Siemens SITRANS TW Operator's Manual

SITRANS T measuring instruments for temperature

© Siemens AG 2009

Transmitters for rail mounting

SITRANS TW

four-wire system, universal, HART

3

■

Overview

The user-friendly transmitters for the control room

The SITRANS TW universal transmitter is a further development

of the service-proven SITRANS T for the 4-wire system in a

mounting rail housing. With numerous new functions it sets new

standards for temperature transmitters.

With its diagnostics and simulation functions the SITRANS TW

provides the necessary insight during commissioning and operation. And using its HART interface the SITRANS TW can be

conveniently adapted with SIMATIC PDM to every measurement

task.

All SITRANS TW control room devices are available in a nonintrinsically safe version as well as in an intrinsically safe version

for use with the most stringent requirements.

■

Application

The SITRANS TW transmitter is a four-wire rail-mounted device

with a universal input circuit for connection to the following sensors and signal sources:

• Resistance thermometers

• Thermocouple elements

• Resistance-based sensors/potentiometers

• mV sensors

• As special version:

- V sources

- Current sources

The 4-wire rail-mounted SITRANS TW transmitter wire is designed for control room installation. It must not be mounted in

potentially explosive atmospheres.

All SITRANS TW control room devices are available in a nonintrinsically safe version as well as in an intrinsically safe version

for use with the most stringent requirements.

