Siemens Sivacon S8 Planning Information

Totally Integrated Power

SIVACON S8

Technical Planning Information · 10/2015

www.siemens.com/sivacon-s8

Qualifiziertes Personal

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING, death or severe personal injury may result if proper

precautions are not taken.

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

SIVACON S8

Technical Planning Information

System-based power distribution

1

1

SIVACON S8 – System overview

Circuit-breaker design

Universal mounting design

In-line design, plug-in

Cubicles in fixed-mounted design

Reactive power compensation

2

3

4

5

6

7

Further planning notes

Conforming to standards and design-verified

Technical annex

Glossary and rated parameters

SIVACON S8 Planning Principles –

8

9

10

11

1

Content

1 System-based power distribution 4

2 SIVACON S8 – System overview 8

2.1 System configuration and cubicle design 10

2.2 Corner cubicle 15

2.3 Main busbar, horizontal 16

2.4 Connection points for earthing and

short-circuit devices 17

2.5 Overview of mounting designs 18

3 Circuit-breaker design 22

3.1 Cubicles with one ACB (3WL) 24

3.2 Cubicles with up to three ACB (3WL) 29

3.3 Cubicles with one MCCB (3VL) 30

3.4 Cubicles for direct supply and direct

feeder 31

4 Universal mounting design 34

4.1 Fixed-mounted design with

compartment door 37

4.2 In-line switch-disconnectors with fuses

(3NJ62 / SASIL plus) 38

4.3 Withdrawable design 38

5 In-line design, plug-in 50

5.1 In-line switch-disconnectors 3NJ62

with fuses 51

5.2 In-line switch-disconnectors SASIL plus

with fuses 53

8 Further planning notes 72

8.1 Installation 72

8.2 Weights and power loss 76

8.3 Environmental conditions 77

9 Conforming to standards and

design-verified 80

9.1 The product standard

IEC 61439-2 80

9.2 Arc resistance 81

9.3 Seismic safety and seismic requirements 83

9.4 Declarations of conformity and certificates 85

10 Technical annex 92

10.1 Power supply systems according to their

type of connection to earth 92

10.2 Loads and dimensioning 95

10.3 Degrees of protection according to

IEC 60529 97

10.4 Forms of internal separation based on

IEC 61439-2 98

10.5 Operating currents of three-phase

asynchronous motors 99

10.6 Three-phase distribution transformers 100

11 Glossary and rated parameters 102

11.1 Terms and definitions 102

11.2 Rated parameters 104

11.3 Index of tables 106

11.4 Index of figures 108

6 Cubicles in fixed-mounted design 56

6.1 In-line design, fixed-mounted 56

6.2 Fixed-mounted design with front cover 59

6.3 Cubicle for customized solutions 63

7 Reactive power compensation 66

7.1 Configuration and calculation 68

7.2 Separately installed compensation cubicles 70

Chapter 1

System-based power

distribution

1 System-based power distribution

PROFINET PROFIBUS ... Industrial Ethernet Modbus

≤ 110 kV

Process / Industrial automation Building automation

Consulting,

planning

OperationOrdering,

delivery

Engineering Service,

modernisation

Installation,

commissioning

Products, systems and solutions

Renewables

Automation

Power distribution

Operation

and

monitoring

Load

manage-

ment

Load

curves,

forecast

Generator

control

Switchboard

manage-

ment

Status

reporting/

Failure

managem.

Power

Quality

Cost

center,

protocols

Mainte-

nance

Energy automation

Storage

technology

Medium-voltage

switchgear and

circuit protection

Transformer Low-voltage switchboard

including circuit protection

and measuring systems

Low voltage

distribution

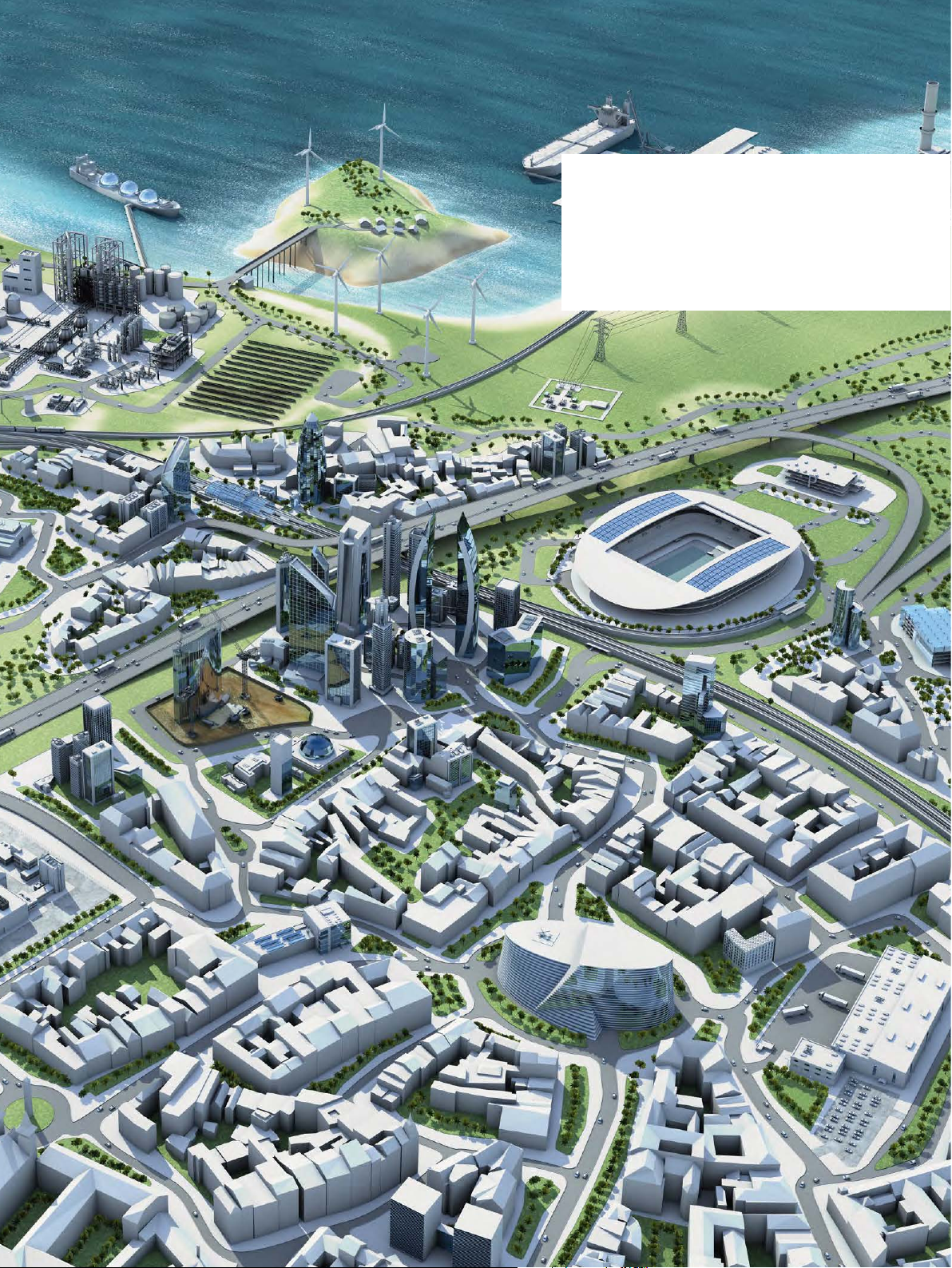

When a power distribution concept is to be developed

which includes dimensioning of systems and devices, its

requirements and feasibility have to be matched by the end

user and the manufacturer. We have prepared this planning

manual for the SIVACON S8 low-voltage switchboard to

support you with this task. Three principles must be observed for optimal power distribution:

• Safety - integrated

• Economic efficiency - right from the start

• Flexibility – through modularity

Comparable to a main artery, electric power supply constitutes the basis for reliable and efficient functioning of all

electrically operated facilities. Electrical power distribution

requires integrated solutions. Totally Integrated Power (TIP)

is a synonym for integrated electrical power distribution

(Fig. 1/1) in industrial applications, infrastructure projects

and buildings.

SIMARIS planning tools

The SIMARIS planning tools by Siemens provide efficient

support for dimensioning electric power distribution systems and determine the devices and distribution boards

required for them.

• SIMARIS design for network calculation and dimensioning

• SIMARIS project for determining the space requirements

of distribution boards and the budget, and for generating

specifications (bills of quantities)

• SIMARIS curves for visualising characteristic tripping

curves, cut-off current and let-through energy curves.

Further information about TIP:

www.siemens.com/tip

Further information about SIMARIS:

www.siemens.com/simaris

Fig. 1/1: Totally Integrated Power (TIP) as holistic approach to electric power distribution

4

SIVACON S8 Planning Principles – System-based power distribution

SIMARIS configuration tools

Tested safety

Configuring and dimensioning a low-voltage switchboard is

very complex. SIVACON S8 switchboards are configured by

experts, effectively supported by the SIMARIS configuration

tools during the stages of switchboard manufacture, operation and maintenance:

• SIMARIS configuration for tender drawing up, order

processing and manufacturing the SIVACON S8

switchboard

• SIMARIS control to efficiently create visualisation systems

for operating and monitoring the SIVACON S8

switchboard

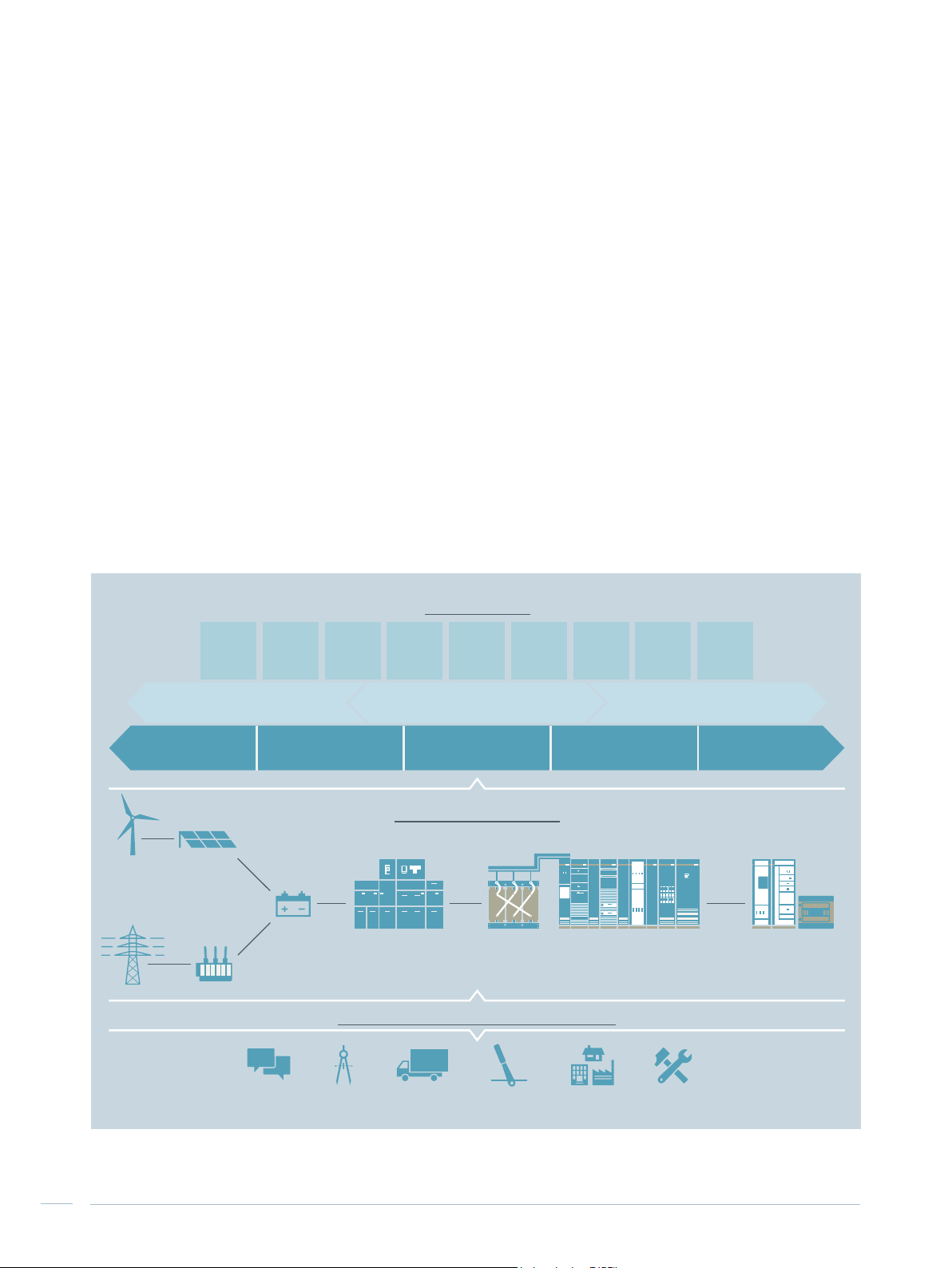

Cost-efficient complete system

The SIVACON S8 low-voltage switchboard sets new standards worldwide as power distribution board (PDB) or motor

control center (MCC) for industrial applications or in infrastructure projects (Fig. 1/2). The switchboard system up to

7,000 A for easy and integrated power distribution ensures

maximum personal safety and plant protection and provides many possibilities for use due to its optimal design. Its

modular construction allows the switchboard to be optimally matched to any requirement when the whole plant is

designed. Maximum safety and modern design now complement each other in an efficient switchboard.

