SMP Switchboards

Selection and application guide

www.siemens.ca/powerdistribution

Switchboards

Contents

Sentron SMP Switchboards

Type SMP

Construction Details Features 2

Features 3

Specification 8

Sentron® SMP Switchboards

Construction Details

Simplified system design.

A typical SMP switchboard consist of

a floor mounted, wall supported service section, and a distribution section.

The wireway can also be added where

required by the local utility or if additional cable termination space is required.

Wireways are modular to allow

flexibility.

The wireway is available in 2 depths to

suit customer needs. Wireway has split

front doors as standard with optional

hinged doors. The lug pads are standard

NEMA hole pattern and accept up to 5

mechanical lugs or 6 compression lugs.

90oC rated wireway.

The termination temperature for main

incoming cables can be sized at 90oC

for bussed pull sections.

Service Entrance Sections house a

variety of equipment.

b

Service Entrance Sections.

Service sections can be fed directly from

overhead by cable.

Service entrance sections equipped

for bottom feed will accept cable from

underground directly into the service

section.

b

Utility Metering

In addition to the main device, the

service section contains utility metering

provisions. “Cold” metering provisions

(CT’s on the load side of the main

device) are furnished. The CT’s are

provided by the utility company. The

compartment will be built to utility

company standards, with hinged doors

and provisions for utility metering

equipment.

Distribution Sections have ample

wiring room and front accessibility.

Generous top or bottom gutters have

been created by locating the bus-link in

the top or bottom of the distribution

section, so there’s ample room to run

cables into the distribution section and

make connections.

Standard bolted covers allow complete

access to load conductors. Future

flexibility comes standard in the

Siemens SMP switchboard. The

distribution section can accommodate

any combination of panel mounted

devices, including MCCBs and fusible

disconnect switches.

Operating temperatures are in

accordance with CSA Standards

Bus bars are available in standard

tin-finished aluminum or optional

silver-finished copper. Standard bus is

sized on the basis of heat rise criteria,

in accordance with CSA C22.2 #31. All

bus bars are sized to limit heat rise to

65°C above an ambient temperature of

40°C.

Construction

Bus-Link Connections are accessible

from the front.

The Bus-Link can be bolted from the

front of the switchboard. Each bus-link

is attached by grade five bolts to assure

solid joints between sections, and to

maintain full bus ampacity through the

joint.

To make installation and servicing of the

bus-link easier, all phase and neutral

busses are stacked one above the other.

Cable Terminals

Screw mechanical connectors (lugs) are

provided as standard equipment.

b

User Metering

The service section provides space for

the Siemens Digital Meter with remote

display, and it’s associated components.

b

Main protective device

The MCCB is mounted individually

so that it can be located quickly in an

emergency. SMP switchboards will

accommodate different types of main

circuit breakers. Selection depends on

the characteristics of your individual

electrical system.

2

Sentron® SMP Switchboards

Power and Distribution

SMP Switchboard Introduction

Whether the design is for a 240V AC, 400 ampere

system; a 600V AC, 1200 A ampere system; or

something in between, Siemens Sentron Switchboards

should be considered. Every aspect of design has

been aimed at improving layout convenience, reducing

installation costs, and minimizing the impact and

cost of system changes. These switchboards provide

the space saving construction and service flexibility

necessary in systems for light industrial plants, retail

strip malls, and commercial buildings.

Service entrance sections of the SMP accepts a wide

range of Sentron Molded Case Circuit Breakers as

main disconnect devices.

The SMP switchboard is designed for special

configurations. It can be equipped with incoming and

outgoing cable/conduit connections, supplied with

metering and other special features.

The distribution sections of all Sentron Switchboards

are designed with improved wiring space and

greater accessibility. They’re also designed for easier

installation and maintenance. Conveniently located

bus-link without compromising useful wiring gutter

space, and standard bolted gutter covers offer

complete access to load conductors. Front accessibility

to bus and protective devices makes adding or

replacing circuit breakers or switches quick and easy.

SMP Switchboard Features and Ratings

b

Main bus rated up to 1200 ampere.

b

Rear of all sections aligned so that

switchboard can be floor mounted and

secured against the wall.

b

Front connected and front accessible.

b

Main devices – individually mounted.

Molded Case Breaker: 400-1200 amps.

b

Branch Devices – panel mounted.

Molded Case Breaker: 15–1200 amps fixed.

