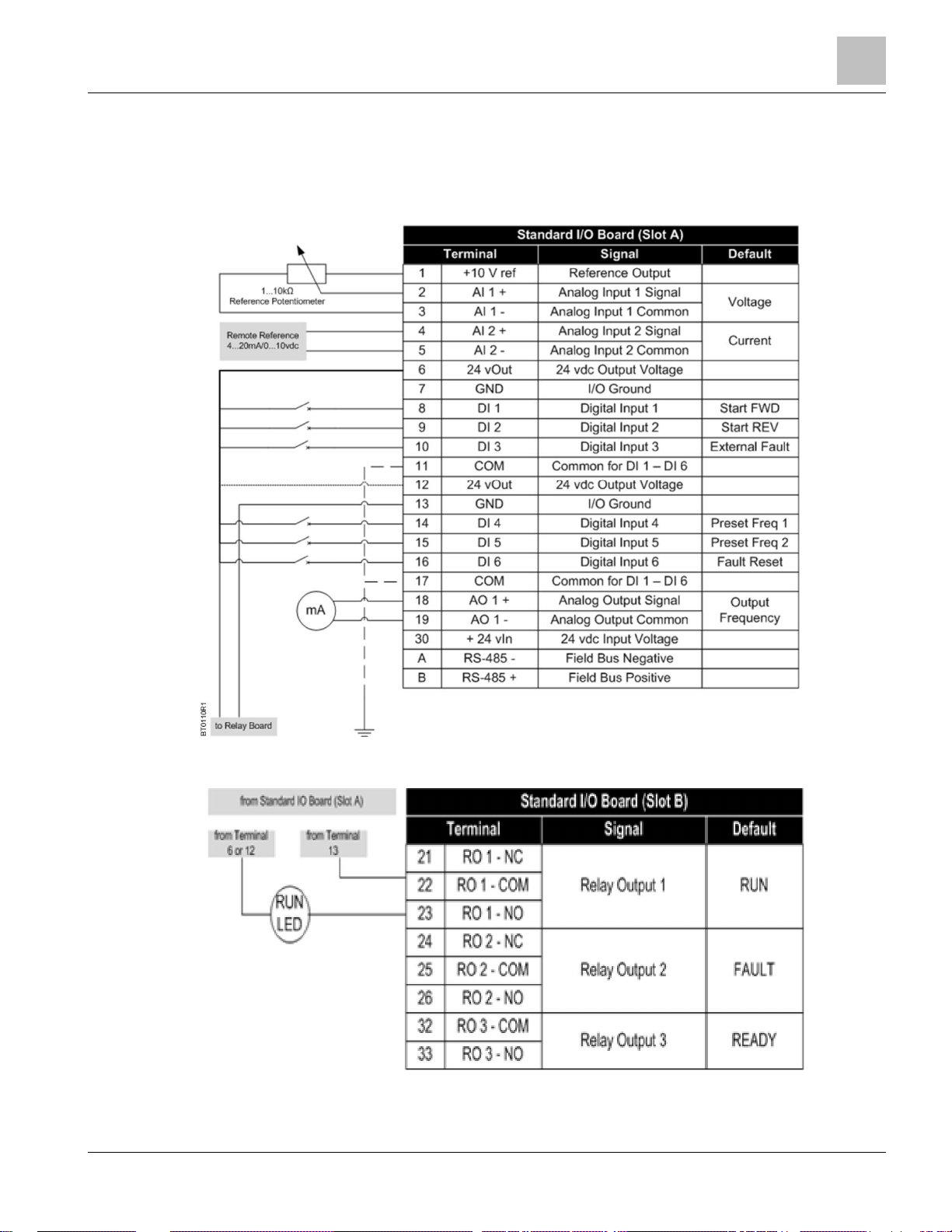

Chapter 2 - Control Board Terminal Connections

The control board terminals are located on the control module. The control module is identical for all sizes of the

BT300 HVAC Drive. It c ontains the keypad, terminals, and the control processor of t he drive.

Connect the control wiring to the BT300 control terminals per the site-specific drawings.

Siemens Industry, Inc.

Figure 3: Slot A Terminal Connections.

Figure 4: Slot B Terminal Connections.

17 |

Chapter 2

-

Control Board Terminal Connections

Analog Input Terminal Connections

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

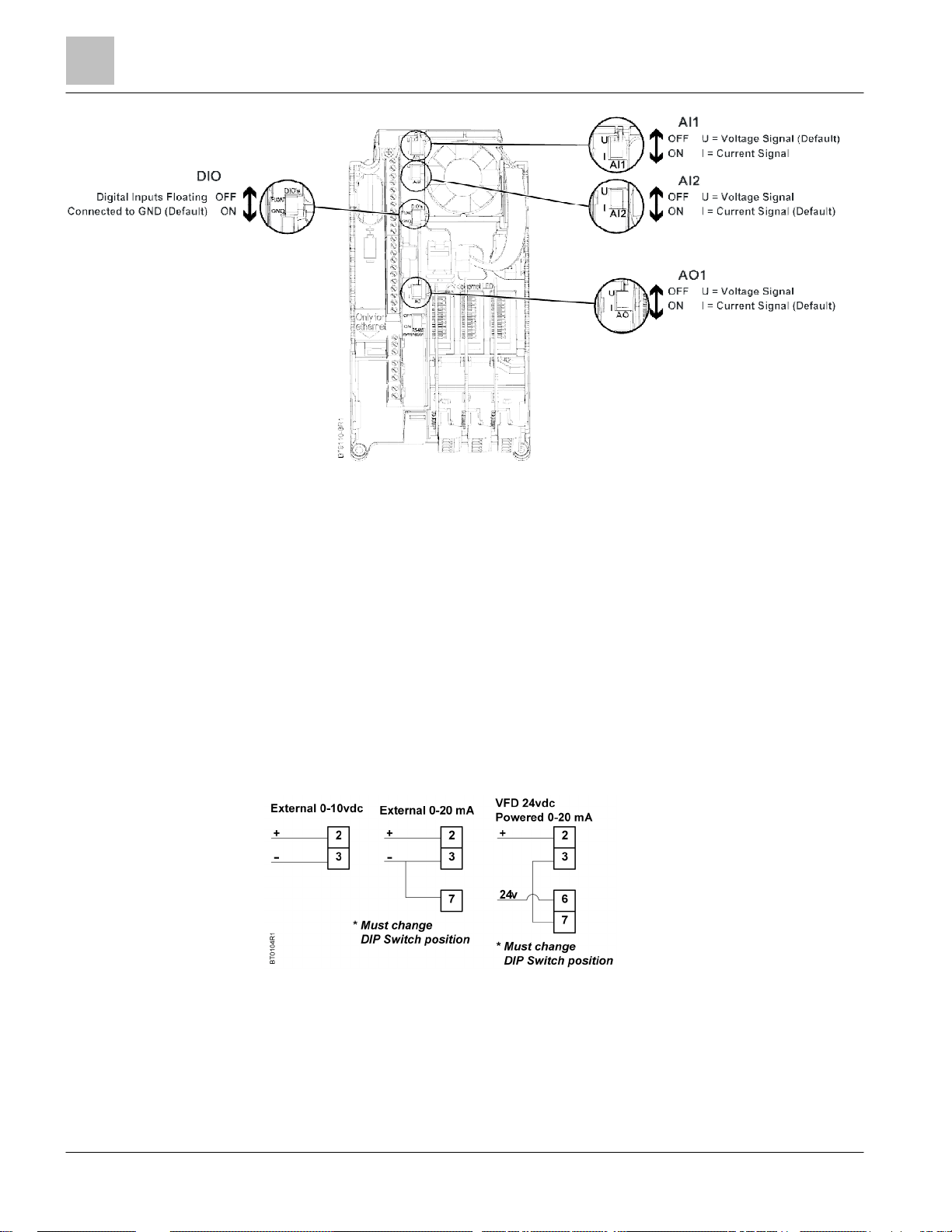

Figure 5: I/O-Related DIP Switches.

Analog Input Terminal Connections

The BT300 HVAC Drive cons ists of two analog inputs built on Slot A. When using analog input s, the DIP switches

must be correctly set and the analog inputs correctly configured before enabling them.

