Siemens SQM5 Series Technical Instructions

SQM5…

Reversing Actuators

ISO 9001

REGISTERED FIRM

Technical Instructions

Document No. 155-517P25

Rev. 1, July, 2000

®

EA0511R1

Description

Features

SQM5... reversing actuators are used for the positioning of flow control valves, butterfly

valves, dampers, or any application requiring rotary motion. The SQM5… actuators

accommodate control input signals of 4-20 mA, 0-135 Ω, 0-10 Vdc, 0-20 mA, position

proportional and floating control. The available output signals include 4-20 mA,

0-135 Ω, 0-10 Vdc, 0-20 mA, and 0-1000 Ω. SQM5… actuators are available with up to

eight internal, easily accessible and adjustable auxiliar y swi tches.

A selection of exchangeable circuit boards provide a variety of functions including

auto/manual selector switch, manual forward/reverse toggle switch, zero and span

adjustment, parallel or master/slave operation, split range control, input signal override,

and selectable electronic linearization.

The SQM5… is engineered for precision. It is particularly well suited to applications

requiring a high degree of modulating accuracy and repeatability. Drive shaft play is

limited to 0.3° with a modulating accuracy of 250 repositions through 90° of travel.

The SQM5… actuator may be mounted in any position. A selection of mounting

brackets and shafts provide installation flexibility and allow for the simple replacement of

most competitive actuators.

• Modulating accuracy of 250 repositions through 90°

• Two limit switches, plus up to six internal auxiliary switches

• Full closed “economy position” switch

• Drive shaft and cam drum disengagement clutches

• Auto/manual switch, manual control forward/reverse toggle switch

• UL, CSA and CE approved 24, 110 and 220 Vac versions

• Field reversible clockwise (cw) or counterclockwise (ccw) operation

• Various torque ratings and running times available

• Selection of field exchangeable one and two ended shafts

• Mounting brackets to replace competitive actuators

Siemens Building Technologies, Inc.

Technical Instructions

Document No. 155-517P25

Rev. 1, July, 2000

Features, Continued

• Connections for both base and face mounting

• Low hysteresis actuator and potentiometer gearing

• Externally visible position indication

• Selection of input and output signals

• Zero and span adjustment

• Field exchangeable circuit boards and potentiometers

• Electronic damper linearization function

• Split range and selectable parallel or master/slave operation

• Adjustable input signal override function

Table Of Contents

Application Page 3

Product Numbers

Product numbers for pre-assembled UL/CSA/CE-approved

actuators, Table 1 Page 3

Product numbers for accessories, Table 2 Page 4

SQM5… Product Number Identification Legend Page 5

Installation and Operating In structions

Shaft Installation Page 6

Rotational Direction Verification Page 7

Actuator Mounting Page 7

Switch Adjustment Page 7

Shaft Adjustment Page 8

Cam Drum Adjustment Page 8

Wiring

Electrical Connection Page 8

Grounding Page 8

Wiring Connections

AGA56.1… circuit boards Page 8

AGA56.41/42/43… circuit boards Page 9

AGA56.9… circuit boards Page 11

Commissioning

Power Actuator Page 12

Modulation Adjustment Page 12

Zero Adjustment Page 12

Span Adjustment Page 12

Position Indicating Dial Adjustment Page 13

Cover Installation Page 13

Features

SQM5x.xxxxxZx actuators Page 14

SQM5x.xxxxxGx actuators Page 15

SQM5x.xxxxxHx actuators Page 15

SQM5x.xxxxxKx actuators Page 15

SQM5x.xxxxxAx actuators Page 16

Service Guide

Reversing Rotational Direction Page 16

Shaft Installation Page 17

Circuit Board Installation Page 17

AGA56.41/42/43… Page 18

AGA56.9A Page 19

AGA56.1A97 Page 21

Potentiometer Removal/Installation Page 22

Specification Data Page 23

Dimensions Page 26

Page 2 Siemens Building Technologies, Inc.