Quick-Make Quick-Break Fusible Switch: 30 - 600A

600 Volts AC Maximum

1200 Ampere Mains

1200 Ampere Maximum Branch

CSA Short Circuit Rating —

65,000A IR Maximum

CSA Certified To: CAN/CSA-22.2 No. 31-14

CSA File #LR 153416 (013076)

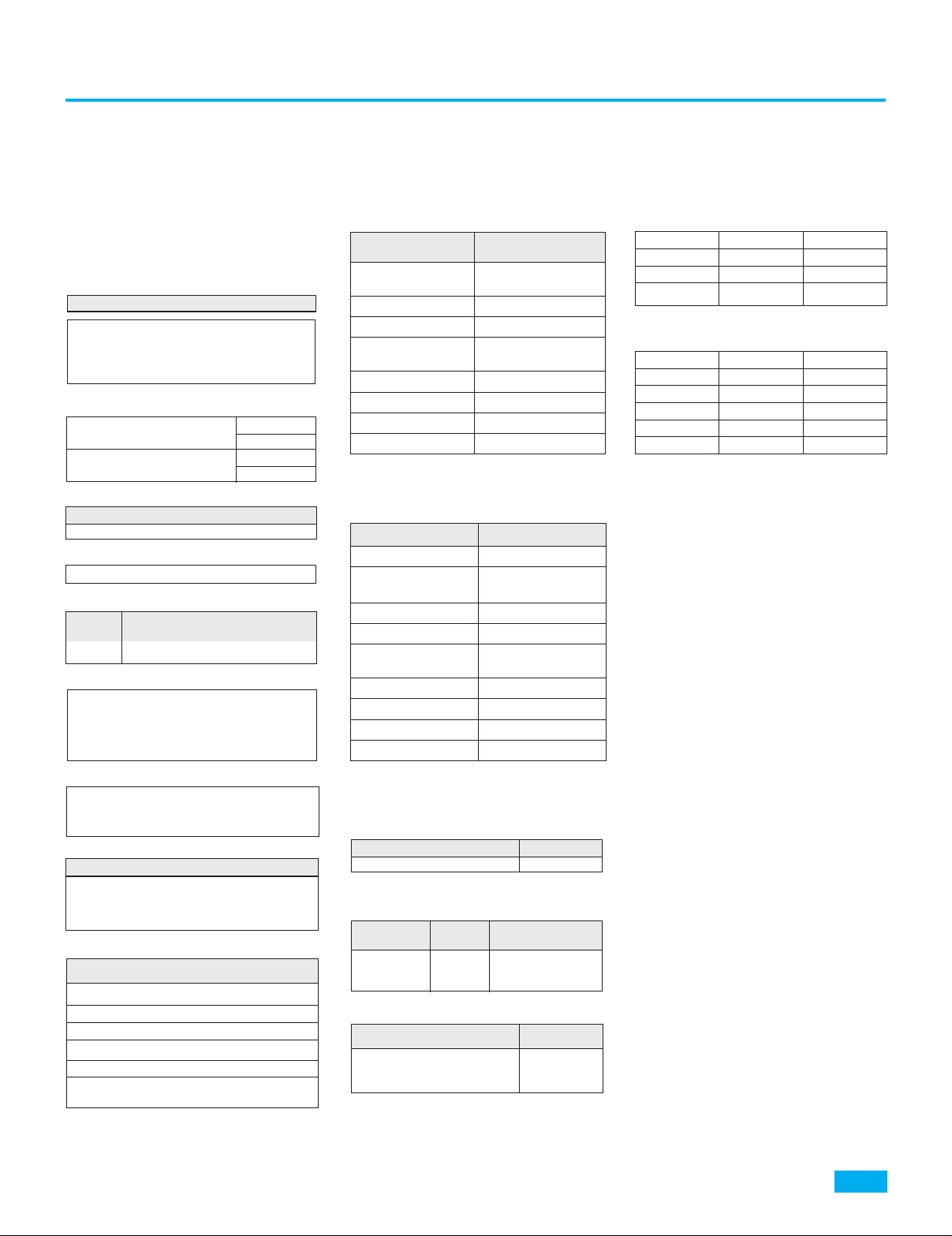

SMP Specifications (Table 1)

SMP Switchboard

Enclosure Type

Dimensions

Main or Distribution

Wireway

Volts 600V Max

Amperes 400-1200A

Bus Type

Bus Bracing

Interrupting Capacity

Entry Cable only (top or bottom)

Main Device

Branch Devices

(Unit Space)

Metering Devices

Other Options

Type 1

Type 2 (dripproof & sprinklerproof)

Optional: Dripshield

38” W x 90” H x 12.75” Dp

24” W x 90” H x 12.75” Dp or 25.5” Dp

Aluminum (tin plated)

Copper (silver finished) optional

50 KA

65 KA (optional)

50 KA

65 KA (optional)

MCCB 400-1200A

b

80% Rated

b

100% Rated (option)

52.5” in Main with Distribution Section, or

22.5” in MUD Section, or

60” in Distribution Section

Siemens Digital Metering with Remote Display

SEM3 Embedded Metering

SPD Units

Sill Channels (1.5”)

Lifting Hooks

Main and Distribution Section Dimensions (Table 2)

Switchboard Type Access

SMP Front 90” (2286) 38” (965) 12.75” (324)

Dimensions - Inches (mm)

H

W D

General

a

Only available as a Wireway.

