DPD01149

Building Technologies

2013-12-03

DPD01149, Rev D

Siemens BT300 HVAC Drive

Operator's Manual

Copyright Notice

2

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Copyright Notice

Notice

Document information is subject to change without notice by Siemens Industry, Inc.

Companies, names, and various data used in examples are fictitious unless otherwise

noted. No part of this document may be reproduced or transmitted in any form or by

any means, electronic or mechanical, for any purpose, without the express written

permission of Siemens Industry, Inc.

Warning

This equipment generates, uses, and can radiate radio frequency energy. If equipment

is not installed and used in accordance with the instructions manual, it may cause

interference to radio communications. Equipment has been tested and found to comply

within the limits for a Class B digital device pursuant to Part 15 of the FCC rules. These

limits are designed to provide reasonable protection against such interference when

operated in a commercial environment. Operation of this equipment in a residential

area is likely to cause interference. Residential area equipment users are required to

take whatever measures necessary to correct the interference at their own expense.

Service Statement

Control devices are combined to make a system. Each control device is mechanical in

nature and all mechanical components must be regularly serviced to optimize their

operation. Siemens Industry, Inc. branch offices and authorized distributors offer

Technical Support Programs that will ensure continuous, trouble-free system

performance.

For further information, contact your nearest Siemens Industry, Inc. representative.

Copyright 2013 by Siemens Industry, Inc.

FCC Regulations

The manual for an intentional or unintentional radiator shall caution the user that

changes or modifications not expressly approved by the party responsible could void

the user’s authority to operate the equipment.

For a Class B digital device or peripheral, the instructions furnished the user shall

include the following or similar statement, placed in a prominent location in the text of

the manual:

NOTE: This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur

in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Copyright Notice

3

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

To the Reader

Your feedback is important to us. If you have comments about this manual, please

submit them to: mailto:Sbt_technical.editor.us.sbt@siemens.com

Credits

APOGEE, APOGEE GO, InfoCenter Administrator, InfoCenter Report Manager,

InfoCenter Server, InfoCenter Suite, and Insight are registered trademarks of Siemens

Industry, Inc.

Other product or company names mentioned herein may be the trademarks of their

respective owners.

Printed in the USA.

Copyright Notice

4

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

5

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Chapter 1 - BT300 Quick Start-up Guide .............................................................................. 9

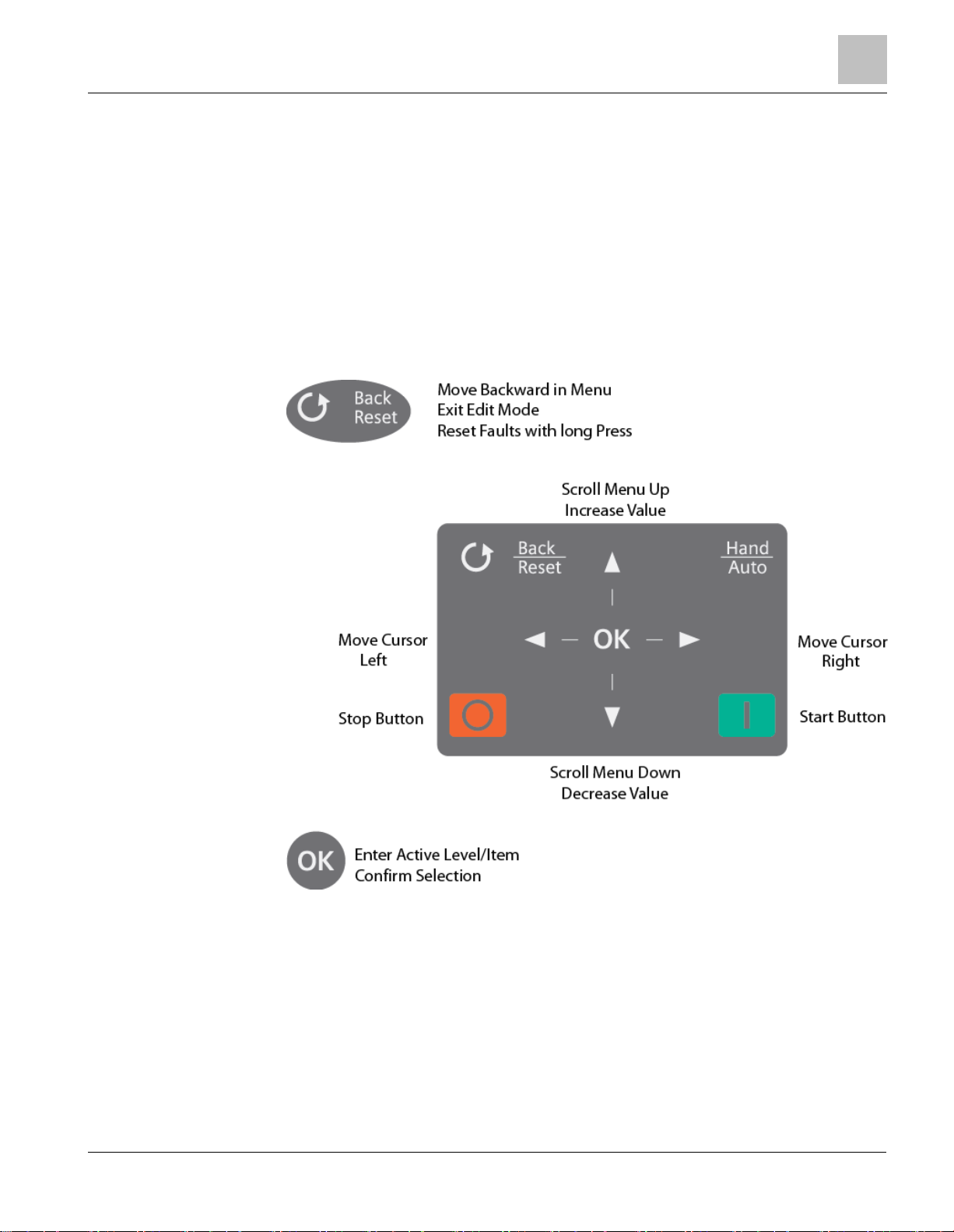

Keypad of the BT300 ............................................................................................................ 9

Keypad buttons ................................................................................................................ 9

Display ............................................................................................................................. 9

Editing values ................................................................................................................ 10

Startup Wizard (P1.19) ....................................................................................................... 11

Siemens Application ........................................................................................................... 12

Specific functions of the Siemens application ............................................................... 12

PID Mini-Wizard (P1.17) ................................................................................................ 13

Multi-pump Mini-wizard (P1.18) ..................................................................................... 15

Fire Mode Wizard (P1.20) ............................................................................................. 15

Bypass Wizard (P1.21) .................................................................................................. 16

Chapter 2 - User interfaces on Siemens BT300 .................................................................. 19

Navigation on keypad ......................................................................................................... 19

Keypad of the drive ............................................................................................................. 19

Siemens keypad with graphical display ......................................................................... 20

Menu structure .................................................................................................................... 27

Quick setup .................................................................................................................... 27

Parameters .................................................................................................................... 27

Siemens NET ...................................................................................................................... 28

Chapter 3 – Quick Setup (M1) ............................................................................................ 29

Chapter 4 - Monitor Menu (M2) ........................................................................................... 31

Group 2: Monitor group ...................................................................................................... 31

Multi-Monitor (M2.1) ...................................................................................................... 31

Basic (M2.2) .................................................................................................................. 32

Timer functions monitoring (M2.3) ................................................................................. 34

PID Controller 1 Monitoring (M2.4) ................................................................................ 34

PID Controller 2 Monitoring (M2.5) ................................................................................ 35

Multi-pump monitoring (M2.6) ....................................................................................... 35

Fieldbus data monitoring (M2.8) .................................................................................... 35

Temperature inputs monitoring (M2.9) .......................................................................... 36

Chapter 5 - Parameters (M3) .............................................................................................. 39

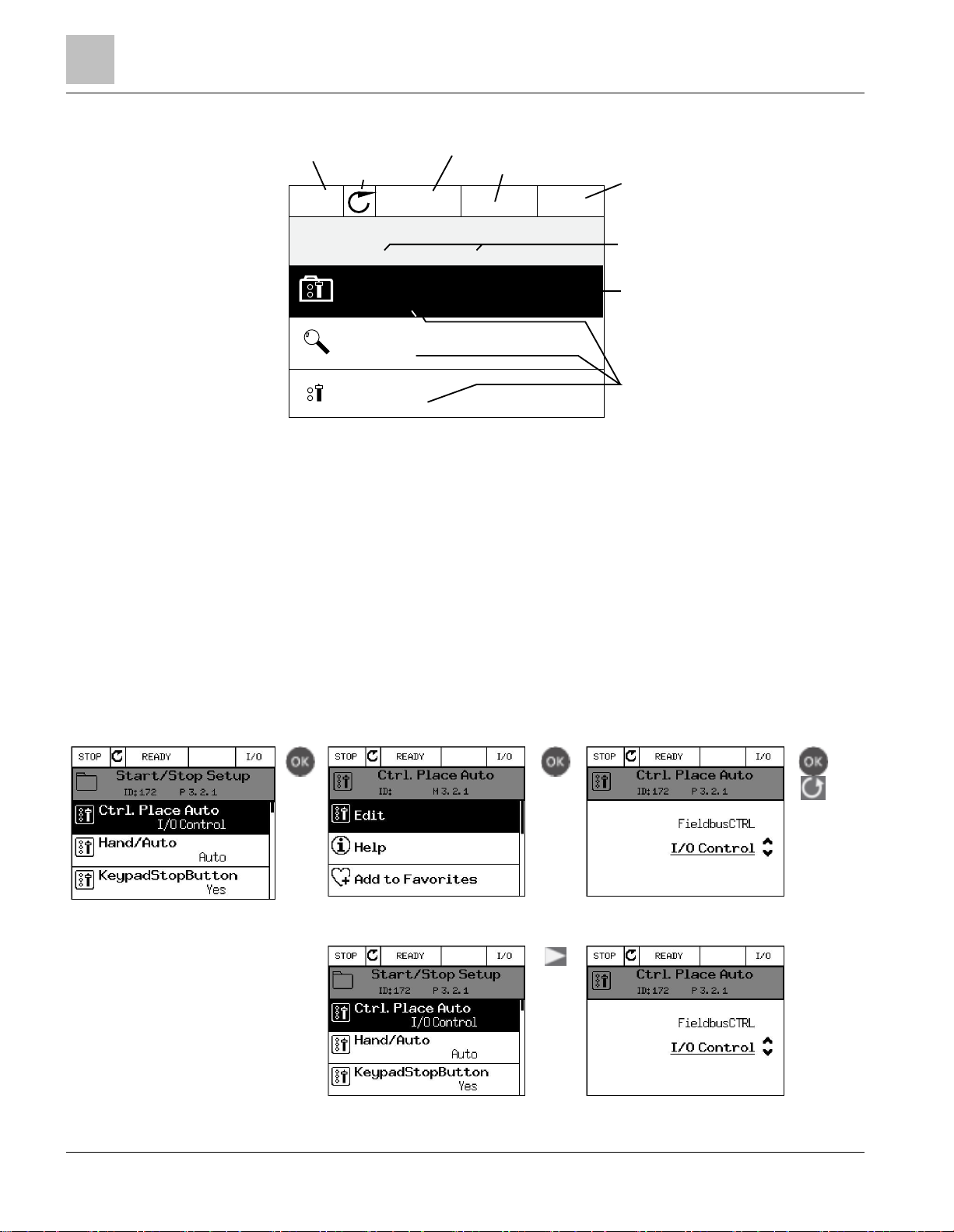

Parameter programming ..................................................................................................... 40

Example Programming with the Graphical Keypad ....................................................... 40

Descriptions of signal sources: ...................................................................................... 41

Column explanations ......................................................................................................... 42

Motor settings (M3.1) .......................................................................................................... 42

Basic Settings ............................................................................................................... 42

Motor Control Settings .................................................................................................. 43

Table of contents

6

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Start/Stop setup (M3.2) ....................................................................................................... 45

Control reference settings (M3.3) ....................................................................................... 46

Ramp & Brakes Setup (M3.4) ............................................................................................. 49

I/O Configuration (M3.5) ..................................................................................................... 50

Digital inputs .................................................................................................................. 50

Analog inputs ................................................................................................................. 52

Digital outputs, slot B (Basic) ......................................................................................... 54

Expander slots C, D, and E digital outputs .................................................................... 55

Analog outputs, Slot A (Standard) ................................................................................. 55

Expander slots C, D, and E Analog Outputs ................................................................. 56

Fieldbus Data Mapping (M3.6) .......................................................................................... 57

Prohibited Frequencies (M3.7) ........................................................................................... 58

Limit supervisions (M3.8) .................................................................................................... 58

Protections (M3.9) .............................................................................................................. 59

Automatic reset (M3.10) ..................................................................................................... 63

Timer functions (M3.11) ...................................................................................................... 64

PID-controller 1 (M3.12) ..................................................................................................... 69

Basic settings ................................................................................................................ 69

