Siemens SXG75 Service Manual

Service Repair Documentation

Level 3 – SXG75

Release Date Department Notes to change

1.0 19.01.2005 CC S CES New document

Page 1 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

Table of contents:

1. Instruction 4

2. List of available spare parts 5

3. Required equipment for level 3 7

4. Required software for level 3 7

5. Radio part 8

5.1 Block diagram RF part 9

5.2 Receiver (RTR6250 and RFR6250) 10

5.2.1 GSM RX 11

5.2.2 UMTS RX 11

5.2.3 GPS 11

5.3 Transmitter (RTR6250) 12

5.3.1 GSM TX modulation 12

5.3.2 GSM dual band TX VCO 12

5.3.3 GSM power amplifier 13

5.3.4 UMTS TX 14

5.4 Antenna switch 15

6. Baseband 17

6.1 Block diagram 17

6.2 MSM6250 processor 18

6.2.1 General features 18

6.2.2 MSM6250 power supplies 19

6.2.3 Clock distribution 20

6.2.4 MSM6250 bootup and mode control 22

6.3 MSM6250 interfaces 23

6.3.1 Logic interfaces 23

6.3.2 Analogue interfaces 27

6.3.3 RF interfaces 29

7. FM radio 32

7.1 FM radio interface 32

8. Power management 34

8.1 PM6650 functional overview 34

8.2 Voltage regulators and voltage converters 36

8.3 Additional power supplies 37

8.4 PM6650 signal interfaces 38

8.5 Power On/Off sequencing 40

8.5.1 Power-On sequence 40

8.5.2 Power-Off sequence 41

Page 2 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

9. Battery/Charging 43

9.1 Battery 43

9.2 Phone shutdown due to low battery 43

9.3 Charging 44

9.3.1 Charging concept 45

9.3.1.1 Overview 45

9.3.1.2 Measurement of battery voltage, battery type and ambient temperature 47

9.3.1.3 Timing of the battery voltage measurement 47

9.3.1.4 Recognition of the battery type 47

9.3.1.5 Trickle charging 48

9.3.1.6 Normal charging (fast charge) 48

9.3.1.7 Pulsed charging 49

9.3.1.8 USB charging 49

10. Audio interference and suspension of pulse charging 50

11. MMI 51

11.1 Display 51

11.1.1 Overview 51

11.1.2 Interface display module 51

11.1.3 Contrast and colour adjustment 53

11.1.4 Illumination 53

11.2 Keypad 54

11.2.1 Keypad mapping 54

11.2.2 Illumination 56

12. Acoustics 58

12.1 Microphone, speaker and hands-free speaker 59

12.2 Audio accessories 59

13. Cameras 60

13.1 2Mpix cameras 60

13.2 CIF camera 60

13.3 Camera bus interface 60

13.4 Camera flash trigger 61

14. Vibramotor 62

15. IrDA and fuel gauge 63

15.1 IrDA transceiver 63

15.2 Battery fuel gauge and IrDA multiplexing 64

16. Bluetooth 66

17. Accessory interface 67

17.1 Overview 67

17.2 UART and USB multiplexing 68

17.3 Connector default configuration 69

17.4 Accessory detection 69

18. UART 70

19. USB 70

20. SIM interface 71

21. MMC interface 72

22. Component placement 73

Page 3 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

1 Instruction

This Service Repair Documentation is intended to carry out repairs on BenQ repair level 4. The

described failures shall be repaired in BenQ authorized local workshops only.

All repairs has to be carried out in an ESD protected environment and with ESD protected

equipment/tools. For all activities the international ESD regulations has to be considered.

Assembling/disassembling has to be done according to the latest SXG75 Level 2 repair

documentation. It has to be ensured that each repaired mobile phone is checked according to the

latest released General Test Instruction document (both documents are available in the technical

support section of the C-market).

Check at least weekly C-market for updates and consider all SXG75 related Customer Care

Information and Repair Information which are relevant for the SXG75.

SXG75 partnumber on IMEI label: S30880-S8900-#xxx

, while # can be any letter (A-Z) and xxx can be any number from 100, 101, 102....

Scrap handling: All scrap informations given in this manual are related to the

SCRAP-Rules and instructions.

Attention: Consider the new "LEAD-FREE" soldering rules

(available in the communication market) and avoid excessive heat.

If you do have any questions regarding the repair procedures or spare parts do not hesitate to contact

our technical support team in Kamp-Lintfort, Germany:

Tel.: +49 2842 95 4666

Fax: +49 2842 95 4302

e-mail: st-support@benq.com

Page 4 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

p

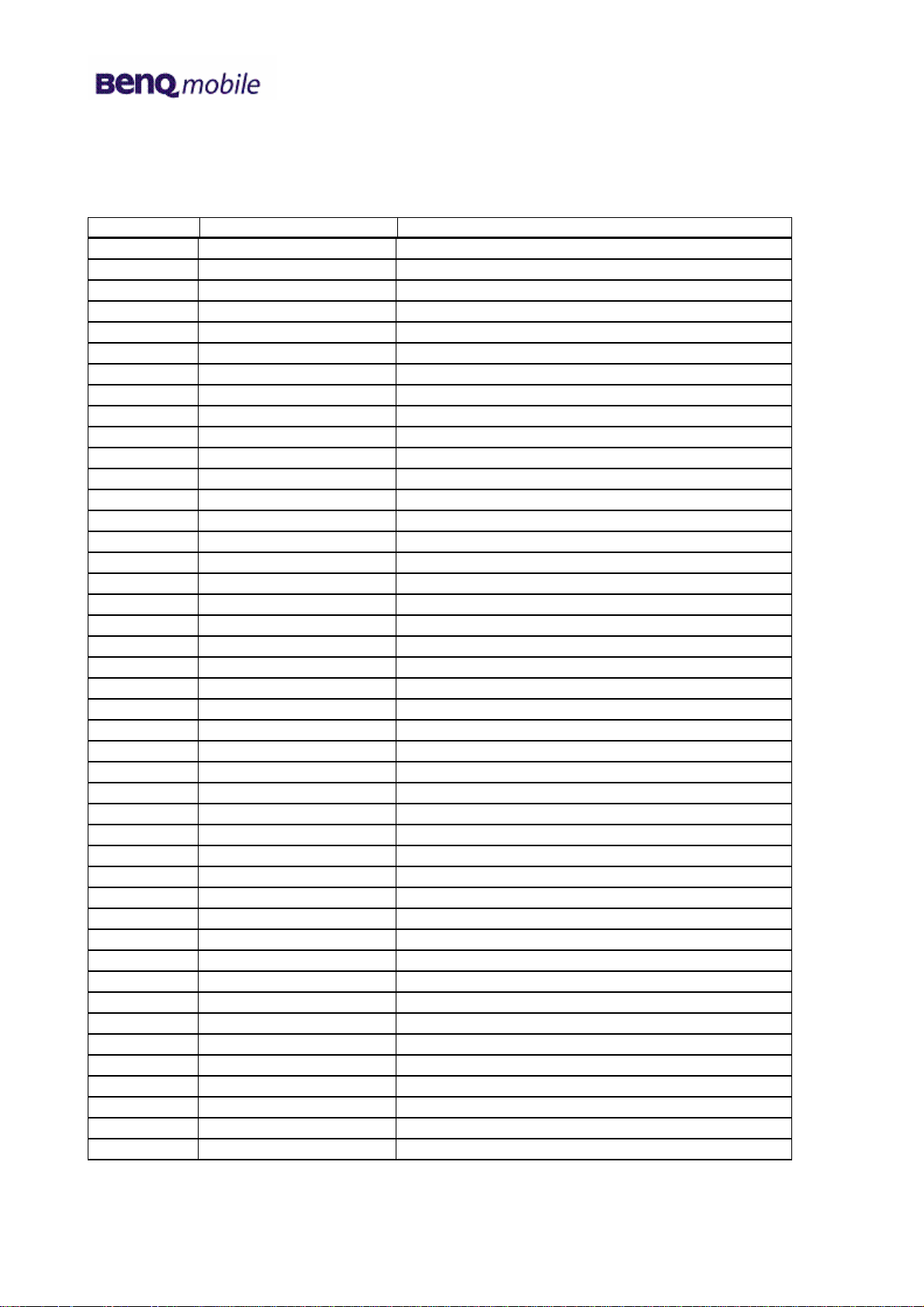

2 List of available spare parts

(according to Component Matrix V1.03 - check C-market for updates)