3

Sentron® SMP Switchboards

Power and Distribution

Protective Devices - Molded Case Circuit Breakers

Standard

Breakers are designed for commercial, industrial, institutional and other

heavy duty applications. They are rated up to 600V AC and 250V DC. Their

interrupting ratings are higher than normal duty breakers.

High Interrupting

Breakers are designed for heavy duty applications where the interrupting

requirements exceed the ratings of heavy duty breakers. They are rated up to

600V AC.

Current Limiting

Molded case breakers incorporate the exclusive I-T-E blow-apart interruption

principle. They meet the CSA requirements for current-limiting breakers.

Current-limiting circuit breakers can limit the let-through I

the I2t of one-half cycle wave of the symmetrical prospective current without

any fusible elements when operating within their current-limiting range.

Main Breaker Selection (Table 3)

Maximum

Interrupting Rating

(kA)

Amperage

Rating

400

600

800

1200

Breaker

Type Trip Type

JXD6

JD6 65 35 25 200, 225, 250, 300, 350, 400

HJD6 100 65 35 200, 225, 250, 30 0, 350, 400

HHJD6 200 100 50 200, 225, 250, 300, 350, 400

CJD6

SJD6

SHJD6 10 0 65 35 200, 300, 40 0

SCJD6 200 150 10 0 200, 300, 40 0

LXD6

LD6 65 35 25 250, 300, 350, 400, 450, 500, 600

HLD6 100 65 35 250, 300, 350, 400, 450, 500, 600

HHLD6 200 100 50 250, 300, 350, 400, 450, 500, 600

CLD6

SLD6

SHLD6 10 0 65 35 300, 400, 50 0, 600

SCLD6 200 150 10 0 300, 400, 50 0, 600

MXD6

MD6 65 50 25 500, 600, 700, 800

HMD6 100 65 50 500, 600, 700, 800

CMD6

SMD6

SHMD6 10 0 65 50 600, 700, 800

SCMD6 20 0 100 65 600, 700, 800

NXD6

ND6 65 50 25 800, 900, 1000, 1200

HND6 100 65 50 800, 900, 1000, 1200

CND6 200 10 0 65 800, 900, 1000, 1200

SND6

SHND6 100 65 50 800, 1000, 1200

SCND6 200 10 0 65 800, 1000, 1200

Thermal

Magnetic

Electronic

(Solid

State)

Thermal

Magnetic

Electronic

(Solid

State)

Thermal

Magnetic

Electronic

(Solid

State)

Thermal

Magnetic

Electronic

(Solid

State)

240V 480V 600V

65 35 25 200, 225, 250, 300, 350, 400

200 150 10 0 200, 225, 250, 300, 350, 40 0

65 35 25 200, 300, 400

65 35 25 450, 500, 600

200 150 10 0 450, 500, 600

65 35 25 300, 400, 500, 600

65 50 25 500, 600, 700, 800

200 100 65 500, 600, 700, 800

65 50 25 600, 700, 800

65 50 25 800, 900, 1000, 1200

65 50 25 800, 1000, 1200

2

t to a value less than

Available Trip Values

Selection

Branch Breaker Gutter Dimensions

For 38”W Distribution Section (Table 5)

3.75” (95)

3.75” (95)

3.75” (95)

3.75” (95)

5” (127)

8.75” (222)

8.75” (222)

6.25” (159)

10" (254)

12” (305)

8.75" (222)

13.98” (355)

11.62” (295)

10” (254)

7.61”(193)

8.75” (222)

8.25” (210)

10.90” (276)

11.76” (299)

7.92” (201)

8” (203)

13.42” (341)

12” (305)

15.5” (393)

13” (330)

12” (305)

13” (330)

14.0” (356)

A A

B B

C C

D D

E E

F

G

H

J

K

L

M

N

O

P

Q

R

F

G

H

K

L

5” (127)

5” (127)

8.75”

(222)

6.25”

(159)

3.75”

(95)

5”

(127)

4

Sentron® SMP Switchboards

Power and Distribution

Branch Circuit Breaker Selectiona (Table 4)

Breaker

Frame

Rating

100

125

150

225

250

400

600

800

1200

Trip

Type Breaker Type Poles Trip Amperage

Thermal

Magnetic

Ground Fault

Circuit Interrupter

Arc Fault Circuit

Interrupter

BL

BLH

HBL 1, 2, 3 15, 20, 25, 30, 40, 50, 60, 70, 80, 90, 100 — 3.75" (95)

e

BQD6

BLE (GFCI) 1, 2 15, 20, 30, 40, 50, 60 — 3.75" (95)

