Page 1

SQM5…

Reversing Actuators

ISO 9000 and 14000

REGISTERED FIRM

¤

Technical Instructions

Document No. 155-517P25

July 9, 2007

EA0511R1

Description

Features

SQM5... reversing actuators are used for the positioning of flow control valves, butterfly

valves, dampers, or any application requiring rotary motion. The SQM5… actuators

accommodate control input signals of 4 to 20 mA, 0 to 135 Ω, 0 to 10 Vdc, 0 to 20 mA,

position proportional and floating control. The available output signals include

4 to 20 mA, 0 to 135 Ω, 0 to 10 Vdc, 0 to 20 mA, and 0 to 1000 Ω. SQM5… actuators

are available with up to six internal, easily adjustable switches.

A selection of exchangeable circuit boards provide a variety of functions including

auto/manual selector switch, manual forward/reverse toggle switch, zero and span

adjustment, parallel or master/slave operation, split range control, input signal override,

and selectable electronic linearization.

The SQM5… is engineered for precision. It is particularly well suited for applications

requiring a high degree of modulating accuracy and repeatability. Drive shaft play is

limited to 0.3° with a modulating accuracy of 250 repositions through 90° of travel.

The SQM5… actuator may be mounted in any position. A selection of mounting

brackets and shafts provides installation flexibility and allows for the simple

replacement of most competitive actuators.

• Modulating accuracy of 250 repositions through 90°

• Two limit switches, plus up to four internal auxiliary switches

• Fully closed “economy position” switch

• Drive shaft and cam drum disengagement clutches

• Auto/manual switch, manual control forward/reverse toggle switch

• UL, CSA approved 24 and 110 Vac versions

• CE approved 220 Vac versions

• Field reversible clockwise (cw) or counterclockwise (ccw) operation

• Various torque ratings and running times available

• Selection of field exchangeable single-ended and dual-ended shafts

• Mounting brackets to replace competitive actuators

Siemens Building Technologies, Inc.

Page 2

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

Features, Continued

• Connections for both base and face mounting

• Low hysteresis actuator and potentiometer gearing

• Externally visible position indication

• Selection of input and output signals

• Zero and span adjustment

• Field exchangeable circuit boards and potentiometers

• Electronic damper linearization function

• Split range and selectable parallel or master/slave operation

• Adjustable input signal override function

Application

SQM5… actuators are uniquely suited for both industrial and commercial

applications. The high level of accuracy permits precise modulating control of

industrial process and process heating applications, often significantly enhancing

performance and product quality.

In commercial and industrial burner applications requiring high turndown and

reliable ignition, the auxiliary switches can be applied to create separate positions

for burner ignition and low fire. In dual fuel applications, additional switches can be

used to create separate high fire, low fire and ignition positions for each fuel. The

economy position switch is used to drive the actuator to the full closed position

when the burner is off.

In all applications, commissioning is simplified. Shaft and cam drum disengagement

clutches allow for the quick manual alignment of the actuator shaft and switch

cams. The forward/reverse toggle switch in combination with the auto/manual

selector switch provides direct manual control.

Page 2 Siemens Building Technologies, Inc.