Setpoints ....................................................................................................................... 71

Feedback ....................................................................................................................... 72

Feedforward ................................................................................................................... 73

Soft fill ............................................................................................................................ 74

Process Supervision ...................................................................................................... 74

Pressure Loss Compensation ...................................................................................... 75

PID-controller 2 (M3.13) ..................................................................................................... 75

Basic settings ................................................................................................................. 75

Setpoints ....................................................................................................................... 77

Feedback ....................................................................................................................... 78

Process supervision ...................................................................................................... 79

Multi-pump (M3.14) ............................................................................................................. 80

Fire mode (M3.16) .............................................................................................................. 81

Application settings (M3.17) ............................................................................................... 82

Chapter 6 - Diagnostics (M4) .............................................................................................. 83

Active faults (M4.1) ............................................................................................................. 83

Reset faults (M4.2) ............................................................................................................. 83

Fault history (M4.3) ............................................................................................................. 83

Fault history ................................................................................................................... 84

Total counters (M4.4) .......................................................................................................... 84

Trip counters (M4.5) ........................................................................................................... 85

Software info (M4.6) ........................................................................................................... 85

Chapter 7 - I/O and hardware (M5) ..................................................................................... 87

Basic I/O (M5.1) .................................................................................................................. 87

Option board slots ............................................................................................................... 88

Real time clock (M5.5) ........................................................................................................ 88

Power unit settings, Cooling Fan control (M5.6)................................................................. 89

7

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Sine filter ............................................................................................................................. 89

Keypad (M5.7) .................................................................................................................... 89

Fieldbus (M5.8) ................................................................................................................... 90

Chapter 8 - User Settings, Favorites, and User Level Menus .............................................. 93

User settings (M6) .............................................................................................................. 93

Parameter backup ........................................................................................................ 93

Favorites (M7) ..................................................................................................................... 94

User levels .......................................................................................................................... 94

Chapter 9 - HVAC Application - Additional parameter information ....................................... 97

Group 3.1: Motor Settings .................................................................................................. 97

Group 3.2: Start/Stop Setup ............................................................................................... 98

Group 3.3: Control Reference Settings ............................................................................ 104

Group 3.4: Ramp & Brakes Setup .................................................................................... 105

Group 3.5: I/O Configuration ............................................................................................ 106

Group 3.9: Protections................................................................................................. 109

Group 3.10: Automatic Reset ...................................................................................... 113

Group 3.12: PID Controller 1 ....................................................................................... 114

Group 3.14: Multi-Pump ................................................................................................... 118

Chapter 10 - Fault tracing ................................................................................................. 125

Fault Displays ................................................................................................................... 125

Fault history ...................................................................................................................... 126

Fault codes ....................................................................................................................... 126

8

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Chapter 1 - BT300 Quick Start-up Guide

1

Keypad of the BT300

9

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Chapter 1 - BT300 Quick Start-up Guide

Keypad of the BT300

The control keypad is the interface between the BT300 Drivedrive and the user. With

the control keypad it is possible to control the speed of a motor, to supervise the state

of the equipment and to set the BT300 Drive. The following Figure shows the BT300

Drive

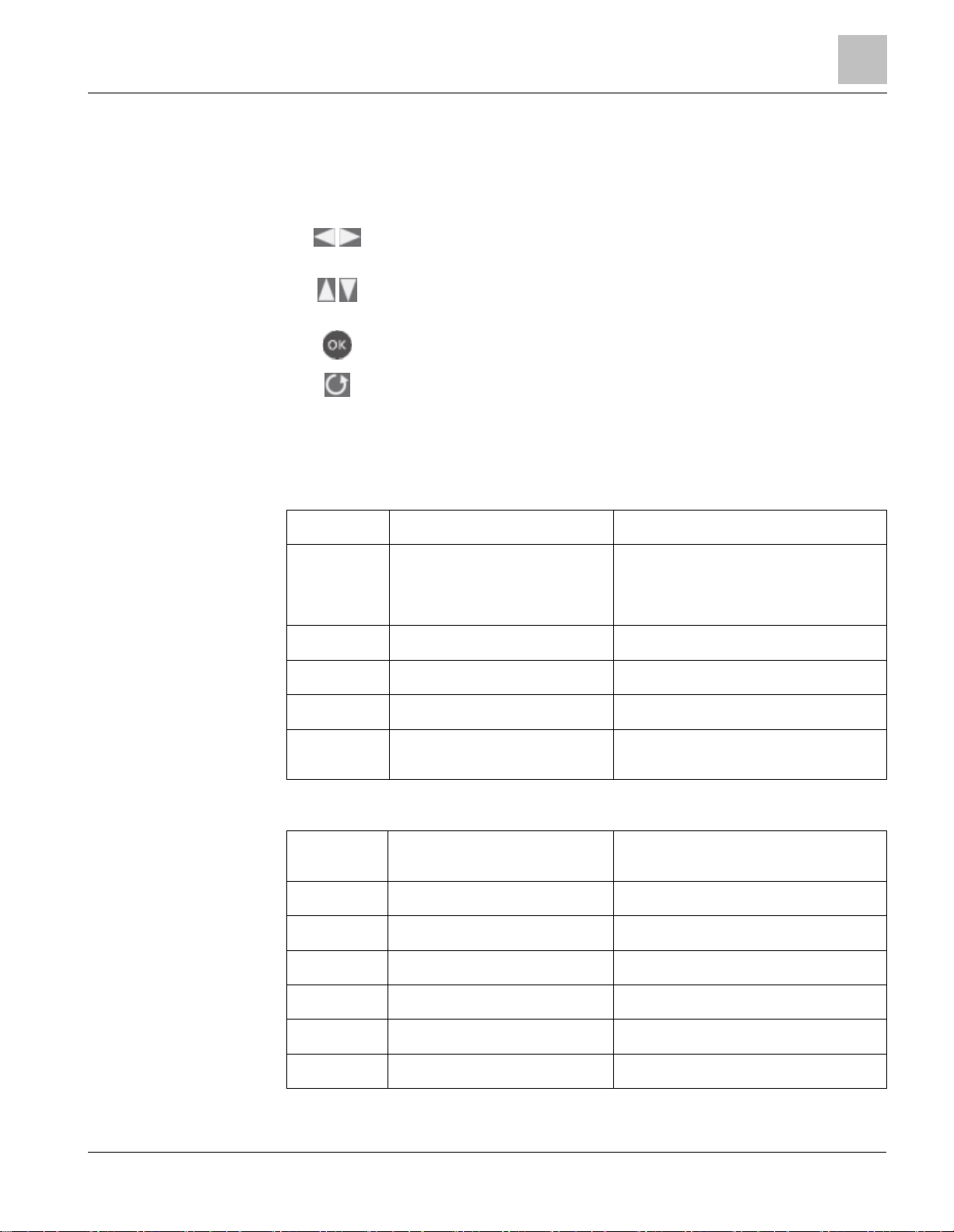

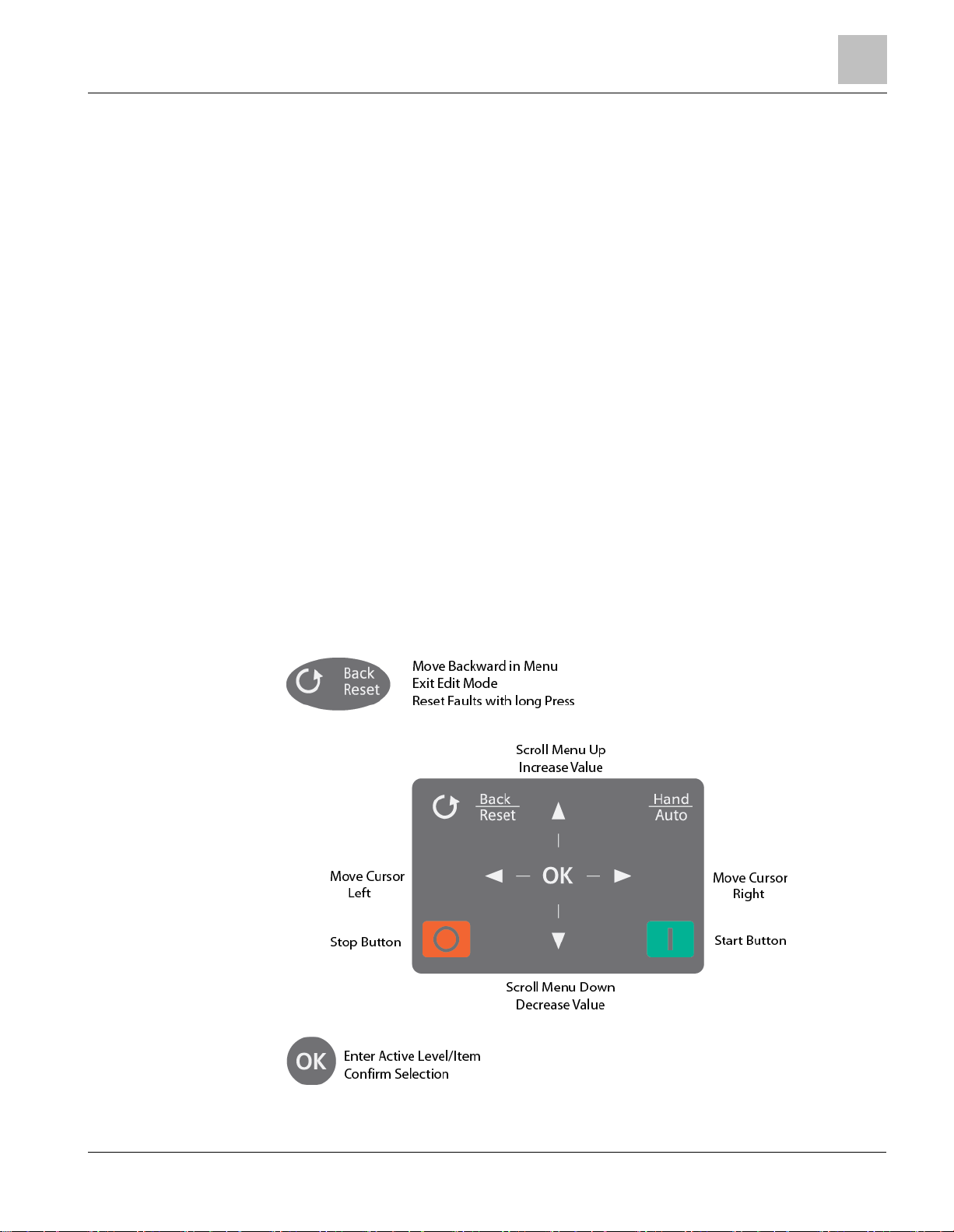

Keypad buttons

Figure 1: Siemens BT300 Keypad.

Display

The keypad display indicates the status of the motor and the drive and any

irregularities in the motor or drive functions. On the display, the user sees information

about the drive and the present location in the menu structure and the item displayed.

1

Chapter 1 - BT300 Quick Start-up Guide

Keypad of the BT300

10

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

9159.emf

( 17 )

( 12 )

0

STOP READY I/O

ID: M1

( 5 )

0

Main Menu

Quick Setup

Parameters

Monitor

Status field

STOP/RUN

Direction

ALARM

Status field

READY/NOT READY/ FAULT

Control place:

PC/IO/KEYPAD/FIELDBUS

Activated group/item:

Press OK to enter

Number of items

in the group

Location field

(Parameter ID number and

current menu location

Figure 2:

