Siemens SITRANS WW300 Operating Instructions Manual

Weighfeeders

SITRANS WW300

Operating Instructions

05/2015Edition

Safety Guidelines

Copyright Siemens AG 2015. All Rights Reserved

Disclaimer of Liability

Technical data subject to change.

Warning notices must be observed to ensure personal safety as well as that of others, and to protect the product and the connected equipment.

These warning notices are accompanied by a clarification of the level of caution to be observed.

Qualified Personnel

This device/system may only be set up and operated in conjunction with this manual. Qualified personnel are only authorized to install and

operate this equipment in accordance with established safety practices and standards.

Unit Repair and Excluded Liability:

• The user is responsible for all changes and repairs made to the device by the user or the user’s agent.

• All new components are to be provided by Siemens.

• Restrict repair to faulty components only.

• Do not reuse faulty components.

Warning: Cardboard shipping package provides limited humidity and moisture protection. This product can only function properly and safely if

it is correctly transported, stored, installed, set up, operated, and maintained.

This product is intended for use in industrial areas. Operation of this equipment in a residential area may cause interference to several

frequency based communications.

Note: Always use product in accordance with specifications.

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic versions as

designed and authored by Siemens. Siemens will not be

responsible for the contents of partial or whole

reproductions of either bound or electronic versions.

MILLTRONICS®is a registered trademark of Siemens AG.

While we have verified the contents of this

manual for agreement with the instrumentation

described, variations remain possible. Thus we

cannot guarantee full agreement. The contents of

this manual are regularly reviewed and

corrections are included in subsequent editions.

We welcome all suggestions for improvement.

Contact Technical Publications European Authorized Representative

at the following address:

Technical Publications Siemens AG

Siemens Canada Limited Industry Sector

1954 Technology Drive, P.O. Box 4225 76181 Karlsruhe

Peterborough, Ontario, Canada, K9J 7B1 Deutschland

Email:

techpubs.smpi@siemens.com

• For a selection of Siemens level measurement manuals, go to:

www. siemens.com/processautomation. Select Products & Systems, then under Process Instrumentation, select

Manual archives can be found on the Support page by product family.

• For a selection of Siemens weighing manuals, go to:

www. siemens.com/processautomation. Under Products & Systems, select

Manual archives can be found on the Support page by product family.

Weighing and Batching Systems.

Level Measurement.

© Siemens AG 2015

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SITRANS

Weighfeeders

SITRANS WW300

Operating Instructions

05/2015

A5E33560691

Introduction

1

Safety information

2

Description

3

Installing

4

Calibrating

5

Connecting

6

Commissioning

7

Maintenance

8

Troubleshooting

9

Technical data

10

Dimension drawings

11

SITRANS WW300

-AB

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: A5E33560691

Ⓟ

Copyright © Siemens AG 2015.

All rights reserved

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific task

in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication may

be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions.

05/2015 Subject to change

Table of contents

1 Introduction ................................................................................................................................................ 5

1.1 The manual ............................................................................................................................... 5

2 Safety information ...................................................................................................................................... 7

2.1 Safety and general precautions ................................................................................................ 7

3 Description ................................................................................................................................................. 9

3.1 Weighfeeder operation ............................................................................................................. 9

4 Installing .................................................................................................................................................. 11

4.1 Installation steps ..................................................................................................................... 12

5 Calibrating ............................................................................................................................................... 15

5.1 Test load ................................................................................................................................. 15

5.2 Zero ......................................................................................................................................... 15

5.3 Span ........................................................................................................................................ 15

6 Connecting .............................................................................................................................................. 17

7 Commissioning ........................................................................................................................................ 19

7.1 Shear gate .............................................................................................................................. 19

7.2 Skirtboards .............................................................................................................................. 19

7.3 Changing the conveyor belt .................................................................................................... 20

7.4 Belt tension ............................................................................................................................. 21

7.5 Belt tracking ............................................................................................................................ 21

7.6 Telescoper adjustment ........................................................................................................... 22

7.7 Weigh idler alignment ............................................................................................................. 23

7.8 Quick startup overview ........................................................................................................... 23

7.9 Load cell replacement ............................................................................................................. 23

7.9.1 Removing old load cell ............................................................................................................ 24

7.9.2 Installing new load cell ............................................................................................................ 25

7.9.3 Recalibration ........................................................................................................................... 25

SITRANS WW300

Operating Instructions, 05/2015, A5E33560691-AB

3

Table of contents

8 Maintenance ............................................................................................................................................ 27

8.1 Preventative maintenance ..................................................................................................... 27

8.1.1 Recommended preventative maintenance schedule ............................................................. 28

8.2 General maintenance ............................................................................................................. 28

