Siemens SITRANS TS100, SITRANS TSthermowell, SITRANS TS200, SITRANS TS300, SITRANS TS500 Compact Operating Instructions

...

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SITRANS

Temperature sensors TS100/TS200/TS300/TS500/TSinse rt/TSthermowell

Compact Operating Instructions

01/2018

A5E03920348

Introduction

1

Safety notes

2

Description

3

Installing

4

Connecting

5

Commissioning

6

Service and maintenance

7

Technical data

8

Dimension drawings

9

Appendix

A

-AE

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E03920348

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

03/2018 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 7

2 Safety notes .......................................................................................................................................... 11

3 Description ............................................................................................................................................ 17

4 Installing ............................................................................................................................................... 23

1.1 Purpose of this documentation ................................................................................................. 7

1.2 Scope of this documentation .................................................................................................... 7

1.3 Document history ...................................................................................................................... 8

1.4 Checking the consignment ....................................................................................................... 8

1.5 Security information .................................................................................................................. 9

1.6 Transportation and storage ....................................................................................................... 9

1.7 Notes on warranty ................................................................................................................... 10

2.1 Preconditions for use .............................................................................................................. 11

2.1.1 Laws and directives ................................................................................................................ 11

2.1.2 Conformity with European directives ...................................................................................... 12

2.2 Improper device modifications ................................................................................................ 12

2.3 Requirements for special applications .................................................................................... 13

2.4 Use in hazardous areas .......................................................................................................... 13

2.4.1 Qualified personnel for hazardous area applications ............................................................. 13

2.5 Use in flameproof enclosures "d" and protection in enclosures "tb" ....................................... 14

2.5.1 For SITRANS TS500 .............................................................................................................. 15

2.5.2 For SITRANS TSinsert/TS100/TS200/TS500 ........................................................................ 16

3.1 Overview ................................................................................................................................. 17

3.2 Application .............................................................................................................................. 18

3.3 Functional principles ............................................................................................................... 18

3.4 Nameplate structure ................................................................................................................ 18

3.5 Temperature transmitter for SITRANS TS500 ........................................................................ 19

3.6 Measuring inserts for SITRANS TS500 .................................................................................. 20

3.7 Connection heads for SITRANS TS500 ................................................................................. 21

4.1 Basic safety notes ................................................................................................................... 23

4.1.1 Installation and location requirements .................................................................................... 24

4.1.2 Proper mounting ..................................................................................................................... 25

4.2 Install ....................................................................................................................................... 27

4.3 Install SITRANS TS300 Clamp-on .......................................................................................... 29

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

3

Table of contents

5 Connecting ........................................................................................................................................... 31

6 Commissioning ..................................................................................................................................... 39

7 Service and maintenance ...................................................................................................................... 41

8 Technical data ...................................................................................................................................... 45

9 Dimension drawings .............................................................................................................................. 65

4.4 Disassembly ........................................................................................................................... 30

5.1 Basic safety notes .................................................................................................................. 31

5.1.1 For SITRANS TSinsert ........................................................................................................... 34

5.1.2 For SITRANS TSinsert/TS100/TS200/TS500 ........................................................................ 34

5.1.3 For SITRANS TS100/TS200 .................................................................................................. 34

5.1.4 For SITRANS TS500 ............................................................................................................. 35

5.2 Electrical connection .............................................................................................................. 35

5.3 Electrical connection of resistance thermometers ................................................................. 36

5.4 Electrical connection of thermocouples ................................................................................. 37

5.5 Electrical connection of connectors ....................................................................................... 37

6.1 Basic safety notes .................................................................................................................. 39

6.2 Commissioning....................................................................................................................... 40

7.1 Cleaning ................................................................................................................................. 43

7.2 Return procedure ................................................................................................................... 43

7.3 Disposal ................................................................................................................................. 44

8.1 Rated conditions .................................................................................................................... 45

8.1.1 Maximum permissible ambient temperatures in the connection area of the sensor ............. 45

8.1.1.1 General limitations for compression fittings ........................................................................... 45

8.1.1.2 SITRANS TS100 .................................................................................................................... 46

8.1.1.3 SITRANS TS500 .................................................................................................................... 47

8.1.2 Maximum permitted sample temperatures within the process .............................................. 54

8.1.3 Measuring range .................................................................................................................... 56

8.2 Construction ........................................................................................................................... 56

8.3 Electrical data ......................................................................................................................... 57

8.4 Measuring tolerances for resistance thermometers ............................................................... 58

8.5 Measuring accuracy for thermocouples ................................................................................. 59

8.6 Certificates and approvals ..................................................................................................... 60

8.6.1 SITRANS TSInsert/TS100/TS200/TS500 .............................................................................. 60

8.6.2 SITRANS TS500 .................................................................................................................... 62

9.1 Overview ................................................................................................................................ 65

9.2 SITRANS TS100 .................................................................................................................... 69

9.3 SITRANS TS200 .................................................................................................................... 70

9.4 SITRANS TS300 .................................................................................................................... 71

9.5 SITRANS TS500 .................................................................................................................... 75

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

4 Compact Operating Instructions, 01/2018, A5E03920348-AE

Table of contents

A Appendix............................................................................................................................................. 107

Index................................................................................................................................................... 109

9.5.1 SITRANS TS500, types 2 and 2N .......................................................................................... 75

9.5.2 SITRANS TS500, types 2G and 2F ........................................................................................ 76

9.5.3 SITRANS TS500, type 3 ......................................................................................................... 77

9.5.4 SITRANS TS500, types 3G and 3F ........................................................................................ 78

9.5.5 SITRANS TS500, types 4 and 4F ........................................................................................... 79

