Siemens SITRANS F,SITRANS FCS200 Operating Instruction

Coriolis flowmeters

SITRANS FCS200

Operating instructions • 02/2011

SITRANS F

1

Introduction

2

Safety notes

3

Description

SITRANS F

4

Installing/Mounting

Coriolis Flowmeters

SITRANS FCS200

5

Connecting

6

Commissioning

Operating Instructions

7

Service and maintenance

8

Troubleshooting/FAQs

9

Technical data

A

Appendix

Coriolis flow sensor for use with SITRANS F C

transmitter types SIFLOW FC070 and MASS 6000

02/2011

A5E02508199-01

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation for the specific task, in particular its warning notices and

safety instructions. Qualified personnel are those who, based on their training and experience, are capable of

identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG order number: A5E02508199 Copyright © Siemens AG 2011.

Industry Sector Ⓟ 04/2011 Technical data subject to change

Postfach 48 48

90026 NÜRNBERG

GERMANY

SITRANS FCS200

Operating Instructions, 02/2011, A5E02508199-01

3

Table of contents

1 Introduction................................................................................................................................................ 5

1.1 Items supplied................................................................................................................................5

1.2 Device identification.......................................................................................................................5

1.3 History............................................................................................................................................6

1.4 Further Information ........................................................................................................................7

1.5 Notes on warranty..........................................................................................................................7

2 Safety notes............................................................................................................................................... 9

2.1 General safety instructions ............................................................................................................9

2.2 Laws and directives .......................................................................................................................9

2.3 Installation in hazardous area......................................................................................................10

2.4 Certificates ...................................................................................................................................12

3 Description............................................................................................................................................... 13

3.1 Theory of operation......................................................................................................................14

4 Installing/Mounting................................................................................................................................... 15

4.1 Installation safety precautions......................................................................................................15

4.2 Orienting the sensor.....................................................................................................................16

4.3 Mounting the sensor ....................................................................................................................17

5 Connecting .............................................................................................................................................. 19

5.1 Wiring FCS200.............................................................................................................................20

6 Commissioning ........................................................................................................................................ 21

6.1 Zero point adjustment ..................................................................................................................21

7 Service and maintenance ........................................................................................................................ 23

7.1 Maintenance.................................................................................................................................23

7.2 Recalibration ................................................................................................................................23

7.3 Unit repair.....................................................................................................................................23

7.4 Technical support.........................................................................................................................24

7.5

Transportation and storage..........................................................................................................25

7.6 Return procedures .......................................................................................................................25

7.7 Disposal .......................................................................................................................................26

Table of contents

SITRANS FCS200

4 Operating Instructions, 02/2011, A5E02508199-01

8 Troubleshooting/FAQs............................................................................................................................. 27

8.1 General information..................................................................................................................... 27

8.2 Step 1: Inspecting the application ............................................................................................... 27

8.3 Step 2: Improving the application................................................................................................ 28

9 Technical data ......................................................................................................................................... 29

9.1 Pressure / temperature range ..................................................................................................... 30

9.2 Pressure drop.............................................................................................................................. 31

9.3 Electrical connection schematics................................................................................................ 32

9.4 Dimensions ................................................................................................................................. 34

A Appendix.................................................................................................................................................. 37

A.1 Ordering ...................................................................................................................................... 37

A.2 Serial number structure............................................................................................................... 37

Glossary .................................................................................................................................................. 39

Index........................................................................................................................................................ 41

SITRANS FCS200

Operating Instructions, 02/2011, A5E02508199-01

5

Introduction

1

These instructions contain all the information you need for using the device.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it as well as service and

maintenance engineers.

Note

It is the responsibilit

y of the customer that the instructions and directions provided in the

operating instructions are read, understood and followed by the relevant personnel before

installing the device.

1.1 Items supplied

SITRANS FCS200

Sensorprom Memory unit

Calibration certificate

Quick Start Guide

SITRANS F C Literature CD-ROM

1.2 Device identification

Inspection

1. Check for mechanical damage due to possible improper handling during shipment. All

claims for damage are to be made promptly to the shipper.