When using an analog input for speed reference, the signal is automatically sc aled f or Minimum Frequency (P3.3.1)

to Maximum Frequency (P3.3.2) in accordance with the signal range (for example, on a 0 to 10 Vdc signal, 0V

represents Minimum Frequency and 10V represents Maximum Frequency). This scaling can be modified. See the

analog input parameters listed in

Analo g Input 1

By default, Analog Input 1 is configured for a 0 to 10 Vdc signal source. The wiring is shown below. See Figure 5

for the location of the AI1 DIP switch. The DIP sw itch is set to the U (volt age) position at the factory. AI1 Signal

Range (P3.5.2.3) is used for programming the signal range of the analog input. Possible settings are 0 to 10 Vdc/0

to 20 mA or 2 to 10 Vdc/4 to 20 mA.

Chapter 3

.

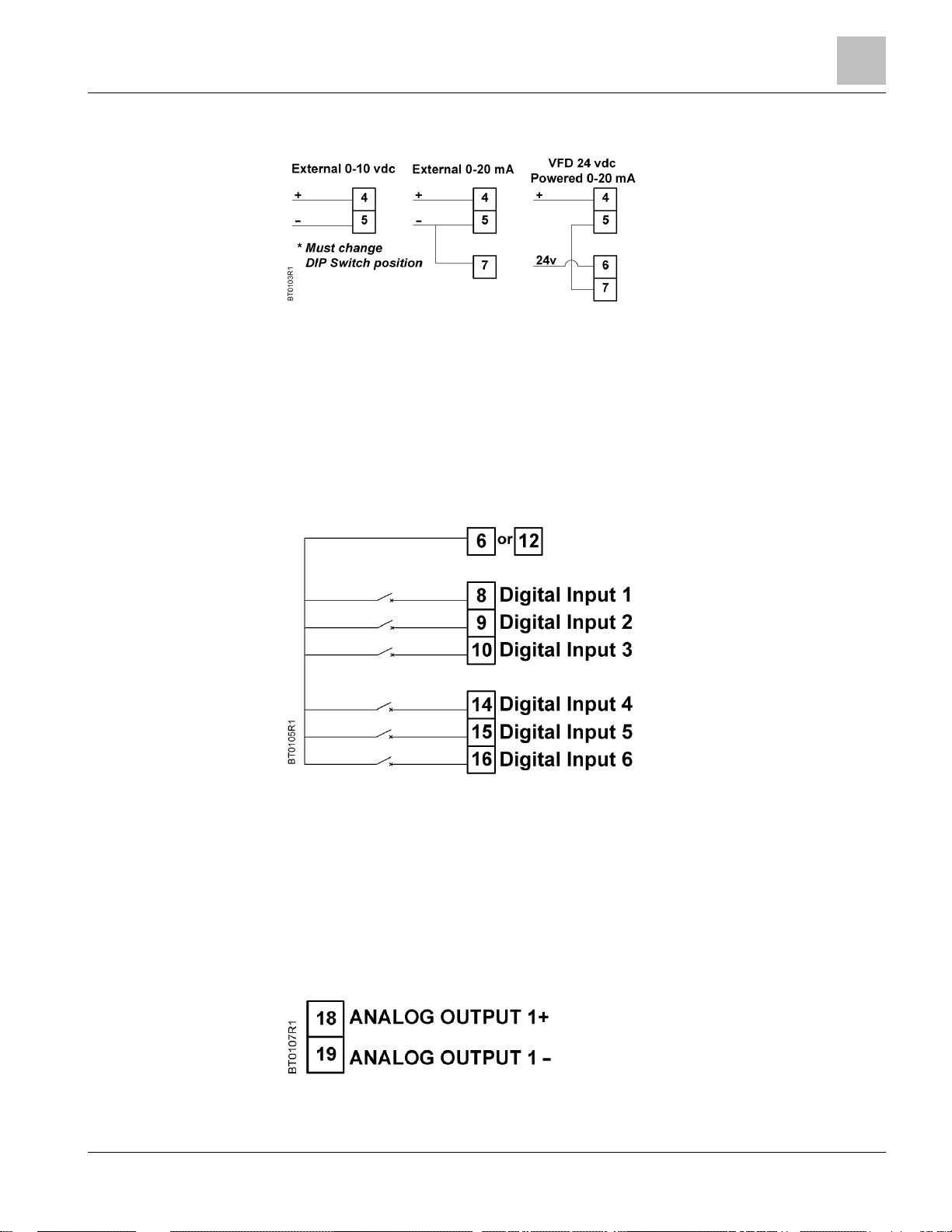

Analo g Input 2

By default, Analog Input 2 is configured for a 4 to 20 mA signal source. The wiring is shown below. See Figure 5

for the location of the AI2 DIP switch. The DIP switch is set to the I (current) position at the factory. AI2 Signal

18 | 180

Figure 6: Analog Input 1 Terminal Connections.

Chapter 2

-

Control Board Terminal Connections

Digital Input T

erminal Connections

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Range (P3. 5.2.9) is used for programming the signal range of the analog input . Possible settings are 0 to 10 Vdc/0

to 20 mA or 2 to 10 Vdc/4 to 20 mA.

Figure 7: Analog Input 2 Terminal Connections.

Digital Input Terminal Connections

The BT300 HVAC Drive consists of six digital inputs built on Slot A. When using digital input s, the DIP switch must

be correctly set and digit al inputs correctly configured before enabling them.

Digital Inputs 1 through 6

See Figure 5 for the location of the DIO DIP switch. The DIP switch is set to the GND (Grounded) position at the

factory.

Analog Output Terminal Connections

The BT300 HVAC consists of one analog output built on Slot A. When us ing the analog output, the DI P switch

must be correctly set and the analog output correct ly configured.

Analog Output 1

By default, Analog Output 1 is configured for a 4 to 20 mA signal. The wiring is shown below. See Figure 5 for the

location of the AO1 DIP switch. The DIP switch is set to the I (current) position at the factory.

Siemens Industry, Inc.

Figure 8: Digital Input Terminal Connections.

Figure 9: Analog Output 1 Terminal Connections.