Page 3

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Table Of Contents

Application Page 2 Product Numbers

Product numbers for pre-assembled UL/CSA/CE-approved

actuators, Table 1 Page 4

Product numbers for accessories, Table 2 Page 5

SQM5… Product Number Identification Legend Page 6

Installation and Operating Instructions

Shaft Installation Page 7

Rotational Direction Verification Page 8

Actuator Mounting Page 8

Switch Adjustment Page 8

Shaft Adjustment Page 9

Cam Drum Adjustment Page 9

Wiring

Electrical Connection Page 9

Grounding Page 9

Wiring Connections

AGA56.1… circuit boards Page 10

AGA56.41/42/43… circuit boards Page 11

AGA56.9… circuit boards Page 13

Commissioning

Modulation Adjustment Page 15

Zero Adjustment Page 15

Span Adjustment Page 15

Cover Installation Page 16

Features

SQM5x.xxxxxZx actuators Page 16

SQM5x.xxxxxGx actuators Page 18

SQM5x.xxxxxHx actuators Page 18

SQM5x.xxxxxKx actuators Page 18

SQM5x.xxxxxAx actuators Page 18

Service Guide

Reversing Rotational Direction Page 18

Shaft Installation Page 20

Circuit Board Installation Page 20

AGA56.41/42/43… Page 20

AGA56.9A Page 22

AGA56.1A97 Page 24

Potentiometer Removal/Installation Page 25

Specification Data Page 26

Dimensions Page 29

Siemens Building Technologies, Inc. Page 3

Page 4

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

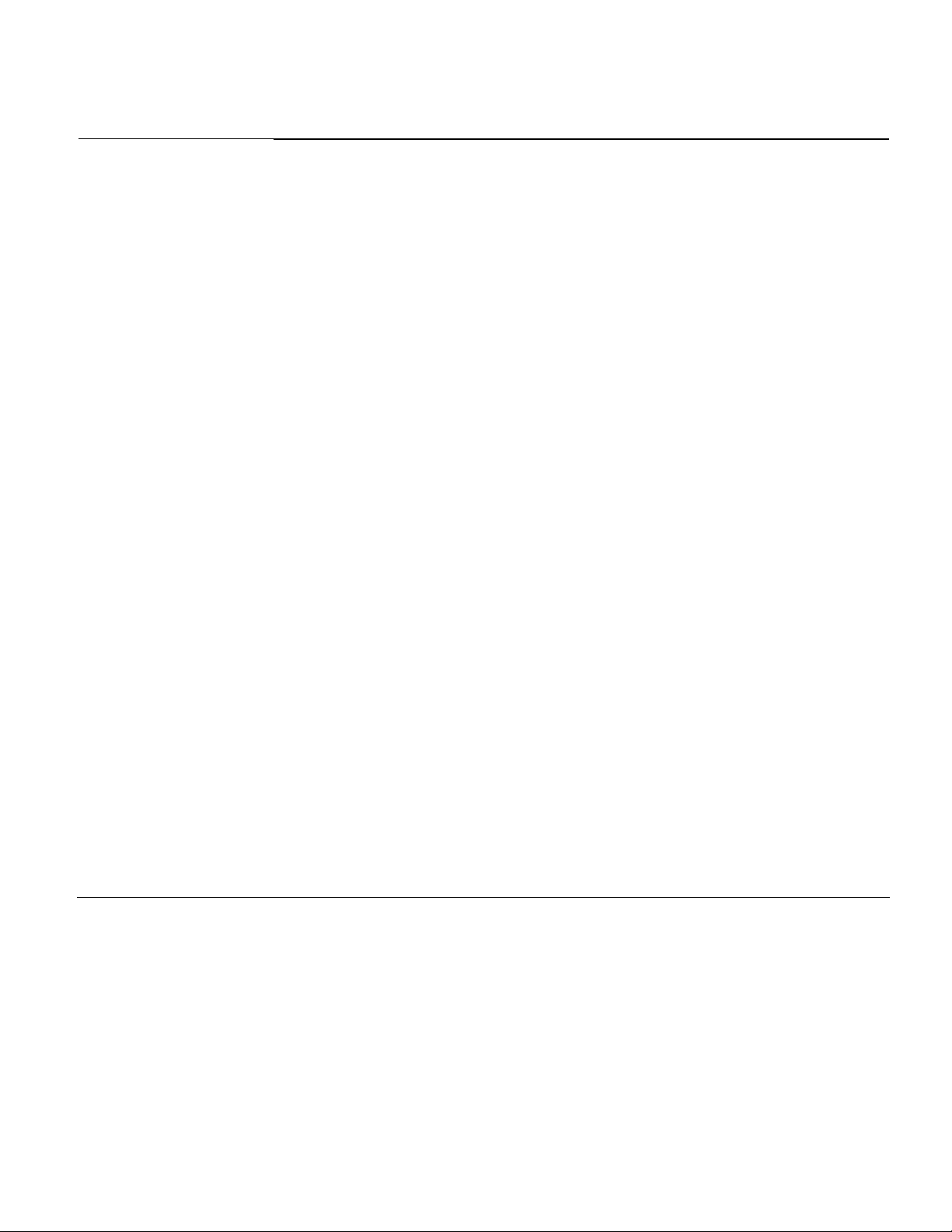

Product Numbers

1. Torque will vary with the selection of the shaft. See Specifications.

2. Running time for 135° Æ multiply by 1.5. For 50 Hz Æ multiply by 1.2

3. SQM5x.xxxxxZx models also accept a 0 to 20 mA input signal.

1

Torque

[lb-in] 90°@ 60

90 8 ccw x x SQM50.261R1G3

90 8 cw x x SQM50.261R1G3R

90 8 ccw x SQM50.264R1A SQM50.264R2A

90 8 cw x SQM50.264R1A0R

90 8 ccw x SQM50.264R1A3

90 8 cw x x SQM50.264R1G3R

90 8 ccw x x SQM50.264R1G4

140 12 ccw x x SQM50.361R1G3

140 12 cw x x SQM50.361R1G3R

140 12 ccw x x SQM50.361R1G7

140 12 ccw x x SQM50.364R1G3

140 12 cw x x SQM50.364R1G3R

140 25 ccw x SQM50.461R1A

140 25 ccw x SQM50.461R1A3

140 25 ccw x x SQM50.461R1G3

140 25 cw x x SQM50.461R1G3R

140 25 ccw x x SQM50.461R1H3

140 25 ccw x x x x SQM50.461R1Z3

140 25 ccw x x x x SQM50.461R1Z7

140 25 ccw x SQM50.464R1A SQM50.464R8A

140 25 cw x SQM50.464R1A0R

140 25 ccw x SQM50.464R1A3

140 25 cw x SQM50.464R1A3R

140 25 ccw x x SQM50.464R1G3 SQM50.464R8G3

140 25 cw x x SQM50.464R1G3R SQM50.464R2G3R

140 25 ccw x x SQM50.464R1G7

140 25 cw x x SQM50.464R1G7R

140 25 ccw x x SQM50.464R1H3 SQM50.464R8H3

140 25 ccw x x x x SQM50.464R1Z3 SQM50.464R2Z3 SQM50.464R8Z3

200 25 ccw x SQM53.464R1A

200 25 ccw x SQM53.464R1A3

200 25 ccw x x SQM53.464R1G3

200 25 ccw x x SQM53.464R1G7

200 25 cw x x SQM53.464R1G7R

200 25 ccw x x x x SQM53.464R1Z3 SQM53.464R2Z3

200 25 ccw x x x x SQM53.467R1Z3

200 25 cw x x x x SQM53.467R1Z3R

200 25 ccw x SQM53.467R2A3

310 37 ccw x SQM56.564R1A

310 37 ccw x x SQM56.564R1G4

310 37 ccw x x SQM56.564R1G7

310 37 ccw x x SQM56.564R1H4

310 37 ccw x x x x SQM56.564R1Z3

400 50 ccw x x SQM56.664R1G3

400 50 ccw x x x x SQM56.664R1Z3

400 50 cw x SQM56.667R1A3R

400 50 ccw x x SQM56.667R1G3

400 50 cw x x SQM56.667R1G7R

400 50 ccw x x x x SQM56.667R1Z3

Running

2

Time

Hzsec

Rotation

direction

Table 1. Product Numbers for Pre-assembled Actuators.

Input Control Signals

Line

Voltage

4-20 mA

Ω

0-135

3

110 V 220 V 24 V

0-10 Vdc

Product Number

Page 4 Siemens Building Technologies, Inc.

Page 5

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Table 2. Product Numbers for Accessories.

Electronic Circuit Boards

AGA56.1A97 24-250 Vac (A) board for SQM5x.xxxxxAx

AGA56.9A87 24 Vac (Z) board for SQM5x.xxxxxZx

AGA56.9A17 110 Vac (Z) board for SQM5x.xxxxxZx

AGA56.9A27 220 Vac (Z) board for SQM5x.xxxxxZx

AGA56.41A87 24 Vac (G) board for SQM5x.xxxxxGx

AGA56.41A17 110 Vac (G) board for SQM5x.xxxxxGx

AGA56.41A27 220 Vac (G) board for SQM5x.xxxxxGx

AGA56.42A87 24 Vac (H) board for SQM5x.xxxxxHx

AGA56.42A17 110 Vac (H) board for SQM5x.xxxxxHx

AGA56.42A27 220 Vac (H) board for SQM5x.xxxxxHx

AGA56.43A87 24 Vac (K) board for SQM5x.xxxxxKx

AGA56.43A17 110 Vac (K) board for SQM5x.xxxxxKx

AGA56.43A27 220 Vac (K) board for SQM5x.xxxxxKx

See Product Number Identification Legend, Figure 1.

Mounting Brackets & Adapters

AGA57.3 for replacement of Honeywell MOD III, IV

actuators

AGA57.4 for replacement of Honeywell M640/740/940 and

Barber Colman EA20/40/50/60 actuators. Directly

adaptable to Eclipse butterfly valves.

ASK33.9 mounting kit for direct attachment to Siemens

VKF41... butterfly valve. (Shaft AGA58.1

required)

Shafts

AGA58.1 10 mm round with key. Gear end only.

AGA58.2 12 mm round with key. Gear end only.

AGA58.3 9 mm square. Dual-ended.

AGA58.4 3/8 inch square. Dual-ended.

AGA58.7 14 mm round with key. Gear end only.

For exact shaft sizes, see Dimensions.

Crank Arm, Push Rods

338 031 Crank arm kit. Includes two crank arms for

connecting the AGA58.4 shaft to a ∅ 1/2-inch

damper shaft with two ball joints. (Does not include

push rod.)

338 041 ∅ 5/16" damper push rod, 12 inches long.

338 042 ∅ 5/16" damper push rod, 15 inches long.

338 043 ∅ 5/16" damper push rod, 18 inches long.

338 044 ∅ 5/16" damper push rod, 24 inches long.

338 045 ∅ 5/16" damper push rod, 36 inches long.

338 046 ∅ 5/16" damper push rod, 48 inches long.

Potentiometers

ASZ12.803 and ASZ12.30 1000Ω, 90°

ASZ12.833 and ASZ12.33 1000Ω, 135°

ASZ22.803 and ASZ22.30 1000/1000Ω double

potentiometer, 90°

ASZ22.833 and ASZ22.33 1000/1000Ω double

potentiometer, 135°

ASZ16.703 135Ω, 90° (wire wound)

ASZ16.733 135Ω, 135° (wire wound)

ASZ66.733 135Ω/135Ω, double potentiometer 135°

(wire wound)

Additional potentiometer models available. See

Siemens technical data sheet 7921.

Siemens Building Technologies, Inc. Page 5

Page 6

Technical Instructions SQM5… Reversing Actuators

y

f

(

)

(SQ

G

SZ…)

A

(1000 O

G

)

Clockwi

Fi

6

)

Document No. 155-517P25

July 9, 2007

Product Number Identification Legend

For actuator identification only. To select product numbers for ordering, see Table 1.

Actuator famil

Torque in-lb @ 60 (50) Hz.

Running time for 90°

Number of SPDT switches

Shaft selection

Approvals

Operating voltage (Vac @50-60 Hz)

Internal circuit board

Potentiometer

90 for 8 (10) sec. running time

0

140 for 12 (15), 25 (30), 37 (45) sec.

0

200 for 25 (30) sec.

3

310 for 37 (45) sec.

6

400 for 50 (60), 75 (90)sec.

6

Not all actuator running tim es are

available in each torque.

Refer to table 1

60 Hz.

8 sec.

2

12 sec.

3

25 sec.

4

37 sec.

5

50 sec.

6

2 limit and 4 auxiliary switches

6

no sha

0

round 10 mm, single ended (for use with VKF41... butterfly valves)

1

square 3/8 inch, dual ended

4

round 14 mm, single ended

7

UL recognized, CSA certified

R

110-120 Vac

1

220-240 Vac

2

24 Vac

8

AGA56.1A97 (position proportional control)

AGA56.41A... (4 to 20 mA input)

G

AGA56.42A... (0 to 135 Ohm input)

H

AGA56.43A... (0 to 10 Vdc input)

K

AGA56.9... (all inputs/outputs, linearization, split ranging, override and pre-set positioning)

Z

ASZ12.30 (1000 ohm, 90°)

3

ASZ12.33 (1000 Ohm, 135°)

4

ASZ22.30 (1000/1000 Ohm, 90°)

7

ASZ22.33 (1000/1000 Ohm, 135°)

8

ASZ16.703 (135 Ohm, 90°)

B

ASZ16.733 (135 Ohm, 135°)

C

ASZ66.733 (135/135 Ohm, 135°)

L

Figure 1. SQM5… Product Number Identification Legend.

SQM50 .4 8 0 R 1 Z 3 R

50 Hz.

10 sec.

2

15 sec.

3

30 sec.

4

45 sec.

5

60 sec.

6

t

shaft must be ordered separately

M5x.xxxxx

hm required when using SQM5x.xxxxx

, H, K , Z

x actuators require potentiomet er A

, H, K, Z

x actuators

Rotational Direction

R

se (when facing gear end. See

(Product numbers ending without R are ccw)

gure

.

Page 6 Siemens Building Technologies, Inc.

Page 7

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Installation and

Operation

Instructions

SQM5… actuators are sometimes shipped without the shaft installed. To install the

selected shaft:

1. Loosen the two screws on the actuator cover corners. See Figure 2.

2. Lift the screws and raise the cover. See Figure 3.

Shaft Installation

EA0564R1

Figure 2.

EA0568R1

Figure 3.

3. Each shaft is supplied with two washers and a “C” clip. See Figure 4. Using

spreading pliers, remove the “C” clip and the washers from the shaft.

KEY END

INSERT END

SHAFT KEY

WASHERS ON

BOTH SIDES

OF THE BEARING

EA0559R1

C-CLIP

Figure 4.

4. Insert the “insert end” of the shaft into the “gear end” of the actuator.

5. Push the shaft until the “insert end” reaches just short of the brass bushing at the

other end of the actuator.