Com

V101 L50640-D4060-D670 DISDIODE DUAL ESD-PROTECTION SOT23

V200 L50630-C1101-D670 DISTRANS SI1555DL

N200 L50645-K280-Y337 IC FEM LMSP43MA-288TEMP GSM UMTS SMD

Z203 L50645-K280-Y323 FILTER DUPLEX WCDMA

Z200 L50645-K280-Y331 FILT SAW RX PCS1900MHZ B7846

Z201 L50645-K280-Y332 FILT SAW RX DCS1800MHZ B7844

Z202 L50645-K280-Y333 FILT SAW RX GSM900MHZ B7837

D500 L50620-L6165-D670 IC TELEC TRANSCIEVER RTR6250 QFN56

N300 Not defined yet IC MODUL PA PF0814 (PA-Type3) PB Free

V300 L50630-C1101-D670 DISTRANS SI1555DL

Z300 L50645-G100-Y108 OSCOSCI TXVCO 824-1910MHZ SMD

Z400 L50645-K260-Y93 ISOLATOR 1920MHZ-1980MHZ SMD

D400 L50651-Z2002-A66 IC TELEC ACPM-7881 SMD

V400 L50630-C1101-D670 DISTRANS SI1555DL

Z402 L50697-F5005-F88 IC TELEC RF-DETECTOR SOT23-6L

Z401 L50645-K280-Y314 FILT SAW UMTS2100 1950MHZ B7754

Z602 L50697-F5020-F34 EPCOS SAW LOW-LOSS-FILTER 2140,0MHZ LG02

X600 L36334-Z97-C334 CONNECTOR COAX SOCKET SWITCHED

Z600 L50645-K280-Y293 FILTER SAW AGPS 1575,42MHZ B7840 SMD

Z601 L50645-K280-Y304 FILSAW 1575,42 MHZ B7829 SMD

N600 L50620-L6166-D670 IC TELEC RECEIVER GPS UMTS RFR6250 QFN48

N700 L50610-U6197-D670 IC ANA STEREO-AMPLIFIER TS4975 CSP12

D800 L50620-L6164-D670 IC TELEC MSM6250 CSP409

Z1000 L50645-G200-Y27 OSCOSCI VCTCXO 19.2MHZ SMD

V1100 L50640-C3008-D670 DISTRANS PNP 0,5A 30V SOT89

V1102 L50630-C3007-D670 DISTRANS P-CH SI2333DS FDN306P SOT23

N1100 L50610-C6181-D670 IC VOLTAGE REG.TPS73601DRBR SMD ADJUSTA

V1101 L50640-D5086-D670 DISDIODE RB551V-30 PMEG3005AEA SOD323

Z1200 L50640-U6064-D670 FILTER EMI (Fi-Type7) PB Free

Z1201 L50610-C6179-D670 IC SPDT SWITCH DUAL MAX4717EBC+T UCSP12

V1303 L50640-D4043-D670 DIODENARRAY ESDA6V

Z1300 L50645-F102-Y42 OSCCRYST 32,768KHZ 7,0PF 30PPM SMD LF

N1300 L50645-J4681-Y57 IC POWER-MANAGMENT PM6650

V1301 L50640-D5086-D670 DISDIODE RB551V-30 PMEG3005AEA SOD323

D1300 L50610-C6183-D670 IC LOGIC NAND 74LVC1G00 SOT886

V1302 L50640-D5086-D670 DISDIODE RB551V-30 PMEG3005AEA SOD323

V1300 L36840-D5076-D670 DIODE SOD323 (Di-Type7)

Z1600 L50645-K280-Y328 FIL BP 2,4GHZ SMD

N1600 L50610-L6155-D670 IC TRANSCEIVER BLUETOOTH BCM2004 SMD

D1800 L50620-L6150-D670 IC TELEC TEA5764HN

V1800 L36840-D61-D670 DIODE 1SV305 (Di-Type4)

V1801 L36840-D61-D670 DIODE 1SV305 (Di-Type4)

V1900 L36840-C4057-D670 TRANSISTOR EMD12 EMT6 (Tra-Type8)

N1900 L50610-C6152-D670 IC ANA REG 2*2,85V 150MA USMD8 LP3986T

onent Ordernumber Description

Page 5 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

D1900 L50610-B6198-D670 IC LOGIC BUFFER 74ALVC16244AZQLR VBGA LF

D1901 L50610-B6198-D670 IC LOGIC BUFFER 74ALVC16244AZQLR VBGA LF

V2000 L36840-C4014-D670 TRANSISTOR BC847BS BC846S (Tra-Type7)

D2100 L50610-B6134-D670 IC LOGIC NC7WZ126L8X MAC08A

V2101 L50640-C4060-D670 DIS TRANS ARRAY EMD9 EMT6

D2200 L50610-B6186-D670 IC LOGIC 2 INPUT AND NC7SZ08L6X

N2201 L50610-C6153-D670 IC ANA RE 2.9V USMD5 PB FREE

V2200 L36840-C4014-D670 TRANSISTOR BC847BS BC846S (Tra-Type7)

V1700 L50640-D5086-D670 DISDIODE RB551V-30 PMEG3005AEA SOD323

Page 6 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

3 Required equipment for level 3

- GSM-Tester (CMU200 or 4400S incl. options)

- PC, incl. monitor, keyboard and mouse

- USB boot cable (F30032-P465-A1)

- Troubleshooting frame SXG75

- Power supply

- Spectrum analyser

- Active RF-Probe incl. power supply

- Oscilloscope incl. probe

- RF-Connector (N<>SMA(f))

- Power supply cables

- Dongle (F30032-P28-A1). If USB-Dongle is used, a special driver for NT is required

- Soldering and BGA soldering equipment for lead free soldering.

Reference: Equipment recommendation

(downloadable from the technical support page)

4 Required software for level 3

- Windows XP

- XFocus V2.06

- GRT V3.07

- Internet unblocking solution (JPICS)

Page 7 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

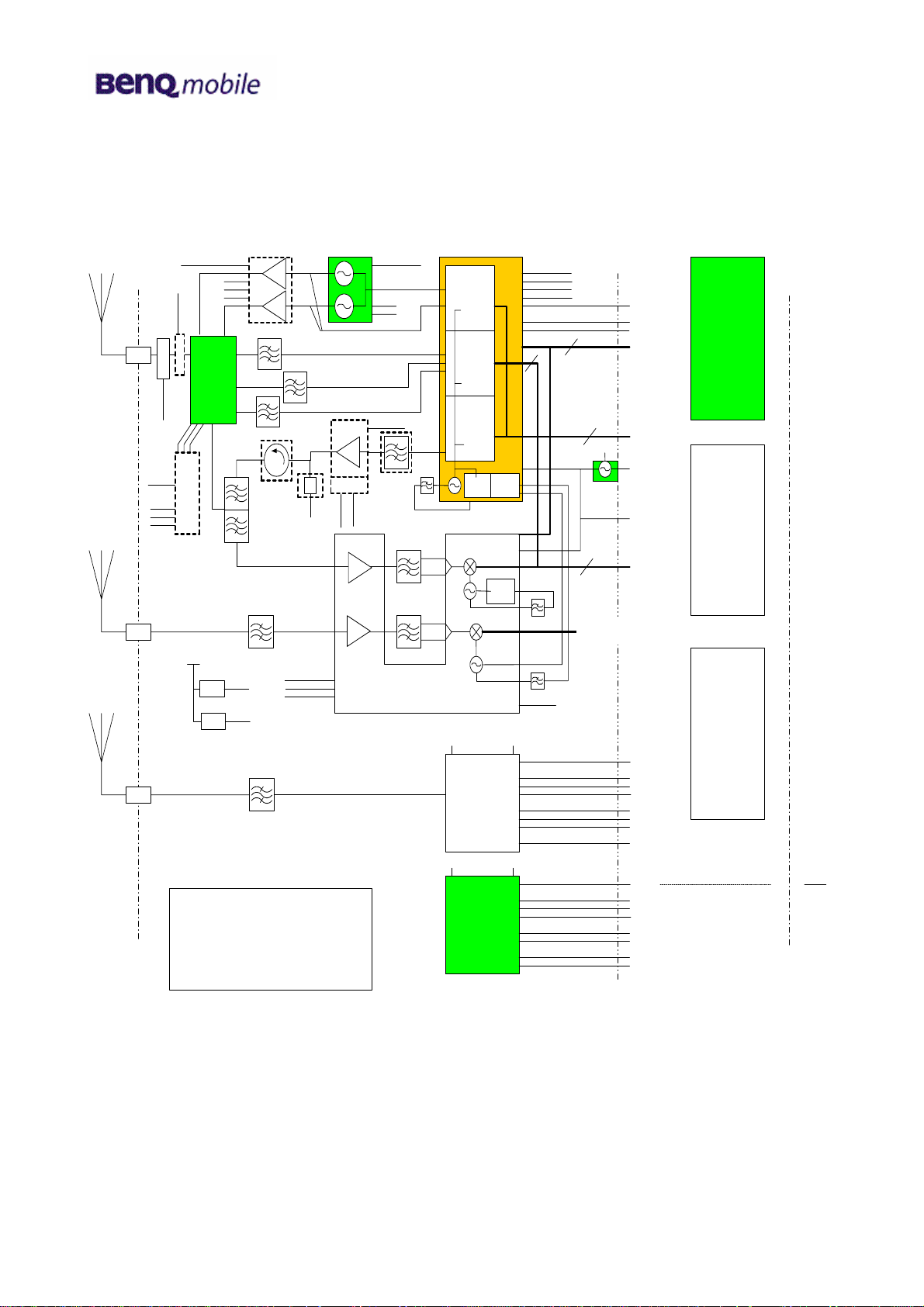

5 Radio part

The RF section consists of three data capable transceivers and two further broadcast receivers. The

first transceiver is an IMS UMTS 2100MHz 3G solution which realizes the conversion of the RF

WCDMA signals from the antenna to the baseband and vice versa. The second transceiver is a GSM

part which realizes the conversion of the GMSK-RF-signals from the antenna to the baseband and

vice versa. The third transceiver is a Bluetooth type Personal Wireless LAN system. The first

broadcast receiver is an RDS compliant FM radio solution. The second is a GPS receiver which is

integrated into the UMTS receiver IC. The GPS software will allow assistance from a suitably enabled

network (A-GPS); standalone operation without network assistance is also supported.

The GSM part supports triple band operation in the frequency ranges EGSM900, DCS1800,

PCS1900 respectively supporting GPRS functionality up to multiclass 10. In the receiving direction,

the RF signals are filtered and then directly down-converted and split into the I- and Q-component and

led to the D/A-converter of the logic part. In the transmission direction, the GMSK-signal is generated

in an Up Conversion Modulation Phase Locked Loop by modulation of the I- and Q-signals which are

generated in the logic part. The high power Tx VCO is external to the RFIC. After that the signals are

amplified in the power amplifier. The GSM transmitter and receiver are never active at the same time

(TDMA system).

The Bluetooth solution is realized in a separate IC with an external SAW filter.

The GPS receiver is integrated into the UMTS receiver RFIC. Two stages of filtering are provided in

front of and behind the LNA. The GPS down-conversion is a direct conversion system.

The FM radio solution is also realized in a separate IC.