SQM5… Reversing Actuators Technical Instructions

155-517P25

Rev. 1, July, 2000

Application

Product Numbers

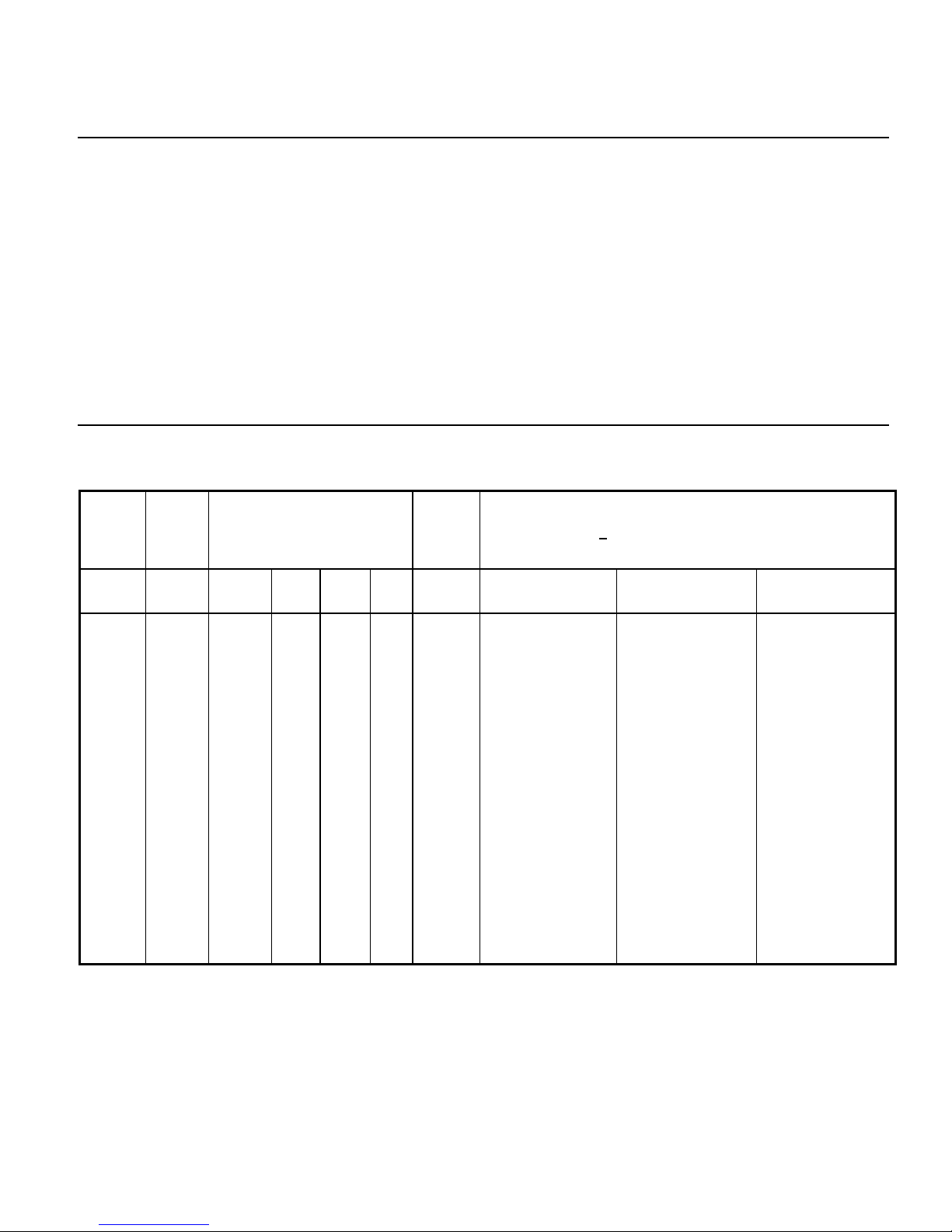

Table 1. Product Numbers for Pre-assembled UL/CSA/CE-Approved Actuators.

Running

Torque

1

lb-in sec Line

90

90

90

140

140

140

140

140

140

Time

90°@

60 Hz

8

8

12

25

25

25

25

25

25

2

Voltage

SQM5… actuators are uniquely suited for both industrial and commercial applications.

The high level of accuracy permits precise modulating control of industrial process and

process heating applications, often significantly enhancing performance and product

quality.

In commercial and industrial burner applications requiring high turndown and reliable

ignition, the auxiliary switches can be applied to create separate positions for burner

light off and low fire. In dual fuel applications, additional switches can be used to create

separate high fire, low fire and light off positions for each fuel. The “economy position”

switch is used to drive the actuator to the full closed position when the burner is off.

In all applications, commissioning is simplified. Shaft and switch cam drum

disengagement clutches allow for the quick manual alignment of the actuator shaft and

switch cams. The forward/reverse toggle switch in combination with the auto/manual

selector switch provides direct manual control.

Input Control Signals

4-20mA0-135

ΩΩΩΩ

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

3

0-10

Vdc

X

X

Number

of

switches

limit/

aux.

2/4

2/4

2/4

2/4

2/6

2/3

2/4

2/4

2/6

For SQM5x.xx0xxxx shafts must be ordered separately

For shaft selection refer to Table 2.