6. Put one of the washers on the insert end of the shaft. See Figure 5.

WASHERS

EA0569R1

Figure 5.

7. Line up the “shaft key” with the key slot on the “gear end” of the actuator and slide

the shaft until the “insert end” is completely through the brass bushing.

8. Place the second washer onto the “insert end” of the shaft. Using spreading pliers,

install the “C” clip.

Siemens Building Technologies, Inc. Page 7

Page 8

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

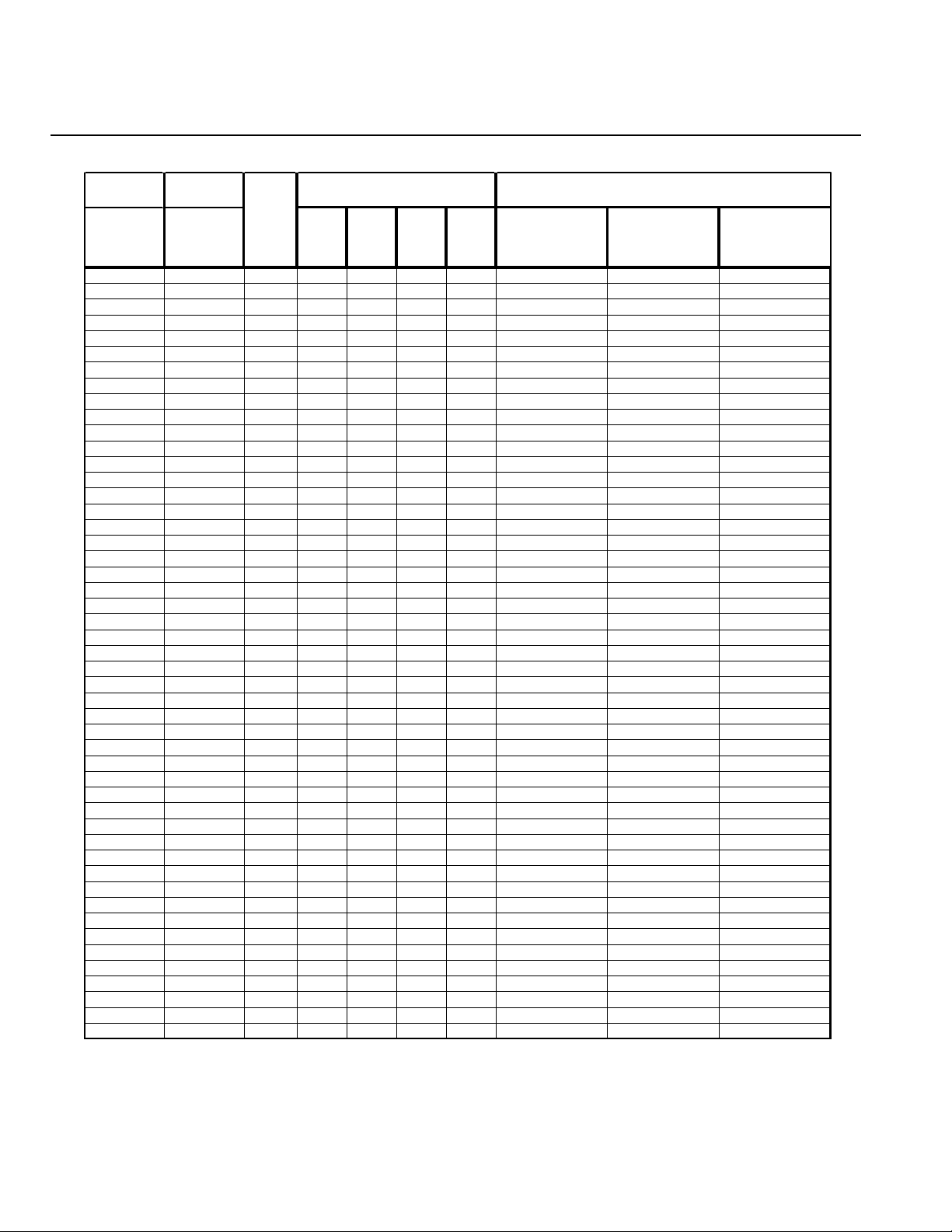

Rotational Direction

Verification

Actuator model numbers that end with “R” are factory configured for clockwise (cw),

minimum to maximum rotation when facing the gear end of the actuator, or

counterclockwise (ccw) rotation when facing the other end of the actuator. The gear end

of the actuator is the side opposite of the visual position indicator.

To field reverse the direction of rotation, see Service Guide, “Reversing Rotational

Direction”.

Actuator Mounting

ACTUATOR POSITION

INDICATING POINTER

CAM DRUM

RELEASE BUTTON

GEAR END

SQM5… actuators can be mounted in any orientation using the four 1/4"-20 UNC

tapped holes located on the bottom corners of the actuator base. Optional base

mounting brackets are available. See Table 2.

SQM5… actuators can also be face mounted using self tapping screws in combination

with the various holes on the face of the actuator gear end.

ACTUATOR

POSITION SCALE

SWITCH CAM I

SET AT MAXIMUM

SWITCH CAM II

SET AT ZERO ("ECONOMY")

50

10

0

30

10

30

10

0

50

0

70

SINGLE SWITCH

CAM POINTER

DOUBLE SWITCH CAM POINTER

SWITCH CAM III

SET AT MINIMUM

50

30

10

0

0

CAM DRUM

ASZ... (1000 Ohm)

FEEDBACK POTENTIOMETER

50

30

10

0

0

DIAL POINTER

ACTUATOR POSITION

INDICATING DIAL

EA0561R3

Figure 6. Component Identification on the Cam Drum Side of the SQM5… Actuator.

Switch Adjustment

See Figure 6.

All SQM5…actuators are factory wired with Switch I (maximum), Switch II (fully closed

“economy position”) and Switch III (minimum). The individual switch cams I, II, and III

are factory set to 90°, 0° and 10° respectively.

NOTE: The single switch cam pointers are used together with the black scales when

configured for counterclockwise (ccw) operation.

The double switch cam pointers are used together with the red scales when

configured for clockwise (cw) operation.

The individual switch cams can be adjusted by hand or with the use of the tool

attached to the outside of the hinged switch terminal protection lid.

Page 8 Siemens Building Technologies, Inc.

Page 9

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Switch Adjustment,

Continued

NOTE: If a potentiometer is installed, the adjustable range of the switches depends

on the range of the potentiometer.

SQM5x.xxxxxAx actuators may be adjusted between 0° and 160°.

SQM5x.xxxxxx3 actuators have a 90° potentiometer and the switches must be

adjusted only between 0 and 90°.

SQM5x.xxxxxx4 actuators have a 135° potentiometer and the switches must

be adjusted only between 0 and 135°.

Shaft Adjustment

See Figure 6.

Cam Drum Adjustment

See Figure 6.

Position Indicating Dial

Adjustment

Wiring

Electrical Connection

The actuator shaft can be disengaged by pressing the silver shaft release button. The

button is located above the grounding screw, under the hinged terminal protection

cover, and to the right of the auto/manual switch. After pressing the shaft release button

in and slightly upward, the shaft can be manually rotated. After the shaft has been

manually aligned to the closed position, re-engage the shaft by pushing the shaft

release button downwards.

Once the shaft has been set, the cam drum must be manually aligned by pressing and

holding the black cam drum release button (see Figure 6). Rotate the cam drum until

the “0” mark on the actuator position scale (left scale on the cam drum) is aligned with

the gray actuator position indicating pointer.

The actual position of the SQM5… actuator is indicated by the gray actuator position

indicating pointer (see Figure 6). The position is also displayed by the indicating dial

through the housing’s window. Ensure that the actuator position indicating dial is

aligned with the actuator position scale. If necessary, rotate the dial in the clockwise

direction.

CAUTION:

Turning the dial in the counterclockwise direction may loosen the

potentiometer locking screw.

SQM5… actuators are equipped with two removable conduit connection plates located

on the upper corner of the gear housing. Each plate is provided with two threaded

connections for 1/2" NPSM conduit connectors. The use of flexible stranded wire is

recommended.

Grounding

CAUTION:

To avoid electro-magnetic interference, the SQM5… actuators must be

grounded.

The ground terminal is located to the right of the auto/manual switch.

Disconnect the circuit board wire marked 51 during high voltage testing.

Reconnect it to the grounding terminal after the test.

Siemens Building Technologies, Inc. Page 9

Page 10

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

Wiring Connections

NOTE: SQM5… actuators require a single source, single phase power supply.

Wiring connections vary depending on which AGA56…. circuit board is installed.

AGA56.1… circuit boards.

See Figures 7 and 8.

Manual Operation

1. Set the AUTO/MAN switch in the MAN position.

2. Connect ground to the screw located below the shaft release button.

3. Connect neutral to the double terminal block, located on the left side of the gray

switch housing.

4. Only terminal "L" must be to enable manual operation. The actuator can now be

driven to the maximum position (switch cam I) or the fully closed "economy

position" (switch cam II) by using the toggle switch located to the left of the

AUTO/MAN switch.