SIVACON S8 is a synonym for safety at the highest level.

The low-voltage switchboard is a design-verified low-voltage switchgear and controlgear assembly in accordance

with IEC 61439-2. Design verification is performed by

testing. Its physical properties were verified in the test area

both for operating and fault situations. Maximum personal

safety is also ensured by a test verification under arcing

fault conditions in accordance with IEC/TR 61641.

Flexible solutions

The SIVACON S8 switchboard is the intelligent solution

which adapts itself to your requirements. The combination

of different mounting designs within one cubicle is unique.

The flexible, modular design allows functional units to be

easily replaced or added. All SIVACON S8 modules are

subject to a continuous innovation process and the complete system always reflects the highest level of technical

progress.

Further information about SIVACON S8:

www.siemens.com/sivacon-s8

1

2

3

4

5

6

Motor control center

Power distribution from the power center to the main and subdistribution board

Chemical &

mineral oil industry

Fig. 1/2: SIVACON S8 for all areas of application

Power industry:

Power plants

and auxiliary systems

SIVACON S8 Planning Principles – System-based power distribution

Capital goods industry:

Production-related systems

Infrastructure:

Building complexes

7

8

9

10

11

5

Use

Advantages of modular design

SIVACON S8 can be used at all application levels in the

low-voltage network (Fig. 1/3):

• Power center or secondary unit substation

• Main switchboard or main distribution board

• Subdistribution board, motor control center, distribution

board for installation devices or industrial use

Power center

Every SIVACON S8 switchboard is manufactured of demand-oriented, standardised, and series-produced modules. All modules are tested and of a high quality. Virtually

every requirement can be satisfied due to the manifold

module combination possibilities. Adaptations to new

performance requirements can easily and rapidly be implemented by replacing or adding modules.

The advantages offered by this modular concept are clear:

• Verification of safety and quality for every switchboard

• Fulfilment of each and every requirement profile

combined with the high quality of series production

• Easy placement of repeat orders and short delivery time

Main distribution

board

Subdistribution

boards

Consumers load

Fig. 1/3: Use of SIVACON S8 in power distribution

6

SIVACON S8 Planning Principles – System-based power distribution

M M M

Motor

control

center (MCC)

M

Chapter 2

SIVACON S8 – System overview

2.1 System configuration and

cubicle design 10

2.2 Corner cubicle 15

2.3 Main busbar, horizontal 16

2.4 Connection points for earthing and

short-circuit devices 17

2.5 Overview of mounting designs 18

2 SIVACON S8 – System overview

The interaction of the components described below results

in an optimal low-voltage switchboard with advantages as

regards:

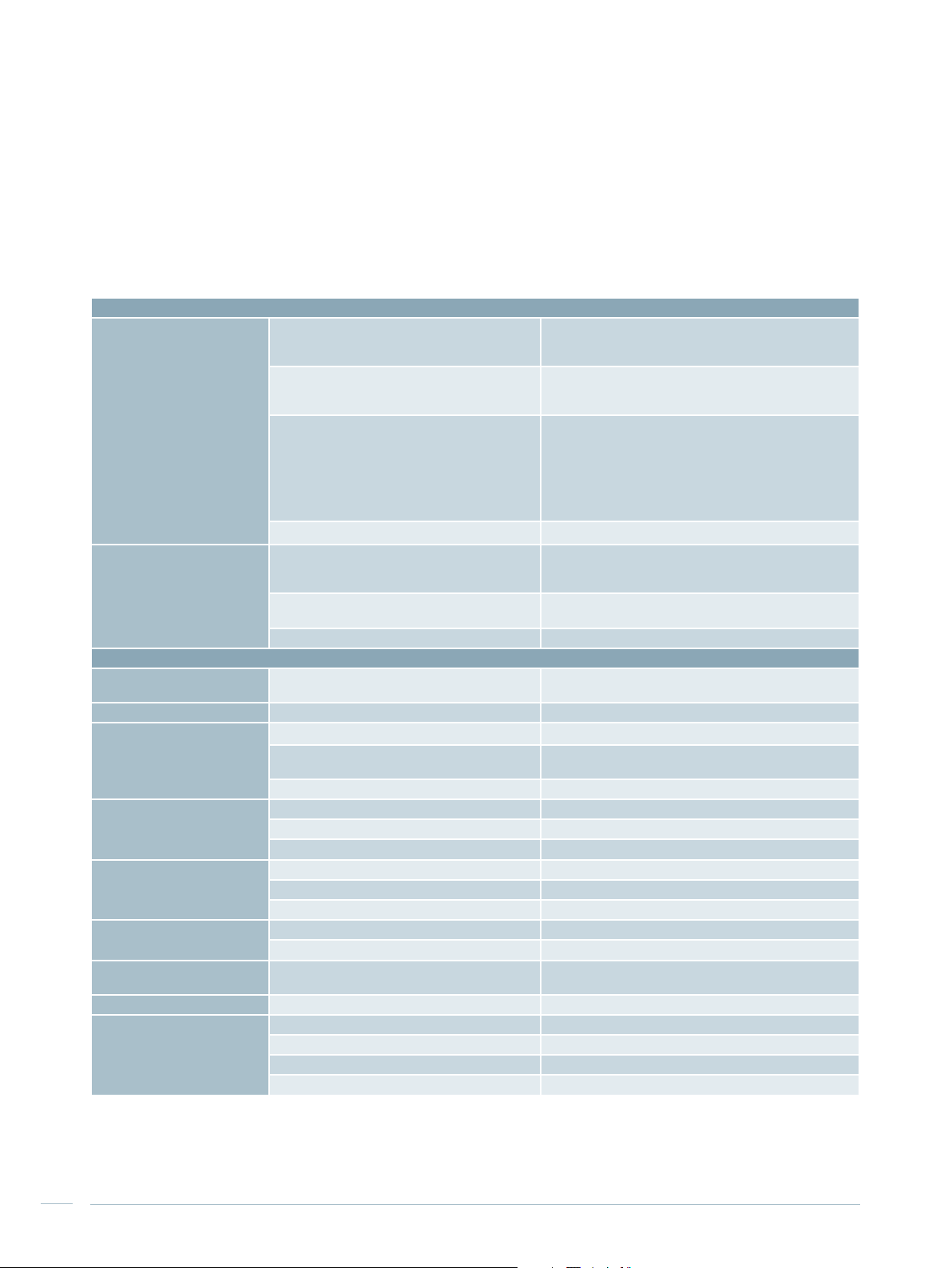

Tab. 2/1: Technical data, standards and approvals for the SIVACON S8 switchboard

Standards and approvals

Standards and regulations Power switchgear and controlgear assembly

Approvals Europe

Technical data

Installation conditions Indoor installation, ambient temperature in the

Rated operating voltage (U

Dimensioning of creepage

distances and clearances

Main busbars, horizontal Rated current Up to 7,010 A

Rated device currents Circuit-breakers Up to 6,300 A

Internal separation IEC 61439-2 Form 1 to form 4

IP degree of protection in accordance with IEC 60529 Ventilated up to IP43

Mechanical strength IEC 62262 Up to IK10

Dimensions Height (without base) 2,000, 2,200 mm

(design verification)

Test of internal fault behaviour (internal arc) IEC/TR 61641

Induced vibrations IEC 60068-3-3

Protection against electric shock EN 50274 (VDE 0660-514)

Russia, Belarus, Kasakhstan

China

Det Norske Veritas

Lloyds Register of Shipping

Shell conformity "DEP Shell"

24-h mean

Main circuit

e)

Rated impulse withstand voltage U

Rated

insulation voltage (U

Degree of pollution 3

Rated peak withstand current (I

Rated short-time withstand current (I

Cable feeders Up to 630 A

Motor feeders Up to 630 A

BS EN 61439-2 Up to form 4 type 7

Height of base (optional) 100, 200 mm

Cubicle width 200, 350, 400, 600, 800, 850, 1,000, 1,200, 1,400 mm

Depth (single-front) 500, 600, 800, 1,000, 1,200 mm

)

i

• Safety - integrated

• Economic efficiency - right from the start

• Flexibility – through modularity

IEC 61439-2

DIN EN 61439-2-2

VDE 0660-600-2

DIN EN 60439-1 Supplement 2

VDE 0660-500 Supplement 2

IEC 60068-2-6

IEC 60068-2-57

IEC 60980

KTA 2201.4

Uniform Building Code (UBC), Edition 1997 Vol. 2,

Ch. 19, Div. IV

CE marking and EC Declaration of Conformity

EAC

CCC

DNV GL Type Approval Certificate

LR Type Approval Certificate

+ 35 °C

(-5 °C to + 40 °C)

Up to 690 V (rated frequency fn 50 Hz)

imp

)

pk

)

cw

8 kV

1,000 V

Up to 330 kA

Up to 150 kA, 1s

Non-ventilated IP54

8

SIVACON S8 Planning Principles – SIVACON S8 – System overview

1

1

10

11

21

9

20

19

18

8

7

15

14

6

17

16

4

2

2

12

3

4

3

13

5

6

5

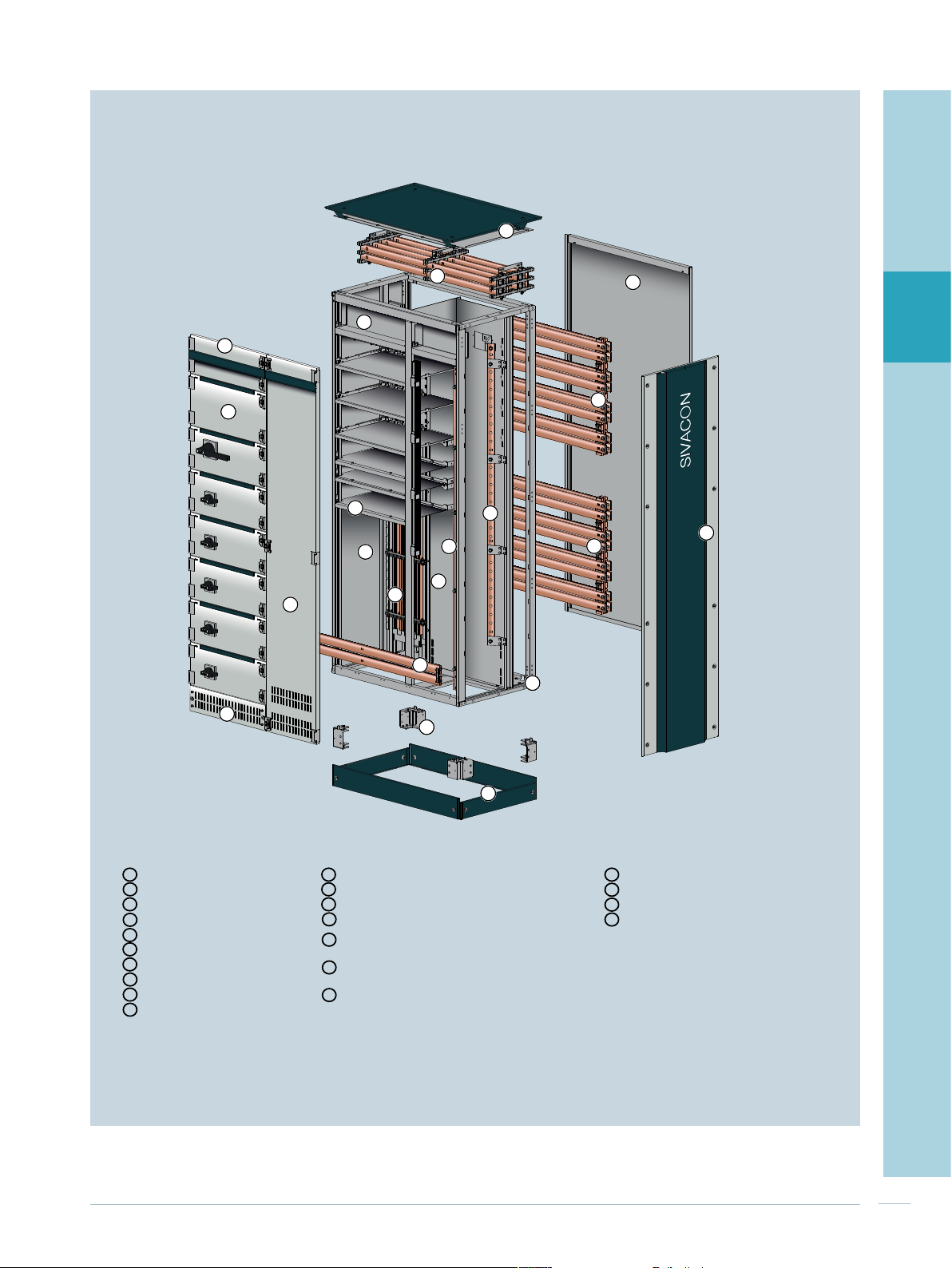

Enclosure Busbars Internal separation

Roof plate Main busbar (L1... L3, N) – top Device compartment/busbar compar tment