110 V 220 V 24 V

SQM50.260R1G4

SQM50.364R1G3

SQM50.464R1A3

SQM50.480R1Z3

SQM50.450R1A

SQM50.460R1G3

SQM50.460R1H3

Product Number

SQM50.260R2A

3

SQM50.480R2Z3

SQM50.480R8Z3

SQM50.450R8A

SQM50.450R8G3

SQM50.450R8H3

3

3

200

200

200

310

310

310

400

400

25

25

25

37

37

37

50

50

X

X

X

X

X

X

X

X

X

X

X

X

X

1. Torque will vary with the selection of the shaft. See Specifications.

2. Running time for 135° ➔ multiply by 1.5 For 50 Hz ➔ multiply by 1.2

3. SQM5x.xxxxxZx models also accept a 0-20 mA input signal.

Siemens Building Technologies, Inc. Page 3

X

X

2/6

2/6

2/4

2/4

2/4

X

X

X

2/4

2/6

2/6

SQM53.480R1Z3

SQM53.480R1G3

SQM53.460R1A

SQM56.560R1A

SQM56.560R1G4

SQM56.564R1H4

SQM56.680R1Z3

SQM56.680R1G3

3

3

Technical Instructions

Document No. 155-517P25

Rev. 1, July, 2000

Table 2. Product Numbers for Accessories.

Electronic circuit boards

AGA56.1A97 24-250 Vac (A) board for SQM5x.xxxxxAx

AGA56.9A87 24 Vac (Z) board for SQM5x.xxxxxZx

AGA56.9A17 120 Vac (Z) board for SQM5x.xxxxxZx

AGA56.9A27 220 Vac (Z) board for SQM5x.xxxxxZx

AGA56.41A87 24 Vac (G) board for SQM5x.xxxxxGx

AGA56.41A17 110 Vac (G) board for SQM5x.xxxxxGx

AGA56.41A27 220 Vac (G) board for SQM5x.xxxxxGx

AGA56.42A17 110 Vac (H) board for SQM5x.xxxxxHx

AGA56.42A27 220 Vac (H) board for SQM5x.xxxxxHx

AGA56.42A87 24 Vac (H) board for SQM5x.xxxxxHx

AGA56.43A17 110 Vac (K) board for SQM5x.xxxxxKx

AGA56.43A27 220 Vac (K) board for SQM5x.xxxxxKx

AGA56.43A87 24 Vac (K) board for SQM5x.xxxxxKx

See Product Number Identification Legend, Figure 1

.

Mounting Brackets & Adapters

AGA57.3 for replacement of Honeywell MOD III, IV

actuators

AGA57.4 for replacement of Honeywell M640/740/940 and

Barber Colman EA20/40/50/60 actuators. Directly

adaptable to Eclipse butterfly valves.

ASK33.9 mounting kit for direct attachment to Siemens

VKF41... butterfly valve. (Shaft AGA58.1 required)

Shafts

AGA58.1 10 mm round with key. Gear end only

AGA58.2 12 mm round with key. Gear end only

AGA58.3 9 mm square. Two ended

AGA58.4 3/8 inch square. Two ended

AGA58.7 14 mm round with key. Gear end only

For exact shaft sizes, refer to DIMENSIONS

.

Crank Arm, Push Rods

338 031 Crank arm kit. Includes two crank arms for

connecting the AGA58.4 shaft to a ∅ 1/2-inch damper

shaft with two ball joints. (does not include push rod)

338 041 ∅ 5/16" damper push rod, 12 inches long.

338 042 ∅ 5/16" damper push rod, 15 inches long.

338 043 ∅ 5/16" damper push rod, 18 inches long.

338 044 ∅ 5/16" damper push rod, 24 inches long.

338 045 ∅ 5/16" damper push rod, 36 inches long.

338 046 ∅ 5/16" damper push rod, 48 inches long.

Potentiometers

ASZ12.803 1000Ω, 90°

ASZ12.833 1000

ASZ22.803 1000/1000

ASZ22.833 1000/1000

, 135°

Ω

double potentiometer, 90°

Ω

double potentiometer, 135°

Ω

Additional potentiometer models available. See

Siemens technical data sheet 7921.

Page 4 Siemens Building Technologies, Inc.