Automatic Operation

1. Set the AUTO/MAN switch in the AUTO position.

2. Connect ground to the screw located below the shaft release button.

3. Connect neutral to the double terminal block located on the left side of the gray

switch housing.

4. Connect line voltage to terminal A to drive the actuator in the opening direction.

5. Connect line voltage to terminal Z to drive the actuator in the closing direction.

CAUTION:

Do not power terminals A and Z simultaneously. Actuator damage will occur.

A

L

Z

AGA56.1A97

51

EA0555R3

N

shown in

auto position

M

MAN AUTO

1213

12

I

11 21

II

12 22 13 23

21 12

wire leads

III

3

actuator switch

Maximum/High fire

I

II

"Economy"/Fully closed

III

Minimum/Low fire

Auxilliary

IV...VI

4

IV

14

24

5

V

25

15

6

VI

26

16

c

b

a

ASZ...

(1000 Ohm)

Figure 7. Basic Functional Diagram of AGA56.1…

Page 10 Siemens Building Technologies, Inc.

Page 11

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Wiring, Continued

AGA56.41/42/43…

Circuit Boards.

See Figures 9 and 10.

AZ L

AZ L

MAN.

0

AUTO.

AGA56.1A97

EA0554R3

Figure 8. AGA56.1A97 Terminal/Auto-Manual Board.

Manual Operation

1. Set the AUTO/MAN switch in the MAN position.

2. Connect ground to the screw located below the shaft release button.

3. Connect neutral to terminal N.

4. Only terminal "L" must be powered to enable manual operation. The actuator can

now be driven to the maximum (high fire) position (switch cam I) or the fully closed

"economy position" (switch cam II) by using the toggle switch located to the left of

the AUTO/MAN switch.

Automatic Operation

1. Set the AUTO/MAN switch in the AUTO position.

2. Connect ground to the screw located below the shaft release button.

3. Connect neutral to terminal N.

4. Connect line voltage at all times to terminal L to provide power to the electronic

circuit board.

5. Connect line voltage to terminal LR to provide power when modulating. Connect

line voltage to Terminal LR only after removing power on terminals A and Z

(otherwise actuator damage may result).

6. Connect line voltage to terminal A to drive the actuator to the maximum (high fire

purge) position.

Once the maximum position is reached, terminal 11 (on switch I) will be energized

to provide position feedback.

7. Connect power to terminal ZL to drive the actuator to the minimum (low-fire)

position. Once the minimum position is reached, terminal 23 (on switch III) will be

energized to provide position feedback. Adjustment of switch III will determine the

low-fire stop position. Switch III (low fire) must be set at a higher position than

switch II (fully closed). Terminal ZL may be energized only after removing power

from terminals A, Z, 13, and LR.

8. Connect line voltage to terminal Z to drive the actuator to the fully closed/economy

position (switch II).

9. Connect the input control signal wires to the appropriate terminals. See Figure 9.

CAUTION:

Do not power terminals A and Z simultaneously. Actuator damage will

occur.

Siemens Building Technologies, Inc. Page 11

Page 12

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

Wiring, Continued

EA0556R5

51

N

EA0553R4

N

shown in

auto position

M

OPE MAX MIN

MAX

MIN

AGA56.41A...

A

Z

L

ZL

13

MAN AUTO

1 2 13 3

123

I II III

11 21

12 22 13 23

21 12

wire leads

Figure 9. Basic Functional Diagram of AGA56.4…

Y- Y+

"G" Board 4 to 20mA

13ZL

LRNL

MAN.

0

AUTO.

LR

actuator switch

Maximum/High fire

I

II

"Economy"/Fully closed

III

Minimum/Low fire

Auxilliary

IV...VI

4

IV

14

24

ZA

AGA56.4...

REG

MAX

MIN

MIN

MAX

Y

for ccw

blue

5

V

25

15

6

VI

26

16

rotation

black

brown

c

b

a

OPE MAX MIN ZALR13NZL L

MAX

MIN

AGA56.42A...

EA0552R4

OPE

MAX

MIN

MAX

MIN

ASZ...

(1000 Ohm)

YM U

0

"H" Board 0 to 135 ohm

Y+

Y-

U

M

Y

M

Y

MAN.

AUTO.

AGA56.41...

("G" board 4...20 mA)

(+2 V)

B

W

R

AGA56.42...

135 Ohm

("H" board

0-135 Ohm)

0...2 V

AGA56.43...

("K" board 0...10 V)

OPE MAX MIN

AGA56.43A...

EA0578R4

YM

M

MAX

MIN

"K" Board 0 to 10V

3

Y

Pos L ZA

L

0

N

LR13NZL A Z L

MAN.

AUTO.

L

Z

Figure 10. AGA56.41/42/43… Terminal and Trim Potentiometer Boards.

Page 12 Siemens Building Technologies, Inc.

Page 13

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

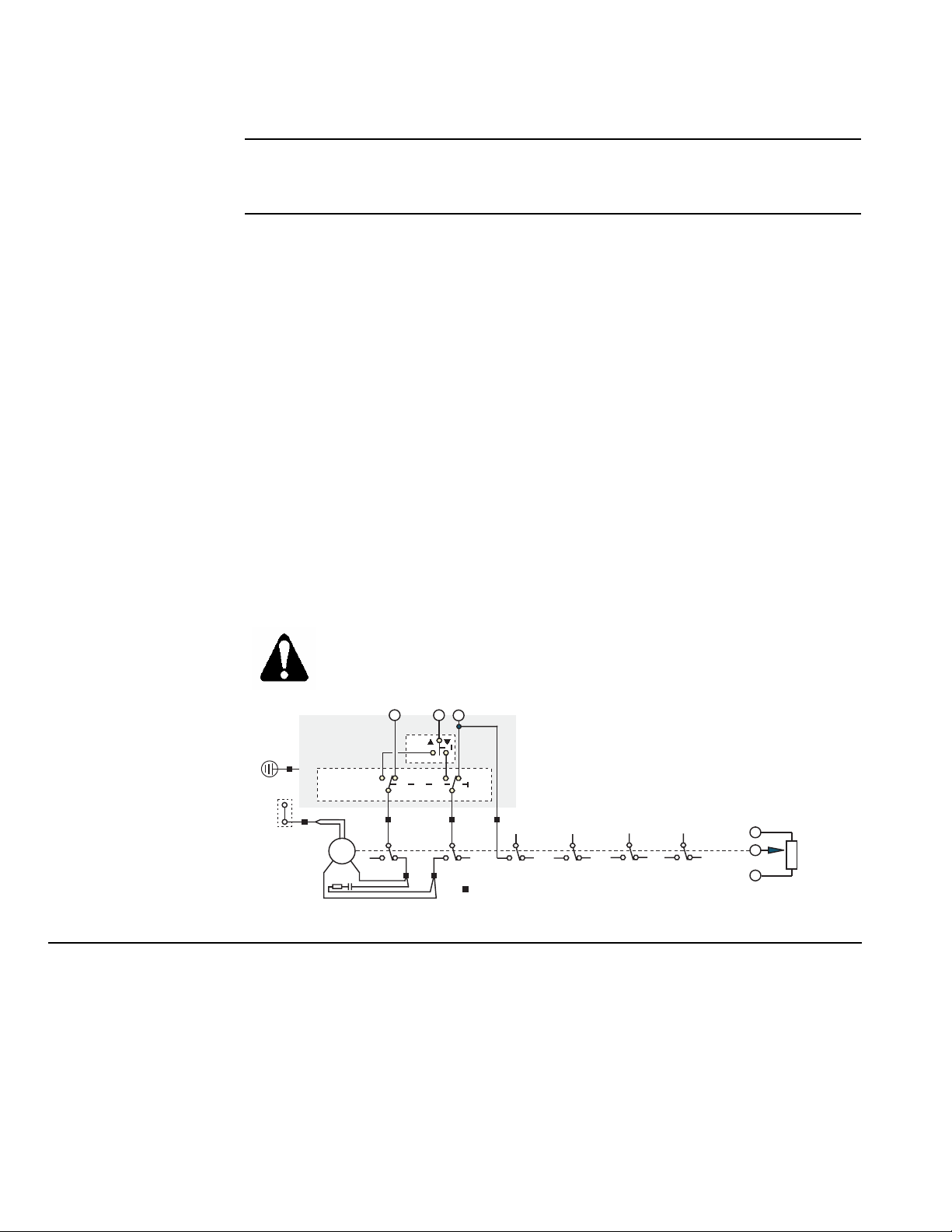

AGA56.9… Circuit

Boards

See Figures 11 and 12.

Manual Operation

1. Set the AUTO/MAN switch in the MAN position.

2. Connect ground to the screw located below the shaft release button.

3. Connect neutral to terminal N.

4. Only terminal "L" must be powered to enable manual operation. The actuator can

now be driven to the maximum (high fire) position (switch cam I) or the fully closed

"economy position" (switch cam II) by using the toggle switch located to the left of

the AUTO/MAN switch.

Automatic Operation

1. Set the AUTO/MAN switch in the AUTO position.

2. Connect ground to the screw located below the shaft release button.

3. Connect neutral to terminal N.

4. Connect line voltage at all times to terminal L to provide power to the electronic

circuit board.