1 11 18

Rear panel Main busbar (L1... L3, N) – rear top Cubicle to cubicle

2 12 19

Design side panel Main busbar (L1... L3, N) – rear bottom Compartment to compartment

3 13 20

Frame Main busbar (PE) – bottom Cross-wiring compartment

4 14 21

Base cover

5

Base

6

Ventilated base compartment cover

7

Ventilated cubicle door

8

Compartment door

9

Head room door

10

Fig. 2/1: Cubicle design of SIVACON S8

Vertical distribution busbar system (L1... L3, N)

15

device compartment

Vertical distribution busbar (PE)

16

cable connection compartment

Vertical distribution busbar (N)

17

cable connection compartment

SIVACON S8 Planning Principles – SIVACON S8 – System overview

7

8

9

10

11

9

2.1 System configuration and

cubicle design

When the system configuration is planned, the following

characteristics must be specified:

• Busbar position (top, rear top, rear bottom, or both rear

top and rear bottom)

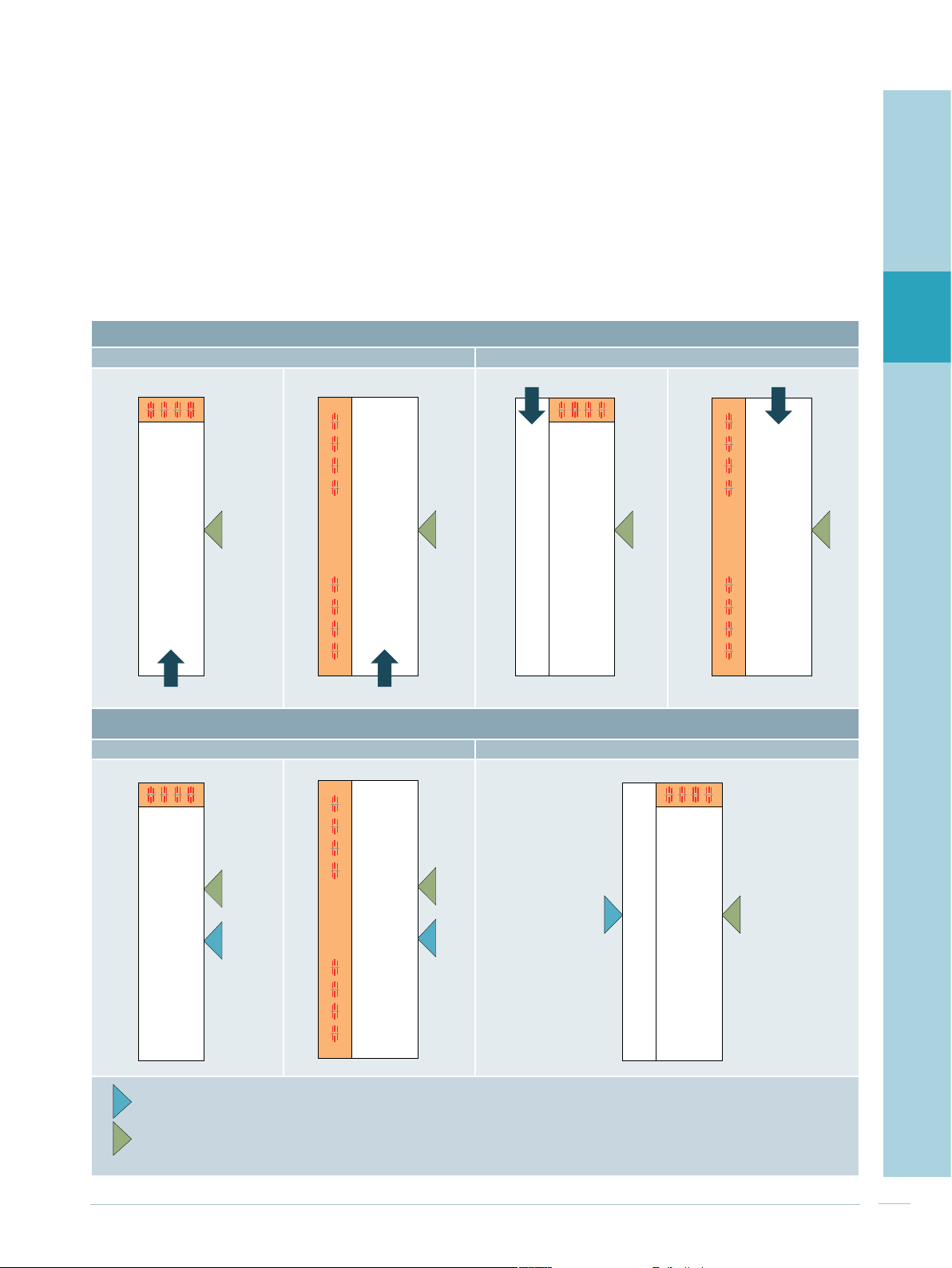

Tab. 2/2: Schematic overview of switchboard configurations for SIVACON S8

Busbar position

Top

Rear

Top Bottom Top and bottom

• Single-front or double-front design

• Cable/busbar entry (from the top or bottom)

• Connection in cubicle (front or rear)

B B B B

Single-front / double-front design

Single front Double front

B B

Side of connection

A

Operating panel

B

B

B

10

SIVACON S8 Planning Principles – SIVACON S8 – System overview

These characteristics depend on the type of installation

among other things:

• Stand-alone

• At the wall (only for single-front design)

• Back to back (only for single-front design)

These determinations allow to specify cubicle design in

more detail (Fig. 2/1, Tab. 2/2 and Tab. 2/3). Further information about the switchboard installation can be found in

Chapter 8 “Further planning notes”.