SQM5… Reversing Actuators Technical Instructions

155-517P25

Rev. 1, July, 2000

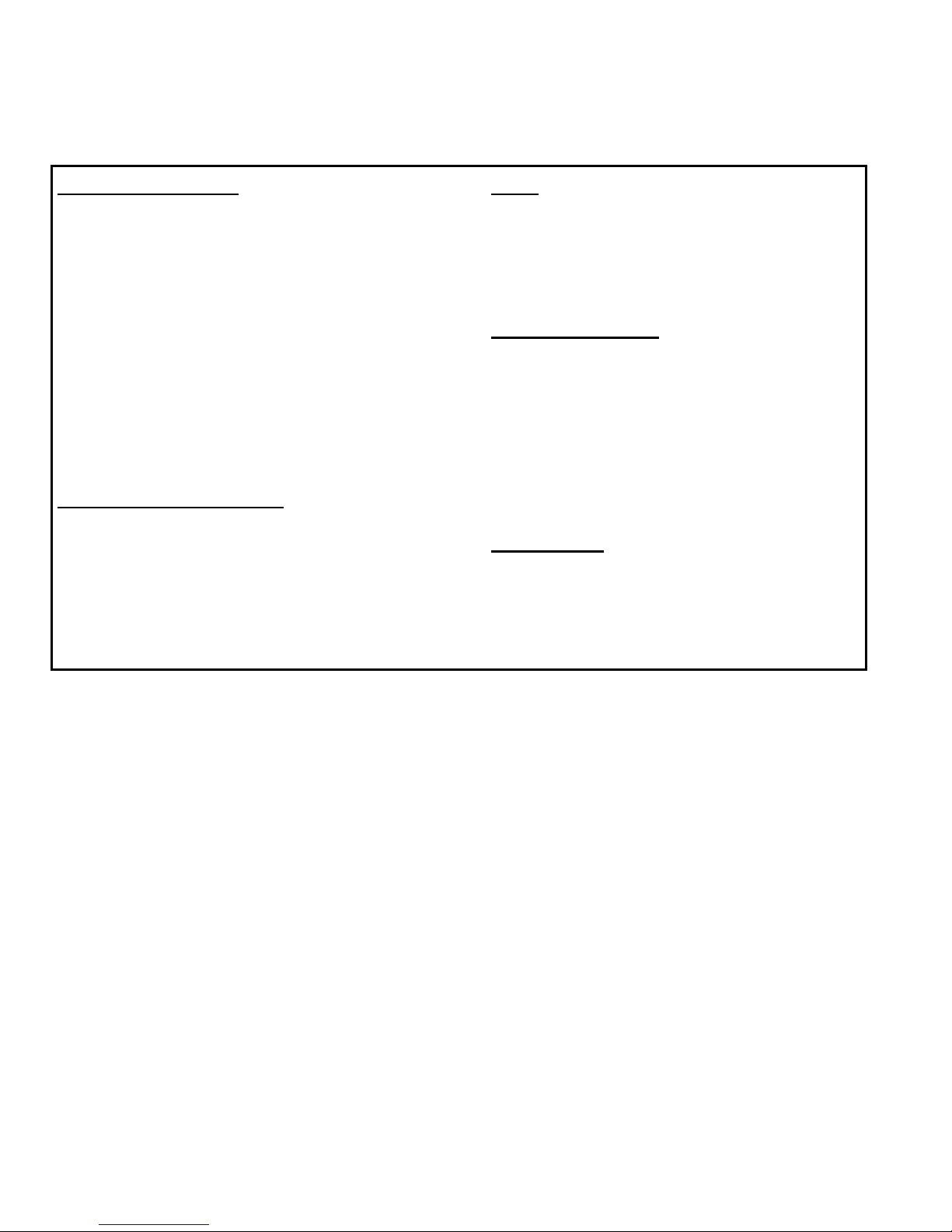

Product Number Identification Legend

For actuator identification only. To select product numbers for ordering, see Table 1.

SQM5 0 .4 8 0 R 1 Z 3

Actuator family

Torque in-lb @ 60 (50) Hz.

0

90 for 8 (10) sec. running time

0

140 for 12 (15), 25 (30), 37 (45) sec.

200 for 25 (30) sec.

3

6

310 for 37 (45) sec.

6

400 for 50 (60), 75 (90)sec.

Running time for 90°

Not all actuator running times are

available in each torque.

Refer to table 1

60 Hz.

2

8 sec.

3

12 sec.

4

25 sec.

5

37 sec.

6

50 sec.

8

75 sec.

Number of SPDT switches

2 limit and 4 auxiliary switches

6

8

2 limit and 6 auxiliary switches

Shaft selection

0

1

2

3

4

7

(shaft must be ordered separately)

no shaft

round 10 mm, one ended (for use with VKF41... butterfly valves)

round 12 mm, one ended

square 9 mm, two ended

square 3/8 inch, two ended

round 14 mm, one ended

50 Hz.

2

3

4

5

6

8

10 sec.

15 sec.

30 sec.

45 sec.

60 sec.

90 sec.

R

Approvals

UL recognize d, CSA certified, CE approved

R

Operating voltage (Vac @50-60 Hz)

1

110-120 Vac

2

220-240 Vac

24 Vac

8

Internal circuit board

A

AGA56.1A97 (position proportional or floating control)

G

AGA56.41A... (4 to 20 mA input)

AGA56.42A... (0 to 135 Ohm input)

H

K

AGA56.43A... (0 to 10 Vdc input)

Z

AGA56.9... (all inputs/outputs, linearization, split ranging, override and pre-set positioning)

Potentiometer

ASZ12.803 (1000 Ohm, 90°)

3

4

ASZ12.833 (1000 Ohm, 135°)

6

ASZ12.863 (1000 Ohm 160°)

7

ASZ22.803 (1000/1000 Ohm, 90°)

8

ASZ22.833 (1000/1000 Ohm, 135°)

Rotational Direction

Clockwise (when facing gear end. See Figure 6.)