9.5.6 SITRANS TS500, type ST, threaded tapered well (7MC65..) ................................................ 81

9.5.7 SITRANS TS500, type SST, threaded tapered well (7MC55..) .............................................. 82

9.5.8 SITRANS TS500, type SS, threaded straight well (7MC65..)................................................. 84

9.5.9 SITRANS TS500, type SS, threaded straight well (7MC55..)................................................. 85

9.5.10 SITRANS TS500, type SR, threaded reduced well (7MC65..) ............................................... 86

9.5.11 SITRANS TS500, type SR, threaded reduced well (7MC55..) ............................................... 87

9.5.12 SITRANS TS500, type FT, flanged tapered well (7MC65..) ................................................... 88

9.5.13 SITRANS TS500, type FST, flanged tapered well (7MC55..)................................................. 89

9.5.14 SITRANS TS500, type FS, flanged straight well (7MC65..) ................................................... 91

9.5.15 SITRANS TS500, type FS, flanged straight well (7MC55..) ................................................... 92

9.5.16 SITRANS TS500, type FR, flanged reduced well (7MC65..) .................................................. 93

9.5.17 SITRANS TS500, type FR, flanged reduced well (7MC55..) .................................................. 94

9.5.18 SITRANS TS500, type SWT, socket tapered well (7MC65..) ................................................. 95

9.5.19 SITRANS TS500, type SWST, socket tapered well (7MC55..) .............................................. 96

9.5.20 SITRANS TS500, type SWS, socket straight well (7MC65..) ................................................. 98

9.5.21 SITRANS TS500, type SWS, socket straight well (7MC55..) ................................................. 99

9.5.22 SITRANS TS500, type SWR, socket reduced well (7MC65..).............................................. 100

9.5.23 SITRANS TS500, type SWR, socket reduced well (7MC55..).............................................. 101

9.5.24 SITRANS TS500 for installation in existing protective tubes ................................................ 102

9.5.25 SITRANS TS500, type GP, general purpose, no well .......................................................... 104

9.6 SITRANS TSinsert - measuring inserts for SITRANS TS500............................................... 105

A.1 Certificates ............................................................................................................................ 107

A.2 Technical support .................................................................................................................. 107

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

5

Table of contents

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

6 Compact Operating Instructions, 01/2018, A5E03920348-AE

1

1.1

Purpose of this documentation

See also

1.2

Scope of this documentation

Article nr.

Product

7MC72..

SITRANS TS200

7MC80..

SITRANS TS300

7MC75..

SITRANS TS500 (European portfolio)

7MC65..

SITRANS TS500 (North American portfolio)

7MC55..

SITRANS TS500 (Asian portfolio)

7MC.01..

TSinsert

7MT..

TSthermowell

These instructions contain all information required to commission and use the device. Read

the instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

The temperature sensor has a modular design. If you integrate a transmitter or a display,

read the instructions of the transmitter and/or the display.

Instructions and manuals (http://www.siemens.com/processinstrumentation/documentation)

7MC71.. SITRANS TS100

"7MC../7MT.." stands for:

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

7

Introduction

1.3

Document history

Edition

Remark

01/2018

TSthermowell added

1.4

Checking the consignment

WARNING

Using a damaged or incomplete device

1.3 Document history

The following table shows major changes in the documentation compared to the previous

edition.

The most important changes in the documentation when compared with the respective

previous edition are given in the following table.

10/2016 Technical data for rated conditions changed

1. Check the packaging and the delivered items for visible damages.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Risk of explosion in hazardous areas.

• Do not use damaged or incomplete devices.

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

8 Compact Operating Instructions, 01/2018, A5E03920348-AE

Introduction

1.5

Security information

1.6

Transportation and storage

NOTICE

Insufficient protection during storage

1.5 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines, and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit:

https://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customer’s exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

https://www.siemens.com/industrialsecurity.

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume

liability for any costs associated with transportation damages.

The packaging only provides limited protection against moisture and infiltration.

• Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in Technical data

(Page 45).

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

9

Introduction

1.7

Notes on warranty

See also

1.7 Notes on warranty

The contents of this manual shall not become part of or modify any prior or existing

agreement, commitment or legal relationship. The sales contract contains all obligations on

the part of Siemens as well as the complete and solely applicable warranty conditions. Any

statements regarding device versions described in the manual do not create new warranties

or modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

Contacts (http://www.siemens.com/processinstrumentation/contacts)

SITRANS T product information (http://www.siemens.com/sitranst)

Instructions and manuals (http://www.siemens.com/processinstrumentation/documentation)

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

10 Compact Operating Instructions, 01/2018, A5E03920348-AE

2

2.1

Preconditions for use

Symbol

Description

Pay attention to the operat

2.1.1

Laws and directives

SITRANS TSthermowell

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or

symbols from the device. Always keep the information and symbols in a completely legible

state.

ing instructions

Observe the safety rules, provisions and laws applicable in your country during connection,

assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EU)

The thermowell is affected by the static, dynamic and chemical load from the process

parameters including static and dynamic load, flow induced vortexes. This has influence on

the shape of the thermometer, stem diameter and insertion length.

Observe the test certification, provisions and laws applicable in your country during

connection, assembly and operation. These include:

● ASME PTC 19.3

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

● DIN 43772 Annex 1-2

● AD-directive

● VDI/VDE 3511-5

11

Safety notes

2.1.2

Conformity with European directives

Electromagnetic compatibi

i

2014/30/EU

Directive of the European Parliament and of the Council on the

approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC.

Atmosphère explosible

ATEX

2014/34/EU

Directive of the European Pa

approximation of the laws of the Member States concerning

equipment and protective systems intended for use in pote

ly explosive atmospheres.