■

Function

Features

• Transmitter in four-wire system with HART interface

• Housing can be mounted on 35 mm rail or 32 mm G rail

• Screw plug connector

• All circuits electrically isolated

• Output signal: 0/4 to 20 mA or 0/2 to 10 V

• Power supplies: 115/230 V AC/DC or 24 V AC/DC

• Explosion protection [EEx ia] or [EEx ib] for measurements

with sensors in the hazardous area

• Temperature-linear characteristic for all temperature sensors

• Temperature-linear characteristic can be selected for all temperature sensors

• Automatic correction of zero and span

• Monitoring of sensor and cable for open-circuit and short-circuit

• Sensor fault and/or limit can be output via an optional sensor

fault/limit monitor

• Hardware write protection for HART communication

• Diagnostic functions

• Slave pointer functions

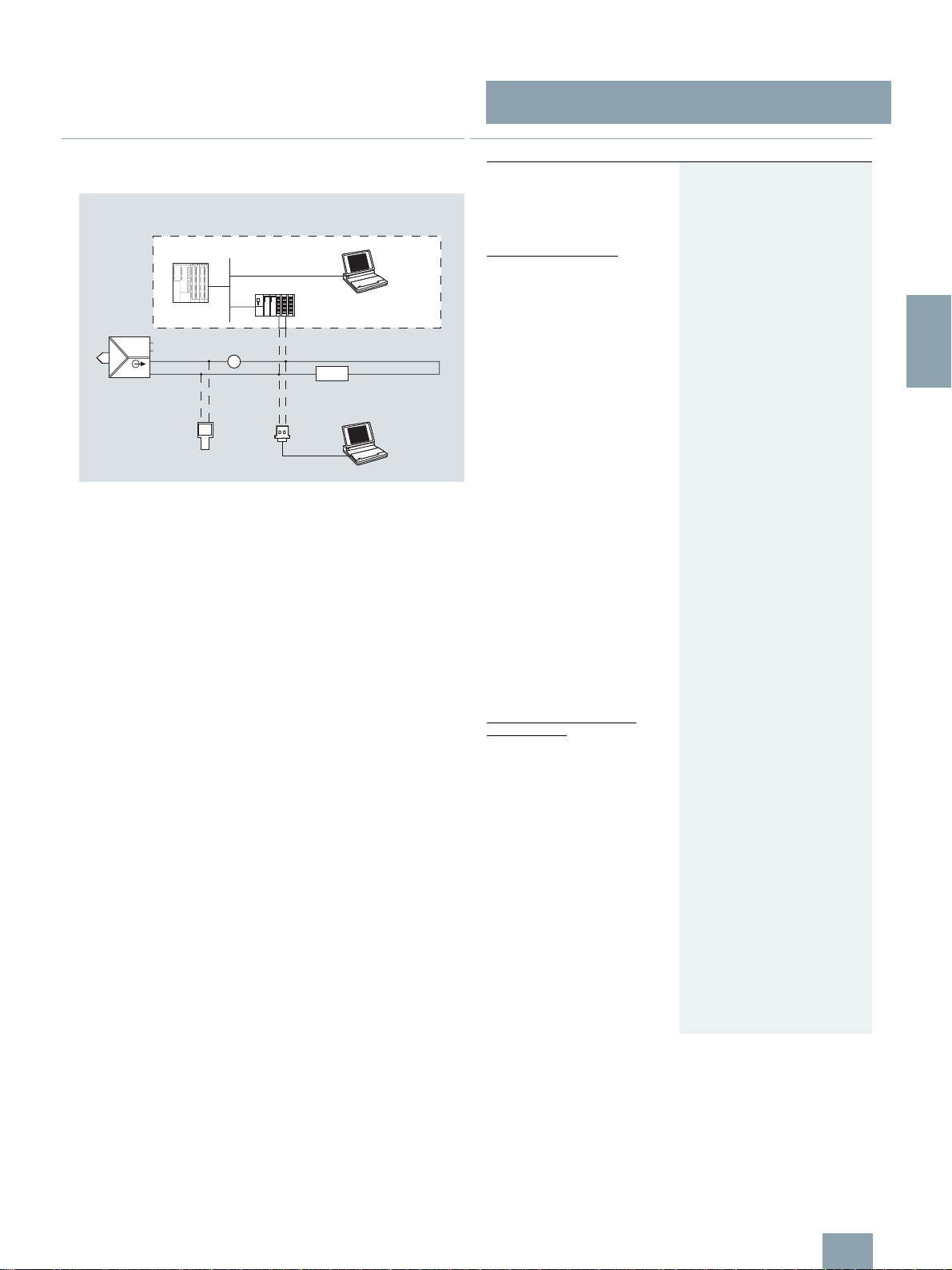

Mode of operation

TC

µC

5

9

Power

supply

7

10

D

Output

11

U or I

A

12

6

13

unit

Current test

A

0/4 ... 20 mA

U

H

HART modem/

communicator

RTD

8

A

1

4

D

2

EEPROM

3

The signal output by a resistance-based sensor (two-wire, threewire, four-wire system), voltage source, current source or thermocouple is converted by the analog-to-digital converter

(1, function diagram) into a digital signal. This is evaluated in the

microcontroller (2), corrected according to the sensor characteristic, and converted by the digital-to-analog converter (6) into an

output current (0/4 to 20 mA) or output voltage (0/2 to 10 V). The

sensor characteristics as well as the electronics data and the

data for the transmitter parameters are stored in the non-volatile

memory (3).

AC or DC voltages can be used as the power supply (13). Any

terminal connections are possible for the power supply as a result of the bridge rectifier in the power supply unit. The PE conductor is required for safety reasons.

A HART modem or a HART communicator permit parameterization of the transmitter using a protocol according to the HART

specification. The transmitter can be directly parameterized at

the point of measurement via the HART output terminals (10).

The operation indicator (4) identifies a fault-free or faulty operating state of the transmitter. The limit monitor (9) enables the signaling of sensor faults and/or limit violations. In the case of a current output, the current can be checked on a meter connected

to test socket (12).

Diagnosis and simulation functions

The SITRANS TW comes with extensive diagnosis and simulation functions.

Physical values can be defined with the simulation function. It is

thus possible to check the complete signal path from the sensor

input to Inside the control system without additional equipment.

The slave pointer functions are used to record the minimum and

maximum of the plant’s process variable.