R

(SQM5x.xxxxx

(requ ired when using SQ M5x.xxxxx

(if no R, rotati on i s ccw)

G, H, K , Z

x actuators require potentiometer ASZ…)

G, H, K, Z

x actuator s)

Figure 1. SQM5… Product Number Identification Legend.

Siemens Building Technologies, Inc. Page 5

Technical Instructions

Document No. 155-517P25

Rev. 1, July, 2000

Installation and

Operation

Instructions

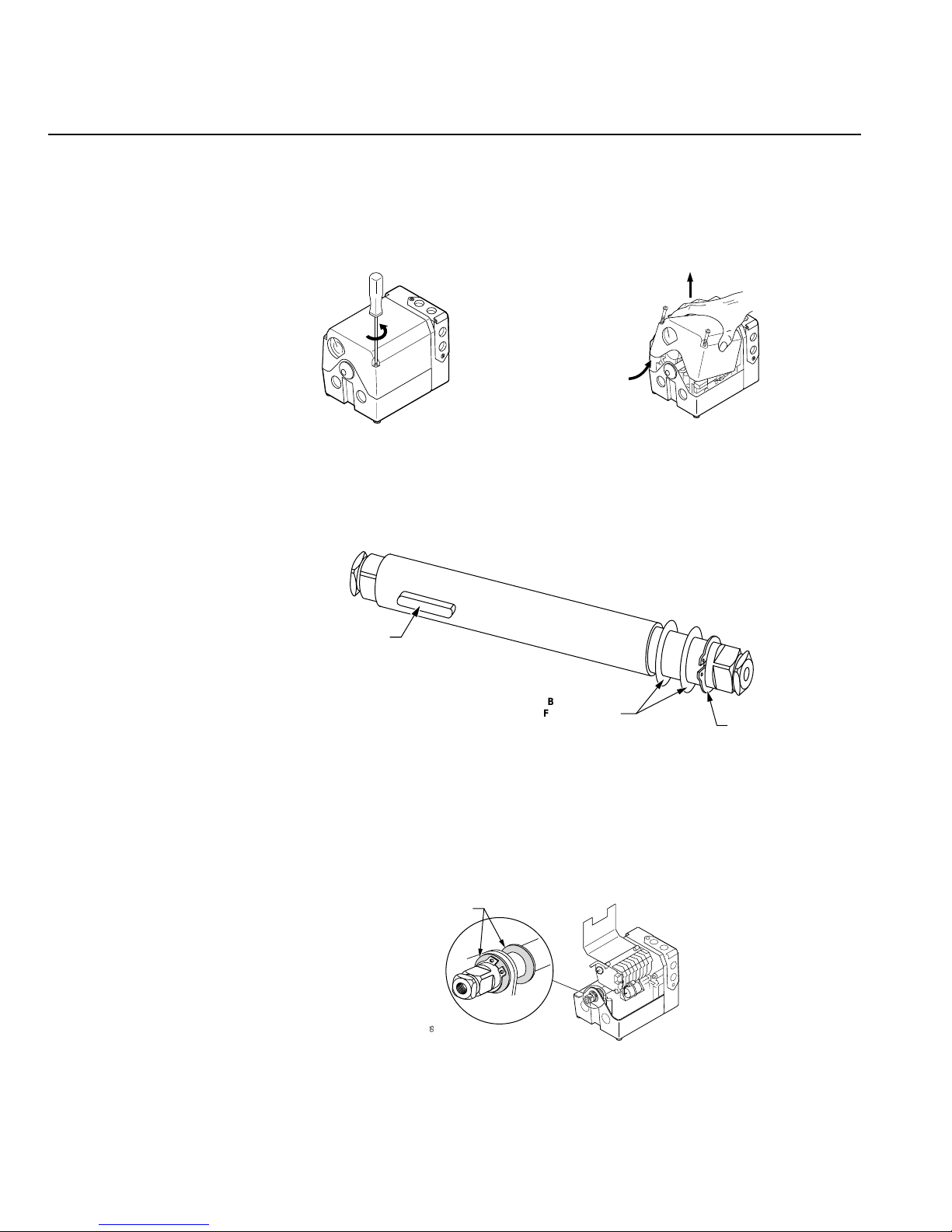

Shaft Installation

SQM5… actuators are generally shipped without the shaft installed. To install the

selected shaft:

1. Loosen the two screws on the actuator cover corners. See Figure 2

2. Lift the screws and raise the cover. See

EA0564R1

Figure 2.

