Siemens WLTS Application Manual

Application Guide

WLTS Hand-Held Test Set

WL Low Voltage Circuit Breakers

www.usa.siemens.com/WLBreaker

Introduction

NOTICE

Erroneous test results may occur when the trip

unit is powered by either:

• Load current

• External 24 vdc control power

All testing should be conducted with the primary

bus de-energized, and external 24 vdc control

power disconnected or turned off.

The WLTS hand-held test unit is the perfect companion for

service personnel and users of Siemens type WL circuit

breakers. It will verify many trip unit functions and, in most

cases, removes the need for primary injection testing.

The WLTS can perform the following functions:

• Verify the continuity of the air-core current sensors

and the energy transducers in each phase of the

circuit breaker.

• Verify connections to external air-core neutral current

sensors in 4-wire residual applications and iron-core

ground CTs (current transformers) in MDGF or other

directly ground-sensed applications.

• Verify the connection from the electronic trip unit and the

tripping solenoid.

• Verify that of each of the main overcurrent protective

functions (long-time, short-time, instantaneous, and

optional ground-fault and neutral overcurrent) will trip

the circuit breaker.

• Help verify communications to an external master by

simulating currents in each of the phases.

By design, the WLTS provides a minimally invasive solution

for circuit breaker testing, allowing maximum up-time. It

allows the operator to quickly determine the health of the

entire trip system, and quickly return the circuit breaker

to service.

The WLTS is the preferred test tool to verify compliance of

the entire trip system of the WL circuit breaker, including the

trip unit, rating plug, trip coil, current sensors, and all

associated wiring.

The WLTS has additional functionality that is beneficial during

startup and commissioning activities.

• The WLTS can be utilized as a temporary power supply

to provide control power for the WL family of trip units

facilitating the programming of the trip unit during

startup and commissioning. The WLTS will supply power

only to the trip unit and display and not any other

connected modules.

• If the circuit breaker includes a COM15 or COM16, the

WLTS can instruct the trip unit to pass along dummy load

data to the communications network, so that

communications between the WL circuit breaker and the

SCADA system can be verified.