3/38

Siemens FI 01 · 2010

SITRANS T measuring instruments for temperature

© Siemens AG 2009

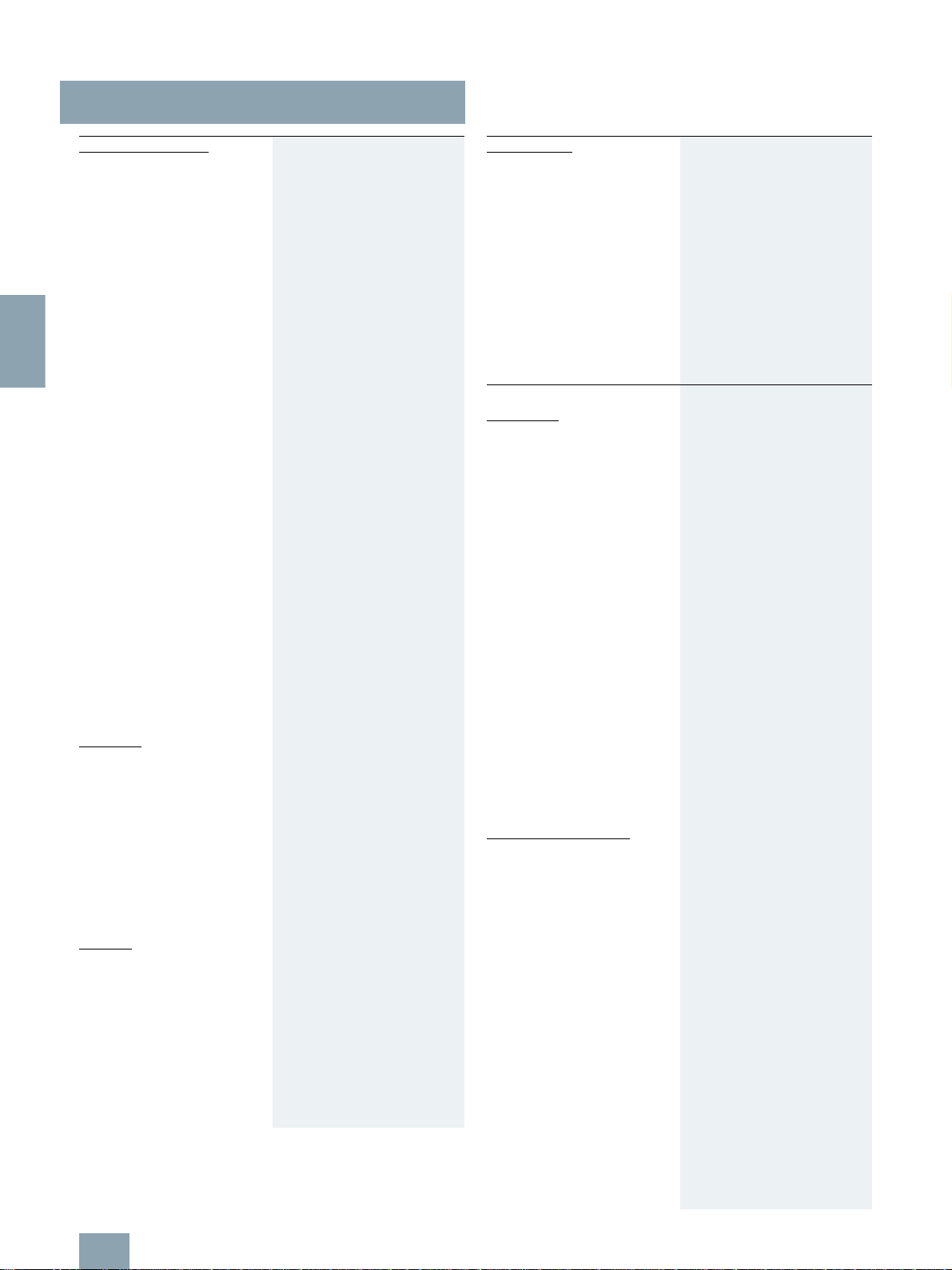

■

Integration

System configuration

SIMATIC S7-400

Control system

U

H

4...20 mA

SITRANS TW

transmitter

HART

communicator

Possible system configurations

A

or

HART

modem

ET 200M

or

Load

RS-232-C

The SITRANS TW transmitter as a four-wire rail-mounted device

can be used in a number of system configurations: as a standalone version or as part of a complex system environment, e.g.

with SIMATIC S7. All device functions are available via HART

communication.