The RF-circuit consists of the following components:

• Qualcomm chip set

RTR6250 for GSM TX/ RX, UMTS TX, LO1, PLL for

GPS LO

• Qualcomm chip set

•

VCTCXO 19,2 MHz

RFR6250 for UMTS RX, GPS RX, UMTS VCO, GPS VCO

• GSM TX VCO

• GSM PA module

• UMTS PA module

• UMTS duplexer and isolator

• BCM2004 Bluetooth IC

• FM radio

Page 8 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

5.1 Block diagram RF part

Ant/RF

External

Cellular

Cellular

Antenna

Antenna

Connector

ANT_POSN

ANT_SEL0

ANT_SEL1

ANT_SEL2

GPS

Antenna

BT

Antenna

VREG_

RFRX_0

VBATT

GPS Bias

LMSP43MA-

288TEMP

Inte rf ac e

VREG_MSMP

GSM_PA_EN

GSM_PA_BA ND

PA_RAMP

SP6T

Murata

ESI-3EAR1.950G01-T

Renesas

PF08143B-06-TB

942.5MHz SAW

EPCOS B7837

1960MHz SAW

1575.42MHz

EPCOS

B7829

2450MHz

TDK

DEA322448BT

EPCOS B7846

Detector

AD8361

VREG_RFRX_1

VREG_TXCO

VREG_MSMP

HDET1

1920-1980MHz

Hitachi Metals

Diplexer

1950-21400MHz

EPCOSB69967N2047A760

PA_THERM

RF_THERM

Wolf 5 RF Block Diagram B1

Issue K

David Pennington

24/1/05

Commercial-in-Confidence

1842.5MHz SAW

EPCOS B7844

Agilent

ACPM 7881

Interface

VREG_

PA_ON0

VREG_RFTX

TX_VCO_1_EN

TX_VCO_0_EN

ALPS

UCVA4XW02A

V_CDMA_PA

RFTX

1950MHz

60MHz

EPCOS

B9031

2140MHz 60MHz

B7728

1575.42MHz

EPCOS

B7840

GSM Tx

GSM Rx

UMTS Tx

PLL1

PLL2

RTR6250

PLL1

RFR6250

VREG_AUX2 VREG_MSMP

BCM2004

VREG_MSMA VREG_MSMP

Philips

TEA5764HN

VREG_RFTX

VREG_SYNTH

VREG_MSMP

VREG_RFRX_0

4

GSM_PA_EN

(GPS Blank)

19.2MHz

88-106MHz

3

VREG_TXCO

19.2MHz

VCTCXO

19.2MHz

Toyocom

TCO-5871

4

4

RF/BB

TX_VCO_1_EN

TX_VCO_0_EN

TX_ON

TX_IREF

TX_AGC_ADJ

SB_**0

GSM_PA_EN

GSM_PA_BAND

PA_RAMP

ANT_SEL0

ANT_SEL1

ANT_SEL2

TX_IQ4

TRK_LO_ADJ

TXCO

PA_THERM

RF_THERM

RX_IQ_0

PA_ON0

PA_R0- Not used

HDET1

RX_IQ_1

VBATT

V_CDMA_PA

VREG_SYNTH

VREG_TXCO

VREG_RFTX

VREG_RFRX_0

VREG_RFRX_1

VREG_MSMP

VREG_AUX2

VREG_MSMA

BT_ENABLE

BT_Tx_RX_N

BT_DATA

BT_CLK

BT_SBDT

BT_SBST

BT_SBCK

BUFF_TCXO_BT

FM_IN

SLEEP_CLK

A_FM_STANDBY

A_RDS_DATA_EXIST

I2C_SCL

I2C_SDA

AUXIP

AUXIM

Memory

MSM6250

PM6650

core/rest

Battery

SIM

MMC

Screen

Camera1

Camera2

Accessory

Connect

J-TAG

Keypad

Audio

IRDa

USB

etc

FM Antenna

Page 9 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

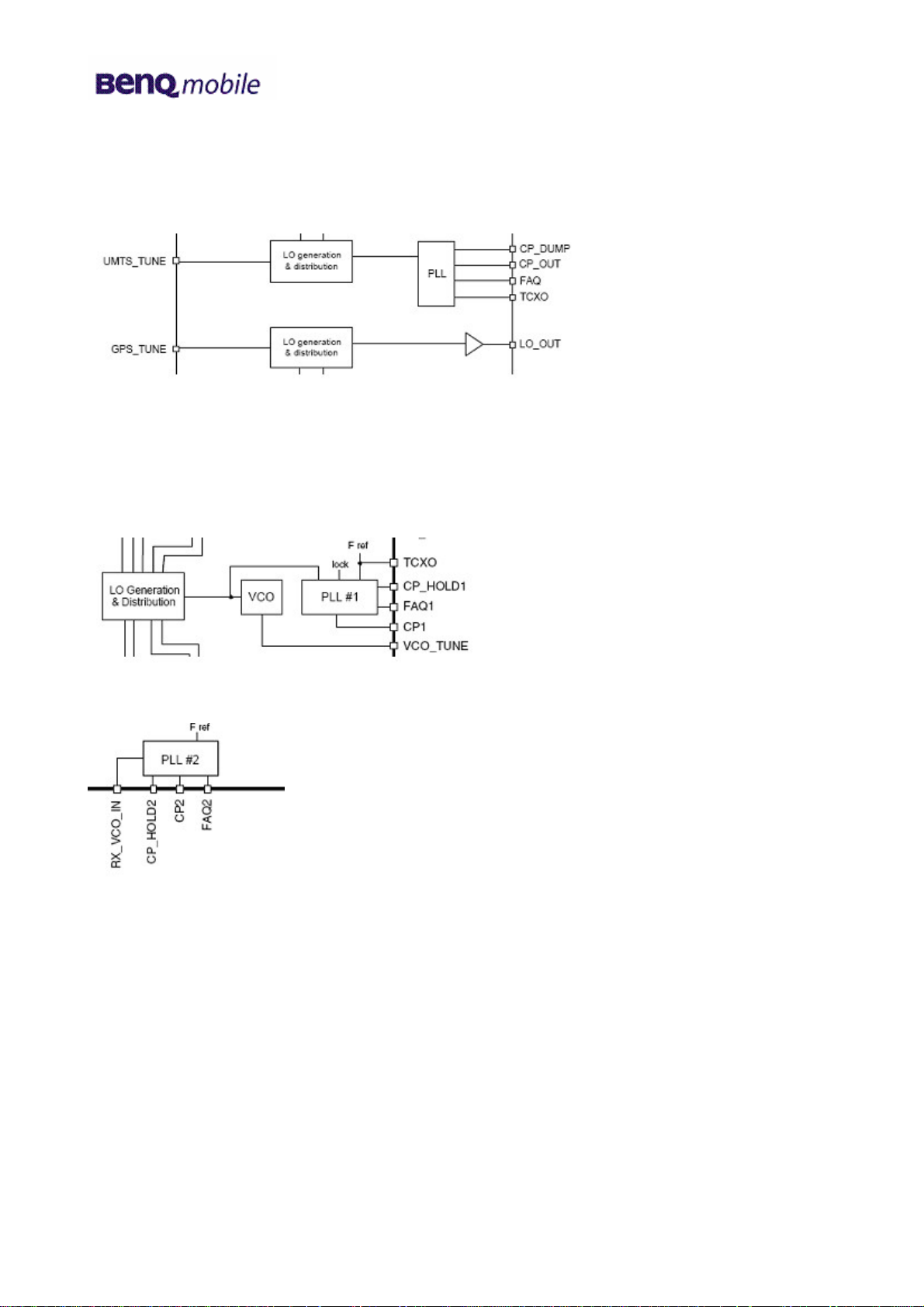

5.2 Receiver (RTR6250 and RFR6250)

The RFR6250 has two VCOs. The first is for the UMTS direct conversion receiver. The second is for

the GPS receiver and the PLL for this VCO is on the RTR6250 RFIC.

Block diagram RFR6250

The RTR6250 contains two PLLs, the first is used by the RTR for all GSM transceiver functions and

for the UMTS TX LO generation. The second PLL is used to control the GPS VCO in the sister

RFR6250 RFIC.

Block diagram RTR6250

Page 10 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

5.2.1 GSM RX

The GSM Receiver is a zero IF architecture with direct conversion by the IC. Although the IC provides

four input paths, the GSM850 Receiver is not used in the SXG75.

Block diagram RTR6250

5.2.2 UMTS RX

The RFR6250 provides an LNA and an output to allow further input filtering. The balanced signal is

reconnected to the RFR6250 and down converted by the Zero IF Quadrature Downconverter. The

UMTS 1900 RX path (PLNA, PMIX) is not used in the SXG75.