OR

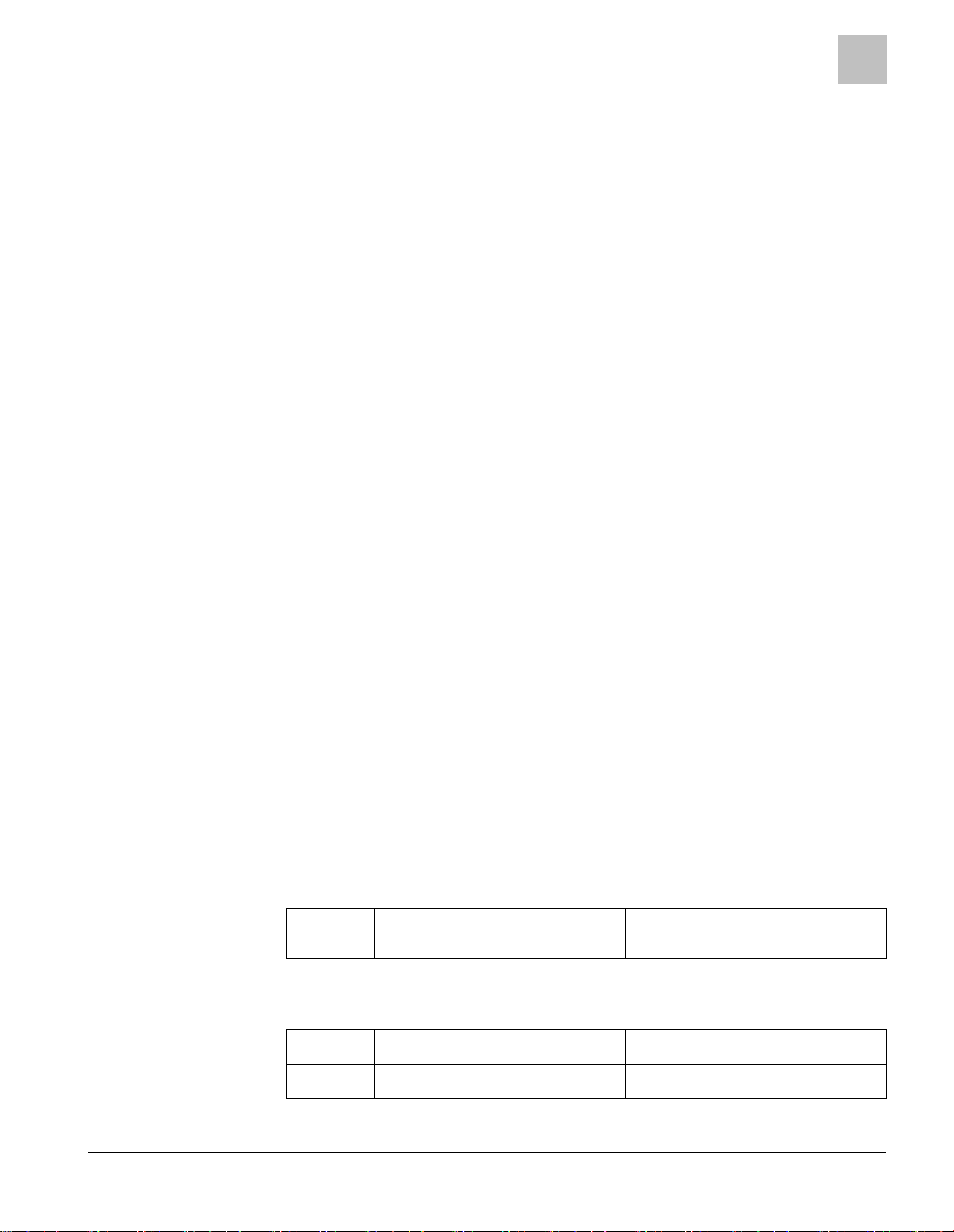

Editing values

Change value of a parameter following the procedure below:

1. Locate the parameter.

2. Enter the

3. Set new value with the arrow buttons up/down. You can also move from digit to

digit with the arrow buttons left/right if the value is numerical and change then the

value with the arrow buttons up/down.

4. Confirm change with OK button or ignore change by returning to previous level with

Back/Reset button.

Table 1: Editing values on graphical keypad.

Edit

mode.

Chapter 1 - BT300 Quick Start-up Guide

1

Startup Wizard (P1.19)

11

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Startup Wizard (P1.19)

Left/Right arrows. Use these to easily move between digits and

decimals.

Up/Down arrows. Use these to move between options in menu and to

change value.

OK button. Confirm selection with this button.

Back/Reset button. Pressing this button, you can return to the previous

question in the Wizard. If pressed at the first question, the Startup

Wizard will be canceled.

1

Language selection (P6.1)

Depends on language package

2

Daylight saving (P5.5.5)

Russia

US

EU

OFF

3

Time (P5.5.2)

hh:mm:ss

4

Year (P5.5.4)

yyyy

5

Day (P5.5.3)

dd.mm.

6

Run Startup Wizard?

Yes

No

7

Choose Application

Pump

Fan 8 Motor Nominal Voltage

Range: Varies

9

Motor Nominal Frequency

Range: 8...320 Hz

10

Motor Nominal Speed

Range: 24...19200 rpm

11

Motor Nominal Current

Range: Varies

12

Motor Cos Phi

0.3...1.0

13

Motor Nominal Power

Range: Varies

In the

Startup Wizard

drive so that it can start controlling your process. In the Wizard, you will need the

following keypad buttons:

, you will be prompted for essential information needed by the

Once you have connected power to your Siemens BT300 variable frequency drive,

follow these instructions to easily set up your drive.

If the option Yes is selected, you will be prompted for the following values:

1

Chapter 1 - BT300 Quick Start-up Guide

Siemens Application

12

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

14

Minimum Frequency

Range: 0.00...60.00 Hz

15

Maximum Frequency

Range: 0.00...320.00 Hz

16

I/O A Ctrl Ref

MotorPot Ref

PID1 Ref

AI1 + AI2

AI2

AI1

Fieldbus

Keypad Ref

PresetFreq0

17

Accel Time 1

0.1...3000.0 s

18

Decel Time 1

0.1...3000.0 s

19

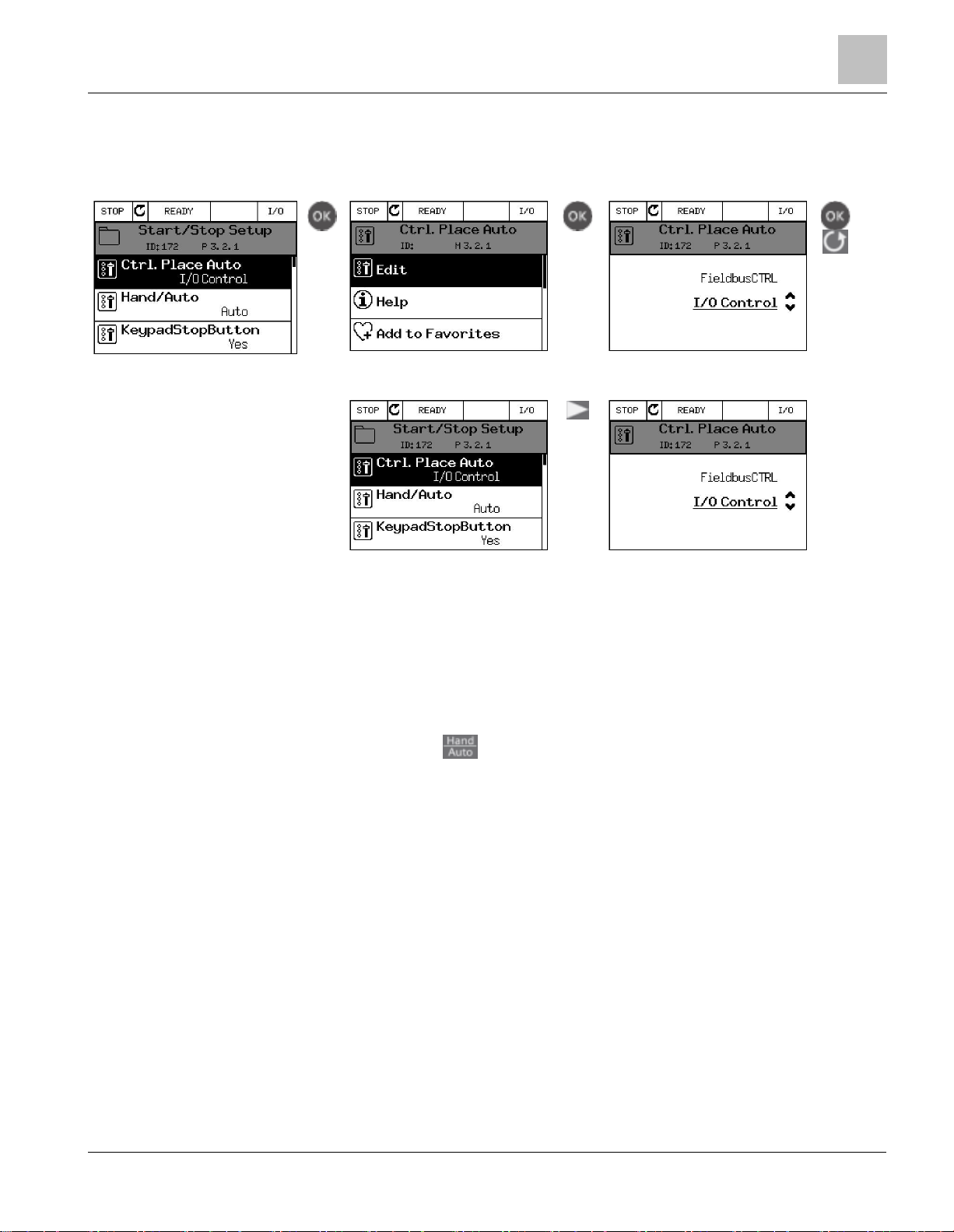

Ctrl. Place Auto

Fieldbus CTRL

I/O Control

20

Automatic Restart

Enabled

Disabled

21

Start Function

Flying Start

Ramping

22

Bypass Wizard

Yes

No

The Startup Wizard is now complete.

The Startup Wizard can be re-initiated by activating the parameter

defaults

(par. P6.5.1) in the

Parameter backup

sub-menu (M6.5) OR with parameter

Restore factory

P1.19 in the Quick setup menu [➙ 29].

Siemens Application

The Siemens drive contains a preloaded application for instant use. Should this

application not meet the requirements of your process please contact the manufacturer

for information on special applications.

The parameters of this application are listed in Chapter 5 - Parameters (M3) [➙ 39]

and explained in more detail in Chapter 9 - HVAC Application - Additional parameter

information [➙ 97].

Specific functions of the Siemens application

The Siemens BT300 application is an easy-to-use application for not only basic pump

and fan applications where only one motor and one drive is needed, but also offers

extensive possibilities for PID control.

Features

Start-Up wizard for extremely fast setup for basic pump or fan applications.

Mini-Wizards to ease the setup of applications.

Chapter 1 - BT300 Quick Start-up Guide

1

Siemens Application

13

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Hand/Auto button for easy change between (keypad) and auto control place. The

1

Process unit selection

(Several selections. See P3.12.1.4 [➙

69])

2

Process unit min

3 Process unit max

auto control place is selectable by parameter (I/O or Fieldbus).

Control page for easy operation and monitoring of the most essential values.

Run interlock input (Damper interlock). Drive will not start before this input is

activated.

Fire mode

Different preheat modes used to avoid condensation problems.

Maximum output frequency 320 Hz.

Selection for the U.S. and metric units. E.g. "kW or "hp", °C or °F (factory preset

according to customer’s wish)

Real-time clock and timer functions available. Possible to program 3 time channels

to achieve different functions on the drive (e.g. Start/Stop and Preset frequencies).

Overtemperature tripping prevention by dropping the switching frequency and the

output frequency (Automatic Derating)

External PID-controller available. Can be used to control e.g. a valve using the

drive’s I/O.

Sleep mode function

which automatically enables and disables drive running with

user defined levels to save energy.

2-zone PID-controller (2 different feedback signals; minimum and maximum

control).

Two setpoint sources for the PID-control. Selectable with digital input.

PID setpoint boost function.

Soft fill function. E.g.: Preset speed is used at start until the pipe is full and the

pressure defined by parameter is reached

Feedforward function

Process value supervision.

Multi-Pump control.

Pressure loss compensation for compensating pressure losses in the pipe work.

to improve the response to the process changes.

For example, when a sensor is incorrectly placed near the pump or fan.

PID Mini-Wizard (P1.17)

The

PID mini wizard

that you are going to use the PID controller in the "one feedback / one setpoint" mode.

The control place will be I/O A and the default process unit ‘%’.

The

PID mini wizard

If a process unit other than % is selected, the following questions display. Otherwise,

the Wizard jumps directly to Step 5.

is activated in the

Quick Setup

menu. This wizard presupposes

asks for the following values to be set:

1

Chapter 1 - BT300 Quick Start-up Guide

Siemens Application

14

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

4

Process unit decimals

0...4

5

Feedback 1 source selection

See the Setpoints [➙ 77] section for

selections.

6

Analog input signal range

0 = 0…10 V / 0…20 mA

1 = 2…10 V / 4…20 mA

See the Analog inputs [➙ 52] section for

more information.

7

Error inversion

0 = Normal

1 = Inverted

8

Setpoint source selection

See the Setpoints [➙ 71] section for

selections.

9

Analog input signal range

0 = 0…10 V / 0…20 mA

1 = 2…10 V / 4…20 mA

See the Analog inputs [➙ 52] section for

more information.

10

Keypad setpoint

11

Sleep function?

No

Yes

12

Sleep frequency limit 1

0.00...320.00 Hz

13

Sleep delay 1

0...3000 s

14

Wake-up level 1

Range depends on selected process

unit.

If one of the analog input signals is selected, Step 6 displays. Otherwise, the Wizard

jumps directly to Step 7.

If one of the analog input signals is selected, Step 9 displays. Otherwise, the Wizard

jumps directly to Step 11.

If either of the options Keypad Setpoint 1 or 2 is selected, then Step 10 displays.

If the option ‘Yes’ is selected, you will be prompted for the following values:

Chapter 1 - BT300 Quick Start-up Guide

1

Siemens Application

15

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Multi-pump Mini-wizard (P1.18)

15

Number of motors

1...4

16

Interlock function

0 = Not used

1 = Enabled

17

Autochange

0 = Disabled

1 = Enabled

18

Include FC

0 = Disabled

1 = Enabled

19

Autochange interval

0.0...3000.0 h

20

Autochange: Frequency limit

0.00...60.00 Hz

21

Bandwidth

0...100%

22

Bandwidth delay

0...3600 s

NOTE:

THE WARRANTY IS VOID, IF THE FIRE MODE FUNCTION IS ACTIVATED.