19 |

Chapter 2

-

Control Board Terminal Connections

Digital Output Terminal Connections

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

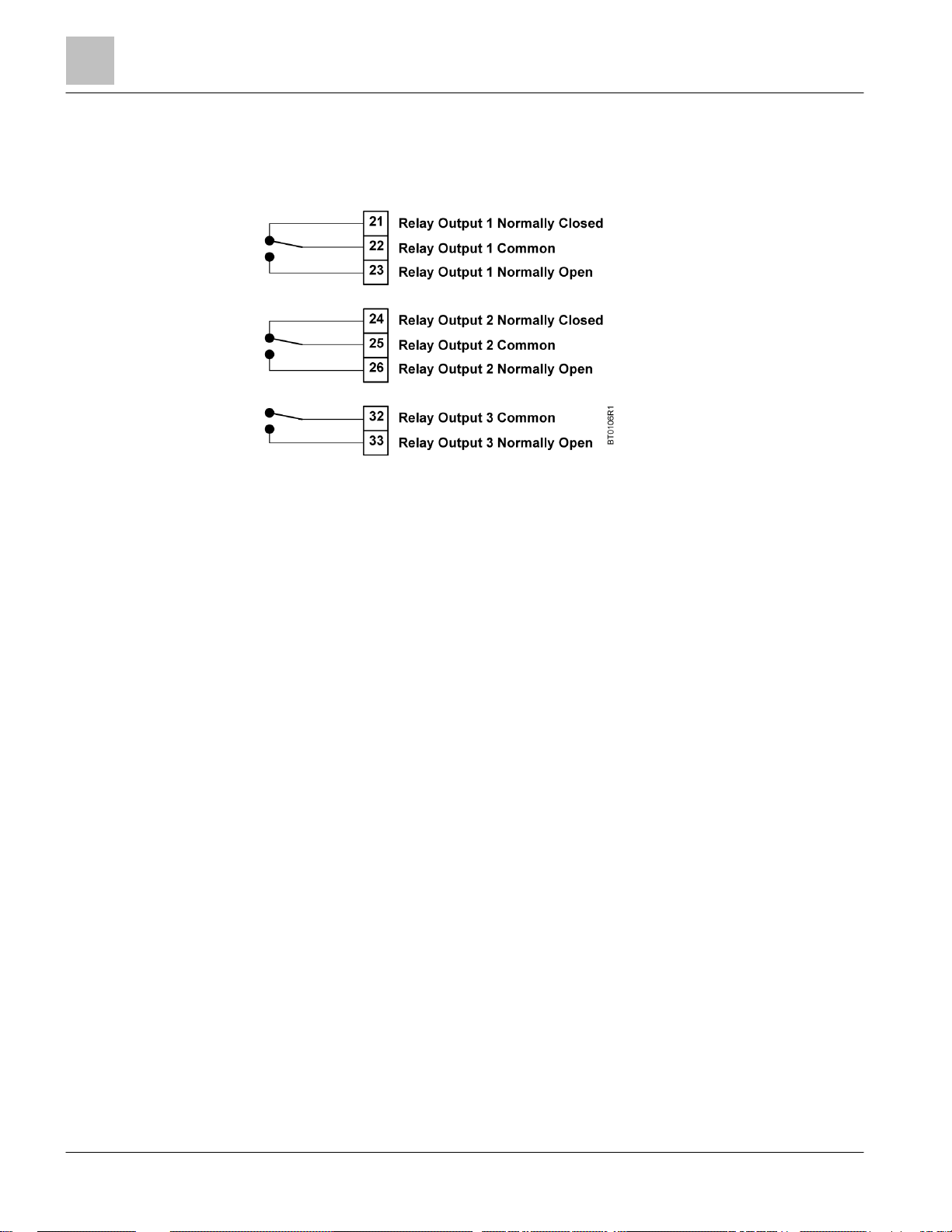

Digital Output Terminal Connections

The BT300 HVAC Drive consists of three digit al (relay) outputs built on Slot B. See Figure 5 for the location of the

DIO DIP switch. When using the digital outputs, the DIP switch must be correctly set and digital outputs correctly

configured.

Figure 10: Digital Output Terminal Connections.

20 | 180

Chapter 3

-

Start-up Information

Procedure and Checklist

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Chapter 3 - Start-up Information

Procedure and Checklist

To provide the most reliable drive available, and to avoid any extra costs related to loss or reduction of warranty

coverage, a factory-certified specialist should complete the startup procedures covered in the

and Checklist

(125-1006).

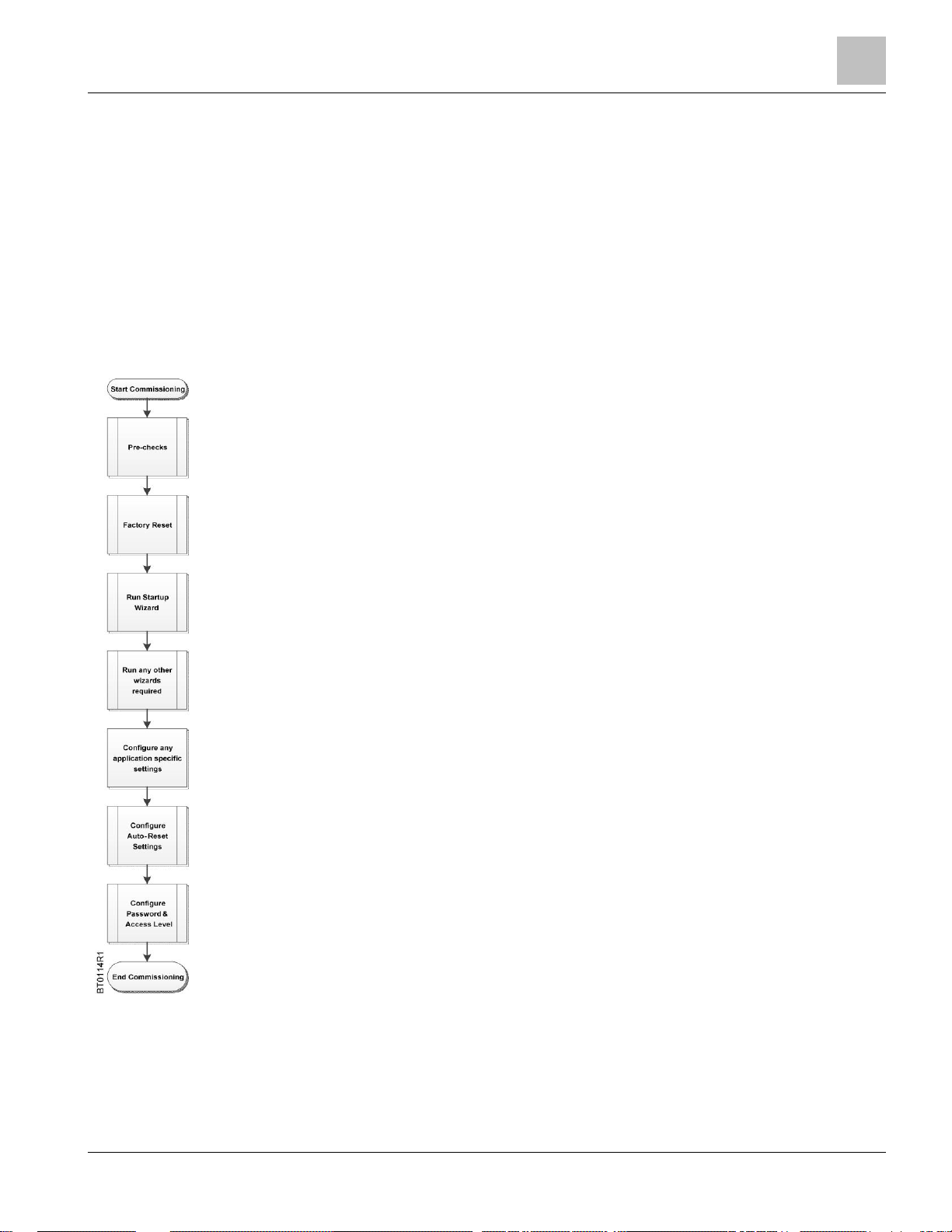

Commissioning Flowchart

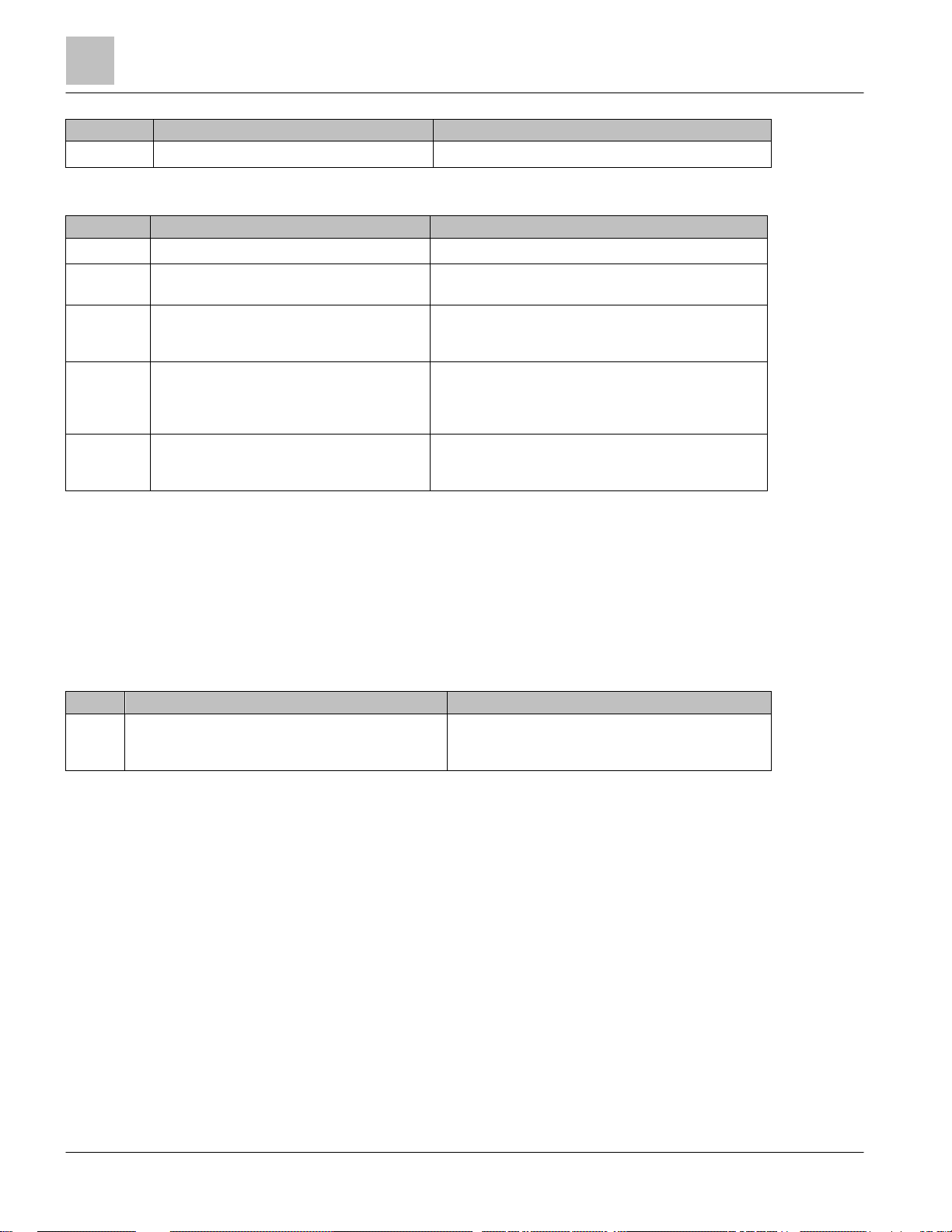

Table 3: Commissioning Flowchart.