Block diagram RFR6250

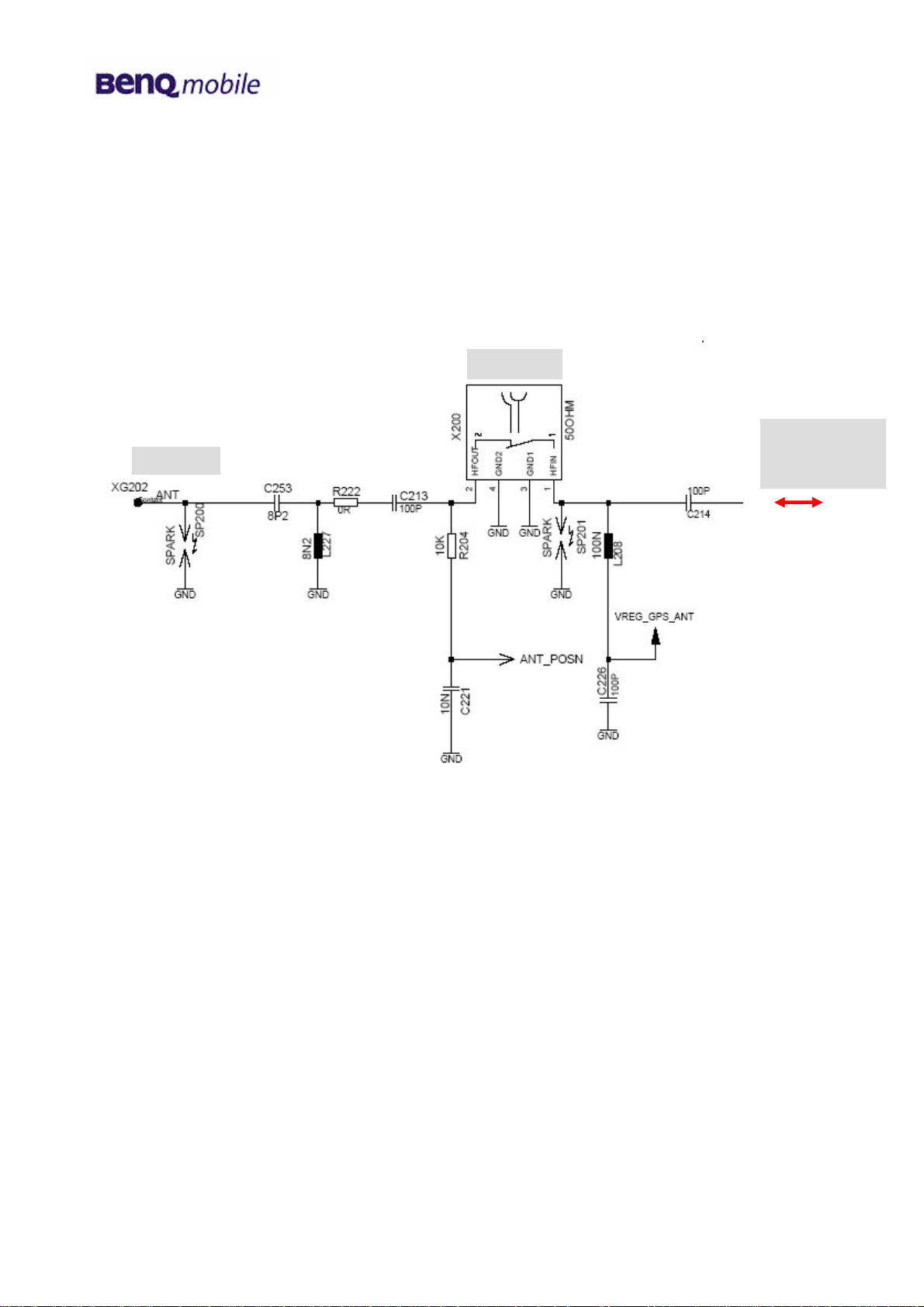

5.2.3 GPS

The GPS path is similar to the UMTS path, but uses a LNA with higher amplification to compensate

the DCS self blocking. The RFR6250 allows the GPS RX path to be switched off during GSM transmit

pulses.

Block diagram RFR6250

Page 11 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

5.3 Transmitter

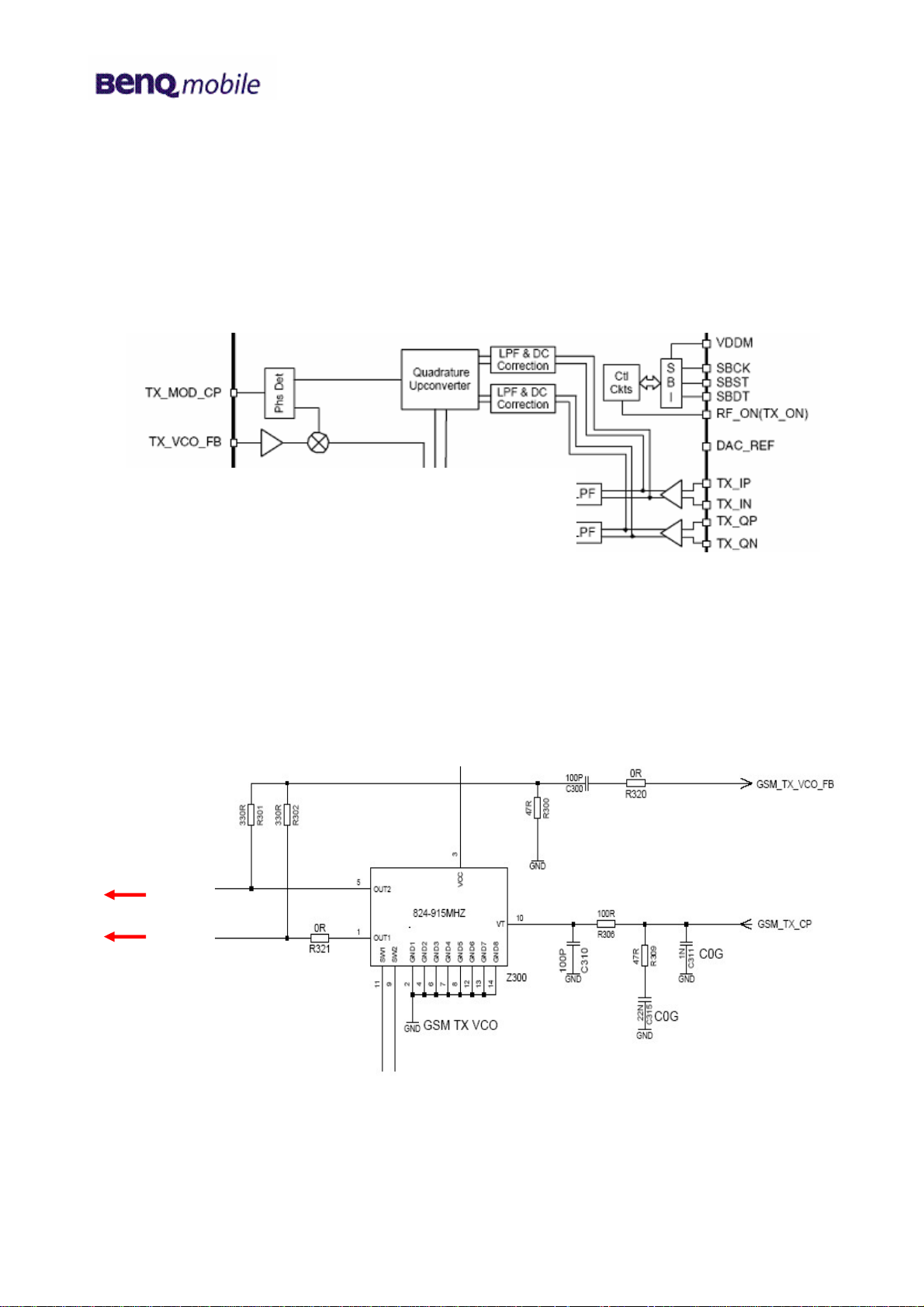

5.3.1 GSM TX modulation

The GSM transmitter uses a Offset Phase Lock Loop Architecture. The high power VCO is external to

the RTR6250. A feedback signal from the VCO is down-converted and the phase compared to that of

an upconverted version of the IQ signals from the baseband. The control signal is filtered and passed

to the high power VCO.

Blockdiagram RTR6250

5.3.2 GSM dual band TX VCO

The GSM TX VCO (Z300) is external to the RTR6250 and uses filtered signals (GSM_TX_CP) from

the RTR6250 to provide the GMSK signal to the power amplifier.

PA

Circuit diagram (sheet 3)

Page 12 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

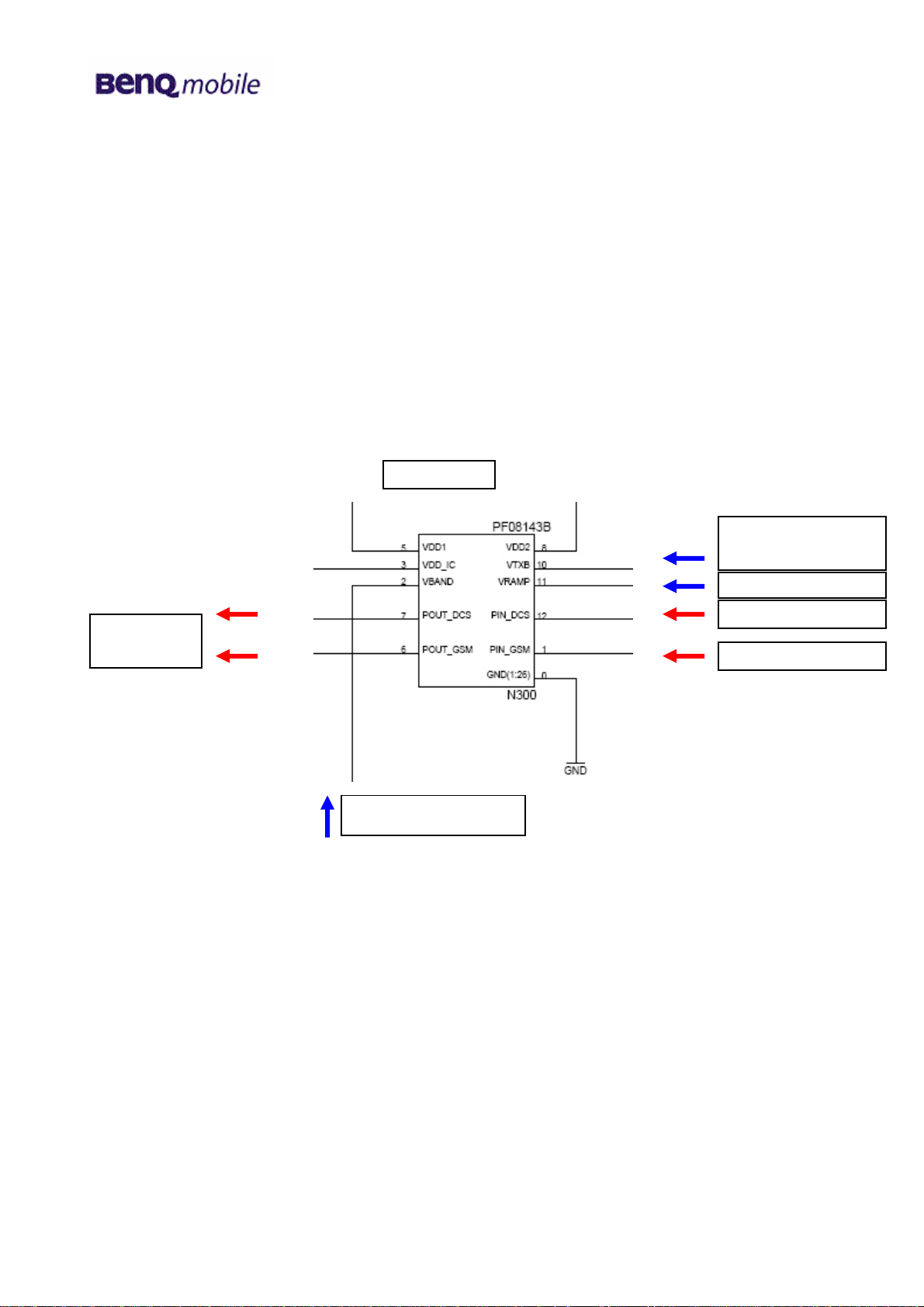

5.3.3

GSM power amplifier

The output signals (OUT1 and OUT2) from the GSM TX VCO are led to the power amplifier. The

power amplifier is the PA-module N300. It contains of two separate amplifier chains for GSM900 and

GSM1800/GSM1900 operation. The amplification is controlled with the signal VRAMP. The

appropriate amplifier chain is activated by the logic signal GSM_PA__BAND which is provided by the

MSM6250. The N300 is activated through the signal VTXB, which is the level shifted GSM_PA_EN

provided by the MSM6250.