See also

2.2

Improper device modifications

WARNING

Improper device modifications

2.2 Improper device modifications

In critical applications, a thermowell stress calculation is recommended:

● ASME PTC 19.3-TW2016

● Dittrich/Klotter-method engineering service

The CE marking on the device symbolizes the conformity with the following European

directives:

l-

ty EMC

rliament and the Council on the

The applicable directives can be found in the EC conformity declaration of the specific

device.

ntial-

Certificates (Page 107)

Risk to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

12 Compact Operating Instructions, 01/2018, A5E03920348-AE

Safety notes

2.3

Requirements for special applications

Note

Operation under special ambient conditions

We highly recommend that you contact your Siemens representative or our application

department before you operate the device under special ambient conditions as can be

encountered in nuclear power plants or when the device is used for research and

developm

2.4

Use in hazardous areas

2.4.1

Qualified personnel for hazardous area applications

Qualified personnel for hazardous area applications

WARNING

Use in hazardous area

2.3 Requirements for special applications

Due to the large number of possible applications, each detail of the described device

versions for each possible scenario during commissioning, operation, maintenance or

operation in systems cannot be considered in the instructions. If you need additional

information not covered by these instructions, contact your local Siemens office or company

representative.

ent purposes.

Persons who install, connect, commission, operate, and service the device in a hazardous

area must have the following specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and

systems according to the safety regulations for electrical circuits, high pressures,

aggressive, and hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for

hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment

according to the pertinent safety regulations.

Risk of explosion.

• Only use equipment that is approved for use in the intended hazardous area and

labelled accordingly.

• Don't use devices that have been operated outside the conditions secified for hazardous

areas. If you have used the device outside the conditions for hazardous areas

permanently make all Ex markings unrecognizable on the nameplate.

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

13

Safety notes

See also

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

2.5

Use in flameproof enclosures "d" and protection in enclosures "tb"

WARNING

Impermissible repair of explosion protected devices

WARNING

Electrostatic charge

2.5 Use in flameproof enclosures "d" and protection in enclosures "tb"

Technical data (Page 45)

If the device has already been operated in non-intrinsically safe circuits or the electrical

specifications have not been observed, the safety of the device is no longer ensured for use

in hazardous areas. There is a risk of explosion.

• Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe

circuit.

• Observe the specifications for the electrical data on the certificate and/or in Technical

data (Page 45).

Risk of explosion in hazardous areas

• Repair must be carried out by Siemens authorized personnel only.

Risk of explosion in hazardous areas if electrostatic charges develop, for example, when

cleaning plastic surfaces with a dry cloth.

• Prevent electrostatic charging in hazardous areas.

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

14 Compact Operating Instructions, 01/2018, A5E03920348-AE

Safety notes

2.5.1

For SITRANS TS500

2.5 Use in flameproof enclosures "d" and protection in enclosures "tb"

● The enclosures types AG0, AH0, AU0, AV0 and SITRANS TF of the temperature

sensors, series TS500 have to be connected by means of suitable cable entry fittings or

conduit systems, which meet the requirements of IEC/EN 60079-1, sections 13.1 and

13.2, and for which a separate examination certificate has been issued.

● Cable entry fittings (conduit threads) and sealing plugs of simple design must not be used

in the transmitter and receiver enclosures.

● Any openings in the transmitter and receiver enclosures that are not used must be closed

as specified in IEC/EN 60079-1, section 11.9.

● The connecting lead of enclosures types AG0, AH0, AU0, AV0 and SITRANS TF of the

temperature sensors, series TS500, must be installed to provide for permanent wiring

and adequate protection against damage.

● If the temperature at entry fittings should exceed 60 °C, the connecting cables used have

to be of the temperature-resistant type.

● If connection is made in the potentially explosive area, the connecting cable

(unconnected cable end) of the enclosure types AG0, AH0, AU0, AV0 and TF of the

temperature sensors, series TS500, must be connected in an enclosure that meets the

requirements of an approved type of protection as specified in IEC/EN 60079-0, section

1.

● All models are to be mounted within Thermowells suitably rated for the application they

are used.

● If a SITRANS TS500 with XP type of protection is combined with a thermowell, consider

the ASME PTC19.3 and a minimum wall thickness of 1 mm.

● To separate zone 1 from zone 2 in a hazardous area, consider a wall thickness of ≥ 1 mm

with austenitic steel. In addition, consider the existing process conditions.

If a thermowell installed correctly and tight at Zone 0, the sensor that is screwed in this

thermowell needs at least zone 1 approval.

● Suitably rated Thermowells are to have thread engagement of 5 full turns wrench tight.

● Notes to this effect must accompany each device in an adequate form.

● Components attached or installed (terminal compartments, bushings, cable entry fittings,

connectors) must be of a technical standard that complies with the specifications on the

Certificate of Conformity as a minimum, and a separate examination certificate must have

been issued for them.

● Use the device to measure temperature in accordance with the technical data for

maximum permitted ambient temperatures in the connection area of the sensor. See

chapter Gas hazardous area: Ex d / XP (Page 52) and Dust hazardous area: Ex i / IS / Ex

tb / DIP (Page 53).

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

15

Safety notes

2.5.2

For SITRANS TSinsert/TS100/TS200/TS500

NOTICE

Ambient temperature too high

2.5 Use in flameproof enclosures "d" and protection in enclosures "tb"

Damage to cable sheath.

• At an ambient temperature ≥ 60 °C (140 °F), use heat-resistant cables suitable for an

ambient temperature at least 20 °C (36 °F) higher.

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

16 Compact Operating Instructions, 01/2018, A5E03920348-AE

3

3.1

Overview

SITRANS TS product family

①

general use, compact design with connecting cable

②

general use, compact design

③

general use, modular design with connection head (European portfolio/ Chinese portfolio)

④

SITRANS TSinsert measuring insert for use in the SITRANS TS500 series

⑤

general use, modular design with connection head (North American portfolio/ Chinese portfolio)

SITRANS TS100 7MC71..

