Page 1

7MF15654 Series

Pressure Transmitter,

PSIG Range for Sensing

Liquid/Gas

Technical Instructions

Document No. 155-768

January 18, 2012

Description

Features

Application

Product Numbers

The 7MF15654 Series Pressure Transmitters measure the gauge pressure of

aggressive and non-aggressive gases as well as the level of liquids and vapors.

• High measuring accuracy

• Sturdy stainless steel housing

• For aggressive and non-aggressive media

• Measures the pressure of liquids, gases and vapor

• Temperature-compensated measuring cell

• Compact design

The 7MF15654 Series Pressure Transmitters are mainly used in the U.S. market for the

following industrial areas:

• Chemical industry

• Pharmaceutical industry

• Food industry

• Mechanical engineering

• Water supply

Table 1.

Product Number Description

7MF15654XX005EA1 Sensor, Liquid/Gas, 4 to 20 mA

7MF15654XX105EA1 Sensor, Liquid/Gas, 0 to 10 Vdc

XX = BB 0 to 15 PSI

BE 0 to 30 PSI

BF 0 to 60 PSI

BG 0 to 100 PSI

CA 0 to 150 PSI

CB 0 to 200 PSI

CD 0 to 300 PSI

Siemens Industry, Inc.

Page 2

Technical Instructions 7MF15654 Pressure Transmitter, PSIG Range for Sensing Liquid/Gas

Document Number 155-768

January 18, 2012

Design

Measuring range

<1 bar (<14.5 psi)

Measuring range

> 1 bar (> 14.5 psi)

The design of the pressure transmitter is dependent on the measuring range.

The main components of the pressure transmitter are:

• Stainless steel housing with piezo-resistive silicon measuring cell (with stainless

steel diaphragm, temperature-compensated) and electronics module.

• Stainless steel process connection 1/4 - 18 NPT Straight.

• Electrical connection is made to DIN 43650 with the cable inlet 1/2 – 14 Taper.

Pressure transmitters with a nominal range < 1 bar g (< 14.5 psi g) are available with or

without explosion protection.

The main components of the pressure transmitter are:

• Stainless steel housing with ceramic measuring cell and electronics module. The

temperature-compensated ceramic measuring cell has a thin-film strain gauge

which is mounted on a ceramic diaphragm. The ceramic diaphragm can also be

used for aggressive media.

• Stainless steel process connection 1/4 - 18 NPT Straight.

Electrical connection is made to DIN 43650 with the cable inlet 1/2 – 14 Taper.

Pressure transmitters with a nominal range

> 1 bar g (>14.5 psi g) are available with or

without explosion protection.

Function

Mode of Operation

Measuring range <1 bar

(<14.5 psi)

The pressure transmitter measures the gauge pressure as well as the level of liquids

and gases.

U

const.