BLF (GFCI) 1, 2 15, 20, 30, 40, 50, 60 — 3.75" (95)

BLHF (GFCI) 1, 2 15, 20, 30, 40, 50, 60 — 3.75" (95)

BAF (AFCI) 1 15, 20 — 3.75" (95)A 14" (356) 10 / /

BAFH (AFCI) 1 15, 20 — 3.75" (95)A 14" (356) 22 / /

1, 2, 3

1, 2, 3

1, 2, 3 15, 20, 30, 40, 50, 60, 70 — 3.75" (95)

ED2 1, 2, 3 15, 20, 30, 40, 50, 60, 70, 80, 90, 100 3.75" (95)

ED4 1, 2, 3 15, 20, 30, 40, 50, 60, 70, 80, 90, 100, 110, 125 3.75" (95)

ED6 1, 2, 3 15, 20, 30, 40, 50, 60, 70, 80, 90, 100, 110, 125 3.75" (95)

HED4 1, 2, 3 15, 20, 30, 40, 50, 60, 70, 80, 90, 100, 110, 125 3.75" (95)

Thermal

Magnetic

CED6 2, 3 15, 20, 30, 40, 50, 60, 70, 80, 90, 100, 110, 125 3.75" (95)3.75" (95)E 7.61" (193) 200 200 100

HEB 2, 3 15, 20, 30, 40, 50, 60, 70, 80, 90, 100, 110, 125 — 3.75" (95)

NGB 1, 2, 3 15, 20, 25, 30, 40, 50 ,60, 70, 80, 90, 100, 110, 125 — 3.75" (95)

NGB2 1, 2, 3 15, 20, 25, 30, 40, 50 ,60, 70, 80, 90, 100, 110, 125 — 3.75" (95)

HGB2 1, 2, 3 15, 20, 25, 30, 40, 50 ,60, 70, 80, 90, 100, 110, 125 — 3.75" (95)

LGB2 1, 2, 3 15, 20, 25, 30, 40, 50 ,60, 70, 80, 90, 100, 110, 125 — 3.75" (95)

(Solid State)

LDG 3 60, 100, 150 — 5" (127) H 10.9" (276) 200 100 18

NDG 3 60, 100, 150 — 5" (127) H 10.9" (276) 65 35 18

Electronic

QR2 2, 3 100, 110, 125, 150, 175, 200, 225 5" (127) 5" (127) F 8.75" (222) 10 / /

Thermal

Magnetic

QRH2 2, 3 100, 110, 125, 150, 175, 200, 225 5" (127) 5" (127) F 8.75" (222) 25 / /

HQR2 2, 3 100, 110, 125, 150, 175, 200, 225 5" (127) 5" (127) F 8.75" (222) 65 / /

HQR2H 2, 3 100, 110, 125, 150, 175, 200, 225 5" (127) 5" (127) F 8.75" (222) 100 / /

Thermal

Magnetic

Electronic

(Solid State)

FXD6, FD6 2, 3 70, 80, 90, 100, 110, 125, 150, 175, 200, 225, 250 5" (127) 5" (127) G 8.25" (210) 65 35 22

HFD6 2, 3 70, 80, 90, 100, 110, 125, 150, 175, 200, 225, 250 5" (127) 5" (127) G 8.25" (210) 100 65 25

CFD6 2, 3 70, 80, 90, 100, 110, 125, 150, 175, 200, 225, 250 — 5" (127) J 11.76" (299) 200 200 100

NFG 3 100, 150, 250 — 5" (127) H 10.9" (276) 65 35 18

LFG 3 100, 150, 250 — 5" (127) H 10.9" (276) 200 100 25

JXD6, JD6 2, 3 200, 225, 250, 300, 350, 400 8.75" (222) 8.75" (222) K 7.92" (201) 65 35 25

Thermal

Magnetic

HJD6 2, 3 200, 225, 250, 300, 350, 400 8.75" (222) 8.75" (222) K 7.92" (201) 100 65 35

HHJD6 2, 3 200, 225, 250, 300, 350, 400 8.75" (222) 8.75" (222) K 7.92" (201) 200 100 50

CJD6 2, 3 200, 225, 250, 300, 350, 400 8.75" (222) — N 12" (305) 200 150 100

SJD6 3 200, 300, 400 8.75" (222) — M 13.42" (341) 65 35 25

Electronic

(Solid State)