3. Each shaft is supplied with two washers and a “C” clip. See

Figure 3.

EA0568R1

Figure 3.

Figure 4

.

. Using

spreading pliers, remove the “C” clip and the washers from the shaft.

KEY END

INSERT END

SHAFT KEY

EA0559R1

WASHERS ON

BOTH SIDES

OF THE BEARING

C-CLIP

Figure 4.

4. Insert the “insert end” of the shaft into the “gear end” of the actuator.

5. Push the shaft until the “insert end” reaches just short of the brass bushing at the

other end of the actuator.

6. Put one of the washers on the insert end of the shaft. See Figure 5

WASHERS

EA0569R1

.

Figure 5.

7. Line up the “shaft key” with the key slot on the “gear end” of the actuator and slide

the shaft until the “insert end” is completely through the brass bushing.

Page 6 Siemens Building Technologies, Inc.

SQM5… Reversing Actuators Technical Instructions

155-517P25

Rev. 1, July, 2000

8. Place the second washer onto the “insert end” of the shaft. Using spreading pliers,

install the “C” clip.

Rotational Direction

Verification

Actuator Mounting

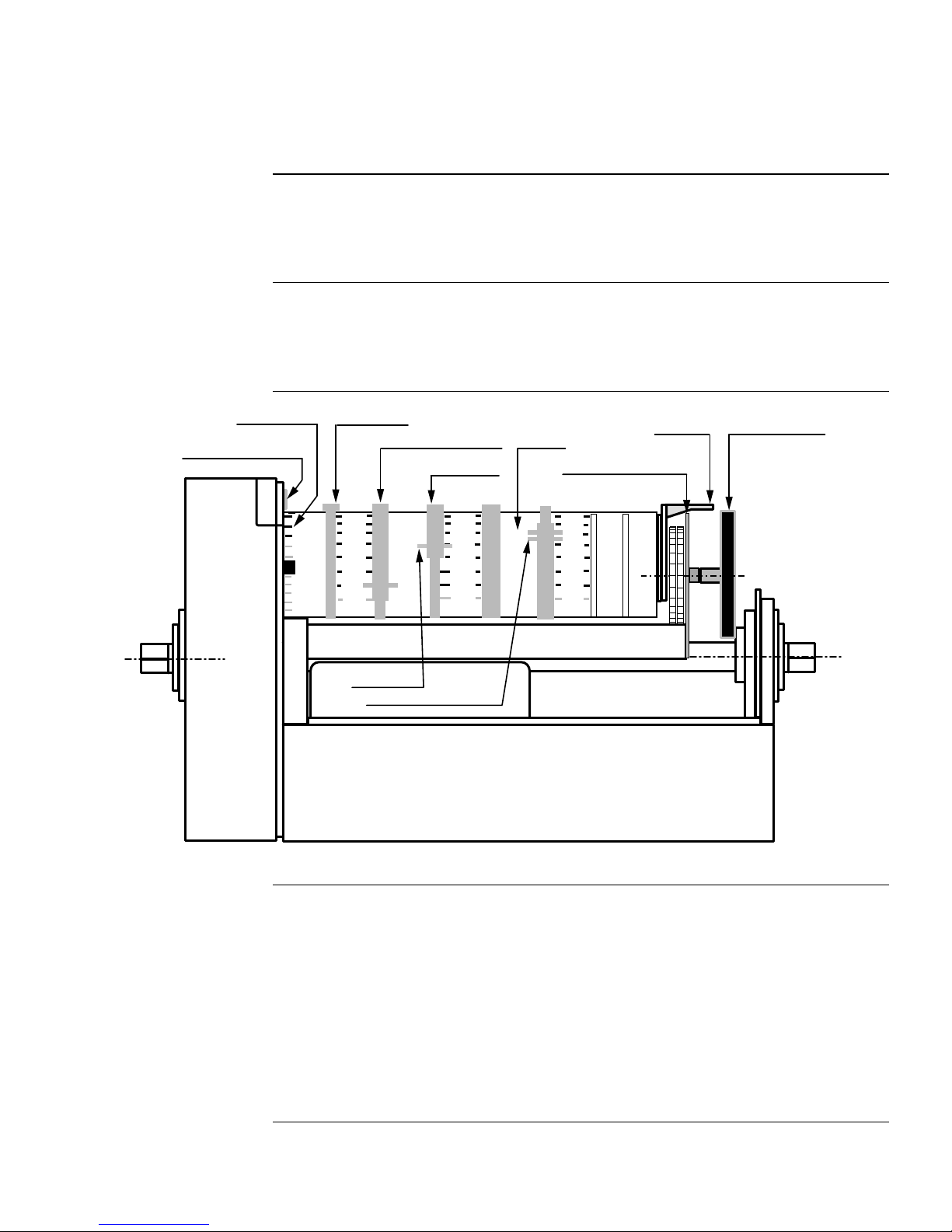

ACTUATOR POSITION

INDICATING POINTER

CAM DRUM

RELEASE BUTTON

Most SQM5… actuators are factory configured for counterclockwise (ccw), minimum to

maximum rotation when facing the gear end of the actuator, or clockwise (cw) rotation

when facing the other end of the actuator. SQM5.xxxxxxxR model numbers, ending with

R are factory configured for clockwise (cw) operation. To field reverse the direction of

rotation, see

Service Guide

, “Reversing Rotational Direction”.