The voltage VBATT is provided by the battery.

GSM_PA_EN

(level shifted)

to antenna

switch

Circuit diagram (sheet 3)

OUT2 from TX VCO

OUT1 from TX VCO

GSM_PA_BAND

Page 13 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

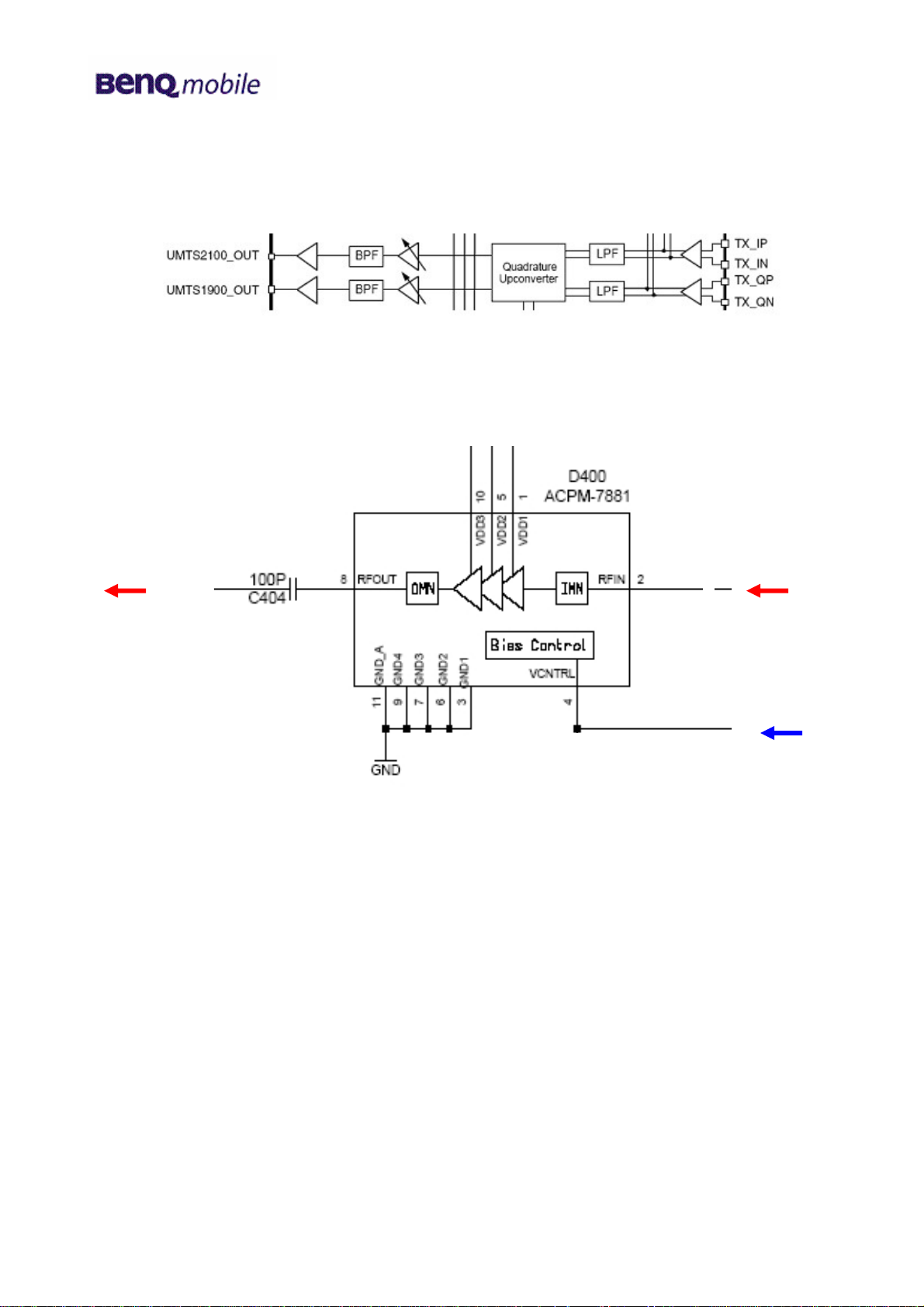

5.3.4 UMTS TX

The IQ signals from the baseband are directly up-converted to the RF band by a Quadrature

Upconverter and passed to the external filter. The UMTS 1900 TX path is not used in the SXG75.

Blockdiagram RTR6250

VBATT

UMTS2100 TXWCDMA TX

PA_ON0

(level shifted)

Circuit diagram (sheet 4)

Page 14 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

5.4 Antenna switch

The SXG75 mobile has two antenna switches:

a) The mechanical antenna switch for the differentiation between the internal and external

antenna.

Internal/external antenna switch

External

to/ from

Internal

switch

module

Circuit diagram (sheet 2)

Page 15 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

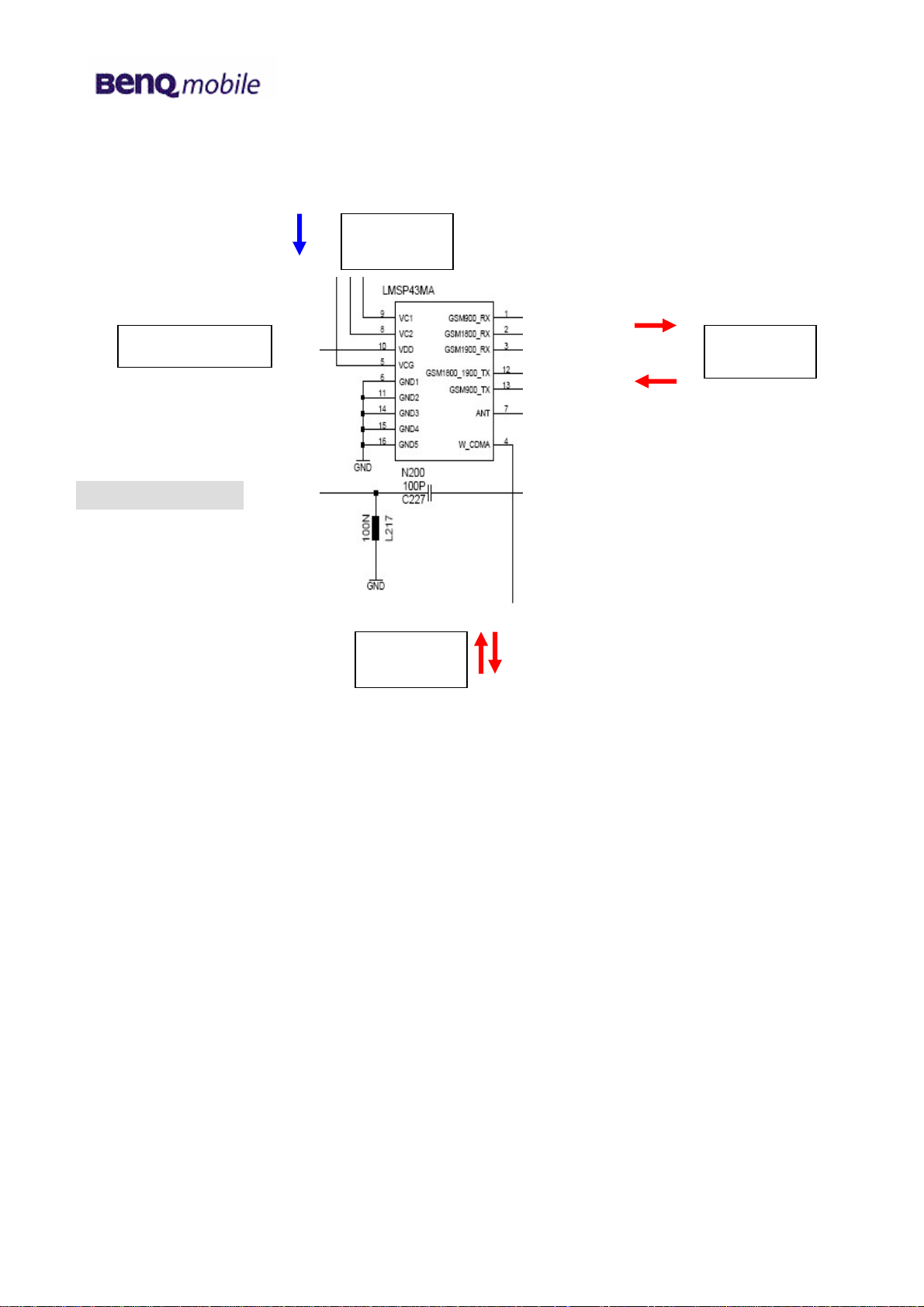

b) The electrical antenna switch for the differentiation between the GSM and UMTS

receiving respectively transmitting signals.

