Siemens SITRANS WM300 MFA Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SITRANS

Motion Sensors

SITRANS WM300 MFA

Operating Instructions

7MH77-.....(WM300 MFA)

08/2018

A5E45090709

Introduction

1

SITRANS WM300 MFA

Overview

2

Installing/mounting

3

Connecting

4

Service and maintenance

5

Parameter assignment

6

Troubleshooting

7

Technical data

8

Dimension drawings

9

Technical Reference

A

Applications

B

Support

C

-AA

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E45090709

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personn el

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

02/2019 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 7

2 SITRANS WM300 MFA Overview ........................................................................................................... 9

3 Installing/mounting ................................................................................................................................ 11

4 Connecting ........................................................................................................................................... 19

5 Service and maintenance ...................................................................................................................... 29

6 Parameter assignment .......................................................................................................................... 31

1.1 Purpose of this documentation ................................................................................................. 7

1.2 Document history ...................................................................................................................... 7

1.3 FW revision history ................................................................................................................... 7

1.4 Checking the consignment ....................................................................................................... 8

1.5 Unit repair and excluded liability ............................................................................................... 8

3.1 Safety Note ............................................................................................................................. 11

3.2 Location Requirements ........................................................................................................... 11

3.3 Proper Mounting ..................................................................................................................... 12

3.4 Mounting Details ..................................................................................................................... 13

3.5 Wiring ...................................................................................................................................... 16