1

Fire Mode frequency source

(P3.17.2)

Several selections, see the Table

Fire

Mode Parameters

in the Fire mode

(M3.16) [➙ 81] section.

The Multi-Pump mini-wizard asks the most important questions for setting up a MultiPump system. The PID mini-wizard always precedes the Multi-Pump mini-wizard. The

keypad guides you through the steps in the PID Mini-Wizard (P1.17) [➙ 13] and then

continues with the following set of questions:

If the Auto-change function is enabled, the following questions will display. Otherwise,

the Wizard jumps directly to Step 21.

After this, the keypad will show the digital input and relay output configuration done by

the application. Write these values down for future reference.

Fire Mode Wizard (P1.20)

Test Mode can be used to test the Fire Mode function without voiding the warranty.

Read important information about the password and warranty issues in chapter 8.13,

before you proceed.

Fire Mode Wizard is intended for easy commissioning of the Fire Mode function. The

Fire Mode Wizard can be initiated by choosing

Quick setup menu.

Activate

for parameter 1.1.2 in the

1

Chapter 1 - BT300 Quick Start-up Guide

Siemens Application

16

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

If any other source than ‘

2

Fire Mode frequency (P3.17.3)

8.00 Hz...MaxFreqRef (P3.3.1.2)

3

Signal activation?

Should the signal activate on opening or

closing contact?

0 = Open contact

1 = Closed contact

4

Fire Mode activation on OPEN

(P3.17.4)/

Fire Mode activation on CLOSE

(P3.17.5)

Choose the digital input to activate Fire

mode. See also chapter 8.13.

5

Fire Mode reverse (P3.17.6)

Choose the digital input to activate the

reverse direction in Fire mode.

DigIn Slot0.1 = Always direction

FORWARD

DigIn Slot0.2 = Always direction

REVERSE

6

Fire Mode password (P3.17.1)

Choose password to enable the Fire Mode

function.

1234 = Enable Test mode

1002 = Enable Fire Mode

1

Select the Bypass mode.

Electronic

Conventional

Disabled

2

Set the delay when switching

between Drive and Bypass

modes.

Min: 1.0 s

Max: 30.0 s

Default: 1.0 s

3

Enable essential services?

Enabled

Disabled

4

Select a digital input to control

essential services.

Min:

Max:

Default: DigIN SlotA.6

to question 3.

Fire mode frequency

’ is selected the wizard will jump directly

Bypass Wizard (P1.21)

The Bypass wizard helps you to easily commission the Bypass function. The Bypass

I/O are automatically configured based on the mode selected.

If Electronic is selected, the following steps display. Otherwise, the display returns to

the Main Menu.

If Enabled is selected, Step 4 displays. Otherwise, the Wizard jumps directly to Step 5.

Chapter 1 - BT300 Quick Start-up Guide

1

Siemens Application

17

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

5

Enable the Remote Bypass?

Enabled

Disabled

6

Select the Start command source

in Remote Bypass and Auto

mode.

FieldbusCTRL

I/O Control

7

Enable Interlock logic?

Enabled

Disabled

8

Select an Interlock logic delay.

Min: 0.0 s

Max: 120.0 s

Default: 0.0 s

9

Enable Auto Bypass?

Enabled

Disabled

10

Set the delay between the fault

occurrence and Auto Bypass

activation.

Min: 0.0 s

Max: 30.0 s

Default: 1.0 s

11

Using the right arrow button ,

select the faults that will the drive

to automatically switch to Bypass

mode.

Any Fault

Undervoltage

Overvoltage

Overcurrent

AI Low

Unit Temperature

Motor Overtemp

External Fault

Underload Fault

If Enabled is selected, Step 6 displays. Otherwise, the Wizard jumps directly to Step 7.

If Enabled is selected, Step 8 displays. Otherwise, the Wizard jumps directly to Step 9.

If Enabled is selected, Step 10 displays. Otherwise, the Wizard jumps directly to Step

11.

The Bypass Wizard is now complete. Press OK to return to the Main Menu.

For more information on the Bypass, see the

(DPD01375) and the

Bypass Operator's Manual

Bypass Installation Instructions

(DPD01391).

1

Chapter 1 - BT300 Quick Start-up Guide

Siemens Application

18

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Chapter 2 - User interfaces on Siemens BT300

2

Navigation on keypad

19

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Chapter 2 - User interfaces on Siemens BT300

This chapter presents the different user interfaces on Siemens BT300 :

Keypad

Siemens NET

Fieldbus

Navigation on keypad

See the keypad button and display description in the Siemens keypad with graphical

display [➙ 20] section.

The data on the control keypad are arranged in menus and submenus. Use the Up and

Down arrows to move between the menus. Enter the group/item by pressing the OK

button and return to the former level by pressing the Back/Reset button.

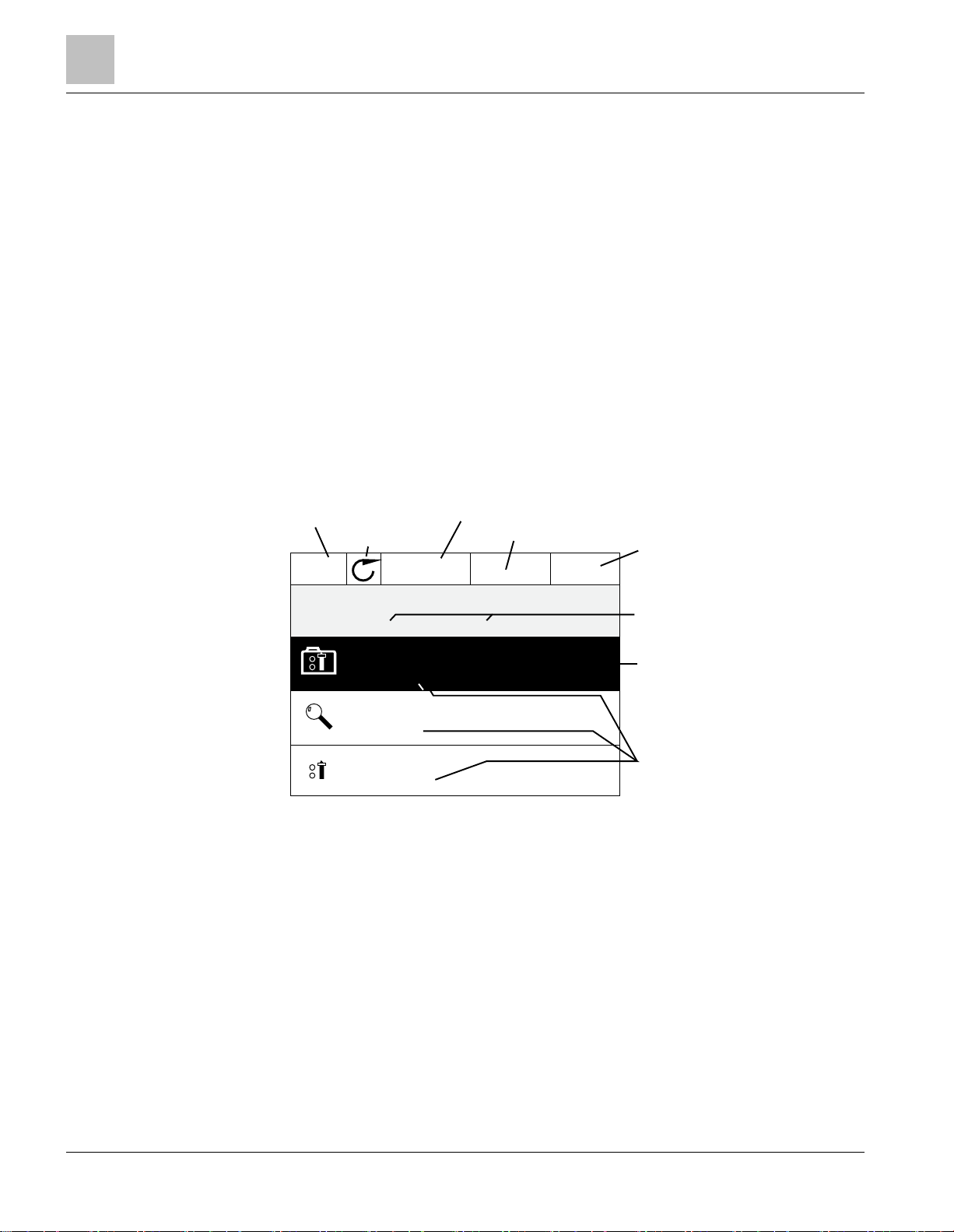

The Location field indicates your current location. The Status field gives information

about the present status of the drive. See the Figure Main Menu [➙ 20].

The basic menu structure is depicted in the Menu structure [➙ 27] section.

Keypad of the drive

The control keypad with graphical interface is the interface between the Siemens

BT300 variable frequency drive and the user. With the control keypad it is possible to

control the speed of a motor, to supervise the state of the equipment and to set the

variable frequency driver's parameters.

Figure 3: Keypad buttons.

2

Chapter 2 - User interfaces on Siemens BT300

Keypad of the drive

20

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Siemens keypad with graphical display

9159.emf

( 17 )

( 12 )

0

STOP READY I/O

ID: M1

( 5 )

0

Main Menu

Quick Setup

Parameters

Monitor

Status field

STOP/RUN

Direction

ALARM

Status field

READY/NOT READY/ FAULT

Control place:

PC/IO/KEYPAD/FIELDBUS

Activated group/item:

Press OK to enter

Number of items

in the group

Location field

(Parameter ID number and

current menu location

The graphical keypad features an LCD display and 9 buttons.

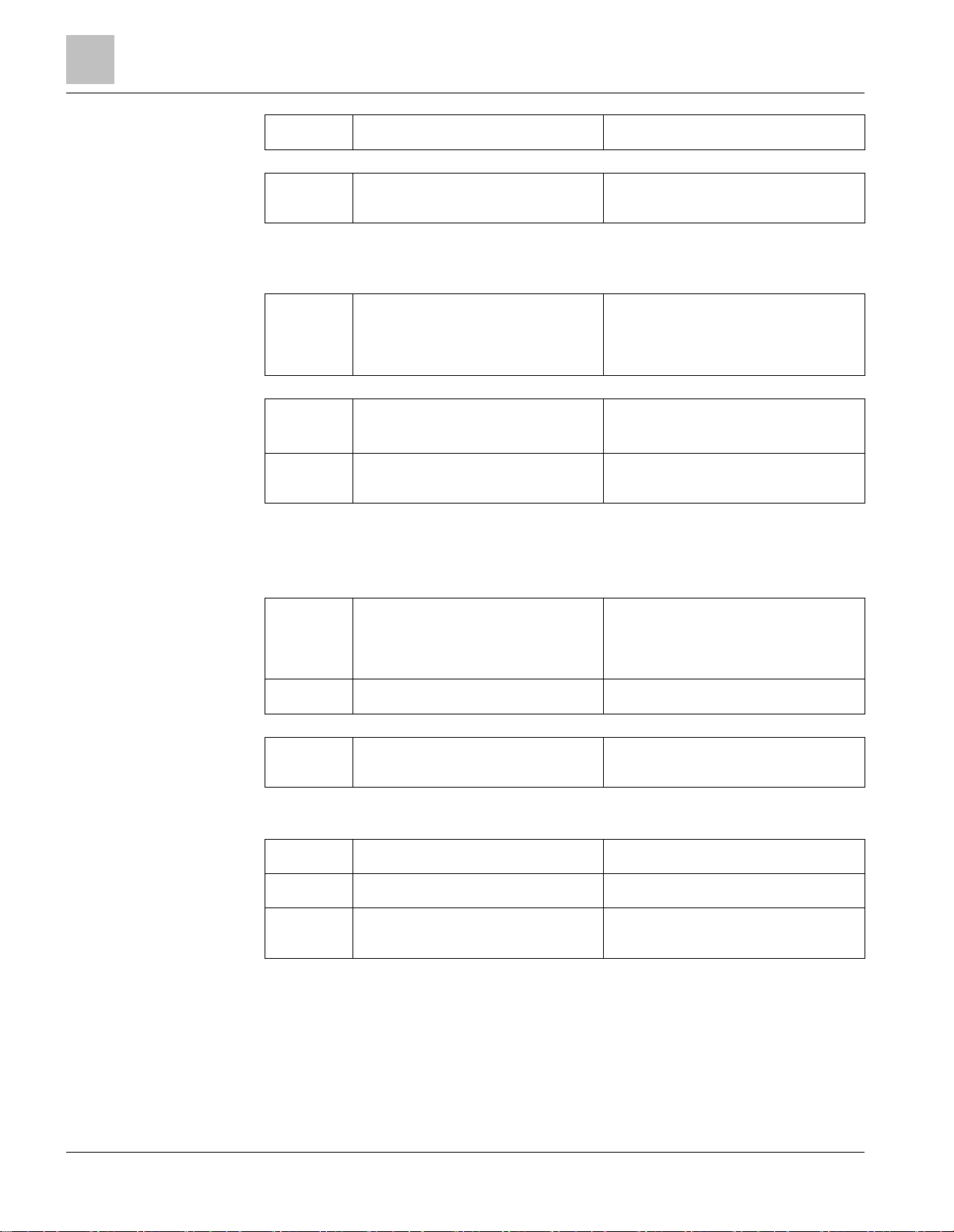

Keypad display

The keypad display indicates the status of the motor and the drive and any

irregularities in motor or drive functions. On the display, the user sees information

about his present location in the menu structure and the item displayed.