There are several pre-chec ks that s hould be complet ed prior to powering up and commissioning th e

BT300 HVAC Drive. See

This step should be completed on all drives at start-up to ensure a good, known starting point. Select:

User Settings (M6) > Parameter Backup (M6.5) > Restore Factory Defaults (P6.5.1).

This step should be completed on all drives at start-up. This will be automatically s tarted at the end of

the Factory Reset. Select: Quick Setup > Star tu p Wizard (P1.19), if necessary.

the BT300 Startup Procedure and Checklist

Startup Procedure

(125-1006) for more details.

If any other wizards are needed, select one of the following:

Quick Setup > PID M in i-Wizard (M1.17) > Quick Setup/Mul t i-Pump Wizard (M1.20)

Quick Setup > St artup Wiza rd (M1.19) > Quick Setup/Fire Mode Wizard (M1.20)

Quick Setup > Bypass Wizard (M1.21)

Any other application-specific settings should be completed at this time.

Even if enabled during the Startup Wizard, the Auto-R eset sh ould be c onfigure d for the site’s

requirements. There are several parameters to configure in this menu. Review all paramet ers.

Select: Pa ramet ers (M3) > Automatic Reset (M3.10)

This forces the Mo nitor, Favorites, and User Level menus only. This prevents un authorized

parameterization through the keypad.

Select: User Levels (M8) > Acce ss Code (P8.2) . Set to desired access code ( such as 4521).

User Levels (M8)/User Level (P8.1). Set to Monitoring.

To return to edit menus, select: User Lev els (M8) > Us er Level (P8.1), and set to Normal. Enter the

Acces s code whe n prompted.

Siemens Industry, Inc.

21 |

Chapter 3

-

Start-up Information

Wizards

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Wizards

Wizards are available in t he Quick Set up (M1) menu. The wizards assist you with various start-up and

commissioning functions. There are five wizards available in the BT300 HVAC Drive that prompt for essential

information needed for the following:

● Start-up Wizard - Easy commissioning of the drive.

● PID Mini-Wizar d - Proper configuration of internal PID Loop Controller 1.

● Multi-Pump Wizard - Proper configuration of the Multi-pump application.

● Fire-Mode Wizar d - Proper configuration of the Fire-mode.

● Bypass Wizard - Proper configuration of the bypass options (if connected).

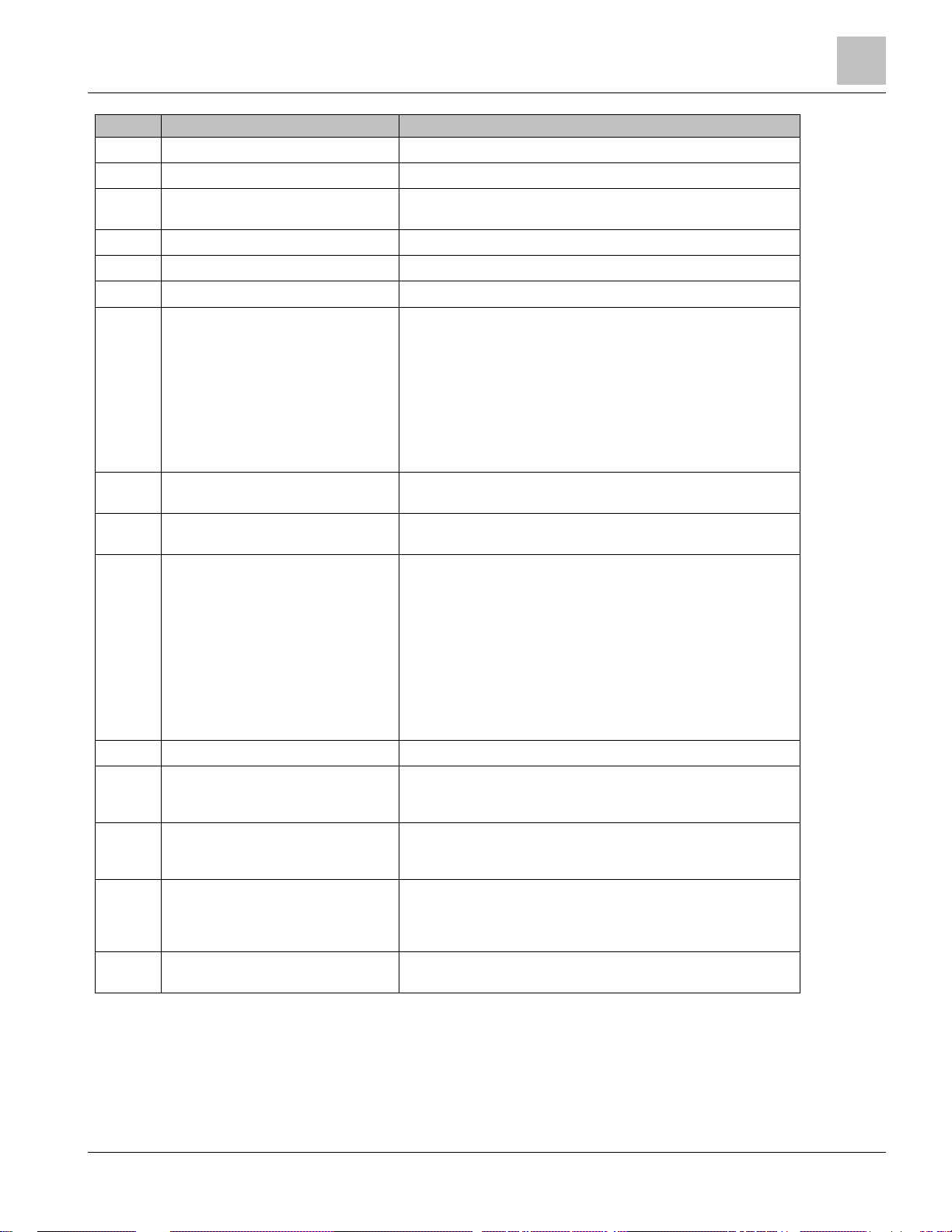

Startup Wi za rd (P1.19)

The Startup Wizard prompts you for the essent ial information needed by the driv e so that it can start controlling the

output as desired. Once power is connected to the BT300 HVAC Drive, the Startup Wizard should run

automatically. If it is not running, it can be activated in the Quick Set up (M1) menu or by completing Restore

Factory Def aults (P6.5.1)

The following steps are required to successf ully complete the Startup Wizard:

Step Parameter/Q uestion Settings

1 Language Selections (P6.1)

2 Daylight Saving (P5.5.5)

3 Time (P5.5.2)

4 Year (P5.5.4)

5 Date (P5.5.3)

6 Startup Wizard? Specify if the Startup Wizard should be activated: Yes , No

Select the icon for the languag e you want applied to the keypad. This

varies depending upon th e language packag e install ed.

Select the Daylight Sav ing Rul e

1 = Off

2 = EU

3 = US

4 = Russia

Specify the curre nt time of day in the following format: hh:mm:ss where

h = hour, m = minute, s = seconds.

Specify the current year in the following format: yyyy where

yyyy = 4-digit year.

Specify the current date in the following format: dd.mm where

dd = 2-digit day, mm = 2-di gi t month.