SHJD6 3 200, 300, 400 8.75" (222) — M 13.42" (341) 100 65 35

SCJD6 3 200, 300, 400 8.75" (222) — N 12" (305) 200 150 100

NJG 3 250, 400 6.25" (159) 6.25" (159) L 8" (203) 65 35 25

LJG 3 250, 400 6.25" (159) 6.25" (159) L 8" (203) 200 100 25

LXD6 2, 3 450, 500, 600 8.75" (222) — M 13.42" (341) 65 35 25

Thermal

Magnetic

LD6 2, 3 250, 300, 350, 400, 450, 500, 600 8.75" (222) — M 13.42" (341) 65 35 25

HLD6 2, 3 250, 300, 350, 400, 450, 500, 600 8.75" (222) — M 13.42" (341) 100 65 35

HHLD6 2, 3 250, 300, 350, 400, 450, 500, 600 8.75" (222) — M 13.42" (341) 200 100 50

CLD6 2, 3 450, 500, 600 8.75" (222) — N 12" (305) 200 150 100

Electronic

(Solid State)

SLD6 3 300, 400, 500, 600 8.75" (222) — M 13.42" (341) 65 35 25

SHLD6 3 300, 400, 500, 600 8.75" (222) — M 13.42" (341) 100 65 35

SCLD6 3 300, 400, 500, 600 8.75" (222) — N 12" (305) 200 150 100

MXD6 2, 3 500, 600, 700, 800 10" (254) — P 13" (330) 65 50 25

Thermal

Magnetic

MD6 2, 3 500, 600, 700, 800 10" (254) — P 13" (330) 65 50 25

HMD6 2, 3 500, 600, 700, 800 10" (254) — P 13" (330) 100 65 50

CMD6 2, 3 500, 600, 700, 800 10" (254) — P 13" (330) 200 100 65

Electronic

(Solid State)

SMD6 3 600, 700, 800 10" (254) — Q 12" (305) 65 50 25

SHMD6 3 600, 700, 800 10" (254) — Q 12" (305) 100 65 50

SCMD6 3 600, 700, 800 10" (254) — Q 12" (305) 200 100 65

NXD6 2, 3 800, 900, 1000, 1200 10" (254) — P 13" (330) 65 50 25

Thermal

Magnetic

ND6 2, 3 800, 900, 1000, 1200 10" (254) — P 13" (330) 65 50 25

HND6 2, 3 800, 900, 1000, 1200 10" (254) — P 13" (330) 100 65 50

CND6 2, 3 800, 900, 1000, 1200 10" (254) — P 13" (330) 200 100 65

SND6 3 800, 1000, 1200 10" (254) — Q 12" (305) 65 50 25

Electronic

(Solid State)

SHND6 3 800, 1000, 1200 10" (254) — Q 12" (305) 100 65 50

SCND6 3 800, 1000, 1200 10" (254) — Q 12" (305) 200 100 65

15, 20, 25, 30, 40, 50, 60, 70, 80, 90, 100

15, 20, 25, 30, 40, 50, 60, 70, 80, 90, 100

Selection

Mounting Height Inches (mm) Max IC Rating (kA)

Single Twin Gutter

—

—

3.75" (95)

3.75" (95)

3.75" (95)

3.75" (95)

3.75" (95)

3.75" (95)

A

14" (356)

A

14" (356)1022//

A 14" (356) 65 / /

A 14" (356) 65 / 10

A 14" (356) 10 / /

A 14" (356) 10 / /

A 14" (356) 22 / /

D 10" (254) 10 / /

D 10" (254) 65 18 /

D 10" (254) 100 18 18

D 10" (254) 100 65 30

C 11.62 (295) 100 65 25

B 13.98" (355) 100 25 14

B 13.98" (355) 100 25 14

B 13.98" (355) 100 35 22

B 13.98" (355) 100 65 25

f

240V 480V 600V

/

/

a

Space includes housing frame plate with blank cover

plate. Provision includes all necessary mounting hardware, less circuit breaker, and includes housing frame

cover plate with breaker handle opening.

1 to 6 poles may be mounted in 3.75” (95) of unit space

Accessories such as shunt trips on three pole breakers

require 6.25” (159) of unit space.

Ground fault is not available on branch Sensitrip breakers.

e

Also 10kA at 600Y/347 Volts.

f

Refer to Table 5 for layout dimensions.