See Menu structure [➙ 27] for a comprehensive view of the menu structure.

Main menu

The data on the control keypad are arranged in menus and sub-menus. Use the Up

and Down arrows to move between the menus. Enter the group/item by pressing the

OK button and return to the previous level by pressing the Back/Reset button.

The

Location field

about the present status of the drive. See the following Figure.

indicates your current location. The

Status field

gives information

Figure 4: Main menu.

Using the graphical keypad

Editing values

Change value of a parameter following the procedure below:

1. Locate the parameter.

2. Enter the

3. Set new value with the arrow buttons up/down. You can also move from digit to

Edit

mode.

digit with the arrow buttons left/right if the value is numerical and change then the

value with the arrow buttons up/down.

Chapter 2 - User interfaces on Siemens BT300

2

Keypad of the drive

21

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

4. Confirm change with OK button or ignore change by returning to previous level with

OR

Back/Reset button.

Table 2: Editing values on graphical keypad.

Resetting a Fault

Instructions for how to reset a fault can be found in the Fault Displays [➙ 125] section

of

Chapter 10

.

Hand/Auto control button

The Hand/Auto button is used for two functions: to quickly access the Control

page and to easily change between the Hand (Keypad/Loc) and Auto control places.

Control places

The

control place

Every control place has its own parameter for selecting the frequency reference

source. In the HVAC drive, the

control place

place is displayed on the right side of the keypad status bar.

Auto control place

I/O A, I/O B and Fieldbus can be used as Auto control places.

I/O A and Fieldbus have the lowest priority and can be chosen with parameter

P3.2.1

I/O B can bypass the Auto control place selected with parameter P3.2.1 using a

digital input. The digital input is selected with parameter P3.5.1.5

is the source of control where the drive can be started and stopped.

Hand control place

is always the keypad. The

Auto

is determined by parameter P1.15 (I/O or Fieldbus). The selected control

(Ctrl. Place Auto)

.

(I/O B Ctrl Force)

.

2

Chapter 2 - User interfaces on Siemens BT300

Keypad of the drive

22

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Hand control

The keypad is always used as control place while in Hand control.

Hand control has a higher priority than Auto control. Therefore, if, for example,

bypassed by parameter P3.5.1.5 through digital input while in

place will still switch to Keypad if Hand is selected. Switching between Hand and

Auto control can be done by pressing the HAND/AUTO button on the keypad or by

using the

Hand/Auto

(ID211) parameter.

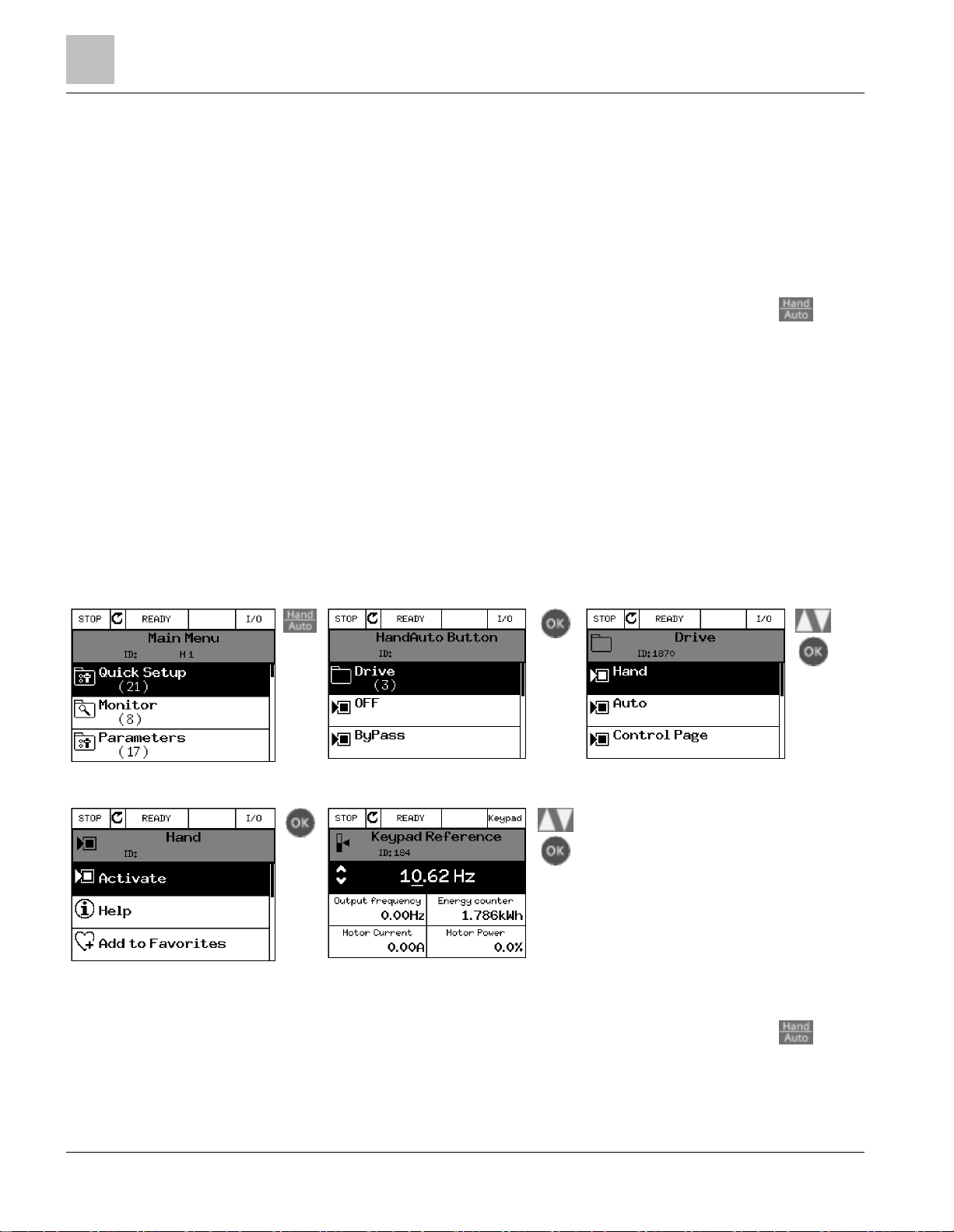

Changing the Control Place from Auto to Hand.

1. From any screen in the menu structure, press the HAND/AUTO button .

The HandAuto Button menu displays with Drive selected.

2. Press OK to display the Drive menu.

3. Use the Arrow up or the Arrow down button to select Hand and press OK to

confirm.

The Hand menu displays with Activate selected.

4. Press OK to enter Hand mode and display the Keypad Reference menu.

5. Use the Arrow up or the Arrow down button to set the reference values and press

OK to confirm.

The control place is now in Hand mode.

Table 3: Changing the Control Place from Auto to Hand.

Auto

, the control

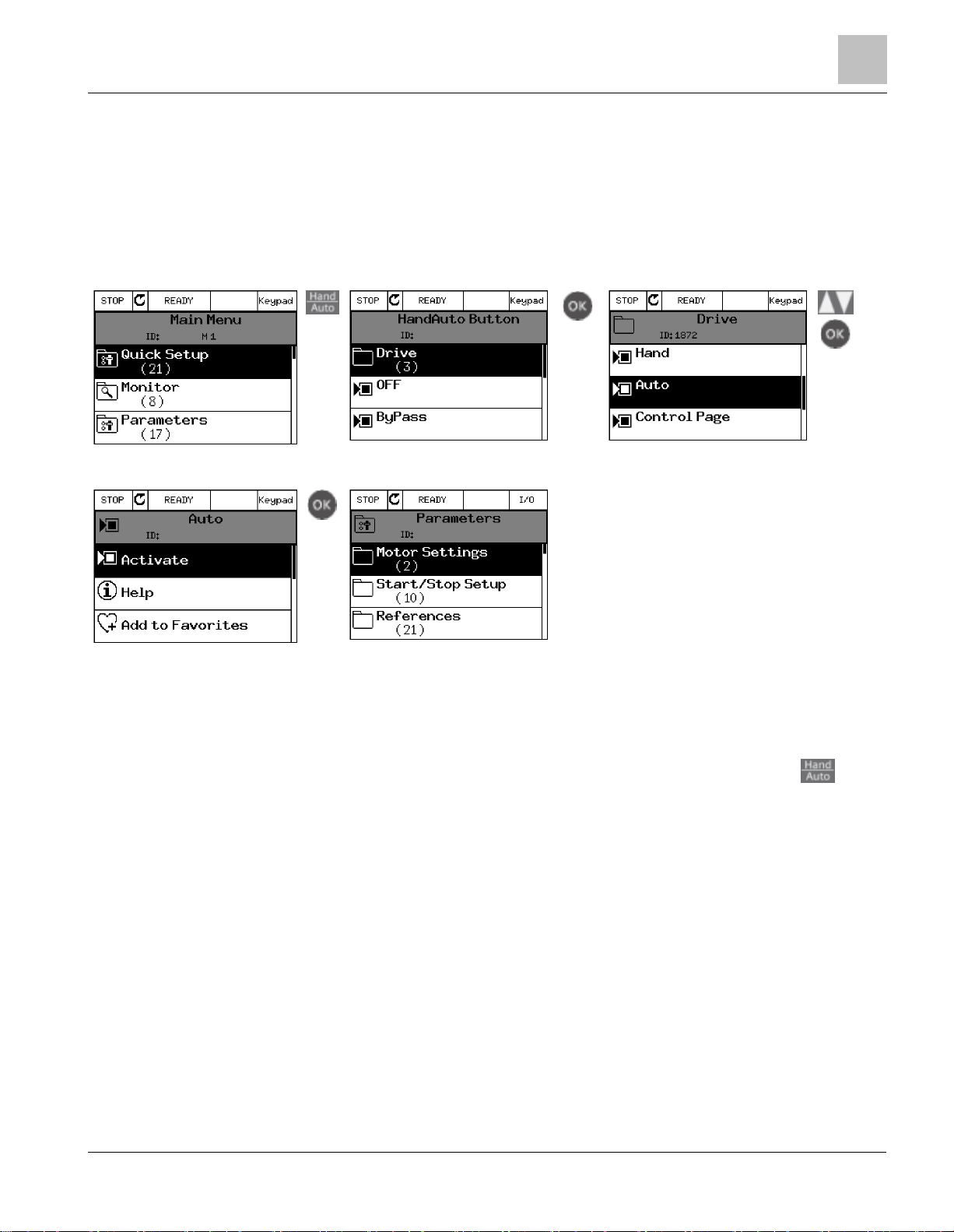

Changing the Control Place from Hand to Auto.

1. From any screen in the menu structure, press the HAND/AUTO button .

2. Press OK to display the Drive menu.

The HandAuto Button menu displays with Drive selected.

Chapter 2 - User interfaces on Siemens BT300

2

Keypad of the drive

23

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

3. Use the Arrow up or the Arrow down button to select Auto and press OK to

confirm.

The Auto menu displays with Activate selected.

4. Press OK to enter Auto mode.

The control place is now in Auto mode.

Table 4: Changing the Control Place from Hand to Auto.

