Siemens SQM50 series Installation Instructions Manual

Installation Instructions

Document No. 129-401

January 18, 2008

SQM5… Reversing Actuators, with Multiple Analog Control Input

Signals

Product Description

Reversing actuator used to position flow control

valves, butterfly valves, dampers, or any application

requiring rotary motion with multiple analog input

signals.

Product Numbers

SQM5x.xxxRxZx for 4 to 20 mA, 0 to 135 ohm and

0 to 10 Vdc input signals

Actuator Torque:

SQM50.2… 90 in/lb

SQM50.3… 90 in/lb

SQM50.4… 140 in/lb

SQM53.4… 200 in/lb

SQM56.5… 310 in/lb

SQM56.6… 400 in/lb

SQM… motors allow torque on either end of the

AGA58.3 and AGA58.4 shafts.

NOTE: For detailed information, see Technical

Instructions (155-517P25).

Max Shaft Torque:

AGA58.1 200 in/lb

AGA58.3 220 in/lb

AGA58.4 270 in/lb

AGA58.7 400 in/lb

Caution Notations

CAUTION:

Equipment damage may occur

if you do not follow the

procedures as specified.

Installation

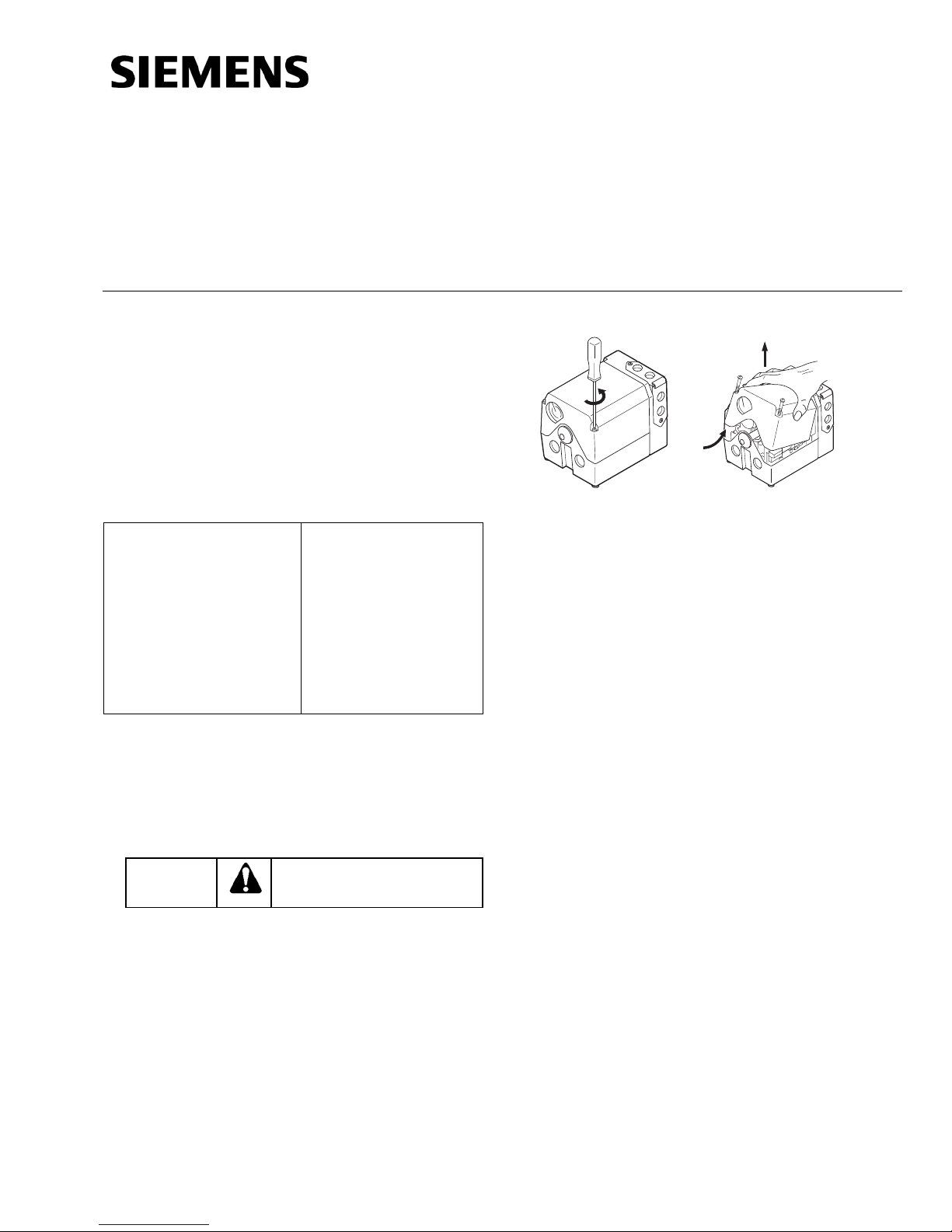

Cover Removal

EA0564R1

Figure 1. Figure 2.

EA0568R1

Rotational Direction Verification

Actuator model numbers that end with “R” are

factory configured for clockwise (cw), minimum to

maximum rotation when facing the gear end of the

actuator, or counterclockwise (ccw) rotation when

facing the other end of the actuator. The gear end of

the actuator is the side opposite of the visual

position indicator.

Actuator Mounting

SQM5… actuators can be mounted in any

orientation. Optional base mounting brackets are

available.

SQM5… actuators can also be face mounted using

self-tapping screws in combination with the various

holes on the face of the actuator gear end.