If the option Yes is selected for Startup Wizard (recommended), you will be prompted for the following values:

Step Parameter/Q uestion Settings

7

8 Motor Nom Voltg (P3.1.1.1) Defines nominal motor vol tage from motor na meplate d ata.

9 Motor Nom Freq (P3.1.1.2) Defines nominal motor fr equency from motor nameplate data.

22 | 180

Fan o r Pump

(Applica tion Type)

Pump

Automatically sets the followi ng:

Acce l Time 1 (P1.13) = 30

Decel Time 1 (P1.14) = 30

Start Function (P3.2.4) = Ramping

Stop Function (P3.2.5) = Ramping

Fan

Automatically sets the followi ng:

Acce l Time 1 (P1.13) = 120

Decel Time 1 (P1.14) = 12 0

Start Function (P3.2.4) = Flying Start

Stop Function (P3.2.5) = Coast to Stop

Chapter 3

-

Start-up Information

Wizards

80

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Step Parameter/Question Settings

10 Motor Nom Speed (P3.1.1.3) Defines nominal motor spe ed f rom mot or namepl ate data.

11 Motor Nom Currnt (P3.1.1.4) Defines nominal motor current from motor nameplat e data.

12

13 Motor Nom Power (P3.1.1.6) Defines nominal motor power from motor nameplate data.

14 Min Frequency (P3.3.1) Minimum allowed frequency ref erence.

15 Max Frequ e nc y (P3.3.2) Maximum allowed frequency reference.

16 I/O Ctrl Ref (P3.3.3)

17 Accel Time (P3.4.2)

18 Decel Time (P3.4.3)

19 Ctrl Place Auto (P3.2.1)

20 Automatic Reset (P3.10.1) Determines if the Automatic Reset feature can be used.

21 Start Function (P3.2.4)

22 Stop Function (P3.2.5)

23 Motor Switch (P3.1.2.2)

24 Bypass Wizard (P1.21)

Motor Cos Phi (P3.1.1.5)

(Power Factor)

Defines nominal motor Cos Phi (power factor ) from m otor nameplate

data.

Selects location of frequency setpoint source when in I/O A control. In

the following list of possible settings, the main setpoint is selected:

1= Preset Freq 0

2 = Keypad Reference

3 = Fieldbus

4 = AI1

5 = AI2

6 = AI1+AI2

7 = PID 1 Reference

8 = Motor Potentiometer

Defines the time required to increase output frequency from 0 to Max

Frequency (P3.3.1).

Defines the time required to decrease output frequency from Max

Frequency (P3.3.1) to 0 frequency.

Start/Stop commands are given differ ently dependin g upon the control

place. This parameter defines whether the Start/Stop command is

controlled by digital inputs as defined in Control Signal 1 A (P3.5.1.1)

and Control Signal 2 A (P3.5.1.2) in accordance with the I/O A

Start/Stop Logic (P3.2.6) or if the Start/Stop com mand is controlled by

the Fieldbus that is in use.

Settings:

0 = I/O Control (control is from the physical I/O, PID control, or time

channels)

1 = Fieldbus (control is from the configured fieldbus found in Ethernet

or RS-485 settings).

Defines the start function of the drive.

0 = Ramping Start

1 = Flying Start

Defines the stop function of the drive.

0 = Coast to Stop

1 = Ramping Stop

Prevents the driv e from trip ping when a motor swit ch is located

between the drive and motor.

0 = No

1 = Yes

Enable parameter for the Bypass Wizard. This wizard can be act ivated

during the Startup W izard.

The Startup Wizar d is now complete.

Siemens Industry, Inc.

23 | 1

Chapter 3

-

Start-up Information

Wizards

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

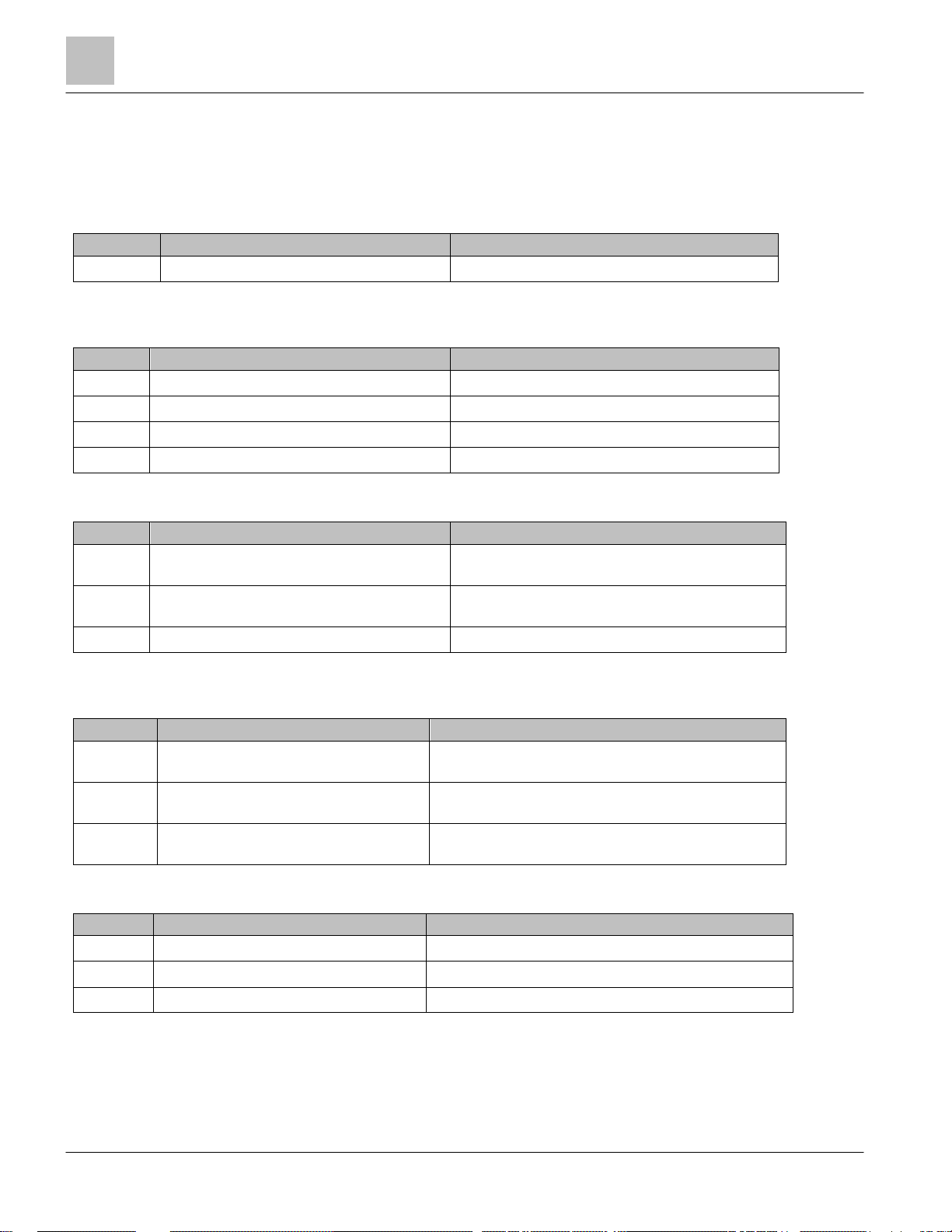

PID Mini-Wizard (P1.17)

The PID Mini-Wizard is activated in the Quick Setup (M1) menu. This wizard will assist with configuring the drive

for use with the PID Controller 1 in a “one-feedback/one-setpoint” mode. The control place will be I/O A and the

default process unit is %.

The following steps ar e required to successfully c omplete the PID Mini-Wizard:

Step Parameter/Question Settings

1

If a process unit other t han % is selected, the following questions display. Otherwise, the wiz ard jumps directly to

Step 5:

Step Parameter/Question Settings

2

3

4

5

If one of the analog input signals is selected, Step 6 displays. Otherwise, the wizard jumps directly to Step 7.

Step Parameter/Question Settings

6

7

8

Process unit selection (P3.12.1.4) Several selections, see P3.12.1.4.

Process Unit Min (P3.12.1.5) Varies

Process Unit Max (P3.12.1.6) Varies

Process Unit Decimals (P3.12.1.7) Range: 0 to 4

Feedba ck 1 Source Selection (P3.12.3.3) Several selections, see P3.12.3.3.

Analog Input Signal Ran ge

Error Inversion (P3.12.1.8)

Setpoint Source Selection (P3.12.2.4) Several selections, see P3.12.3.4.

0 to 10V/0 to 20 mA

2 to 10V/4 to 20 mA

Reverse Acting

Direct Actin g

If one of the analog input signals is selected, Step 9 displays. If the either of the options Keypad SP1 or Keypad

SP2 is selected, then Step 10 displays. Otherwise, the wizard jumps directly to Step 11.