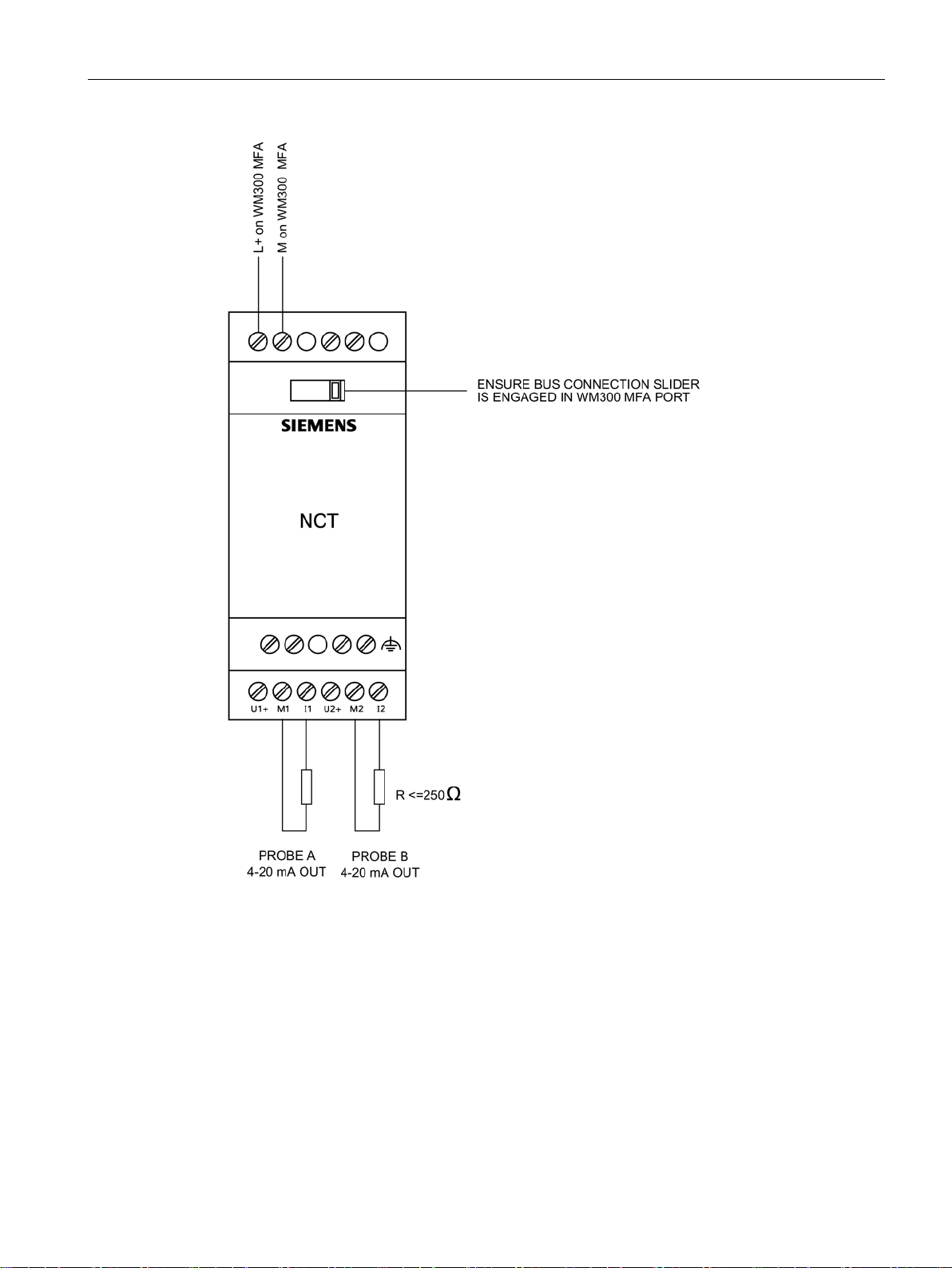

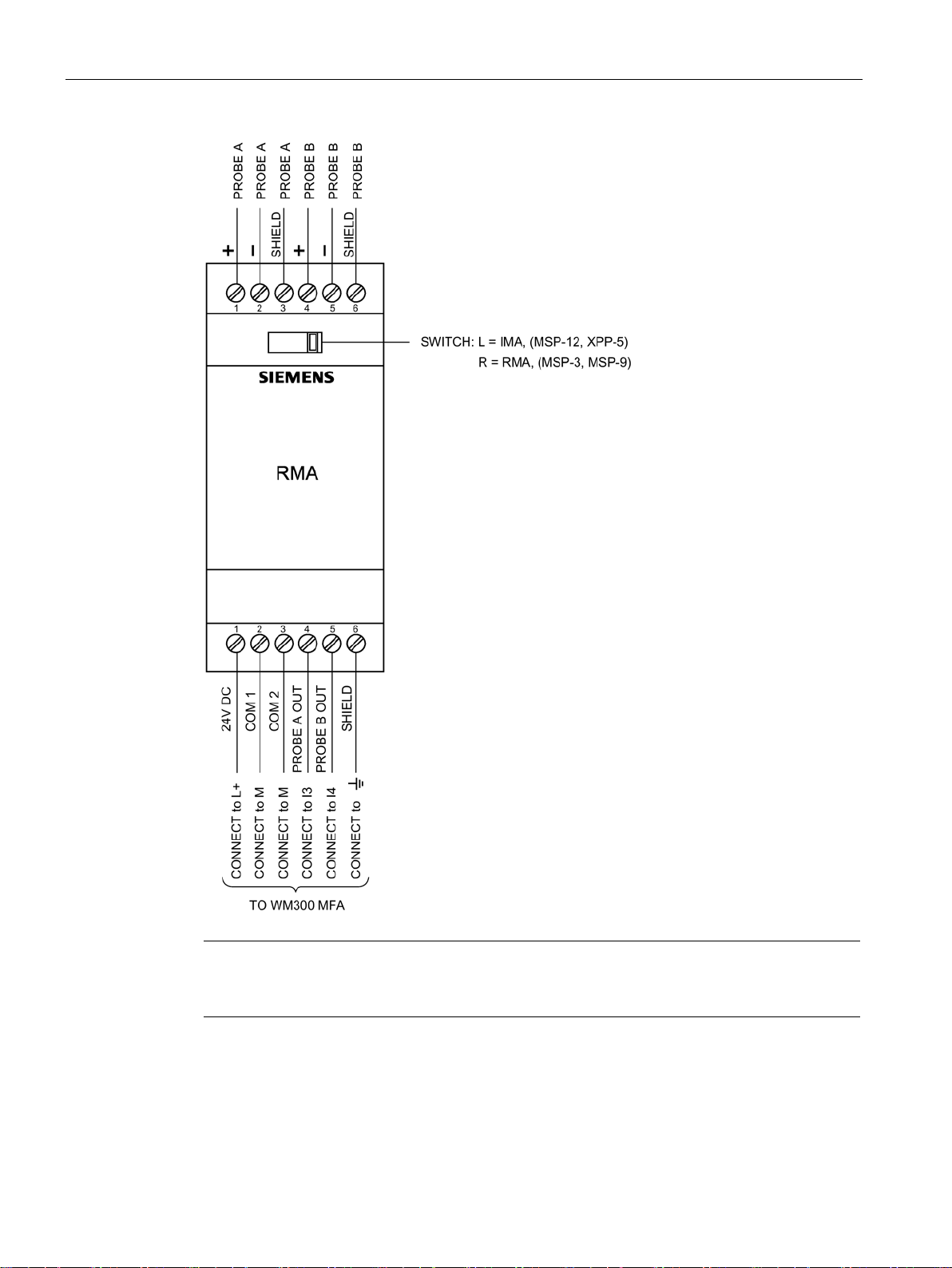

4.1 Interconnection ....................................................................................................................... 19