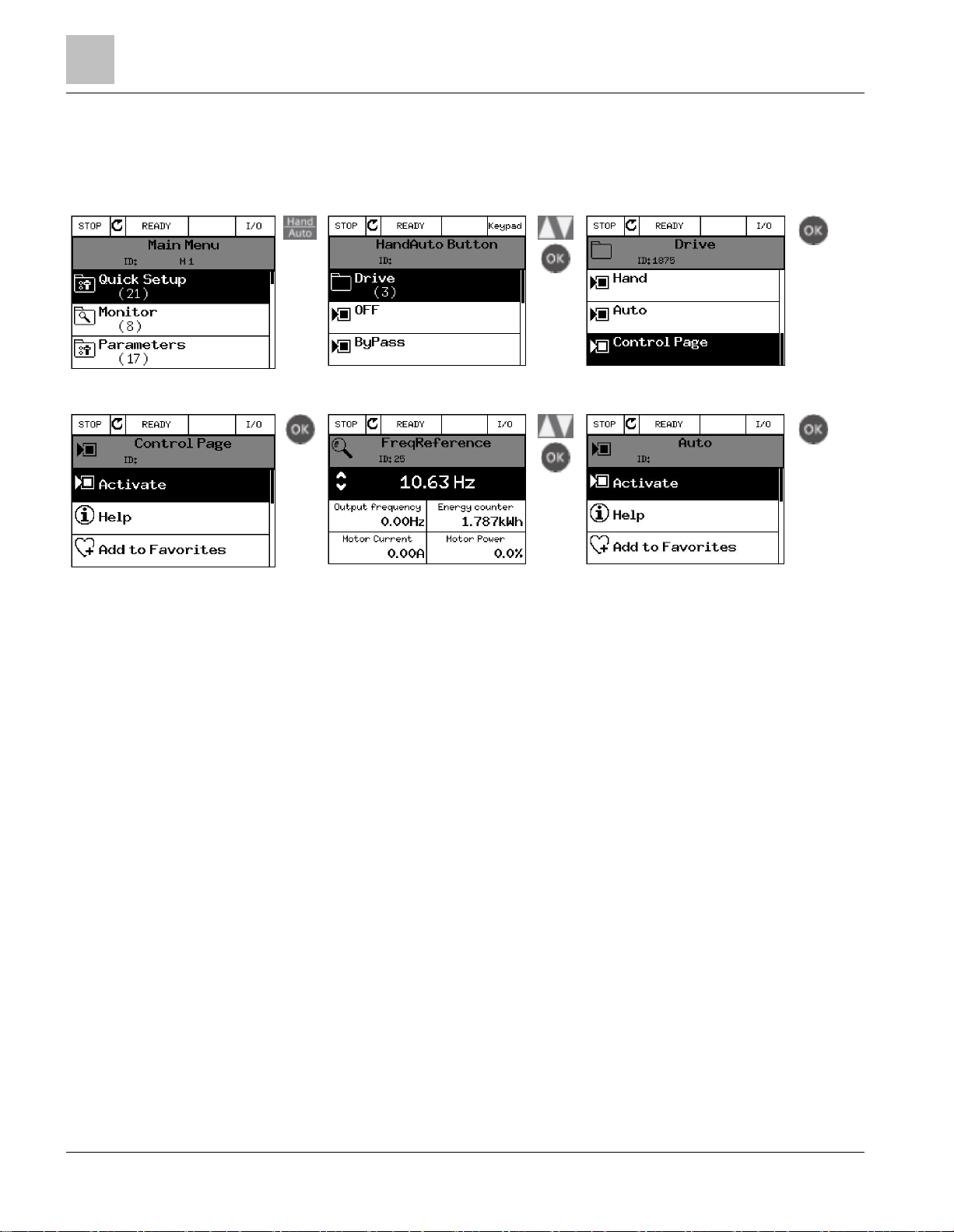

Accessing the Control Page

1. The

2. From any screen in the menu structure, press the HAND/AUTO button .

3. Press OK to display the Drive menu.

4. Use the Arrow up or the Arrow down button to select Control Page and press OK to

5. Press OK.

Control page

is meant for easy operation and monitoring of the most essential

values.

The HandAuto Button menu displays with Drive selected.

confirm.

The Control Page menu displays with Activate selected.

If the keypad control place and the keypad reference are selected to be used,

you can set the

Keypad reference

after pressing the OK button.

If other control places or reference values are used, the Frequency Reference

menu displays, which is not editable.

2

Chapter 2 - User interfaces on Siemens BT300

Keypad of the drive

24

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

The other values on the page are Multi-monitoring values. You can choose

Table 5: Accessing the control page.

which values display here for monitoring. For more information on this

procedure, see Multi-Monitor (M2.1) [➙ 31] in

Chapter 4

.

Copying parameters

The parameter copy function can be used to copy parameters from one drive to

another.

The parameters are first saved to the keypad, then the keypad is detached and

connected to another drive. Finally the parameters are downloaded to the new drive

restoring them from the keypad.

Before any parameters can successfully be copied from one drive to another, the drive

has to be stopped when the parameters are downloaded.

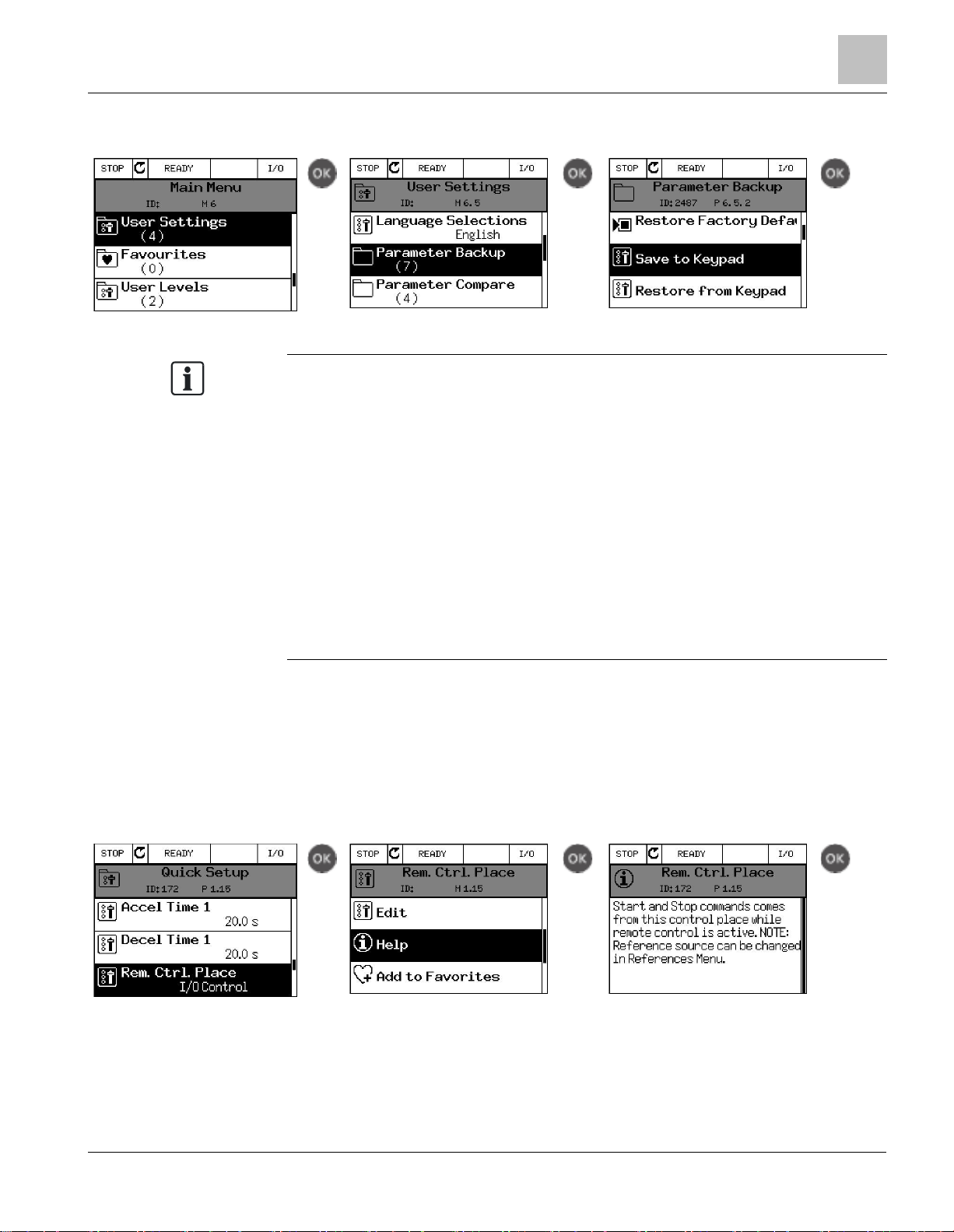

First go into

In the

selected:

–

Restore factory defaults

at the factory.

–

Save to keypad

–

Restore from keypad

User settings

Parameter backup

allows you to copy all parameters to the keypad.

menu and locate the

Parameter backup

sub-menu.

sub-menu, there are three possible functions to be

resets the parameters to the settings originally made

copies all parameters from the keypad to a drive.

Chapter 2 - User interfaces on Siemens BT300

2

Keypad of the drive

25

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Table 6: Parameter copy.

NOTE:

If the keypad is changed between drives of different sizes, the copied values of these

parameters will not be used:

• Motor nominal current (P3.1.1.4)

• Motor nominal voltage (P3.1.1.1)

• Motor nominal speed (P3.1.1.3)

• Motor nominal power (P3.1.1.6)

• Motor nominal frequency (P3.1.1.2)

• Motor Cos Phi (P3.1.1.5)

• Switching frequency (P3.1.2.1)

• Motor current limit (P3.1.1.7)

• Stall current limit (P3.9.12)

• Stall time limit (P3.9.13)

• Stall frequency (P3.9.14)

• Maximum frequency (P3.3.2)

Table 7: Help text example.

Help

The graphical keypad features instant help, and information displays for various items.

All parameters offer an instant help display. Select Help and press the OK button.

Text information is also available for faults, alarms and the startup wizard.

2

Chapter 2 - User interfaces on Siemens BT300

Keypad of the drive

26

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

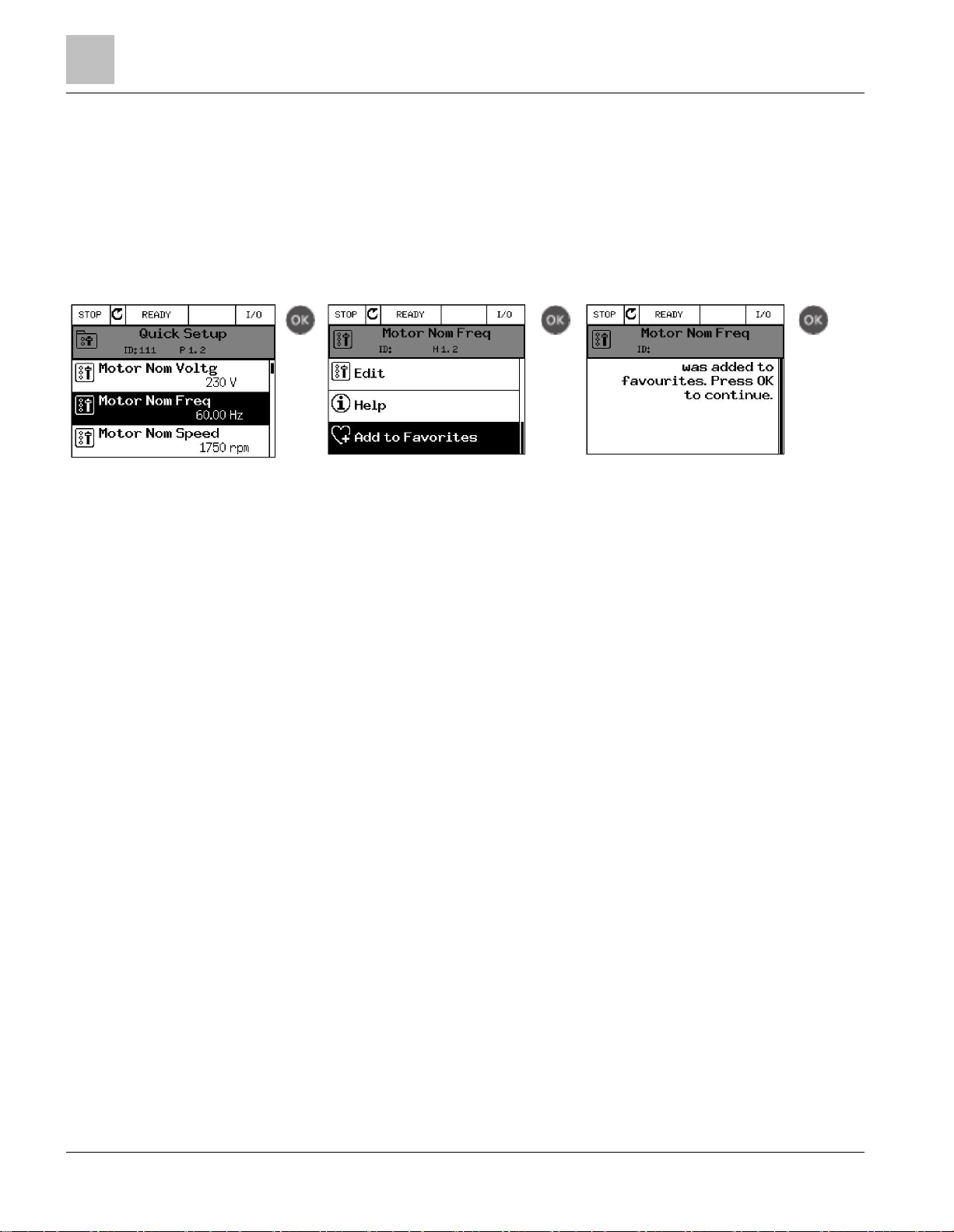

Adding an item to Favorites

You might need to refer to certain parameter values or other items often. Instead of

locating them one by one in the menu structure, you may want to add them to a folder

called

To remove an item from the Favorites, see Favorites (M7) [➙ 94] in

Table 8: Adding item to Favorites.

Favorites,

where they can easily be reached.

Chapter 8

.