5

Sentron® SMP Switchboards

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

(

)

Power and Distribution

Protective Devices - Fusible Disconnects

Fuse Selection

The Proper Fuse Type for the Application

is Selected Using the Following

Parameters:

b Voltage Requirements

b Conductor Ampacity

b Horsepower Requirements

b Maximum Available RMS Fault Current

b CSA Fuse Class

Branch Switch Gutter Dimensions

For 38W Distribution Section (Table 8)

7.5"(191

7.5"(191

7.5"(191

10.0"(254

10.0"(254

10.0" (254)

8.0"(203

9.25"(235

30/30A VK Switch

60/60A VK Switch

100/100A VK Switch

200/200A VK Switch

30/30A VB Switch

60/60A VB Switch

100/100A VB Switch

200/200A VB Switch

400A thru 600A

VB Switch

6.25"(159

6.25"(159

7.5"(191

7.5"(191

7.5"(191

7.5"

10.0"(254

15.0"(381

10.0" (254)5.0"(127

Branch Switches 600V Maximum (Table 11)

Rating Max Fusing Mounting

Ampere Voltage Height 38”W

191

30/30A & 60/60A (VK)

10 0/100A (VK)

200/200A (VK)

30/30A & 60/60A (VB) 600V Class J 7.5” (190)

100/100A (VB) 600V Class J 7.5” (190)

200A (VB) 600V Class J 10.0” (254)

400A & 600A (VB) 60 0V Class J 15.0” (381)

Maximum VB HP Ratings (Table 6)

Volts

Amp 3 Phase Single Phase

Rating 240 480 600 240

30 7.5 15 20 3

60 15 30 50 10

100 30 60 50 15

200 60 125 50 –

400 50 50 50 –

600 50 50 50 –

Maximum VK HP Ratings (Table 9)

Volts

Amp 3 Phase Single Phase

Rating 240 480 600 240

30 7.5 15 20 3

60 1.5 30 50 10

100 30 50 75 15

200 60 125 150 15

e

600V Class J 6.25” (159)

e

60 0V Class J 7.5” (190)

e

600V Class J 10.0” (254)

Selection

Branch Switch Connectors (Table 10)

Switch

Ampere

Rating Wire and Cable Range

30 (1)—#14–#4 AWG (Cu or Al)

60 (1)—#14–#4 AWG (Cu or Al)

100 (1)—#10–#1/0 AWG (Cu or Al)

200 (1)—#6 AWG-350kcmil (Cu or Al)

40 0 (1)—#1/0 AWG-750 MCM OR

(2)—#1/0 AWG-250 MCM (Cu or Al)

60 0 (1)—#1/0 AWG-750 MCM OR

(2)—#1/0 AWG-250 MCM (Cu or Al)

Switch Interrupting Ratings

Interrupting Rating

Switch

Type

(kA)

240V 480V 600V

VB 20 0 10 0 10 0

VK 20 0 20 0 20 0

Gutters (Table 12)

End Gutters Side Gutters

Ampere Minimum - Minimum Rating Inches (mm) Inches (mm)

400 12” (305) 7.9” (201)

600 12” (305) 7.9” (201)

Switch Accessories (Table 13)

Fuse Pullers (VK)

30 or 60 Amp FP2

100 Amp FP3

200 Amp FP4

Cat. No.

CSA Fuse Classes (Table 14)

Class Amperes Volts (AC) I2t, Ip (Let-Thru) Circuits

H Standard Code 1-600A 250 and 600V — Less than

or less — 10,000A available

a

K

Fast Acting 1-600A 250 and 600V — Feeder circuits

(One time) or less

J Fast Acting 1-600A 600V or less Ip and I2t-Low Feeder circuits

and Time Delay (motor load small %) Motor circuits

RK1 Fast Acting 1/10-600A 600V or less I2t-Slightly > J Feeder circuits

and Time Delay 250V or less Ip-Slightly > J Motor circuits

RK5 Fast Acting 1/10-600A 600V or less I2t- > RK-1 Feeder circuits

and Time Delay 250V or less Ip- > RK-1 Motor circuits

C Moderate 2-600A 600V or less I2t- < RK-5 Motor circuits

(FORM II)

Delay Ip- < RK-5

T Fast Acting 1-600A 300 and 600V I2t-Low Non-motor loads

or less Ip-Low

L Fast Acting 601-5000A 600V or less I2t-Low Feeder circuits

and Time Delay motor loads Motor circuits

a

Fuse clips do not prohibit the use of Class H type fuse

in switch.

Refer to Siemens for single phase and DC horsepower

requirements.

Ratings are based on UL test procedure.

Connector range applies to VB Switches only.

5

Not suitable for use in distribution space in main section.

6

Sentron® SMP Switchboards

Power and Distribution

Special Construction, Additions and Accessories

When required, special constructions

or additions to standard Switchboards

may be specified for all factory-

assembled Power and Distribution

Switchboards. Listed below are those

available for Type SMP Switchboards.