Communication options through the HART interface:

• HART communicator

• HART modem connected to PC/laptop on which the appropriate software is available, e.g. SIMATIC PDM

• HART-compatible control system (e.g. SIMATIC S7-400 with

ET 200M)

SIMATIC PDM

PC/laptop with

SIMATIC PDM

Transmitters for rail mounting

four-wire system, universal, HART

■

Technical specifications

Input

Selectable filters to suppress the

line frequency

Resistance thermometer

Measured variable Temperature

Measured range

Measured span

Sensor type

• DIN IEC 751 Pt100 (DIN IEC 751)

• Acc. to JIS C 1604-81

• Acc. to DIN 43760

• Special type (R

Voltage measurement

Type of connection

Connection

Measuring range limits

Sensor breakage monitoring

Sensor short-circuit monitoring

Resistance-based sensors,

potentiometers

Measured variable Ohmic impedance

Measured range

Measured span

Voltage measurement

Type of connection

Connection

Input range

Sensor breakage monitoring

Sensor short-circuit monitoring

≤ 500 Ω) Multiples or parts of the defined

RTD

50 Hz, 60 Hz, also 10 Hz for special applications (line frequency

filter is similar with measuring frequency)

Parameterizable

Min. 25 °C (45 °F) x 1/scaling

factor

Pt100 (JIS C1604-81)

Ni100 (DIN 43760)

characteristic values can be

parameterized (e.g. Pt500, Ni120)

Temperature-linear, resistancelinear or customer-specific

• Normal connection

• Sum or parallel connection

• Mean-value or differential

connection

2, 3 or 4-wire circuit

Depending on type of connected

thermometer (defined range of

resistance thermometer)

Monitoring of all connections for

open-circuit (function can be

switched off)

Parameterizable response threshold (function can be switched off)

Parameterizable

Min. 10 Ω

Resistance-linear or customer-

specific

• Normal connection

• Differential connection

• Mean-value connection

2, 3 or 4-wire circuit

0 ... 6000 Ω;

with mean-value and difference circuits: 0 ... 3000 Ω;

Monitoring of all connections for

open-circuit (function can be

switched off)

Parameterizable response threshold (function can be switched off)

SITRANS TW

3

Siemens FI 01 · 2010

3/39

SITRANS T measuring instruments for temperature

© Siemens AG 2009

Transmitters for rail mounting

SITRANS TW

four-wire system, universal, HART

3

Thermocouple elements

Measured variable Temperature

Measured range

Measured span

Measuring range limits

Thermocouple

• Type B Pt30 %Rh/Pt6 %Rh (DIN IEC 584)

• Type C

• Type D

• Type E

• Type J

• Type K

• Type L

• Type N

• Type R

• Type S

• Type T

• Type U

Voltage measurement

Type of connection

Cold junction compensation

Sensor breakage monitoring

mV sensors

Measured variable DC voltage

Measured range

Measured span

Input range

Voltage measurement

Overload capacity of inputs

Input resistance

Sensor current

Sensor breakage monitoring

V sources

Measured variable DC voltage

Measured range

Voltage measurement

Input range/min. span

• Devices with 7NG3242-xxxx1 or

7NG3242-xxxx 0 with U/I plug

• Devices with 7NG3242-xxxx2

• Devices with 7NG3242-xxxx3

Sensor breakage monitoring

Parameterizable

Min. 50 °C (32.22 °F) x 1/scaling

factor

Depend. on type of thermocouple

element

W5 %-Re (ASTM 988)

W3 %-Re (ASTM 988)

NiCr/CuNi (DIN IEC 584)

Fe/CuNi (DIN IEC 584)

NiCr/Ni (DIN IEC 584)

