Siemens SQM45,SQM48.497A9,SQM48.697A9,SQM48 Series,SQM45.291A9,SQM45.295A9 Series Manual

CC1N7814en

31.10.2002

Siemens Building Technologies

HVAC Products

ISO 9001

7

814

Actuators

SQM45...

SQM48...

for air dampers and control valves of oil and gas burners

Electromotoric actuators

· Torques: – SQM45... up to 3 Nm

– SQM48... up to 20 Nm

– SQM48.6... up to 35 Nm

· Running times:

1)

– SQM45... 10 ... 120 s

– SQM48... 30 ... 120 s

– SQM48.6... 60 ... 120 s

1)

Depending on the basic unit (LMV...)

· Versions: – Choice of drive shafts (refer to «Type summary»)

The SQM45... / SQM48... and this Data Sheet are intended for use by OEMs which

integrate the actuators in their products!

Use

The actuators of the SQM45... / SQM48... range are used to drive gas dampers, air

dampers, oil control valves and other ancillary equipment.

When used in connection with burner controls or electronic fuel / air ratio control, the

associated controlling elements are controlled depending on burner output.

2/8

Siemens Building Technologies CC1N7814en

HVAC Products 31.10.2002

Warning notes

To avoid injury to persons, damage to property or the environment, the following

warning notes should be observed!

Do not open, interfere with or modify the actuators!

· Ensure protection against electric shock hazard by providing adequate protection

for the connection terminals

· Check to ensure that wiring is in an orderly state and that the wires are firmly con-

nected

Mounting notes

· Ensure that the relevant national safety regulations are complied with

· The connection between actuator drive shaft and controlling element must be rigid

with no mechanical play

Possible connection with drive shaft or hub:

· Groove with Woodruff key

· Drive shaft with flat edge and matching counterpiece

To avoid inadmissible loads on bearings caused by rigid hubs, it is recommended to

use compensating clutches with no mechanical play (e.g. metal bellows clutches).