SITRANS TS200 7MC72..

SITRANS TS500 7MC75../7MC55..

SITRANS TS500 7MC65../7MC55..

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

17

Description

Elementary sensors

3.2

Application

3.3

Functional principles

3.4

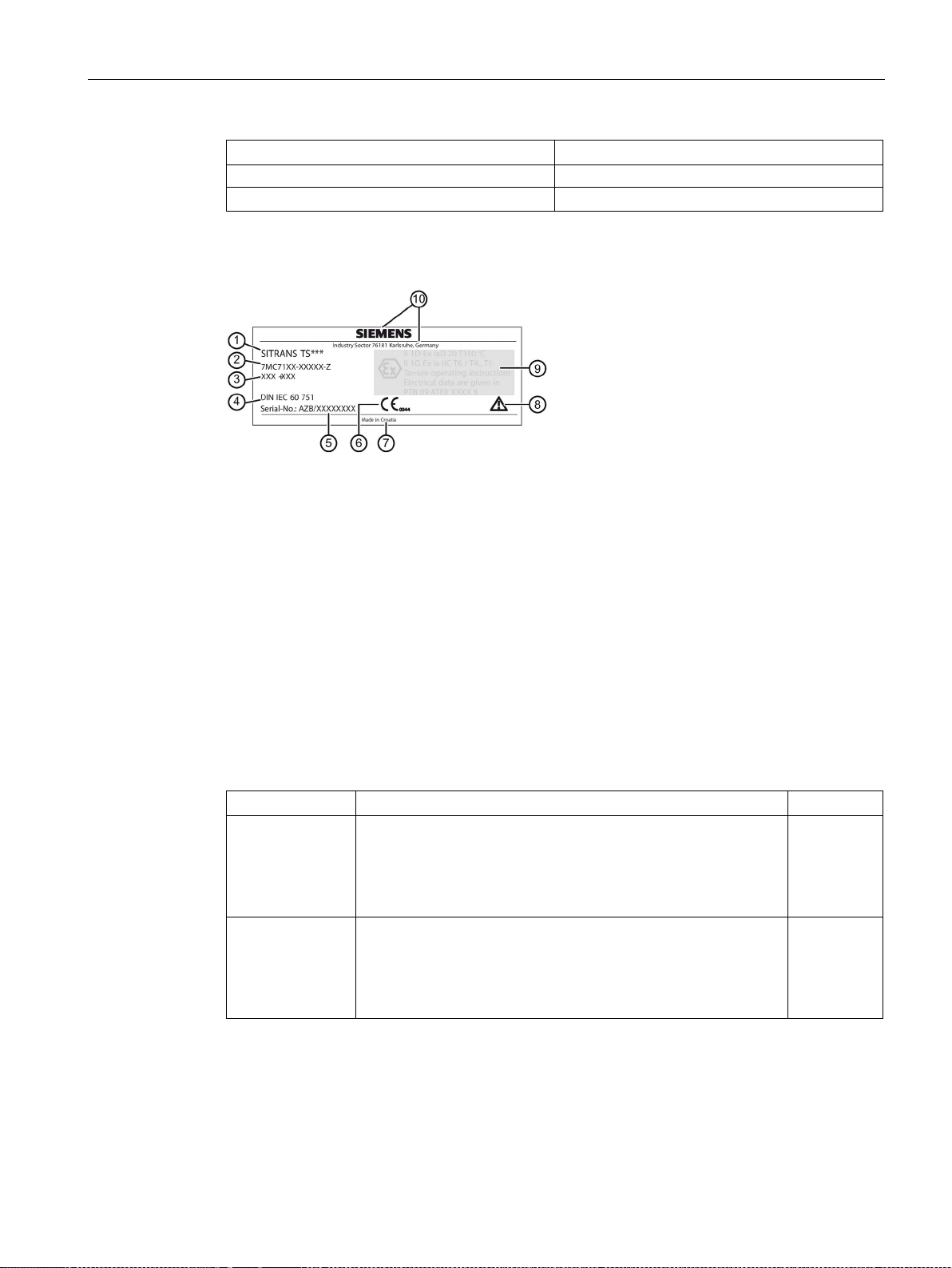

Nameplate structure

Positioning of nameplate

Note

SITRANS TS100/TS200 nameplate

Before commissioning, make sure the nameplate is securely fas

sensor in a visible location.

Device

Positioning of the nameplate

outer periphery of the ANSI adapter.

SITRANS TS100 7MC71..

On the sensor cable

3.2 Application

Resistance thermometers or thermocouples can be used for temperature measurement.

The temperature sensors of the SITRANS TS product family are used for measuring

temperatures in industrial plants.

Depending on the specifications, sensors can be combined with different connection heads,

extension tubes, and process connections. This makes the sensors suitable for a variety of

process engineering applications, in the following sectors:

● Petrochemical industry

● Pharmaceuticals industry

● Biotechnology

● Food production

Two different measuring principles are used for measuring temperatures.

● With resistance thermometers, the temperature is measured as a change in resistance.

Resistance thermometers, also called Resistance Temperature Devices (RTD), contain

sensor elements, like the Pt100 sensor elements in accordance with IEC 60751.

● With thermocouples, the temperature is the change in voltage (Seebeck effect). The

thermocouples are in accordance with IEC 584/DIN EN 60584.

tened to the temperature

SITRANS TSinsert 7MC701. On the bottom of the connecting plate or at the

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

18 Compact Operating Instructions, 01/2018, A5E03920348-AE

Description

Device

Positioning of the nameplate

SITRANS TS200 7MC72..