1

Cable/busbar entry

From the bottom From the top

B

Connection in cubicle

Front Rear

B

2

3

4

B

B

5

6

7

Side of connection

A

Operating panel

B

8

B

A

B

A

A

B

9

10

11

SIVACON S8 Planning Principles – SIVACON S8 – System overview

11

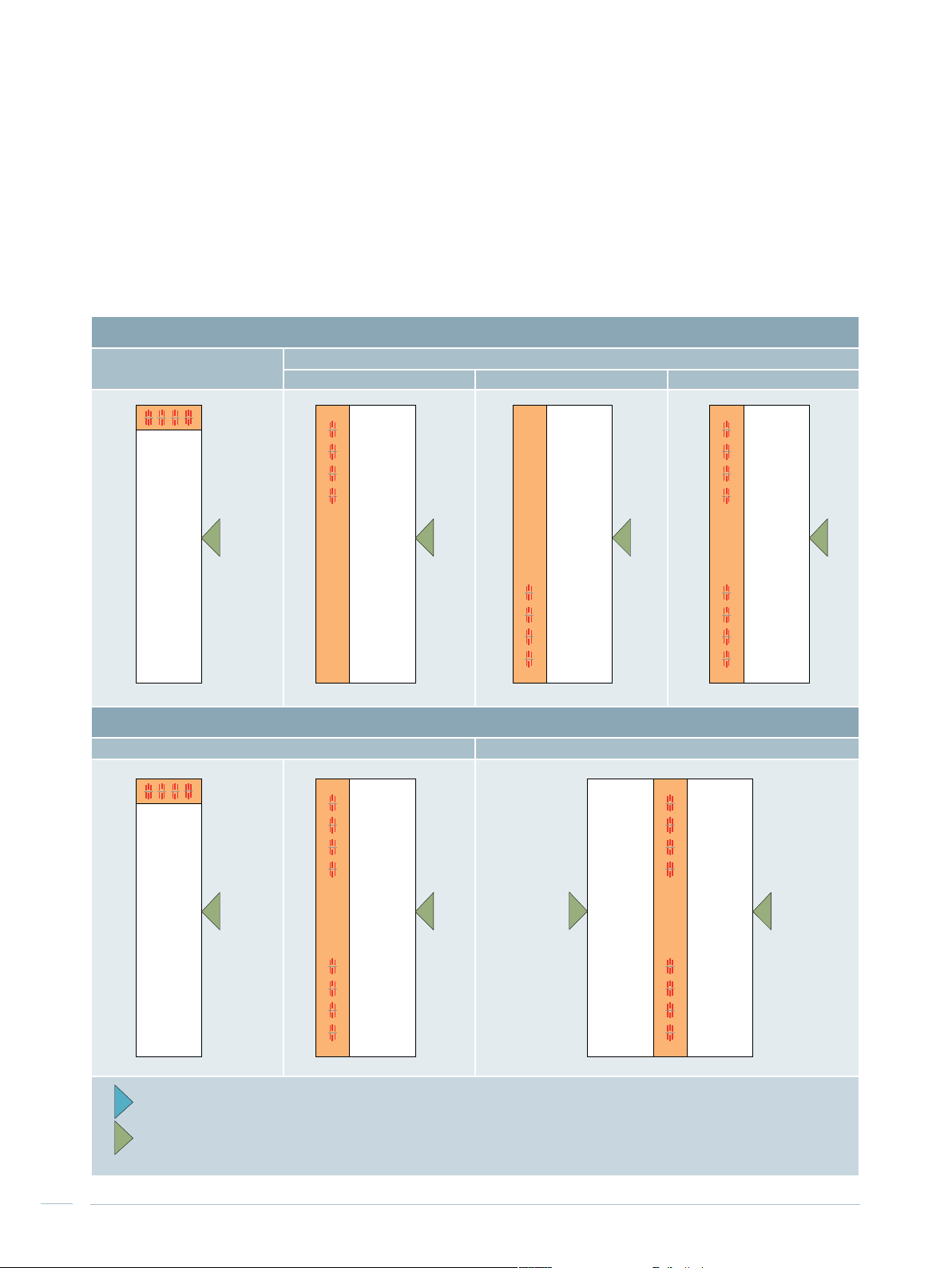

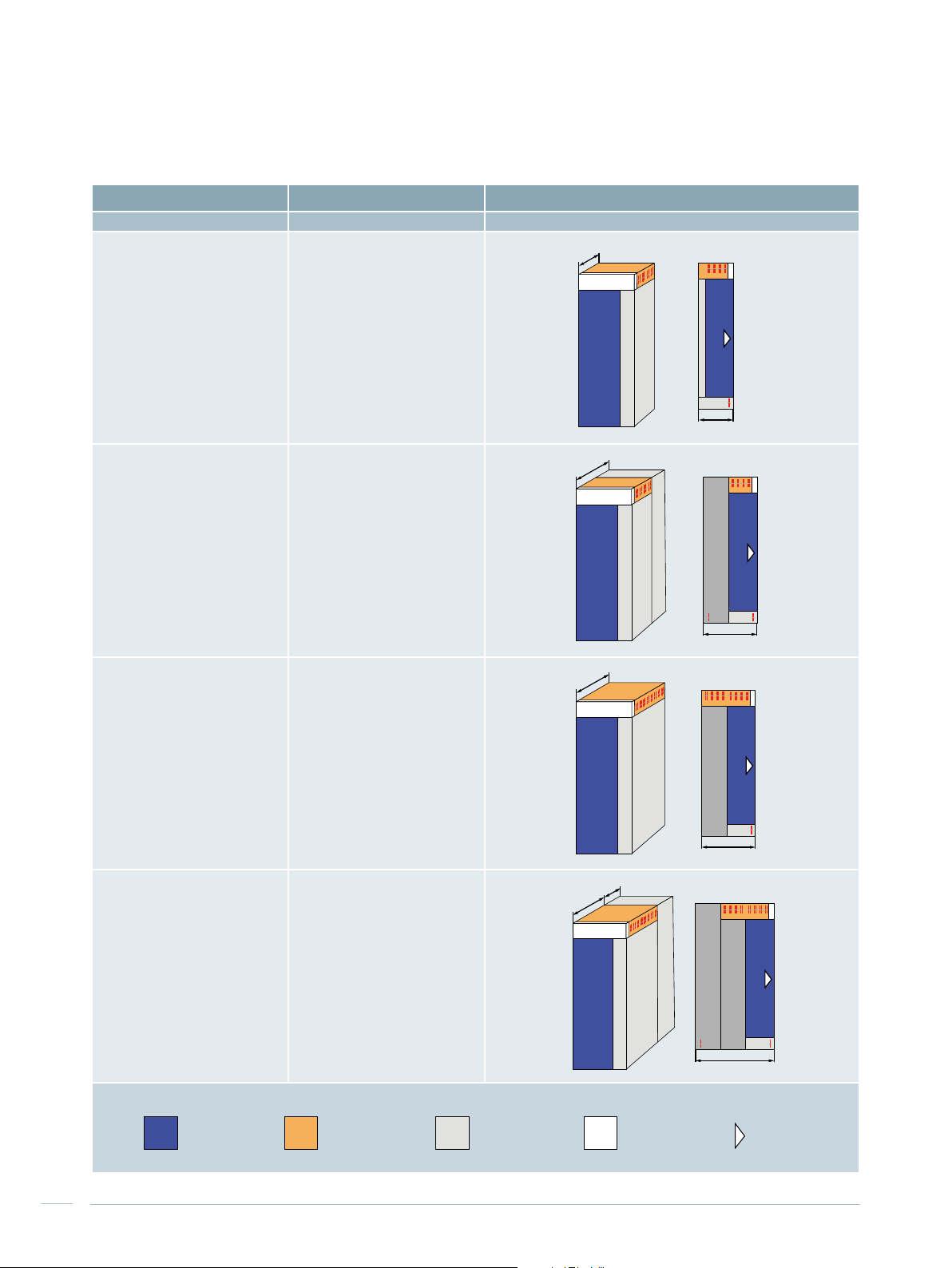

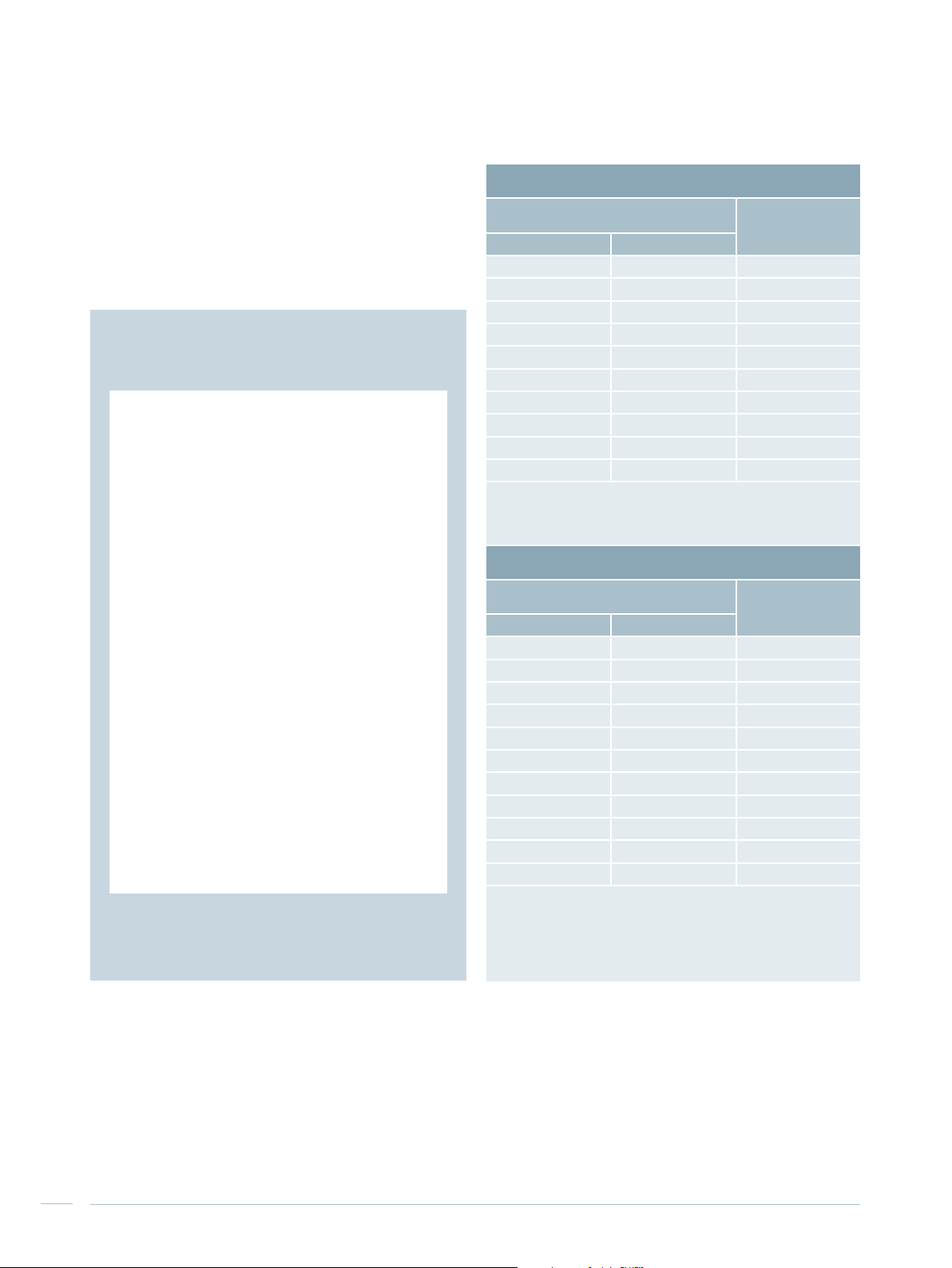

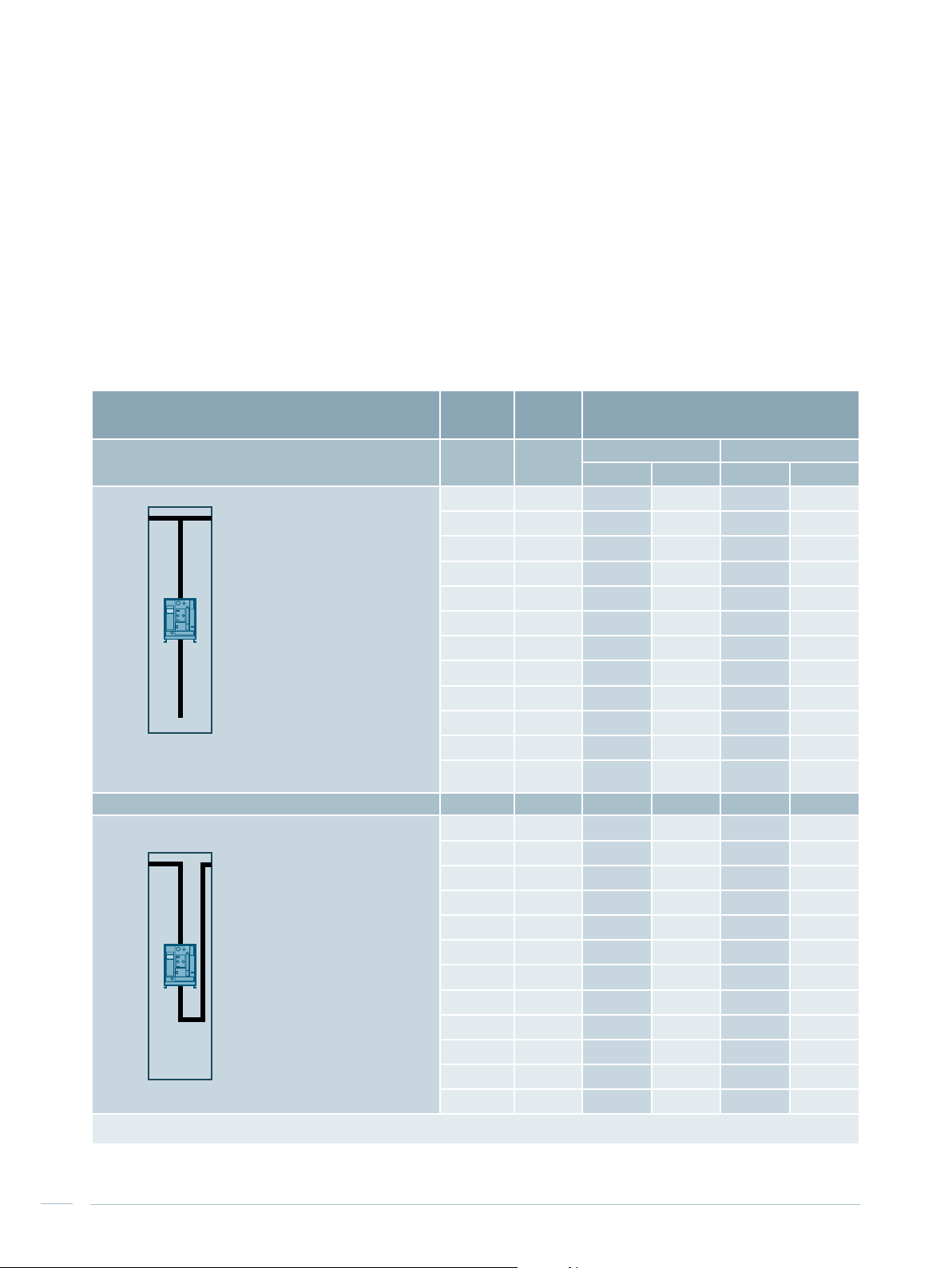

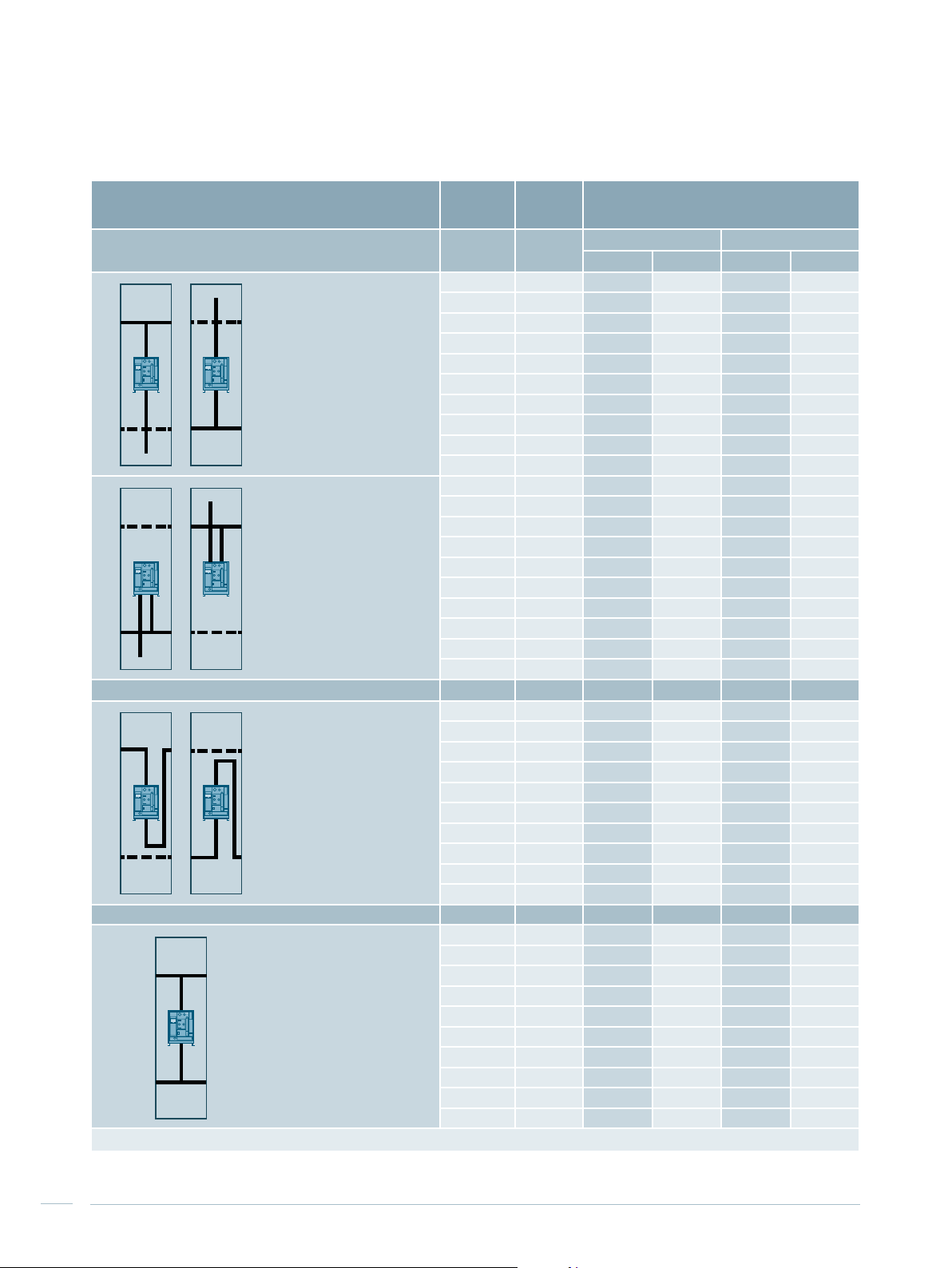

Tab. 2/3: Cubicle types and busbar arrangement

Top busbar position

Busbar system Cubicle design

Busbar position

Rated current

Cable/busbar entry

Connection in cubicle

Top

Up to 3,270 A

Bottom

Front

500

800

N L3 L2 L1

500

PE

N L3 L2 L1

Busbar position

Rated current

Cable/busbar entry

Connection in cubicle

Busbar position

Rated current

Cable/busbar entry

Connection in cubicle

Busbar position

Rated current

Cable/busbar entry

Connection in cubicle

Top

Up to 3,270 A

Top

Front or rear

Top

Up to 6,300 A

Bottom

Front

Top

Up to 6,300 A

Top

Front or rear

PE

PE

800

800

N L3 L2 L1

N L3 L2 L1

PE

800

400

800

N L3 L2 L1

N L3 L2 L1

Device/functional

compartment

12

SIVACON S8 Planning Principles – SIVACON S8 – System overview

Busbar

compartment

Cable / busbar

connection

compartment

Cross-wiring

compartment

1,200

PE

PE

Operating

panels

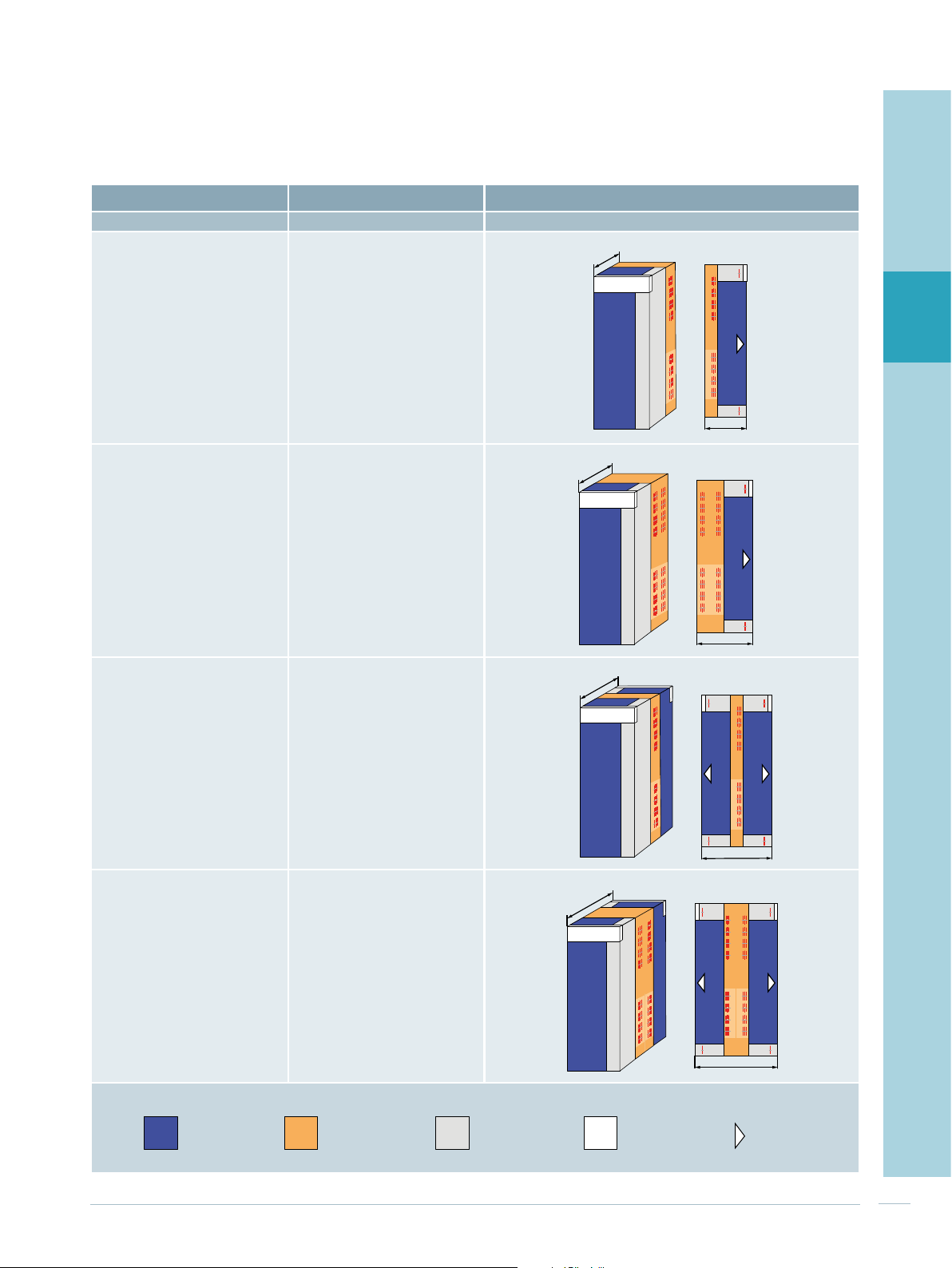

Rear busbar position

Busbar system Cubicle design

Rear

Busbar position

Top or bottom

Top and bottom

Rated current

Cable/busbar entry