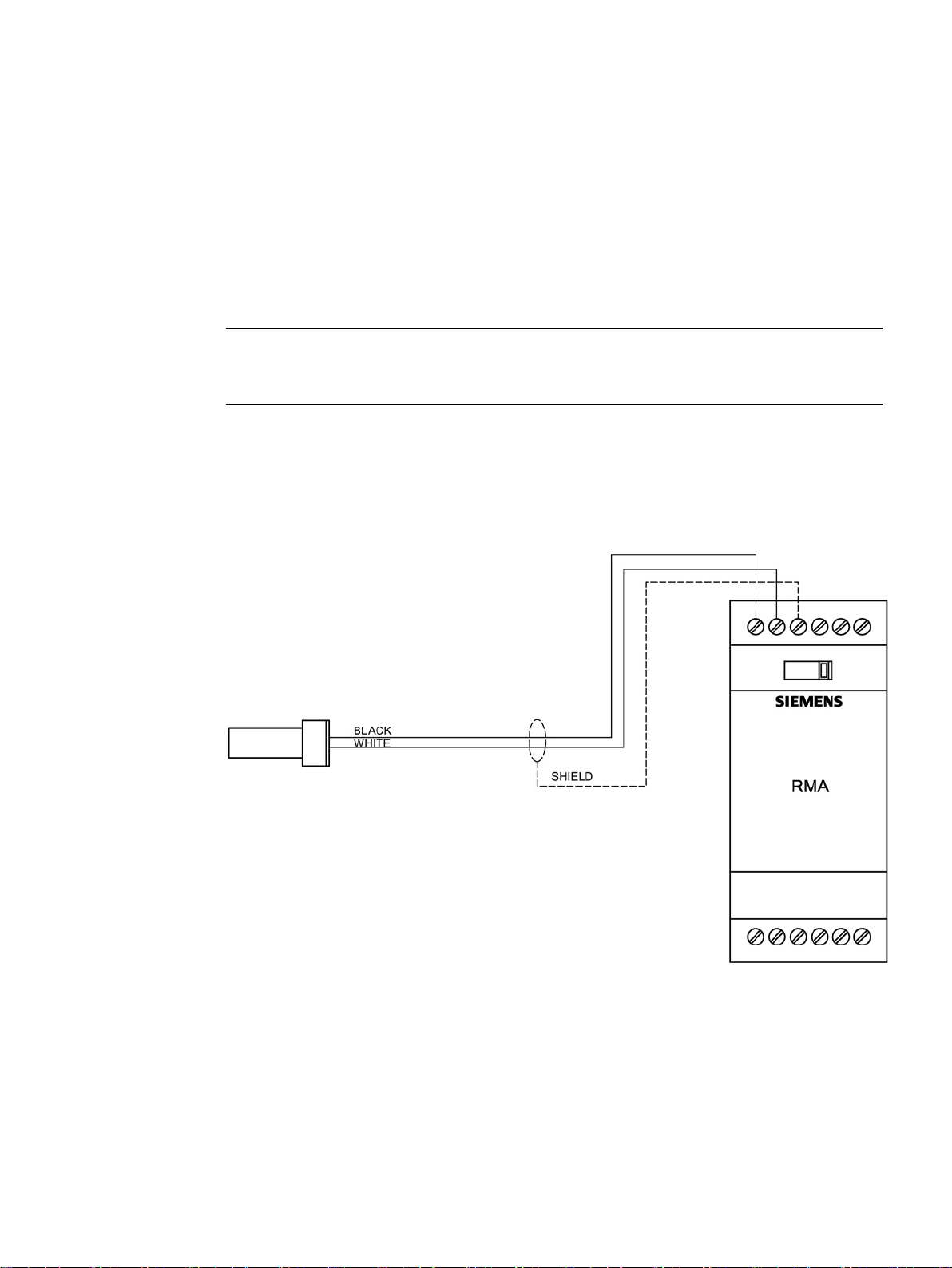

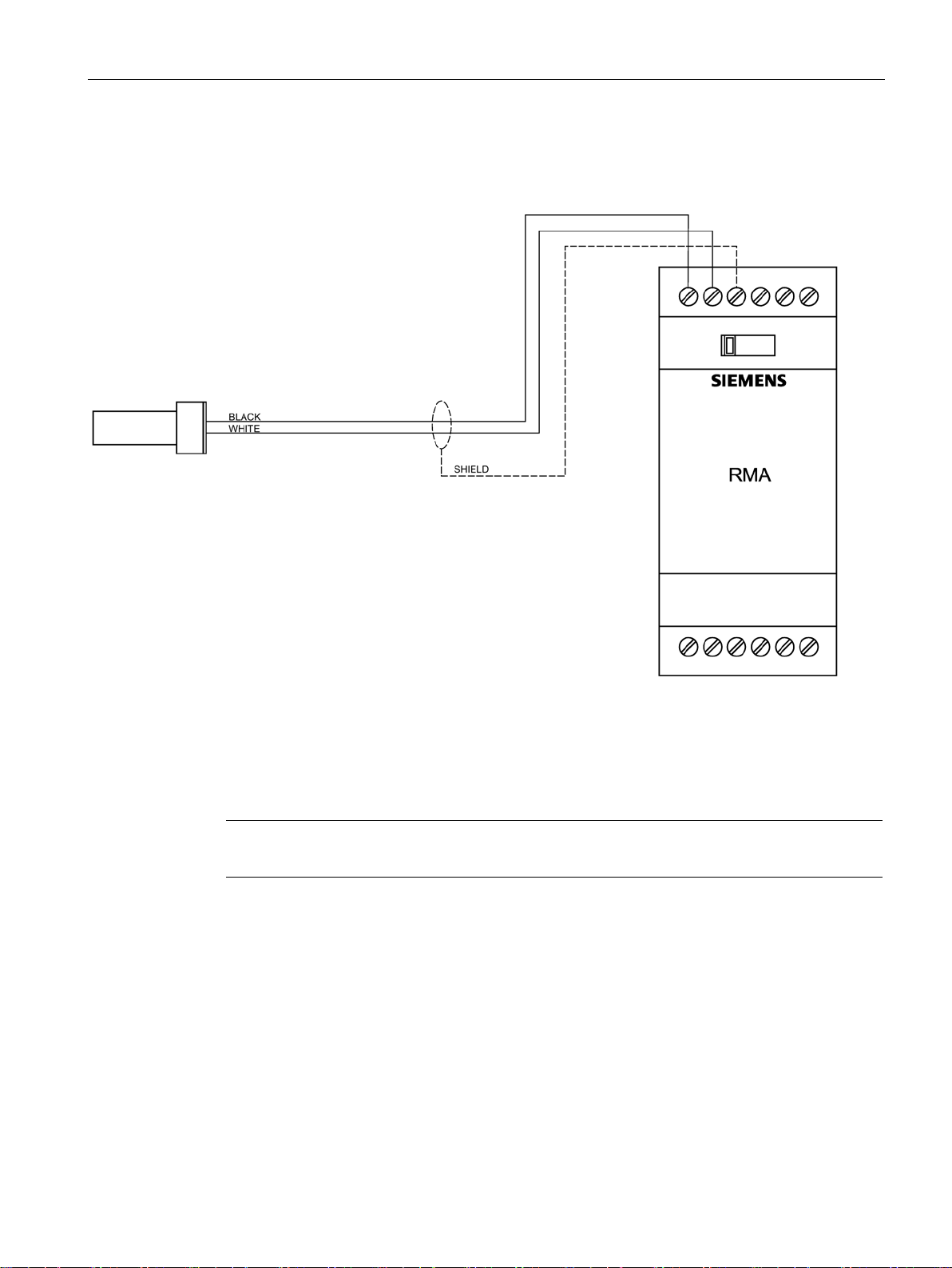

4.1.1 MSP-3 or MSP-9 Probe with RMA (remote mounted amplifier) ............................................. 19

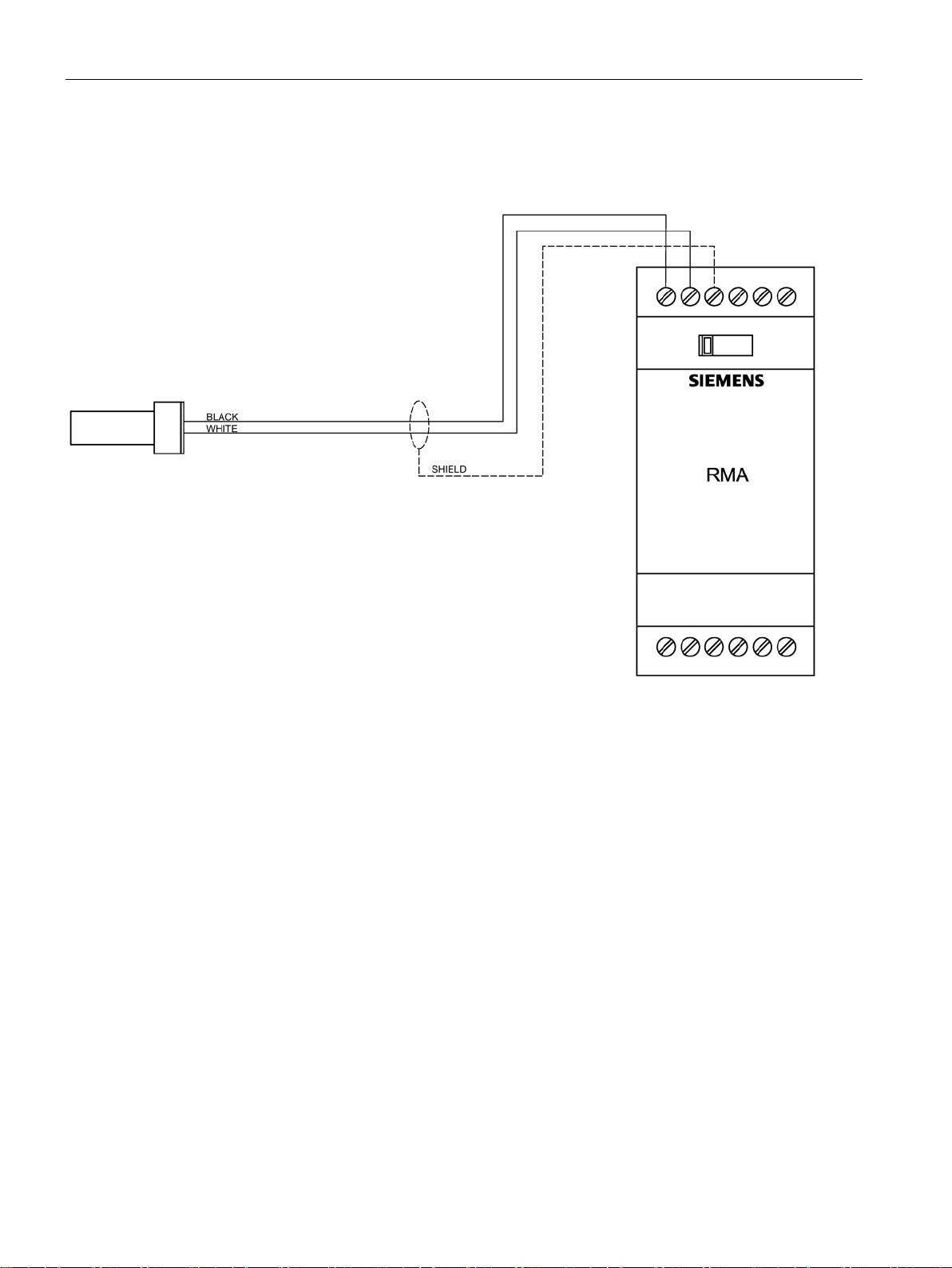

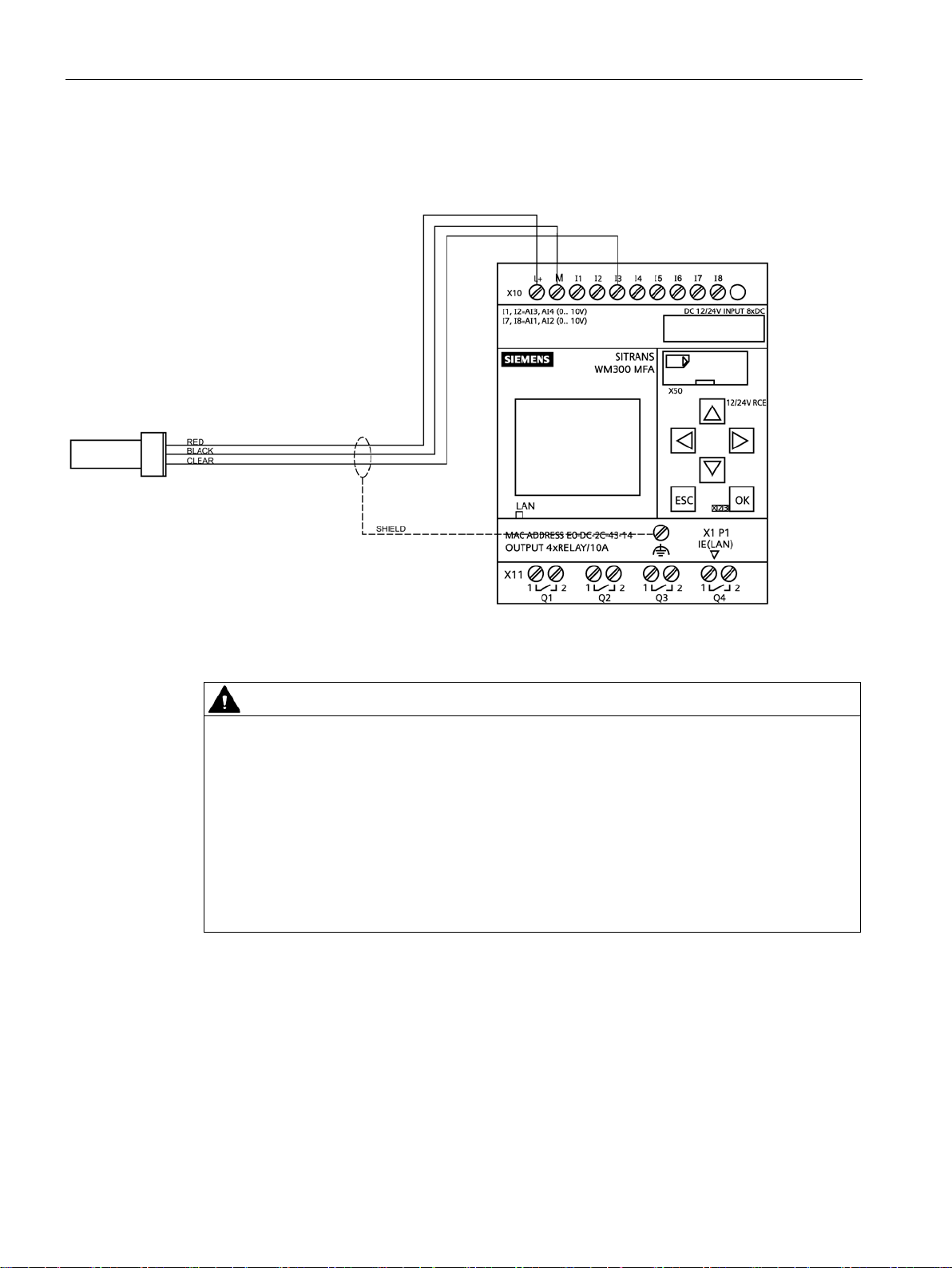

4.1.2 MSP-12 Probe with RMA (internally mounted pre-amplifier) .................................................. 20

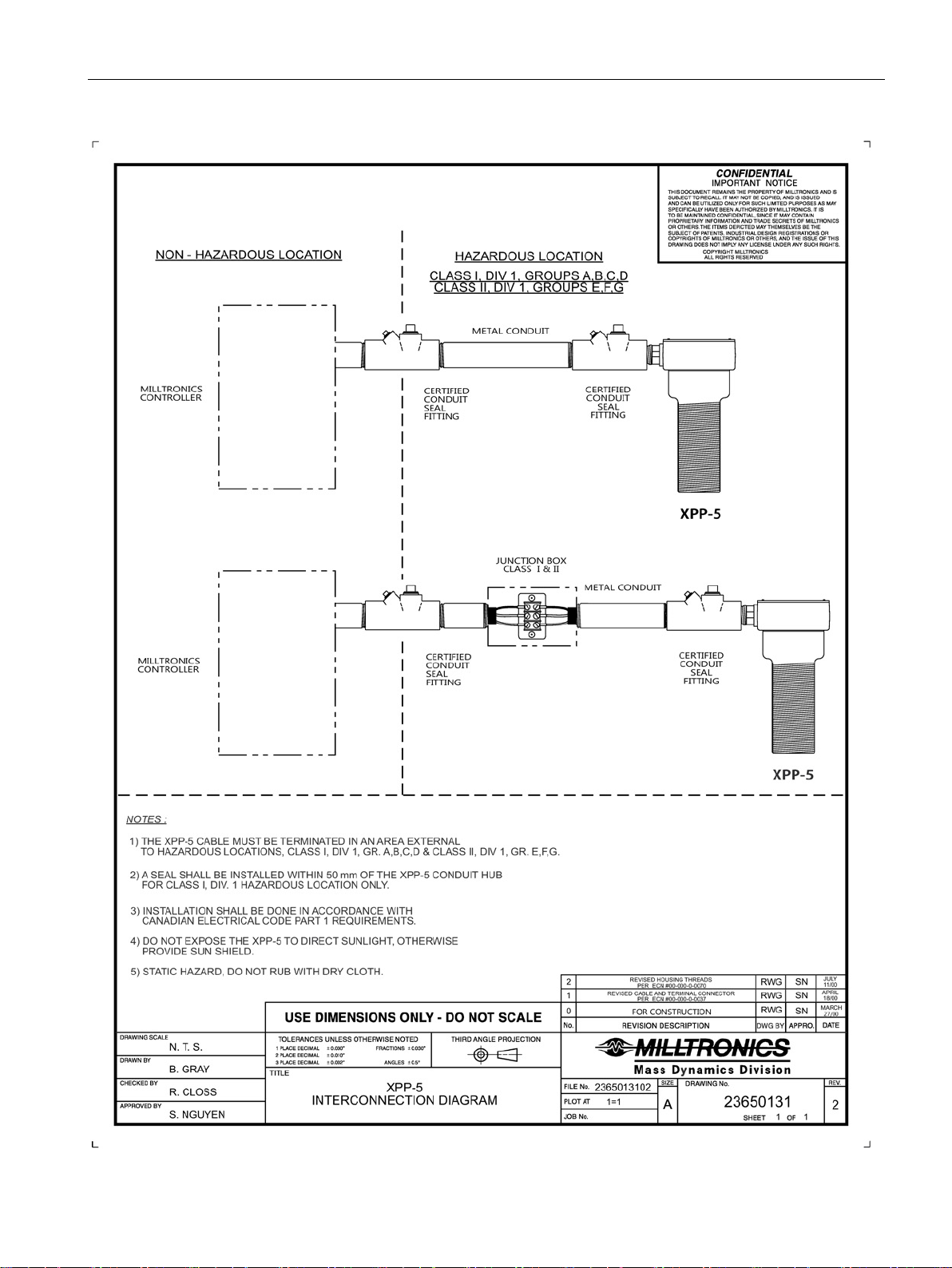

4.1.3 XPP-5 with RMA (internally mounted pre-amplifier) ............................................................... 21

4.1.4 MSP-7 with IMA (internally mounted pre-amplifier) ................................................................ 22

4.1.5 Cable length from RMA or IMA to WM300 MFA ..................................................................... 23

4.1.6 Interconnection Diagram for XPP-5 ........................................................................................ 24

4.2 Connection to Power............................................................................................................... 26

5.1 Setup ....................................................................................................................................... 29

5.1.1 Calibration ............................................................................................................................... 29

5.2 Maintenance ........................................................................................................................... 29

6.1 Menu structure ........................................................................................................................ 31

6.2 Motion failure alarm ................................................................................................................ 32

6.3 Startup delay ........................................................................................................................... 34

6.3.1 Start up delay (P001) .............................................................................................................. 34

6.3.2 Start up delay (P002) .............................................................................................................. 35

6.4 Alarm delay ............................................................................................................................. 36

6.4.1 Alarm delay (P003) ................................................................................................................. 36

6.4.2 Alarm delay (P004) ................................................................................................................. 37

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

3

Table of contents

7 Troubleshooting .................................................................................................................................... 53

8 Technical data ...................................................................................................................................... 55

9 Dimension drawings .............................................................................................................................. 59

A Technical Reference ............................................................................................................................. 67

B Applications .......................................................................................................................................... 71

6.5 Slow speed ............................................................................................................................. 38

6.5.1 Slow speed (P005) ................................................................................................................. 38