p

SEN0444R1

U

I

U

I

1

B0

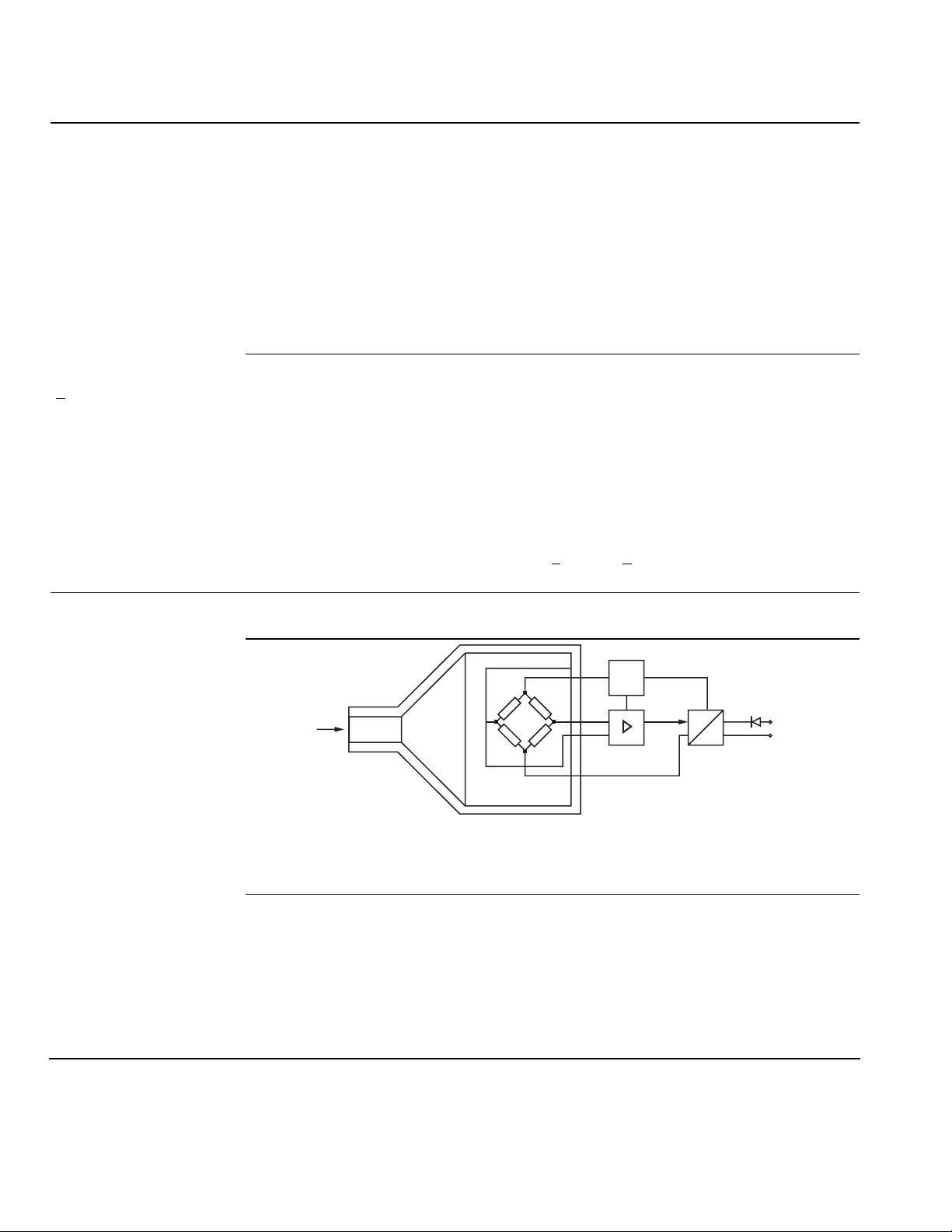

Figure 1. Functional Diagram.

The mode of operation of the pressure transmitter is dependent on the measuring

range.

The silicon measuring cell of the pressure transmitter has a piezo-resistive bridge to

which the operating pressure is transmitted through silicone oil and a stainless steel

diaphragm.

The measuring cell output voltage is fed to an amplifier and converted into a 4 to 20 mA

output current.

The output is linearly proportional to the input pressure.

Page 2 Siemens Industry, Inc.

Page 3

7MF15654 Pressure Transmitter, PSIG Range for Sensing Liquid/Gas Technical Instructions

Document Number 155-768

January 18, 2012

Measuring range ≥1 bar

(≥14.5 psi)

The thin-film measuring cell has a thin-film resistance bridge to which the operating

pressure p is transmitted through a ceramic diaphragm.

The measuring cell output voltage is converted by an amplifier into an output current.

The output is linearly proportional to the input pressure.

Specifications

Mode or Operation

Input Media Range

Output Signal

Accuracy

Rated Operating

Conditions

Design

Input Power Supply U

Measuring range Piezo-resistive

<1 bar (<14.5 psi)

Measuring range Thin-film strain gauge

>1 bar (<14.5 psi)

Measured variable Gauge pressure

Measured range

Pressure 0 to 300 psi g (0 to 21 bar g)

Current output signal 4 to 20 mA

Voltage output signal 0 to 10 Vdc

To EN 60770-1

Error in measurement (at 77°F [25°C]), 0.25% of full-scale value – typical

including conformity error, hysteresis and

repeatability

Response time T

< 0.1 second

99

Long-term drift

Start of scale 0.25% of full scale value/year

Full-scale value 0.25% of full scale value/year

Influence of ambient temperature

Start of scale 0.25%/10 K of full-scale value

Full-scale value 0.25%/10 K of full-scale value

Process temperature -22°F to 248°F (-30°C to 120°C)

Ambient temperature -13°F to 185°F (-25°C to 84°F)

Storage temperature -58°F to 212°F (-50°C to 100°C)

Degree of protection to EN60529 IP65

Weight ≈ 0.55 lb (≈ 0.25 kg)

Wetted parts materials:

Measuring cell

Measuring range < 1 bar (< 14.5 psi) Stainless steel, 1.456 1/316Ti

Measuring range

> 1 bar (> 14.5 psi) AI2O3 – 96%

Process connection Stainless steel, mat. No. 1.4571/316Ti

Gasket Viton

Terminal voltage on pressure transmitter

H

For current output 10 to 36 Vdc

Siemens Industry, Inc. Page 3

Page 4

Technical Instructions 7MF15654 Pressure Transmitter, PSIG Range for Sensing Liquid/Gas

Document Number 155-768

January 18, 2012

Specifications,

Continued

Certificates and

Approvals

Classification according to pressure For gases of fluid group 1 and liquids

equipment directive (DRGL 97/23/EC) of fluid 1; complies with requirements

of article 3, paragraph 3 (sound

engineering practice)

Explosion protection

Intrinsic safety ”i” (only with current output TÜV 02 ATEX 1953X

Identification) Ex II 1/2G EEx ia IIC T4

Intrinsic safety “T.I.S.”(only with current output) Applied

Lloyd’s Register of Shipping Certificate No. 03/30003

Wiring Diagram

Dimensions

I

Output current

0

U

Power supply

B

R

Load

L

Connections:

1 (-UB)

2 (-UB)

U

Output current

0

U

Power supply

B

R

Load

L

Connections:

1 (+UB)

2 (-UB)

3 (U0)

Signal

Signal

SEN0446R1

1+

2-

1+

3+

2-

I

0

U

0

+

U

R

L

R

L

B

+

U

B

Figure 2. Wiring Diagram with Current Output (Top) and Voltage Output

(Bottom).

Figure 3. Dimensions in Millimeters (Inches).

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. Product or company names mentioned herein may be the trademarks of their respective owners.

© 2012 Siemens Industry, Inc.

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089

USA

+ 1 847-215-1000

Your feedback is important to us. If you have

comments about this document, please send them to

SBT_technical.editor.us.sbt@siemens.com

Document No. 155-768

Printed in the USA

Page 4

Loading...

Loading...