Chapter 2 - User interfaces on Siemens BT300

2

Menu structure

27

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

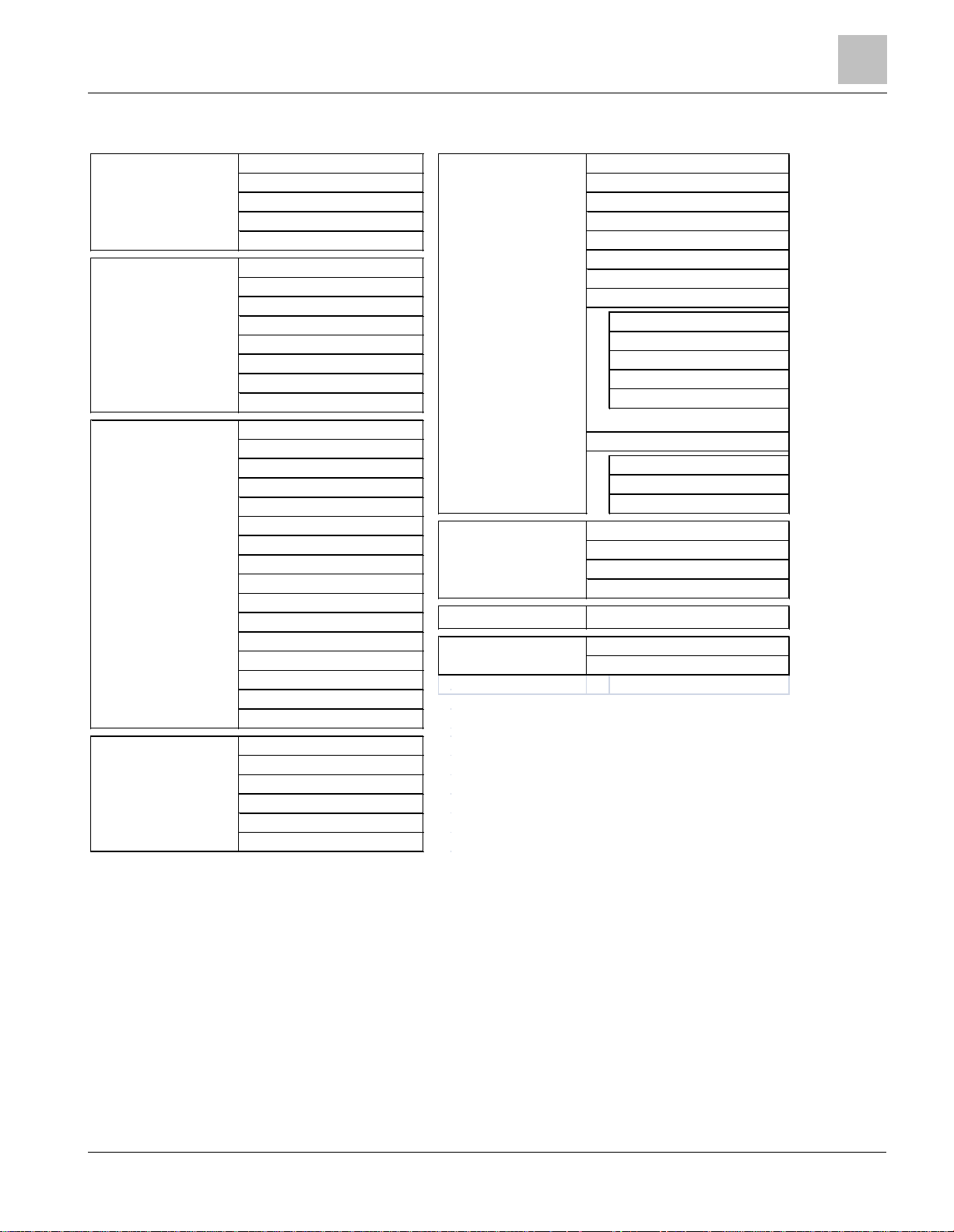

Menu structure

P1.17 PID Mini-Wizard

P1.18 Multipump Wizard

P1.19 Startup Wizard

P1.20 Fire Mode Wizard

P1.21 Bypass Wizard

M2.1 Multimonitor

M2.2 Basic

M2.3 Timer Functions

M2.4 PID Controller 1

M2.5 PID Controller 2

M2.6 Multi-Pump

M2.8 Fieldbus Data

M2.9 Temp. Inputs

M3.1 Motor Settings

M3.2 Start/Stop Setup

M3.3 References

M3.4 Ramps and Brakes

M3.5 I/O Config

M3.6 Fieldbus DataMap

M3.7 Prohibit Freq

M3.8 Limit Superv

M3.9 Protections

M3.10 Automatic Reset

M3.11 Timer Function

M3.12 PID Controller 1

M3.13 PID Controller 2

M3.14 Multi-Pump

M3.16 Fire Mode

M3.17 Appl. Settings

M4.1 Active Faults

M4.2 Reset Faults

M4.3 Fault History

M4.4 Total Counters

M4.5 Trip Counters

M4.6 Software Info

M1 Quick Setup

M2 Monitor

M3 Parameters

M4 Diagnostics

M5.2 Slot C

M5.3 Slot D

M5.4 Slot E

M5.5 Real Time Clock

M5.6 Power Unit Settings

M5.7 Keypad

M5.8 RS-485

M5.8.1 Common Settings

* M5.8.3 BACnetMSTP

* M5.8.3 Modbus RTU

* M5.8.3 N2

* M5.8.3 P1

* Based on Common Settings

M5.9 Ethernet

M5.9.1 Common Settings

M5.9.2 Modbus TCP

M5.9.3 BACnet IP

P6.1 Language Selections

M6.5 Parameter Backup

M6.6 Parameter Compare

P6.7 Drive Name

M7 Favourites

P8.1 User Level

P8.2 Access Code

M5 I/O and

Hardware

M5.1 Basic IO

M6 User Settings

M8 User Levels

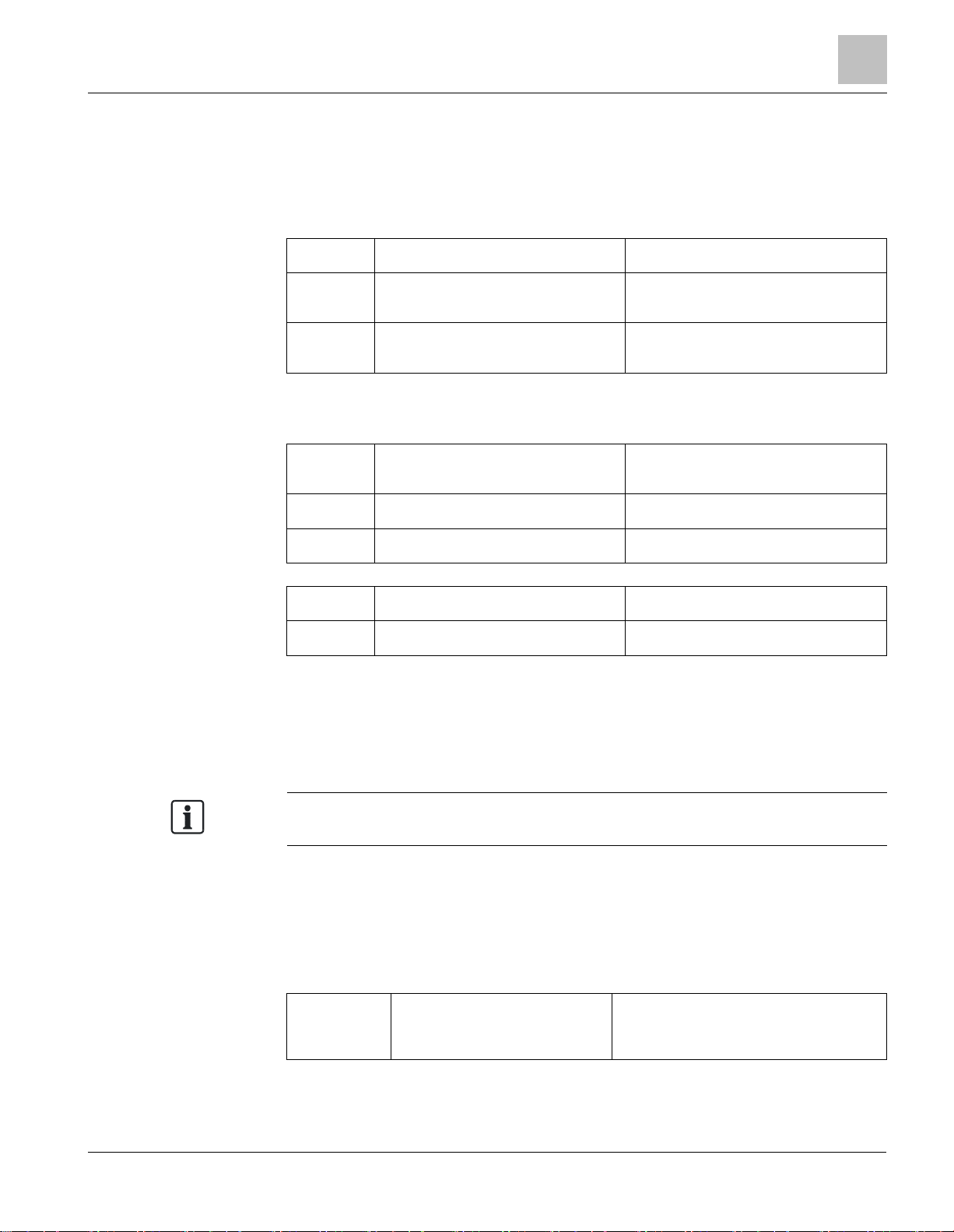

Quick setup

The Quick Setup Menu includes the minimum set of most commonly used parameters

during installation and commissioning. You can find more detailed information on the

parameters of this group in Basic Settings [➙ 42]

Parameters

Through this sub-menu, you can reach the application parameter groups and

parameters. You can find more information on parameters in Chapter 5 - Parameters

(M3) [➙ 39].

2

Chapter 2 - User interfaces on Siemens BT300

Siemens NET

28

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

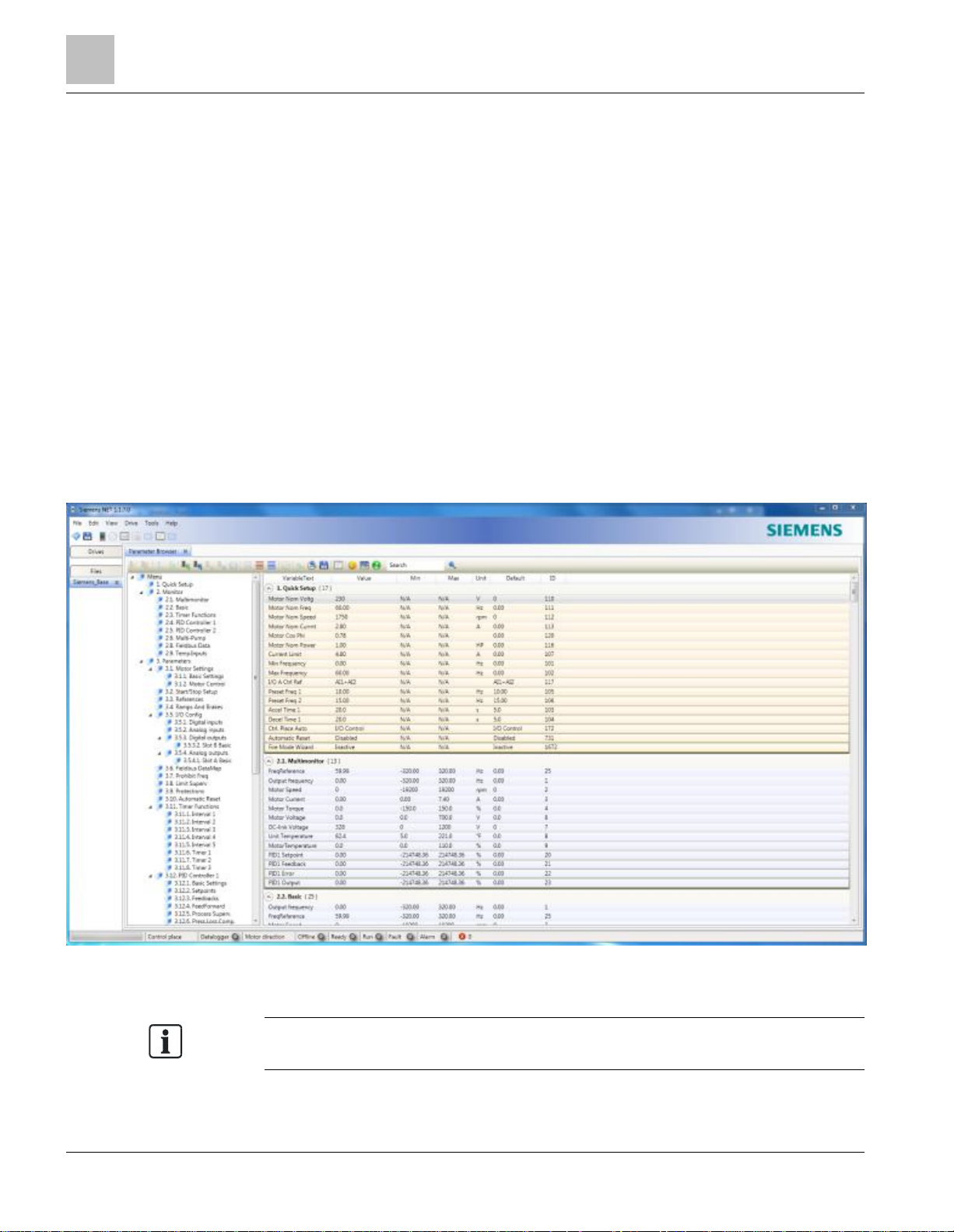

Siemens NET

NOTE:

Find more information on using Siemens NET in the program help.