6.5.2 Slow speed (P010) ................................................................................................................. 38

6.5.3 Slow speed (P011) ................................................................................................................. 39

6.5.4 Slow speed (P012) ................................................................................................................. 40

6.5.5 Slow speed (P013) ................................................................................................................. 41

6.5.6 Process variable overview displ ay ......................................................................................... 42

6.5.7 Standard version motion failure alarm ................................................................................... 43

6.5.7.1 Standard speed (P020 - P021) .............................................................................................. 43

6.5.7.2 Standard speed (P022 - P023) .............................................................................................. 44

6.6 Tachometer Function ............................................................................................................. 45

6.6.1 Tachometer Function (P031 - P032) ..................................................................................... 45

6.6.2 Non-contacting tachometer (P030) ........................................................................................ 46

6.7 Differential speed detection ................................................................................................... 46

6.7.1 Differential speed detection (P040)........................................................................................ 46

6.7.2 Maximum frequency setpoint (P041 - P042) ......................................................................... 47

6.7.3 Differential alarm setpoints (P043 - P044) ............................................................................. 49

6.7.4 Operator display ..................................................................................................................... 50

7.1 Troubleshooting ..................................................................................................................... 53

8.1 Safety Note ............................................................................................................................ 55

8.2 Power ..................................................................................................................................... 55

8.3 Outputs ................................................................................................................................... 55

8.4 Inputs ..................................................................................................................................... 56

8.5 Performance ........................................................................................................................... 56

8.6 Design .................................................................................................................................... 57

8.7 Approvals ............................................................................................................................... 57

8.8 Operating Conditions ............................................................................................................. 57

9.1 SITRANS WM300 MFA dimensions ...................................................................................... 59

9.2 High Temperature Probe MSP-3 ........................................................................................... 61

9.3 Stainless Steel Probe MSP-9 ................................................................................................. 62