Signal

selection

VREG_RFRX_0

from/ to antenna

Circuit diagram (sheet 2)

GSM

signals

UMTS

signals

Page 16 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

6 Baseband

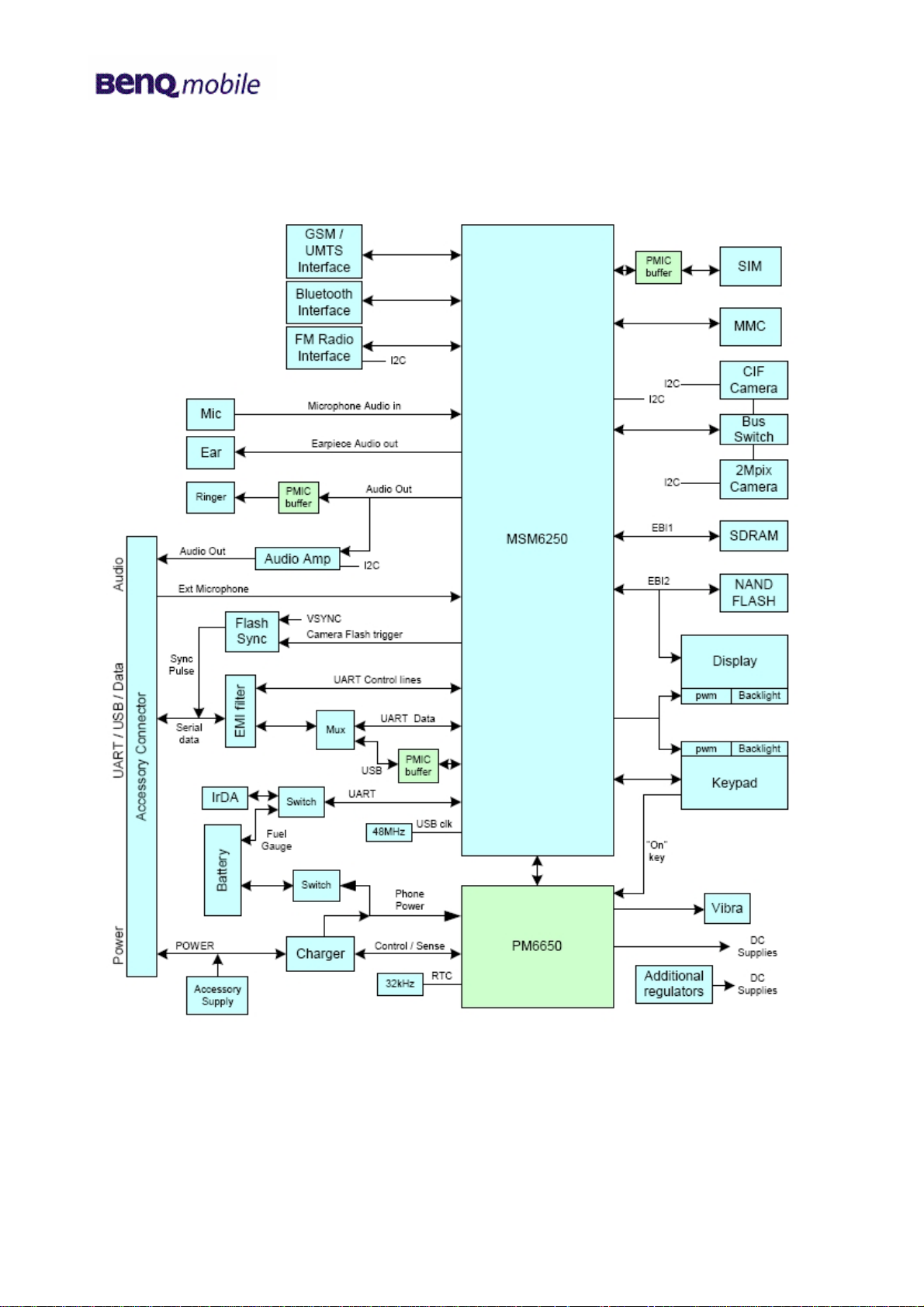

6.1 Block diagram

Page 17 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

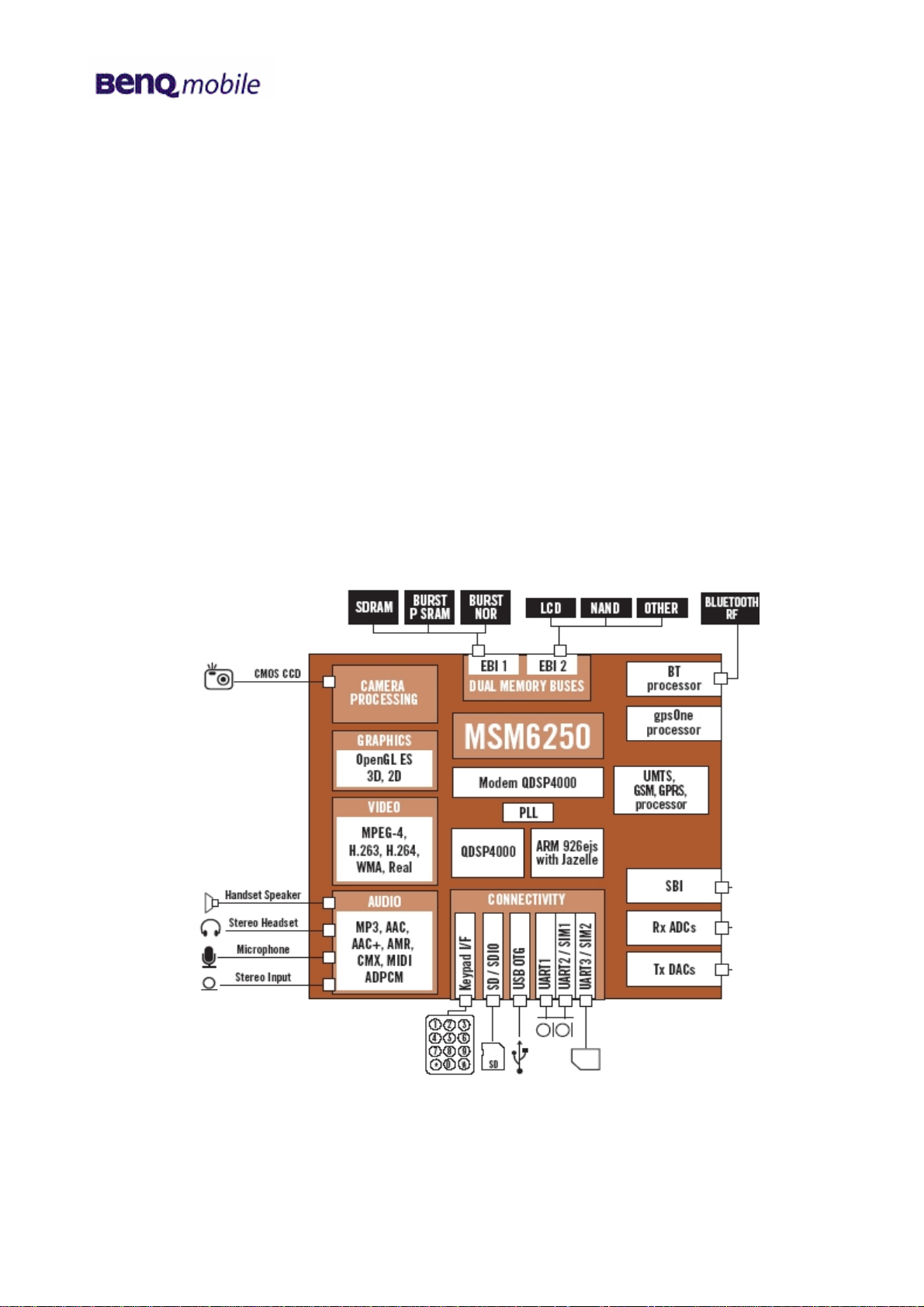

6.2 MSM6250 processor

6.2.1 General features

• Supports UMTS FDD release 99 September 2002 standard air interface

• Supports GSM/GPRS in addition to W-CDMA

• Supports low-power, low-frequency crystal to enable TCXO shutoff

• radioOne™ Zero IF interface Zero IF support - DC offset cancellation and digital variable gain

amplifier

• Software-controlled power management features

• Hardware support for inter-frequency and inter-radio access technology searching in CM

(WCDMA-GSM)

• Higher-speed serial bus interface, operating at up to 10 MHz and capable of handling four hardware