Siemens NET is a PC-tool for commissioning and maintenance of new generation

drives (Siemens10, Siemens20, Siemens100). Siemens NET tool can be downloaded

from www.Siemens.com.

Siemens NET includes the following features:

Parameterization, monitoring, drive info, data logger, etc.

Software download tool Siemens Loader is integrated.

Support for RS-422 and Ethernet

Windows 7 support

Languages supported: English, German, Spanish, Finnish, French, Italian,

Russian, Swedish, Chinese, Czech, Danish, Dutch, Polish, Portuguese, Romanian,

Slovak and Turkish.

Connection can be made by using Siemens’s black USB/RS-422 cable or Ethernet

cable (Siemens BT300)

RS-422 drivers are installed automatically during the Siemens NET installation.

When the connection is made, Siemens NET finds the connected drive

automatically

Figure 5: Siemens NET - Main Window.

Chapter 3 – Quick Setup (M1)

3

29

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Quick setup parameter group.

Code

Parameter

Min

Max

Unit

Default

ID

Description

P1.1

Motor nominal voltage

Varies

Varies

V

Varies

110

Find this value Un on the

rating plate of the motor. See

Motor settings (M3.1) [➙ 42].

P1.2

Motor nominal frequency

8.00

320.00

Hz

60.00

111

Find this value fn on the

rating plate of the motor. See

Motor settings (M3.1) [➙ 42].

P1.3

Motor nominal speed

24

19200

rpm

Varies

112

Find this value nn on the

rating plate of the motor.

P1.4

Motor nominal current

Varies

Varies

A

Varies

113

Find this value In on the

rating plate of the motor.

P1.5

Motor COS PHI

0.30

1.00

Varies

120

Find this value on the rating

plate of the motor.

P1.6

Motor nominal power

Varies

Varies

hp

Varies

116

Find this value In on the

rating plate of the motor.

P1.7

Motor current limit

Varies

Varies

A

Varies

107

Maximum motor current from

drive.

P1.8

Minimum frequency

0.00

P3.3.1 [➙

46]

Hz

Varies

101

Minimum allowed frequency

reference.

P1.9

Maximum frequency

P3.3.1 [➙

46]

320.00

Hz

60.00

102

Maximum allowed frequency

reference.

P1.10

I/O control reference A

selection

1 8 6 117

Selection of ref source when

control place is I/O A. See

Control reference settings

(M3.3) [➙ 46] for selections.

P1.11

Preset frequency 1

P3.3.1 [➙

46]

300.00

Hz

10.00

105

Select with digital input:

Preset frequency selection 0

(P3.5.1.15 [➙ 50])

P1.12

Preset frequency 2

P3.3.1 [➙

46]

300.00

Hz

15.00

106

Select with digital input:

Preset frequency selection 1

(P3.5.1.16 [➙ 50])

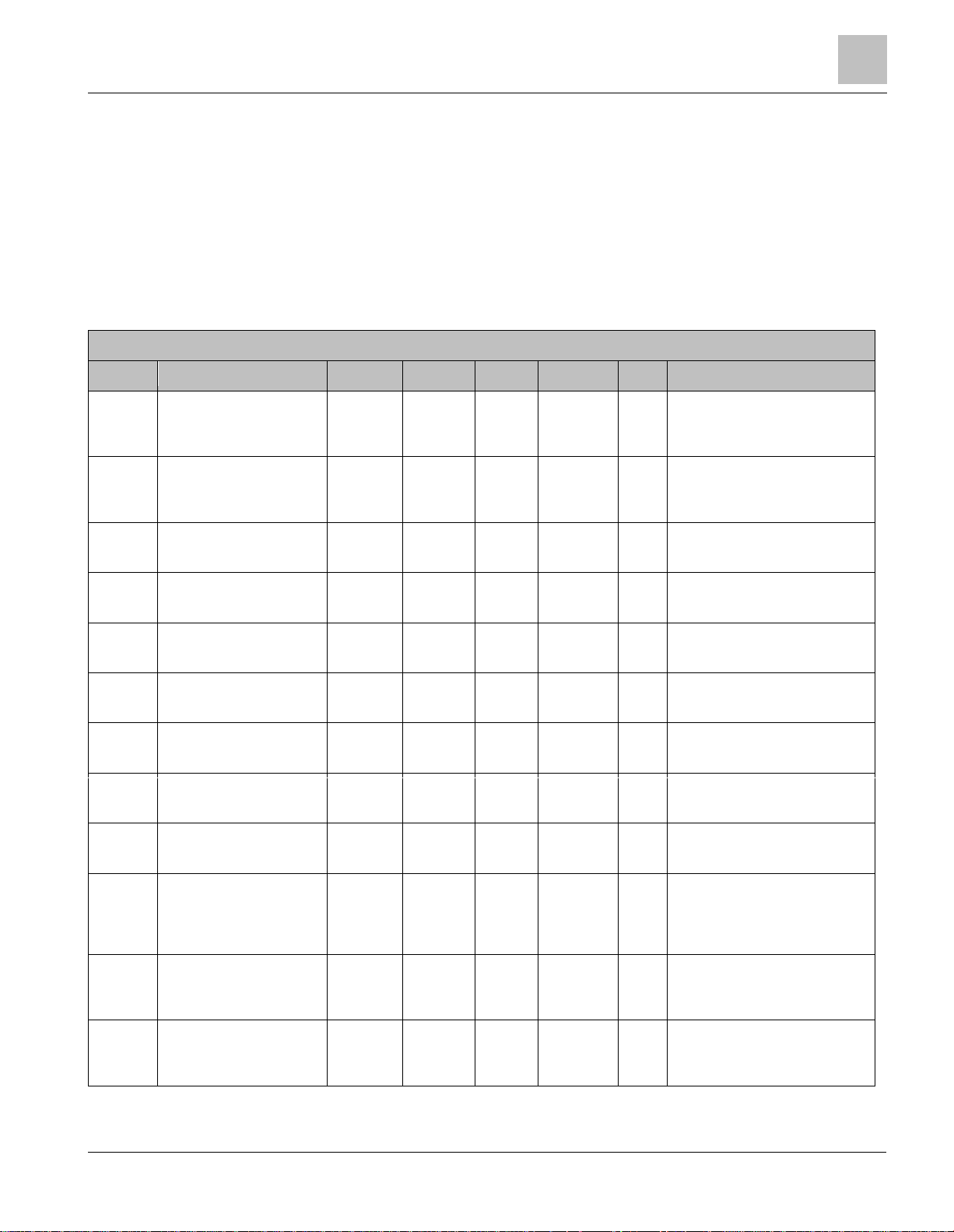

Table 9:

Chapter 3 – Quick Setup (M1)

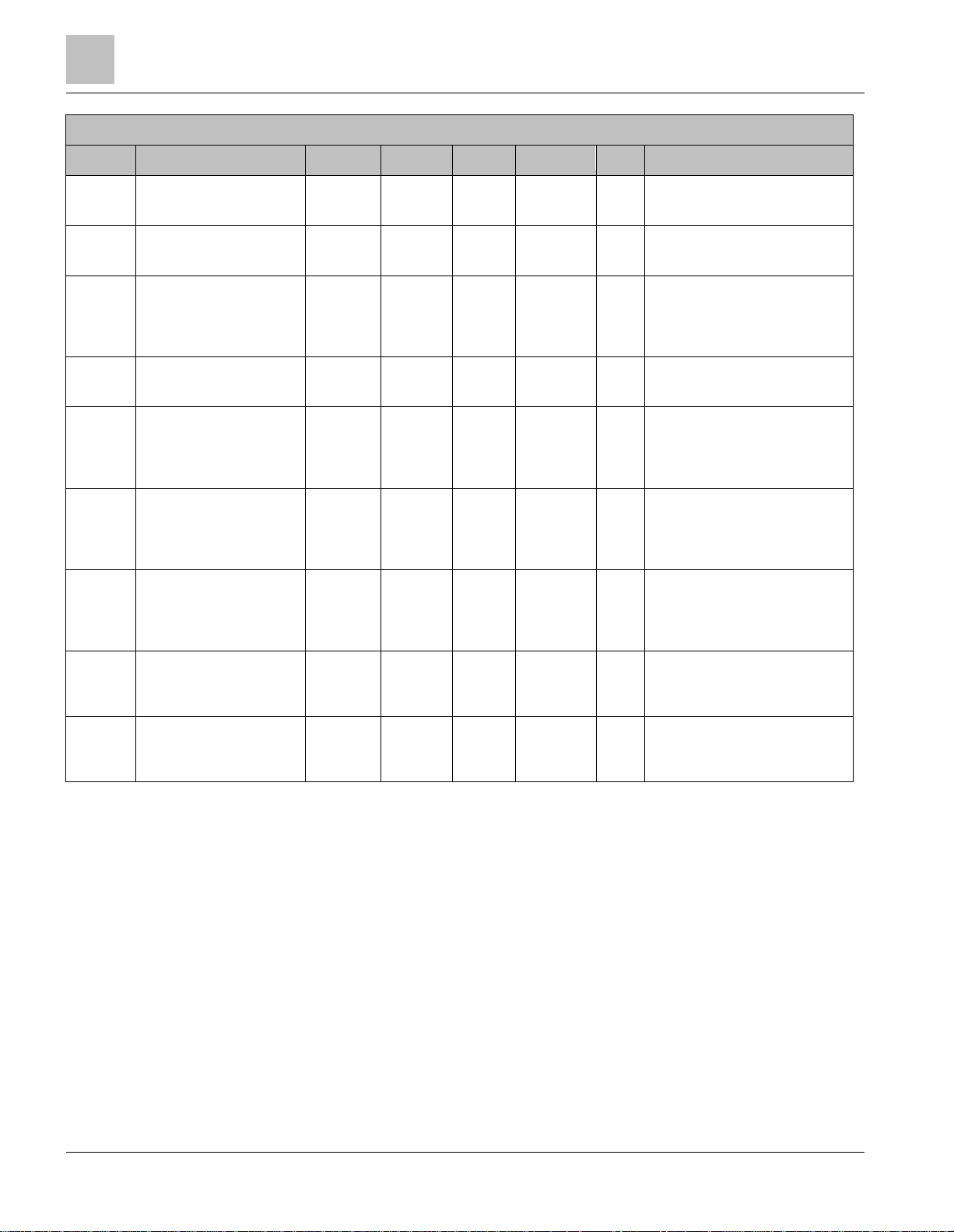

The Quick Setup parameter group is a collection of parameters that are most

commonly used during installation and commissioning. They are collected in the first

parameter group so that they can be found fast and easily. However, they can be also

reached and edited in their actual parameter groups. Changing a parameter value in

the Quick setup group also changes the value of this parameter in its actual group.

3

Chapter 3 – Quick Setup (M1)

30

Siemens Industry, Inc.

BT300 HVAC Drive Operator's Manual

DPD01149

2013-12-03

Quick setup parameter group.

Code

Parameter

Min

Max

Unit

Default

ID

Description

P1.13

Acceleration time 1

0.1

3000.0

s

20.0

103

Time to accelerate from zero to

maximum frequency.

P1.14

Deceleration time 1

0.1

3000.0

s

20.0

104

Time to decelerate from

minimum to zero frequency.

P1.15

Auto control place

1 2 1 172

Selection of Auto control place

(start/stop)

1 = I/O

2 = Fieldbus

P1.16

Automatic reset

0 1 0 731

0 = Disabled

1 = Enabled

P1.17

PID Mini-Wizard

0 1 0 1803

0 = Inactive

1 = Activate

See PID Mini-Wizard (P1.17)

[➙ 13].

P1.18

Multi-Pump Wizard

0 1 0

0 = Inactive

1 = Activate

See Multi-pump Mini-wizard

(P1.18) [➙ 15].

P1.19

Startup Wizard

0 1 0 1171

0 = Inactive

1 = Activate

See Startup Wizard (P1.19) [➙

11].

P1.20

Fire Mode Wizard

0 1 0 1672

Choosing

Activate

initiates Fire

Mode Wizard (see Fire Mode

Wizard (P1.20) [➙ 15]).

P.1.21

Bypass Wizard

0 1 0 1823

See the

Siemens BT300

Bypass Operator's Manual

(DPD01391).

Loading...

Loading...