1. Enclosure Type

38” Enclosure Types

Type 1

Type 2 (dripproof & sprinklerproof)

Optional: Dripshield

2. Wireway Options

24”W x 90”H x 12.75” Dp

24”W x 90”H x 25.5” Dp

Hinged Door

Door Covers

Hinged Door

Door Covers

3. Painted Finish

Touch-Up Paint (ASA61, Light Grey)

12 oz. aerosol can, Cat. # TUP-61

4. Miscellaneous Accessories

Nameplate - laminated and engraved

5. Bus-Link (One Set Per Panel)

Ampere Unit Space Occupied in MUD -

Rating Inches (mm)

400-1200 Consult Factory

6. Grounding of SMP Switchboard

Non-Insulated Equipment Ground Bus

Including Ground Lug

Continuous Solid Copper Ground

(optional)

7. Main Bus

Standard Main bus and Neutral bus are

tin plated aluminum or silver finished

copper (option).

8. Lugs

For Main Device and Neutral

For Main Breakers please see SpeedFax

section #6

Neutral - please consult factory

9.SPD Modules

Sentron TPS3 05

100KA

150KA

200KA

250KA

300KA

Options: Surge Counter

Remote Monitor

10. Circuit Breaker Accessories

Handle Blocking Device

Blocks handle in either the “ON” or

“OFF” position. Available for:

Breaker Type Cat. Number

BL, BLH, HBL, BQ,

BQH, HBQ

All BQD, GB BQDHBD

All QR HPLQR

All BQD, NGB, NGB2,

HGB2, LGB2

All ED E2HBL

All FD FD6HB1

All JD, LD JD6HBL

All MD, ND, PD MN6BL

Padlocking Device — Padlocks in

“OFF” position. Available for:

Breaker Type Cat. Number

BQ, BQH, BL, BLH, HBL ECQLD3

One Pole BL, BLF, BE,

BAF

Two-Pole BL, BLF, BE ECPLD2

All QR HPLQR

All BQD, NGB, NGB2,

HGB2, LGB2

All ED ED2HPL

All FD FD6PL1

All JD, LD JD6HPL

All MD, ND, PD, RD MN6PLD

Handle Extensions - For replacement

(one extension shipped with breaker)

Breaker Type Cat. Number

All MD, ND, PD EX11

Ground Fault Sensing Relay Kit

Equipment Protection (30 mA)

For Use with Number Catalogue Number

Breaker Types of Poles Description

ED4, ED6,

HED4 1, 2, 3

Shunt Trip on Main or Branch

Description Cat. Number

BL, BQD6 (branch only)

ED2, ED4, HED4 (branch only)

All others through 1200A

ECQL1

BQDHBD

ECPLD1

BQDPLD

See breaker section

of this catalogue.

See breaker

portion of this

catalogue

Selection

VK Switch For Use With FPP6

Panelboards

30/30 VK23611JP 6.25 (159)

60/60 VK23622JP 6.25 (159)

100/100 VK33633JP 7.5 (90)

200/200 VK73644JP 10 (254)

VB Switch For Use With VB6

Panelboards

30/30 V7E3611JP 7.5(190)

60/60 V7E3622JP 75(190)

100/100 V7E3633JP 7.5(190)

200 V7F3604JP 10(254)

400 V7H3605JP 15(381)

600 V7H3606JP 15(381)

7

Sentron® SMP Switchboards

A. Scope

Furnish and install, as shown on the plans,

a secondary distribution switchboard, as

specified herein, for the system indicated

below:

120/208V 3-phase 3-wire

347/600V 4-wire

600V

B. Configuration

The switchboard enclosure shall be of

bolted construction:

Type 1 indoor.

Type 1 with dripshield (optional).

Type 2.

Switchboard shall be bolted together to

form one metal enclosed rigid switchboard.

Switchboard shall include all protective

devices and equipment as listed on

drawings with necessary interconnections,

instrumentation and control wiring.

All groups of control wires leaving the

switchboard shall be provided with terminal

blocks with suitable numbering strips.

The switchboard shall have space or

provisions for future expansion as noted on

the plans. Switchboard shall be constructed

and certified in accordance with CSA

22.2.31 standards and shall be Siemens

type (SMP) or approved equal. Individual

sections shall be front accessible, not less

than 12.75” (324) deep, and the rear of all

sections shall align.

Distribution sections shall be designed to

accommodate the intermixing of Molded

Case Breakers and Fusible Disconnects in

the same distribution interior.

C. Bus Requirements

The bus shall be tin-finished aluminum

silver-finished copper (option) of

sufficient size to limit the temperature

rise to 65°C. The bus shall be braced for

50,000 or 65,000 (option) amperes

symmetrical and supported to withstand

mechanical forces exerted during short

circuit conditions when directly connected

to a power source having the indicated

available short circuit current.

D. Incoming Service

Overhead or Underground Service:

Cable Entry

This section shall be bussed and

sealable per local utility requirements.