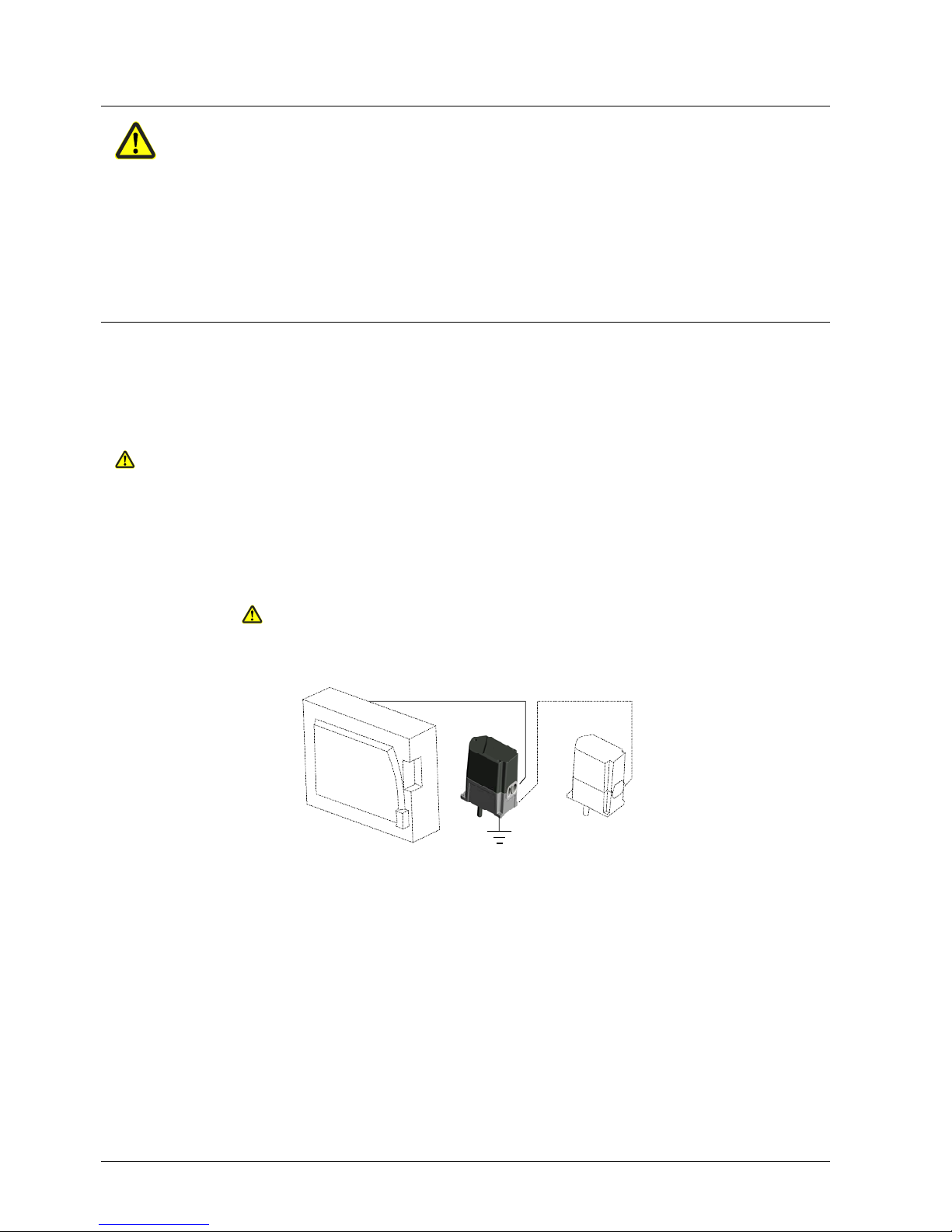

Only the specified cable may be used (refer to Basic Documentation P7550). The cable’s shielding must be connected to the printed circuit board using the tab provided.

Ensure that the actuator’s housing is connected to functional earth (FE) of the system.

If necessary, remove isolating layers of paint from the fixing points on the burner’s

casing or run separate earth wires.

For detailed information, refer to «Installation Inctructions for the LMV5x system»

J7550.1.

CAN bus

AGG5.6...

SQM4...

FE

B

a

s

i

c

u

n

i

t

L

M

V

5

.

.

.