Step Parameter/Question Settings

9

10

11

Analog Input Signal Ran ge

Keyp ad SP 1 (P3.12.2.1) or Keypad SP2

(P3.12.2.2)

Sleep Function?

0 to 10V/0 to 20 mA

2 to 10V/4 to 20 mA

Varies

No

Yes

If the option Yes is selected for Sleep Function, you will be prompt ed for the sleep function settings:

Step Parameter/Question Settings

12

13

14

Sleep Frequency Lim it 1 (P3.13.2.7) Varies

Sleep Delay 1 (P3.12.2.8) Varies

Wake-up Level 1 (P3.12.2.9) Varies

The PID Mini-Wizard is now com plete.

24 | 180

Chapter 3

-

Start-up Information

Wizards

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Multi-Pump Wiza rd (P1. 18 )

NOTE:

The Multi-Pump Wizard is activated in the Quick Setup (M1) menu. This wizard assists with configuring the drive for

use with PID Controller 1, and then asks the most important questions for setting up a multi-pump system.

The following steps are required to successf ully complete the Multi-Pump Wizard:

Step Parameter/Question Settings

1 – 14

15

16

17

If the Auto-change function is enabled, the following will display. Otherwis e, the wizard jumps directly to St ep 21:

Step Parameter/Question Settings

18

19

20

21

22

Same as PID Mini-Wizard

Numb er of Motors (P3.14.1) 1 to 4

Interlock Function (P3.14.2)

Auto-change (P3.14.4)

Include FC (P3.14.3)

Auto-c hange Inter v a l (P3.14.5) 0.0 to 3000.0 h

Auto-change Fr equency Limit (P3.14.6) 0.0 to 60.0 Hz

Bandwidth (P3.14.8) 0 to 100%

Bandwidth Delay (P3.14.9) 0 to 3600 s

Not Used

Enabled

Disabled

Enabled

Disabled

Enabled

After this, the keypad displays the digital input and relay output configuration done by the application. It is

recommended that these values are written down for fut ure reference.

The Multi-Pump Wizard is now complete.

Fire Mode Wizard (P1.20)

The Fire Mode feature of the drive is designed t o place the drive in a mode that ignores all commands from the

keypad, fieldbuses, and the personal com puter tool. In addition, the driv e will ignore all alarms and faults of the

drive and continue providing frequency to the attached motor. This is designed for instances when the destruction of

equipment is better than loss of life. The Fire Mode feature can be operated so that the PID loop is still in control of

the attached motor. The Fire Mode Wizard allows for easy commissioning of the Fire Mode function.

The Fire Mode Wizard is activated in the Quick Setup (M1) menu. The wizard assists with configuring the drive for

use with the Fire Mode feature.

The warranty is void if t he Fire Mode function is activ ated. Test Mode can be used to

test the Fire Mode function without voiding the warranty. Read important information

about the password and warranty issues in Chapter 4 before you proc eed.

Test Mode can be used to test the Fire Mode function without voiding the warranty.

The Fire Mode Wizard can be initiated by choos ing Activate for Fire Mode Wizard (P 1.20) in the Quick Setup (M1)

Menu.

The following steps are required to successf ully complete the Fire-Mode Wizard:

Siemens Industry, Inc.

25 |

Chapter 3

-

Start-up Information

Wizards

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Step Parameter/Question Settings

1

Fire Mo de F requency Sourc e (P3.16.5) Several selections; see P3.16.5.

If Fire Mode Frequency is selected, the following will display. Otherwise, the wizard jumps directly to Step 3:

Step Parameter/Question Settings

2

3

4

5

6

Fire Mo de Fr e q ue nc y (P3.16.4) Range: 0 to Maximum Frequency (P1.9)

Signal Activation?

Fire Mo de A ctivation Open (P3.16.2)

Or

Fire Mo de A ctivation Clos e (P3.16.3)

Fire Mo de R ev erse (P3.16.6)

Fire Mo de Passwor d (P3.16.1)

Open Contact

Closed Contact

Choose the digital input to activate Fire Mode.

Choose the digital input to activate the reverse command in

Fire Mode.

DigIN Slot0.1 = FORWARD

DigIN Slot0.2 = REVERSE

Choose the password to enable the Fire Mode Function.:

1234 = Tes t M od e

1002 = En ab le Fire Mode

The Fire Mode Wizar d is now complete.

Bypass Wizard (P1.21)

The Bypass Wizard is activated in the Quick Setup (M1) menu. The wizard assists with configuring the drive for use

with the Conventional or Electronic Bypass options. If the Electronic Bypass option is selected, additional f eatures

can be enabled, if desired. The standard I/O is re-mapped for use with the Electronic Bypass option. Additional

parameters are available when the Electronic Bypass option is enabled.

The following steps are required to successf ully complete the Bypass Wizard:

Step Parameter/Question Settings

1

Select the Bypass (P3.17.4) mode

Electronic

Conventional

Disabled

If Conventional is selected, the following changes occur automatically, the wizard completes, and the message:

Bypass Wizard is now complete. Press OK to continue. displays.

● Control Signal 2 A (P3.5.1.2) is set to DigIN Slot0.1 to disable the reverse command on Digital Input 2.

● Run Interlock 2 (P3.5.1.13) is set to DigIN SlotA.2 to enable the run int erlock on Digital Input 2. The status of

the Output Contactor (M2) is factory-wired to digit al input 2.

● Preset Freq Sel0 (P3.5.1.15) is set to DigIN Slot0.1 to disable the Preset Frequency Selection 0 on Digit al Input

4.

● Overload (P3.5.1.53) is set to DigIN SlotA.5 to enable the overload on Digital Input 5. The stat us of the

Overload is factory -wired to Digital Input 5.

If Electronic is selected, the following change occ urs automatically:

Overload (P3.5.1.53) is set to DigIN SlotA.5 to enable the overload on Digital Input 5. The status of the Overload is

factory-wir ed to Digital Input 5.

The wizard continues with the following steps:

26 | 180

Chapter 3

-

Start-up Information

Wizards

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Step Parameter/Question Settings

2

Bypass Delay (P3.18.1) Time

3

Essential Services* (P3.18.5)

Defines the amount of time between the un it being

placed into Bypass mode and the M1 contact or closin g.

Range: 1 to 30 s

Enabled

Disabled

If Enabled is selected for Essential Services, Step 4 displays. Other wise, the wizard jumps directly to Step 5.

Step Parameter/Question Settings

4

Essential Services Activation (P3.5.1.52) DigIN SlotA.6

5

Remote Bypass* (P3.18.6)

Enabled

Disabled

If Enabled is selected for Remote Bypass, Step 6 displays. Otherwise, the wizard jumps directly to Step 7.

Step Parameter/Question Settings

6

Command Source (P3.5.1.1)

7

Interlock* (P3.2.11)

Fieldbus CTRL

I/O Control

Enabled

Disabled

If Enabled is selected for Interlock, Step 8 displays. Otherwise, the wizard jumps directly to Step 9.

Step Parameter/Question Settings

8

Interlock Delay (P3.2.12) Range: 0 to 120 s

9

Auto Bypass* (P3.18.2)

Enabled

Disabled

If Enabled is selected for Auto By pass, Step 10 displays. Otherwise, the wizard jumps directly to Step 11.

Step Parameter/Question Settings

10

Auto Bypass Delay (P3.18.4) Range: 0 to 30 s

11

Fault Se lec tion (P3.18.3)

* Feature of the Electronic Bypass Option. For more details, see

Select faults to enable auto Bypass:

Any Fault

Undervoltage

Overvoltage

Overcurrent

AI Low

Unit Temperature

Motor Overtemp

External Fault

Underload Fault

BT300 Bypass Operator’s Manual

(DPD01391)

The Bypass Wizar d is now complete. The following message displays: Bypass Wizard is now complete.

Press OK to continue.

If Disabled is selected, no changes occur and the wizard completes T he following message displays: Bypass

Wizard is now complete. Press OK to continue.

For more information on the bypass options, see the

Instruct ions

(DPD01375) and the

BT300 Variable Frequency Drive Bypass Operator’s Manual

BT300 Variable Frequency Dr ive Bypass Installation

(DPD01391).

Siemens Industry, Inc.