Connection in cubicle

Busbar position

Up to 4,000 A

Bottom or top

Front

Rear

Top or bottom

Rated current

Cable/busbar entry

Connection in cubicle

Up to 7,010 A

Bottom or top

Front

800

600

1

PE

N

L1

L2

L3

L1

L2

L3

N

PE

600

PE

N

L1

L2

L3

L1

L2

L3

N

PE

800

2

3

4

5

Busbar position

Rated current

Cable/busbar entry

Connection in cubicle

Busbar position

Rated current

Cable/busbar entry

Connection in cubicle

Device/functional

compartment

Rear

Top or bottom

Top and bottom

Up to 6,300 A

Bottom or top

Front

Rear

Top or bottom

Up to 7,010 A

Bottom, top

Front

Busbar

compartment

Cable / busbar

connection

compartment

1,000

1,200

Cross-wiring

compartment

PE

PE

N

L1

L2

L3

L1

L2

L3

N

PE

PE

1,000

7

8

6

N

L1

L2

L3

L1

L2

L3

N

1,200

N

L1

L2

L3

L1

L2

L3

N

PE

PE

Operating

panels

9

10

11

PE

PE

SIVACON S8 Planning Principles – SIVACON S8 – System overview

13

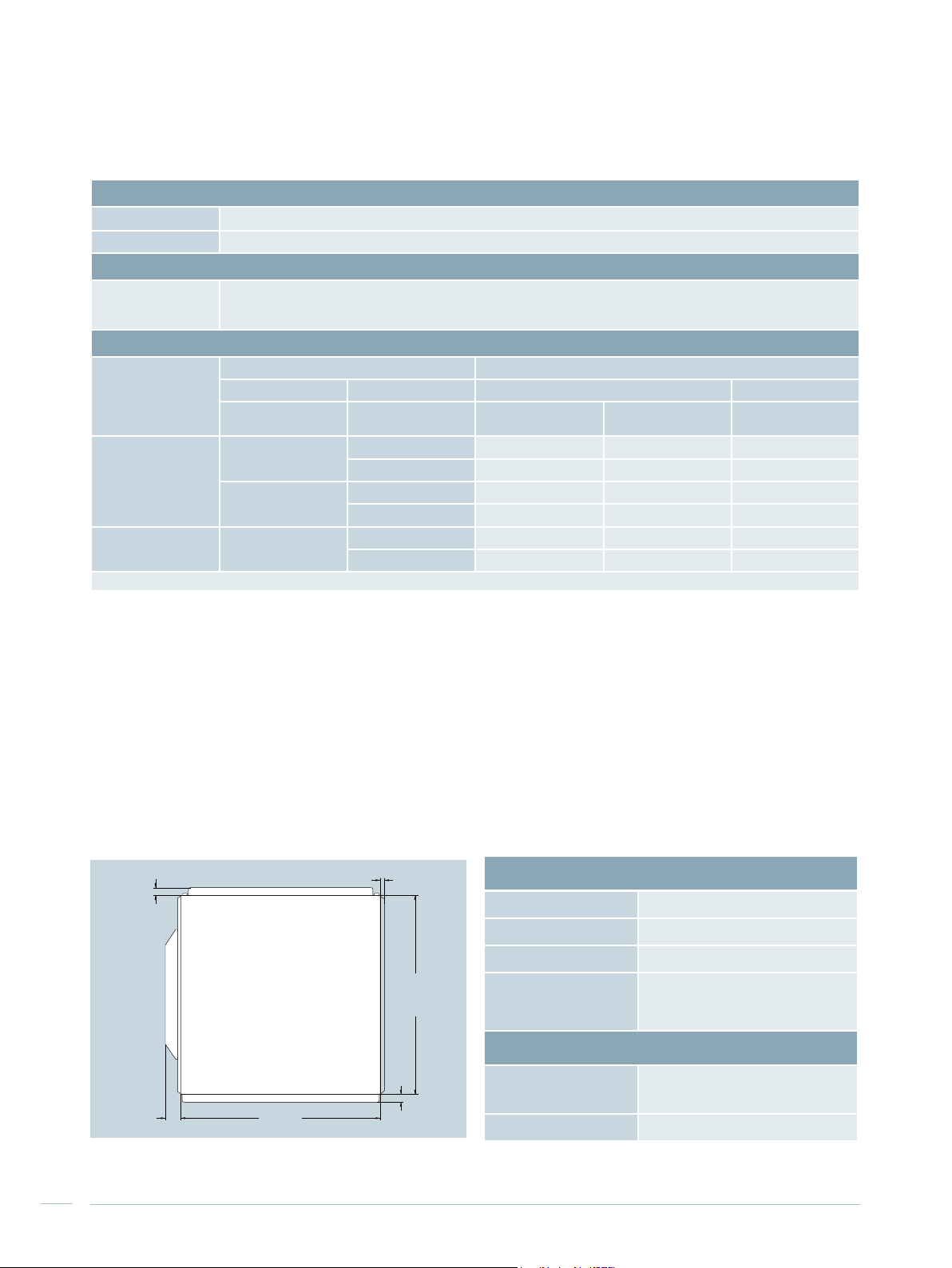

Tab. 2/4: Cubicle dimensions

Cubicle height

Frame 2,000, 2,200 mm

Base Without, 100, 200 mm

Cubicle width

Dependent of:

Cubicle depth

Type

Single front

Double front Rear

1)

Frame height 2,200 mm

- Cubicle type

- Rated device current

- Connecting position and/or cable/busbar entry

Main busbar Cubicle depth

Location Rated current Front connection Rear connection

Top

Rear

Entry from the

bottom

3,270 A 500, 800 mm 800 mm 800 mm

1)

6,300 A

4,000 A 600 mm 600 mm -

7,010 A 800 mm 800 mm -

4,000 A 1,000 mm 1,000 mm -

1)