2. Make sure the scope of delivery, and the information on the type plate corresponds to the

ordering information

Introduction

1.3 History

SITRANS FCS200

6 Operating Instructions, 02/2011, A5E02508199-01

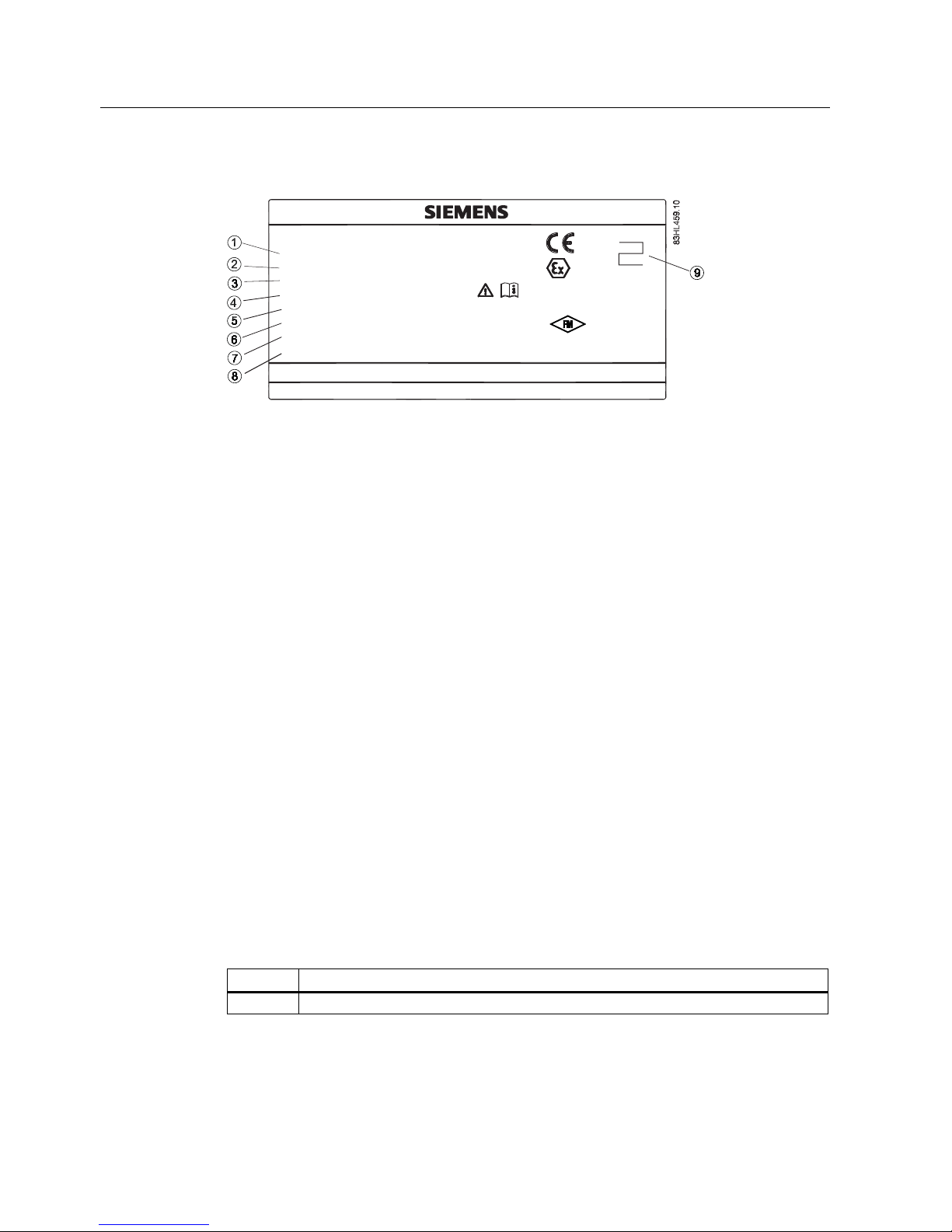

Identification

([LD,,&77

%96$7(;(;

(;&,7(5&,5&8,7(&

,6,17(5)$&(

6HH0DQXDO

6LHPHQV$6)ORZ,QWUXPHQWV1RUGERUJYHM1RUGERUJ

0DGHLQ*HUPDQ\

6,75$16)&6

,,*

C US

$33529('

CI, I, DIV 1,GPS ABCD, T*

Controldrawing nr. A5E03442871A

Entity

Intrinsically

safe for:

2UGHU1R

6HULDO1R

&RQQHFWLRQ

0DWHULDO

&DO)DFWRU

7PHGLD

4PLQ

36

0('1$$

+(-$

ರ137

8161

r&WRr&7DPS r&WRr&

NJK4PD[ NJK

EDU37 31%RG\ EDU

① Order No. Device specific code number

② Serial No. Device specific serial number

③ Connection Process connector type

④ Material Tube material designation

⑤ Cal. Factor Calibration factor and temperature parameter

Tmedia Process media temperature

⑥

Tamb Ambient temperature

Qmin Minimum measuring capacity

⑦

Qmax Maximum measuring capacity

PS Maximum permissible process pressure

⑧

PT

Test pressure

PN Body

Maximum permissible enclosure pressure

⑨ PTB Approval number

Figure 1-1 FCS200 Nameplate example

See also

Serial number structure (Page 37)

1.3 History

The contents of these instructions are regularly reviewed and corrections are included in

subsequent editions. We welcome all suggestions for improvement.