Screw-type mechanical lugs,

compression lugs to terminate,

aluminum, copper cable, shall be

__________ kcmil, and ___ cables per

phase. Main breaker standard aluminum

mechanical lugs suitable for aluminum or

copper. (No wireway)

E. Metering Service Section

The service section shall be designed

for the system parameters indicated in

section “A” above. The metering service

section shall have a Utility Metering

compartment per utility requirements.

User metering as indicated below and

as shown on plans.

Main (service) section:

Siemens Digital metering with

remote display

_______ current transformer(s)

_______ /5 or suitable rating

SEM3 Embedded Metering

Ground fault Protection (3-Phase, 4-Wire):

Furnish and install on the service

equipment and/or switchboard a Ground

Fault protection system and indication

equipment as specified herein and as

shown on drawings in accordance with

CEC Section 14-102.

All new Ground Fault Protection and

Indication equipment shall be factory

installed, wired and tested by the

switchboard manufacturer.

F. Switchboard SMP Guide Specification

The complete switchboard shall be finished

with light grey, ASA-61 paint.

Each switchboard main section shall have a

metal nameplate permanently affixed to it,

listing the following information:

b Name of manufacturer

b System voltage

b Ampacity

b Type

b Manufacturer’s shop order number and

date

b Each section of switchboard shall bear a

CSA certification mark and a short circuit

rating label.

The switchboard shall be per the

arrangement below.

F1. Switchboard Type Panel-Mounted,

Front Accessible.

Switchboard shall be of Siemens SMP

type, or approved equal. Individual sections

shall be front accessible, floor mounted

rear supported, not less than 12.75” (324)

deep, and rear, of all sections shall align.

Incoming line termination, main device

connection and all bolts used to join

current-carrying parts shall be installed so

as to permit servicing from the front only

so that no rear access is required. The

branch devices shall be front removable

and panel mounted with line and load side

connections front accessible.

G. Main Protective Devices

The main protective device, to be installed

in the main device section, shall be as

indicated below:

G1. Molded Case Circuit Breaker

Molded case circuit breaker shall be of the

quick-make, quick-break, trip-free,

(standard) (High Interrupting)

(Current Limiting) (solid state

Sensitrip III) type.

It shall be _______ frame (3-pole)

(240V) (600V) breaker with a trip

current rating of:

400A, 600A, 800A, 1000A

1200 A

a

of an interrupting capacity

a

,

Specification

of not less than _______ amperes RMS

symmetrical at the system voltage.

The following accessory options are to be

included:

Shunt trip

Ground fault relay

Long time (Sensitrip III only)

Long time delay (Sensitrip III only)

Short time (Sensitrip III only)

Short time delay (Sensitrip III only)

Integral ground fault (Sensitrip III only)

Other_______ (list)

H. Branch Protective Devices

(Select as necessary)

All molded case circuit breakers, and

fusible disconnect units used as a

protective device in a branch circuit will

meet the requirements of the appropriate

paragraph below

H1. Molded Case Circuit Breaker

Molded case circuit breakers shall be

of quick-make, quick-break, trip-free

(thermal magnetic type) (current limiting)

(solid state) with frame, trip and voltage

rating, either 2-pole or 3-pole, as

indicated on the plans. All breakers shall

have an interrupting capacity of not less

than _______ amperes RMS symmetrical

at the system voltage. All breakers shall

be removable from the front of the

switchboard without distributing adjacent

units. The switchboard shall have space or

provisions for future units shown on the

plans.

H2. Current Limiting Circuit Breaker

Current limiting circuit breakers shall

provide inverse time delay, instantaneous

circuit protection, and also limit the letthrough I2t to a value less than I2t of

one-half cycle wave of the symmetrical

prospective current without any fusible

elements. Breakers shall have an

interrupting capacity of not less than

_______ ampere RMS symmetrical at the

system voltage.

H3. Fusible Disconnect

Fusible disconnects shall be quick-make,

quick-break units utilizing the double-break

principle of circuit rupturing to minimize

arcing and pitting and shall conform to the

ratings shown on the plans.

Each disconnect shall have an individual

door over the front, equipped with a

voidable interlock that prevents the door

from being opened when the switch is

in the ON position unless the interlock

is purposely defeated by activation of

the voiding mechanism. All disconnects

shall have externally operated handles.

Disconnects shall be equipped with

Class J (standard), Class R rejection

type, Class L (standard), Class T fuse

holders as indicated on the plans suitable

for application on system with _______

amperes symmetrical available fault

current.

a

Ground fault protection required, per CEC section 14-102 when “the current is O 1000A at 60 0 volts.”

8

Siemens Canada Limited

Low Voltage & Products

1577 North Service Road East

Oakville, ON L6H 0H6

Canada

Customer Interaction Centre

Tel: 1 (888) 303-3353

cic.ca@siemens.com

Order number: SI-LP-1668

www.siemens.ca/powerdistribution

Loading...

Loading...