Fe-CuNi (DIN 43710)

NiCrSi-NiSi (DIN IEC 584)

Pt13 %Rh/Pt (DIN IEC 584)

Pt10 %Rh/Pt (DIN IEC 584)

Cu/CuNi (DIN IEC 584)

Cu/CuNi (DIN 43710)

Special type

(-10 mV ≤ UTC ≤ 100 mV)

Temperature-linear, voltage-linear

or customer-specific

• Normal connection

• Sum connection

• Mean-value connection

• Differential connection

None, internal measurement, exter-

nal measurement or predefined

fixed value

Function can be switched off

Parameterizable

Min. 4 mV

-120 ... +1000 mV

Voltage-linear or customer-specific

Max. ± 3.5 V

≥ 1MΩ

Approx. 180 µA

Function can be switched off

Parameterizable

Voltage-linear or customer-specific

-1.2 V ... +10 V/0.04 V

-12 V ... +100 V/0.4 V

-120 V ... +140 V/4.0 V

Not possible

µA, mA sources

Measured variable DC voltage

Measured range

Voltage measurement

Input range/min. span

• Devices with 7NG3242-xxxx4 -12 µA ... +100 µA/0.4 µA

• Devices with 7NG3242-xxxx5

• Devices with 7NG3242-xxxx6

• Devices with 7NG3242-xxxx7 or

7NG3242-xxxx 0 with U/I plug

• Devices with 7NG3242-xxxx8

Sensor breakage monitoring

Output

Output signal Load-independent direct current

Current 0/4 ... 20 mA

• Overrange -0.5 ... +23.0 mA, continuously

• Output range following sensor fault

•Load

• Open-circuit voltage

Voltage 0/2 ... 10 V

• Overrange -0.25 ... +10.75 V, continuously

• Output range following sensor fault

• Load resistance

• Load capacitance

• Short-circuit voltage

• Electrical damping

- Adjustable time constant T

• Current source/voltage source

Sensor fault/limit signalling

Operation indicator

• Limit violation

• Overrange

Relay output

• Switching capacity

• Switching voltage

• Switching current

Overrange

Limit monitoring

• Operating delay 0 ... 10 s

• Monitoring functions of limit

module

• Hysteresis

By operation indicator, relay output

Parameterizable

Current-linear or customer-

specific

-120 µA ... +1000 µA/4 µA

-1.2 mA ... +10 mA/0.04 mA

-12 mA ... +100 mA/0.4 mA

-120 mA ... +1000 mA/4 mA

Not possible

0/4 ... 20 mA, can be switched to

load-independent DC voltage

0/2 ... 10 V using plug-in jumpers.

adjustable

-0.5 ... +23.0 mA, continuously

adjustable

≤ 650 Ω

≤ 30 V

adjustable

-0.25 ... +10.75 V, continuously

adjustable

≥ 1kΩ

≤ 10 nF

≤ 100 mA (not permanently short-

circuit-proof)

0 ... 100 s, in steps of 0.1 s

63

Continuously adjustable within the

total operating range

or HART interface

Flashing signal

Flashing frequency 5 Hz

Flashing frequency 1 Hz

Either as NO or NC contact with

1 changeover contact

≤ 150 W, ≤ 625 VA

≤ 125 V DC, ≤ 250 V AC

≤ DC 2.5 A

Signalling of sensor or line breakage and sensor short-circuit

• Sensor fault (breakage and/or

short-circuit)

• Lower and upper limit

• Window (combination of lower

and upper limits)