The following table shows the most important changes in the documentation compared to

each previous edition.

Edition Remarks

02/2011 First edition

Introduction

1.4 Further Information

SITRANS FCS200

Operating Instructions, 02/2011, A5E02508199-01

7

1.4 Further Information

Product information on the Internet

The Operating Instructions are available on the CD-ROM shipped with the device, and on

the Internet on the Siemens homepage, where further information on the range of SITRANS

F flowmeters may also be found:

Product information on the internet (http://www.siemens.com/flowdocumentation

)

Worldwide contact person

If you need more information or have particular problems not covered sufficiently by these

Operating Instructions, get in touch with your contact person. You can find contact

information for your local contact person on the Internet:

Local contact person (http://www.automation.siemens.com/partner

)

See also

Technical support (Page 24)

1.5 Notes on warranty

The contents of this manual shall not become part of or modify any prior or existing

agreement, commitment or legal relationship. The sales contract contains all obligations on

the part of Siemens as well as the complete and solely applicable warranty conditions. Any

statements regarding device versions described in the manual do not create new warranties

or modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

Introduction

1.5 Notes on warranty

SITRANS FCS200

8 Operating Instructions, 02/2011, A5E02508199-01

SITRANS FCS200

Operating Instructions, 02/2011, A5E02508199-01

9

Safety notes

2

2.1 General safety instructions

CAUTION

Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance. Only qualified personnel should

install or operate this instrument.

Note

Alterations to the product, including opening or improper modifications of the product, are not

permitted.

If this requirement is not observed, the CE mark and the manufacturer's warranty will expire.

2.2 Laws and directives

General requirements

Installation of the equipment must comply with national regulations. For example EN 6007914 for the European Community.

Instrument safety standards

The device has been tested at the factory, based on the safety requirements. In order to

maintain this condition over the expected life of the device the requirements described in

these Operating Instructions must be observed.

CE marked equipment

The CE-mark symbolizes the compliance of the device with the following directives:

● EMC directive 2004/108EC

● Pressure equipment directive (PED/DGRL) 97/23/EC

● ATEX directive 94/9/EC

Safety notes

2.3 Installation in hazardous area

SITRANS FCS200

10 Operating Instructions, 02/2011, A5E02508199-01

2.3 Installation in hazardous area

WARNING

Equipment used in hazardous areas must be Ex-approved and marked accordingly. It is

required that the special conditions for safe use provided in the manual and in the Ex

certificate are followed!

Hazardous area approvals

The device is approved for use in hazardous area and has the following approval:

● II 1/2 G Ex ia IIC T5-T4

WARNING

Make sure the hazardous area approval is suitable for the environment in which the

device will be installed.

WARNING

Due to the increased safety concept, SITRANS F C MASS 6000 and SIFLOW FC070

Ex have to be mounted in the safe area.