9.4 Standard Probe MSP-12 and MSP-7 ..................................................................................... 63

9.5 Hazardous Locations XPP-5 .................................................................................................. 64

A.1 Principles of Operation ........................................................................................................... 67

B.1 Bucket Elevators .................................................................................................................... 71

B.2 Bucket Elevator ...................................................................................................................... 72

SITRANS WM300 MFA

4 Operating Instructions, 08/2018, A5E45090709-AA

Table of contents

C Support ................................................................................................................................................. 79

Index..................................................................................................................................................... 81

B.3 Shafts ...................................................................................................................................... 73

B.4 Rotating Shaft of Rotary Feeder ............................................................................................. 74

B.5 Drive Sprocket on Rotary Feeder ........................................................................................... 74

B.6 Belt Conveyors ........................................................................................................................ 75

B.7 Screw Conveyors .................................................................................................................... 75

B.8 Screw Conveyor Flights .......................................................................................................... 76

B.9 End Bearing on Screw Conveyor ............................................................................................ 76

B.10 Non-ferrous Window ............................................................................................................... 77

C.1 Technical support .................................................................................................................... 79

C.2 Certificates .............................................................................................................................. 79

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

5

Table of contents

SITRANS WM300 MFA

6 Operating Instructions, 08/2018, A5E45090709-AA

1

1.1

Purpose of this documentation

1.2

Document history

Edition

Note

1.3

FW revision history

Firmware revision

Date

Changes

These instructions are a brief summary of important features, functions and safety

information, and contain all information required for safe use of the device. Read the

instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons who install and commission the device.

To realize optimum performance from the device, read the complete operating instructions.

The following table shows major changes in the documentation compared to the previous

edition.

1/2019 First edition

1.00.00 January 1, 2019

• Initial release

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

7

Introduction

1.4

Checking the consignment

WARNING

Using a damaged or incomp le te devic e

CAUTION

Insufficient protection during storage

1.5

Unit repair and excluded liability

Note

This product is intended for use in industrial areas.

In a domestic environment this device may cause radio interference.

1.4 Checking the consignment

1. Check the packaging and the delivered items for visible damages.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Risk of explosion in hazardous areas.