On the connector or on the sensor

Example of nameplate

①

②

code)

③

Additional information on the type

④

Valid standard for the device

⑤

Serial number

⑥

CE marking

⑦

Place of manufacture

⑧

Consult the operating instructions.

⑨

tection/electrical data

⑩

3.5

Temperature transmitter for SITRANS TS500

Transmitter

Features

Sensor

3.5 Temperature transmitter for SITRANS TS500

SITRANS TS500 7MC.5.. On the connection head

Product name

Order number (machine-readable product

Type-specific information Explosion pro-

Manufacturer´s specifications

The following head-mounted transmitters can be combined with the temperature sensors

SITRANS TS500:

1)

TH100

TH200

• Base device

• Output 4 ... 20 mA

• Can be configured using simple software

: 12.5 mW

• P

o

• Universal device

• Output 4 ... 20 mA

• Can be configured using simple software

: 37 mW

• P

o

only

1)

or 2)

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

19

Description

Transmitter

Features

Sensor

1)

Resistance thermometers

2)

Thermocouple

Note

SITRANS TS500 IEC Ex

If the contained SITRANS TH transmitter is not IEC Ex compliant, the TS500 nameplate has

ATEX marking only.

3.6

Measuring inserts for SITRANS TS500

3.6 Measuring inserts for SITRANS TS500

TH300

TH400

• Universal

• Output 4 ... 20 mA / HART

• Diagnostic functions

: 37 mW

• P

o

• Output: PROFIBUS PA or FOUNDATION Fieldbus

• Sensor redundancy

• Diagnostics

: 12 mW

• P

o

1)

or 2)

1)

or 2)

Measuring inserts for SITRANS TS500 temperature sensors are available in three variants:

● Variant 1:

DIN mounting disk for accommodating a transmitter or ceramic socket.

● Variant 2:

Fixed connection of the ends of the mineral insulated cable with a DIN ceramic socket.

● Variant 3:

Measuring insert in a spring-loaded adapter (ANSI).

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

20 Compact Operating Instructions, 01/2018, A5E03920348-AE

Description

3.7

Connection heads for SITRANS TS500

3.7 Connection heads for SITRANS TS500

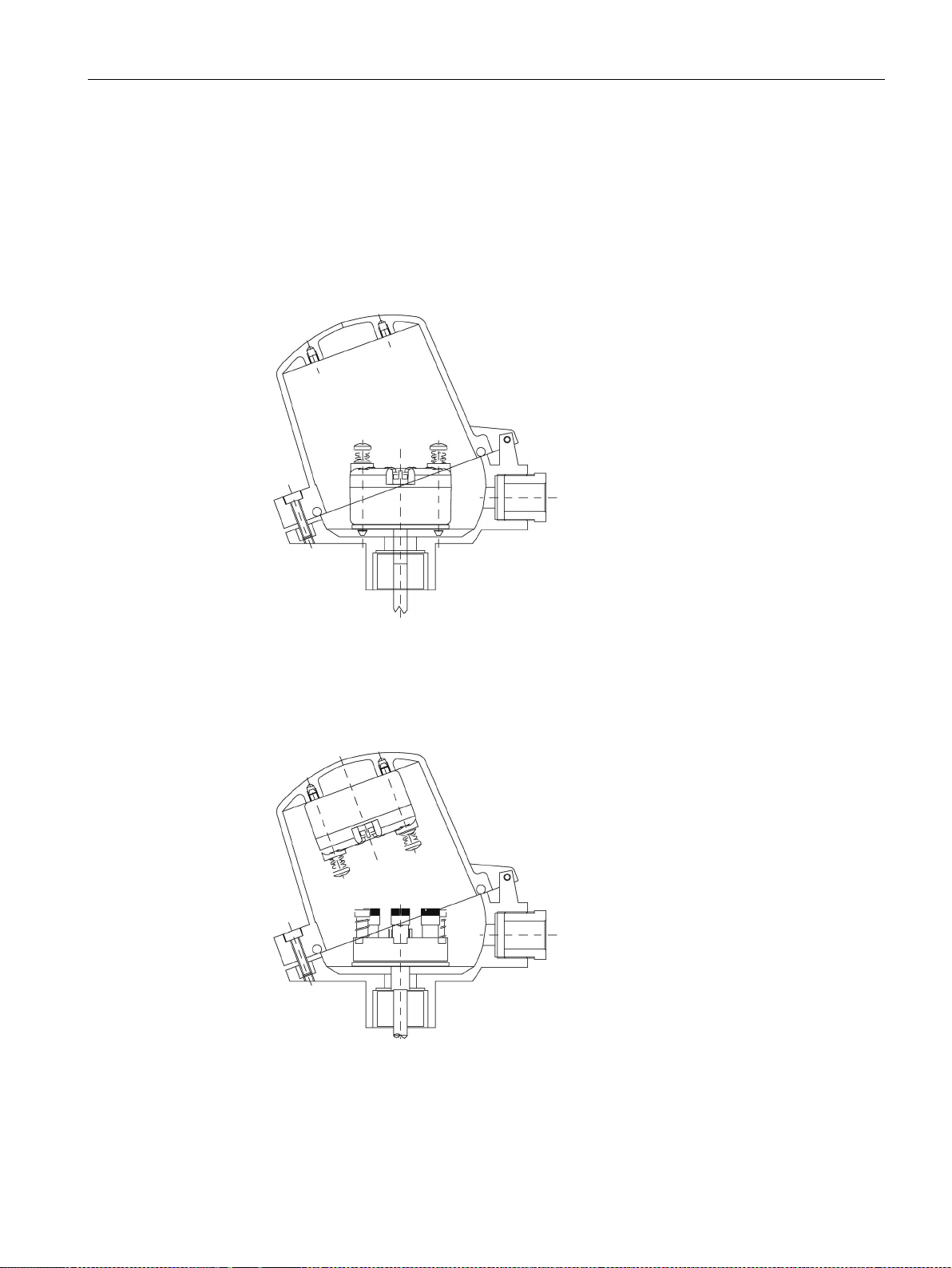

The transmitters can be mounted in connection heads of type B and bigger. The following

mounting types are possible:

● Measuring insert mounting

– Standard type with compact design

– Measuring insert (sensor) and transmitter form one unit

Figure 3-1 Measuring insert mounting of transmitter

● Hinged cover mounting

– Standard type for connection heads of type BC0: B head with high hinged cover

– Separate maintenance of the measuring insert and the transmitter is possible.