SQM5… actuators can be mounted in any orientation using the four 1/4"-20 UNC tapped

holes located on the bottom corners of the actuator base. Optional base mounting

brackets are available. See Table 2 - Product Numbers for Accessories

. SQM5…

actuators can also be face mounted using self tapping screws in combination with the

various holes on the face of the actuator gear end.

ACTUATOR

POSITION SCALE

10

0

10

30

50

70

SWITCH CAM I

SET AT MAXIMUM

SET AT ZERO ("ECONOMY")

50

30

10

0

0

SWITCH CAM II

SWITCH CAM III

SET AT MINIMUM

50

30

10

0

0

CAM DRUM

ASZ... (1000 Ohm)

FEEDBACK POTENTIOMETER

50

30

10

0

0

BOARD

DIAL POINTER

ACTUATOR POSITION

INDICATING DIAL

GEAR END

EA0561R2

Figure 6. Component Identification on the Cam Drum Side of the SQM5… Actuator.

Switch Adjustment

See

Figure 6

.

SINGLE SWITCH

CAM POINTER

DOUBLE SWITCH CAM POINTER

All SQM5…actuators are factory wired with Switch I (maximum), Switch II (full closed

“economy position”) and Switch III (minimum). The individual switch cams I, II, and III

are factory set to 90°, 0° and 30° respectively.

NOTE: The single switch cam pointers are used together with the black scales when

configured for counterclockwise (ccw) operation.

The double switch cam pointers are used together with the red scales when

configured for clockwise (cw) operation.

The individual switch cams can be adjusted by hand or with the use of the tool

attached to the outside of the hinged switch terminal protection lid.

Siemens Building Technologies, Inc. Page 7

Technical Instructions

Document No. 155-517P25

Rev. 1, July, 2000

Switch Adjustment,

continued

Shaft Adjustment

See

Figure 6

.

Cam Drum Adjustment

See

Figure 6

.

Wiring

Electrical Connection

Grounding

NOTE: SQM5x.xxxxxAx actuators may be adjusted between 0° and 160°.

SQM5x.xxxxxx3 actuators have a 90° potentiometer and the switches must be

adjusted only between 0 and 90°. SQM5x.xxxxxx4 actuators have a 135°

potentiometer and the switches must be adjusted only between 0 and 135°.

The actuator shaft can be disengaged by pressing the silver shaft release button located

to the right of the auto/manual switch. The shaft can be manually r ota t e d when the

button is pressed. Once pressed, the button can be locked by pushing it slightly

upwards. After the shaft has been manually aligned, re-engage the shaft by pushing the

shaft release button downwards.

The cam drum must be manually aligned by pressing and holding the black cam drum

release button. The cam drum must be rotated until the “0” mark on the cam drum

position scale (left scale on the cam drum) is aligned with the gray actuator position

indicating pointer.

SQM5… actuators are equipped with two removable conduit connection plates located

on the upper corner of the gear housing. Each plate is provided with two threaded

connections for 1/2" NPSM conduit connectors. The use of flexible stranded wire is

recommended.

To avoid electro-magnetic interference, the SQM5… actuators must be grounded.

The ground terminal is located to the right of the auto/manual switch.