5. Connect line voltage to terminal L1 to provide power when modulating. Connect line

voltage to terminal L1 only after removing power on terminals A and Z (otherwise

actuator damage may result).

6. Connect line voltage to terminal A to drive the actuator to the maximum (high fire

purge) position. Once the maximum position is reached, terminal 11 (on switch I)

will be energized to provide position feedback.

7. Connect power to terminal ZL to drive the actuator to the minimum (low-fire)

position. Once the minimum position is reached, terminal 23 (on switch III) will be

energized to provide position feedback. Adjustment of switch III will determine the

low-fire stop position. Switch III (low fire) must be set at a higher position than

switch II (fully closed). Terminal ZL may be energized only after removing power

from terminals A, Z, 13, and LR.

8. Connect line voltage to terminal Z to drive the actuator to the fully closed/economy

position (switch II).

9. Connect the input control signal wires to the appropriate terminals. See Figure 11.

CAUTION:

Do not power terminals A and Z simultaneously. Actuator damage will

occur.

Siemens Building Technologies, Inc. Page 13

Page 14

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

Wiring, Continued

A

1 2 13 3

123

I

11 21

51

EA0557R6

N

shown in

auto position

N

M

Z

L

MAN AUTO

II

12 22 13 23

21 12

wire leads

ZL

III

1

L

actuator switch

I

II

III

IV...VI

45

IV V

141524 25

P

AGA56.9...

POS

POS

0...3

Y

POS

REG

MAX

MIN

MIN MAX

Maximum/High fire

"Economy"/Fully closed

Minimum/Low fire

Auxilliary

0...3

Y

6

VI

26

16

OPE

MAX

MIN

1

2

1

2

20 mA

25% 50%

SHIFT

18 mA

16 mA

14 mA

0 or 12 mA

10 mA

8 mA

ZF =

6 mA

4 mA

75%

MAX

0...3

Y

ZF

M

U

4

M

0

Y

M

3

Y

M

1

Y

M

Y2

U

3

U

2

U

1

M

4...20 mA

(+2 V)

B

135 Ohm

W

0...2 V

R

4...20 mA

0...10 V

0...20 mA

4...20 mA

0...20 mA

0...10 V

common

LIN

MAX

75%

50%

25%

MIN

J1

LIN

MIN

MIN

MAX

0...3

Y

J2

for ccw

rotation

black

blue

brown

c

b

a

ASZ...

(1000 Ohm)

EA0558R3

Figure 11. Basic Functional Diagram of AGA56.9…

MU

4

ZF

M

Y1Y2Y

Y

0

U

MUU

1

3

23

1

LZAL

MAN.

0

AUTO.

ZLNP

1

OPE

MAX

MIN

MAX POS MIN

3-POSITION

SWITCH

1

2

J2

U1...U3

2

LIN

J1

JUMPERS

POT. METERS

AGA56.9A...

Figure 12. AGA56.9… Terminal and Trim Potentiometer/Jumper Board.

Page 14 Siemens Building Technologies, Inc.

Page 15

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Modulation Adjustment

See Figures 10 and 12.

The blue trim potentiometers allow the adjustment of the minimum (zero) and

maximum (span) positions.

The factory setting of the MIN trim potentiometer is rotated fully counter clockwise.

The factory setting of the MAX trim potentiometer is rotated fully clockwise.

Zero Adjustment

Span Adjustment

90 deg.

EA0562R1

Set the OPE/MAX/MIN slide switch to MIN. The blue MIN trim potentiometer can now

be gently adjusted to the required minimum position. Return the OPE/MAX/MIN slide

switch to OPE for operation.

NOTE: Do not set switch cam I higher than:

90° when using feedback potentiometers ASZxx.30

135° when using feedback potentiometers ASZxx.33

Set the OPE/MAX/MIN slide switch to MAX. The blue MAX trim potentiometer can now

be gently adjusted to the required maximum position. Return the OPE/MAX/MIN slide

switch to OPE for operation.

Example of limit switch I and III

and trim potentiometer settings

Switch I setting

MAX trim potentiometer setting

MIN trim potentiometer setting

Switch III setting

0 deg.

Figure 13. Switch cam and Trim

Potentiometer Setting.

NOTE: The actual minimum and maximum

modulating range is determined either

by the setting of the MIN and MAX trim

potentiometers or the setting of switch

cam III (Minimum) and switch cam I

(Maximum). The actuator can never

modulate outside of the range set by

switch cam I and III. If the MIN and MAX

trim potentiometers are set outside the

setting range of switch cams I and III,

then the switch cam settings determine

the modulating range. If a soft stop is

desired, the modulating range can be

defined by the trim potentiometers if the

MIN and MAX trim potentiometers are

set inside the setting range of switch

cams I and III. See the example in

Figure 13.

Siemens Building Technologies, Inc. Page 15

Page 16

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

Cover Installation

1. Lift the two screws on the cover corners and slide the cover end into the grooves

at the gear end of the actuator. See Figure 14.

2. Press the cover into place and then press the screws inward and tighten. See

Figure 15.

Features of

SQM5x.xxxxxZx

Actuators

Multiple Input Signals

Multiple Output Signals

EA0567R1

Figure 14.

EA0563R1

Figure 15.

SQM5xx.xxxxxZx actuators contain the AGA56.9A… multi function circuit board. This

circuit board provides the following features:

The AGA56.9A… circuit board accepts the following input signals:

Line voltage

• Power to A drives the actuator open to the setting of switch cam I (Maximum).

• Power to ZL drives the actuator closed to the setting of switch cam III (Minimum).

• Power to Z drives the actuator closed to the setting of switch cam II (Economy).

• 4 to 20 mA (Signal to Y3, common to M)

• 0 to 135 Ω (Slide wire signal to Y0, potentiometer connected to M and U4)

• 0 to 10 Vdc (Signal to Y1, common to M)

• 0 to 20 mA (Signal to Y2, common to M)

The AGA56.9A… circuit board provides the following output signals:

• 4 to 20 mA (Signal from U3, common to M)

• 0 to 10Vdc (Signal from U1, common to M)

• 0 to 20mA (Signal from U2, common to M)

Double potentiometers ASZ22… provide additional output signals.

Page 16 Siemens Building Technologies, Inc.

Page 17

SQM5… Reversing Actuators Technical Instructions

.3

Document No. 155-517P25

July 9, 2007

Electronic Linearization

Function

Butterfly valves have non-linear flow characteristics. Near the fully closed position, a

small change in the valve’s position will produce a very large change in flow. Near the

fully open position, a large position change will produce a relatively small change in flow.

The linearization function is intended to minimize the initial steep flow curve

characteristics of a typical butterfly valve. The linearization function is enabled when

Jumper J1 is in position 1 (upper position). Consequently, the actuator will make smaller

rotational movements when subjected to lower input signals and larger rotational

movements when subjected to higher input signals.

For example (based on a 90° modulating range), a change in input signal from 4 to 8 mA

will cause a rotational movement of 11.25°. An equal change from 16 to 20 mA will cause

a rotational movement of 45°. Thus, with the linearization function enabled, the change in

flow is closely proportional to the change in input signal.

The linearization function is disabled when Jumper J1 is in position 2 (lower position).

When disabled, the rotational movement of the shaft is proportional to the input signal.

Input Signal Override

Parallel Operation

Master/Slave Operation

Split Ranging

Line voltage to terminal P will drive the actuator to a pre-set adjustable position,

overriding all modulating input signals. Use the potentiometer marked POS to adjust the

override position to any setting within the setting range of switch cams I and III.

NOTE: The input signal override can also be used for the ignition position of burners if

different from the low fire position.

Set Jumper J2 in position 1 (upper position) to configure the actuator for parallel

operation. Input signals Y0, Y1, Y2 or Y3 are directly shunted to output signals U1, U2

and U3. All output signals are available regardless of which input signal is applied.

Set J2 in position 2 (lower position) to configure the actuator for master/slave operation.

The output signals U1, U2 and U3 reflect actual shaft position.

AGA56.9… circuit boards have a modulating signal shift feature which can be used for

split ranging. If no signal is present on Y0, Y1, Y2 or Y3, the actuator will modulate

through the full rotational range in response to a 12 to 20 mA signal applied at ZF. If a

maximum signal is present on Y0, Y1, Y2, or Y3, then the actuator will modulate through

the full rotational range in response to a 4 to 12 mA signal applied at ZF. (Maximum

signal can be easily achieved by bridging terminals U4 and Y0.) See Figure 16.

NOTE: It is possible to configure the actuator for split range operation 12 to 4 mA and

20 to 12 mA. Consult your authorized Siemens Building Technologies

combustion products sales representative for details.

MAX

75%

50%

25%

MIN

EA0560R1

20 mA

25% 50% 75% MAXMIN

14 mA

12 mA

10 mA

8 mA

6 mA

4 mA

Y

0..

16 mA

18 mA

Figure 16. Split Ranging.