SITRANS F C MASS 6000 Ex d is allowed for use in hazardous area

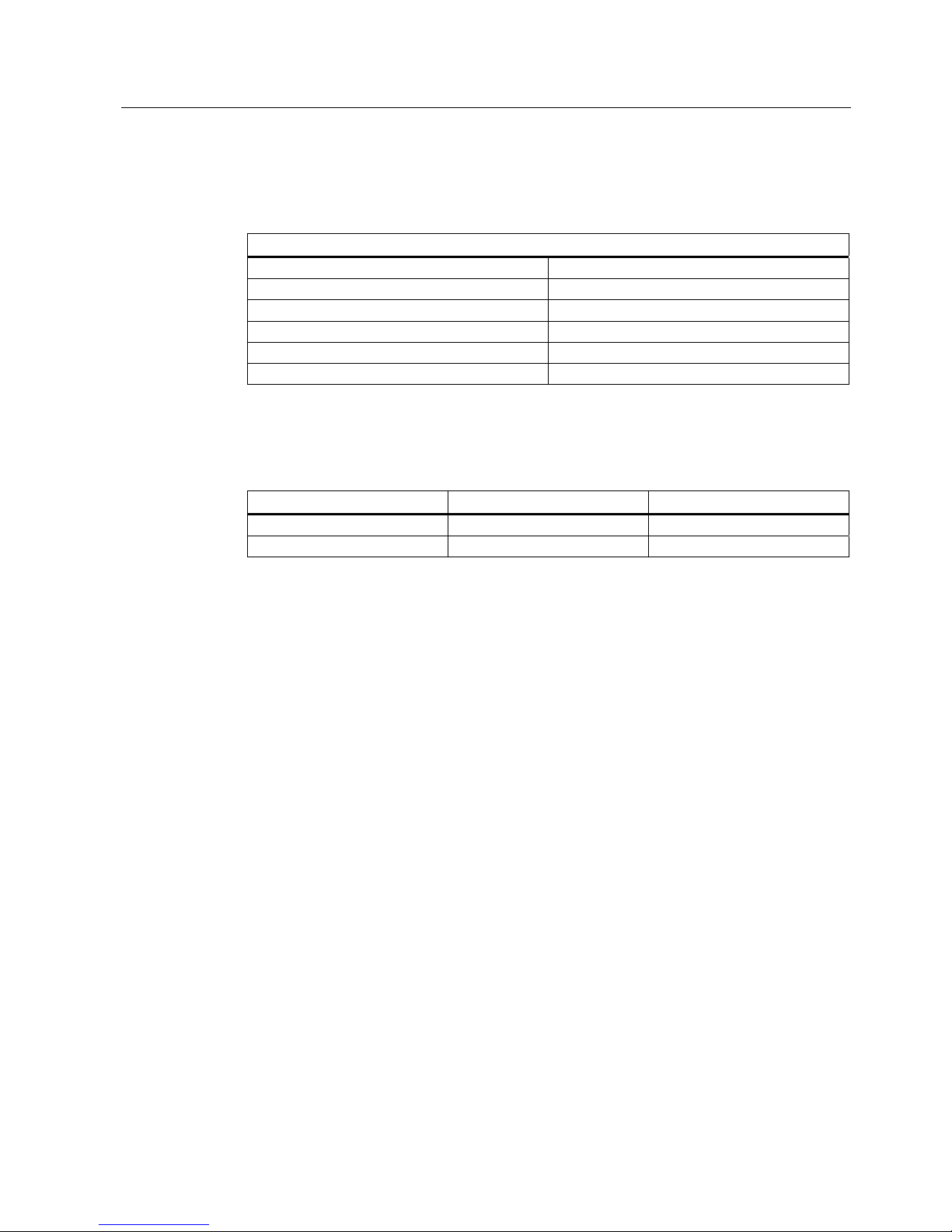

Intrinsically safe data

Table 2- 1 Exciter circuit, DN10 and DN15

Exciter circuit EC1 (Terminal 1-2), DN10 and DN15

Ui 30 V DC

Ii 130 mA

Pi 0.5 W

Ci Insignificant

Li 2 mH

Table 2- 2 Exciter circuit, DN25

Exciter circuit EC2 (Terminal 1-2), DN25

Vo 30 V DC

Io 130 mA

Po 0.5 W

Connection of an intrinsically safe circuit level of protection Ex ia and the following maximum values

Safety notes

2.3 Installation in hazardous area

SITRANS FCS200

Operating Instructions, 02/2011, A5E02508199-01

11

Table 2- 3 Sensor circuit

Sensor circuit (Terminal 5-6 and 7-8)

Ui 30 V DC

Ii 50 mA

Pi 0.4 W

Ci Insignificant

Li 14 mH

Uo 0.3 V AC

Temperature specifications for use in hazardous area

Table 2- 4 Temperature specifications

Temperature class Max. process temperature [°C] Ambient temperature [°C]

T4 125 -40 ... +60

T5 70 -40 ... +60

Special conditions for safe use

It is required that:

● Electrical connections are in accordance with IEC/EN60079-14 (Installing Electrical

Systems in Explosion Hazardous Areas).

● The protective cover over the power supply is properly installed. For intrinsically safe

circuits the connection area can be opened.

● Appropriate cable connectors are used for the output circuits:

– Intrinsically safe: blue

– Non-intrinsically safe: black

● Sensor and transmitter are connected to potential equalization.

For intrinsically safe output circuits potential equalization must be maintained along the

entire connection path.

● When protective earth (PE) is connected, no potential difference between the protective

earth (PE) and the potential equalization (PA) can exist, even during a fault condition.

Safety notes

2.4 Certificates

SITRANS FCS200

12 Operating Instructions, 02/2011, A5E02508199-01

2.4 Certificates

Certificates are posted on the Internet and on the documentation CD-ROM shipped with the

device.

See also

Certificates (http://www.siemens.com/processinstrumentation/certificates)

UL control drawings on the internet (http://www.automation.siemens.com/w1/automation-

technology-process-instrumentation-18092.htm#lb-61,related-installationdrawings)

Loading...

Loading...