7,010 A

800, 1,000 mm 1,200 mm 1,200 mm

1,200 mm 1,200 mm -

Entry from the top

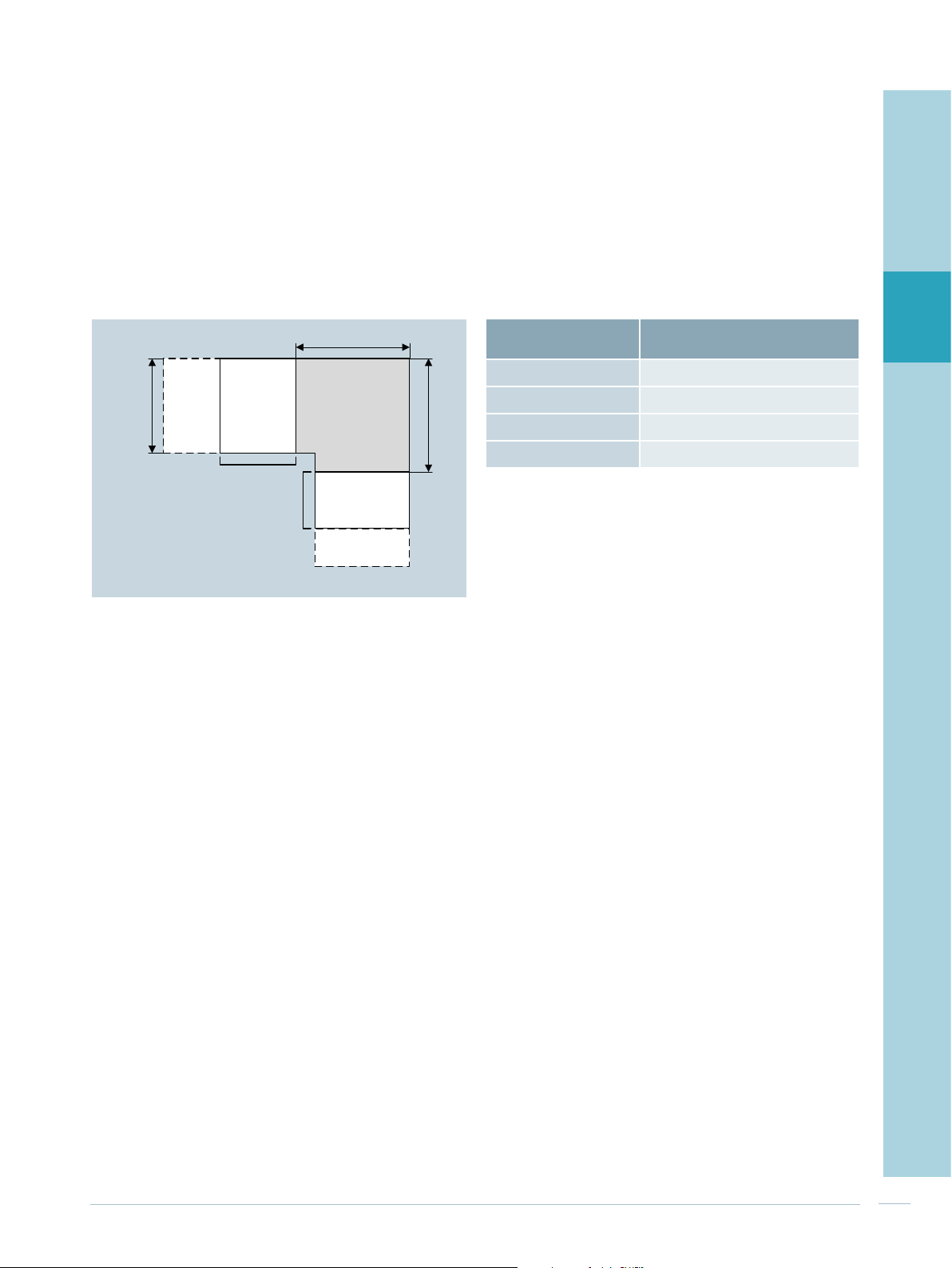

The cubicle dimensions listed in Tab. 2/4 do not factor in

the enclosure parts and no outer built-on parts.

For the dimensions of the cubicles' enclosure parts, please

refer to Fig. 2/2. For degrees of protection IPX1 and IPX3,

additional ventilation roof panels are mounted on the

cubicle.

The dimensions of the enclosure parts are within the

required minimum clearances for erecting the switchboard.

Doors can be fitted so that they close in escape direction.

9 mm

25 mm

Rear panel

Side panel

with

design strip

45 mm

Door

Width

Side panel

without

design strip

Depth

25 mm

The door stop can easily be changed later. The door hinges

allow for a door opening angle of up to 180° in case of

single installation of a cubicle and at least 125° when

cubicles are lined up. For more details, please refer to

Chapter 8 “Further planning notes”. The condition of surfaces of structural and enclosure parts is described in

Tab. 2/5.

Tab. 2/5: Surface treatment

Surface treatment

Frame components Sendzimir-galvanised

Enclosure Sendzimir-galvanised / powder-coated

Doors Powder-coated

Copper bars

Colour

Powder-coated

components

(layer thickness 100 ± 25 μm)

Design components Blue Green Basic

Bare copper,

optionally silver-plated,

optionally tin-plated

RAL7035, light grey (in accordance

with DIN 43656) or upon request

Fig. 2/2: Dimensions of enclosure parts

14

SIVACON S8 Planning Principles – SIVACON S8 – System overview

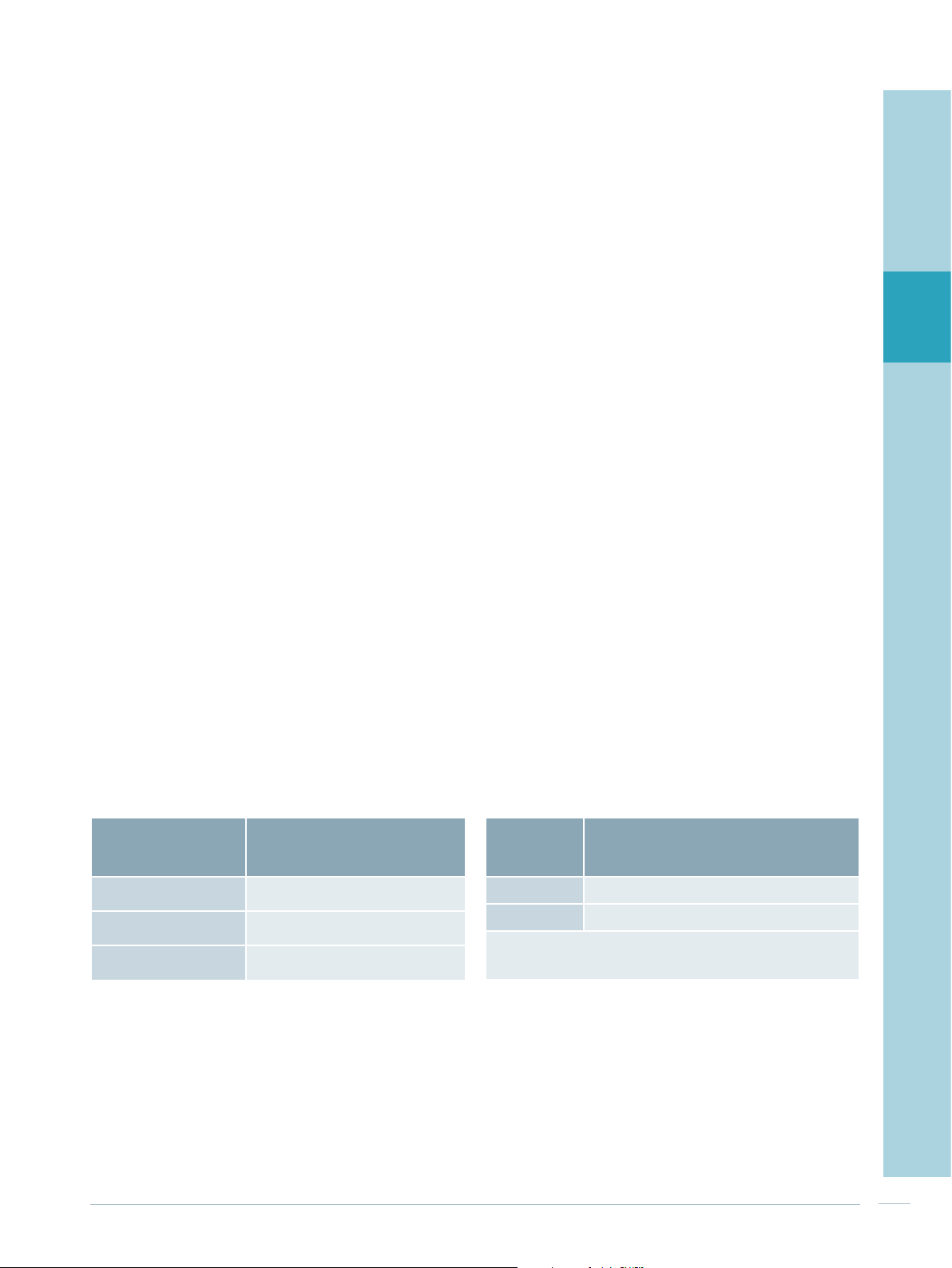

2.2 Corner cubicle

The corner cubicle connects two segments, positioned at

right angles to each other, of a switchboard in single-board

design (Fig. 2/3). The corner cubicle contains as functional

rooms only the busbar compartment and the cross-wiring

compartment. These compartments cannot be accessed via

doors. The frame width resp. frame depth of the cubicles

are listed in Tab. 2/6.

1

Tab. 2/6: Dimensions of the corner cubicles

D

Operation panel

Fig. 2/3: Integration of the corner cubicle

Corner cubicle

W

W

Cubicle depth D

500 mm 600 mm

600 mm 700 mm

800 mm 900 mm

1,200 mm 900 mm

Frame width / depth W

of the corner cubicle

2

3

4

5

6

7

SIVACON S8 Planning Principles – SIVACON S8 – System overview

8

9

10

11

15

2.3 Main busbar, horizontal

Tab. 2/7 lists the rating data for the two possibilities how to

position the main busbar – top or rear – (Fig. 2/4). Chapter

10 describes how ambient temperatures must be observed

in respect of the current carrying capacity.

Tab. 2/7: Rating of the main busbar

Top busbar position

Rated current I

temperature

Ventilated Non-ventilated

at 35 °C ambient

n

Rated short-time

withstand current

I

(1 s)

cw

1,190 A 965 A 35 kA

1,630 A 1,310 A 50 kA

1,920 A 1,480 A 65 kA

2,470 A 1,870 A 85 kA

3,010 A 2,250 A 100 kA

3,270 A 2,450 A 100 kA

1)

3,700 A

1)

4,660 A

1)

5,620 A

1)

6,300 A

1)

If circuit-breakers with a very high power loss are used, the

3,000 A

3,680 A

4,360 A

4,980 A

1)

1)

1)

1)

100 kA

100 kA

150 kA

150 kA

following correction factors must be applied:

3WL1350: 0.95

3WL1363: 0.88

Rear busbar position

Rated current In at 35 °C ambient

temperature

Ventilated Non-ventilated

1)

Rated short-time

withstand current

I

(1 s)

cw

1,280 A 1,160 A 50 kA

1,630 A 1,400 A 65 kA

2,200 A 1,800 A 65 kA

2,520 A 2,010 A 85 kA

2,830 A 2,210 A 100 kA

3,170 A 2,490 A 100 kA

4,000 A 3,160 A 100 kA

2)

4,910 A

2)

5,340 A

2)

5,780 A

2)

7,010 A

1)

When operating two systems per cubicle at the same time

3,730 A

4,080 A

4,440 A

5,440 A

2)

2)

2)

2)

100 kA

100 kA

100 kA

150 kA

(busbar position rear top and rear bottom),

a reduction factor has to be considered::

for ventilated boards: 0,94

for unventilated boards: 0,98

2)

Busbar position rear top or rear bottom

Fig. 2/4: Variable busbar position for SIVACON S8

16

SIVACON S8 Planning Principles – SIVACON S8 – System overview

2.4 Connection points for earthing

and short-circuit devices

Short-circuiting and earthing devices (SED)

For short-circuiting and earthing, short-circuiting and

earthing devices (SED) are available. For mounting the SED,

appropriate fastening points are fitted at the points to be

earthed. To accommodate the SED for the main busbar, a

cubicle for customized solutions is inserted (see Chapter

6.3 “Cubicle for customized solutions”). The cubicle widths

are given in Tab. 2/8.