27 |

Chapter 4

-

Parameters and Menu S tructure

Wizards

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

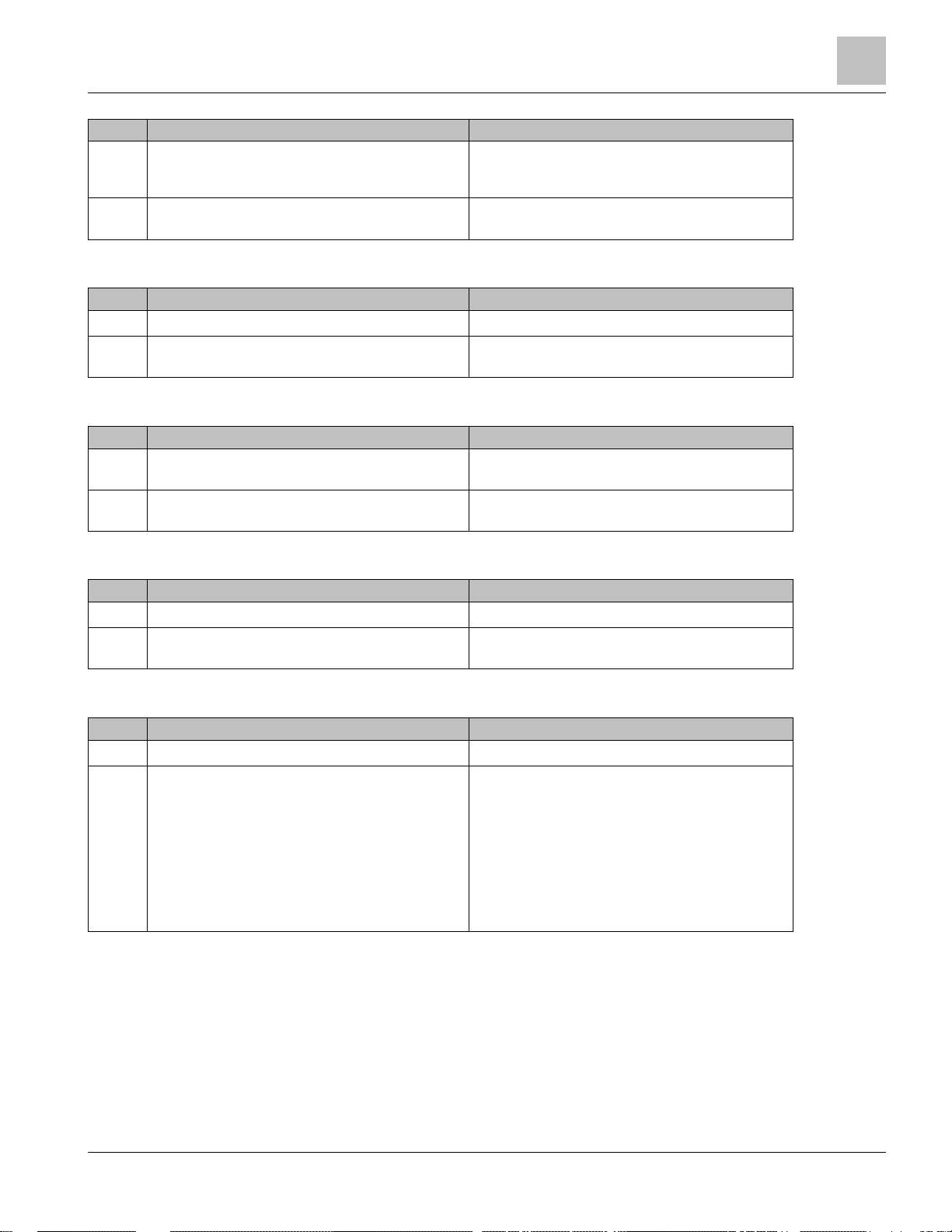

Chapter 4 - Parameters and Menu Structure

All information and param eters are organized in a menu struc ture:

Quick Setup (M1)

All basic pa ra me ter s

required to quickly setup

the BT300 VFD for

operation and all av ailable

wizards.

Monitor (M2)

Acces s to the Multimonitor display an d

parameters used f or

monitoring.

Parameters (M3)

Parameters used for

basic and advanced

configu ration

requirements.

P1.17 PID Mi ni-Wizard

P1.18 Mult i-Pump Wiz ar d M4.2 Reset Faults

P1.19 Star tu p Wizard M4.3 Fault History

P1.20 Fir e Mode Wiz ard M4.4 Total Counters

P1.21 By pass Wizard M4.5 Trip Counters

M2.1 Mult im o nit or M4.6 Sof tware Info

M2.2 Basic

M2.3 Timer Functions M5.2 Sl ot C

M2.4 PID Controll er 1 M5.3 Slot D

M2.5 PID Controll er 2 M5.4 Slot E

M2.6 Mult i-Pump M5.5 Real T ime Clock

M2.8 Fieldbus Data M5.6 Power Unit Settings

M2.9 Tem p. I nputs M5.7 Keyp ad

M3.1 Motor Settings M5.8 RS-485

M3.2 Start/Stop Setup M5.8.1 Common Settings

M3.3 References M5.8.3 BAC net MSTP

M3.4 Ra mps and Brakes M5.8.3 Modbus RTU

M3.5 I/O C onfig M5.8.3 N2

M3.5.1 Digital Inputs M5.8.3 P1

M3.5.2 Analog Inputs M5.9 Ethernet

M3.5.3 Digital Outputs M5.9.1 Common Settings

M3.5.4 Analog Outputs M5.9.2 Modbus TCP

M3.6 Fieldbus DataMap M5.9. 3 BACnet IP

M3.7 Pro hibit Freq

M3.8 Limit Superv M6.5 Parameter B ackup

M3.9 Protec tions M6 .6 Parameter Co mpare

M3.10 Automatic Reset M6.7 Drive Name

M3.11 Timer Function

M3.12 PID Control ler 1

M3.13 PID Control ler 2

M3.14 Multi-Pump

M3.16 Fire Mode P8.2 Access Code

M3.17 Appl. Setttings

M3.18 Bypass

2 1

Diagnostics (M4)

Diagnostics information such

as active faults, fault history

and counters.

I/O and Hardware (M5)

Parameters for status of I/O,

real time clock, keypad, and

fieldbus configuration.

User Settings (M6)

User information such as

keypad language selection,

paramet er backup/restor e, an d

drive nam e.

Favorites (M7)

List of user-defined para m eter

list.

User Levels (M8)

Restricts the visibility of

parameters

Displayed based on value of Protocol (P5.8.1.1)

2

Displayed based on value of Bypass (P3.17.4)

M4.1 Active Fa ults

M5.1 Basic IO

1

1

1

1

M6.1 Language S election

P8.1 User Level

28 | 180

Chapter 4

-

Parameters an

d Menu Structure

Quick Setup (M1)