Siemens Building Technologies, Inc. Page 17

Page 18

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

Features of

SQM5x.xxxxxGx,

SQM5x.xxxxx

SQM5x.xxxxx

Hx,

Kx

Actuators

Input Signals

Output Signals

Features of

SQM5x.xxxxx

Actuators

Input Signals

Ax

SQM5x.xxxxxGx actuators contain the AGA56.41A… circuit board with terminals Y- and

Y+ for 4 to 20 mA modulating input.

SQM5x.xxxxxHx actuators contain the AGA56.42A… circuit board with terminals Y, M

and U for 0 to 135 Ω modulating input.

SQM5x.xxxxxKx actuators contain the AGA56.43A… circuit board with terminals Y and M

for 0 to 10 Vdc modulating input.

The AGA56.4xA… circuit boards accept the following additional input signal:

Line voltage

• Power to A drives the actuator open to the setting of switch cam I (Maximum).

• Power to Z drives the actuator closed to the setting of switch cam II (Economy).

• Power to ZL drives the actuator closed to the setting of switch cam III (Minimum).

The AGA56.4xA… circuit boards do not provide output signals. Install a double

potentiometer ASZ22…to obtain a 0 to 1000 Ω actuator position output signal.

The AGA56.1A97… circuit boards accept the following additional input signal:

Line voltage

• Power to A drives the actuator open to the setting of switch cam I (Maximum).

• Power to Z drives the actuator closed to the setting of switch cam II (Economy).

• Power to switch III, terminal 3 drives the actuator to the setting of switch cam III

(Minimum).

Output Signals

Service Guide

Reversing Rotational

Direction

The AGA56.1A97 circuit board provides no output signals. Install an ASZ… potentiometer

to obtain an actuator position output signal.

WARNING:

Disconnect the power supply to the actuator before performing any service

functions.

1. Disconnect the wires marked 21 and 12, and reverse.

2. Adjust all switch cams to the desired settings (see Figure 6):

• For CCW rotation use the black cam drum scales and the single switch cam

pointers.

• For CW rotation, use the red cam drum scales and the double switch cam pointers.

NOTE: Press and hold the black cam drum release button to rotate the cam drum.

This will give easy access to the switch cams and a better view of the cam

drum scales.

If no potentiometer ASZ… is installed, the reversing procedure is complete. If a

potentiometer ASZ… is installed, complete Steps 3 through 9.

Page 18 Siemens Building Technologies, Inc.

Page 19

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Reversing Rotational Direction,

Continued

BLUE

BROWN

BLACK

BLUE

POSITION

INDICATION

min.

max.

POINTER

BLACK

BROWN

POSITION

min.

max.

INDICATION

POINTER

EA1210R1

EA1199R1

GEAR WITH MARK "1" FOR

COUNTERCLOCKWISE ROTATION

POTENTIOMETER GEAR

ALIGNMENT POINTER

POTENTIOMETER GEAR

ATTACHMENT SCREW

EA0517R1

Figure 17a. Reversing Rotational Direction on the ASZ Potentiometer (Gear Models).

min.

max.

EA1209R1

EA1200R1

BLACK

BROWN

BLUE

BLACK

BLUE

BROWN

min.

max.

POSITION

INDICATION

POINTER

min.

max.

Counterclockwise

Figure 17. Reversing Rotational Direction on the ASZ Potentiometer.

BOARD

ALIGNMENT

1

POTENTIOMETER

SCREW

TERMINAL

BLOCK

BROWN

BLACK

BLUE

POTENTIOMETER GEAR

ALIGNMENT POINTER

EA0518R1

GEAR WITH MARK "0"

FOR CLOCKWISE

ROTATION

POTENTIOMETER GEAR

ATTACHMENT SCREW

3. Disconnect the blue and brown wires from the terminal block located on the ASZ…

potentiometer circuit board and reverse. The black wire remains connected to the

middle terminal. See Figures 17 and 17a.

min.

max.

Clockwise

0

POTENTIOMETER

min.

max.

POSITION

INDICATION

POINTER

min.

max.

BOARD

ALIGNMENT

SCREW

TERMINAL

BLOCK

BLUE

BLACK

BROWN

4. Remove the white plastic actuator position-indicating dial by gently pulling while rotating

in the clockwise direction. See Figure 6.

5. The actuator position indicating pointer, located near the actuator gear end of the cam

drum, must point to the “0” mark on the actuator position scale (scale on the cam drum

nearest to the actuator gear end). Press and hold the black cam drum release button

while manually rotating the cam drum.

6. Loosen the black potentiometer cam attachment screw approximately one turn. Gently

wedge a small screwdriver between the potentiometer and the gray plastic housing.

Gently twist the screwdriver until the potentiometer releases from the cam drum shaft.

7. Change potentiometer end position:

• Manually rotate the potentiometer position indication pointer exactly to the other

end mark (see Figure 17).

• Gear models (see Figure 17a):

For clockwise rotation, manually rotate the potentiometer gear until the white line

next to the “0” mark on the potentiometer gear face is exactly in alignment with the

potentiometer gear alignment pointer.

For counterclockwise rotation, manually rotate the potentiometer gear until the

white line next to the “1” mark on the potentiometer gear face is exactly in

alignment with the potentiometer gear alignment pointer

Siemens Building Technologies, Inc. Page 19

Page 20

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

Reversing Rotational

Direction, Continued

8. Firmly tighten the black potentiometer cam attachment screw while manually

holding the potentiometer position indication pointer in alignment. Check the

alignment again.

9. Re-install the white actuator-indicating dial by gently pressing it onto the

potentiometer cam attachment screw. Align scale position “0” on the actuator

position indicating dial with the dial pointer by rotating the dial in the clockwise

direction to avoid loosening the potentiometer cam attachment screw.

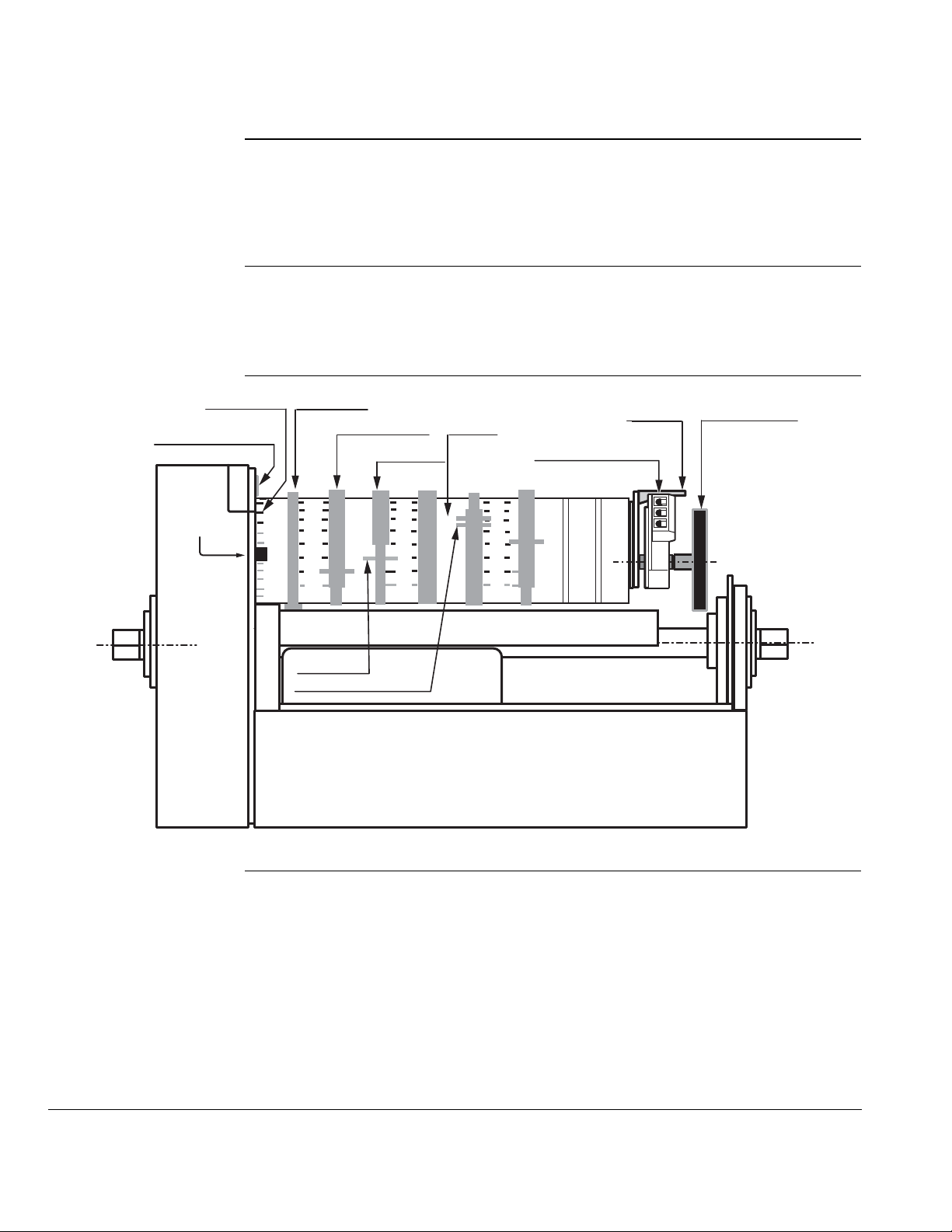

Shaft Installation

Preparation Before

Circuit Board Installation

See Installation and Operation Instructions.