Switch Adjustment

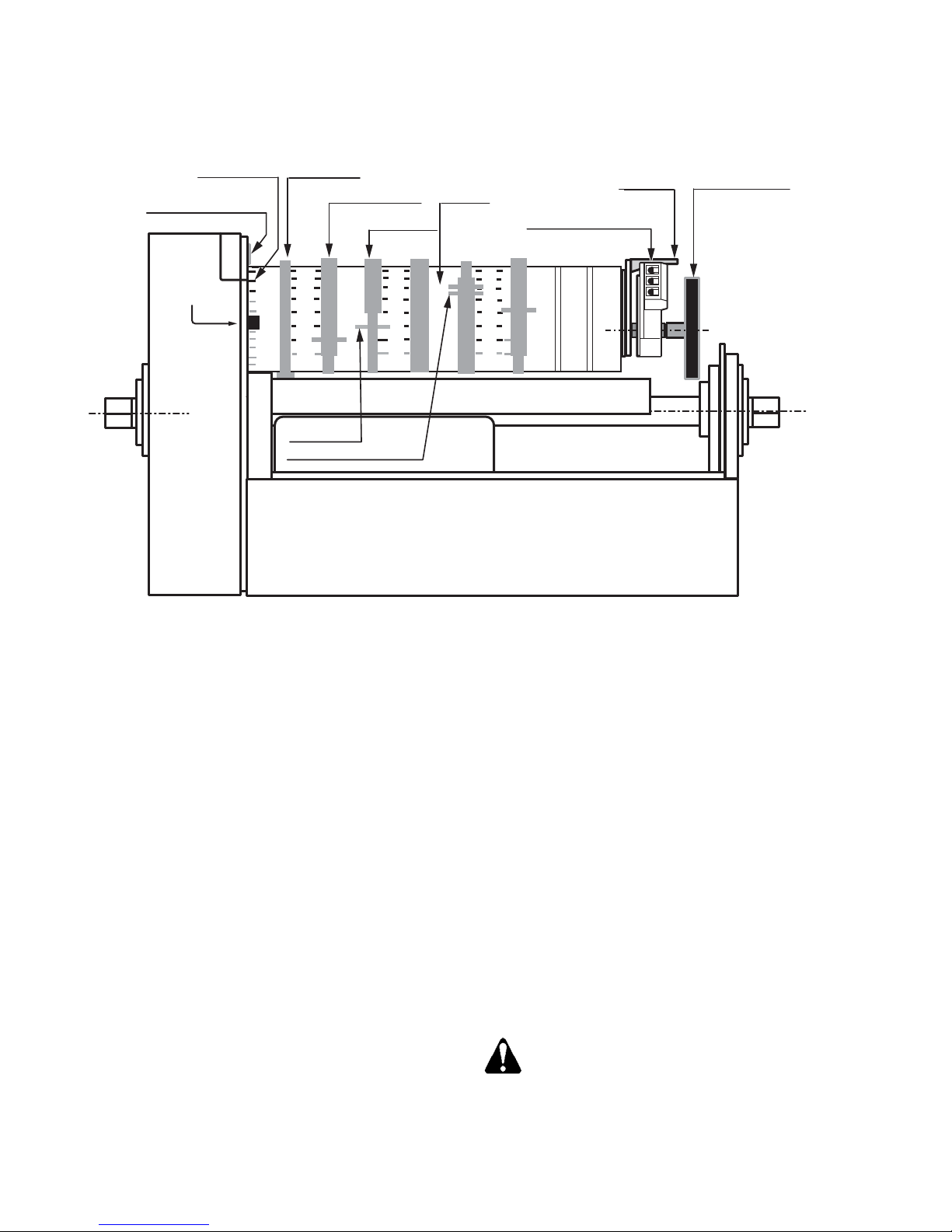

SQM5…actuators are factory-wired with Switch I

(maximum), Switch II (fully closed/economy position)

and Switch III (minimum/low-fire). The individual

switch cams I, II, and III are factory set to 90°, 0°

and 10°, respectively. See Figures 3 and 4.

Use a Phillips screwdriver to loosen the two screws

on the actuator cover corners. See Figure 1.

Lift the screws and raise the cover. See Figure 2.

Item Number 129-401, Rev. DA Page 1 of 6

Document No. 129-401

Installation Instructions

January 18, 2008

EA0561R3

ACTUATOR

POSITION SCALE

ACTUATOR POSITION

INDICATING POINTER

CAM DRUM

RELEASE BUTTON

GEAR END

SWITCH CAM I

SET AT MAXIMUM

SWITCH CAM II

SET AT ZERO ("ECONOMY")

50

10

0

30

10

30

10

0

50

0

70

SINGLE SWITCH

CAM POINTER

DOUBLE SWITCH CAM POINTER

SWITCH CAM III

SET AT MINIMUM

50

30

10

0

0

Figure 3. Component Identification on the Cam Drum Side of the SQM5…Actuator.

NOTE: The single switch cam pointers are used

together with the black scales when

configured for ccw operation.

The double switch cam pointers are used

together with the red scales when

configured for cw operation.

The individual switch cams can be adjusted by hand

or with the use of the tool attached to the outside of

the hinged switch terminal protection lid.

The adjustable range of the switches is limited by

the potentiometer range.

SQM5x.xxxRxZ3 actuators have a 90° potentiometer

and the switches must be adjusted between 0° and

90°.

SQM5x.xxxRxZ4 actuators have a 135°