Wiring connections

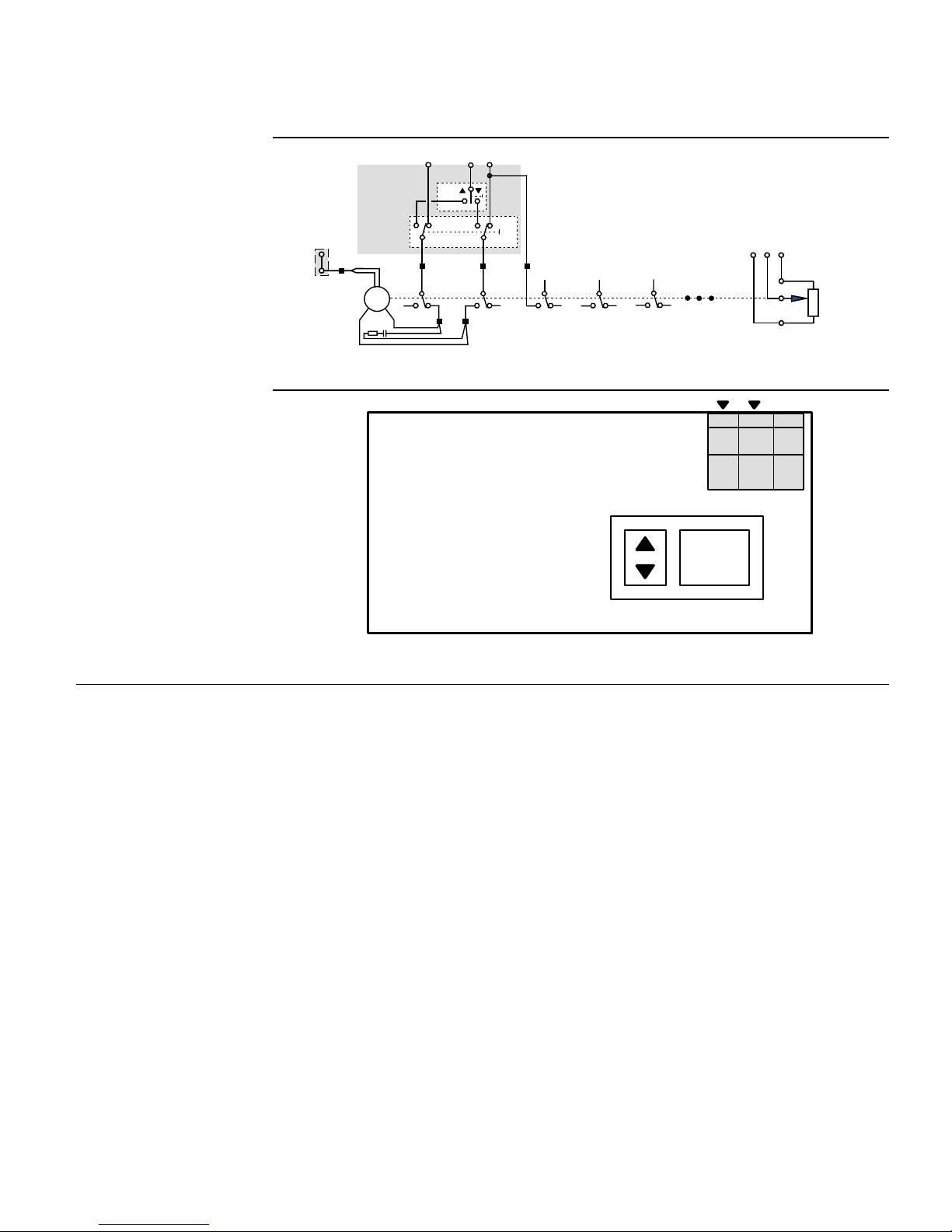

AGA56.1… circuit boards.

See Figures 7 and 8

.

NOTE: SQM5… actuators require a single source, single phase power supply.

Wiring connections vary depending on which AGA56…. circuit board is installed.

1. Connect line voltage to terminal L. Terminal L must be powered to enable manual

operation.

2. Connect neutral to the double terminal block with the two gray motor wires, located

on the left side of the gray switch housing.

3. Connect line voltage to terminal A to drive the actuator in the opening direction.

4. Connect line voltage to terminal Z to drive the actuator in the closing direction.

Page 8 Siemens Building Technologies, Inc.

SQM5… Reversing Actuators Technical Instructions

155-517P25

Rev. 1, July, 2000

Wiring, continued

N

EA0555R2

ALZ

IV

I

maximum

II

"economy"

III

minimum

auxilliary

4

AGA56.1A97

5

V

SW1

SW 2

1213

12

III

M

11 21

MAN

AUTO

III

12 22 13 23 14 1524 25

IV...VIII

3

Figure 7. Basic Functional Diagram of AGA56.1…

MAN.

0

AUTO.

ASZ...

AZ L

AGA56.41/42/43…

circuit boards.

See

Figures 9 and 10

AGA56.1A97

EA0554R2

Figure 8. AGA56.1A97 Terminal/Auto-Manual Board.

1. Connect line voltage to terminal L. Terminal L must be powered at all times.

2. Connect neutral to terminal N.

.

3. Connect ground to the terminal located to the right of the auto/manual switch.

4. For applications where terminals Z, ZL, A and 13 are not used, bridge terminal LR

and L. If any terminals Z, ZL, A or 13 are used, terminal LR must not be bridged with

terminal L. In addition, terminal LR must never be powered simultaneously with any

terminals Z, ZL, A or 13. However, terminal LR must be powered once Z, ZL, A and

13 are no longer powered and modulating operation is required (refer to application

guide for typical installation examples).

5. Connect the input control signal wires to the appropriate terminals.

Siemens Building Technologies, Inc. Page 9

Loading...

Loading...