WARNING:

Disconnect the power supply to the actuator before replacing the circuit

boards.

The black circuit board mounting

bracket, installed on the inside base of

the SQM5… actuator has four vertical,

slotted circuit board supports. Remove

the terminal section and circuit board(s)

from the mounting bracket.

The actuator motor capacitor is

attached to the lower section of the gray

plastic switch housing using snap-on

holding clips. Gently pull the capacitor

forward until it unclips and temporarily

place it on top of the gear housing. See

Figure 18.

CAUTION:

Do not disconnect any capacitor wiring.

EA0570R1

Figure 18.

CAPACITOR

AGA56.41/42/43

Circuit Board

Installation

1. Remove the AGA56.41/42/43…

circuit board from the packaging. The

circuit board is shipped as one board.

TERMINAL

SECTION

2. Separate the board at the perforation

by holding the circuit board at both

ends and gently bending the board

until it separates.

3. Move the terminal section containing

the auto/manual switch to the

opposite end of the base circuit

board.

4. From the switch housing side of the

actuator, guide the base circuit board

into the bottom of the circuit board

mounting bracket. See Figure 19.

EA0574R1

BASE

CIRCUIT

BOARD

Figure 19.

Page 20 Siemens Building Technologies, Inc.

Page 21

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

AGA56.41/42/43

Circuit Board

Installation,

Continued

5. Re-install the actuator motor capacitor.

See Figure 20.

6. Gently guide the terminal section into

the support slots and slide the terminal

board downward until both supports

snap into place. Ensure that the four

brown wires and the flat white

connector cable which connect the two

circuit boards are positioned correctly

in their respective corners allowing the

board to freely slide into place without

pinching either wire. See Figure 21.

7. Connect the bundled blue, black and

brown potentiometer wires to the

terminal block located on the ASZ…

potentiometer circuit board. See

Potentiometer Installation.

EA0575R1

Figure 20.

TERMINAL

SECTION

CAPACITOR

EA0576R1

Figure 21.

Siemens Building Technologies, Inc. Page 21

Page 22

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

AGA56.41/42/43

Circuit Board

Installation, Continued

8. Make the following connections to the

actuator: See Figure 22.

a. Connect the wire, marked “1” from

the circuit board to switch I,

terminal 1.

b. Connect the wire, marked “2” from

11

12

13

14

15

16

17

18

27

28

7

8

VII

VIII

24

25

26

4

5

6

IV

V

VI

211222

23

3

II

III

I

13

the circuit board to switch II,

terminal 2.

c. Connect the wire, marked “3” from

the circuit board to switch III,

terminal 3.

d. Connect the wire, marked “13”

from the circuit board to switch III,

N

TERMINAL

BLOCK

3

2

1

terminal 13.

e. Connect the blue neutral wire

marked “N” to the double terminal

block located on the outer end of

the switch housing

f. Connect the grounding wire

marked "51" to the ground terminal

located to the right of the

auto/manual switch.

EA0577R2

Figure 22.

MAN.

0

AUTO

N

51

AGA56.9A…

Circuit Board

Installation

1. Remove the ASZ... potentiometer if

already installed on the SQM5...

actuator. See Potentiometer

Removal/Installation Instructions.

2. Remove the AGA56.9A… circuit

boards from the packaging. The three

separate AGA56.9A circuit boards are

shipped in a circuit board mounting

bracket.

3. Remove the two upright circuit boards

from the mounting bracket by gently

pulling aside the vertical supports and

sliding the boards upward. Remove

the base circuit board from the bottom

of the mounting bracket. Discard the

shipping mounting bracket.

Page 22 Siemens Building Technologies, Inc.

Page 23

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

AGA56.9A…

Circuit Board

Installation, Continued

4. Guide the base circuit board from the

switch housing side of the actuator into

the bottom of the circuit board mounting

bracket. See Figure 23.

5. Re-install the actuator motor capacitor.

See Figure 24.

6. Gently guide the terminal board into the

support slots and slide the terminal

board downward until both supports

snap into place. See Figure 25.

7. See Figure 26 and make the following

EA0571R1

Figure 23.

BASE

CIRCUIT

BOARD

connections to the actuator:

a. Connect the wire, marked “1” from

the circuit board to switch I,

terminal 1.

b. Connect the wire, marked “2” from

the circuit board to switch II,

terminal 2. Connect the white wire,

marked “3” from the circuit board to

switch III, terminal 3.

c. Connect the wire, marked “13” from

the circuit board to switch III,

terminal 13.

d. Connect the neutral wire, marked

“N” to the double terminal block

located on the outer end of the

switch housing.

e. Connect the grounding wire marked

"51" to the ground terminal located

to the right of the auto/manual

switch.

EA0572R1

CAPACITOR

Figure 24.

TERMINAL

SECTION

EA0573R1

Figure 25.

Siemens Building Technologies, Inc. Page 23

Page 24

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

AGA56.9A…

Circuit Board

Installation, Continued

8. Gently guide the L-shaped circuit

board containing the three blue trim

potentiometers into the vertical support

slots located on the cam drum side of

the actuator. See Figure 27.

18

27

28

7

8

VII

VIII

24

25

26

4

5

6

IV

V

VI

211222

23

3

I

II

III

13

11

12

13

14

15

16

17

9. Slide the circuit board downward until

both supports snap into place. Install

the ASZ… potentiometer. (See

Potentiometer Removal/Installation

Instructions.)

N

3

2

1

10. Connect the bundled blue, black and

brown potentiometer wires to the

terminal block located on the ASZ…

potentiometer circuit board.

MAN.

0

AUTO

AGA56.1A97

Circuit Board

Installation

N

EA0565R2

51

Figure 26.

L-SHAPED

CIRCUIT

BOARD

EA0566R1

Figure 27.

1. Install the AGA56.1A97 circuit board into the two slotted circuit board supports

located on the switch housing side of the actuator.

2. Gently guide the AGA56.1A97 circuit board into the support slots and slide the board

downward until both supports snap into place.

3. Make the following connections to the actuator:

a. Connect the wire, marked “1” from the circuit board to switch I, terminal 1.

b. Connect the wire, marked “2” from the circuit board to switch II, terminal 2.

c. Connect the wire, marked “13” from the circuit board to switch III, terminal 13.

Page 24 Siemens Building Technologies, Inc.

Page 25

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Potentiometer

Removal

9. Remove the white plastic actuator position-indicating dial by gently pulling while

rotating in the clockwise direction. See Figure 6.

10. Disconnect the blue, black and brown wire from the potentiometer terminal block. See

Figure 17.

11. Remove the silver potentiometer alignment screw.

12. Loosen the black potentiometer cam attachment screw approximately one turn.

13. Gently wedge a small screwdriver between the potentiometer and the gray plastic

housing.

14. Carefully twist the screwdriver until the potentiometer releases from the cam drum

shaft. Remove the ASZ… potentiometer.

Potentiometer

Installation

1. Install the new ASZ… potentiometer by gently sliding the bushing over the cam drum

shaft.

2. Align the potentiometer alignment screw hole with the hole in the gray plastic housing

and install the potentiometer alignment screw. See Figures 17 and 17a.

3. The actuator position indicating pointer, located near the actuator gear end of the cam

drum, must point to the “0” mark on the actuator position scale. See Figure 6. The

scale is located on the cam drum nearest to the actuator gear end. Press and hold

the black cam drum release button while manually rotating the cam drum.

4. If installing a potentiometer without gear, manually rotate the potentiometer pointer

until the pointer is exactly in the “min” position. See Figure 17. Firmly tighten the

black potentiometer cam attachment screw while manually holding the potentiometer

pointer in alignment. Check the alignment again.

5. If installing a gear model potentiometer, manually rotate the potentiometer gear until

the white line next to the “0” or “1” mark on the potentiometer gear face is exactly in

alignment with the potentiometer gear alignment pointer. See Figure 17a.

For counterclockwise (ccw) operation the line beside the “1” mark must exactly align

with potentiometer gear alignment pointer. For clockwise (cw) operation the line

beside the “0” mark must exactly align with potentiometer gear alignment pointer.

Firmly tighten the black potentiometer cam attachment screw while manually holding

the potentiometer gear in alignment. Check the alignment again.

6. Connect the bundled blue, black and brown potentiometer wires to the terminal block

located on the ASZ… potentiometer board. See Potentiometer Installation and

Figures 17 and 17a.

7. Re-install the white actuator-indicating dial by gently pressing it onto the

potentiometer cam attachment screw. Align scale position “0” on the actuator position

indicating dial with the dial pointer by rotating the dial in the clockwise direction to

avoid loosening the potentiometer gear attachment screw. See Figure 6.