requests

• Multimedia card hardware support

• Serial bus controller: standard 100 kbps and fast 400 kbps

• MPEG4 video encoder

• 2-D and 3-D graphics accelerator for gaming applications

• Hardware acceleration supporting video capture and video telephony

• USB slave functionality

• Integrated wideband stereo CODEC for digital audio application

Block diagram MSM6250

Page 18 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

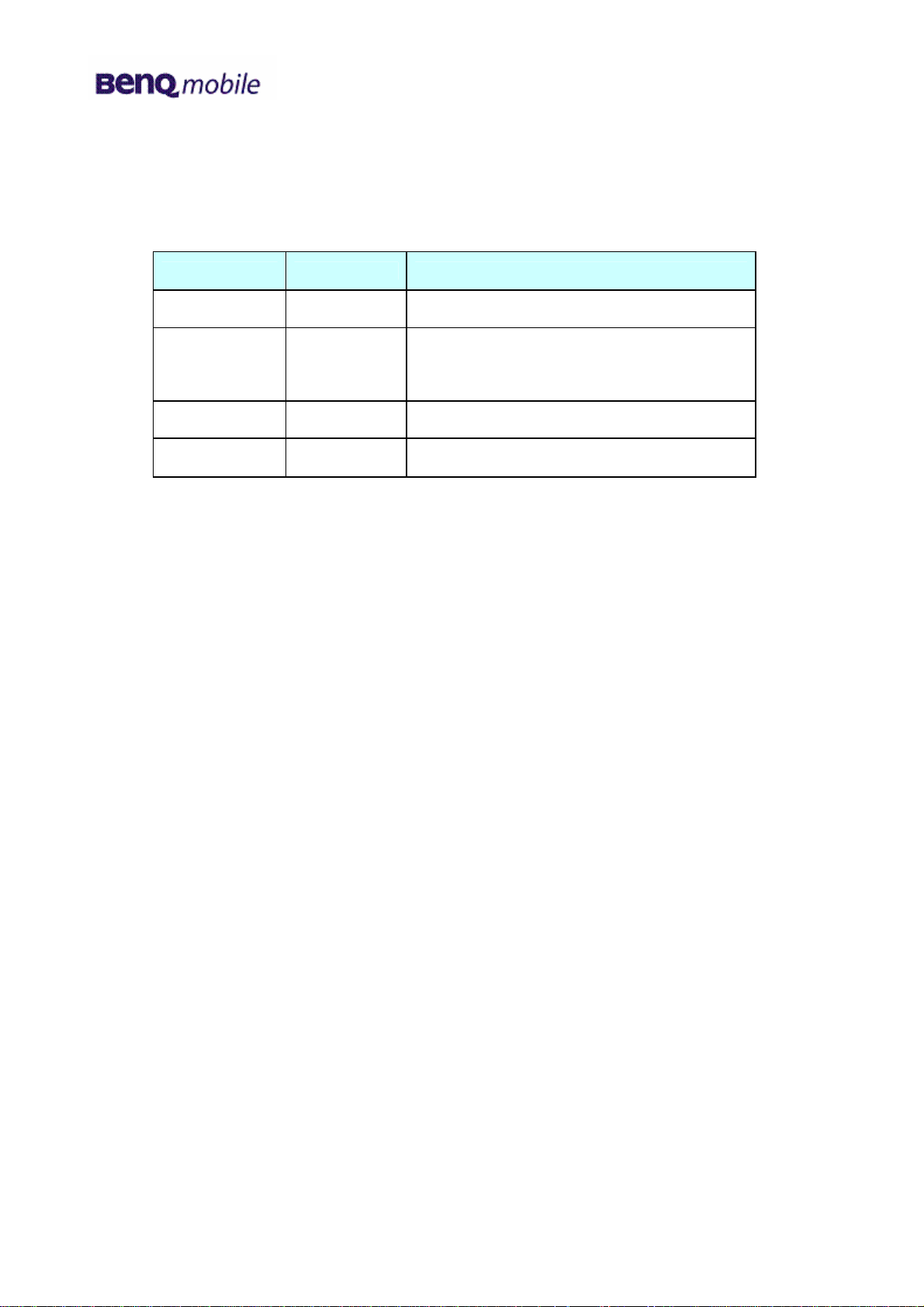

6.2.2 MSM6250 power supplies

The supplies used by the MSM6250 are generated by the PM6650 (Section 5).

They are as follows:

Supply Name Value Power Domain

VREG_MSMC 1.375 V (±3%) Digital Core only.

VREG_MSME 1.850 V (±3%)

VREG_MSMA 2.600 V (±3%) Analog circuits

VREG_MSMP 2.600 V (±3%) Supply voltage for IO pad group 3

SDRAM interface (EBI1 bus), NAND FLASH

and LCD interface (EBI2 bus), supply voltage

for IO Pad group 2

MSM6250 power supplies

Each supply has a zero-ohm series resistor (R804, R805, R806, R808) before the MSM6250

decoupling capacitors. The supplies become active while the phone is in the reset state during

“Phone On” operation (PON_RST_N from the PM6650 is low). They remain active until the phone is

turned off.

Page 19 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

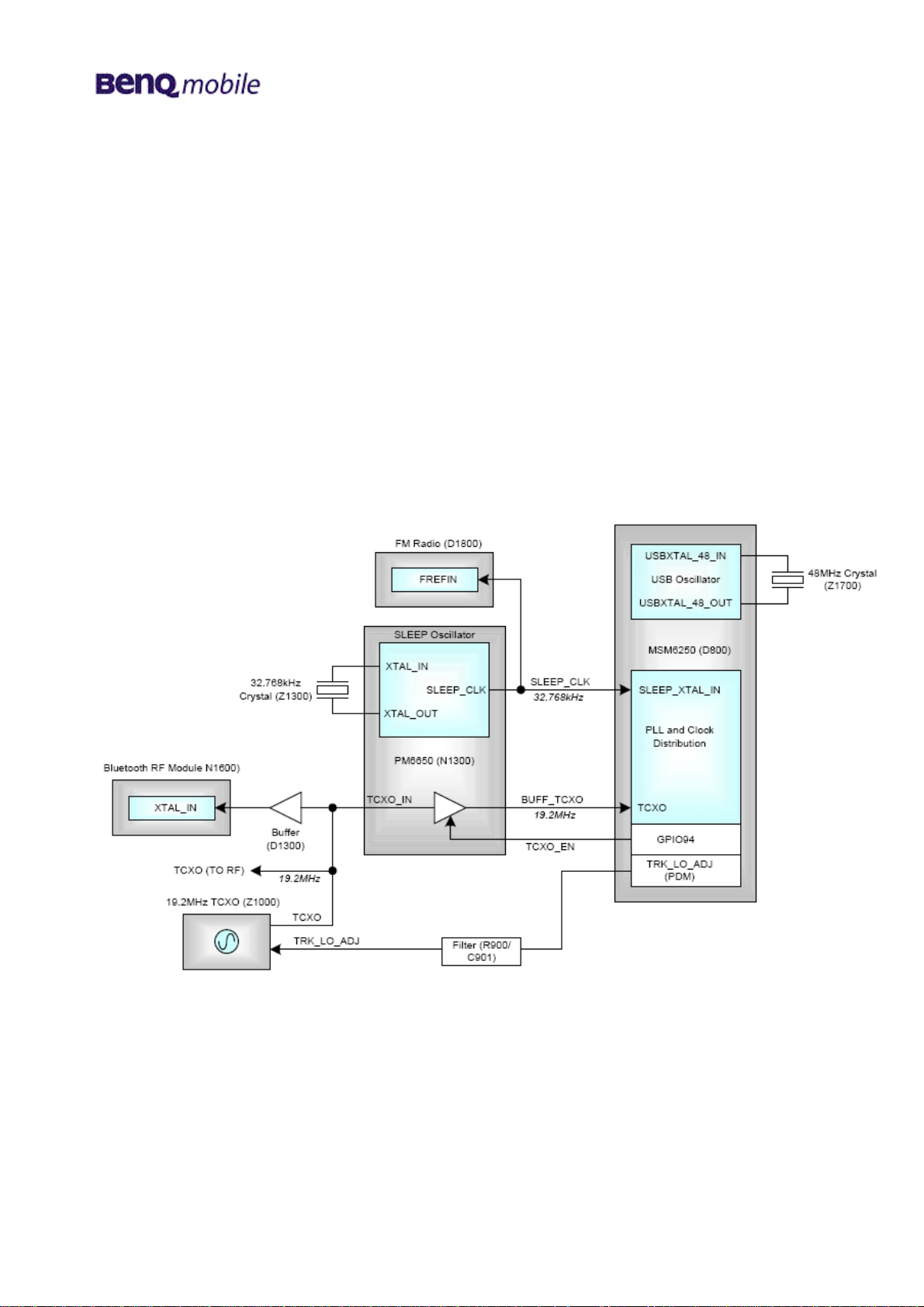

6.2.3 Clock distribution

The master clock for Wolf 5 baseband and RF systems runs at 19.2MHz. The clock is generated by

Voltage-Controlled-Temperature-Compensated-Crystal-Oscillator Z1000. The clock is buffered to

VREG_MSMP (2.6V) levels within the PM6650, and then sent to the MSM6250. The PM6650 buffer is

enabled by logic control TCXO_EN from the MSM6250. The MSM6250 integrates a phase-locked

loop and digital dividers to derive internal clocks from the TCXO clock input.

The TCXO is also buffered by D1300 to feed the Bluetooth RF Module, N1600. This buffer is only

enabled when the Bluetooth supply (VREG_AUX2) is active.

A 32.768 kHz clock (SLEEP_CLK) is generated by the PM6650, and fed to the MSM6250. This clock

is used for low-power operation during phone idle periods when the TCXO is disabled. It also drives a

Real-Time-Clock circuit in the PM6650. The power supply for the Sleep Oscillator and associated

Real-Time-Clock is derived from the battery voltage and backup capacitor C1312. This means the

clock is active when the phone is powered off, and for 40 seconds when the battery is removed.

A 48MHz clock is provided by Z1700. This is used internally by the MSM6250 to control USB

functions.