• Do not use damaged or incomplete devices.

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume

liability for any costs associated with transportation damages.

The packaging only provides limited protection against moisture and infiltration.

• Provide additional packaging as necessary.

All changes and repairs must be done by qualified personnel, and applicable safety

regulations must be followed. Please note the following:

● The user is responsible for all changes and repairs made to the device.

● All new components must be provided by Siemens.

● Restrict repair to faulty components only.

● Do not re-use faulty components.

SITRANS WM300 MFA

8 Operating Instructions, 08/2018, A5E45090709-AA

2

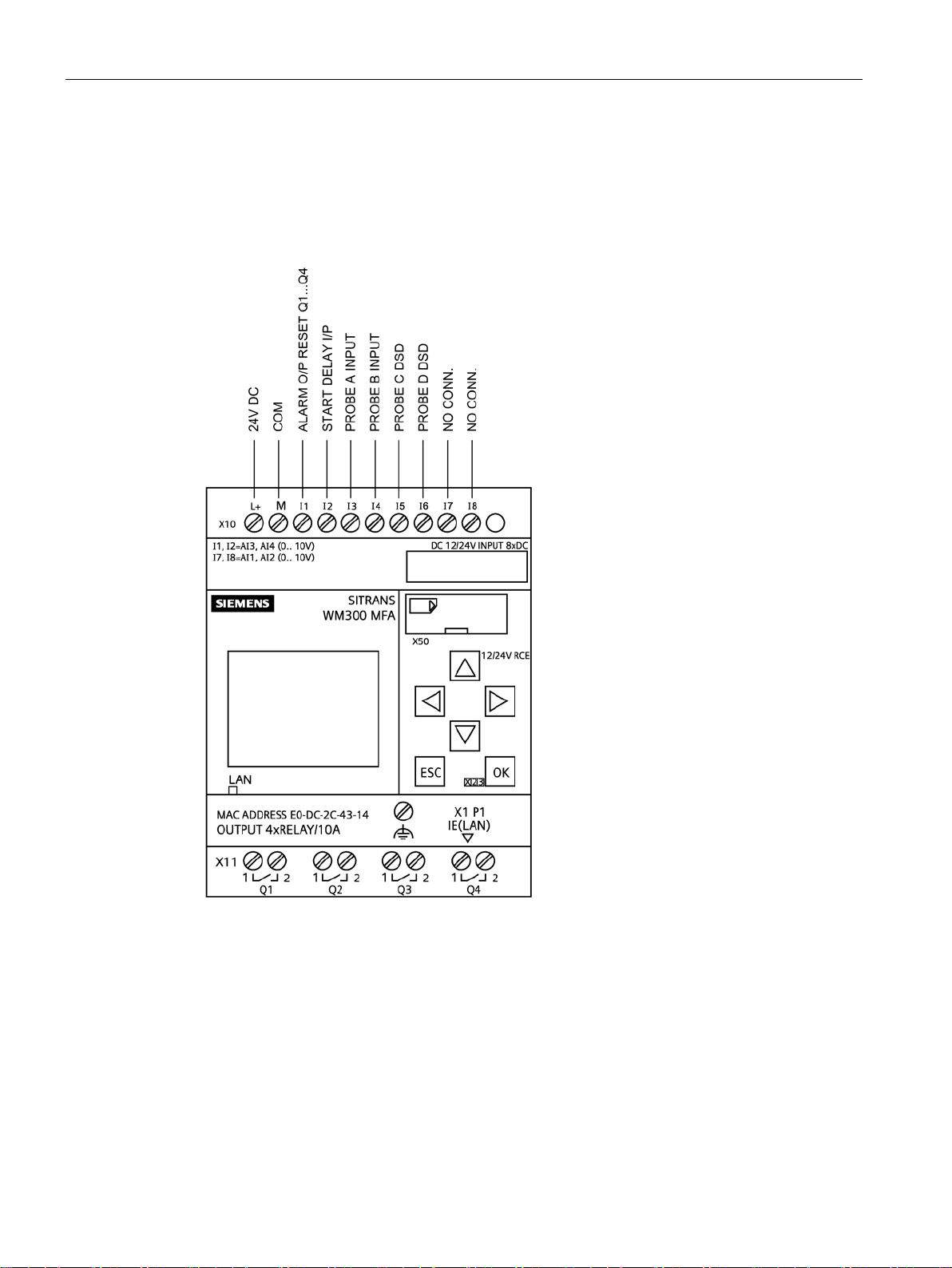

SITRANS WM300 MFA is a highly sensitive, dual setpoint motion sensor alarm unit, used

with MSP and XPP probes. The probe detects an increase or decrease in the speed of

rotating, reciprocating, or conveying equipment and sends the information to the SITRANS

WM300 MFA. The SITRANS WM300 MFA works with a pre-amplifier which can be internal

to the motion sensing probe or remote from the motion sensing probe.

Pulses generated from the probe are continually compared to the adjustable setpoint. If the

pulse rate is lower or higher than the setpoint, the alarm relays operating in a faiI-safe mode

will de-energize, indicating failure. The relays will not energize until the pulse rate increases

above or below the setpoint.

The relays can be reset automatically or manually. See Motion Failure Alarm (Page 32).

The SITRANS WM300 MFA is configured for a specific application and must be programmed

and hardwired according to application requirements. Unused inputs or outputs have no

effect on the devices specific operation and must not be wired to any other any other

peripheral equipment.

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

9

SITRANS WM300 MFA Overview

SITRANS WM300 MFA

10 Operating Instructions, 08/2018, A5E45090709-AA

3

3.1

Safety Note

Note

Installation shall only be performed by qualified personnel and in accordance with local

governing regulations.

3.2

Location Requirements

The SITRANS WM300 MFA (and RMA or NCT and power supply converter if applicable)

must be mounted in a non-hazardous area that is clean, dry, vibration-free, within the

ambient temperature range, and non-corrosive to the electronics or its enclosure. The

cabinet door should be accessible for viewing and to allow calibration of the SITRANS

WM300 MFA.

Consider the probe location carefully before installation. Avoid strong magnetic fields

(50/60 Hz) from nearby power transformers, heater elements, or large industrial motors,

because these can affect the probe’s performance.

An additional remote display can be connected to the SITRANS WM300 MFA for access to

the unit within an enclosure.

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

11

Installing/mounting

Note

Do not mount SITRANS WM300 MFA in direct sunlight.

3.3

Proper Mounting

Functionality loss indicators:

3.3 Proper Mounting

The SITRANS WM300 MFA can be DIN or wall mounted. In a stand-alone enclosure or

panel arrangement, the device can use a power transformer to take AC to DC voltage. An

additional NCT analog output module is necessary to be integrated into the SITRANS

WM300 MFA bus connection and additional RMA depending on the application

requirements.