Figure 3-2 Hinged cover mounting of transmitter

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

21

Description

3.7 Connection heads for SITRANS TS500

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

22 Compact Operating Instructions, 01/2018, A5E03920348-AE

4

4.1

Basic safety notes

WARNING

Exceeded maximum permissible operating pressure

WARNING

Unsuitable connecting parts

See also

CAUTION

Gasket between extension and protective tube

WARNING

Incorrect mounting at Zone 0

Risk of injury or poisoning.

The maximum permissible operating pressure depends on the device version, pressure

limit and temperature rating. The device can be damaged if the operating pressure is

exceeded. Hot, toxic and corrosive process media could be released.

Ensure that maximum permissible operating pressure of the device is not exceeded. Refer

to the information on the nameplate and/or in Technical data (Page 45).

Risk of injury or poisoning.

In case of improper mounting, hot, toxic, and corrosive process media could be released at

the connections.

• Ensure that connecting parts (such as flange gaskets and bolts) are suitable for

connection and process media.

Technical data (Page 45)

• Use gasket between device extension and protective tube only once.

Risk of explosion in hazardous areas.

• Ensure sufficient tightness at the process connection.

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

• Observe the standard IEC/EN 60079-14.

23

Installing

CAUTION

Hot surfaces resulting from hot process media

CAUTION

External stresses and loads

4.1.1

Installation and location requirements

CAUTION

High vibration area

CAUTION

Direct sunlight

4.1 Basic safety notes

Risk of burns resulting from surface temperatures above 65 °C (149 °F).

• Take appropriate protective measures, for example contact protection.

• Make sure that protective measures do not cause the maximum permissible ambient

temperature to be exceeded. Refer to the information in Technical data (Page 45).

Damage to device by severe external stresses and loads (e.g. thermal expansion or pipe

tension). Process media can be released.

• Prevent severe external stresses and loads from acting on the device.

Especially with the stainless steel housing version of TS500, use short extensions or

external supports when used in a high vibration area.

When TS100/200 sensors are installed in a high vibrating area, use also external supports

to fix the probe stem: the unsupported length must not exceed 150 mm and the free end

must not exceed 100 mm.

Device damage.

The device can overheat or materials become brittle due to UV exposure.

• Protect the device from direct sunlight.

• Make sure that the maximum permissible ambient temperature is not exceeded. Refer

to the information in Technical data (Page 45).

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

24 Compact Operating Instructions, 01/2018, A5E03920348-AE

Installing

CAUTION

Process load

4.1.2

Proper mounting

DANGER

Protective tube ruptures

WARNING

Electrostatic charge

Note

Penetration of water into the plastic head type BM0

Device failure.

•

4.1 Basic safety notes

The thermowell is affected by the static, dynamic and chemical load from the process

parameters, e.g. static and dynamic load, flow induced vortexes. This has influence to the

shape of the thermometer, stem diameter and insertion length.

Ensure that the applicable and relevant directives and standards are respected, e.g. ASME

PTC 19.3, DIN43772 Annex 1-2, AD-directive, VDI/VDE 3511-5.

In critical applications, a thermowell stress calculation according ASME PTC 19.3-TW2016

or Dittrich/Klotter-method is recommended as an engineering service.

Protective tubes that are not suitable for the process or application in question can rupture

and result in serious damage to property and personal injuries.

• Make sure that the protective tube is suitable for the respective mounting method and

application. If necessary, check the selection and order data of your protective tube.

Danger of explosion in hazardous areas if electrostatic charges develop, for example, in

strong airflows in close proximity to belt conveyors.

• Avoid electrostatic charge at the plastic head type BM0 when defining the installation

site.