Siemens Building Technologies, Inc. Page 25

Page 26

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

Specifications

SQM5... Reversing

Actuator

SQM5... Reversing actuator

Agency approvals UL, CSA, CE

Operating voltage 24 Vac +10%-15%

110 Vac-15% to 120 Vac +10%

220 Vac-15% to 240 Vac +10%

Operating frequency 50 to 60 Hz

Power consumption 20 VA

Type of motor Reversing synchronous motor

Duty cycle 100%

Torque See Table 1.

Maximum shaft torque

AGA58.1 90 lb-in

AGA58.2 200 lb-in

AGA58.3 220 lb-in

AGA58.4 270 lb-in

AGA58.7 400 lb-in

Timings See Table 1.

Rotational range of operation

SQM5x.xxxxxA models 0° to 160°

SQM5x.xxxxxx3 models 0° to 90°

SQM5x.xxxxxx4 models 0° to 135°

SQMSx.xxxxxx6 models 0° to 160°

Direction of rotation Reversible

Shaft Selectable. See Table 2.

Custom versions on request

Shaft disengagement Independent, cam and drive shaft

Number of auxiliary switches

4 switches (standard, maximum 6)

Limit switches 2 switches (standard)

Electrical rating of auxiliary switches 7.5 (3) A, 250 Vac

Mounting position Optional

Ambient operating temperature -5°F to 140°F (-20°C to 60°C)

Shipping temperature -58°F to 140°F (-50°C to 60°C)

NEMA ratings NEMA 1, 2, 3, 3R, 3S, 5, 12, and 13

Connections

Switches Spade connectors

Boards Screwed and spade connectors

Dimensions See Figures 28 through 31.

Weight 7.3 lb (3.3 kg)

Housing Aluminum pressure die casting

Enclosure (cover) Lexan

Motor Lock resistant

Disengagements Manual for drive and cam shaft

Page 26 Siemens Building Technologies, Inc.

Page 27

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Specifications

SQM5... Reversing

Actuator, Continued

Circuit Boards

Conduit connection Two removable inserts with two

1/2-inch NPSM threads.

Each insert allows insertion of entire

cable tree for easy servicing

Gears and bearings Maintenance-free

Mounting Four 1/4"-20 UNC screws in bottom

Face mounting at gear side also

possible

Adaptation to other actuator brands Screw pattern and shaft height

Adaptation with AGA57... adapters

See Table 2.

AGA56.1A97 Switch circuit board

Operating voltage Voltage independent

Operating frequency 50 to 60 Hz

AGA56.1A97

AGA56.41A…

AGA56.42A…

Auto/manual switch 2-position switch

Manual toggle switch 3-position switch

Ambient operating temperature -5°F to 140°F (-20°C to 60°C)

Shipping temperature -58°F to 140°F (-50°C to 60°C)

Weight 0.22 lb (0.1 kg)

AGA56.41A… Electronic circuit boards Single potentiometer

ASZ... (1000 ohm) is required

Operating voltage 24 Vac +10%-15%

110 Vac -15% to 120 Vac +10%

220 Vac -15% to 240 Vac +10%

Operating frequency 50 to 60 Hz

Ambient operating temperature -5°F to 140°F (-20°C to 60°C)

Shipping temperature -58°F to 140°F (-50°C to 60°C)

Input signal 4 to 20 mA

Impedance

Current input ≤300 Ω

Zero adjustment MIN: 0 to 75%

Span adjustment MAX: min 100%

Auto/manual switch 2-position switch

Manual toggle switch 3-position switch

Weight 0.7 lb (0.33 kg)

AGA56.42A… Electronic circuit boards Same specifications as AGA56.41A

except

Input signal 0 to 135 ohm

Impedance

Current input ≤300 Ω

Voltage input ≥100K Ω

Siemens Building Technologies, Inc. Page 27

Page 28

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

Specifications,

continued

AGA56.43A…

AGA56.9A

ASZ... Potentiometers

AGA56.43A… Electronic circuit boards Same specifications as AGA56.41A

except:

Input signal 0 to 10 Vdc

Impedance

Voltage input ≥100K Ω

AGA56.9A… Multi function electronic Single potentiometer

circuit boards ASZ... (1000 ohm) is required

Operating voltage 24 Vac +10%-15%

110 Vac -15% to 120 Vac +10%

220 Vac -15% to 240 Vac +10%

Operating frequency 50 to 60 Hz

Input signals 4 to 20 mA

0 to 20 mA

0 to 10 Vdc

0 to 135 ohm

Impedance

Current input ≤300 Ω

Voltage input ≥100K Ω

Output signals 4 to 20 mA

0 to 20 mA

0 to 10 Vdc

Max output load

Current output <600 ohm

Voltage output > 1.5K ohm

Zero adjustment MIN: 0 to 75%

Span adjustment MAX: min-100%

Split ranging (SHIFT) 4 to 20 mA on terminal ZF

Input signal override (POS) Line voltage (... Vac) on terminal P

adjust with POS potentiometer

Ambient operating temperature -5°F to 140°F (-20°C to 60°C)

Shipping temperature -58°F to 140°F (-50°C to 60°C)

Auto/manual switch 2-position switch

Manual toggle switch 3-position switch

Weight 0.7 lb (0.33 kg)

ASZ... Potentiometers

Versions Single and double potentiometer

Resistor values See Table 2 and Data Sheet 7921.

Hysteresis < 0.3% related to drive shaft

Page 28 Siemens Building Technologies, Inc.

Page 29

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Dimensions

The first dimension given is measured in inches. Millimeters are shown in parentheses.

5-1/4

(133)

2-5/8

(67)

EA0522R1

1/16

(1)

ALLOW 3.5" SPACE FOR

COVER REMOVAL

4-7/16

(113)

1/4"-20

UNC

7-1/16

(180)

7-1/16

(180)

1-3/16

(30)

3/8

(10)

3-1/8

(80)

5/8

(16)

1/8

(3.5)

5-3/16

(132)

Pg 13.5 / 1/2"

NPSM

1-7/16

(36)

1-3/16

(30)

1/4

(6)

M 8

6-7/16

EA0542R2

5/16

(8.5)

(164)

5/16

(7.5)

Figure 28. SQM5x.xxxRxx Dimensions.

Siemens Building Technologies, Inc. Page 29

Page 30

Technical Instructions SQM5… Reversing Actuators

Document No. 155-517P25

July 9, 2007

Dimensions, Continued

6-7/16

11/16

(18)

(164)

4-1/16

(103.3)

9/16

(14.5)

5-5/16

(135)

4-3/4

(120.65)

4-7/16

(113)

1/8

(3)

EA0519R2

7/16

(11)

3-1/8

(80)

2-3/8

(60.4)

AGA57.3

4-7/16

(113)

C

L

4 X 1/4

(7)

Figure 29. Mounting Bracket AGA57.3.

7-5/16

(185)

5/16

(7.94)

1-3/8

(35)

(57.15)

5/16

(8.73)

2-1/4

(7.94)

5/16

(8.73)

5/16

6-7/16

(164)

AGA57.4

C

L

1-9/16

(40)

3-1/8

(80)

4 X 1/4

(7)

4-7/8

(123.8)

2-1/2

(63.5)

3-1/8

(80)

(101.5)

4-7/16

(113)

4

5/16

(7.94)

EA0520R2

1/2

(12.5)

13/16

(20.3)

1-5/8

(42)

2-3/8

(60.64)

1-1/2

(38.1)

1/8

(3)

2

(50.8)

1-11/16

(43)

4545

13/16

(20.3)

All non-sized holes

O 5/16 (7.62)

Figure 30. AGA57.4 Mounting Bracket.

Page 30 Siemens Building Technologies, Inc.

Page 31

SQM5… Reversing Actuators Technical Instructions

Document No. 155-517P25

July 9, 2007

Dimensions, Continued

0.31

(8)

7.09

(180)

AGA58.1

AGA58.2

1

(25.5)

0.79

(20)

1

(25.5)

0.79

(20)

GEAR SIDE

0.35

(9)

0.44

(11.2)

0.35

(9)

0.52

(13.2)

0.39

(10)

0.47

(12)

0.12

(3)

0.12

(3)

0.35

(9)

0.375

(9.5)

M5 x 9

8-32 UNC

28 x 0.56

(14.2)

0.35

(9)

0.27

(6.9)

0.42

(10.6)

0.05

(1.3)

0.81

(20.5)

0.67

(17)

AGA58.3

AGA58.4

AGA58.7

0.85

(21.5)

0.78

(19.8)

(10.6)

0.42

0.05

(1.3)

1.71

(43.5)

1.10

(28)

0.43

(11)

0.27

(6.9)

M5 x 9

8-32 UNC

28 x 0.56

(14.2)

0.20

(5)

0.60

(15.1)

0.35

(9)

0.375

(9.5)

0.55

(14)

0.20

(5)

EA0543R1

Figure 31. Shaft Dimensions.

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. Other product or company names mentioned herein may be the trademarks of their respective owners.

© 2007 Siemens Building Technologies, Inc.

Siemens Building Technologies, Inc.

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

U.S.A.

Your feedback is important to us. If you have

comments about this document, please send them

to SBT_technical.editor.us.sbt@siemens.com

Document No.155-517P25

Country of Origin: US

Page 31

Loading...

Loading...