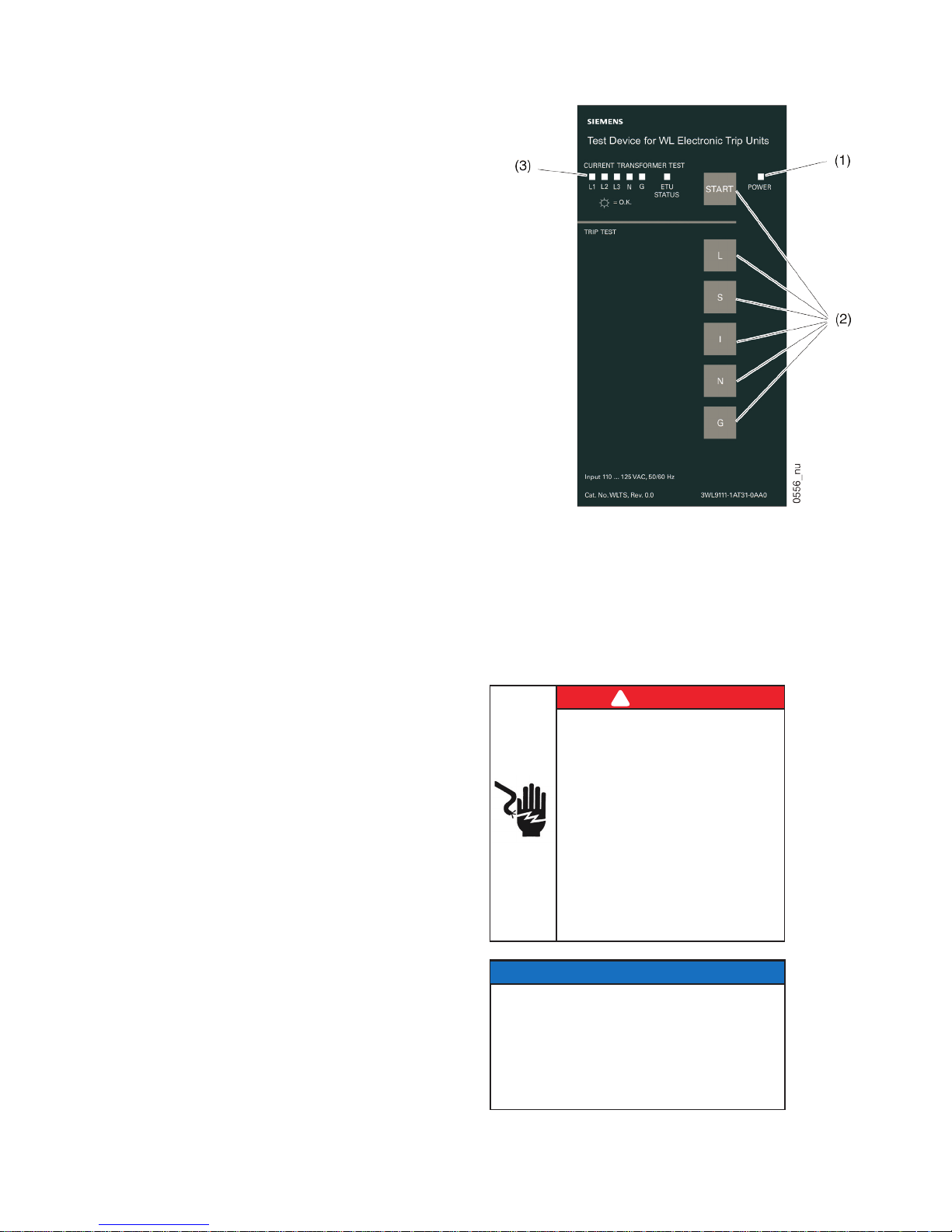

Orientation

(1) Power indicator

(2) Buttons to initiate tests

(3) LEDs to indicate sensor / CT continuity and status

Functional Testing

Preparing to test

!

DANGER

Hazardous Voltage.

Will cause death or serious injury.

Qualified personnel only.

Disconnect and lock off all power before

working on this equipment.

• Always work on de-energized

equipment.

• Always de-energize before

performing any tests, maintenance,

or repair.

• Follow safety related work practices,

as described in NFPA 70E, at all times.

1

Modified Differential Ground Fault System

2

NOTICE

Erroneous test results may occur when the trip

unit is powered by either:

• Load current

• External 24 vdc control power

All testing should be conducted with the primary

bus de-energized, and external 24 vdc control

power disconnected or turned off.

Remove the trip unit cover (Catalog number WLTSC55 or

WLTSC76), if present, and the cover over the X25 test port.

Record the settings of the trip unit and set long time pickup

(IR) to 1.0 x In.

Connecting to the trip unit

1. Plug the ribbon cable into the test port

Table 1

Indicator Definition

1x WLTS in need of repair

2x Trip unit needs replacement

3x Trip unit externally powered

WLTS connected while powered

4x Parameter conflict

Current sensor not connected

Incorrect rating plug

Missing rating plug

5x Tripping solenoid not connected

1

2. Plug the ribbon cable into the tester

3. Plug in the power cord

1. ETU test port

The start-up tests can be repeated at any time by holding

down the "START" button for three seconds.

Testing the current and energy sensors

To test the current sensors and energy transducers, press the

"START" button.

A lit-up LED confirms the proper operation of the

corresponding sensor/transducer. If an LED flashes, the

corresponding sensor/converter is not present, not properly

connected, or is in need of replacement.

Whether a flashing N- or G-LED is due to a non-conforming

current sensor depends the position of the draw-out circuit

breaker when tested and the ground fault scheme being

used. In the draw out position, external sensors are not

connected and both N- and G-LEDs will flash. A circuit breaker

used in a 3-wire residual GF scheme will always show flashing

N- and G-LEDs because there are no external sensors

connected, regardless of the position. A circuit breaker used

in a 4-wire residual GF scheme will show a flashing G-LED

because there is no iron-core G CT connected. A circuit

breaker used in an MDGF GF scheme may show a flashing

N-LED depending on whether a neutral current sensor is

in use.

2. Ribbon cable

3. Tester power cord

After applying power to the WLTS, it will begin to communicate with the trip unit and verify that critical subsystems are

operational. Once all checks have been successfully completed, the “ETU STATUS” LED will turn on, and remain lit until

a function button is pressed. A flashing “ETU STATUS” LED is

indication of an error. A full list of the error codes is found in

Table 1.

2

The "ETU STATUS" LED may blink twice when the trip unit is powered by an

external power supply. This is not an error. It is recommended that the trip unit

be tested without external control power.

3

Loading...

Loading...