8.3 Lubrication .............................................................................................................................. 29

8.4 Weighfeeder storage recommendations ................................................................................ 29

8.4.1 Load cell care ......................................................................................................................... 29

8.4.2 Gear reducer .......................................................................................................................... 29

8.4.3 Electrical ................................................................................................................................. 29

8.4.4 Lubrication .............................................................................................................................. 30

8.4.5 Belt care ................................................................................................................................. 30

9 Troubleshooting ....................................................................................................................................... 31

9.1 Mechanical troubleshooting ................................................................................................... 31

9.2 Zero Drift, non-repeatability, or non-linearity ......................................................................... 31

10 Technical data ......................................................................................................................................... 33

10.1 Specifications ......................................................................................................................... 33

11 Dimension drawings ................................................................................................................................ 35

11.1 Open unit ................................................................................................................................ 35

11.2 Enclosed unit .......................................................................................................................... 36

Index ........................................................................................................................................................ 37

SITRANS WW300

4 Operating Instructions, 05/2015, A5E33560691-AB

1

Note

The Siemens weighfeeder is to be used only in the manner outlined in this instruction

manual.

1.1 The manual

This instruction manual covers the operation, installation, and maintenance of the Siemens

weighfeeder. Specific information for your weighfeeder model is also included with the product

such as testing documents.

Follow these operating instructions for quick, trouble-free installation, and maximum accuracy

and reliability of your device.

We always welcome suggestions and comments about manual content, design, and

accessibility. Please direct your comments to:

Technical publications (mailto:techpubs.smpi@siemens.com)

For the complete library of Siemens manuals, go to:

Process Automation portal (http://www.siemens.com/processautomation)

SITRANS WW300

Operating Instructions, 05/2015, A5E33560691-AB

5

Introduction

1.1 The manual

SITRANS WW300

6 Operating Instructions, 05/2015, A5E33560691-AB

2

WARNING

WARNING

Note

A weighfeeder can be dangerous. Pinch points exist along the conveyor belt line.

2.1 Safety and general precautions

ALWAYS STOP the belt, lock-out, and/or place a "Do Not Energize" tag on the main

disconnect before working on or around the weighfeeder.

Always follow established safe operating practices when working on or around the

weighfeeder, especially in wet environments and when adjacent to conductive steel

mounting framework.

Secure the weighfeeder when:

• replacing the belt

• working on or around the load cell(s)

• working on or around the speed sensor

• working on or around the drive components

• working on or around the motor

SITRANS WW300

Operating Instructions, 05/2015, A5E33560691-AB

7

Safety information

2.1 Safety and general precautions

SITRANS WW300

8 Operating Instructions, 05/2015, A5E33560691-AB

3

SITRANS WW300 is a medium-to-high capacity weighfeeder for macro ingredient additives. It is

designed for industrial applications such as mining, cement, chemical processing, pulp and

paper, and other heavy-duty industries.

SITRANS WW300 comes with a weigh bridge, and speed sensor. An adjustable mechanical

shear gate profiles the material and fixes the correct material bed depth for a given material

application. The belt speed can be automatically adjusted to attain the correct feed rate. An

integrator and test weights are required to complete the system.

3.1 Weighfeeder operation

Weighfeeders weigh bulk material while it is conveyed. An accurate rate of flow and totalized

weight measurement is received without interrupting the flow of material in process. A

weighfeeder can also control the rate of flow of the conveyed product.

In-motion weighing requires accurate transmission of the product load to load cells. The resulting

voltage signal corresponding to weight is transmitted to the integrator and becomes one of the

two inputs required for integration.

Unlike static weighing, in-motion weighing integration requires a second input: a pulse signal

proportional to the speed of the conveyor belt. Each belt speed sensor pulse represents a fixed

distance of belt travel.

Since the force measured by the load cell is represented as weight per unit length, it can be

multiplied by the distance of belt travel (one speed sensor pulse) to provide product weight for

that segment of the belt (lbs/ft x ft = lbs, or kg/m x m = kg).

Adding the samples provides total throughput weight of product across the scale. With proper

scaling and calibration, the total weight can be displayed in kilograms, pounds, short tons, long

tons, metric tons, or other appropriate units.