180

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

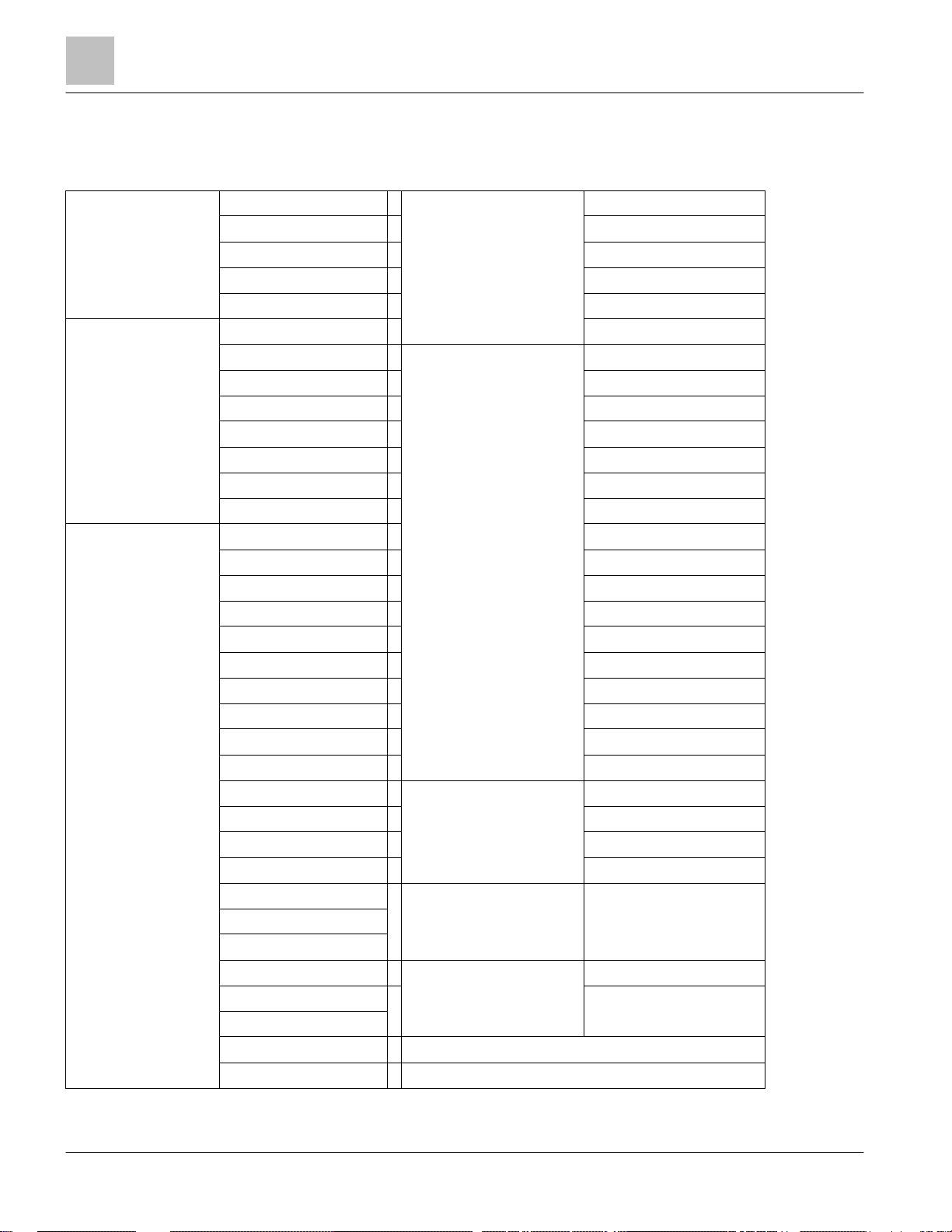

Quick Setup (M1)

The Quick Setup param eter group is a collection of parameters that are the most commonly us ed during installation

and commissioning. They are collected in the first parameter group so that they can be found quickly and easily.

However, they can be also be reached and edited in the actual parameter gr oups. Changing a parameter value in

the Quick Setup group als o changes the value of this parameter in its actual group.

The Quick Setup param eters are presented in the following table:

Table 4: Quick Setup Parameters.

Structure Parameter Unit ID Description

P1.1 Motor Nom Voltg V 110

P1.2 Motor Nom Freq Hz 111

P1.3 Motor Nom Speed rpm 112

P1.4 Motor Nom Currnt A 113

P1.5 Motor Cos Phi 120

P1.6 Motor Nom Power hp 116

P1.7 Current Limit A 107

P1.8 Min Frequency Hz 101

P1.9 Max Frequ enc y Hz 102

P1.10 I/O A Ctrl Ref 117

P1.11 Preset Fr eq 1 Hz 105

P1.12 Preset Fr eq 2 Hz 106

P1.13 Accel Tim e 1 s 103

P1.14 D ecel Time 1 s 104

Defines nominal motor vol tage from motor na meplate d ata.

Also see

Defines nominal motor fr equency from motor nameplate data.

Also see

Defines nominal motor spe ed f rom mot or namepl ate data.

Also see

Defines nominal motor current fr om motor nameplate data.

Also see

Defines nominal motor Cos Phi (power factor) from m otor nameplate data.

Also see

Defines nominal motor power from motor nameplate data.

Also see

Defines maximum current limit for mot or. Sugges ted to use Motor Nominal

Current (P1.4) multipli ed by motor service factor from motor nameplate data.

Also see

Sets minimum moto r frequenc y at which motor wil l run irrespective of

frequency setpoint.

Also see

Sets maximum motor frequency at which motor will run irrespective of

frequency setpoint.

Also see

Selects location of frequency setpoint source when in I/O A control. In the

following list of possible settings, the main setpoint is selected:

1= Preset Freq 0

2 = Keypad Reference

3 = Fieldbus

4 = AI1

5 = AI2

6 = AI1+AI2

7 = PID 1 Reference

8 = Motor Potentiometer

Also see

Used according to state of digital i nput defined for Preset Frequency

Selection 1 (P3.5.1.16). Decodin g mode chosen with Preset Frequency M ode

(P3.3.10). Also see

Used acc ording to state of digi tal inputs Preset Frequency Selection 2

(P3.5.1.17). Decoding mode chosen with Preset Frequency Mode (P3.3.10).

Also see

Time allowed for motor to acc elerate fro m a standstill (0) up to Maximum

Frequency (P1.9).

This parameter can also be found in Menu Str ucture P3.4.2

Time allowed for motor to decelerate from Maximum Frequency (P1.9) to a

standstill (0). Also see

Menu Structure P3.1.1.1

Menu Structure P3.1.1.2.

Menu Structure P3.1.1.3

Menu Structure P3.1.1.4

Menu Structure P3.1.1.5

Menu Structure P3.1.1.6.

Menu Structure P3.1.1.7.

Menu Structure P3.3.1.

Menu Structure P3.3.2.

Menu Structure P3.3.3.

Menu Struc ture P3.3.12

Menu Structure P3.3.13

Menu Structure P3.4.3

.

.

.

.

.

.

.

Siemens Industry, Inc.

29 |

Chapter 4

-

Parameters and Menu S tructure

Monitor Menu (M2)

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2017-09-28

Structure Parameter Unit ID Description

P1.15 Ct rl. Place A uto 172

P1.16 Automatic Reset 731

P1.17 PI D Mi ni-Wizar d 1803

P1.18 MultiPump Wizard

P1.19 Startup Wizard 1171

P1.20 Fir e Mode Wizard 1672 Enable parameter for the F ire Mode Wizard.

P1.21 Bypass Wizard 1823

Start/Stop commands are given differently depending upon the control place.

This parameter defines w hether the Start/Stop command is controlled by

digital inputs as defined i n Control Signal 1 A (P3.5.1.1) and Con trol Sig nal 2

A (P3.5.1.2) in accordance with the I/O A Start/Stop Logic (P3.2.6) or if the

Start/Stop command is controlled by the Fieldbus that is in use.

Settings:

0 = I/O Control (control is from the physical I/O, PID control, or time channels)

1 = Fieldbus (control is from the configured fieldbus found in Ethernet or RS485 settings)

Also see

Enable parameter for the A utomatic Reset function of the drive. This feature

is config ured in the Parameters (M3) … Automatic Reset (M3.10) menu.

Also see

Enable parameter for the PID Mini-Wizard. This wizard as sists w ith the

configu ration of the PID Controller 1 using a single feedback and single

setpoint.

Enable parameter for the Multi-Pu mp Wizard . This wizard assis ts with the

configuration of the Multi-Pump function of the drive. The PID Mini Wiz ard will

precede this wizard.

Enable parameter for the Startup Wizard. This wizard assist with the essential

information required for drive operation.

This wizard is automatically e nabled after Restore Factory Defaults (P6.5.1) is

activated.

Enable parameter for the Bypas s Wizard. This wizard c an be act ivated during

the Startup Wizard.

Menu Structure P3.2.1

Menu Structure P3.10.1

.

.

Monitor Menu (M2)

The Siemens BT300 HVAC Drive allows you to monitor actual values, parameters, and signals as well as status

and measurements. Some of the monitored values are customizable.

Table 5: Monitor Menu.

Menu and Parameter Group Description

Multimonitor (M2.1) Display of 9 monitored values.

Basic (M2.2) Display of basic drive mo nitorin g parameters.

Timer Functions (M2.3) Display of timer function specific monitoring par ameters.

PID Controller 1 (M2.4) Display of PID Controller 1 specific monitoring parameters.

PID Controller 2 (M2.5) Display of PID Controller 2 specific monitoring parameters.

Multi-Pump (M2.6) Display of Multi-Pump specific monitoring parameters.

Fieldbus Data (M2.8) Display of Mappe d Fieldbus Data monitorin g parameters.

Temp. Inputs (M2.9) Display of connected temperature inputs.

Multimo nitor (M2.1)

On the Multi-Monitor page, you can collect nine values to monitor. The display fields can be changed by selecting

the display field to be changed with the and arrow buttons, and then pressing the button. Scroll

30 | 180

Loading...

Loading...