potentiometer and the switches must be adjusted

between 0° and 135°.

Shaft Adjustment

The actuator shaft can be disengaged by pressing

the silver shaft release button. The shaft release

button is located above the grounding screw, under

the hinged terminal protection cover, and to the right

of the auto/manual switch. After pressing the shaft

release button in and slightly upward, the shaft can

ACTUATOR POSITION

CAM DRUM

ASZ... (1000 Ohm)

FEEDBACK POTENTIOMETER

50

30

10

0

0

DIAL POINTER

INDICATING DIAL

be manually rotated. After the shaft has been

manually aligned to the closed position, re-engage

the shaft by pushing the shaft release button

downwards.

Cam Drum Adjustment

Once the shaft has been set to the closed position,

the cam drum must be manually aligned by pressing

and holding the black cam drum release button (see

Figure 3). Rotate the cam drum until the “0” mark on

the actuator position scale (left scale on the cam

drum) is aligned with the gray actuator position

indicating pointer.

Position Indicating Dial Adjustment

The actual position of the SQM5… actuator is

indicated by the gray actuator position indicating

pointer (see

by the indicating dial through the housing’s window.

Ensure that the actuator position indicating dial is

aligned with the actuator position scale. If

necessary, rotate the dial in the clockwise direction.

Figure 3). The position is also displayed

CAUTION:

Turning the dial in the counterclockwise

direction may loosen the potentiometer

locking screw.

Page 2 of 6 Siemens Building Technologies, Inc.

Loading...

Loading...