The probe should be mounted onto a vibration free structure using the mounting flange. The

gap between probe and target should be large enough to prevent the target from damaging

the probe. The probe environment must be within the probe's ambient temperature range

and non-corrosive to the probe's body. Refer to Applications (Page 71).

The probe design detects a changing magnetic field, typically caused by a ferromagnetic

target disturbing the probe's magnetic field. Extremely strong magnetic fields (like those

produced by the 30 A/m requirements of 1EC 60004-8, Power Frequency Magnetic Field

Immunity test) will be detected and will result in loss of functionality.

● Alarm conditions by relay output

SITRANS WM300 MFA

12 Operating Instructions, 08/2018, A5E45090709-AA

Installing/mounting

3.4

Mounting Details

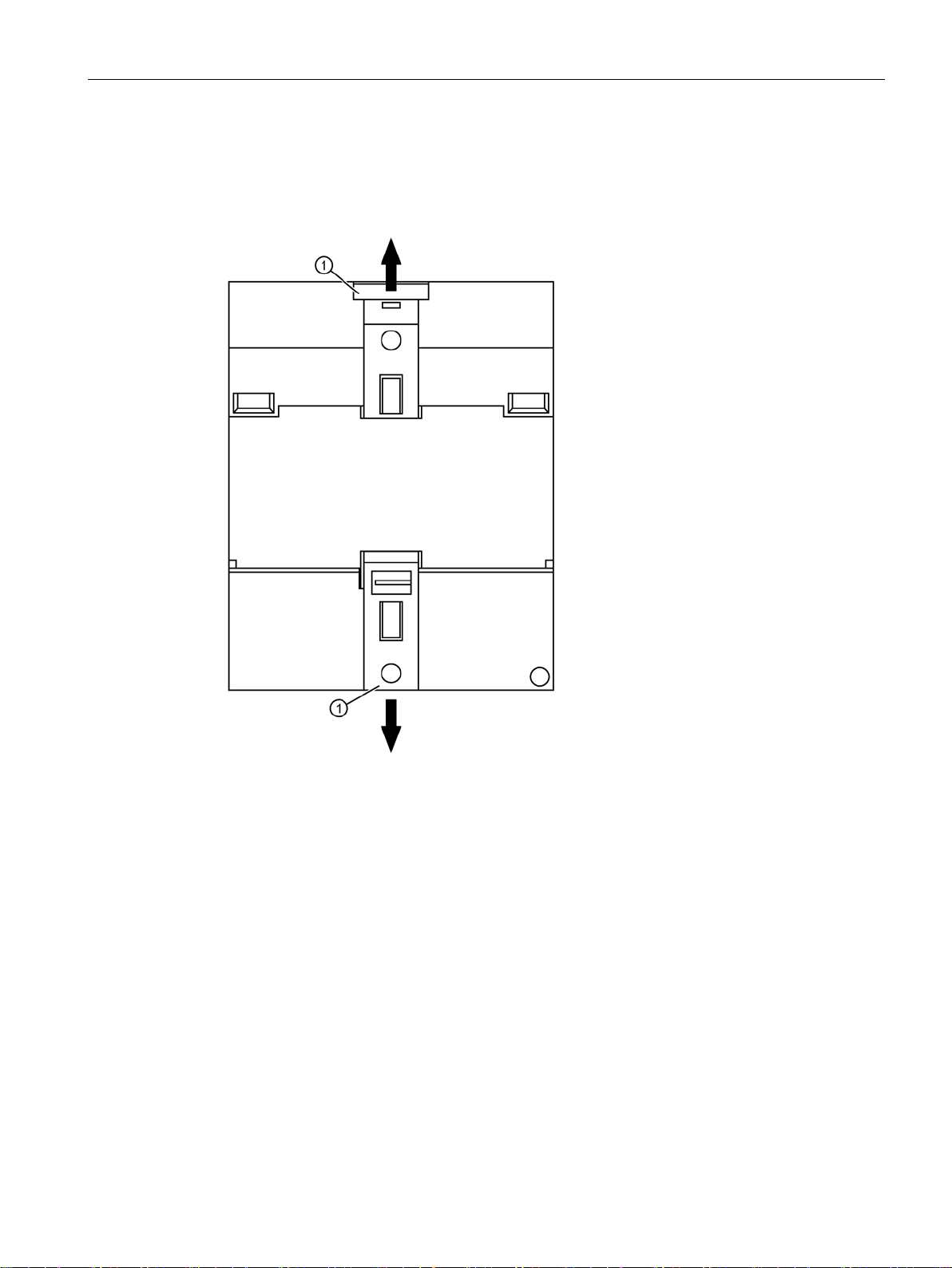

①

Mounting slide

3.4 Mounting Details

To mount the SITRANS WM300 MFA or other components, slide the DIN rail mounting clips

outside of the enclosure and to the mounting holes.

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

13

Installing/mounting

For wall mounting slide the tabs out and mount to the wall/post with M4 screws.