Central earthing point (CEP) and main earthing busbar

(MEB)

When voltage sources, which are located far apart, are

earthed, for example secondary unit substation and

standby generator set, the separate earthing of their neutral points results in compensating currents through foreign

conductive building structures. Undesired electro-magnetic

interference is created, caused by the building currents on

the one hand and the lack of summation current in the

respective cables on the other.

If the requirement is parallel operation of several voltage

sources and if building currents shall be reduced as far as

possible, the preferable technical solution is implementing

the central earthing point (CEP). In this case, the neutral

points of all voltage sources are connected to the system

protective conductor / system earth at a single point only.

The effect is that despite potential differences of the

neutral points, building currents cannot be formed any

more.

Tab. 2/8: Cubicle widths for earthing short-circuit points

The central earthing point can only be used in the

power supply system L1, L2, L3, PEN (insulated) + PE.

To implement the central earthing point (CEP) - with or

without a main earthing busbar (MEB) - a cubicle for

customized solutions is inserted (see Chapter 6.3 “Cubicle

for customized solutions”).

CEP design

The CEP is designed as a bridge between the separately

wired (insulated) PEN and the PE conductor of the switchboard. Measuring current transformers can be mounted on

the bridge for residual current measurements. In order to

be able to remove the current transformer in case of a

defect, a second, parallel bridge is provided. This prevents

cancelling the protective measure due to a missing connection between the separately wired PEN and PE conductor.

A mounting plate in the cubicle is provided for placing the

residual-current monitors. The cubicle widths are given in

Tab. 2/8.

MEB design

In addition to the central earthing point, the MEB can

optionally be mounted as a horizontal bar. This connecting

bar is separately installed in the cubicle and rigidly connected to the PE conductor. Depending on how the cable is

entered, the MEB is installed at the top or bottom of the

cubicle. The cubicle widths can be found in Tab. 2/8 and

information about the cable terminals can be found in

Tab. 2/9.

Tab. 2/9: Cable terminal for the main earthing busbar

1

2

3

4

5

6

7

Earthing and shortcircuit points

Short-circuiting and

earthing devices (SED)

Central earthing point

(CEP)

Main earthing busbar

(MEB)

Cubicle widths

400 mm (200 mm as cubicle

extension)

600 mm, 1,000 mm (200 mm as

cubicle extension)

600 mm, 1,000 mm

Cubicle width

600 mm 10 x 185 mm

1,000 mm 20 x 185 mm2 (M10) + 22 x 240 mm2 (M12)

1)

300 mm² cable lugs can be used with M12 screw,

but this cable lug does not comply with DIN 46235, although it is

supplied by some manufacturers.

SIVACON S8 Planning Principles – SIVACON S8 – System overview

Max. number of cables connectible with

cable lug DIN 46235 (screw)

2

(M10) + 12 x 240 mm2 (M12)

1)

1)

8

9

10

11

17

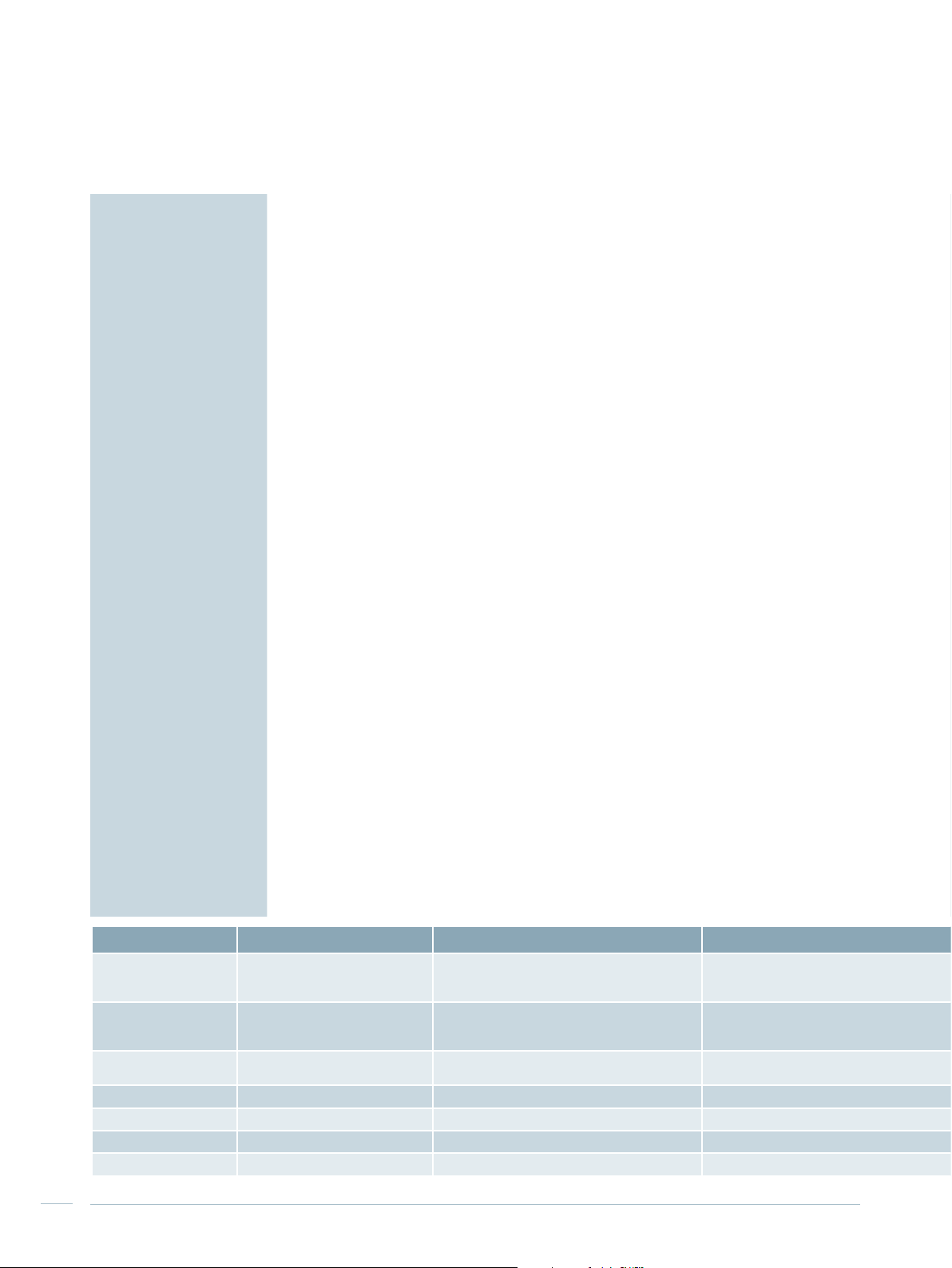

2.5 Overview of mounting designs

Tab. 2/10: Basic data of the different mounting designs

Circuit-breaker design Universal mounting design In-line design, plug-in Fixed-mounted design

Mounting design

Functions

Rated current I

Connection type Front and rear side Front and rear side Front side Front side Front side Front side

Cubicle width 400, 600, 800, 1,000, 1,400 mm 600, 1,000, 1,200 mm 1,000, 1,200 mm 1,000, 1,200 mm 600, 800, 1,000 mm 800 mm

Internal separation Form 1, 2b, 3a, 4b, 4 type 7 (BS) Form 3b, 4a, 4b, 4 type 7 (BS) Form 3b, 4b Form 1, 2b, 3b, 4a, 4b Form 1, 2b Form 1, 2b

Busbar position Rear, top Rear, top Rear, top Rear, top Rear Rear, top, without

18

SIVACON S8 Planning Principles – SIVACON S8 – System overview

n

Withdrawable design

Fixed mounted design

Incoming unit

Outgoing unit

Coupler

Up to 6,300 A Up to 630 A Up to 630 A Up to 630 A Up to 630 A

Withdrawable design

Fixed-mounted design with compartment doors

Plug-in design

Cable feeders

Motor feeders (MCC)

Plug-in design Fixed-mounted design with front covers Fixed mounted design Fixed mounted design

Cable feeders Cable feeders Cable feeders Central compensation of reactive power

1

2

3

4

5

6

In-line design,

fixed-mounted

Reactive power compensation

Non-choked up to 600 kvar

Choked up to 500 kvar

SIVACON S8 Planning Principles – SIVACON S8 – System overview

7

8

9

10

11

19

20

SIVACON S8 Planning Principles – SIVACON S8 – System overview

Chapter 3

Circuit-breaker design

3.1 Cubicles with one ACB (3WL) 24

3.2 Cubicles with up to three ACB (3WL) 29

3.3 Cubicles with one MCCB (3VL) 30

3.4 Cubicles for direct supply and

direct feeder 31

3 Circuit-breaker design

The cubicles for 3W. and 3V. circuit-breakers ensure both

personal safety and long-term operational safety (Fig. 3/1).

The incoming, outgoing and coupling units in circuit-breaker design are equipped with 3W. air circuit-breakers (ACB) in withdrawable or fixed-mounted design or

alternatively with 3V. moulded-case circuit-breakers (MCCB)

(Tab. 3/1).

The cubicle dimensions are tailored to the circuit-breaker

sizes and can be selected according to the individual requirements. The circuit-breaker design provides optimal

connect conditions for every nominal current range. In

addition to cable connections, the system also provides

design-verified connections to SIVACON 8PS busbar trunking systems.

Fig. 3/1: Cubicles in circuit-breaker design

22

SIVACON S8 Planning Principles – Circuit-breaker design

Tab. 3/1: General cubicle characteristics in circuit-breaker design

Application

range

Degrees of protection - Up to IP43 Ventilated

Form of internal separation - Form 1, 2b Door cubicle high

Design options - Air circuit-breaker (ACB) in fixed-mounted or withdrawable design

1)

Also form 4b type 7 in acc. with BS EN 61439-2 possible

2)

Information about 3WT circuit-breakers is available from your Siemens contact

3)

Information about moulded-case circuit-breakers in plug-in/withdrawable design is available from your Siemens contact

The circuit-breaker cubicles allow the installation of a

current transformer (L1, L2 and L3) at the customer connection side. Information about the installation of additional transformers is available from your Siemens contact.

Cubicle with forced cooling

The circuit-breaker cubicles with forced cooling are

equipped with fans (Fig. 3/2). Controlled fans are installed

in the cubicle front below the circuit-breaker. The forced

cooling makes for an increase of the rated current of the

circuit-breaker cubicle. The other cubicle characteristics are

identical to the cubicle without forced cooling.

- Incoming circuit-breakers

- Coupling circuit-breakers (longitudinal and transverse couplers)

- Outgoing circuit-breakers

- Direct incoming/outgoing feeders (without circuit-breakers)

- IP54 Non-ventilated

- Form 3a, 4b

- Moulded-case circuit-breaker (MCCB) in fixed-mounted design

1)

Door divided in 3 parts

2)

3)

1

2

3

4

5

The fan control comes completely configured. No further

settings are required upon start-up of the switchboard. The

fans are dimensioned such that the required cooling is still

ensured if a fan fails. Failure of the fan or non-permissible

temperature rises are signalled. Forced cooling is available

for selected ACB (3WL) in withdrawable design.

The use of fans brings about additional noise emission.

Under normal operating conditions, the noise emission

may be 85 dB at the maximum. Higher noise emissions

only occur in the case of a fault.

Observing local regulations on noise protection and occupational safety and health is mandatory. Rating data for

cubicles with forced cooling is available from your

Siemens contact.

6

7

8

9

Fig. 3/2: Forced cooling in a circuit-breaker cubicle

10

11

SIVACON S8 Planning Principles – Circuit-breaker design

23

3.1 Cubicles with one ACB (3WL)

The widths for the different cubicle types are listed by ACB

type in Tab. 3/2 to Tab. 3/4.