7814z03e/0502

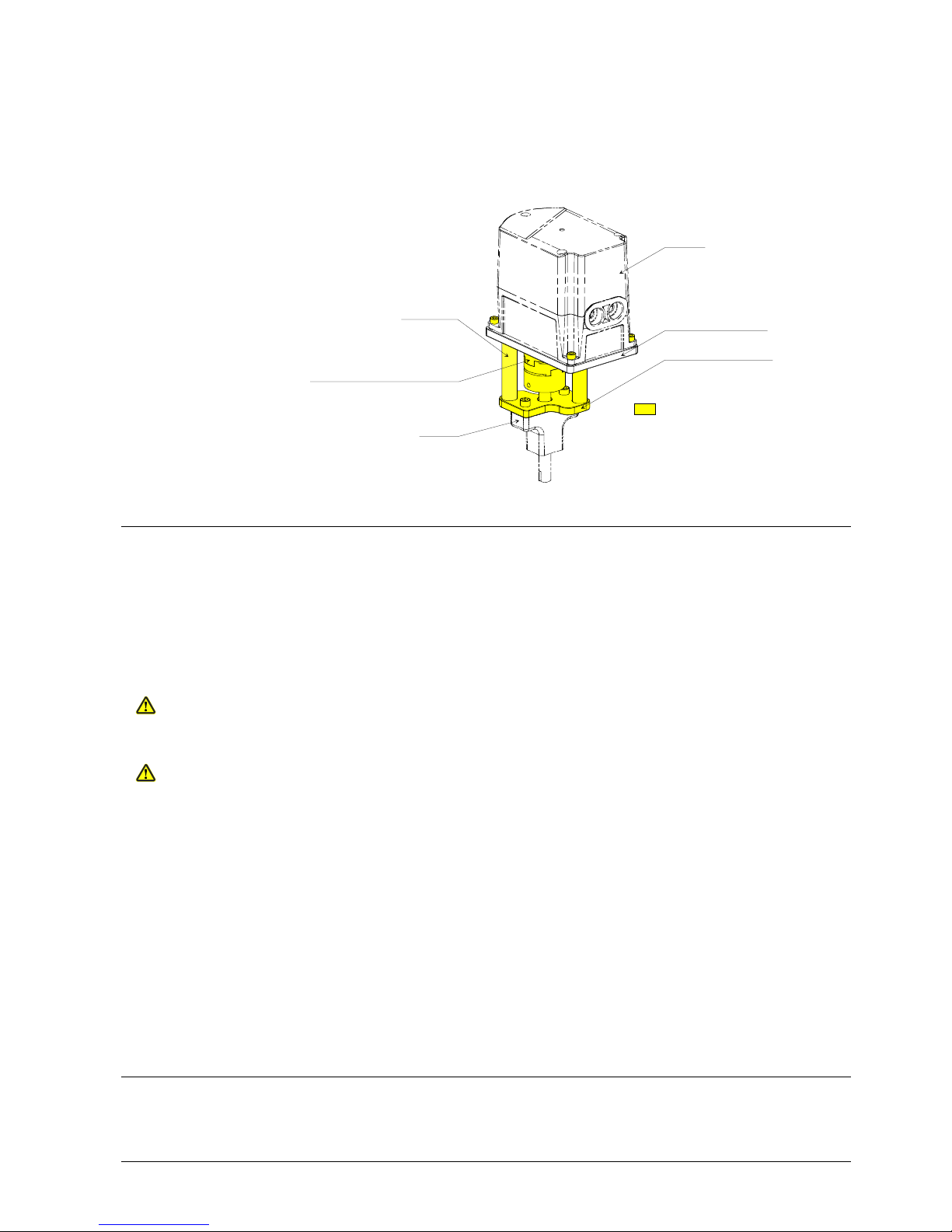

The working range is given on the type field and must be observed when mounting the

actuator. To ensure the actuator is accurately located on the burner, a positioning pin of

6 mm diameter must be fitted on the mounting surface.

Positive connection

Cable and cable

shielding

Working range of

actuator

3/8

Siemens Building Technologies CC1N7814en

HVAC Products 31.10.2002

To ensure degree of protection IP 54, suitable Pg glands must be fitted in the actuator’s Pg11 openings.

The Pg glands used must feature cable strain relief.

To ensure degree of protection IP 54 during the actuator’s entire service life, the bearing of the drive shaft must be located such that it will not be directly exposed to water or

dust.

SQM4...

Mounting plate SQM4...

Secure coupling piece to drive shaft

such that intermediate plastic

piece has an axial play of about

0.2 to 0.5 mm

Mounting plate VKF41...

Spacer

VKF41...

7814z02e/0502

ASK33.4

Installation notes

· Installation work must be carried out by qualified staff

· Always run the high-voltage ignition cables separate from the unit and other cables

while observing the greatest possible distance

· To ensure protection against electric shock hazard, make certain that the AC 230 V

section of the SQM4... is strictly segregated from the functional low-voltage section

· The holding torque is reduced when the actuator’s power supply is switched off

The housing cover may only be removed for short periods of time for wiring or when

making the addressing. It must be made certain that dust or dirt will not get inside the

actuator while such work is carried out.

The actuator contains a printed circuit board with ESD-sensitive components.

The top side of the board carries a cover which affords protection against direct contact. This protective cover may not be removed! The underside side of the board may

not be touched.

Addressing (assignment of functions) defines whether the SQM4... shall operate as a

· fuel actuator

· air damper actuator, or

· auxiliary actuator,

and is made with the display and operating unit AZL... and the addressing button on the

actuator, which is located under the housing cover (refer to Basic Documentation

P7550).

The correct assignment of actuator functions can be checked with the help of flashing

LEDs.

For the maximum permissible cable length, refer to the Basic Documentation.

Cabling must be strictly serial (no branching permitted!).

Commissioning notes

· Commissioning work must be carried out by qualified staff

IP 54

Mounting example

Housing cover

ESD

Addressing

Cable length

Topology

Loading...

Loading...