①

Mounting slide

3.4 Mounting Details

SITRANS WM300 MFA

14 Operating Instructions, 08/2018, A5E45090709-AA

Installing/mounting

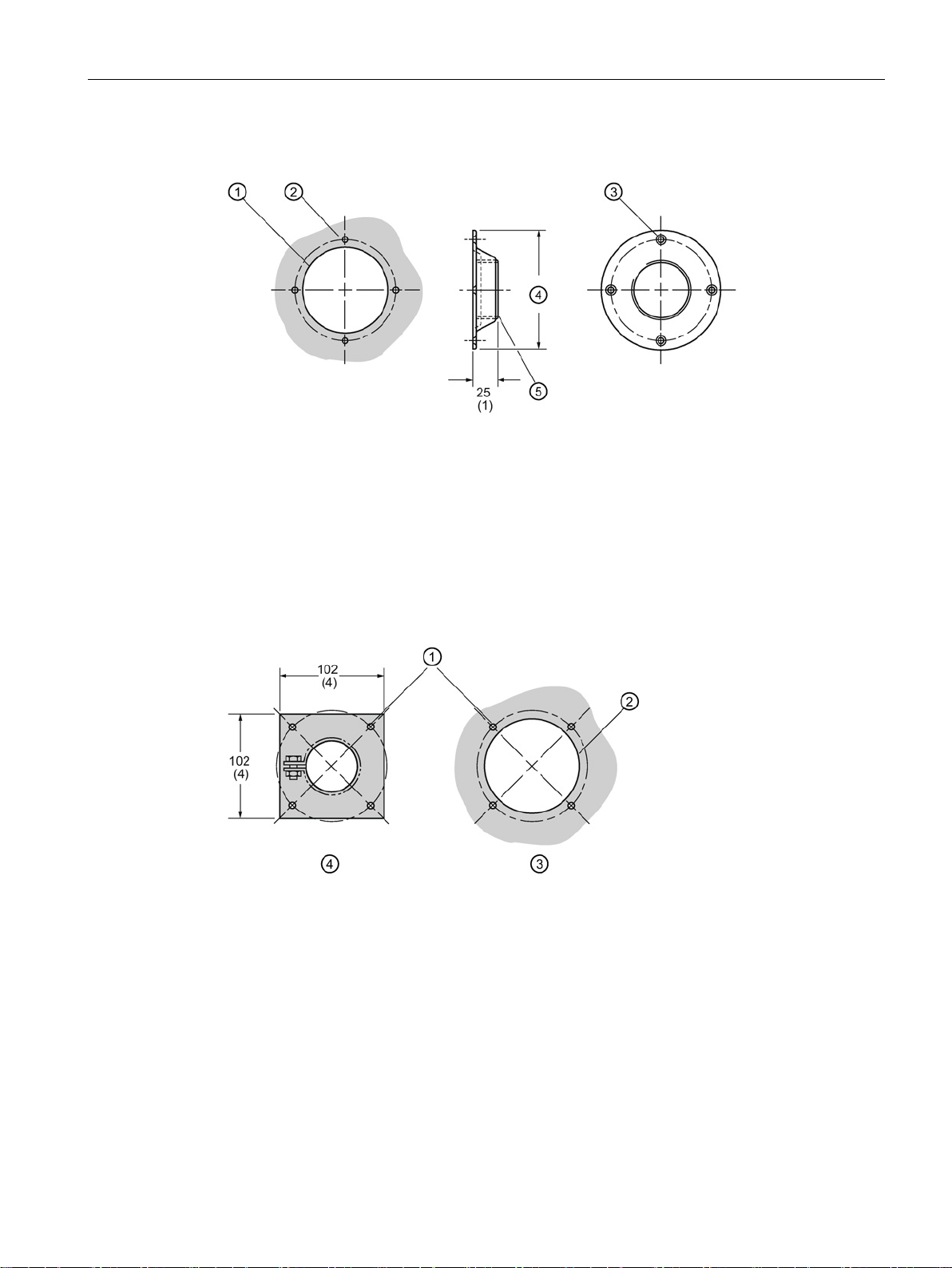

MSP-3, MSP-7, MSP-12, XP P-5 Mounting Details

MSP-9 Mounting Details

3.4 Mounting Details

Dimensions in mm (inch)

① 95 (3.75) ∅ probe clearance hole

② 6 (0.25) ∅ hole for ¼ - 20 nut and bolt or drill and tap, four holes on 114 (4.5) BCD

③ 6 (0.25) ∅ hole for ¼ - 20 bolt on 114 (4.5) BCD, four places

④ 113 (5.25) O.D.

⑤ 2" NSPL

Dimensions in mm (inch)

① 6 (0.25) ∅ 4 holes equally spaced on a 114 (4.5) BCD

② 95 (3.75) ∅ probe clearance hole

③ Panel cutout

④ Probe flange

● For high temperature and corrosion resistant applications

● 304 stainless steel body comes with stainless steel clamp and silicone gasket

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

15

Installing/mounting

3.5

Wiring

3.5 Wiring

Where possible, the probe components should be interconnected via flexible conduit. This

allows for easier removal or adjustment of the probe and mounting flange assembly.

SITRANS WM300 MFA

16 Operating Instructions, 08/2018, A5E45090709-AA

Installing/mounting

3.5 Wiring

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

17

Installing/mounting

Note

RMA not required for use with MSP

correct signal conditioning. Improper switch selection may damage the device.

3.5 Wiring

-7. Proper switch s elec t ion must be made to ens ure

SITRANS WM300 MFA

18 Operating Instructions, 08/2018, A5E45090709-AA

4

4.1

Interconnection

Note

Use

differential ground loops.

4.1.1

MSP-3 or MSP-9 Probe with RMA (remote mounted amplifier)

shielded cable and connect all cable shields to the MFA shield terminals to avoid

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

● RMA selector switch to the right

● Maximum cable length from probe to RMA is 30 m/100 ft of shielded cable, 18 ga. wire.

● 1.5 m (5 ft) Belden 83321 Teflon

See Cable length from RMA or IMA to WM300 MFA (Page 23) for cable lengths from

RMA to main group.

1)

Teflon is a registered trademark of E.I. du Pont de Nemours and Company

1)

cable potted in probe

19

Connecting

4.1.2

MSP-12 Probe with RMA (internally mounted pre-amplifier)

4.1 Interconnection

● RMA selector switch to the left.

● Wire can be run in conduit common to motor supply or control wiring. Connection to

probe terminals can be made under probe cap.

See cable lengths (Page 23)for maximum separation from probe to RMA.

SITRANS WM300 MFA

20 Operating Instructions, 08/2018, A5E45090709-AA

Connecting

4.1.3

XPP-5 with RMA (internally mounted pre-amplifier)

Note

Refer to

4.1 Interconnection

● RMA selector switch to the left.

● XPP-5 cable must be run in dedicated, approved metal conduit, boxes and fittings and to

procedures in accordance with all governing regulations. See Cable length from RMA or

IMA to WM300 MFA (Page 23) for cable lengths from probe at SITRANS WM300 MFA.

See cable lengths for maximum separation from probe to RMA.

Interconnection Diagram for XPP-5 (Page 24)

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

21

Connecting

4.1.4

MSP-7 with IMA (internally mounted pre-amplifier)

WARNING

Unsuitable cables, cable glands and/or plugs

4.1 Interconnection

Wire can be run in conduit. Connection to probe terminals can be made under probe cap.

See cable lengths (Page 23) for maximum separation from probe to SITRANS WM300 MFA.

Risk of explosion in hazardous areas.

• Use only cable glands/plugs that comply with the requirements for the relevant type of

protection.

• Tighten the cable glands in accordance with the torques specified in Cable length from

RMA or IMA to WM300 MFA (Page 23).

• Close unused cable inlets for the electrical connections.

• When replacing cable glands, only use cable glands of the same type.

• After installation, check that the cables are seated firmly.

SITRANS WM300 MFA

22 Operating Instructions, 08/2018, A5E45090709-AA

Connecting

WARNING

Incorrect conduit system

4.1.5

Cable length from RMA or IMA to WM300 MFA

Wire gauge

Length in feet

Length in meters

22 AWG (0.34 mm2)

2 500

760

18 AWG (0.75 mm2)

5 000

1 520

12 AWG (4 mm2)

25 000

7 600

4.1 Interconnection

Risk of explosion in hazardous areas as result of open cable inlet or incorrect conduit

system.

• In the case of a conduit system, mount a spark barrier at a defined distance from the

device input. Observe national regulations and the requirements stated in the relevant

approvals.

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

23

Connecting

4.1.6

Interconnection Diagram for XPP-5

4.1 Interconnection

SITRANS WM300 MFA

24 Operating Instructions, 08/2018, A5E45090709-AA

Connecting

4.1 Interconnection

SITRANS WM300 MFA

Operating Instructions, 08/2018, A5E45090709-AA

25

Loading...

Loading...