Block diagram

Page 20 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

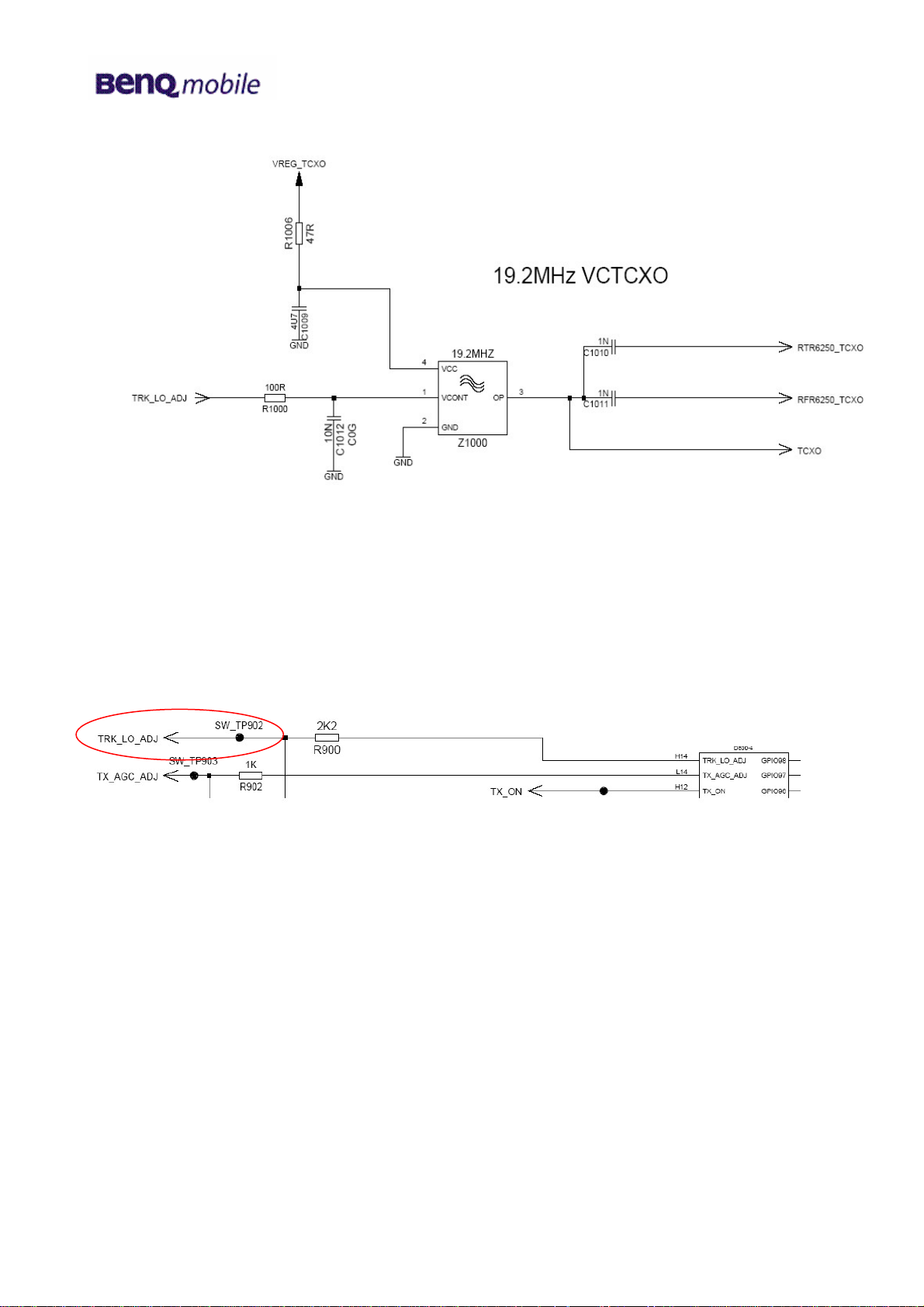

Circuit diagram (sheet 10)

The oscillator output signal TCXO is connected to the power management IC (PMIC, N1300, Pin 58).

The oscillator output signals RFR6250_TCXO and RTR6250_TCXO are connected to the RF chips

RFR6250 (N600, Pin 33) resp. RTR6250 (D500, Pin 6).

To compensate frequency drifts the oscillator frequency is controlled by the TRX_LO_ADJ signal,

generated through the MSM6250 (D800, SW_TP902).

Circuit diagram (sheet 9)

Page 21 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

6.2.4 MSM6250 bootup and mode control

The MSM6250 supports booting from the NAND FLASH memory. The high pull-up (R1700) on the

bootmode input pin is used to indicate to the MSM hardware that FLASH boot-up is required. After

power-on reset, the MSM hardware automatically loads the boot code from NAND flash to an on-chip

boot SRAM, and then releases the ARM to execute from this boot SRAM. By executing the boot code,

the ARM processor transfers the entire phone software to the SDRAM, and then branches to the

SDRAM to execute the phone software and completes the boot-up process.

The MSM6250 runs in “Native” mode. This mode is selected by the Mode 0, Mode 1 and Mode 2 pins

(Schematic sheet 17). The pins are left floating (internal pulldown resistors) to select Native mode.

Note that the Mode pins are connected to additional MSM6250 pins. This is a requirement of the

device – the signals are not required for any external functions.

MSM6250 Function Signal Function

TCXO BUFF_TCXO TCXO clock input from PM6650

USB_XTAL48_IN (48MHz crystal) 48 MHz crystal oscillator input

USB_XTAL48_OUT (48MHz crystal) 48 MHz crystal oscillator

SLEEP_XTAL_IN

SLEEP_CLK

Low-power sleep crystal oscillator from PM6650

SLEEP_XTAL_OUT

RESIN_N PON_RST_N Hardware reset input from PM6650

RESOUT_N

RESOUT_N_EBI1 RESOUT1_N

WDOG_EN

MODE[2]

MODE[1]

MODE[0]

BOOT_MODE

MSM6250 clocks and mode control

(not used)

(not used)

Reset output generated by RESIN_N and by

wdog_reset. Reset to LCD, NAND FLASH

(not used)

(not used)

(not used)

(not used)

pull-up to VREG_MSMP (boot from NAND)

Page 22 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

6.3 MSM6250 interfaces

6.3.1 Logic interfaces

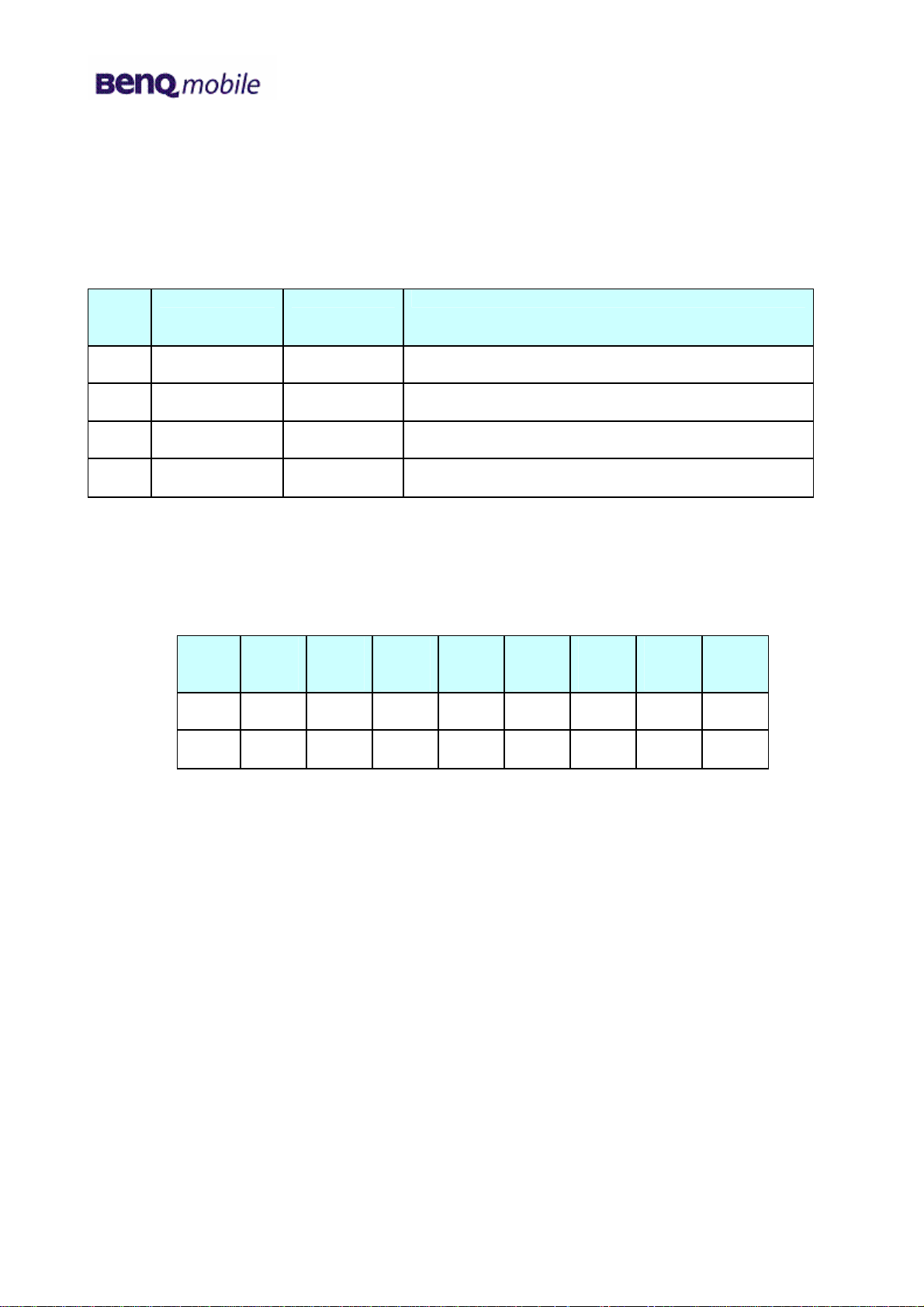

Each IO pin on the MSM6250 has an associated pad group. The pad group, and hence the IO pin, is

powered from the supplies as below:

Pad

Group

1 VREG_MSME 1.850 V (±3%) EBI1 bus to SDRAM

2 VREG_MSME 1.850 V (±3%) EBI2 bus to NAND FLASH and LCD. Plus some GPIO

3 VREG_MSMP 2.600 V (±3%) Most peripheral interfaces

4 VREG_MSMP 2.600 V (±3%) SIM bus (to PM6650). Plus one GPIO.

Supply Name Value Pad Group Connections

MSM6250 pad group supplies

The maximum and minimum possible logic levels seen on the I/O pins (allowing for maximum supply

variation and loading) should be within:

Pad

Group

VOL

min

(V)

VOL

max

(V)

VOH

min

(V)

VOH

max

(V)

ViL

min

(V)

ViL

max

(V)

ViH

min

(V)

ViH

max

(V)

1, 2 0 0.45 1.344 1.906 -0.3 0.628 1.239 2.085

2, 3 0 0.45 2.027 2.678 -0.3 0.883 1.741 2.822

MSM6250 logic specification

Peripheral systems on the phone are controlled by the MSM6250 logic signals listed below. These

signals uses General Purpose IO (GPIO) pins on the MSM6250 and are configured to perform the

required function by software.

A brief description of the signals is given in the following table:

Page 23 of 74

TD_Repair_L3_SXG75_R1.0.pdf Release 1.0

Loading...

Loading...