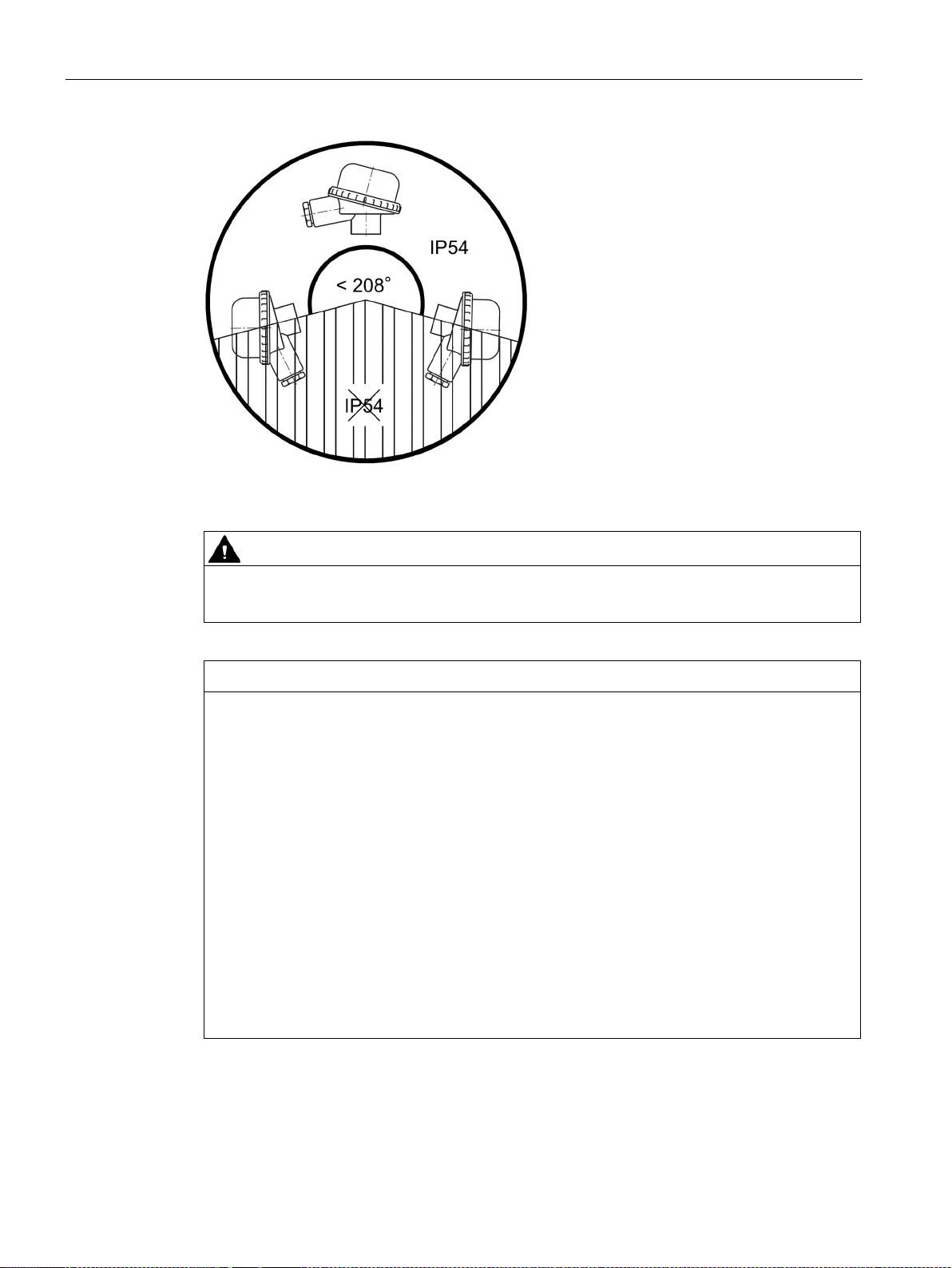

To reach IP54 with a plastic head type BM0, make sure that the mounting angle is in the

range of -14 to 194° (208°, see image below).

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

25

Installing

CAUTION

Loss of IP protection

NOTICE

Incorrect mounting

4.1 Basic safety notes

Figure 4-1 Mounting angle of plastic head type BM0

Do not unscrew the device housing from the mounted parts with NPT threaded connection.

The device can be damaged, destroyed, or its functionality impaired through improper

mounting.

• Before installing, ensure there is no visible damage to the device.

• Make sure that process connectors are clean, and suitable gaskets and glands are

used.

• Mount the device using suitable tools. Refer to the information in Technical data

(Page 45) for installation torque requirements.

• Avoid temperature or mechanical shocks during mounting.

• Avoid excessive force or damaging of the on-site mechanical connections.

• Do not deform or adapt the thermowells.

• The use of additive seal or sealant (not in scope of delivery) is recommended between

sensor and thermowell.

• Thermowells from carbon steel are protected against corrosion. Clean the thermowell

before mounting to avoid poisoning of the sensor and mounting problems.

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

26 Compact Operating Instructions, 01/2018, A5E03920348-AE

Installing

Note

Loss of degree of protection

Damage to device if the enclosure is open or not properly closed. The degree of protection

specified on the nameplate is no longer guaranteed.

4.2

Install

Condition

Procedure

4.2 Install

Prior to mounting, make sure that the device is appropriately applied for the process

connection, media compatibility, temperature resistance and measuring range. See chapter

Technical data (Page 45).

1. Prevent faults caused by heat dissipation in non-representative placings by observing the

following rules:

2. Select an optimal immersion depth. Estimate the immersion depth using the formulas in

Table 8-16 Estimation of immersion depth (Page 57).

If the flow rate allows, sensor placing between 1/3 and 1/2 of the pipe diameter is

recommended.

3. If the process load on the thermowell allows the exposition, select a measurement

location with a high flow rate.