• Limit and sensor fault detection

can be combined

Parameterizable between 0 and

100 % of measuring range

3/40

Siemens FI 01 · 2010

SITRANS T measuring instruments for temperature

© Siemens AG 2009

Transmitters for rail mounting

SITRANS TW

four-wire system, universal, HART

Power supply

Universal power supply unit 115/230 V AC/DC or 24 V AC/DC

Tolerance range for power supply

• With 115/230 V AC/DC PSU 80 ... 300 V DC; 90 ... 250 V AC

• With 24 V AC/DC PSU

Tolerance range for mains frequency

Power consumption with

• 230 V AC ≤ 5 VA

• 230 V DC

• 24 V AC

• 24 V DC

Electrical isolation

Electrically isolated circuits Input, output, power supply and

Working voltage between all electrically isolated circuits

Measuring accuracy

Measurement error

• Error in the internal cold junction ≤ 3°C ± 0,1 °C/10 °C

• Error of external cold junction terminal 7NG3092-8AV

• Digital output

• Analog output I

Influencing effects (referred to the

digital output)

• Temperature drift

• Long-term drift

Influencing effects referred to the

analog output I

• Temperature drift

• Power supply

• Load with current output

• Load with voltage output

• Long-term drift (start-of-scale

value, span)

Response time (T

cal damping)

Electromagnetic compatibility

Certificate and approvals

ATEX To DIN EN 50014: 1997,

Intrinsic safety to EN 50 020

• for 7NG3242-xAxxx II (1) G D [EEx ia/ib ] IIB

• for 7NG3242-xBxxx

EC-Type Examination Certificate

or U

AN

or U

AN

AN

without electri-

63

AN

18 ... 80 V DC; 20.4 ... 55.2 V AC

(in each case interruption-resistant

up to 20 ms in the complete tolerance range)

47 ... 63 Hz

≤ 5 W

≤ 5 VA

≤ 5 W

sensor fault/limit monitoring output

are electrically isolated from one

another. The HART interface is

electrically connected to the output.

The voltage U

terminals must not exceed 300 V

(≤ 5.4 °F ± 0,18 °F/18 °F)

≤ 0.5 °C ± 0,1 °C/10 °C

(≤ 0.9 °F ± 0.18 °F/18 °F)

See "Digital error"

≤ 0.05 % of span in addition to

digital error

Compared to the max. span:

≤ 0.08 %/10 °C (≤ 0.08 %/18 °F)

≤ 0.2 % in the range -10 ... +60 °C

(14 ... 140 °F)

≤ 0.1 %/year

Compared to the span:

≤ 0.08 %/10°C (≤ 0.08 %/18 °F)

≤ 0.2 % in the range -10 ... +60 °C

(14 ... 140 °F)

≤ 0.05 %/10 V

≤ 0.05 % with change from

50 ... 650 Ω

≤ 0.1 % with change in load current

from 0 ... 10 mA

≤ 0.03 %/month

≤ 0.2 s

According to EN 61326 and

NAMUR NE21

EN 50020: 1994

II (1) G D [EEx ia/ib ] IIC

TÜV (German Technical Inspec-

torate) 01 ATEX 1675

between any two

eff

Rated conditions

Installation conditions

Location (for devices with explo-

sion protection)

• Transmitters Outside the potentially explosive

•Sensor

Ambient conditions

Permissible ambient temperature -25 ... +70 °C (-13 ... +158 °F)

Permissible storage temperature

Climatic class

• Relative humidity 5 ... 95 %, no condensation

Design

Weight Approx. 0.24 kg (0.53 lb)

Enclosure material

Degree of protection to IEC 529

Degree of protection to VDE 0100

Type of installation

Electrical connection/process connection

Parameterization interface

Protocol HART, version 5.9

Load with connection of

• HART communicator 230 ... 650 Ω

•HART modem

Software for PC/laptop

atmosphere

Within the potentially explosive

atmosphere zone 1 (also in zone 0

in conjunction with the prescribed

protection requirements for the

sensor)

-40 ... +85 °C (-40 ... +185 °F)

PBT, glass-fibre reinforced

IP20

Protection class I

35-mm top hat rail (1.38 inch)

(DIN EN 50022) or 32-mm G-type

rail (1.26 inch) (DIN EN 50035)

Screw plug connectors,

max. 2.5 mm² (0.01 inch²)

230 ... 500 Ω

SIMATIC PDM version V5.1 and

later

3

Siemens FI 01 · 2010

3/41

Loading...

Loading...