SITRANS WW300

Operating Instructions, 05/2015, A5E33560691-AB

9

Description

3.1 Weighfeeder operation

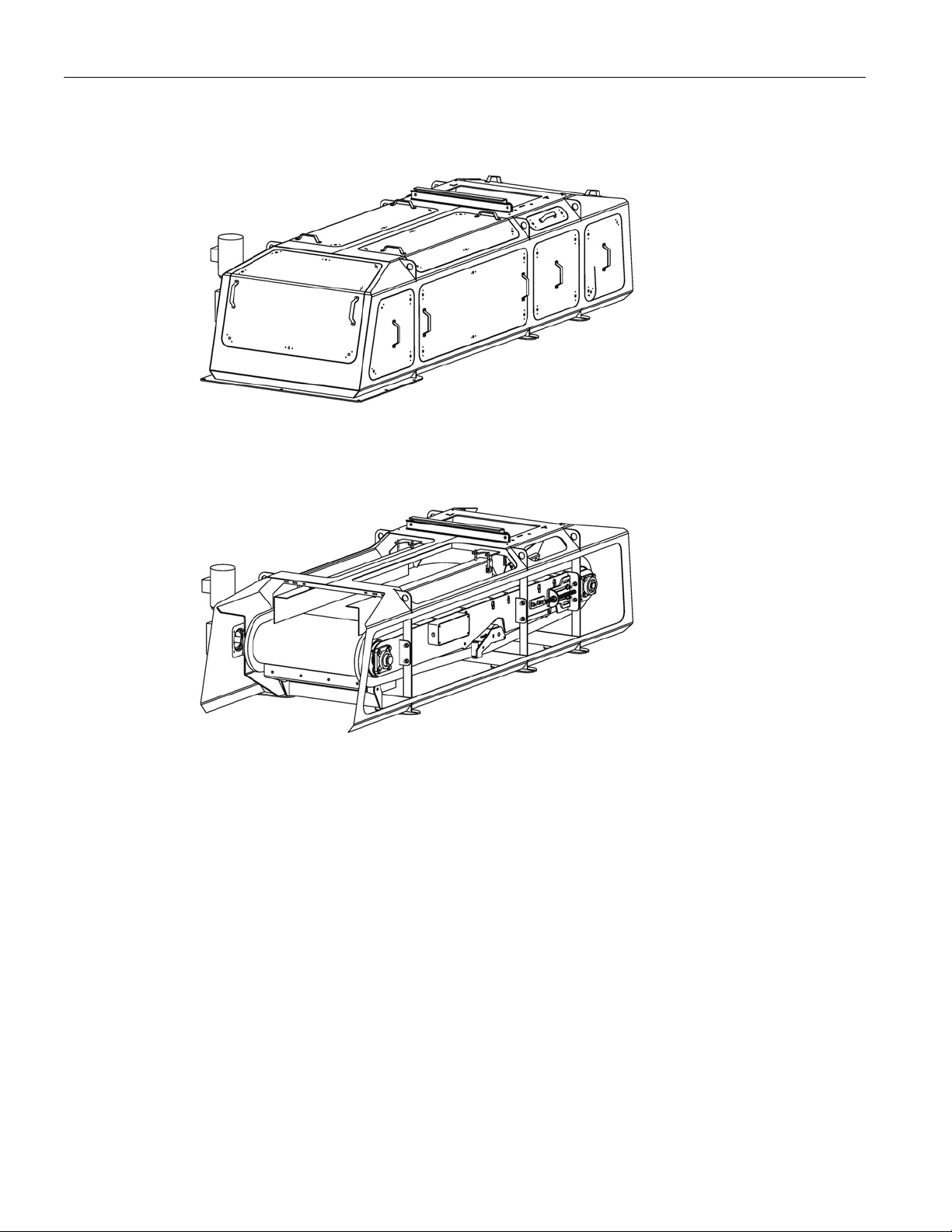

Enclosed unit

Open unit

SITRANS WW300

10 Operating Instructions, 05/2015, A5E33560691-AB

4

Note

When lifting the weighfeeder, connect to the lifting points at the top of the unit, and follow

local governing code for lifting/hoisting.

Note

Do not remove equipment from

shipping damage. Contact the carrier immediately if damage is noted.

Note

• The frame of the weighfeeder needs to be grounded to ensure accurate signal processing

•

•

near the weighfeeder while the load cell is connected to the electronic

•

Perform a thorough and systematic inspection of containers immediately upon receipt of your

Siemens weighfeeder. The containers are packed to separate each item and provide protection

during shipping.

shipping crates or boxes until you check for possible

Your weighfeeder has been designed, assembled, and factory tested for your specific

application.

to the integrator.

Do NOT remove the tagged load cell shipping bolt(s) until the installation is complete to

prevent load cell damage.

Do NOT weld on or

integrator. Damage to the integrator may result if the load cell is not disconnected from

the integrator.

Follow a scheduled, preventative maintenance program to ensure optimum performance

and long equipment life.

SITRANS WW300

Operating Instructions, 05/2015, A5E33560691-AB

11

Loading...

Loading...