4. Ensure sufficient thermal insulation of the external components of the thermometer.

5. Ensure that external parts have as small surfaces as possible.

6. Select the optimum mounting position for the process in question.

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

27

Installing

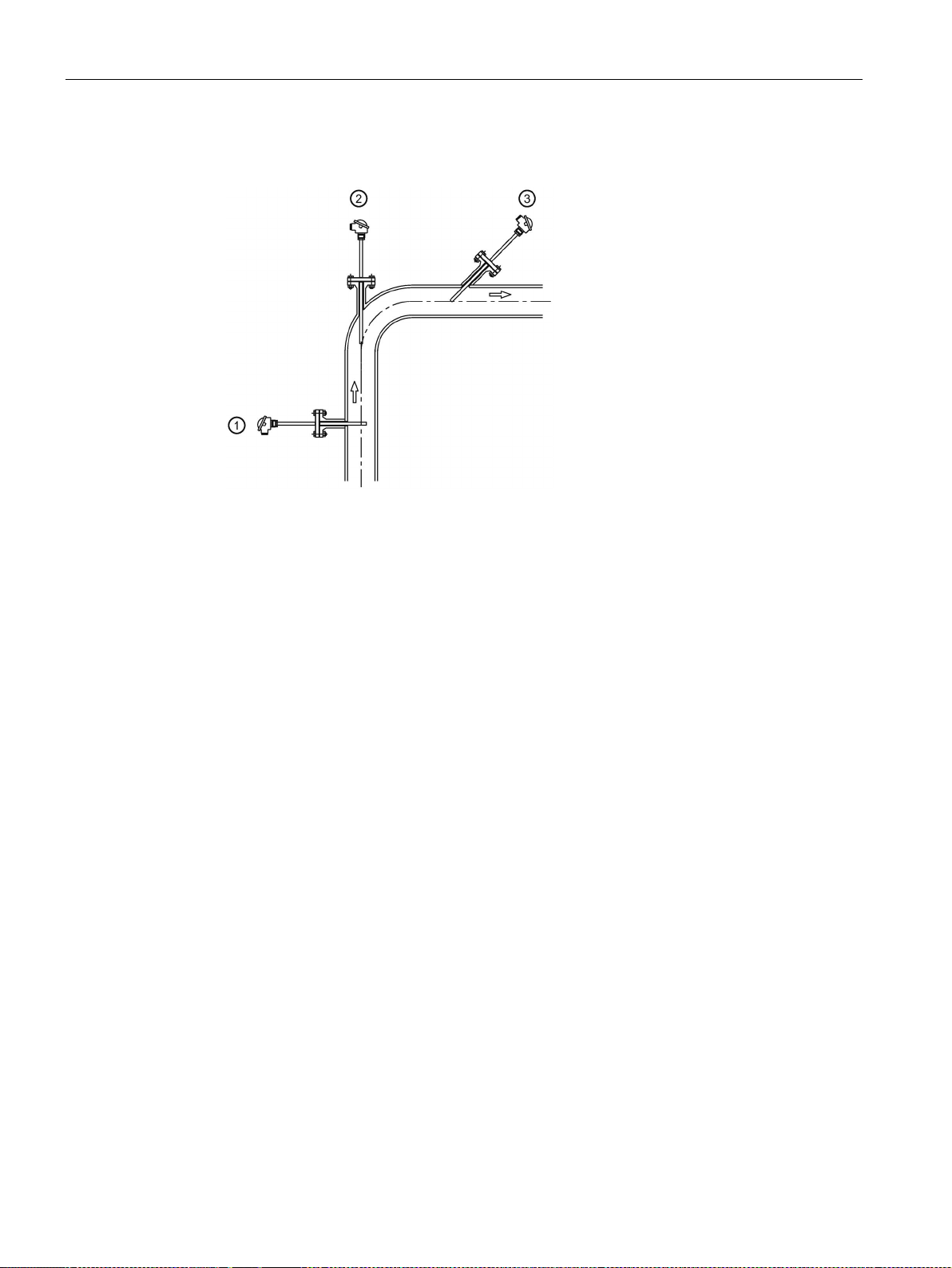

①

At a right angle to the flow

②

In a bend upstream

③

In an angle upstream

See also

4.2 Install

7. With small pipe diameters, mount the sensors upstream at an angle ③ or upstream in a

②.

bend

Figure 4-2 Possible mounting positions of the sensor

8. Use required torque values between device extension and protective tube as in Table 814 Torque values between device extension and protective tube (Page 56).

– If customer adjustments are necessary (M24 connections only), use required torque

values between device head and extension as in Table 8-15 Torque values between

device head and extension (Page 56).

– For SITRANS TS500 barstock version (only European portfolio 7MC752..) without

flange (type 4), use required torque values to complete the mounting of the device

extension to the protective tube as in Table 8-14 Torque values between device

extension and protective tube (Page 56).

Construction (Page 56)

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

28 Compact Operating Instructions, 01/2018, A5E03920348-AE

Installing

4.3

Install SITRANS TS300 Clamp-on

Note

Measurement position

Install on circular pipes only. Avoid installation next to angled pipes, near slide valves,

valves, pum

4.3 Install SITRANS TS300 Clamp-on

ps, etc.

1. Define the measurement position.

2. Apply heat sink compound to the metallic part of the temperature sensor.

3. For standard version: halved pipe collar allows for quick and easy mounting on the pipe

using two mounting screws.

For bracket version: mount on pipe using one mounting screw.

– If the pipe is not fully occupied by medium during installation, mount the temperature

sensor on the underside of the pipe.

4. Firmly tighten the mounting screws (4 Nm torque).

5. Mount the vibration protection and hand-tighten.

– You can remove the measuring insert only after you have released the RTD recessed

grip screw(s).

– Do not twist the housing.

– Use RTD recessed grip screw for installation, only.

– Do not apply force to the transmitter housing (e. g. during opening/closing of lid).

– Because the locking plugs are fitted with internal gaskets, they are only suited for

ambient temperatures to 100 °C (212 °F).

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

Compact Operating Instructions, 01/2018, A5E03920348-AE

29

Installing

4.4

Disassembly

WARNING

Incorrect disassembly

4.4 Disassembly

The following risks may result from incorrect disassembly:

- Injury through electric shock

- Risk through emerging media when connected to the process

- Risk of explosion in hazardous area

In order to disassemble correctly, observe the following:

• Before starting work, make sure that you have switched off all physical variables such

as pressure, temperature, electricity etc. or that they have a harmless value.

• If the device contains hazardous media, it must be emptied prior to disassembly. Make

sure that no environmentally hazardous media are released.

• Secure the remaining connections so that no damage can result if the process is started

unintentionally.

TS100/TS200/TS300/TS500/TSinsert/TSthermowell

30 Compact Operating Instructions, 01/2018, A5E03920348-AE

Loading...

Loading...