Tab. 3/2: Cubicle dimensions for top busbar position

Cubicle type

ACB type

Nominal

device

Cubicle width in mm

current

Incoming / outgoing unit

Cable connection Busbar connection

3-pole 4-pole 3-pole 4-pole

3WL1106 630 A 400/600 600 - -

3WL1108 800 A 400/600 600 - -

3WL1110 1,000 A 400/600 600 - -

3WL1112 1,250 A 400/600 600 - -

Top busbar position,

cable / busbar entry from the

top or bottom

3WL1116 1,600 A 400/600 600 400/600 600

3WL1120 2,000 A 400/600 600 400/600 600

3WL1220 2,000 A 600/800 800 600/800 800

3WL1225 2,500 A 600/800 800 600/800 800

3WL1232 3,200 A 600/800 800 600/800 800

2)

800 1,000 800 1,000

The position of the connecting bars is identical for cable entry

from the top or bottom

3WL1340 4,000 A

1)

3WL1350

3WL1363

5,000 A 2)- - 1,000 1,000

1)

6,300 A 2)- - 1,000 1,000

Longitudinal coupler 3-pole 4-pole

3WL1106 630 A 600 800 - -

3WL1108 800 A 600 800 - -

3WL1110 1,000 A 600 800 - -

3WL1112 1,250 A 600 800 - -

3WL1116 1,600 A 600 800 - -

Top busbar position

3WL1120 2,000 A 600 800 - -

3WL1220 2,000 A 800 1,000 - -

3WL1225 2,500 A 800 1,000 - -

3WL1232 3,200 A 800 1,000 - -

2)

1,000 1,200 - -

1)

Withdrawable design, frame height 2,200 mm

2)

Main busbar up to 6,300 A

3WL1340 4,000 A

1)

3WL1350

3WL1363

5,000 A 2)1,200 1,200 - -

1)

6,300 A 2)1,200 1,200 - -

24

SIVACON S8 Planning Principles – Circuit-breaker design

Tab. 3/3: Cubicle dimensions for rear busbar position

Cubicle type

Incoming / outgoing unit

1 busbar system in the cubicle:

rear top busbar position and

cable / busbar entry from the

bottom

or

rear bottom busbar position

and

cable / busbar entry from the

top

1 busbar system in the cubicle:

rear bottom busbar position

and

cable / busbar entry from the

bottom

or

rear top busbar position and

cable / busbar entry from the

top

Longitudinal coupler 3-pole 4-pole

1 busbar system in the cubicle:

rear top busbar position

or

rear bottom busbar position

1)

Withdrawable design, frame height 2,200 mm

2)

Main busbar up to 7,010 A

3)

Frame height 2,200 mm

ACB type

3WL1106 630 A 400/600 600 - -

3WL1108 800 A 400/600 600 - -

3WL1110 1,000 A 400/600 600 - -

3WL1112 1,250 A 400/600 600 - -

3WL1116 1,600 A 400/600 600 400/600 600

3WL1120 2,000 A 400/600 600 400/600 600

3WL1220 2,000 A 600/800 800 600/800 800

3WL1225 2,500 A 600/800 800 600/800 800

3WL1232 3,200 A 600/800 800 600/800 800

3WL1340 4,000 A 1,000 1,000

3WL1350

3WL1363

3WL1106 630 A 400/600 600 - -

3WL1108 800 A 400/600 600 - -

3WL1110 1,000 A 400/600 600 - -

3WL1112 1,250 A 400/600 600 - -

3WL1116 1,600 A 400/600 600 400/600 600

3WL1120 2,000 A 400/600 600 400/600 600

3WL1220 2,000 A 600/800 800 600/800 800

3WL1225 2,500 A 600/800 800 600/800 800

3WL1232 3,200 A 600/800 800 600/800 800

3WL1340 4,000 A - -

3WL1106 630 A 600 600 - -

3WL1108 800 A 600 600 - -

3WL1110 1,000 A 600 600 - -

3WL1112 1,250 A 600 600 - -

3WL1116 1,600 A 600 600 - -

3WL1120 2,000 A 600 600 - -

3WL1220 2,000 A 800 800 - -

3WL1225 2,500 A 800 1,000 - -

3WL1232 3,200 A 800 1,400 - -

3WL1340 4,000 A 1,000 1,000 - -

3WL1350

3WL1363

Nominal

device

current

1)

5,000 A 2)- - 1,000 1,000

1)

6,300 A 2)- - 1,000 1,000

1)

5,000 A 2)1,400 1,400 - -

1)

6,300 A 2)1,400 1,400 - -

Cubicle width in mm

Cable connection Busbar connection

3-pole 4-pole 3-pole 4-pole

8001)/1,000

8003)/1,000

1,000

1,000

1

2

3

4

5

6

7

8

9

10

11

SIVACON S8 Planning Principles – Circuit-breaker design

25

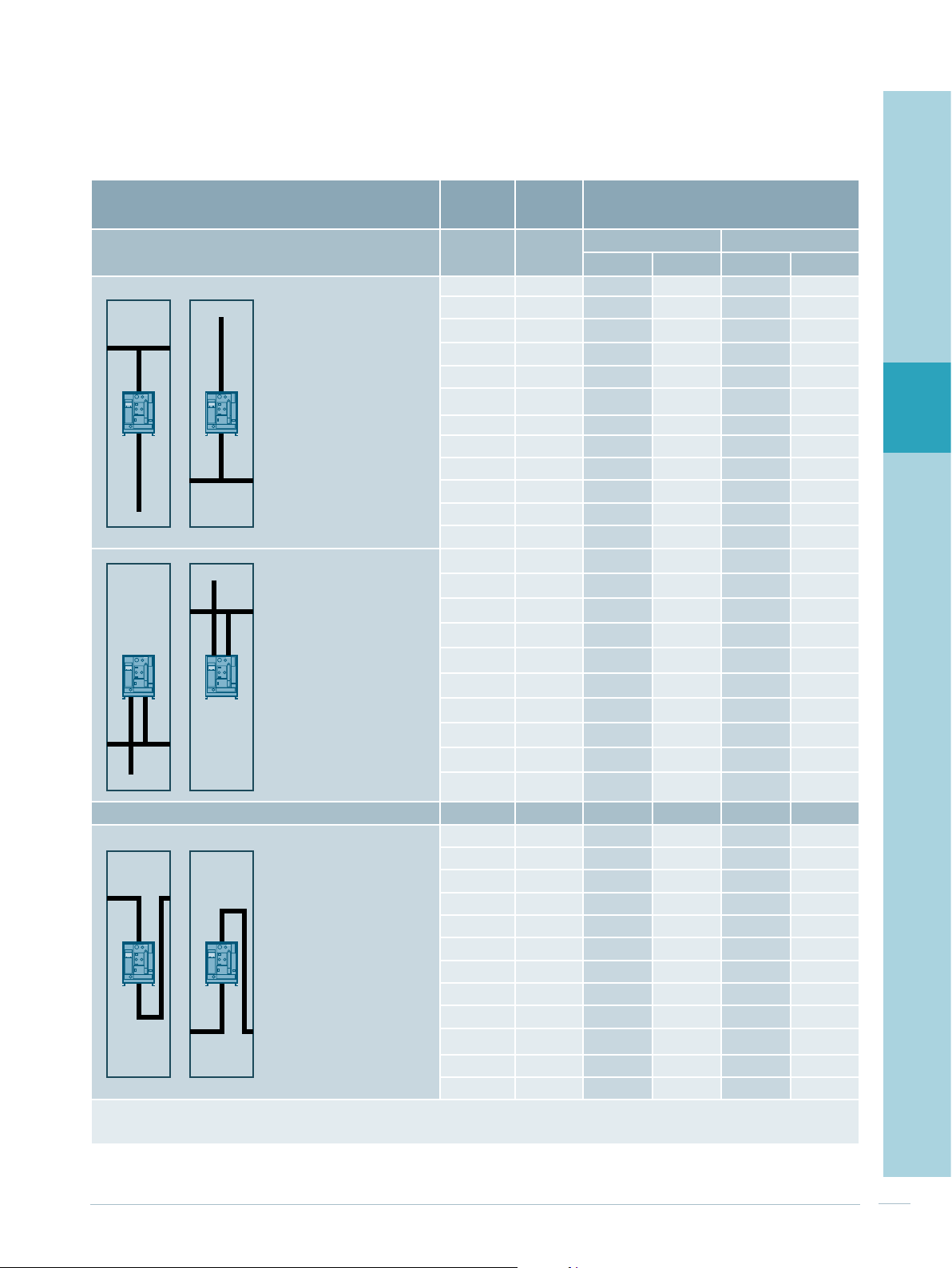

Tab. 3/4: Cubicle dimensions for rear busbar position with two busbar systems in the cubicle

Cubicle type

ACB type

Nominal

device

Cubicle width in mm

current

Incoming / outgoing unit

2 busbar systems in the

cubicle:

rear top busbar position and

cable / busbar entry from the

bottom

or

rear bottom busbar position

and

cable / busbar entry from the

top

2 busbar systems in the

cubicle:

rear bottom busbar position

and

cable / busbar entry from the

bottom

or

rear top busbar position and

cable / busbar entry from the

top

3WL1106 630 A 400/600 600 - -

3WL1108 800 A 400/600 600 - -

3WL1110 1,000 A 400/600 600 - -

3WL1112 1,250 A 400/600 600 - -

3WL1116 1,600 A 400/600 600 400/600 600

3WL1120 2,000 A 400/600 600 400/600 600

3WL1220 2,000 A 600/800 800 600/800 800

3WL1225 2,500 A 600/800 800 600/800 800

3WL1232 3,200 A 600/800 800 600/800 800

3WL1340 4,000 A 1,000 1,000

3WL1106 630 A 400/600 600 - -

3WL1108 800 A 400/600 600 - -

3WL1110 1,000 A 400/600 600 - -

3WL1112 1,250 A 400/600 600 - -

3WL1116 1,600 A 400/600 600 400/600 600

3WL1120 2,000 A 400/600 600 400/600 600

3WL1220 2,000 A 600/800 800 600/800 800

3WL1225 2,500 A 600/800 800 600/800 800

3WL1232 3,200 A 600/800 800 600/800 800

3WL1340 4,000 A - -

Cable connection Busbar connection

3-pole 4-pole 3-pole 4-pole

Longitudinal coupler 3-pole 4-pole

3WL1106 630 A 600 600 - -

3WL1108 800 A 600 600 - -

2 busbar systems in the

cubicle:

rear top busbar position

or

rear bottom busbar position

3WL1110 1,000 A 600 600 - -

3WL1112 1,250 A 600 600 - -

3WL1116 1,600 A 600 600 - -

3WL1120 2,000 A 600 600 - -

3WL1220 2,000 A 800 800 - -

3WL1225 2,500 A 800 800 - -

3WL1232 3,200 A 800 800 - -

3WL1340 4,000 A 1,000 1,000 - -

Transverse coupler 3-pole 4-pole

3WL1106 630 A 400/600 600 - -

3WL1108 800 A 400/600 600 - -

2 busbar systems in the

cubicle:

rear top busbar position

and

rear bottom busbar position

3WL1110 1,000 A 400/600 600 - -

3WL1112 1,250 A 400/600 600 - -

3WL1116 1,600 A 400/600 600 - -

3WL1120 2,000 A 400/600 600 - -

3WL1220 2,000 A 600/800 800 - -

3WL1225 2,500 A 600/800 800 - -

3WL1232 3,200 A 600/800 800 - -

3WL1340 4,000 A 1,000 1,000 - -

1)

Frame height 2,200 mm

8001)/1,000

8001)/1,000

1,000

1,000

26

SIVACON S8 Planning Principles – Circuit-breaker design

Cable and busbar connection

Short-circuiting and earthing device (SED)

The number of connectible cables, as stated in Tab. 3/5,

may be restricted by the available roof/floor panel openings

and/or door installations. The position of the connecting

bars is identical for front or rear connection in the cubicle.

Connection to the SIVACON 8PS busbar trunking system is

effected by means of an installed busbar trunking connector. The SIVACON S8 connecting system is located completely within the cubicle. The busbars can be connected

both from the top and from the bottom, thus allowing

flexible connection. The factory-provided copper plating

guarantees high short-circuit strength, which is verified by

a design test, as is the temperature rise limits.

Tab. 3/5: Cable connection for cubicles with 3WL

Max. number of cables connectible per phase

Cable lug DIN 46235

(240 mm2, M12)

1)

It is possible to use 300 mm2 cable lugs with a M12 screw, but this cable lug is not in compliance with DIN 46235, although it is supplied by

some manufacturers

2)

5,000 A and 6,300 A circuit-breakers with busbar connection

1)

dependent on breaker size

3WL11

up to 1,000 A

4 6 6 12 14

3WL11

1,250 to 2,000 A

For short-circuiting and earthing, short-circuiting and

earthing devices (SED) are available for the circuit-breaker

cubicle. Suitable mounting points are affixed to the points

to be earthed, which ease SED installation.

3WL12

up to 1,600 A

3WL12

2,000 to 3,200 A

2)

3WL13

up to 4,000 A

1

2

3

4

5

6

7

8

9

10

11

SIVACON S8 Planning Principles – Circuit-breaker design

27

Loading...

Loading...